AZ31 Magnesium Alloy Roll-Forming Springback Prediction Considering Anisotropic and Asymmetric Properties

Abstract

1. Introduction

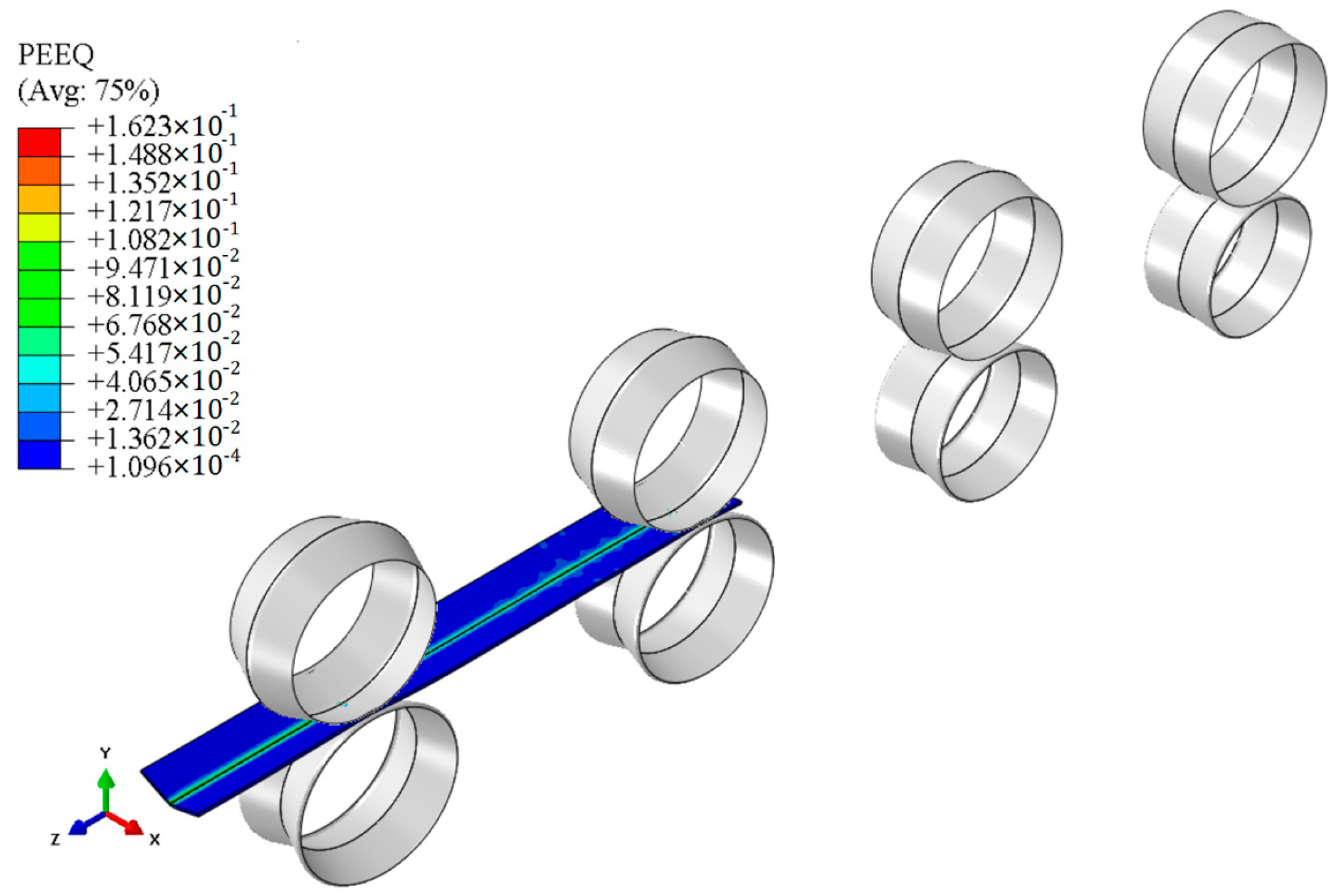

2. Materials and Methods

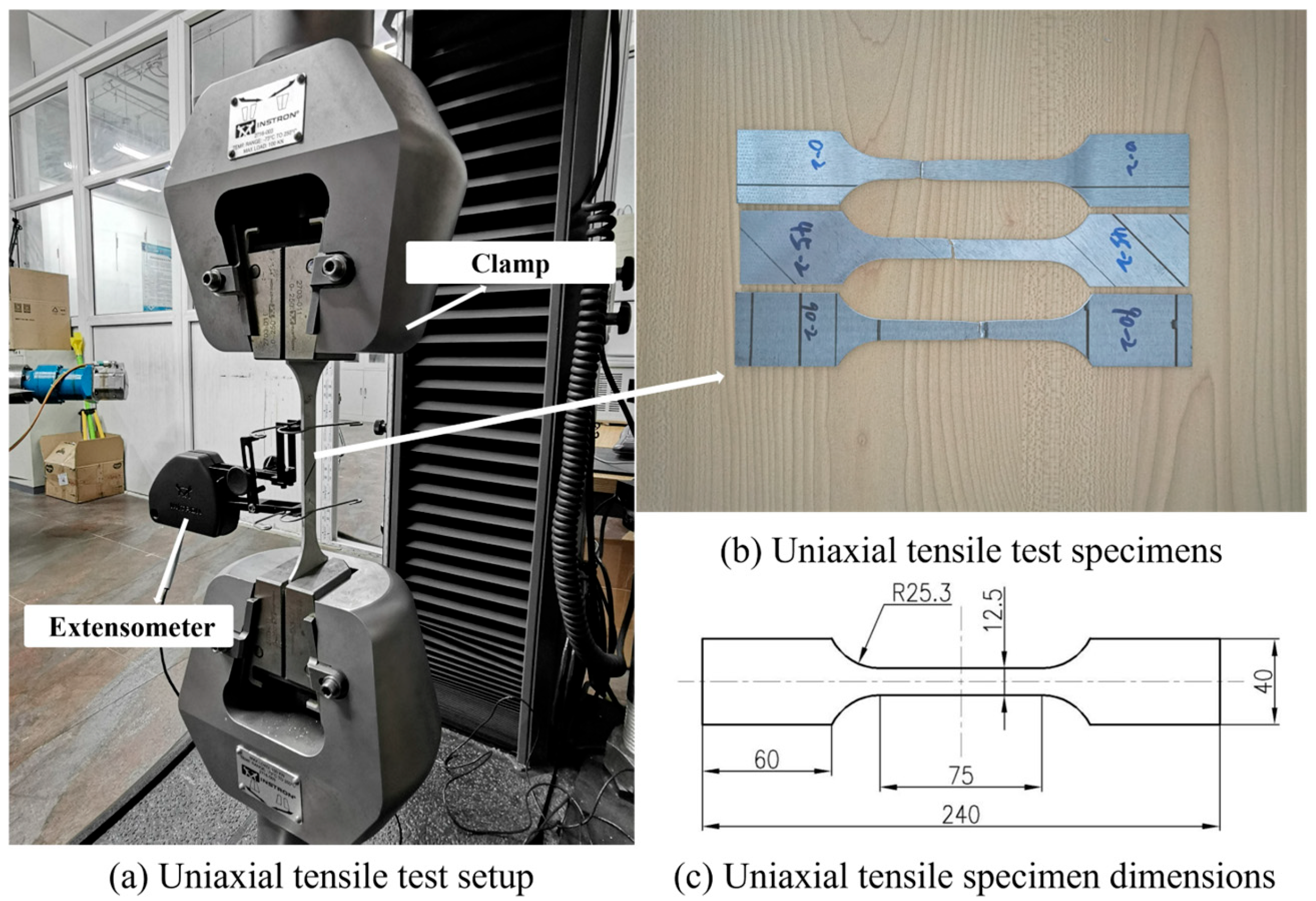

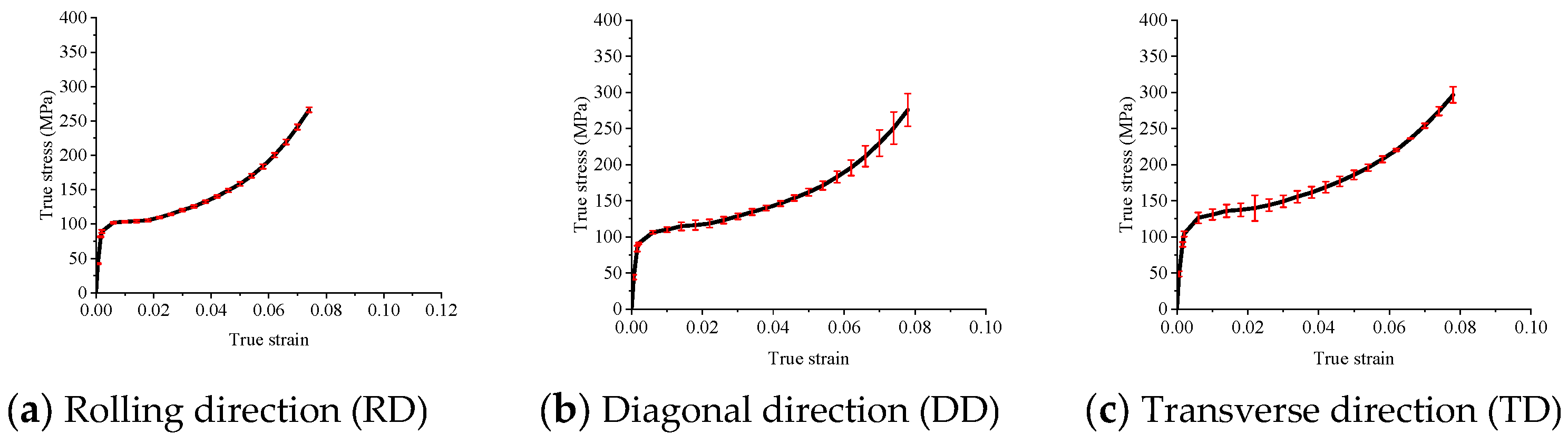

2.1. Uniaxial Tensile Tests

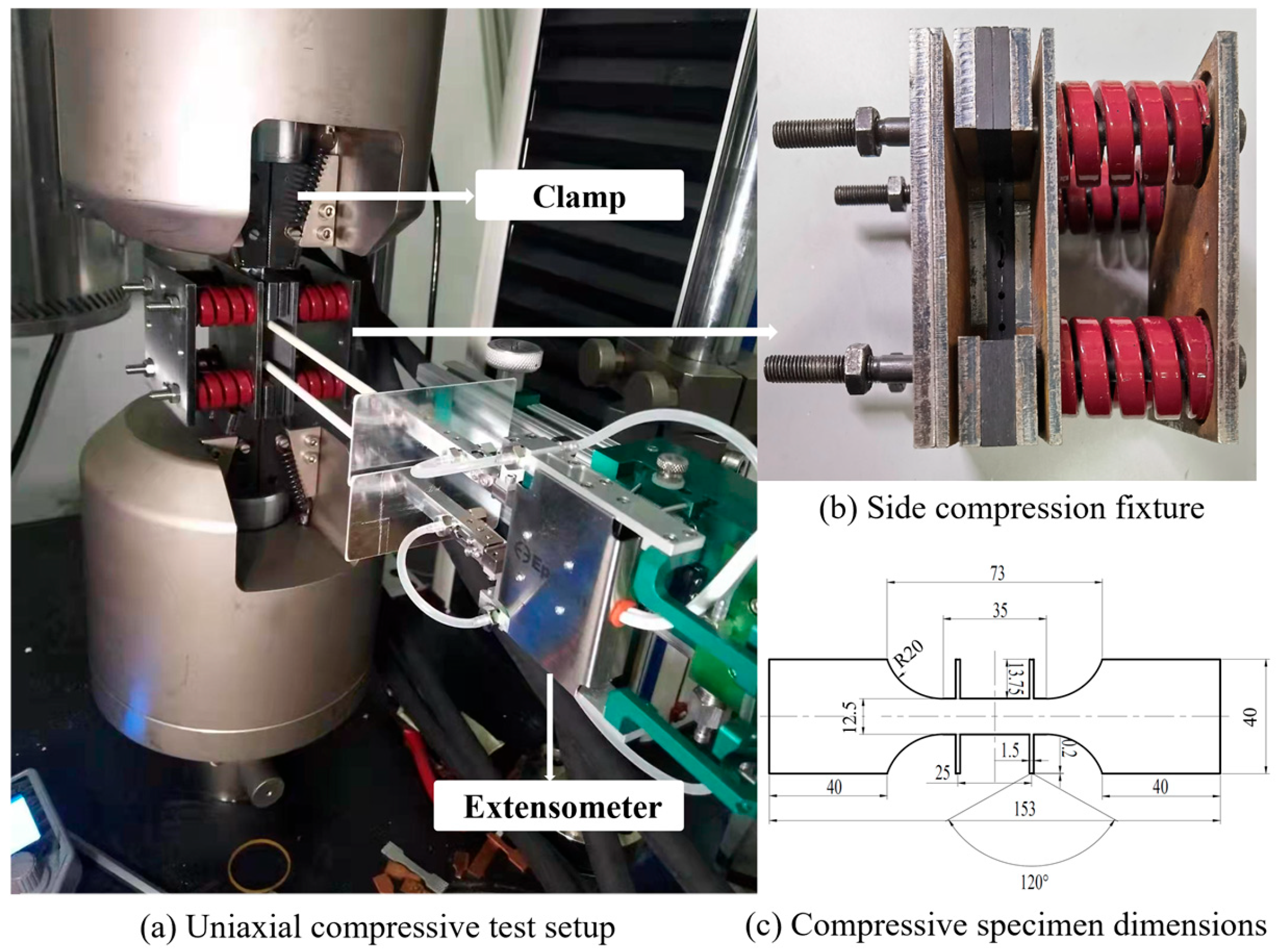

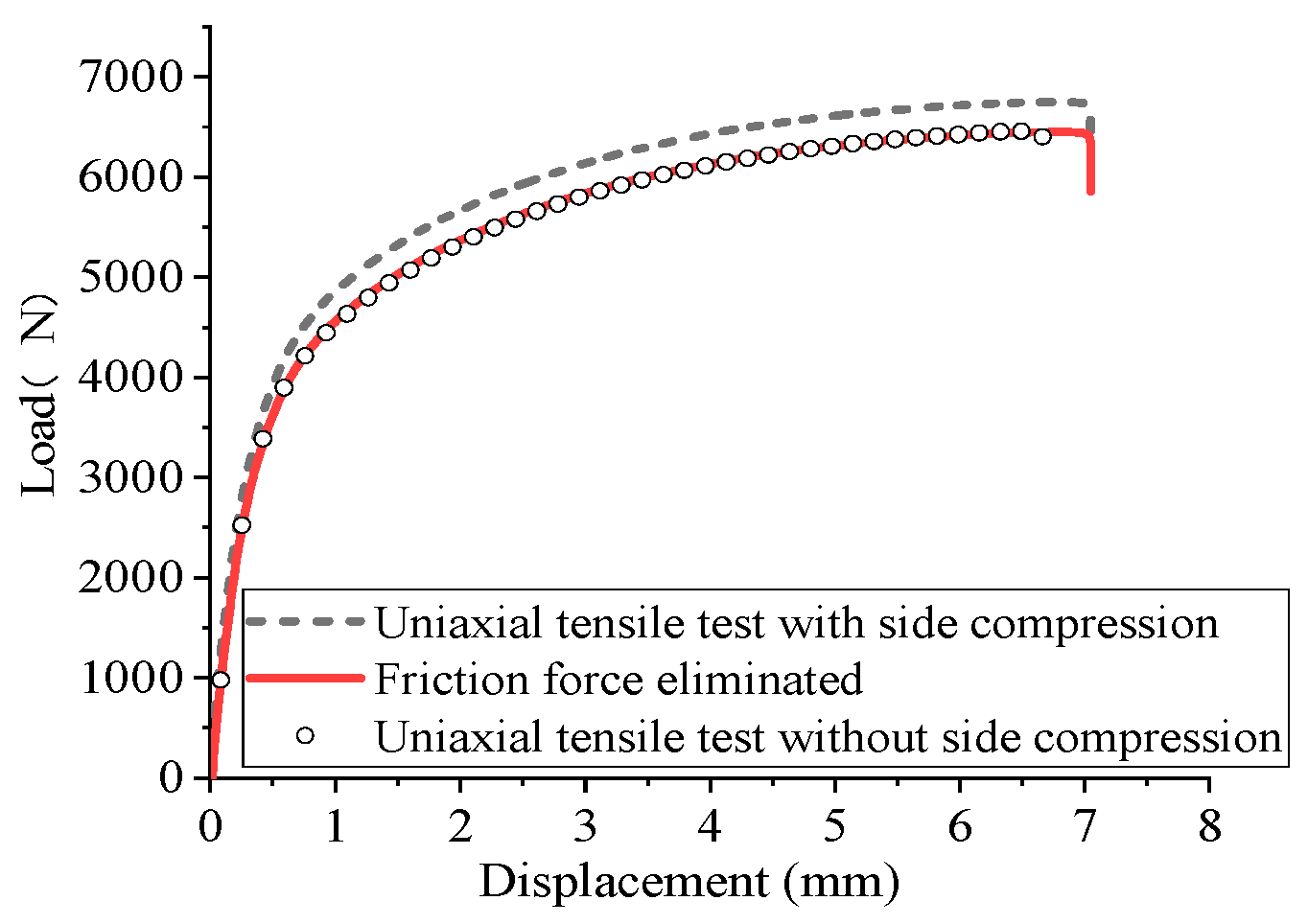

2.2. Uniaxial Compressive Tests

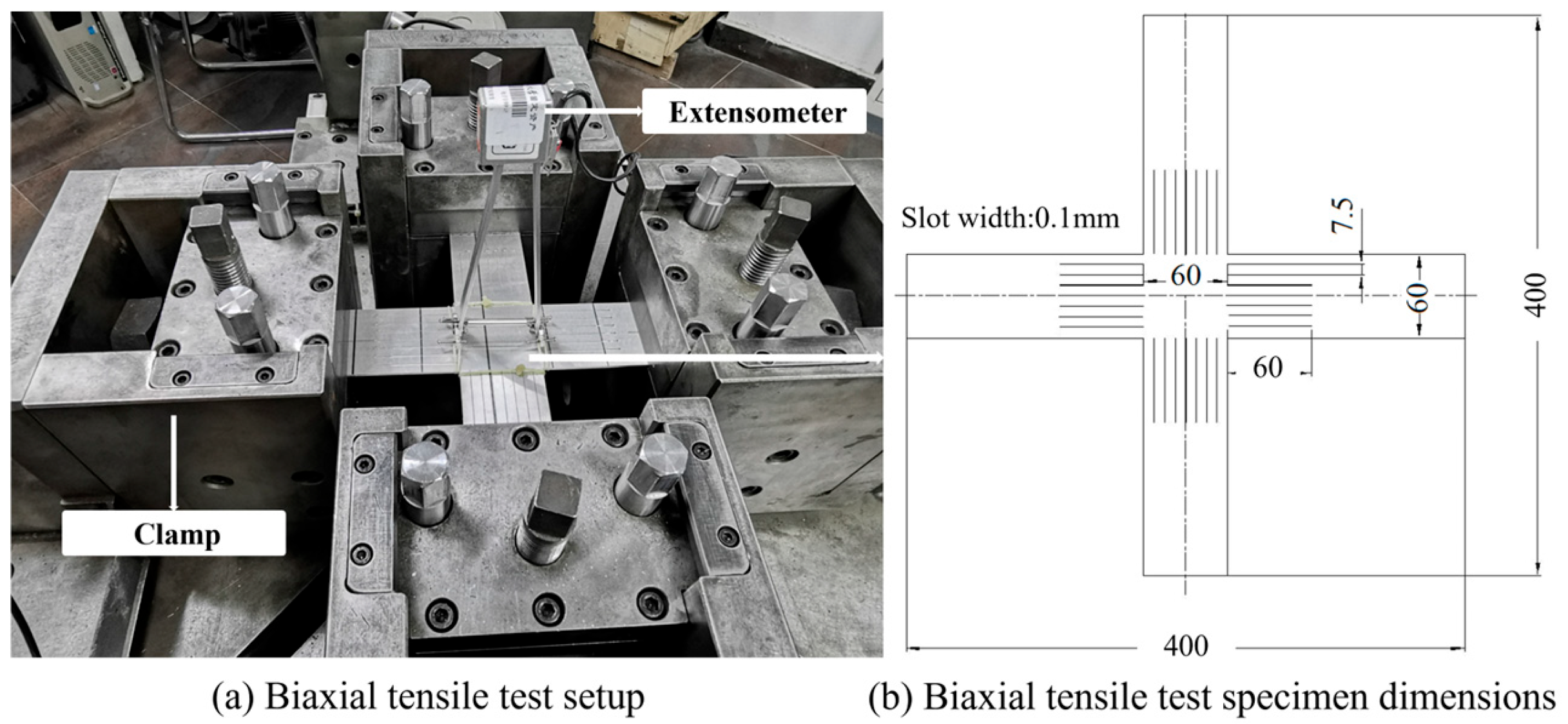

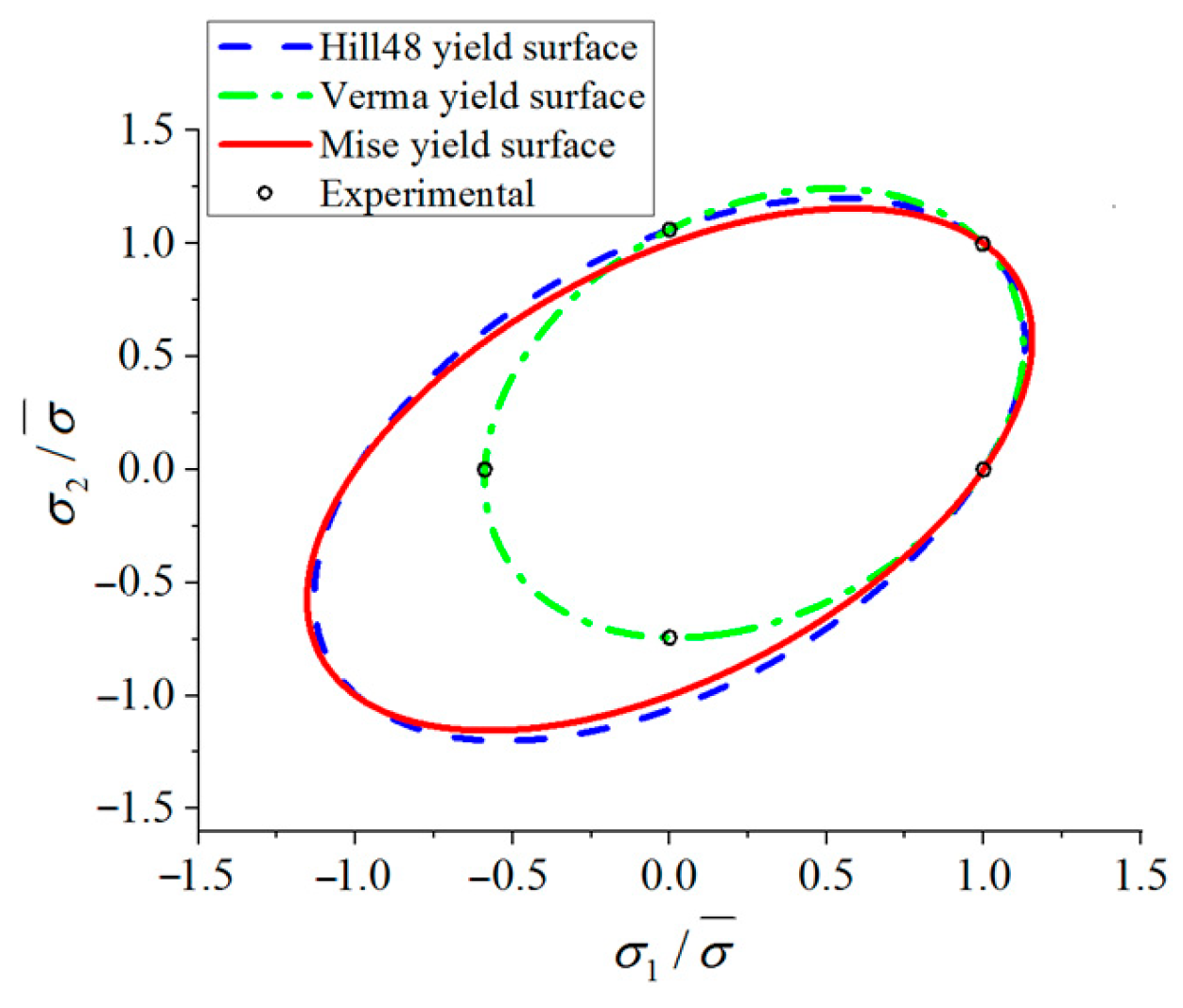

2.3. Biaxial Tensile Tests

2.4. Yield Stresses of AZ31B Obtained from Tensile and Compressive Tests

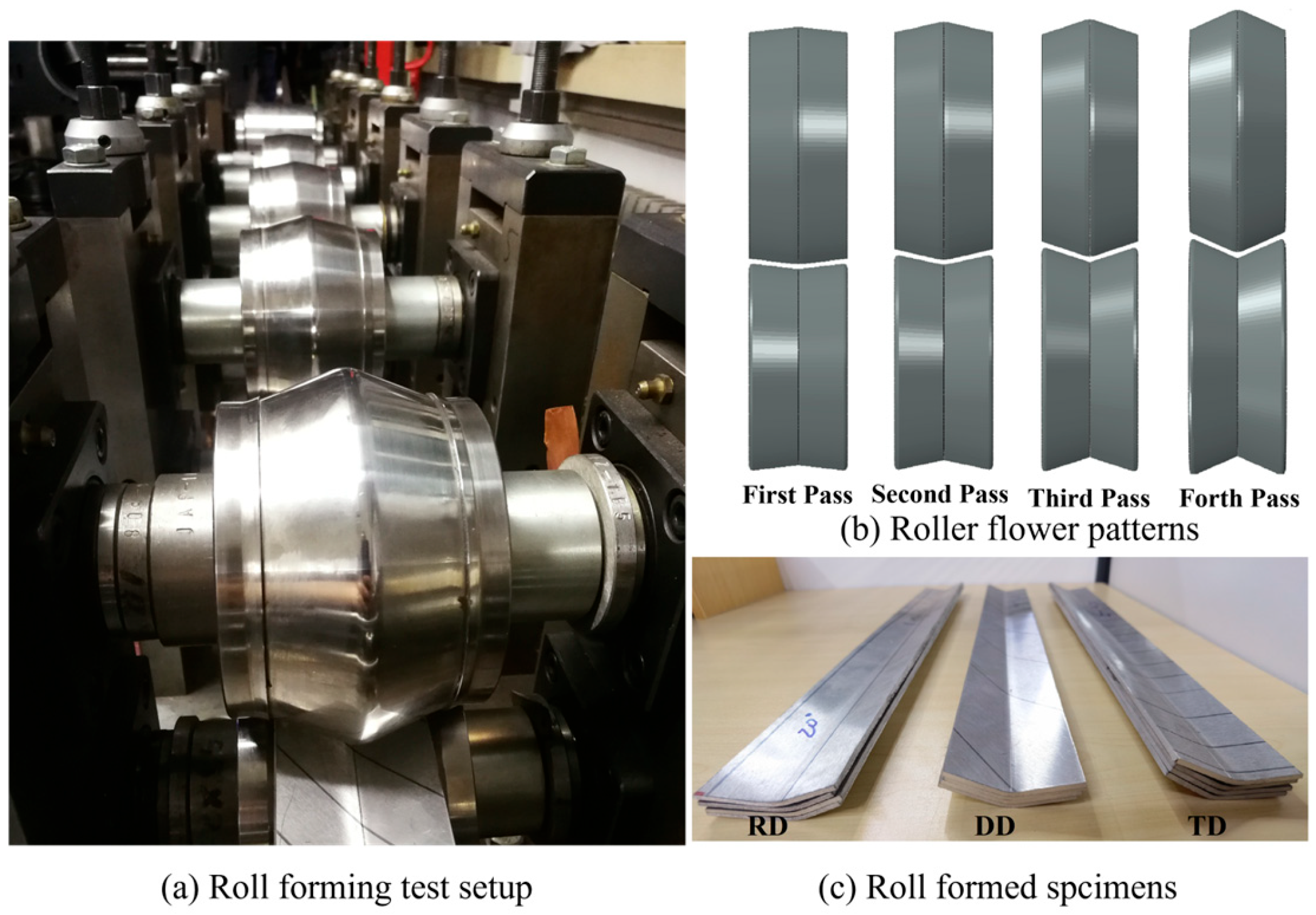

2.5. Roll-Forming Experiment

2.6. Roll-Forming and Springback Process Simulations

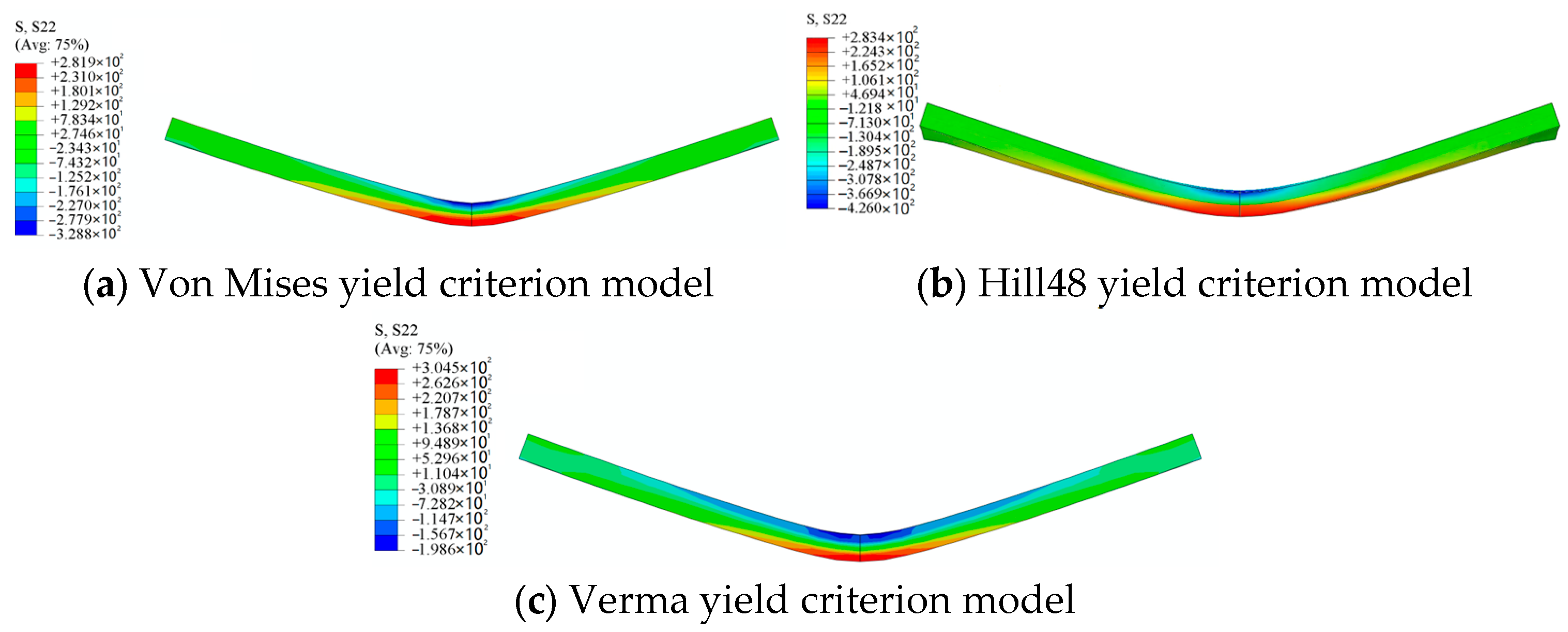

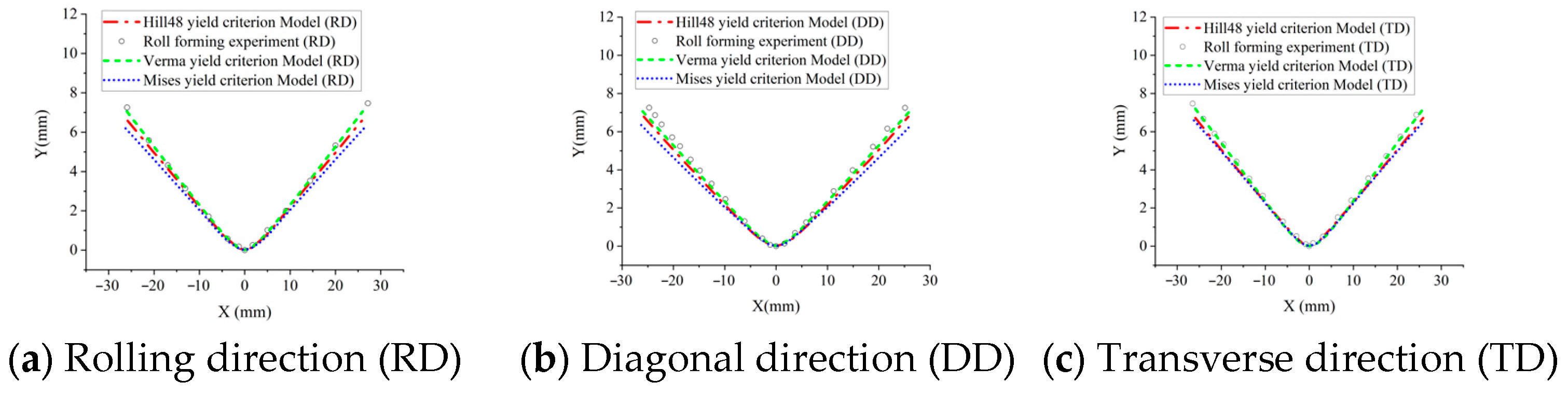

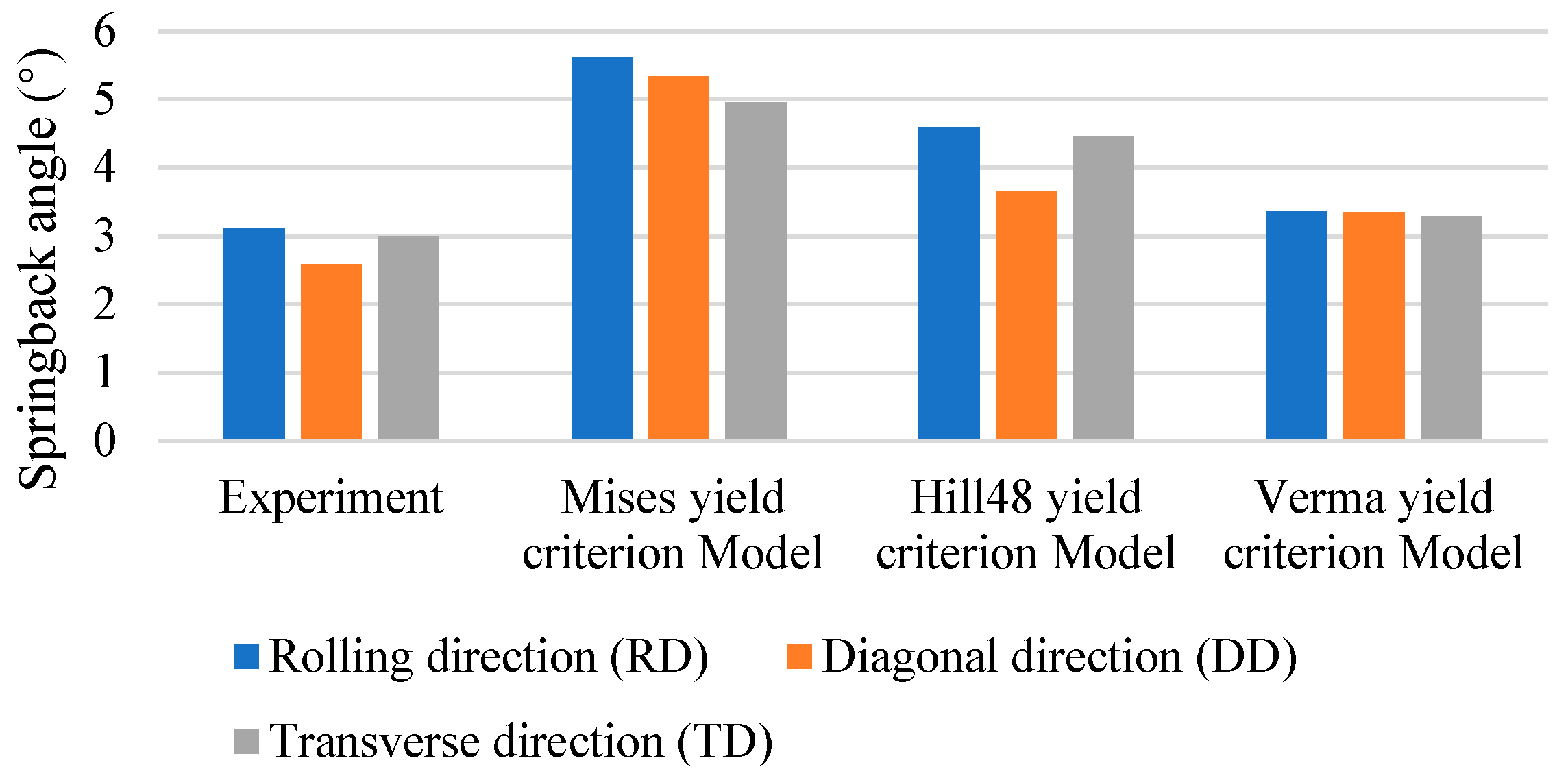

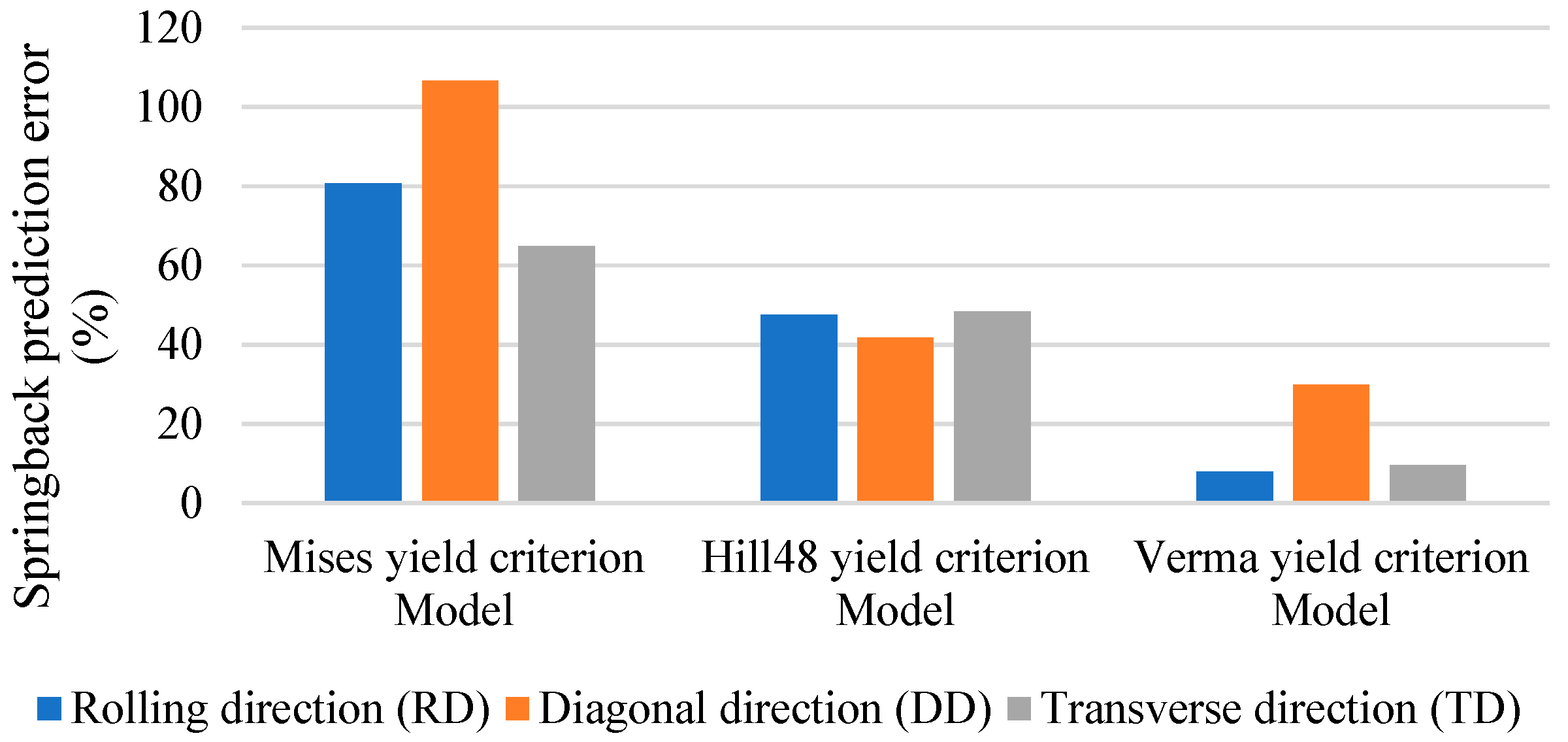

3. Results and Discussion

3.1. Uniaxial Tensile Tests Analysis

3.2. Uniaxial Compressive Tests Analysis

3.3. Hill48 Yield Criterion Under Plane Stress State

- (1)

- The Hill48 stress method based on the yield stress of different tension directions to calculate the parameters

- (2)

- The Hill48–r method that through the r of different tension directions can be used to calculate the following parameters

3.4. Verma Yield Criterion for Plane Stress Condition

3.5. Roll Forming and Springback Analysis

4. Conclusions

- (1)

- The uniaxial tensile tests, compressive tests and biaxial tensile tests of AZ31 magnesium alloy sheets were conducted along different material orientations. The results indicate that besides anisotropy, the material also exhibits obvious tension–compression asymmetry.

- (2)

- A comprehensive comparative analysis of various yield criteria specifically for AZ31B magnesium alloy roll forming is carried out, which has not been extensively studied in this context. The parameters of the Hill48 anisotropic yield criterion (considering anisotropic properties) and the Verma yield criterion (considering both anisotropic and asymmetric properties) are calibrated based on the experimental results.

- (3)

- So as to consider the tension–compression asymmetry in the FEM simulation of AZ31 Mg alloy roll-forming and springback process, the user-subroutine VUMAT including the established Verma yield criterion was developed.

- (4)

- Compared with the von Mises and Hill48 yield criterion FEM models which ignore the tension–compression asymmetry, the final cross-sections calculated with the Verma yield criterion FEM model (Error: 8.04%) are much closer to the roll-forming experimental results than those from the von Mises yield criterion FEM model (80.7%) and Hill48 yield criterion FEM model (47.59%). This demonstrates that the proposed FEM modeling method based on the Verma yield criterion is reliable in magnesium alloy roll-forming and springback simulations. In roll forming, the tensile and compressive deformation amount is substantial. The results highlight the importance of considering tension–compression asymmetry in magnesium alloys roll forming for the first time, and they also emphasize the importance of adopting the proper yield criterion that can reflect the asymmetric yield behaviors in the magnesium alloy forming and springback predictions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, X.J.; Xu, D.K.; Wu, R.Z.; Chen, X.B.; Peng, Q.M.; Jin, L.; Xin, Y.C.; Zhang, Z.Q.; Liu, Y.; Chen, X.H.; et al. What is going on in magnesium alloys. Mater. Sci. Technol. 2018, 34, 245–247. [Google Scholar] [CrossRef]

- Yin, D.D.; Boehlert, C.J.; Long, L.J.; Huang, G.; Zhou, H.; Zheng, J.; Wang, Q.D. Tension-compression asymmetry and the underlying slip/twinning activity in extruded Mg–Y sheets. Int. J. Plast. 2021, 136, 102878. [Google Scholar] [CrossRef]

- Sun, D.; Ponga, M.; Bhattacharya, K.; Ortiz, M. Proliferation of twinning in hexagonal close-packed metals: Application to magnesium. J. Mech. Phys. Solids 2018, 112, 368–384. [Google Scholar] [CrossRef]

- Paralikas, J.; Salonitis, K.; Chryssolouris, G. Energy efficiency of cold roll forming process. Int. J. Adv. Manuf. Technol. 2013, 66, 1271–1284. [Google Scholar] [CrossRef]

- Abeyrathna, B.; Rolfe, B.; Hodgson, P.; Weiss, M. An extension of the flower pattern diagram for roll forming. Int. J. Adv. Manuf. Technol. 2016, 83, 1683–1695. [Google Scholar] [CrossRef]

- Mohanraj, M.; Muhammad, S.; Won, J.D. Experimental and Numerical Investigation of AA5052-H32 Al Alloy with U-Profile in Cold Roll Forming. Materials 2021, 14, 470. [Google Scholar] [CrossRef]

- Suckow, T.; Schroeder, J.; Groche, P. Roll forming of a high strength AA7075 aluminum tube. Prod. Eng. Res. Dev. 2021, 15, 573–586. [Google Scholar] [CrossRef]

- Wang, Y.; Mehari, Z.A.; Wu, J.; Han, J. Optimization design of process parameters for cold and hot composite roll forming of the AHSS square tube using response surface methodology. Int. J. Adv. Manuf. Technol. 2022, 123, 527–542. [Google Scholar] [CrossRef]

- Juchmann, P.; Wolff, S. Mobile with Magnesium Sheet, Magnesium. In Proceedings of the IMA-Proceedings 65th Annual world magnesium Conference, Wauconda, IL, USA, 7–8 November 2008; pp. 75–84. [Google Scholar]

- Nguyen, D.-T.; Yang, S.-H.; Jung, D.-W.; Banh, T.-L.; Kim, Y.-S. A study on material modeling to predict spring-back in V-bending of AZ31 magnesium alloy sheet at various temperatures. Int. J. Adv. Manuf. Technol. 2012, 62, 551–562. [Google Scholar] [CrossRef]

- Hill, R. The Mathematical Theory of Plasticity; Clarendon Press: Oxford, UK, 1950. [Google Scholar]

- Dassault Systèmes. ABAQUS 6.11 Analysis User’s Manual; Dassault Systèmes: Velizy-Villacoublay, France, 2011; Volume III. [Google Scholar]

- Bagherzadeh, S.; Mirnia, M.J.; Dariani, B.M. Numerical and experimental investigations of hydro-mechanical deep drawing process of laminated aluminum/steel sheets. J. Manuf. Process. 2015, 18, 131–140. [Google Scholar] [CrossRef]

- Hu, W. A novel quadratic yield model to describe the feature of multi-yield-surface of rolled sheet metals. Int. J. Plast. 2007, 23, 2004–2028. [Google Scholar] [CrossRef]

- Hussaini, S.M.; Krishna, G.; Gupta, A.K.; Singh, S.K. Development of experimental and theoretical forming limit diagrams for warm forming of austenitic stainless steel 316. J. Manuf. Process. 2015, 18, 151–158. [Google Scholar] [CrossRef]

- Ahmadi, S.; Eivani, A.R.; Akbarzadeh, A. Experimental and analytical studies on the prediction of forming limit diagrams. Comput. Mater. Sci. 2009, 44, 1252–1257. [Google Scholar] [CrossRef]

- Mises, R. Mechanics of Solids in Plastic State; Göttinger Nachrichten Math PhysKl; Göttingen Academy of Sciences: Göttingen, Germany, 1913. [Google Scholar]

- Banabic, D.; Hußnätter, W. Modeling the material behavior of magnesium alloy AZ31 using different yield criteria. Int. J. Adv. Manuf. Technol. 2009, 44, 969–976. [Google Scholar] [CrossRef]

- Kurukuri, S.; Worswick, M.J.; Tari, D.G.; Mishra, P.K.; Carter, J.T. Rate sensitivity and tension–compression asymmetry in AZ31B magnesium alloy sheet. Philos. Trans. R. Soc. A 2014, 372, 20130126. [Google Scholar] [CrossRef]

- Nguyen, N.T.; Seo, O.S.; Lee, C.A.; Lee, M.G.; Kim, J.M.; Kim, H.Y. Mechanical Behavior of AZ31B Mg Alloy Sheets under Monotonic and Cyclic Loadings at Room and Moderately Elevated Temperatures. Materials 2014, 7, 1271–1295. [Google Scholar] [CrossRef]

- Steglich, D.; Tian, X.; Bohlen, J.; Kuwabara, T. Mechanical Testing of Thin Sheet Magnesium Alloys in Biaxial Tension and Uniaxial Compression. Exp. Mech. 2014, 54, 1247–1258. [Google Scholar] [CrossRef]

- Shi, B.; Yang, C.; Peng, Y.; Zhang, F.; Pan, F. Anisotropy of wrought magnesium alloys: A focused overview. J. Magnes. Alloys 2022, 10, 1476–1510. [Google Scholar] [CrossRef]

- Chandola, N.; Lebensohn, R.A.; Cazacu, O.; Revil-Baudard, B.; Mishra, R.K.; Barlat, F. Combined effects of anisotropy and tension-compression asymmetry on the torsional response of AZ31 Mg. Int. J. Solids Struct. 2015, 58, 190–200. [Google Scholar] [CrossRef]

- Wang, Y.J.; Zhang, Y.; Jiang, H. Tension-compression asymmetry and corresponding deformation mechanism in ZA21 magnesium bars with bimodal structure. Int. J. Miner. Metall. Mater. 2021, 30, 92–103. [Google Scholar] [CrossRef]

- Tari, D.G.; Worswick, M.J.; Ali, U.; Gharghouri, M.A. Mechanical response of AZ31B magnesium alloy: Experimental characterization and material modeling considering proportional loading at room temperature. Int. J. Plast. 2014, 55, 247–267. [Google Scholar] [CrossRef]

- Habib, S.A.; Khan, A.S.; Gnäupel-Herold, T.; Lloyd, J.T.; Schoenfeld, S. Anisotropy, tension-compression asymmetry and texture evolution of a rare-earth-containing magnesium alloy sheet, ZEK100, at different strain rates and temperatures: Experiments and modeling. Int. J. Plast. 2017, 95, 163–190. [Google Scholar] [CrossRef]

- Muhammad, W.; Mohammadi, M.; Kang, J.D.; Mishra, R.K.; Inal, K. An elasto-plastic constitutive model for evolving asymmetric/anisotropic hardening behavior of AZ31B and ZEK100 magnesium alloy sheets considering monotonic and reverse loading paths. Int. J. Plast. 2015, 70, 30–59. [Google Scholar] [CrossRef]

- Zhou, P.; Beeh, E.; Friedrich, H.E. Influence of Tension-Compression Asymmetry on the Mechanical Behavior of AZ31B Magnesium Alloy Sheets in Bending. J. Mater. Eng. Perform. 2016, 25, 853–865. [Google Scholar] [CrossRef]

- Nobre, J.P.; Noster, U.; Kornmeier, M.; Morão, D.A.; Scholtes, B. Deformation Asymmetry of AZ31 Wrought Magnesium Alloy. Key Eng. Mater. 2002, 455, 267–270. [Google Scholar] [CrossRef]

- Emile, R.; Pascale, B.; Ludovic, C. Effect of tension-compression asymmetry of AZ31B magnesium alloys on four-point bending. Mech. Res. Commun. 2021, 114, 103672. [Google Scholar] [CrossRef]

- Cazacu, O.; Barlat, F. A criterion for description of anisotropy and yield differential effects in pressure-insensitive metals. Int. J. Plast. 2004, 20, 2027–2045. [Google Scholar] [CrossRef]

- Kim, J.; Ryou, H.; Kim, D.; Kim, D.; Lee, W.; Hong, S.H.; Chung, K. Constitutive law for AZ31B Mg alloy sheets and finite element simulation for three-point bending. Int. J. Mech. Sci. 2008, 50, 1510–1518. [Google Scholar] [CrossRef]

- Cazacu, O.; Plunkett, B.; Barlat, F. Orthotropic yield criterion for hexagonal closed packed metals. Int. J. Plast. 2006, 22, 1171–1194. [Google Scholar] [CrossRef]

- Verma, R.; Kuwabara, T.; Chung, K.; Haldar, A. Experimental evaluation and constitutive modeling of non-proportional deformation for asymmetric steels. Int. J. Plast. 2011, 27, 82–101. [Google Scholar] [CrossRef]

- Hill, R. A Theory of the Yielding and Plastic Flow of Anisotropic Metals. Proc. R. Soc. Lond. 1948, 193, 281–297. [Google Scholar] [CrossRef]

- Hoffman, O. The Brittle Strength of Orthotropic Materials. J. Compos. Mater. 1967, 1, 200–206. [Google Scholar] [CrossRef]

- GB/T 228.1-2021; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. Chinese Standard Press: Beijing, China, 2021.

- Bae, G.H.; Huh, H. Tension/compression test of auto-body steel sheets with the variation of the pre-strain and the strain rate. Trans. Eng. Sci. 2011, 72, 213–225. [Google Scholar]

- Yoshida, F.; Uemori, T.; Fujiwara, K. Elastic–plastic behavior of steel sheets under in-plane cyclic tension–compression at large strain. Int. J. Plast. 2002, 18, 633–659. [Google Scholar] [CrossRef]

- Kuwabara, T.; Kumano, Y.; Ziegelheim, J.; Kurosaki, I. Tension–compression asymmetry of phosphor bronze for electronic parts and its effect on bending behavior. Int. J. Plast. 2009, 25, 1759–1776. [Google Scholar] [CrossRef]

- Dong, H.; Li, X.; Li, Y.; Wang, H.; Peng, X.; Zhang, S.; Meng, B.; Yang, Y.; Li, D.; Balan, T. An experimental and modelling study of cyclic tension-compression behavior of AA7075-T6 under electrically-assisted condition. J. Mater. Process. Technol. 2022, 307, 117661. [Google Scholar] [CrossRef]

- Lou, X.Y.; Li, M.; Boger, R.K.; Agnew, S.R.; Wagoner, R.H. Hardening evolution of AZ31B Mg sheet. Int. J. Plast. 2007, 23, 44–86. [Google Scholar] [CrossRef]

- Wang, R.; Xue, S.; Zhou, W.; Wang, X.; Li, Z.; Meng, Z.; Ma, L. Microstructure evolution and springback behavior in single-pass roll bending of magnesium alloy plates. J. Alloys Compd. 2024, 1009, 14. [Google Scholar] [CrossRef]

| 168.92 | 174.43 | 179.11 | 168. 50 | 99.43 | 104.19 | 125.61 |

| F | G | H | N | R11 | R22 | R33 | R12 | R13 | R23 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Hill48 | 0.45 | 0.56 | 0.44 | 1.37 | 1 | 1.06 | 1.00 | 1.09 | 1.09 | 1.09 |

| a | A | B | C | k1 | k2 | |

|---|---|---|---|---|---|---|

| Verma | 1.349 | 0.395 | 0.719 | 2.073 | 0.349 | 0.201 |

| Hill48 Inner | Hill48 Outer | Verma Inner | Verma Outer | Von Mises Inner | Von Mises Outer | |

|---|---|---|---|---|---|---|

| Average bending stress (MPa) | −317.43 | 252.07 | −291.5 | 243.3 | −306.12 | 324.4 |

| Experiment (°) | Von Mises Yield Criterion Model Error (%) | Hill48 Yield Criterion Model Error (%) | Verma Yield Criterion Model Error (%) | |

|---|---|---|---|---|

| Rolling direction (RD) | 3.11 | 80.7 | 47.59 | 8.04 |

| Diagonal direction (DD) | 2.58 | 106.6 | 41.86 | 29.84 |

| Transverse direction (TD) | 3.00 | 65.0 | 48.33 | 9.67 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, Y.; Xu, H.; Wang, H.; Bao, J. AZ31 Magnesium Alloy Roll-Forming Springback Prediction Considering Anisotropic and Asymmetric Properties. Materials 2025, 18, 3111. https://doi.org/10.3390/ma18133111

Yan Y, Xu H, Wang H, Bao J. AZ31 Magnesium Alloy Roll-Forming Springback Prediction Considering Anisotropic and Asymmetric Properties. Materials. 2025; 18(13):3111. https://doi.org/10.3390/ma18133111

Chicago/Turabian StyleYan, Yu, Hanzhong Xu, Haibo Wang, and Jie Bao. 2025. "AZ31 Magnesium Alloy Roll-Forming Springback Prediction Considering Anisotropic and Asymmetric Properties" Materials 18, no. 13: 3111. https://doi.org/10.3390/ma18133111

APA StyleYan, Y., Xu, H., Wang, H., & Bao, J. (2025). AZ31 Magnesium Alloy Roll-Forming Springback Prediction Considering Anisotropic and Asymmetric Properties. Materials, 18(13), 3111. https://doi.org/10.3390/ma18133111