Experimental and Numerical Assessment of Sustainable Concrete Using Recycled Concrete Powder (RCP) as a Partial Replacement for Cement

Abstract

1. Introduction

2. Research Significance

- -

- Address existing research gaps by investigating the use of recycled concrete powder (RCP) as a partial replacement for cement.

- -

- Evaluate the potential of RCP to lower CO₂ emissions while maintaining the mechanical performance of concrete.

- -

- Examine the effects of RCP on the mechanical and microstructural properties of concrete.

- -

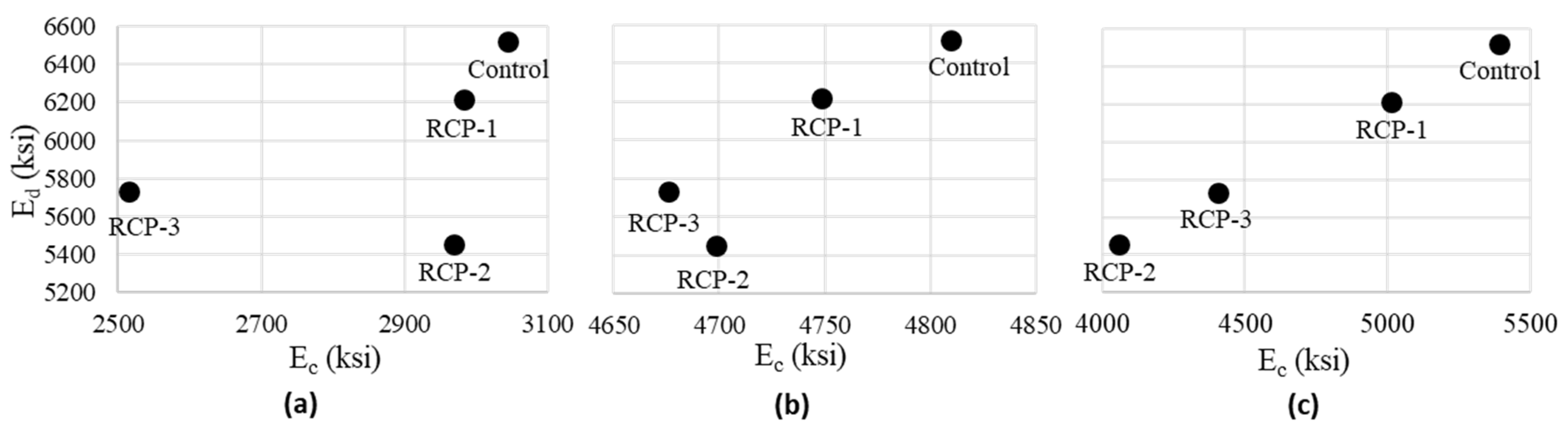

- Compare the dynamic and static elastic moduli in concrete mixes that include RCP.

- -

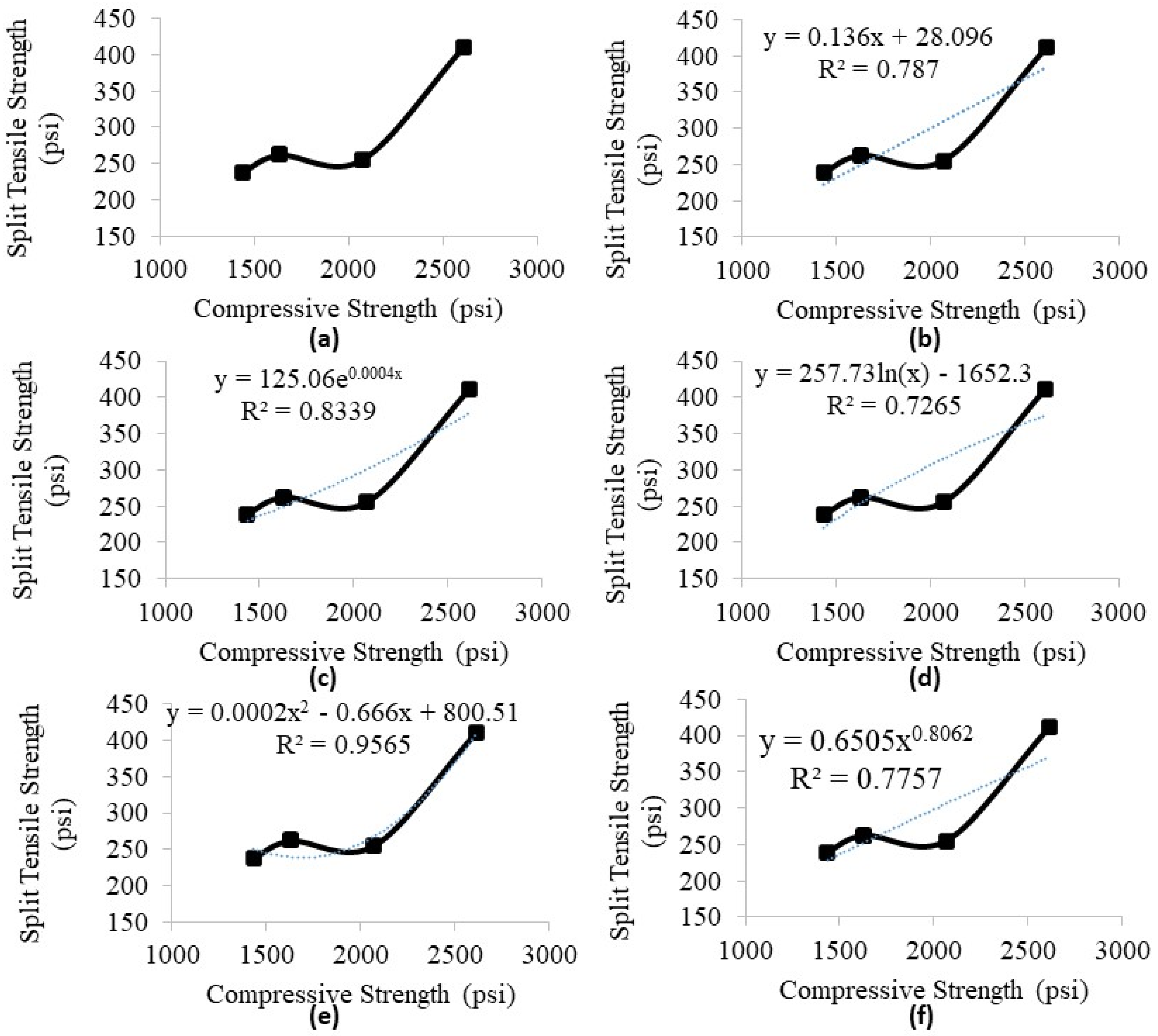

- Develop a regression model that correlates compressive strength and split tensile strength.

- -

- Utilize finite element analysis to gain insights into the structural behavior of concrete modified with RCP.

3. Experimental Work

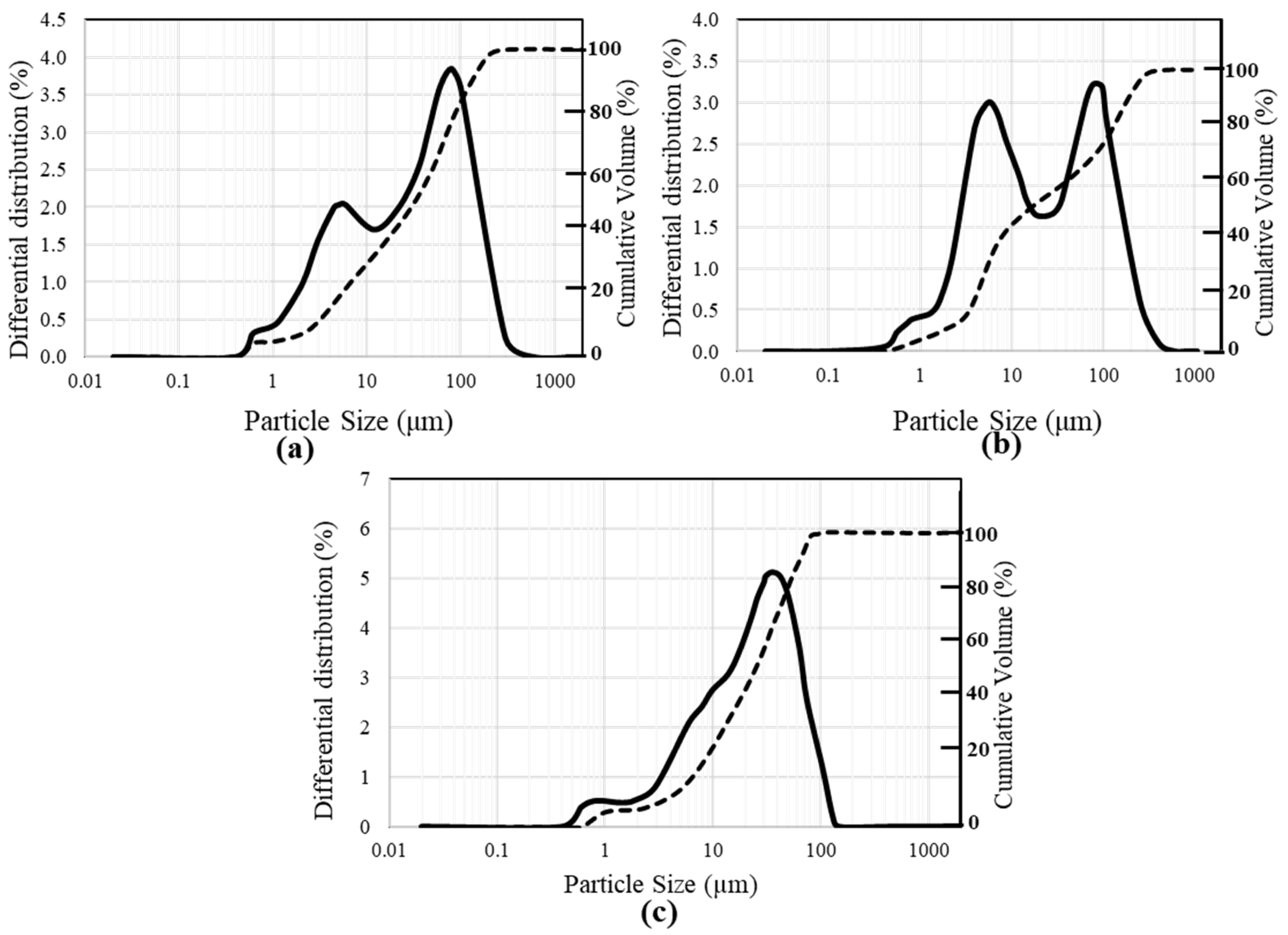

3.1. Materials

3.1.1. Cement

3.1.2. Recycled Concrete Powder (RCP)

3.1.3. Characterization of Cement and RCP via XRF

3.1.4. Characterization of Cement and RCP via XRD

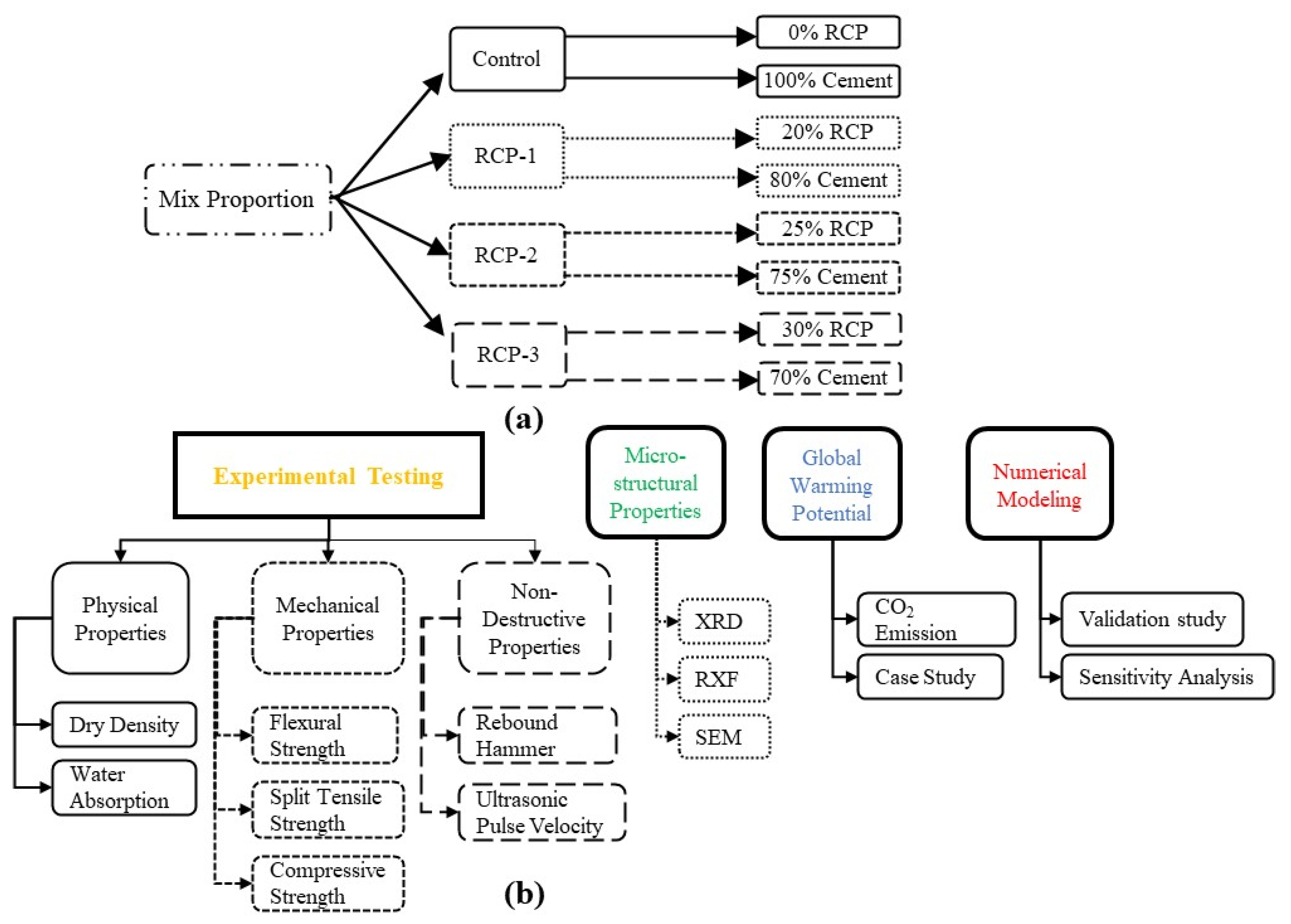

3.2. Mix Proportions

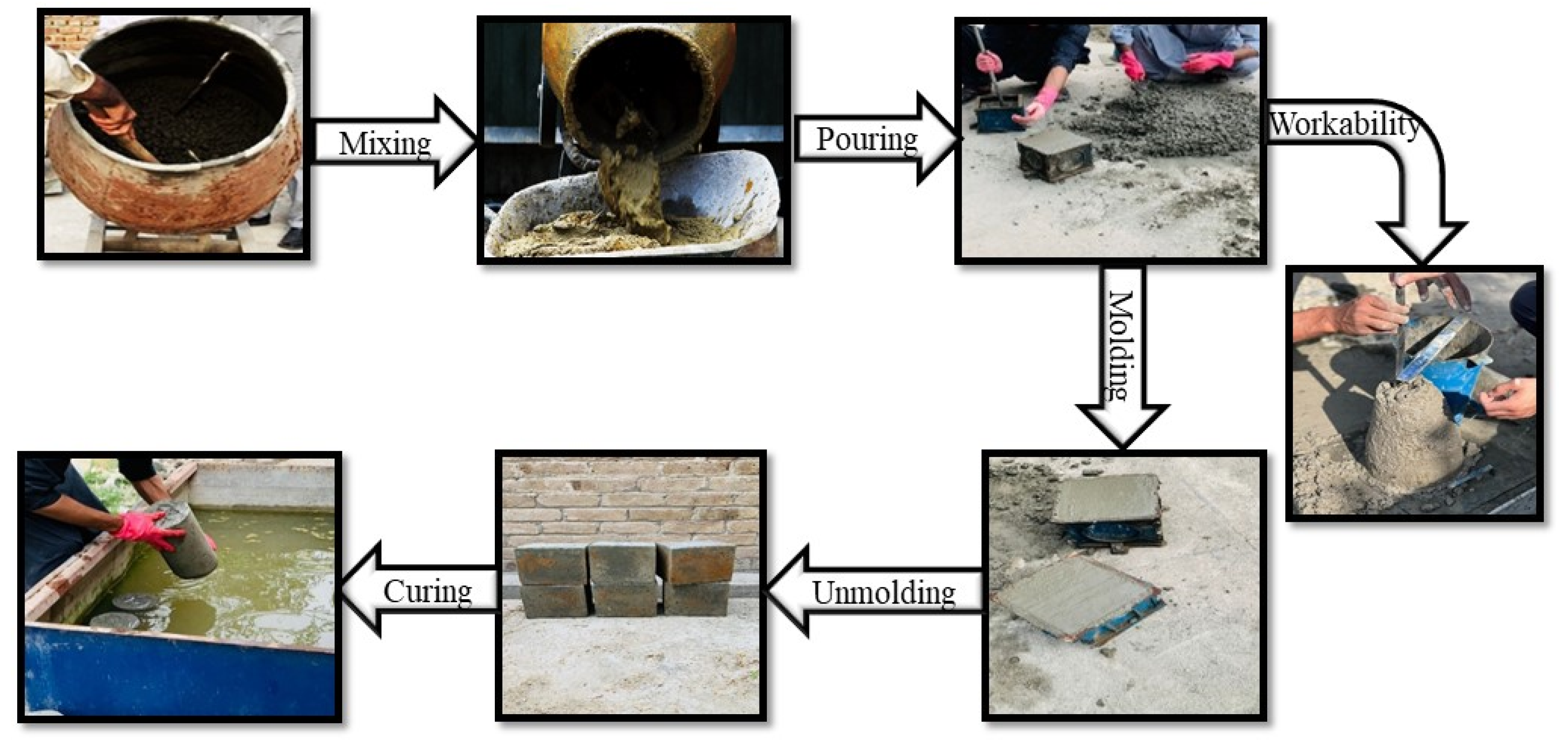

3.3. Testing Procedure

3.3.1. Physical Properties

Water Absorption

Dry Density

3.3.2. Mechanical Properties

3.3.3. Non-Destructive Testing

3.3.4. Microstructural Behavior Using Scanning Electron Microscopy

3.4. Global Warming Potential (GWP)

4. Numerical Modeling

4.1. Concrete Damage Plasticity

4.2. Geometry and Meshing

4.3. Loading and Boundary Conditions

5. Results and Discussion

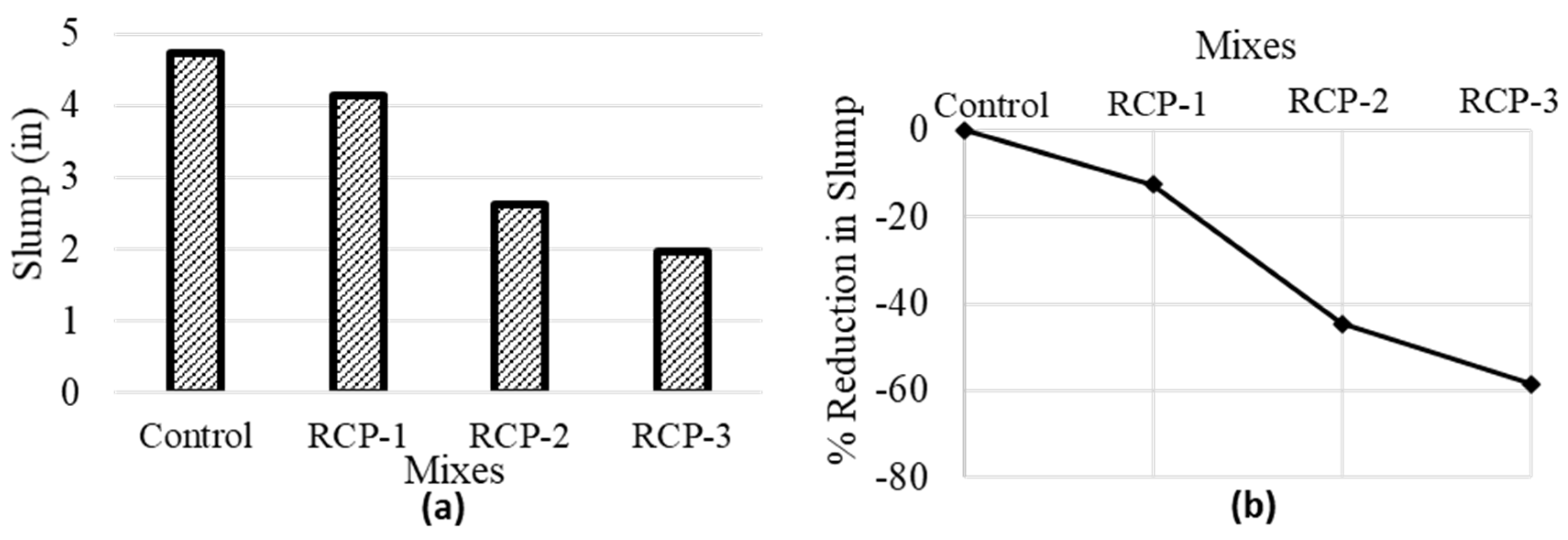

5.1. Fresh Properties

5.1.1. Standard Consistency

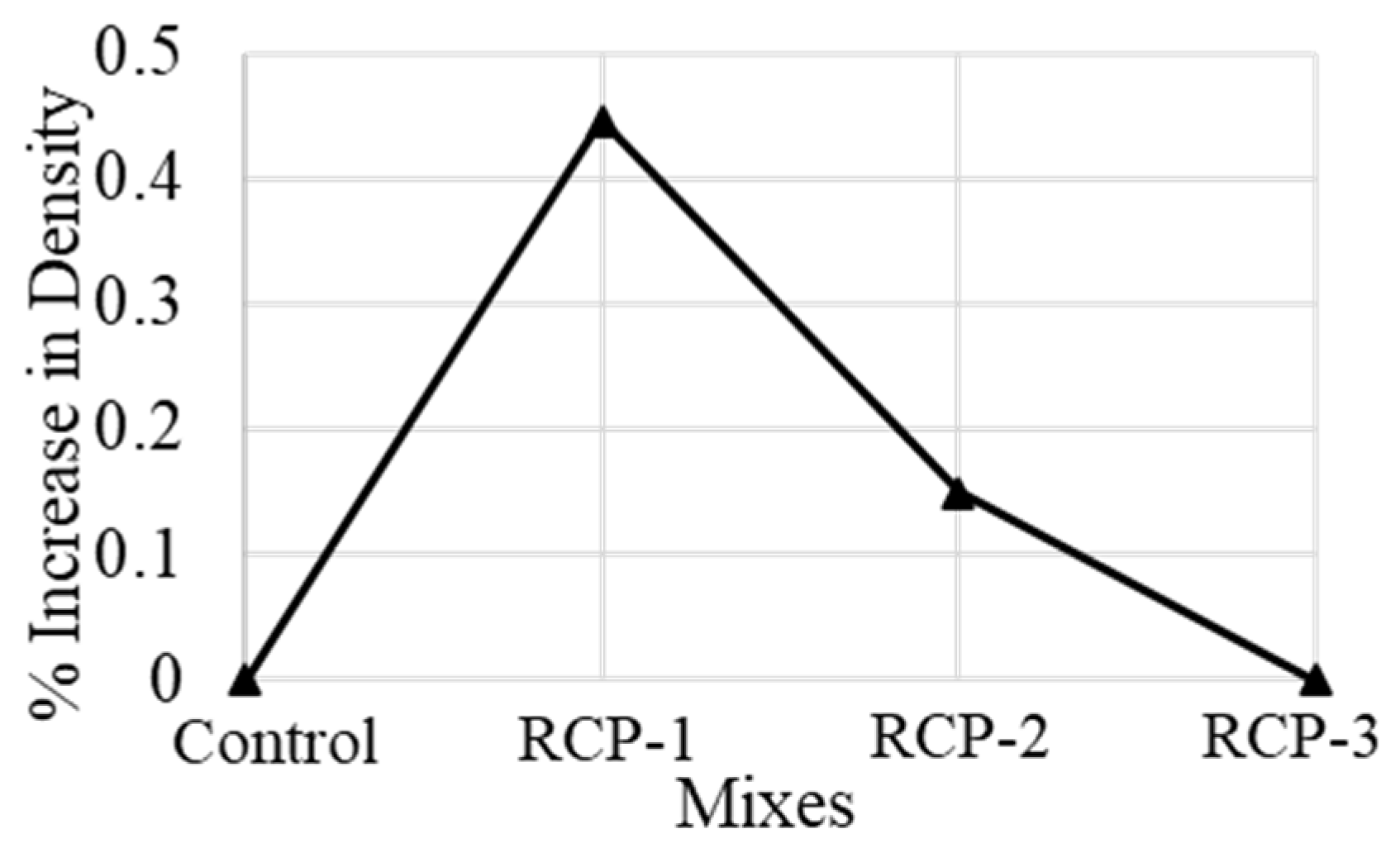

5.1.2. Dry Density

5.1.3. Water Absorption

5.2. Mechanical Properties

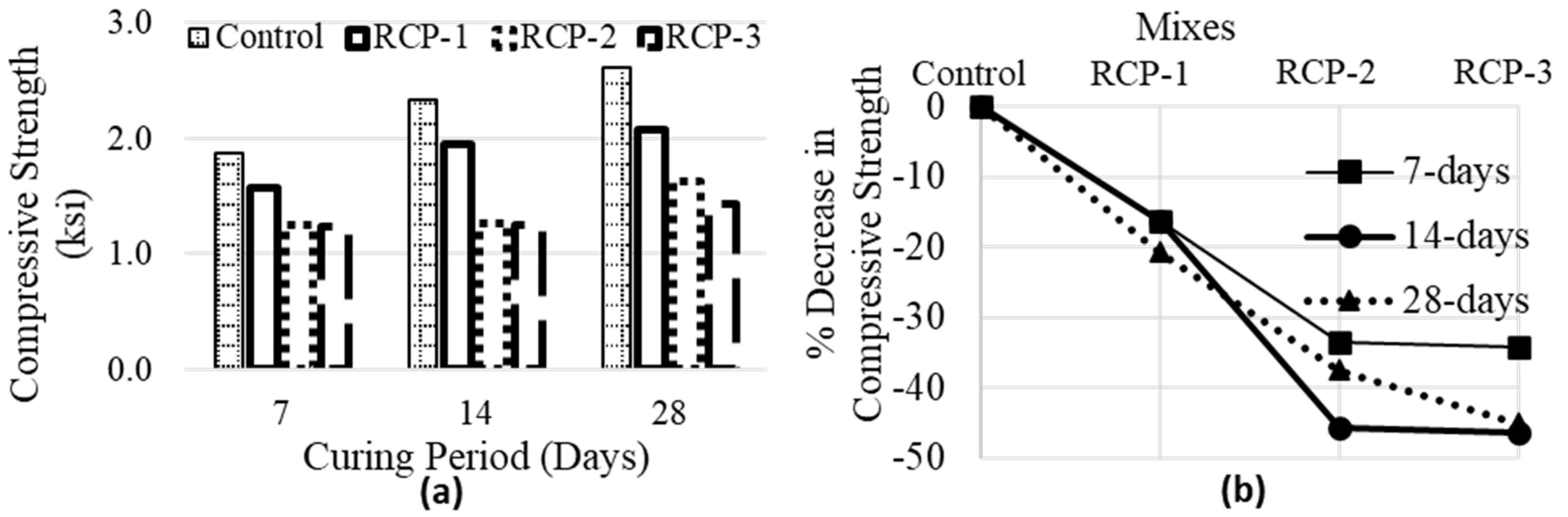

5.2.1. Compressive Strength

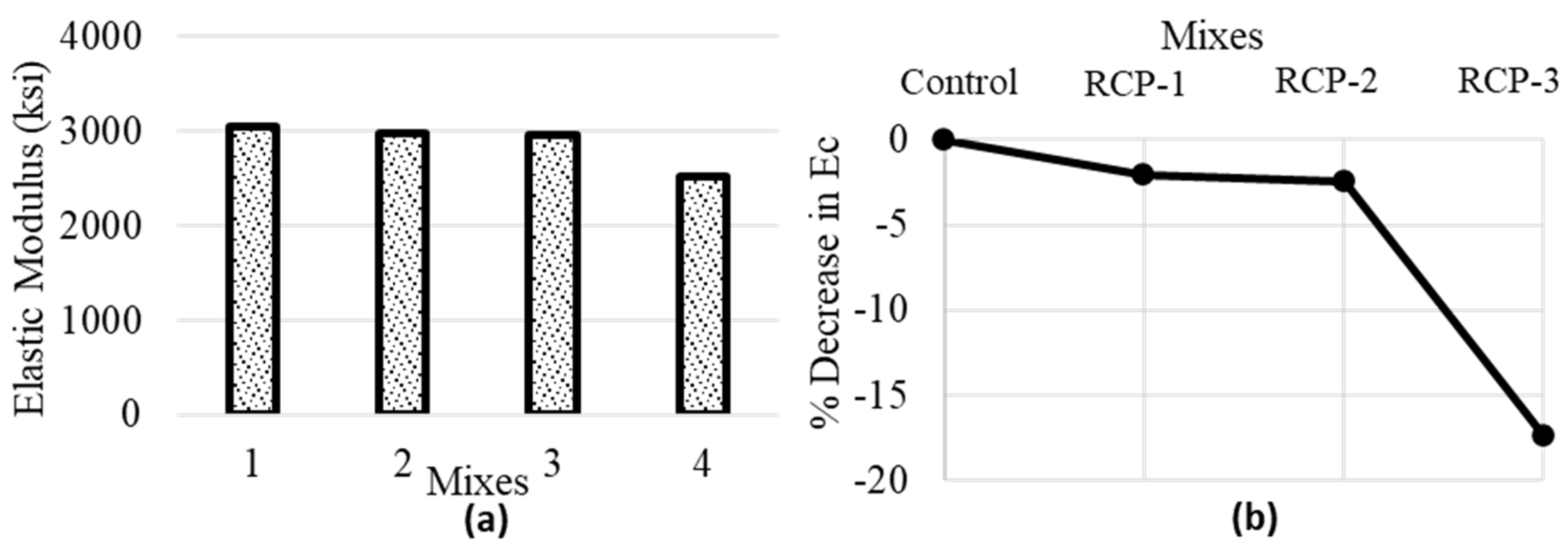

5.2.2. Static Modulus of Elasticity

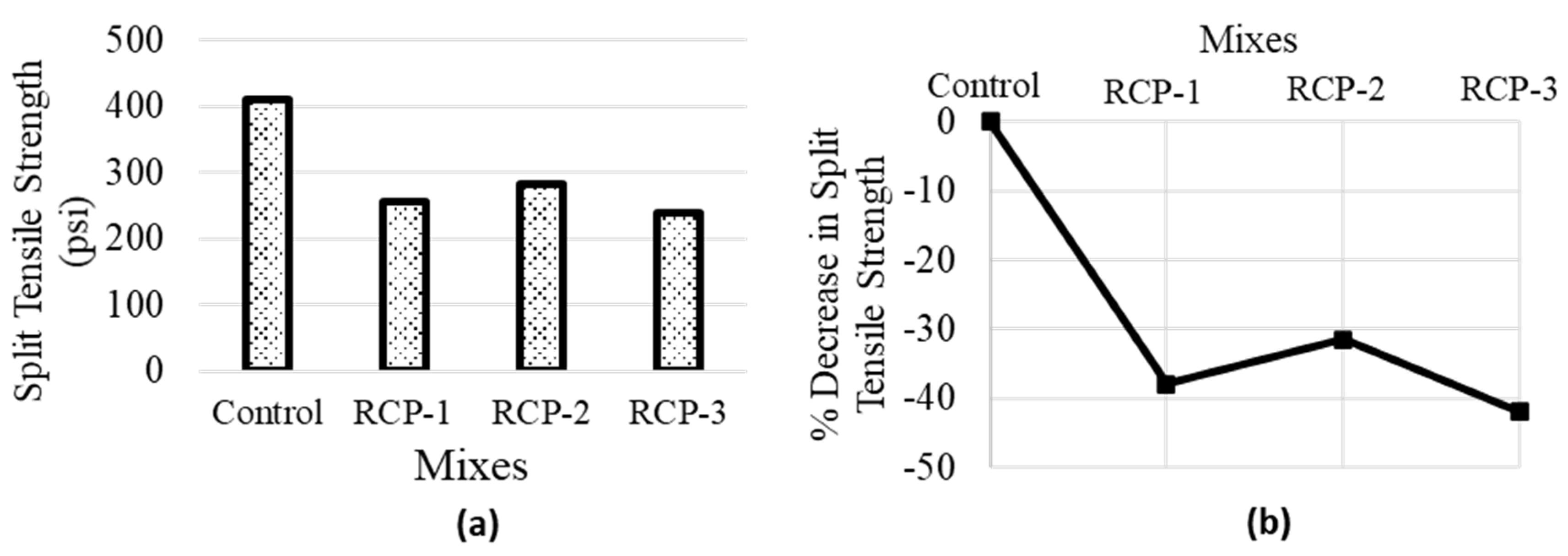

5.2.3. Split Tensile Strength

5.2.4. Correlation of Compressive Strength with Split Tensile Strength

5.3. Non-Destructive Testing

5.3.1. Surface Hardness

5.3.2. Ultrasonic Pulse Velocity

5.3.3. Dynamic Modulus of Elasticity

5.3.4. Correlation of Dynamic and Static Elastic Moduli

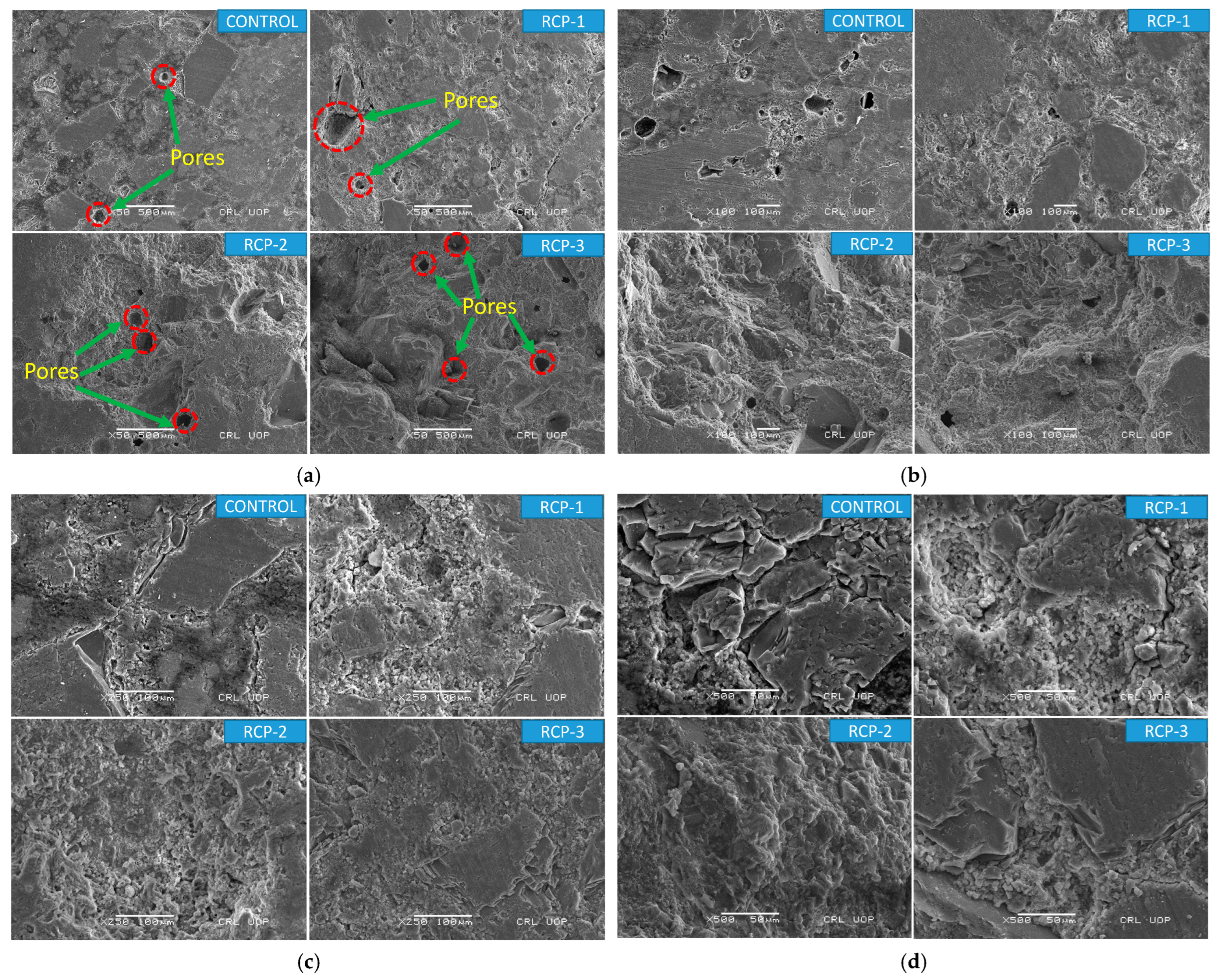

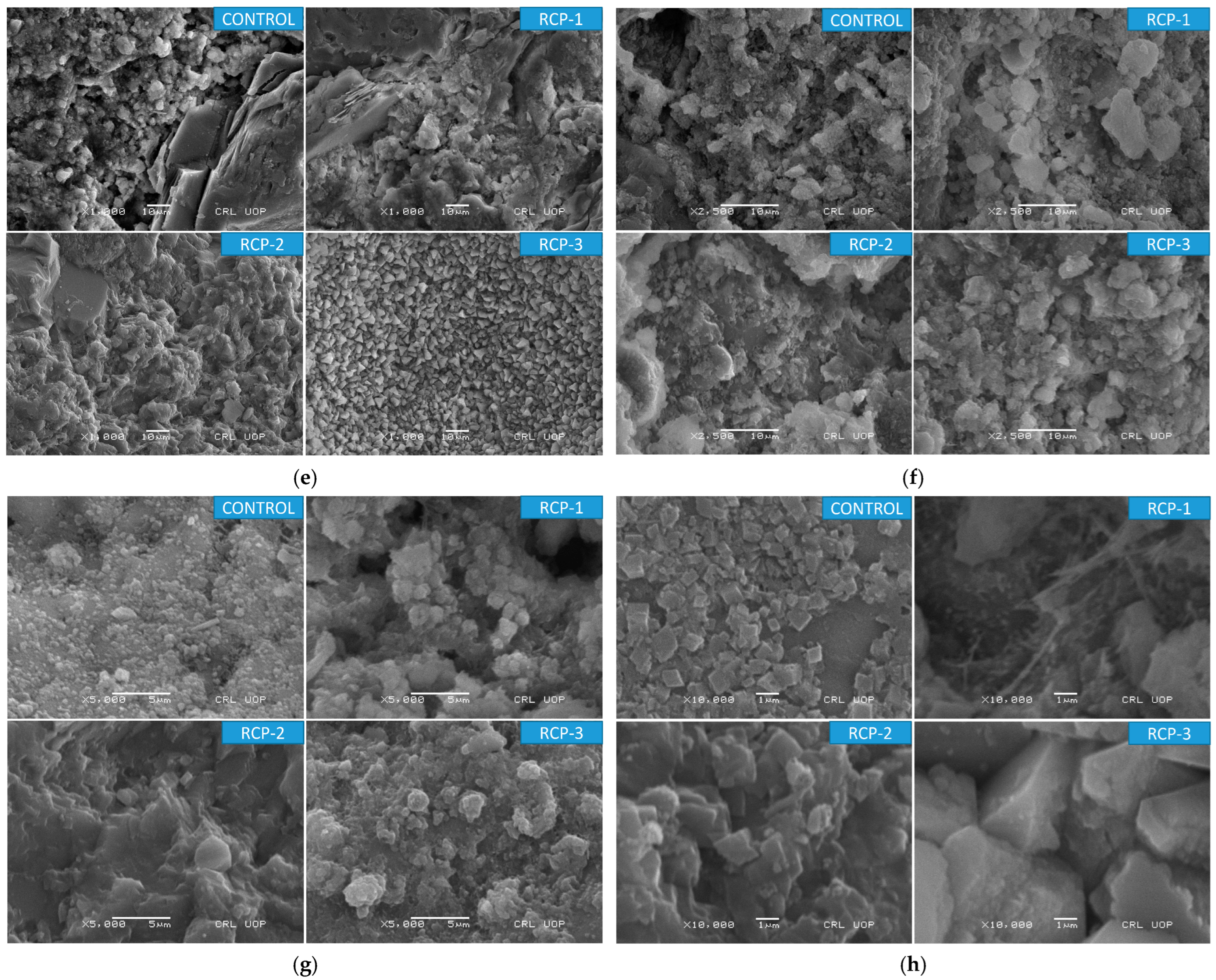

5.4. Analysis of Microstructure

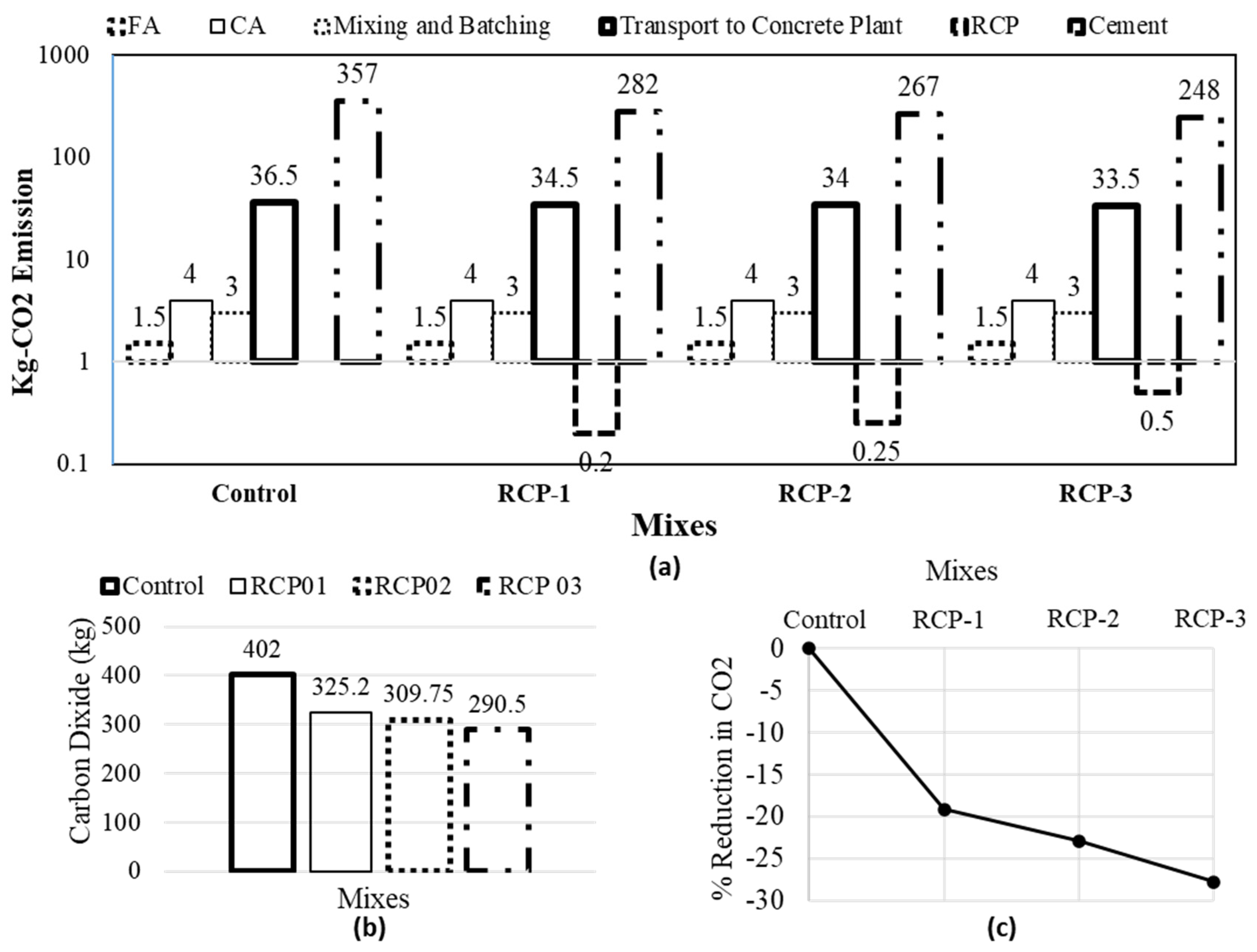

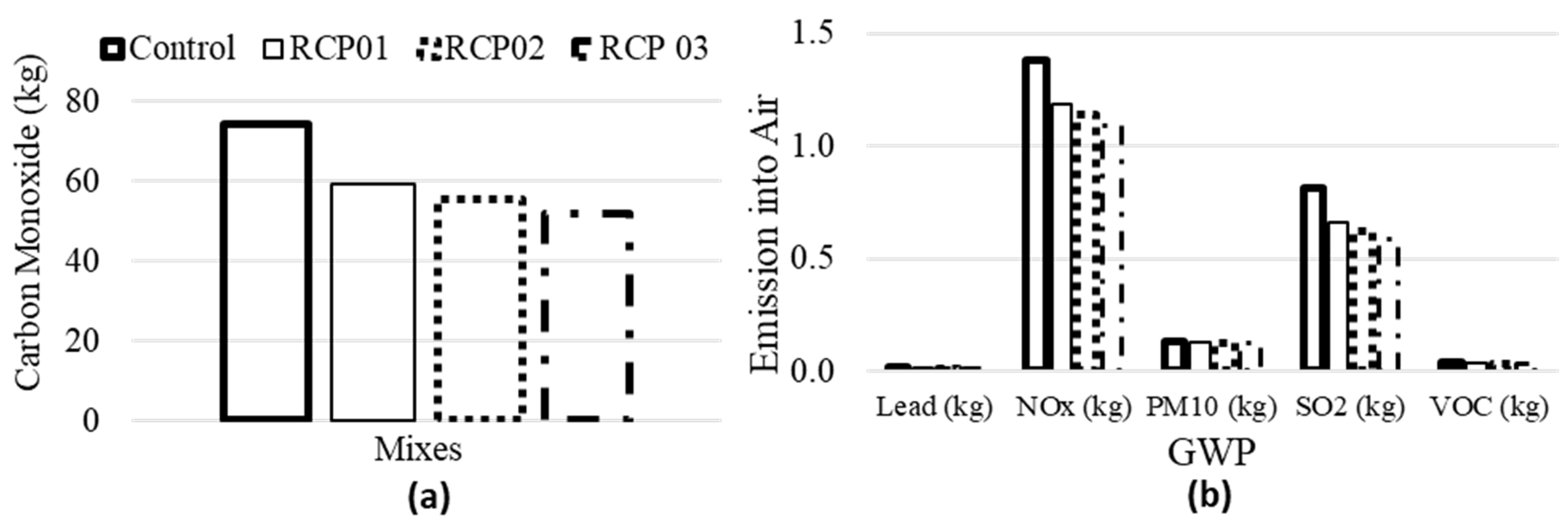

5.5. Global Warming Potential

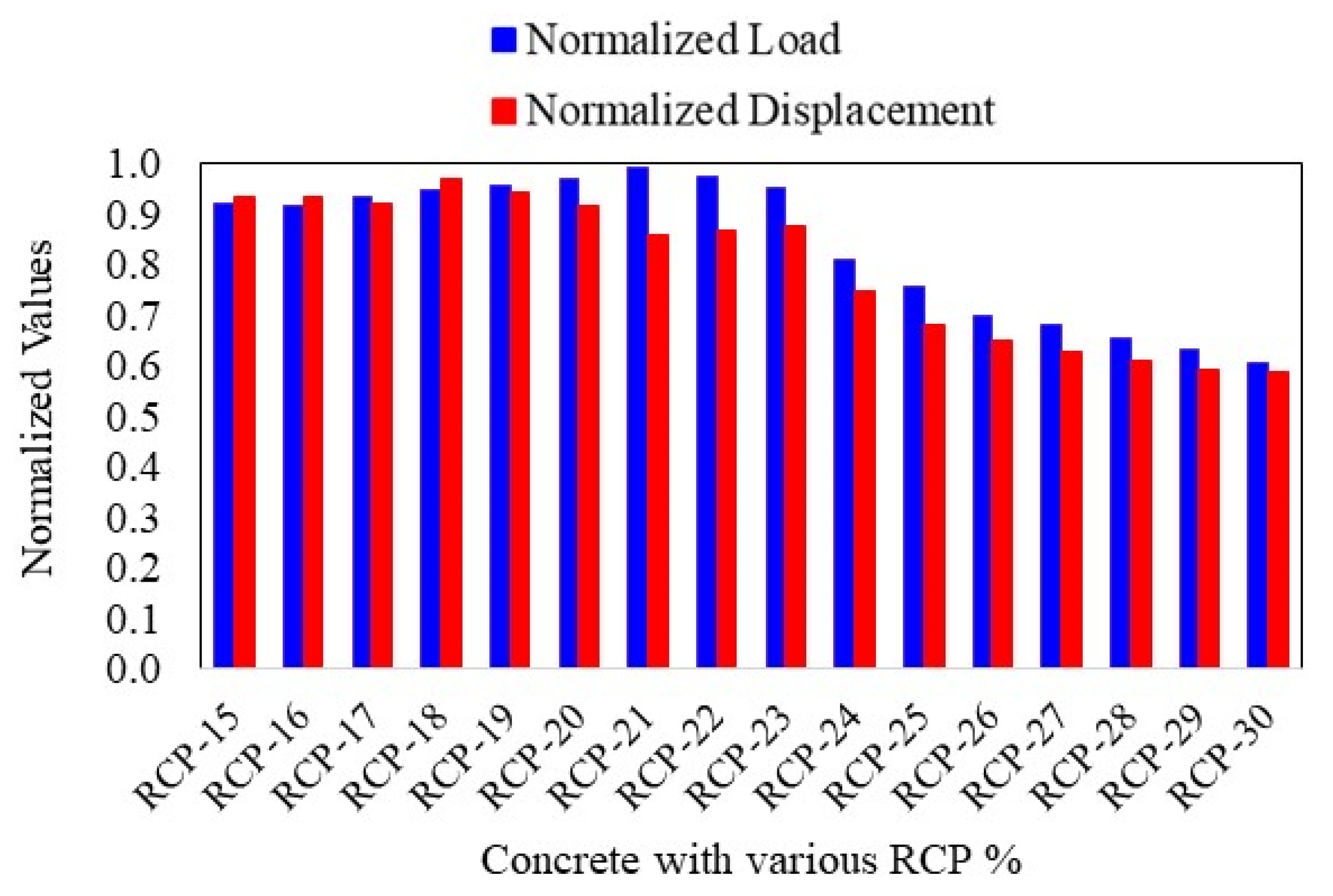

6. FE Model, Results, and Discussion

Sensitivity Analysis

7. Conclusions

- (1)

- As the replacement quantity of RCP increased, a corresponding reduction in slump was detected, signifying a decrease in workability for all the mixes. This conclusion proposes that larger replacement quantities harm the workability of the concrete.

- (2)

- The suitable quantity of RCP can have the least impact on the strength of concrete at different curing ages. The best results were obtained for the RCP-1 mix (20% RCP contents), which had a 16.3% reduction in compressive strength at 7 days, a 16% reduction on 14 days, and a 20.7% reduction on 28 days as compared to the control mix. The reasons influencing the mechanical properties of concrete by RCP have been well examined and discussed. Nevertheless, the durability of concrete is yet to be considered under these conditions; the performance against fatigue and creep will also be considered in subsequent studies.

- (3)

- In particular, the RCP-1 showed better performance, and various parameters used, e.g., split tensile strength, static elastic modulus, dynamic elastic modulus, rebound hammer test, ultrasonic pulse velocity test, etc., indicated the efficiency of RCP-1 in comparison with the control mix.

- (4)

- With the SEM, it was revealed that in RCP-1, the shape and morphology are irregular, but the particle is larger, which may affect the hydration process and also reduce the workability of the mix. Moreover, the C-S-H gel between the particles is weak, affecting concrete performance. This pattern gets stronger as the amount of RCP is increased, and RCP-2 and RCP-3 depict weaker C-S-H gel and an excessive number of pores, resulting in permeability increment.

- (5)

- In the case of RCP-2 (25% RCP contents) and RCP-3 (30% RCP contents), when the replacement rate increased from 20%, it started affecting the properties of concrete adversely, both at the fresh state as well as hardened state, indicating the rate to be kept around 20% maximum.

- (6)

- The GWP study provides strong support for the use of RCP (recycled concrete powder) as a substitute for traditional cement. This replacement results in a substantial decrease in CO2 emissions associated with concrete production, making it a more environmentally friendly option. By integrating RCP into construction practices, we can promote sustainability in the industry and reduce the overall carbon footprint of building materials. This shift not only benefits the environment but also aligns with the growing demand for greener construction solutions.

- (7)

- An optimization study performed through numerical modeling reveals that up to 23% replacement of cement with RCP can be performed without compromising the mechanical properties of concrete.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, C.-Q.; Cheng, L.-X.; Ying, Y.; Yang, F.-H. Utilization of all components of waste concrete: Recycled aggregate strengthening, recycled fine powder activity, composite recycled concrete and life cycle assessment. J. Build. Eng. 2024, 82, 108255. [Google Scholar] [CrossRef]

- Al Shouny, A.; Issa, U.H.; Miky, Y.; Sharaky, I.A. Evaluating and selecting the best sustainable concrete mixes based on recycled waste materials. Case Stud. Constr. Mater. 2023, 19, e02382. [Google Scholar] [CrossRef]

- Meng, T.; Hong, Y.; Ying, K.; Wang, Z. Comparison of technical properties of cement pastes with different activated recycled powder from con-struction and demolition waste. Cem. Concr. Compos. 2021, 120, 104065. [Google Scholar] [CrossRef]

- Yue, G.; Ma, Z.; Liu, M.; Liang, C.; Ba, G. Damage behavior of the multiple ITZs in recycled aggregate concrete subjected to aggressive ion environment. Constr. Build. Mater. 2020, 245, 118419. [Google Scholar] [CrossRef]

- Tang, Q.; Ma, Z.; Wu, H.; Wang, W. The utilization of eco-friendly recycled powder from concrete and brick waste in new concrete: A critical review. Cem. Concr. Compos. 2020, 114, 103807. [Google Scholar] [CrossRef]

- Gálvez-Martos, J.-L.; Styles, D.; Schoenberger, H.; Zeschmar-Lahl, B. Construction and demolition waste best management practice in Europe. Resour. Conserv. Recycl. 2018, 136, 166–178. [Google Scholar] [CrossRef]

- Huang, B.; Wang, X.; Kua, H.; Geng, Y.; Bleischwitz, R.; Ren, J. Construction and demolition waste management in China through the 3R principle. Resour. Conserv. Recycl. 2018, 129, 36–44. [Google Scholar] [CrossRef]

- Shen, P.; Sun, Y.; Liu, S.; Jiang, Y.; Zheng, H.; Xuan, D.; Lu, J.; Poon, C.S. Synthesis of amorphous nano-silica from recycled concrete fines by two-step wet carbonation. Cem. Concr. Res. 2021, 147, 106526. [Google Scholar] [CrossRef]

- Bogas, J.A.; Carriço, A.; Tenza-Abril, A.J. Microstructure of thermoactivated recycled cement pastes. Cem. Concr. Res. 2020, 138, 106226. [Google Scholar] [CrossRef]

- Bogas, J.A.; Real, S.; Carriço, A.; Abrantes, J.; Guedes, M. Hydration and phase development of recycled cement. Cem. Concr. Compos. 2022, 127, 104405. [Google Scholar] [CrossRef]

- Ren, C.; Yu, J.; Liu, X.; Zhang, Z.; Cai, Y. Cyclic constitutive equations of rock with coupled damage induced by compaction and cracking. Int. J. Min. Sci. Technol. 2022, 32, 1153–1165. [Google Scholar] [CrossRef]

- Ferdous, W.; Manalo, A.; Siddique, R.; Mendis, P.; Zhuge, Y.; Wong, H.S.; Lokuge, W.; Aravinthan, T.; Schubel, P. Recycling of landfill wastes (tyres, plastics and glass) in construction—A review on global waste generation, performance, application and future opportunities. Resour. Conserv. Recycl. 2021, 173, 105745. [Google Scholar] [CrossRef]

- Kaliyavaradhan, S.K.; Ling, T.-C.; Mo, K.H. Valorization of waste powders from cement-concrete life cycle: A pathway to circular future. J. Clean. Prod. 2020, 268, 122358. [Google Scholar] [CrossRef]

- Frías, M.; Martínez-Ramírez, S.; de la Villa, R.V.; Fernández-Carrasco, L.; García, R. Reactivity in cement pastes bearing fine fraction concrete and glass from construction and demolition waste: Microstructural analysis of viability. Cem. Concr. Res. 2021, 148, 106531. [Google Scholar] [CrossRef]

- Ibrahim, M.; Rahman, M.K.; Najamuddin, S.K.; Alhelal, Z.S.; Acero, C.E. A review on utilization of industrial by-products in the production of controlled low strength materials and factors influencing the properties. Constr. Build. Mater. 2022, 325, 126704. [Google Scholar] [CrossRef]

- Kaya, M.; Köksal, F.; Bayram, M.; Nodehi, M.; Gencel, O.; Ozbakkaloglu, T. The effect of marble powder on physico-mechanical and microstructural properties of kaolin-based geo-polymer pastes. Struct. Concr. 2023, 24, 6485–6504. [Google Scholar] [CrossRef]

- Kadhim, A.S.; Atiyah, A.A.; Salih, S.A. Properties of self-compacting mortar containing nano cement kiln dust. Mater. Today Proc. 2020, 20, 499–504. [Google Scholar] [CrossRef]

- Ali, H.A.; Keke, S.; Alrefaei, Y.; Poon, C.S. A study on the use of waste glass in preparing alkali-activated repairing material. Constr. Build. Mater. 2024, 435, 136803. [Google Scholar] [CrossRef]

- Guo, H.; Gao, R.; Liu, S.; Feng, C.; Qin, M.; Sun, G. Effect of ultra-low dosage graphene oxide on the properties of recycled cement-based materials. J. Build. Eng. 2024, 91, 109637. [Google Scholar] [CrossRef]

- Shamass, R.; Rispoli, O.; Limbachiya, V.; Kovacs, R. Mechanical and GWP assessment of concrete using Blast Furnace Slag, Silica Fume and recycled aggregate. Case Stud. Constr. Mater. 2023, 18, e02164. [Google Scholar] [CrossRef]

- Al-Bakri, A.Y.; Ahmed, H.M.; Hefni, M.A. Cement Kiln Dust (CKD): Potential Beneficial Applications and Eco-Sustainable Solutions. Sustainability 2022, 14, 7022. [Google Scholar] [CrossRef]

- Makul, N.; Fediuk, R.; Amran, M.; Zeyad, A.M.; Klyuev, S.; Chulkova, I.; Ozbakkaloglu, T.; Vatin, N.; Karelina, M.; Azevedo, A. Design strategy for recycled aggregate concrete: A review of status and future perspectives. Crystals 2021, 11, 695. [Google Scholar] [CrossRef]

- Joseph, H.S.; Pachiappan, T.; Avudaiappan, S.; Maureira-Carsalade, N.; Roco-Videla, Á.; Guindos, P.; Parra, P.F. A Comprehensive Review on Recycling of Construction Demolition Waste in Concrete. Sustainability 2023, 15, 4932. [Google Scholar] [CrossRef]

- Shi, T.; Liu, Y.; Hu, Z.; Cen, M.; Zeng, C.; Xu, J.; Zhao, Z. Deformation performance and fracture toughness of carbon nanofiber-modified cement-based materials. ACI Mater. J. 2022, 119, 119–128. [Google Scholar]

- Yamada, I.; Toyoda, N. Nano-scale surface modification using gas cluster ion beams—A development history and review of the Japanese nano-technology program. Surf. Coat. Technol. 2007, 201, 8579–8587. [Google Scholar] [CrossRef]

- Zhang, C.; Khorshidi, H.; Najafi, E.; Ghasemi, M. Fresh, mechanical and microstructural properties of alkali-activated composites incorporating nanomaterials: A comprehensive review. J. Clean. Prod. 2023, 384, 135390. [Google Scholar] [CrossRef]

- Khokhar, S.A.; Ahmed, T.; Khushnood, R.A.; Basit, M.U.; Shahnawaz; Javed, S. Development of low carbon engineered cementitious composite (ECC) using nano lime calcined clay cement (nLC3) based matrix. Case Stud. Constr. Mater. 2024, 20, e02669. [Google Scholar] [CrossRef]

- Jin, M.; Ma, Y.; Li, W.; Huang, J.; Yan, Y.; Zeng, H.; Lu, C.; Liu, J. Multi-scale investigation on composition-structure of C-(A)-SH with different Al/Si ratios under attack of de-calcification action. Cem. Concr. Res. 2023, 172, 107251. [Google Scholar] [CrossRef]

- Li, D.; Nie, J.-H.; Wang, H.; Yan, J.-B.; Hu, C.-X.; Shen, P. Damage location, quantification and characterization of steel-concrete composite beams using acoustic emission. Eng. Struct. 2023, 283, 115866. [Google Scholar] [CrossRef]

- Cai, J.; Pan, J.; Li, G. Behaviors of eccentrically loaded ECC-encased CFST columns after fire exposure. Eng. Struct. 2023, 289, 116258. [Google Scholar] [CrossRef]

- Ahmed, H.A.; Tanoli, W.A. Investigating the confinement effects on masonry behavior based on friction interface. Sci. Rep. 2024, 14, 12982. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Bian, Y.; Zhao, J.; Wang, Y.; Yuan, Z. Recycled concrete fine powder (RFP) as cement partial replacement: Influences on the physical properties, hy-dration characteristics, and microstructure of blended cement. J. Build. Eng. 2022, 62, 105326. [Google Scholar] [CrossRef]

- Tang, H.; Yang, Y.; Li, H.; Xiao, L.; Ge, Y. Effects of chloride salt erosion and freeze–thaw cycle on interface shear behavior between ordinary concrete and self-compacting concrete. Structures 2023, 56, 104990. [Google Scholar] [CrossRef]

- Hussein, Y.M.; Elrahman, M.A.; Elsakhawy, Y.; Tayeh, B.A.; Tahwia, A.M. Development and performance of sustainable structural lightweight concrete containing waste clay bricks. J. Mater. Res. Technol. 2022, 21, 4344–4359. [Google Scholar] [CrossRef]

- Ahmed, M.; El-Naggar, K.; Tarek, D.; Ragab, A.; Sameh, H.; Zeyad, A.M.; Tayeh, B.A.; Maafa, I.M.; Yousef, A. Fabrication of thermal insulation geopolymer bricks using ferrosilicon slag and alumina waste. Case Stud. Constr. Mater. 2021, 15, e00737. [Google Scholar] [CrossRef]

- Amran, M.; Samadi, M. Effect of nanomaterials inclusion on sustainability of cement-based. Constr. Build. Mater. 2021, 306, 124850. [Google Scholar]

- Kim, J.; Jang, H. Closed-loop recycling of C&D waste: Mechanical properties of concrete with the repeatedly recycled C&D powder as partial cement replacement. J. Clean. Prod. 2022, 343, 130977. [Google Scholar]

- Kim, J.; Nciri, N.; Sicakova, A.; Kim, N. Characteristics of waste concrete powders from multi-recycled coarse aggregate concrete and their effects as cement replacements. Constr. Build. Mater. 2023, 398, 132525. [Google Scholar] [CrossRef]

- Abdellatief, M.; Elemam, W.E.; Alanazi, H.; Tahwia, A.M. Production and optimization of sustainable cement brick incorporating clay brick wastes using response surface method. Ceram. Int. 2023, 49, 9395–9411. [Google Scholar] [CrossRef]

- Padmalosan, P.; Vanitha, S.; Kumar, V.S.; Anish, M.; Tiwari, R.; Dhapekar, N.K.; Yadav, A.S. An investigation on the use of waste materials from industrial processes in clay brick production. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Terra, I.C.D.C.; Batista, F.G.; Silva, D.W.; Scatolino, M.V.; Alves Júnior, F.T.; Martins, M.A.; Mendes, L.M. Mining waste and coconut fibers as an eco-friendly reinforcement for the production of concrete blocks. Environ. Sci. Pollut. Res. 2023, 30, 62641–62652. [Google Scholar] [CrossRef]

- Nakkeeran, G.; Krishnaraj, L. Developing lightweight concrete bricks by replacing fine aggregate with vermiculite: A regression analysis prediction approach. Asian J. Civ. Eng. 2023, 24, 1529–1537. [Google Scholar] [CrossRef]

- Sathiparan, N.; Anburuvel, A.; Selvam, V.V. Utilization of agro-waste groundnut shell and its derivatives in sustainable construction and building materials—A review. J. Build. Eng. 2023, 66, 105866. [Google Scholar] [CrossRef]

- Amin, M.; Agwa, I.S.; Mashaan, N.; Mahmood, S.; Abd-Elrahman, M.H. Investigation of the Physical Mechanical Properties and Durability of Sustainable Ultra-High Performance Concrete with Recycled Waste Glass. Sustainability 2023, 15, 3085. [Google Scholar] [CrossRef]

- Machado, D.M.; Júnior, B.G.; Simão, L.; Ribeiro, M.J.; Montedo, O.R.K.; Raupp-Pereira, F.; Arcaro, S. Valorization of Brazilian waste foundry sand from circular economy perspective. J. Clean. Prod. 2023, 407, 137046. [Google Scholar] [CrossRef]

- Saleh, A.A.; Abdel-Gawwad, H.A.; El-Moghny, M.G.A.; El-Deab, M.S. The sustainable utilization of weathered cement kiln dust in the cleaner production of alkali activated binder incorporating glass sludge. Constr. Build. Mater. 2021, 300, 124308. [Google Scholar] [CrossRef]

- Mukhtar, F.; El-Tohfa, A. A review on fracture propagation in concrete: Models, methods, and benchmark tests. Eng. Fract. Mech. 2023, 281, 109100. [Google Scholar] [CrossRef]

- Gursel, A.P. Life-Cycle Assessment of Concrete: Decision-Support Tool and Case Study Application. Ph.D. Thesis, University of California, Berkeley, CA, USA, 2014. [Google Scholar]

- ASTM, C 150-07; Standard Specification for Portland Cement. ASTM: West Conshohocken, PA, USA, 2007.

- Yu, K.-Q.; Zhu, W.-J.; Ding, Y.; Lu, Z.-D.; Yu, J.-T.; Xiao, J.-Z. Micro-structural and mechanical properties of ultra-high performance engineered cementitious composites (UHP-ECC) incorporation of recycled fine powder (RFP). Cem. Concr. Res. 2019, 124, 105813. [Google Scholar] [CrossRef]

- Ye, T.; Xiao, J.; Duan, Z.; Li, S. Geopolymers made of recycled brick and concrete powder—A critical review. Constr. Build. Mater. 2022, 330, 127232. [Google Scholar] [CrossRef]

- Sun, C.; Chen, L.; Xiao, J.; Singh, A.; Zeng, J. Compound utilization of construction and industrial waste as cementitious recycled powder in mortar. Resour. Conserv. Recycl. 2021, 170, 105561. [Google Scholar] [CrossRef]

- ASTM, ASTM C 192/C 192M-14; Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory. ASTM: West Conshohocken, PA, USA, 2014.

- ASTM, C39-01; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM: West Conshohocken, PA, USA, 2001.

- ASTM, C 948/23; Standard Test Method for Dry and Wet Bulk Density, Water Absorption, and Apparent Porosity of Thin Sections of Glass-Fiber Reinforced Concrete. ASTM: West Conshohocken, PA, USA, 1981.

- ASTM, C 642/06; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. ASTM: West Conshohocken, PA, USA, 2006.

- ASTM, C 496/C 496M-04; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. ASTM: West Conshohocken, PA, USA, 1996.

- ASTM, C 597/22; Standard Test Method for Pulse Velocity Through Concrete. ASTM: West Conshohocken, PA, USA, 2022.

- ASTM, C 805/02; Standard Test Method for Rebound Number of Hardened Concrete. ASTM: West Conshohocken, PA, USA, 2002.

- Azam, A.; Rafiq, M.; Shafique, M.; Ateeq, M.; Yuan, J. Causality Relationship Between Electricity Supply and Economic Growth: Evidence from Pakistan. Energies 2020, 13, 837. [Google Scholar] [CrossRef]

- Cervenka Consulting. Atena 3D; Cervenka Consulting: Prague, Czech Republic, 2024. [Google Scholar]

- Ahmed, A.; Shahzada, K.; Ali, S.M.; Khan, A.N.; Shah, S.A.A. Confined and unreinforced masonry structures in seismic areas: Validation of macro models and cost analysis. Eng. Struct. 2019, 199, 109612. [Google Scholar] [CrossRef]

- Ahmed, A.; Shahzada, K. Seismic vulnerability assessment of confined masonry structures by macro-modeling approach. Structures 2020, 27, 639–649. [Google Scholar] [CrossRef]

- Ahmed, H.A.; Shahzada, K.; Fahad, M. Performance-based seismic assessment of capacity enhancement of building in-frastructure and its cost-benefit evaluation. Int. J. Disaster Risk Reduct. 2021, 61, 102341. [Google Scholar] [CrossRef]

- Likes, L.; Markandeya, A.; Haider, M.; Bollinger, D.; McCloy, J.S.; Nassiri, S. Recycled concrete and brick powders as supplements to Portland cement for more sustainable concrete. J. Clean. Prod. 2022, 364, 132651. [Google Scholar] [CrossRef]

- Robayo-Salazar, R.; Valencia-Saavedra, W.; De Gutiérrez, R.M. Recycling of concrete, ceramic, and masonry waste via alkaline activation: Obtaining and characterization of hybrid cements. J. Build. Eng. 2022, 46, 103698. [Google Scholar] [CrossRef]

- ACI 363R; High-Strength Concrete. ACI Symposium Publication. Asian Culinary Institute (ACI): Farmington Hills, MI, USA, 2005; Volume 228.

- Danha, L.S.; Khalil, W.I.; Al-Hassani, H.M. Mechanical properties of reactive powder concrete (RPC) with Various Steel Fiber and Silica Fume Contents. Eng. Technol. J. 2013, 31, 3090–3108. [Google Scholar] [CrossRef]

- Kadhem, E.; Ali, A.; Tobeia, S. Experimental comparative study of reactive powder concrete: Mechanical properties and the effective factors. MATEC Web Conf. 2018, 162, 04004. [Google Scholar] [CrossRef]

- Lee, B.J.; Kee, S.-H.; Oh, T.; Kim, Y.-Y. Effect of Cylinder Size on the Modulus of Elasticity and Compressive Strength of Concrete from Static and Dynamic Tests. Adv. Mater. Sci. Eng. 2015, 2015, 580638. [Google Scholar] [CrossRef]

- Noguchi, T.; Tomosawa, F.; Nemati, K.M.; Chiaia, B.M.; Fantilli, A.P. A Practical Equation for Elastic Modulus of Concrete. ACI Struct. J. 2009, 106, 690. [Google Scholar]

- ACI CODE-318-19(22); Building Code Requirements for Structural Concrete and Commentary (Reapproved 2022). American Concrete Institute: Farmington Hills, MI, USA, 2022.

- Lydon, F.D.; Balendran, R.V. Some observations on elastic properties of plain concrete. Cem. Concr. Res. 1986, 16, 314–324. [Google Scholar] [CrossRef]

- BS 8110-2: 1985; Structural Use of Concrete—Part 2: Code of Practice for Special Circumstances. British Standard: London, UK, 1985.

- Sun, D.; Hu, H.; Ma, R.; Hu, X.; Ding, Y.; Wang, A.; Liu, K. Preparation and hydration of low-carbon UHPC with high fraction of activated tuff and recycled fine powders. J. Build. Eng. 2024, 90, 109396. [Google Scholar] [CrossRef]

- Xiao, J.; Ma, Z.; Sui, T.; Akbarnezhad, A.; Duan, Z. Mechanical properties of concrete mixed with recycled powder produced from construction and demolition waste. J. Clean. Prod. 2018, 188, 720–731. [Google Scholar] [CrossRef]

- Schoon, J.; De Buysser, K.; Van Driessche, I.; De Belie, N. Fines extracted from recycled concrete as alternative raw material for Portland cement clinker production. Cem. Concr. Compos. 2015, 58, 70–80. [Google Scholar] [CrossRef]

- Sormunen, P.; Kärki, T. Recycled construction and demolition waste as a possible source of materials for composite manufacturing. J. Build. Eng. 2019, 24, 100742. [Google Scholar] [CrossRef]

| Parameters | Cement | RCP |

|---|---|---|

| SiO2 (Silica) | 20.63 | 22.55 |

| Al2O3 (Aluminum) | 4.94 | 5.90 |

| Fe2O3 (Iron) | 3.10 | 1.57 |

| CaO (Calcium) | 60.47 | 32.40 |

| MgO (Magnesium) | 3.17 | 2.40 |

| SO3 (Sulfite) | 2.52 | 1.94 |

| Loss of Ignition | 3.94 | 28.44 |

| No. | Properties | E (GPa) | GF | v | ft (MPa) | fc (MPa) |

|---|---|---|---|---|---|---|

| 1 | Control | 24.69 | 62.85 | 0.2 | 2.60 | 28.8 |

| 2 | RCP-1 | 23.28 | 45.96 | 0.2 | 1.86 | 18.01 |

| 3 | RCP-2 | 21.20 | 33.68 | 0.2 | 1.35 | 11.30 |

| 4 | RCP-3 | 19.82 | 30.75 | 0.2 | 1.23 | 9.89 |

| Model Proposed by | Relationship | Elastic Modulus Values (ksi) | |||

|---|---|---|---|---|---|

| Normal | RCP-1 | RCP-2 | RCP-3 | ||

| ACI-363.R [67] | 3043.63 | 2819.76 | 2616.22 | 2514.50 | |

| Danha et al., 2013 [68] | 4809.64 | 4748.27 | 4698.65 | 4676.06 | |

| Kadhem et al., 2018 [69] | 4182.06 | 3946.30 | 3719.00 | 3600.03 | |

| CEB-FIP [70] | 3881.36 | 3592.39 | 3319.18 | 3178.36 | |

| Noguchi et al., 2009 [71] | 3165.67 | 2929.98 | 2707.15 | 2592.29 | |

| Specimen No | Pulse Velocity (km/s) |

|---|---|

| Control | 4.64 |

| RCP-1 | 4.52 |

| RCP-2 | 4.24 |

| RCP-3 | 4.35 |

| Ec Obtained by | Ec/Ed | |||

|---|---|---|---|---|

| Normal | RCP-1 | RCP-2 | RCP-3 | |

| ACI-363.R [67] | 0.47 | 0.45 | 0.48 | 0.44 |

| Danha et al., 2013 [68] | 0.74 | 0.76 | 0.86 | 0.82 |

| Kadhem et al., 2018 [69] | 0.64 | 0.63 | 0.68 | 0.63 |

| CEB-FIP [70] | 0.59 | 0.58 | 0.61 | 0.55 |

| Noguchi et al., 2009 [71] | 0.48 | 0.47 | 0.50 | 0.45 |

| No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| RCP Percentage | 15% | 16% | 17% | 18% | 19% | 20% | 21% | 22% | 23% | 24% | 25% | 26% | 27% | 28% | 29% | 30% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmed, H.A.; Tanoli, W.A. Experimental and Numerical Assessment of Sustainable Concrete Using Recycled Concrete Powder (RCP) as a Partial Replacement for Cement. Materials 2025, 18, 3108. https://doi.org/10.3390/ma18133108

Ahmed HA, Tanoli WA. Experimental and Numerical Assessment of Sustainable Concrete Using Recycled Concrete Powder (RCP) as a Partial Replacement for Cement. Materials. 2025; 18(13):3108. https://doi.org/10.3390/ma18133108

Chicago/Turabian StyleAhmed, Hafiz Asfandyar, and Waqas Arshad Tanoli. 2025. "Experimental and Numerical Assessment of Sustainable Concrete Using Recycled Concrete Powder (RCP) as a Partial Replacement for Cement" Materials 18, no. 13: 3108. https://doi.org/10.3390/ma18133108

APA StyleAhmed, H. A., & Tanoli, W. A. (2025). Experimental and Numerical Assessment of Sustainable Concrete Using Recycled Concrete Powder (RCP) as a Partial Replacement for Cement. Materials, 18(13), 3108. https://doi.org/10.3390/ma18133108