Grinding Deformation Behavior of a Lamellar γ-TiAl Alloy

Abstract

1. Introduction

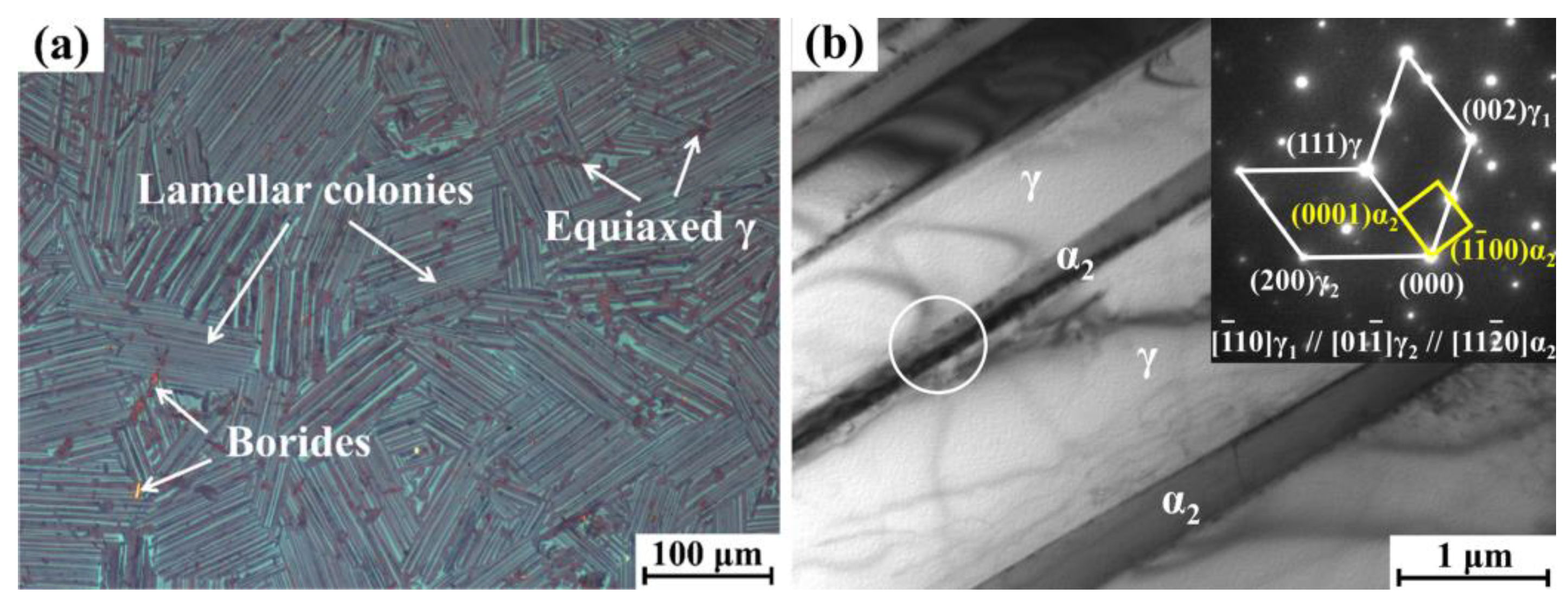

2. Experimental Section

3. Results and Discussion

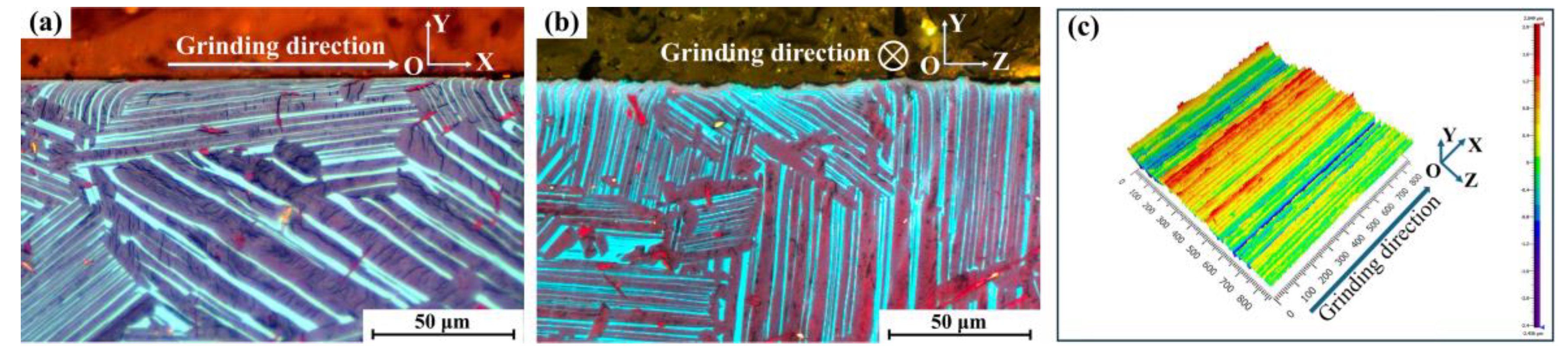

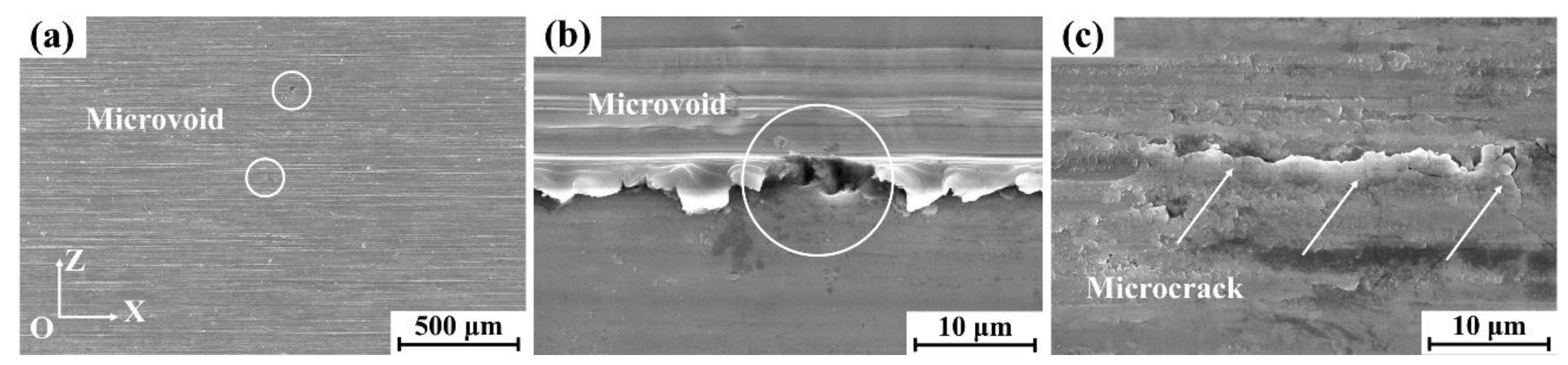

3.1. Grinding-Induced Surface Morphology and Cross-Sectional Characteristics

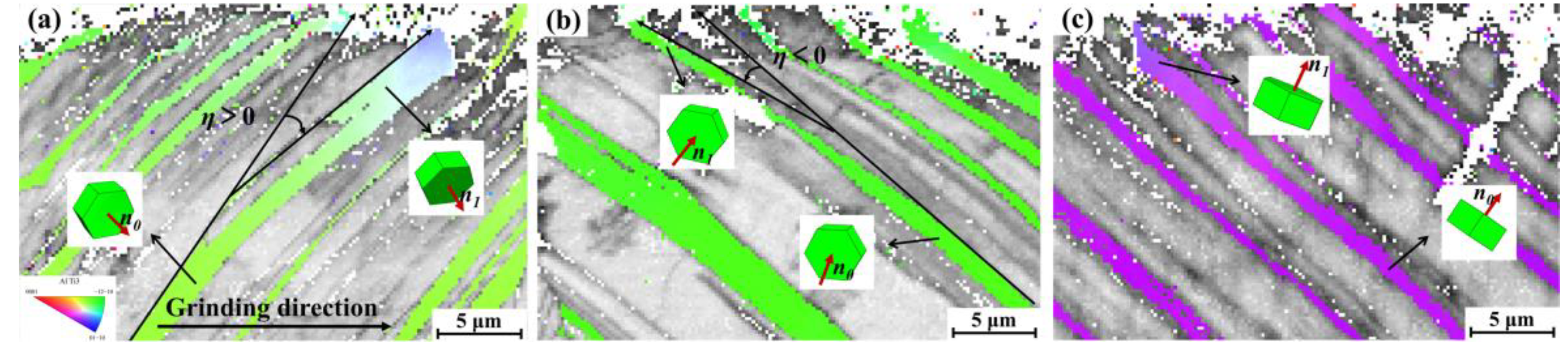

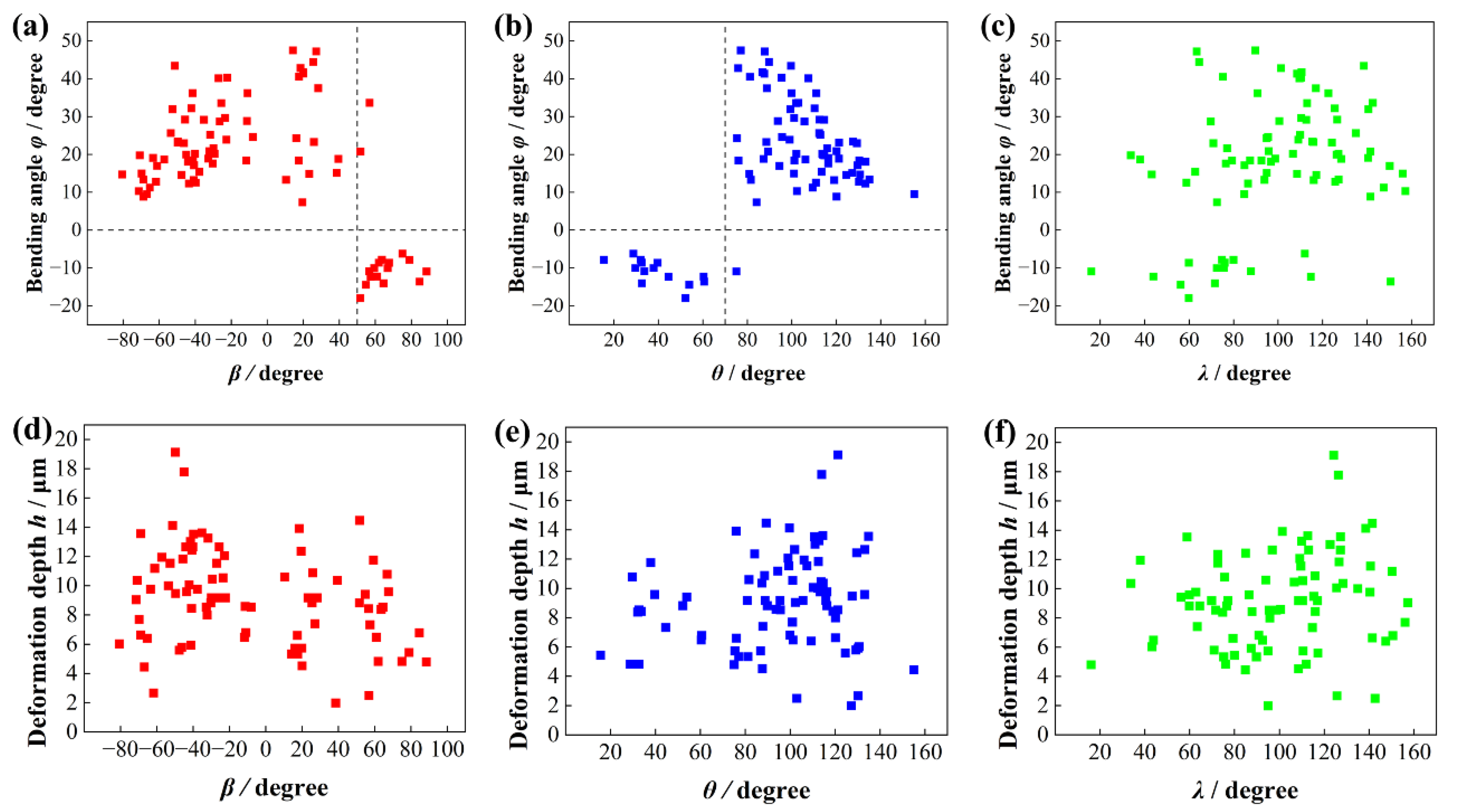

3.2. Orientation-Dependent Evolution of Lamellar Bending Angle and Deformation Depth

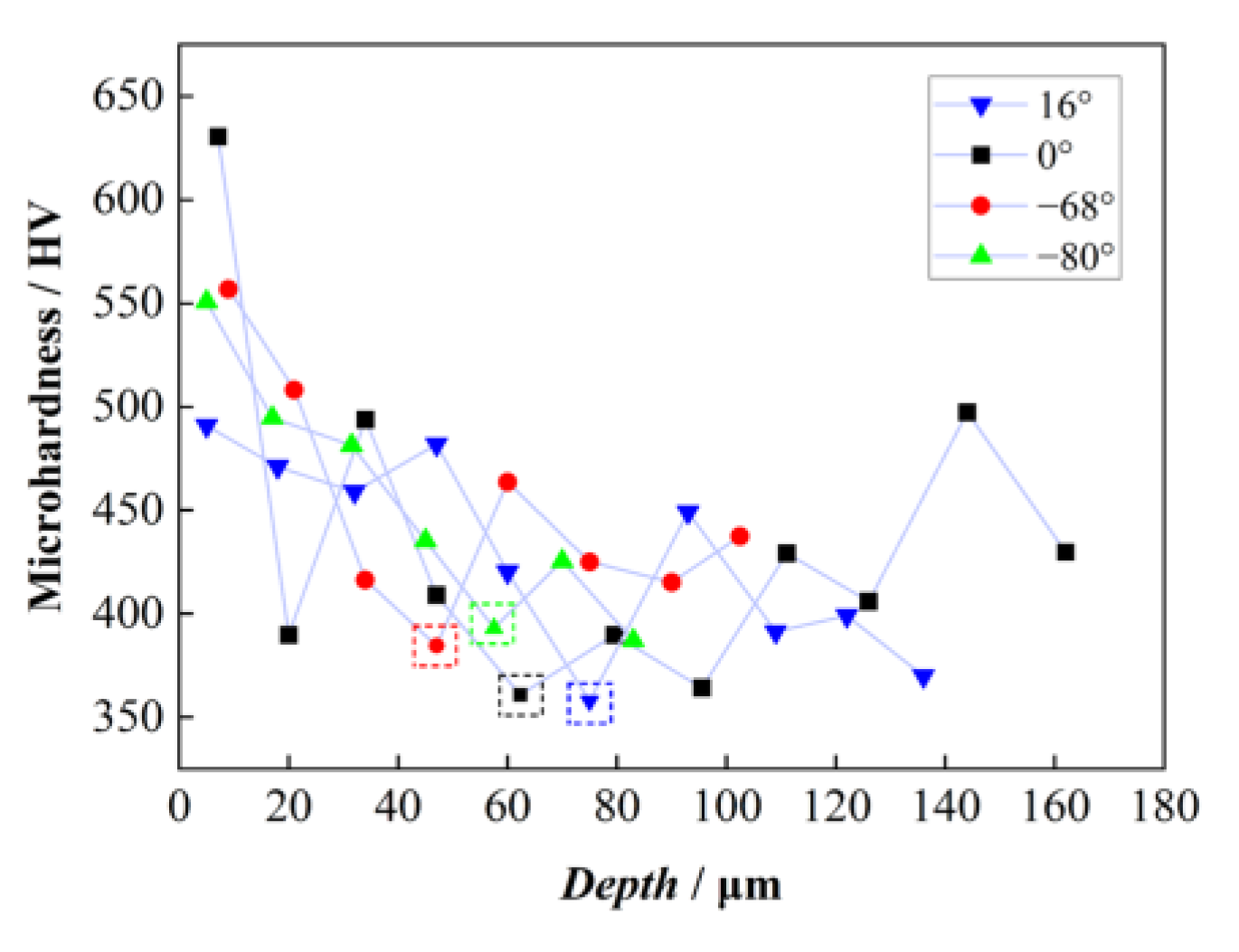

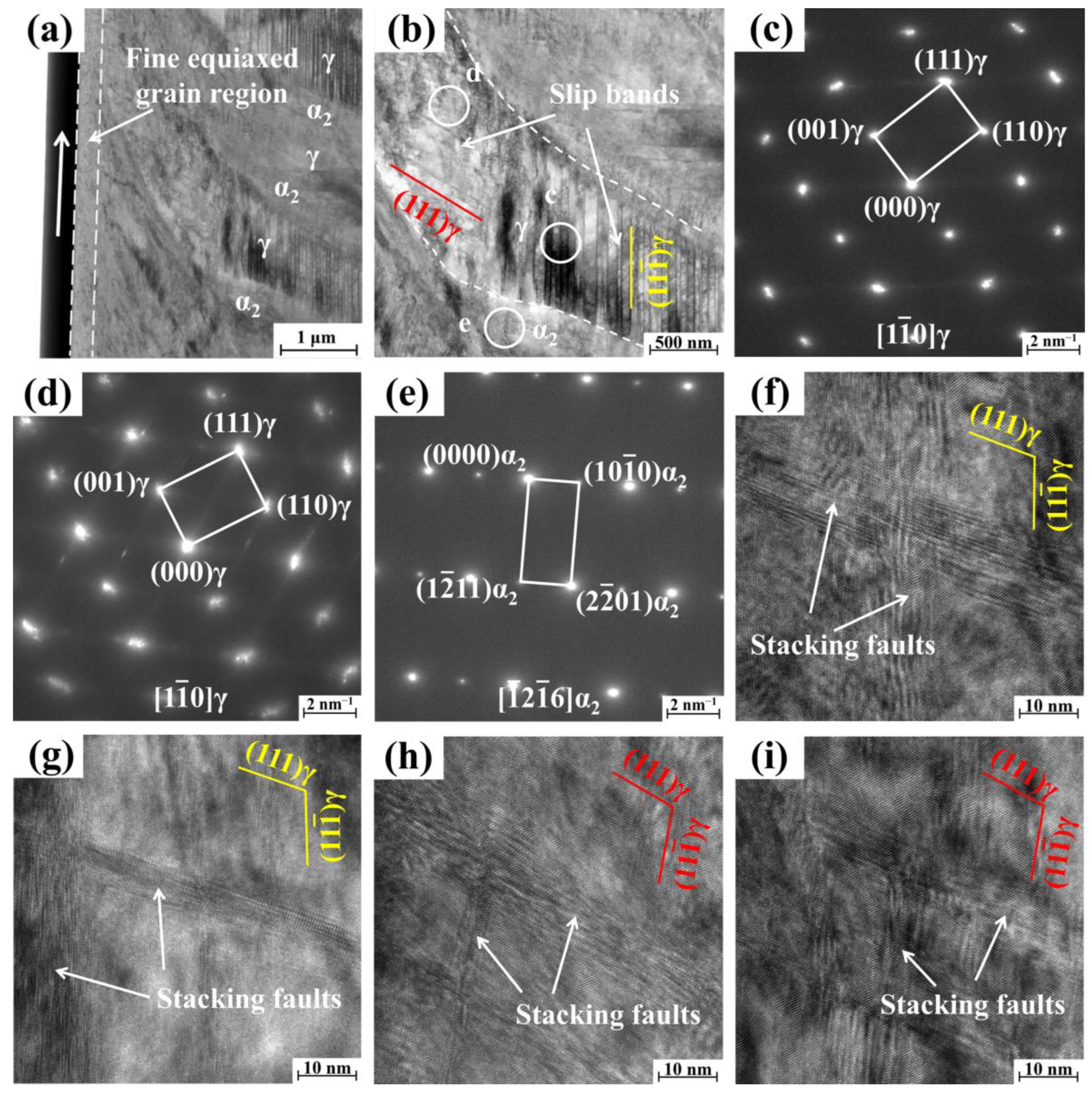

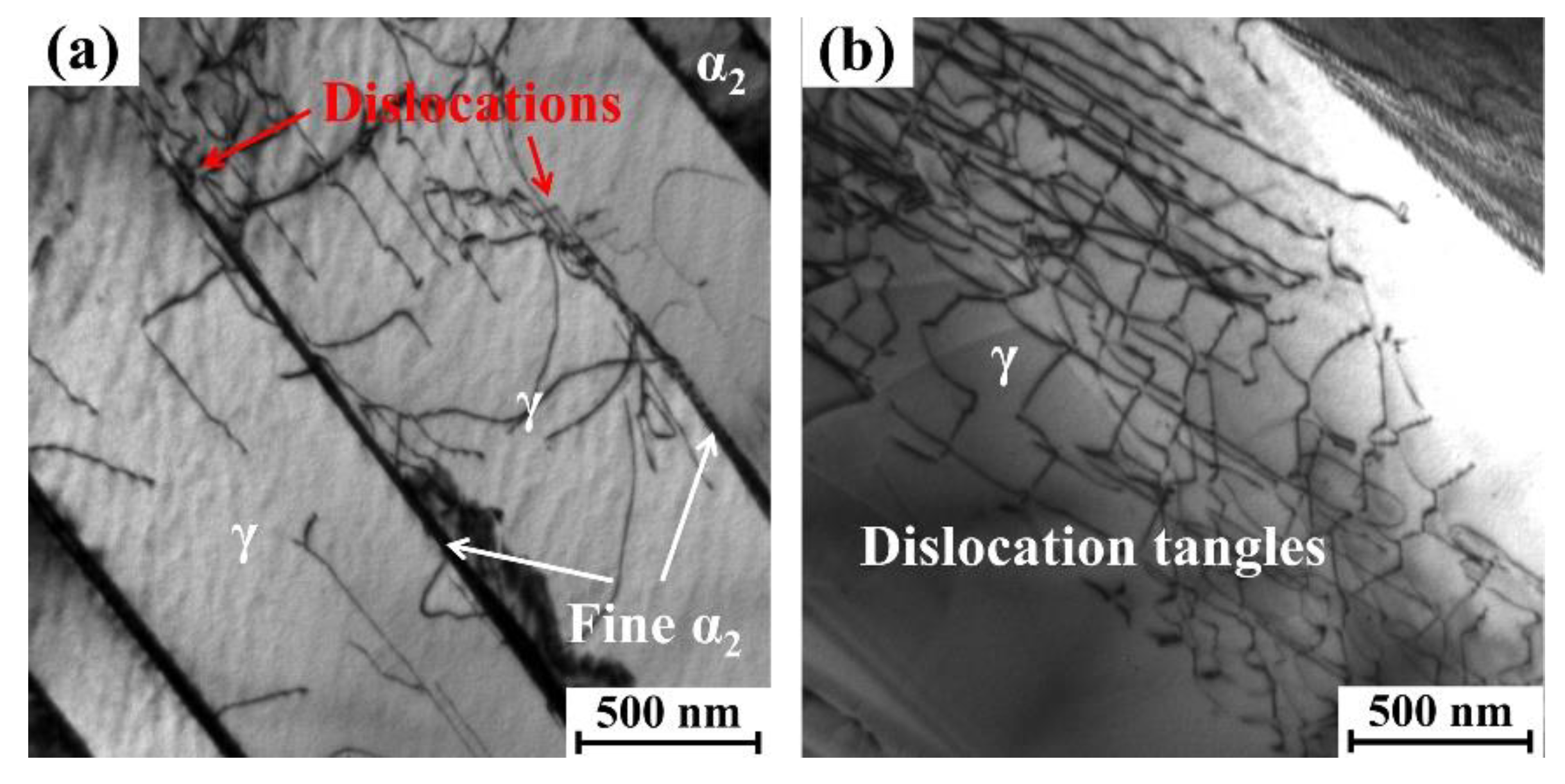

3.3. Underlying Microscale Deformation Mechanisms

4. Conclusions

- The model is established to describe the lamellar bending angle. φ is governed by the coupling between interface normal-grinding direction angle β and interface normal-surface normal angle θ, with β > 50 triggering reverse bending.

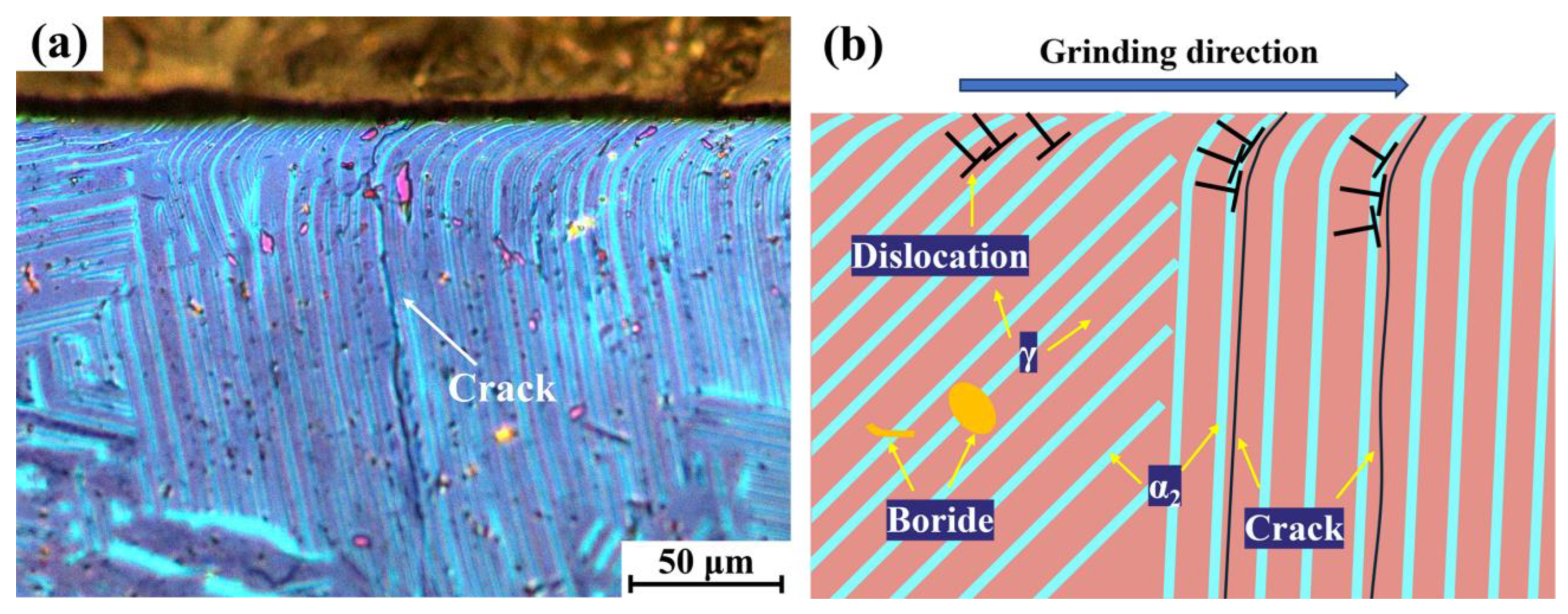

- The ground surface exhibits distinct stratified deformation. Fine equiaxed grains form in conditions of high temperature and strain on the surface. The bending lamella zone is dominated by {111}γ slip bands and stacking faults. The near-surface zone with dislocation tangles and α2-tip activation, devoid of recrystallization.

- Critical crack-orientation relationship: Severe bending at β = 0 (lamellae perpendicular to grinding) triggers dislocation pileups at α2/γ interfaces, exclusively initiating cracks that propagate subsurface. This defines a high-risk orientation for component failure.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dimiduk, D.M. Gamma titanium aluminide alloys-an assessment within the competition of aerospace structural materials. Mater. Sci. Eng. A 1999, 263, 281–288. [Google Scholar] [CrossRef]

- Kim, Y.W. Intermetallic alloys based on gamma titanium aluminide. JOM 1989, 41, 24–30. [Google Scholar] [CrossRef]

- Gao, G.F.; Fu, Z.X.; Wang, Y.; Xiang, D.H.; Zhao, B. Research progress on precision machining of Ti-Al intermetallic compounds. Rare Met. Mater. Eng. 2021, 50, 1867–1882. [Google Scholar] [CrossRef]

- Kumpfert, J. Intermetallic alloys based on orthorhombic titanium aluminide. Adv. Eng. Mater. 2001, 3, 851–864. [Google Scholar] [CrossRef]

- Appel, F.; Wagner, R. Microstructure and deformation of two-phase γ-titanium aluminides. Mat. Sci. Eng. R 1998, 22, 187–268. [Google Scholar] [CrossRef]

- Genc, O.; Unal, R. Development of gamma titanium aluminide (γ-TiAl) alloys: A review. J. Alloys Compd. 2022, 929, 167262. [Google Scholar] [CrossRef]

- Loria, E.A. Gamma titanium aluminides as prospective structural materials. Intermetallics 2000, 8, 1339–1345. [Google Scholar] [CrossRef]

- Bewlay, B.P.; Nag, S.; Suzuki, A.; Weimer, M.J. TiAl alloys in commercial aircraft engines. Mater. High Temp. 2016, 33, 549–559. [Google Scholar] [CrossRef]

- Kim, Y.W. Ordered Intermetallic Alloys, Part III: Gamma titanium aluminides. JOM 1994, 46, 30–39. [Google Scholar] [CrossRef]

- Yang, R. Advances and challenges of TiAl base alloys. Acta Metall. Sin. 2015, 51, 129–147. [Google Scholar] [CrossRef]

- Chen, T.; Wang, X.W.; Zhao, B.; Ding, W.F.; Xu, J.H. Surface integrity evolution during creep feed profile grinding of γ-TiAl blade tenon. Chin. J. Aeronaut. 2024, 37, 496–512. [Google Scholar] [CrossRef]

- Hood, R.; Lechner, F.; Aspinwall, D.K.; Voice, W. Creep feed grinding of gamma titanium aluminide and burn resistant titanium alloys using SiC abrasive. Int. J. Mach. Tool. Manuf. 2007, 47, 1486–1492. [Google Scholar] [CrossRef]

- Sharman, A.R.C.; Aspinwall, D.K.; Dewes, R.C.; Bowen, P. Workpiece surface integrity considerations when finish turning gamma titanium aluminide. Wear 2001, 249, 473–481. [Google Scholar] [CrossRef]

- Aust, E.; Niemann, H.R. Machining of γ-TiAl. Adv. Eng. Mater. 1999, 1, 53–57. [Google Scholar] [CrossRef]

- Ezugwu, E.O.; Wang, Z.M. Titanium alloys and their machinability-a review. J. Mater. Process. Technol. 1997, 68, 262–274. [Google Scholar] [CrossRef]

- Xia, Z.W.; Shan, C.W.; Zhang, M.H.; Cui, M.C.; Luo, M. Machinability of γ-TiAl: A review. Chin. J. Aeronaut. 2023, 36, 40–75. [Google Scholar] [CrossRef]

- Ni, M.J.; Liu, R.C.; Zhou, H.H.; Yang, C.; Ge, S.Y.; Liu, D.; Shi, F.L.; Cui, Y.Y.; Yang, R. Influence of grinding depth on the surface integrity and fatigue property of γ-TiAl alloy. Acta Metall. Sin. 2024, 60, 261–272. Available online: https://www.ams.org.cn/CN/10.11900/0412.1961.2022.00080 (accessed on 7 March 2024).

- Bentley, S.A.; Goh, N.P.; Aspinwall, D.K. Reciprocating surface grinding of a gamma titanium aluminide intermetallic alloy. J. Mater. Process. Technol. 2001, 118, 22–28. [Google Scholar] [CrossRef]

- Klocke, F.; Settineri, L.; Lung, D.; Priarone, P.C.; Arft, M. High performance cutting of gamma titanium aluminides: Influence of lubricoolant strategy on tool wear and surface integrity. Wear 2013, 302, 1136–1144. [Google Scholar] [CrossRef]

- Kolahdouz, S.; Hadi, M.; Arezoo, B.; Zamani, S. Investigation of surface integrity in high speed milling of gamma titanium aluminide under dry and minimum quantity lubricant conditions. Proc. CIRP. 2015, 26, 367–372. [Google Scholar] [CrossRef]

- Krbata, M.; Kohutiar, M.; Escherova, J.; Klučiar, P.; Studeny, Z.; Trembach, B.; Beronská, N.; Breznická, A.; Timárová, Ľ. Continuous Cooling Transformation of Tool Steels X153CrMoV12 and 100MnCrW4: Analysis of Microstructure and Hardness Changes. Appl. Mech. 2025, 6, 16. [Google Scholar] [CrossRef]

- Zang, H.; Wise, M.L.H.; Aspinwall, D.K. The surface quality of hipped gamma titanium aluminide bar after turning. In Proceedings of the Thirty-First International Matador Conference; Red Globe Press: London, UK, 1995; pp. 217–221. [Google Scholar] [CrossRef]

- Furusawa, T.; Hino, H.; Tsuji, S.; Koroyasu, S.; Ichikawa, A. Generation of defects due to machining of TiAl intermetallic compound and their effects on mechanical strength. ASME. J. Manuf. Sci. Eng. 2004, 126, 506–514. [Google Scholar] [CrossRef]

- Zeppenfeld, C.; Klocke, F. Speed stroke grinding of γ-titanium aluminides. CIRP Ann. 2006, 55, 333–338. [Google Scholar] [CrossRef]

- Hood, R.; Aspinwall, D.K.; Sage, C.; Voice, W. High speed ball nose end milling of γ-TiAl alloys. Intermetallics 2013, 32, 284–291. [Google Scholar] [CrossRef]

- Wang, Z.H.; Liu, Y.W. Study of surface integrity of milled gamma titanium aluminide. J. Manuf. Process. 2020, 56, 806–819. [Google Scholar] [CrossRef]

- Mantle, A.L.; Aspinwall, D.K. Surface integrity of a high speed milled gamma titanium aluminide. J. Mater. Process. Technol. 2001, 118, 143–150. [Google Scholar] [CrossRef]

- Pérez, R.G.V. Wear mechanisms of WC inserts in face milling of gamma titanium aluminides. Wear 2005, 259, 1160–1167. [Google Scholar] [CrossRef]

- Paidar, V.; Inui, H.; Kishida, K.; Yamaguchi, M. Dislocation dissociation in TiAl alloys. Mater. Sci. Eng. A 1997, 233, 111–115. [Google Scholar] [CrossRef]

- Cao, R.X.; Liu, R.C.; Yang, C.; Cui, Y.Y.; Yang, R. Structures and formation mechanism of borides with varied morphologies in cast γ-TiAl alloys. Mater. Des. 2023, 232, 112122. [Google Scholar] [CrossRef]

- Wang, D.; Chen, L.; Zhang, Z.P. Study on Force Model and Surface Integrity of Cylindrical Grinding 18CrNiMo7-6 Steels. China Mech. Eng. 2024, 35, 381–393. Available online: http://www.cmemo.org.cn/EN/10.3969/j.issn.1004-132X.2024.03.001 (accessed on 12 September 2024).

- Xi, X.X.; Chen, T.; Ding, W.F. Research on temperature field during grinding of low-pressure turbine blade tenon of TiAl alloys. Diam. Abras. Eng. 2020, 40, 17–22. [Google Scholar] [CrossRef]

- Tian, S.W.; He, A.R.; Liu, J.H.; Zhang, Y.F.; Zhang, S.Y.; Zhang, Y.; Yang, Y.G.; Jiang, H.T. Investigation on the microstructure evolution and dynamic recrystallization mechanisms of TiAl alloy at elevated temperature. J. Mater. Res. Technol. 2021, 14, 968–984. [Google Scholar] [CrossRef]

- Mazánová, V.; Heczko, M.; Miao, J.S.; Mills, M.J.; Murphy-Leonard, A. The role of coherent nano precipitates on stacking fault and deformation twin formation during tensile deformation of wire arc additive manufactured nickel-aluminum-bronze. Mater. Sci. Eng. A 2024, 918, 147426. [Google Scholar] [CrossRef]

- Jiang, Z.; Lei, C.Q.; Ding, J.J.; Zhu, C.N.; Shi, D.F.; Zhang, J.; Wang, G.Q. Synergistic effect of orientation and temperature on slip behavior and precipitation behavior of Al-Cu-Li single crystals. Trans. Nonferr. Met. Soc. 2024, 34, 3554–3568. [Google Scholar] [CrossRef]

- Yue, H.Y.; Peng, H.; Su, Y.J.; Wang, X.P.; Chen, Y.Y. Microstructure and high-temperature tensile property of TiAl alloy produced by selective electron beam melting. Rare Met. 2021, 40, 3635–3644. [Google Scholar] [CrossRef]

- Malaplate, J.; Caillard, D.; Couret, A. Correlation between creep activation parameters and microscopic dislocation behaviour in γ TiAl alloys. Mater. Sci. Eng. A 2005, 400–401, 105–108. [Google Scholar] [CrossRef]

- Xu, X.S.; Ding, H.S.; Huang, H.T.; Liang, H.; Ramanujan, R.V.; Chen, R.R.; Guo, J.J.; Fu, H.Z. Twinning-induced dislocation and coordinated deformation behavior of a high-Nb TiAl alloy during high-cycle fatigue. Int. J. Fatigue. 2023, 171, 107597. [Google Scholar] [CrossRef]

- Guo, H.; Zhang, M.M.; Xu, D.S.; Zhang, J.H.; Qiu, J.K.; Meng, Z.C.; Zheng, S.J.; Ma, Y.J.; Wang, H.; Yang, R. Planar slip triggered by successive dislocation-precipitate interaction in titanium alloys. Mater. Sci. Eng. A 2023, 882, 145468. [Google Scholar] [CrossRef]

- Worsnop, F.F.; Lim, R.E.; Bernier, J.V.; Pagan, D.C.; Xu, Y.L.; McAuliffe, T.P.; Rugg, D.; Dye, D. The influence of alloying on slip intermittency and the implications for dwell fatigue in titanium. Nat. Commun. 2022, 13, 5949. [Google Scholar] [CrossRef]

- Yu, S.W.; An, X.L.; Ni, S.; Song, M. Effects of strain rate and strain on microstructural evolution and mechanical properties of a Ti-10 at.%Al alloy. Mater. Charact. 2021, 179, 111314. [Google Scholar] [CrossRef]

- Youssef, S.S.; Zheng, X.D.; Qi, M.; Ma, Y.J.; Huang, S.S.; Qiu, J.K.; Zheng, S.J.; Lei, J.F.; Yang, R. Effects of Al content and α2 precipitation on the fatigue crack growth behaviors of binary Ti-Al alloys. Mater. Sci. Eng. A 2021, 819, 141513. [Google Scholar] [CrossRef]

- Zhao, Z.Q.; Chu, L.L.; Yu, M.L.; Guo, W.L.; Zhang, Z.H. Advanced TiAl Based Alloys: From Polycrystals to Polysynthetic Twinned Single Crystals. Adv. Funct. Mater. 2024, 34, 2409381. [Google Scholar] [CrossRef]

- Xia, Z.Z.; Liu, R.H.; Shen, Y.Y.; Mohammed, A.; Jia, Q.; Cui, Y.Y.; Yang, R. Creep properties of Ti–48Al–2Cr–2Nb alloy having similarly oriented lamellae with fine lamellar spacing. Mater. Sci. Eng. A 2022, 861, 144362. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, J.; Xu, M.; Liu, R.; Shen, Y.; Shan, Z.; Zhu, Z.; Liu, D.; Cui, Y.; Yang, R. Grinding Deformation Behavior of a Lamellar γ-TiAl Alloy. Materials 2025, 18, 3114. https://doi.org/10.3390/ma18133114

Qin J, Xu M, Liu R, Shen Y, Shan Z, Zhu Z, Liu D, Cui Y, Yang R. Grinding Deformation Behavior of a Lamellar γ-TiAl Alloy. Materials. 2025; 18(13):3114. https://doi.org/10.3390/ma18133114

Chicago/Turabian StyleQin, Jiale, Mengxi Xu, Renci Liu, Yingying Shen, Zhiqiang Shan, Zuohai Zhu, Dong Liu, Yuyou Cui, and Rui Yang. 2025. "Grinding Deformation Behavior of a Lamellar γ-TiAl Alloy" Materials 18, no. 13: 3114. https://doi.org/10.3390/ma18133114

APA StyleQin, J., Xu, M., Liu, R., Shen, Y., Shan, Z., Zhu, Z., Liu, D., Cui, Y., & Yang, R. (2025). Grinding Deformation Behavior of a Lamellar γ-TiAl Alloy. Materials, 18(13), 3114. https://doi.org/10.3390/ma18133114