Effects of Process Parameters on Defect Formation in Laser Additive Manufacturing of a Novel Ni-Based Superalloy

Abstract

1. Introduction

2. Materials and Methods

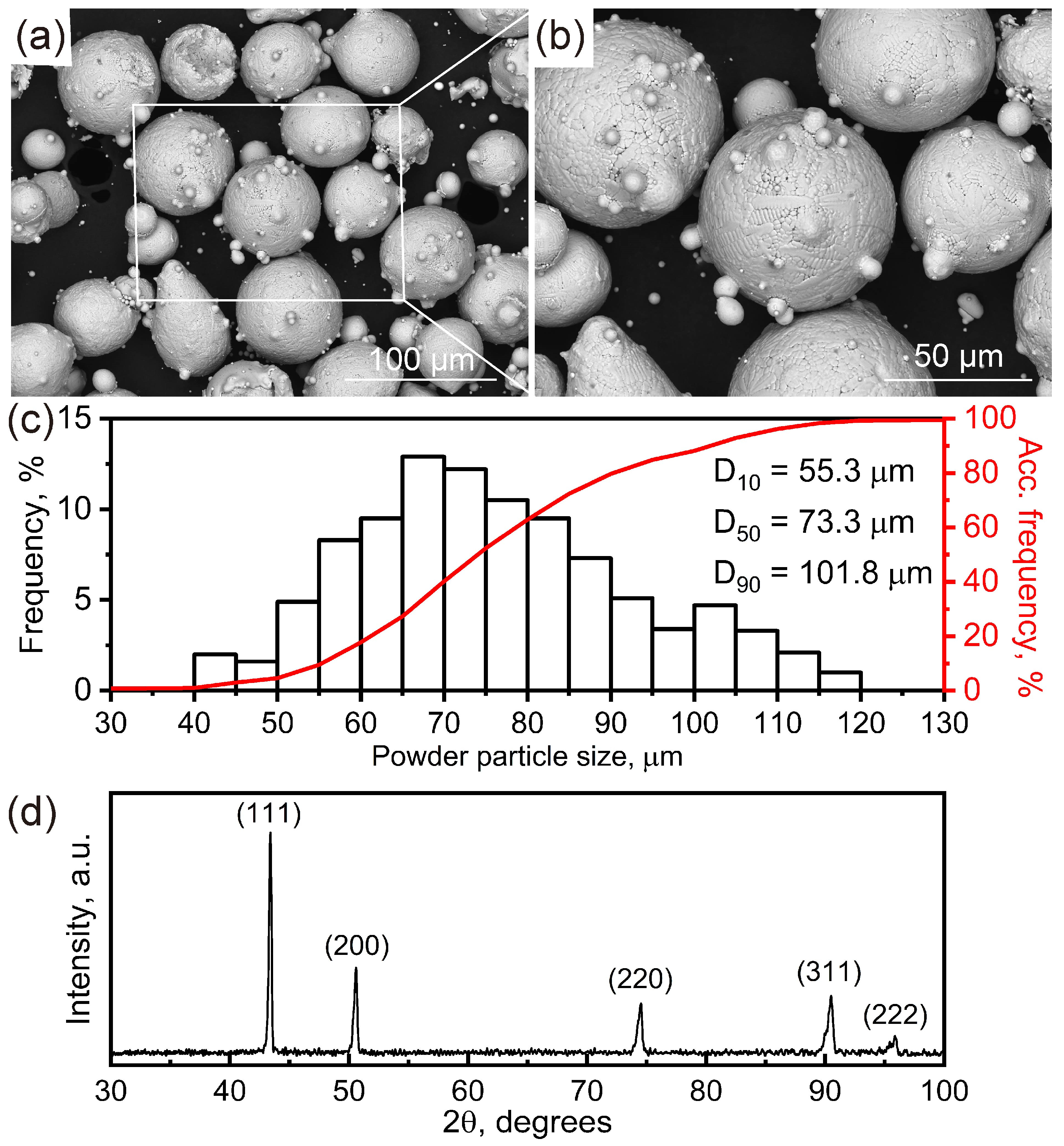

2.1. Characterization of Ni-Based Superalloy Powders

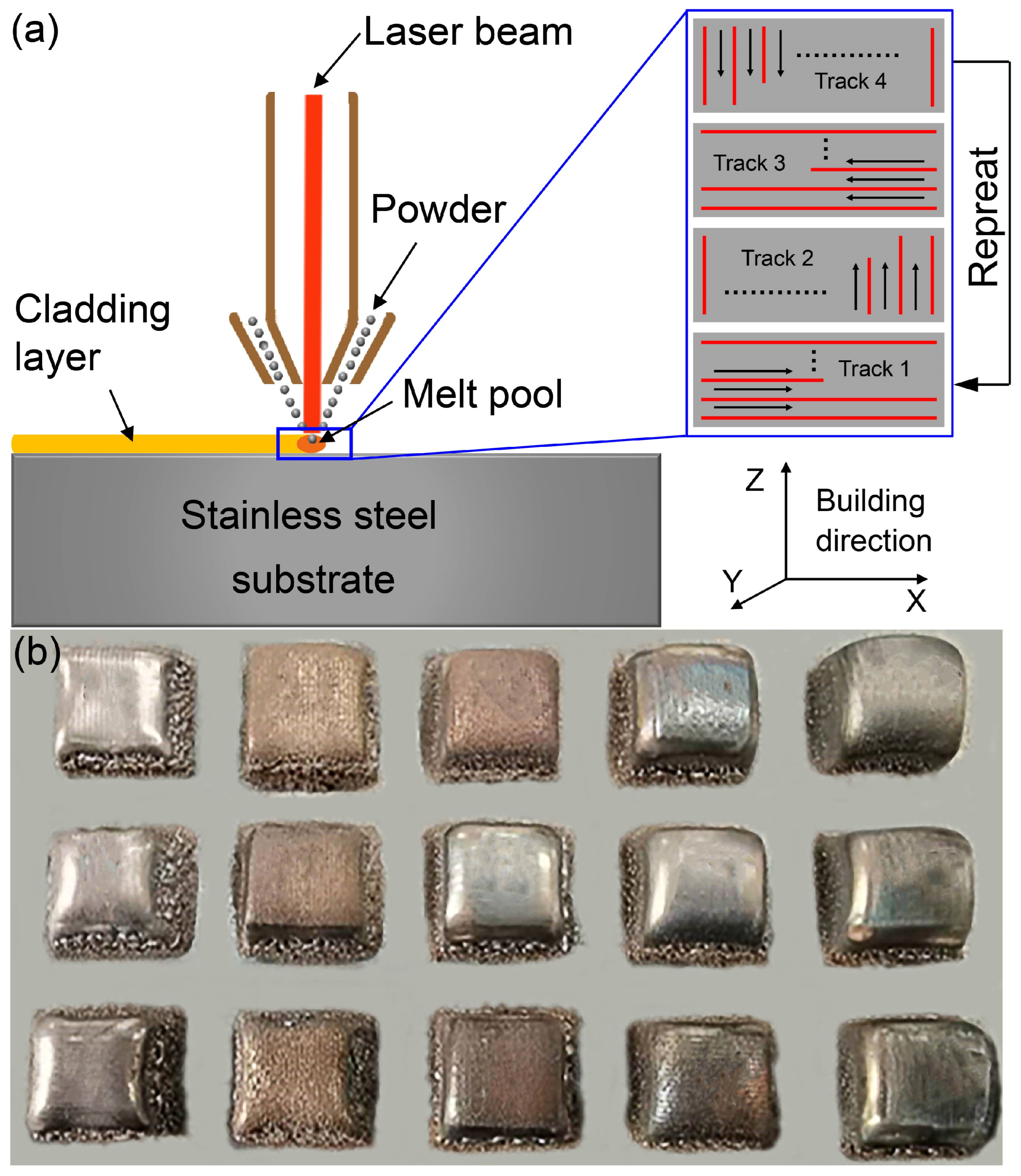

2.2. L-DED Fabrication of Ni-Based Superalloy

2.3. Characterization of Ni-Based Superalloy

3. Results and Discussion

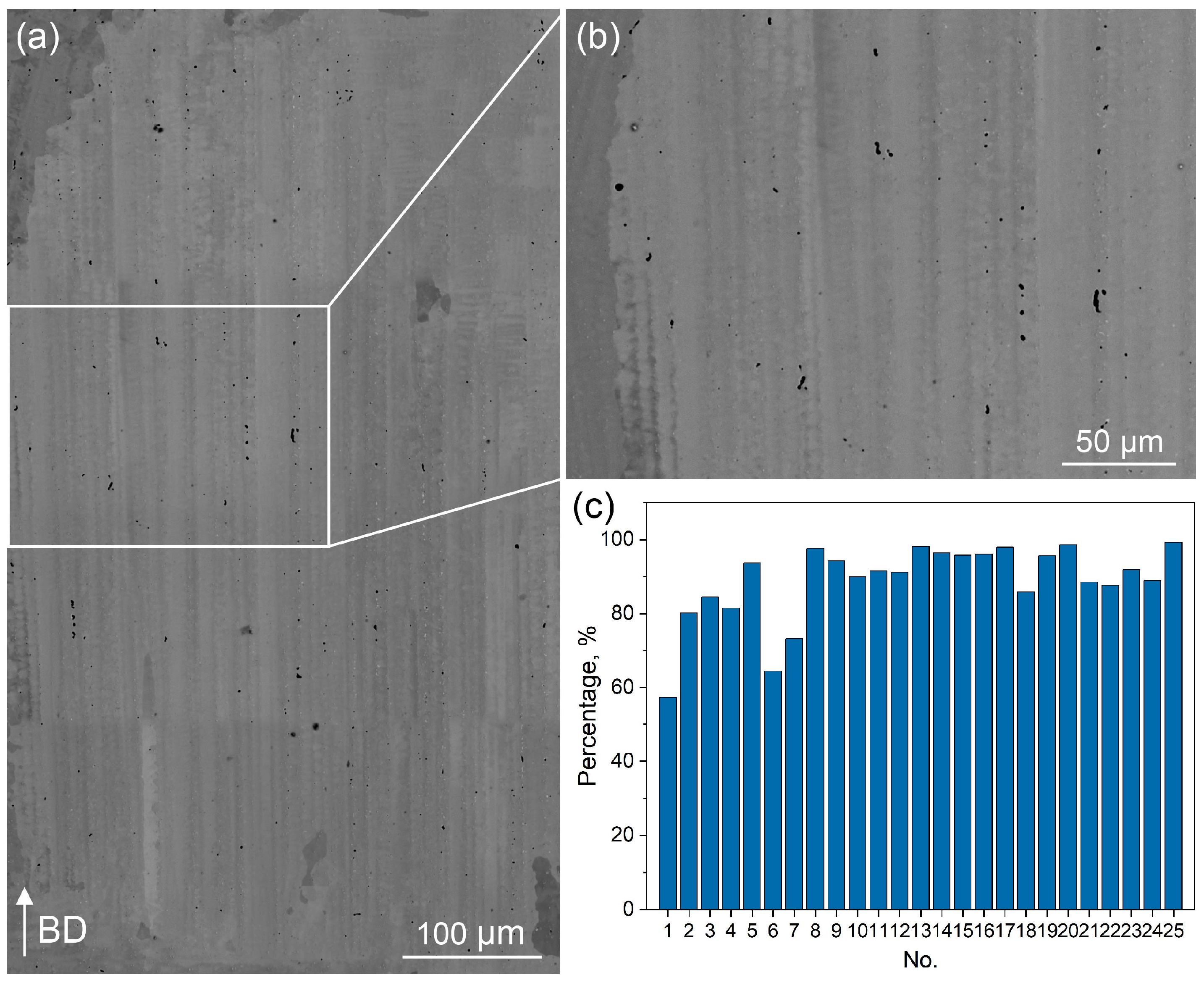

3.1. Ni-Based Superalloy Powders

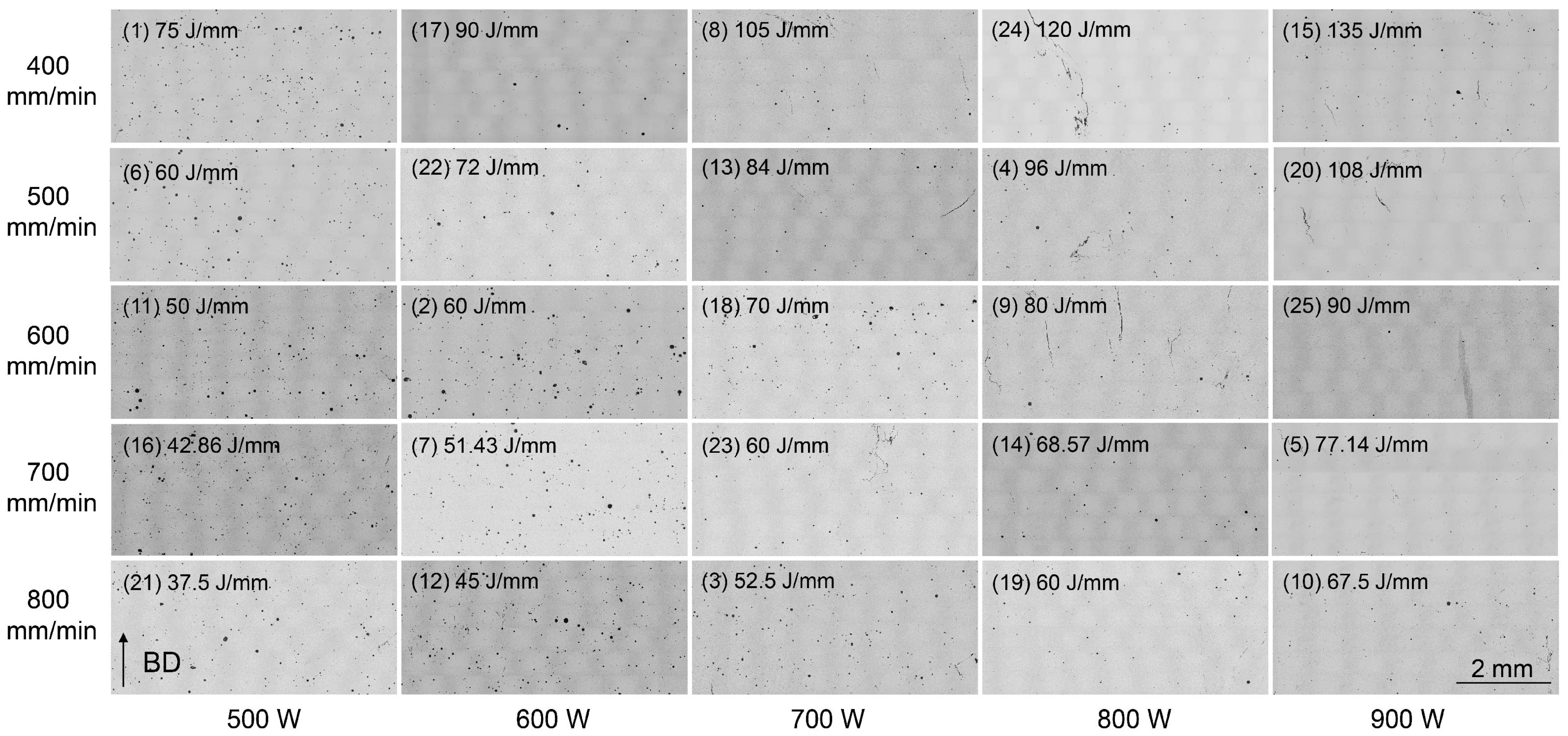

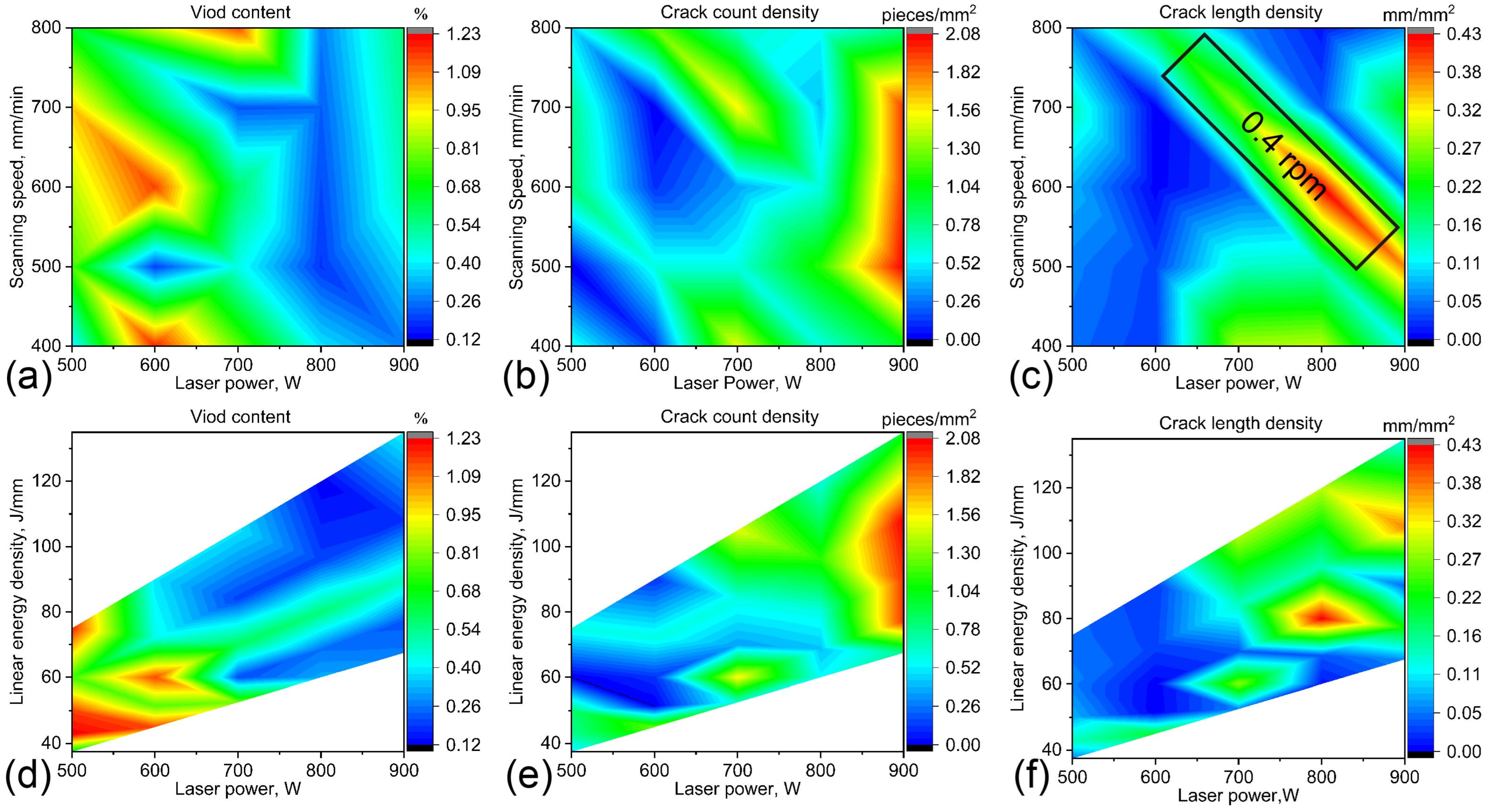

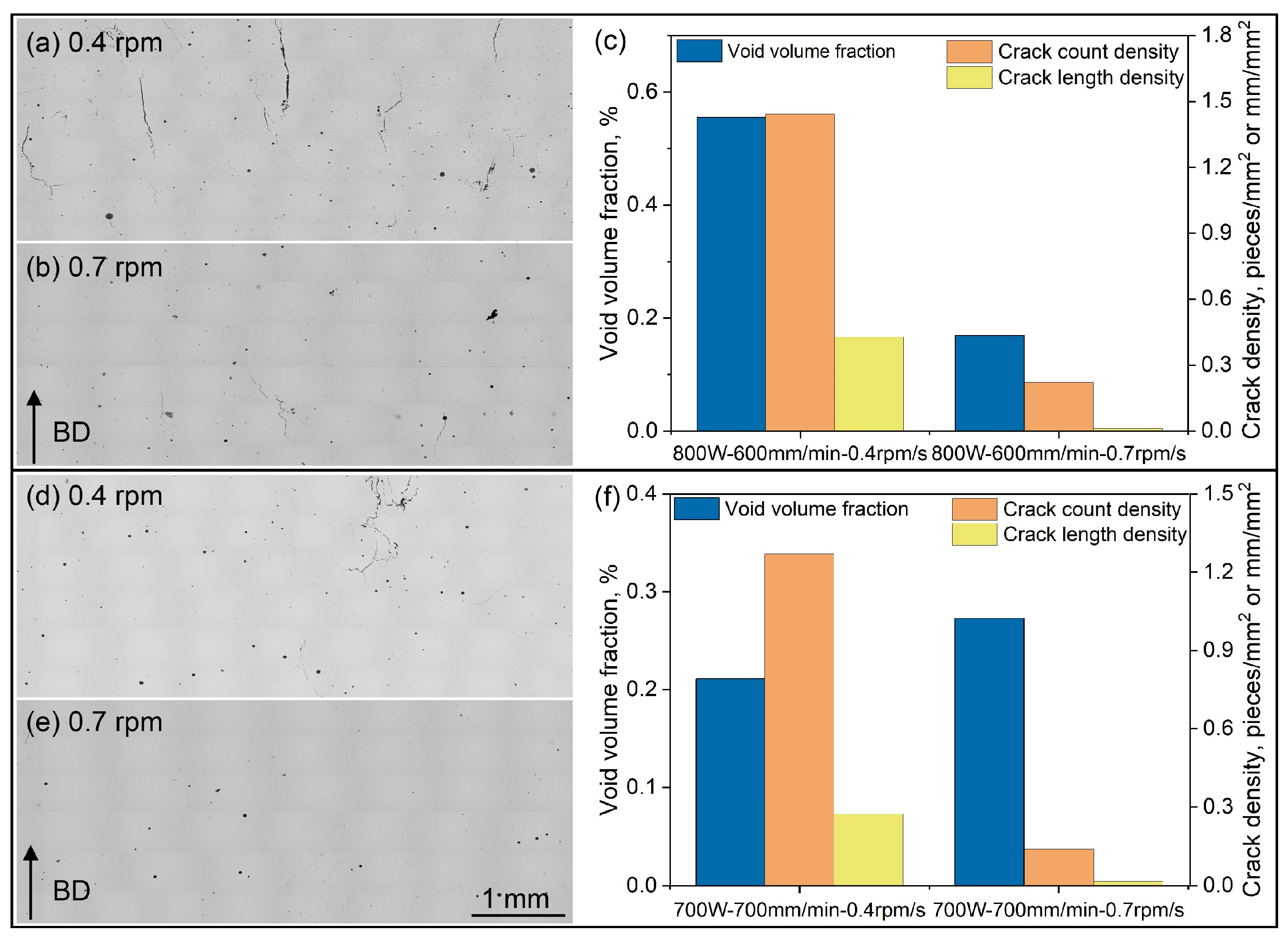

3.2. Quantitative Analysis of Defects in Alloy Microstructure

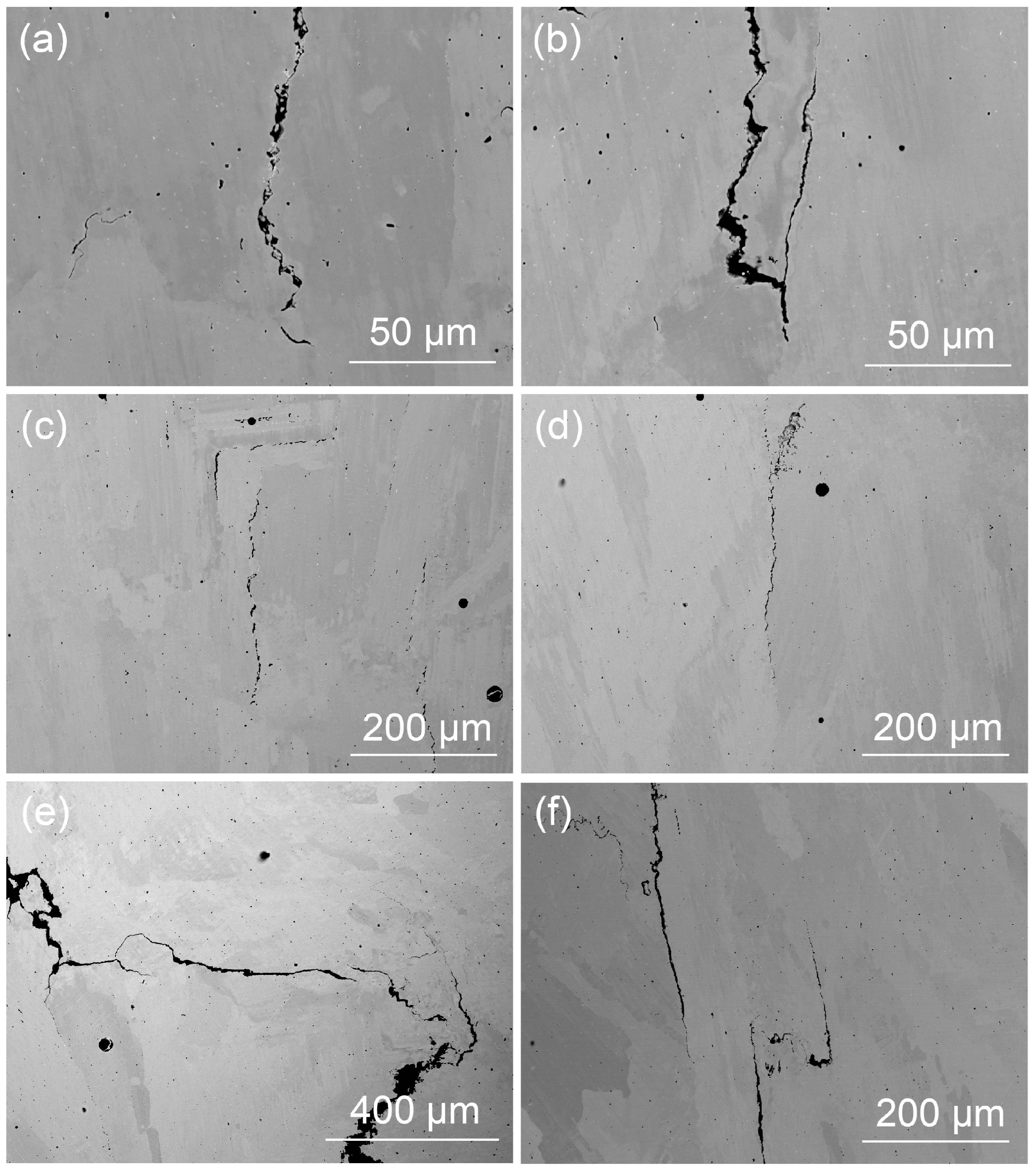

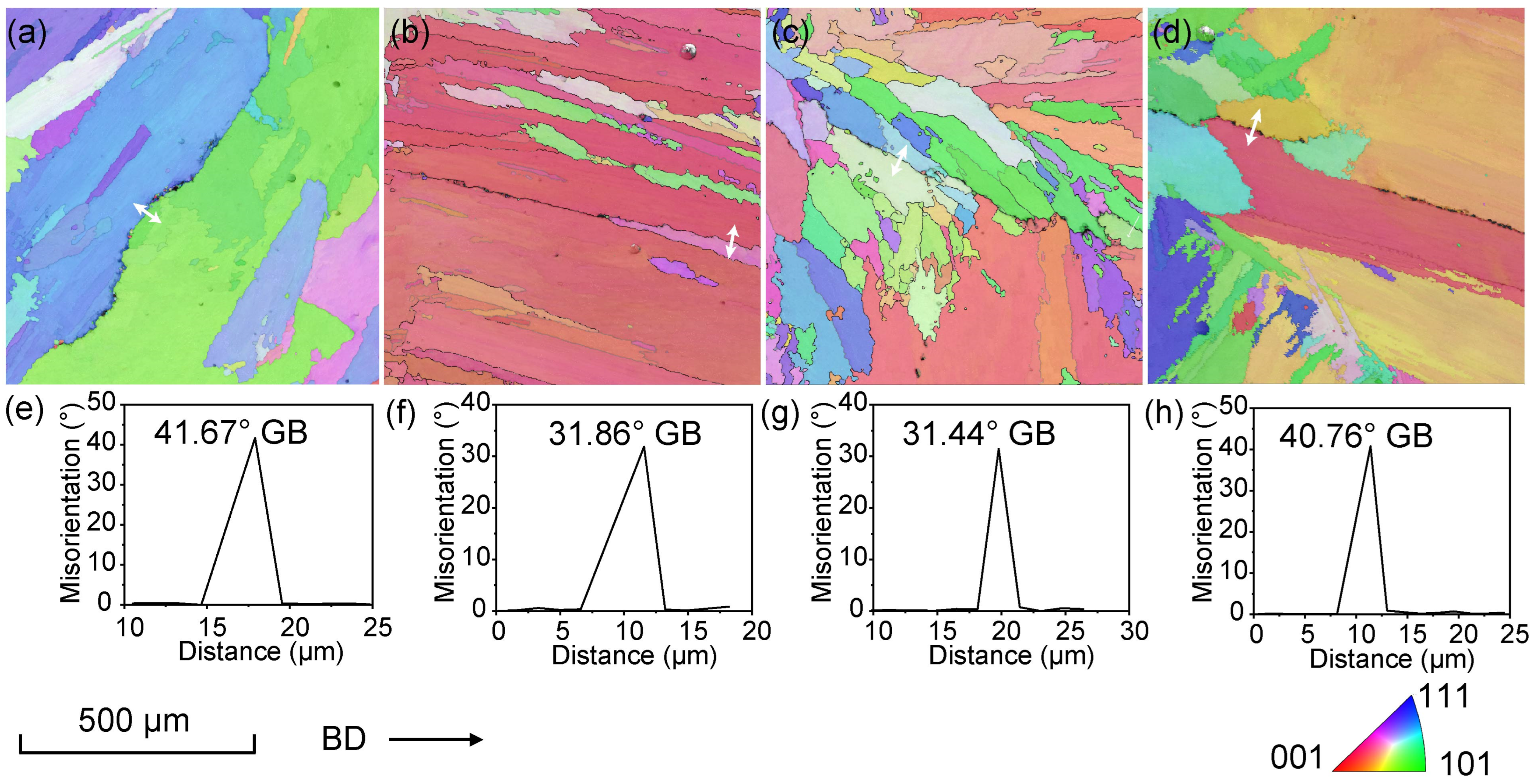

3.3. Cracking Mechanism of Ni-Based Superalloy

4. Conclusions

- Defect quantity maps for the Ni-based superalloy were created by using key AM process parameters of laser power, scanning speed and linear energy density.

- As the laser power increases, the void content in the Ni-based superalloy tends to decrease, whereas the crack count and length densities exhibit an increase. An optimal laser power range of 600~700 W was identified as yielding comparatively low levels of both void contents and crack densities.

- High crack densities were observed in samples produced using a low powder feeding rate of 0.4 rpm. A relatively higher powder feeding rate is recommended to mitigate voids and cracking within alloy samples.

- The presence of fine MC carbides dispersed among the dendrites was found to cause micro-shrinkages and trigger the initiation of solidification cracking.

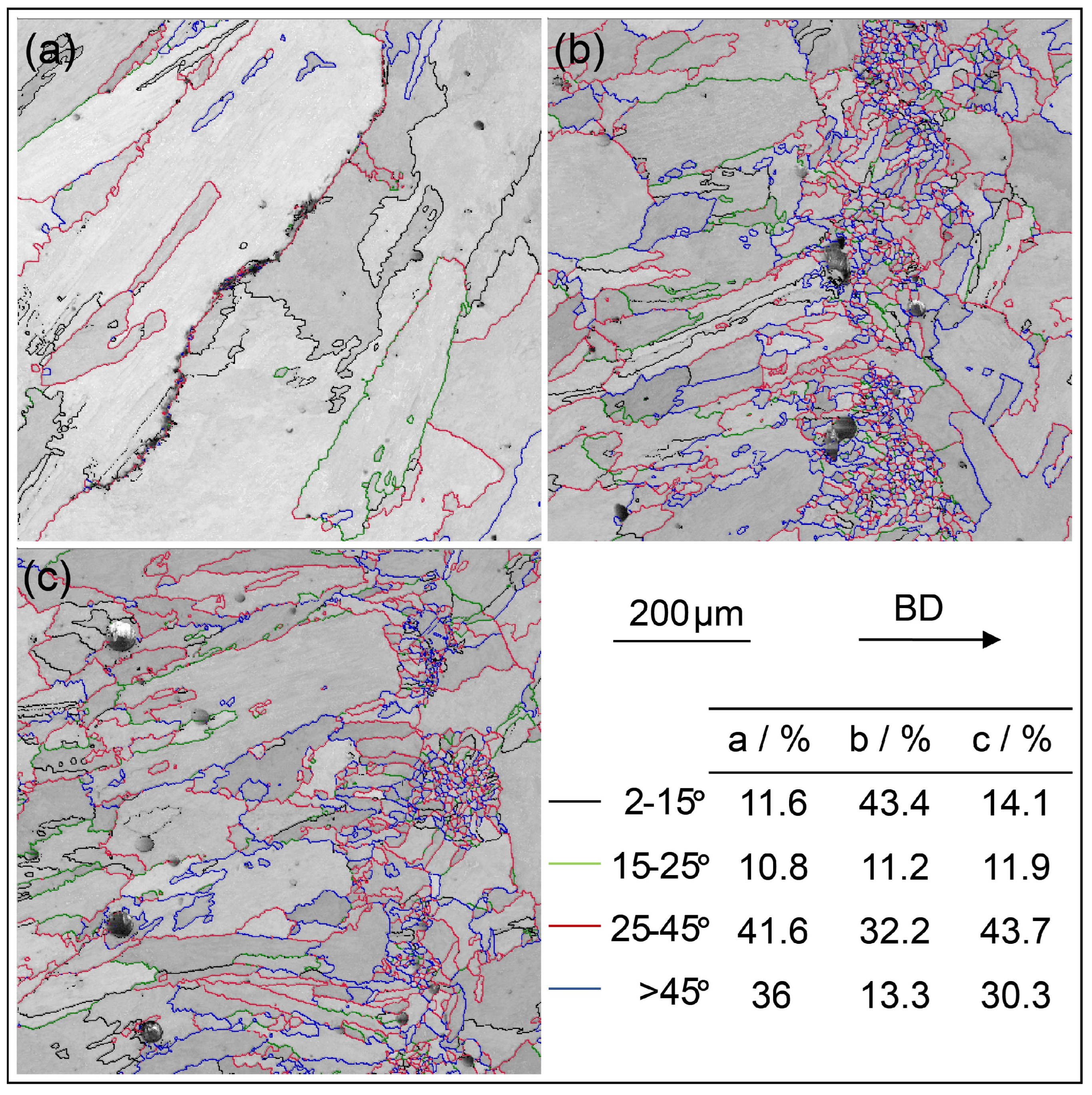

- Grain-boundary misorientations within the range of 31~42° (defined as S-HAGBs) exhibit a high propensity for crack formation, suggesting that S-HAGBs are a critical factor affecting cracking susceptibility.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Reed, R.C. The Superalloys: Fundamentals and Applications; Cambridge University Press: Cambridge, UK, 2006. [Google Scholar] [CrossRef]

- Reed, R.C.; Tao, T.; Warnken, N. Alloys-By-Design: Application to nickel-based single crystal superalloys. Acta Mater. 2009, 57, 5898–5913. [Google Scholar] [CrossRef]

- Pollock, T.M. Alloy design for aircraft engines. Nat. Mater. 2016, 15, 809–815. [Google Scholar] [CrossRef] [PubMed]

- Hamdi, H.; Abedi, H.R. Thermal stability of Ni-based superalloys fabricated through additive manufacturing: A review. J. Mater. Res. Technol. 2024, 30, 4424–4476. [Google Scholar] [CrossRef]

- Gasser, A.; Backes, G.; Kelbassa, I.; Weisheit, A.; Wissenbach, K. Laser Additive Manufacturing. Laser Tech. J. 2010, 7, 58–63. [Google Scholar] [CrossRef]

- Amedei, A.; Meli, E.; Rindi, A.; Romani, B.; Pinelli, L.; Vanti, F.; Arnone, A.; Benvenuti, G.; Fabbrini, M.; Morganti, N. Innovative Design, Structural Optimization and Additive Manufacturing of New-Generation Turbine Blades. In Proceedings of the ASME Turbo Expo 2020: Turbomachinery Technical Conference and Exposition, Virtual, 21–25 September 2020; p. V02CT35A004. [Google Scholar] [CrossRef]

- Tang, Y.T.; Panwisawas, C.; Ghoussoub, J.N.; Gong, Y.; Clark, J.W.G.; Németh, A.A.N.; McCartney, D.G.; Reed, R.C. Alloys-by-design: Application to new superalloys for additive manufacturing. Acta Mater. 2021, 202, 417–436. [Google Scholar] [CrossRef]

- Bassini, E.; Sivo, A.; Martelli, P.A.; Rajczak, E.; Marchese, G.; Calignano, F.; Biamino, S.; Ugues, D. Effects of the solution and first aging treatment applied to as-built and post-HIP CM247 produced via laser powder bed fusion (LPBF). J. Alloys Compd. 2022, 905, 164213. [Google Scholar] [CrossRef]

- Iveković, A.; Montero-Sistiaga, M.L.; Vleugels, J.; Kruth, J.-P.; Vanmeensel, K. Crack mitigation in Laser Powder Bed Fusion processed Hastelloy X using a combined numerical-experimental approach. J. Alloys Compd. 2021, 864, 158803. [Google Scholar] [CrossRef]

- Wang, C.; Yang, L.; Sheng, R.-X.; Guan, S.; Bi, Z.-N.; Zhang, H.; Huang, H.-L.; Jiang, L.; Zhu, L.-L.; Zhou, X. In-situ TiC particle- reinforced Hastelloy X superalloy fabricated by laser additive manufacturing. J. Mater. Res. Technol. 2025, 36, 1511–1521. [Google Scholar] [CrossRef]

- Moradi, M.; Hasani, A.; Pourmand, Z.; Lawrence, J. Direct laser metal deposition additive manufacturing of Inconel 718 superalloy: Statistical modelling and optimization by design of experiments. Opt. Laser Technol. 2021, 144, 107380. [Google Scholar] [CrossRef]

- Rezaei, A.; Kermanpur, A.; Rezaeian, A.; Badrossamay, M.; Foroozmehr, E.; Sadeghi, F.; Han, J.; Park, T.M. Contribution of hot isostatic pressing on densification, microstructure evolution, and mechanical anisotropy of additively manufactured IN718 Ni-based superalloy. Mater. Sci. Eng. A 2021, 823, 141721. [Google Scholar] [CrossRef]

- Leung, C.L.A.; Luczyniec, D.; Guo, E.; Marussi, S.; Atwood, R.C.; Meisnar, M.; Saunders, B.; Lee, P.D. Quantification of Interdependent Dynamics during Laser Additive Manufacturing Using X-Ray Imaging Informed Multi-Physics and Multiphase Simulation. Adv. Sci. 2022, 9, 2203546. [Google Scholar] [CrossRef] [PubMed]

- Karmuhilan, M.; Kumanan, S. A Review on Additive Manufacturing Processes of Inconel 625. J. Mater. Eng. Perform. 2022, 31, 2583–2592. [Google Scholar] [CrossRef]

- Haghdadi, N.; Whitelock, E.; Lim, B.; Chen, H.; Liao, X.; Babu, S.S.; Ringer, S.P.; Primig, S. Multimodal γ′ precipitation in Inconel-738 Ni-based superalloy during electron-beam powder bed fusion additive manufacturing. J. Mater. Sci. 2020, 55, 13342–13350. [Google Scholar] [CrossRef]

- Dang, X.; Li, Y.; Chen, K.; Ramamurty, U.; Luo, S.; Liang, X.; He, W. Avoiding cracks in additively manufactured non-weldable directionally solidified Ni-based superalloys. Addit. Manuf. 2022, 59, 103095. [Google Scholar] [CrossRef]

- Javidrad, H.; Aydin, H.; Karakaş, B.; Alptekin, S.; Kahraman, A.S.; Koc, B. Process parameter optimization for laser powder directed energy deposition of Inconel 738LC. Opt. Laser Technol. 2024, 176, 110940. [Google Scholar] [CrossRef]

- Zhang, F.; Zhou, L.; Xie, X.; Zhang, Z.; Chao, Q.; Fan, G. Crack inhibition and crystallographic texture control in an additively manufactured IN738LC Ni-based superalloy. J. Mater. Res. Technol. 2024, 33, 652–666. [Google Scholar] [CrossRef]

- Marchese, G.; Parizia, S.; Saboori, A.; Manfredi, D.; Lombardi, M.; Fino, P.; Ugues, D.; Biamino, S. The Influence of the Process Parameters on the Densification and Microstructure Development of Laser Powder Bed Fused Inconel 939. Metals 2020, 10, 882. [Google Scholar] [CrossRef]

- Ren, C.; Chen, K.; Liang, J.; Narayan, R.L.; Ramamurty, U.; Li, J. Microstructural evolution and its influence on the wear resistance of a laser directed energy deposited Ni-based single crystal superalloy. J. Mater. Sci. Technol. 2025, 205, 127–138. [Google Scholar] [CrossRef]

- Shaikh, A.S.; Schulz, F.; Minet-Lallemand, K.; Hryha, E. Microstructure and mechanical properties of Haynes 282 superalloy produced by laser powder bed fusion. Mater. Today Commun. 2021, 26, 102038. [Google Scholar] [CrossRef]

- Després, A.; Antonov, S.; Mayer, C.; Tassin, C.; Veron, M.; Blandin, J.-J.; Kontis, P.; Martin, G. On the role of boron, carbon and zirconium on hot cracking and creep resistance of an additively manufactured polycrystalline superalloy. Materialia 2021, 19, 101193. [Google Scholar] [CrossRef]

- Pistor, J.; Breuning, C.; Körner, C. A Single Crystal Process Window for Electron Beam Powder Bed Fusion Additive Manufacturing of a CMSX-4 Type Ni-Based Superalloy. Materials 2021, 14, 3785. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, J.P.; Santos, T.G.; Miranda, R.M. Revisiting fundamental welding concepts to improve additive manufacturing: From theory to practice. Prog. Mater. Sci. 2020, 107, 100590. [Google Scholar] [CrossRef]

- Wang, Y.; Guo, W.; Xu, C.; Zhang, Y.; Ji, Q.; Feng, X.; Han, R.; Zhang, Y.; Wang, C.; Lu, B. Defects, microstructure, and properties in laser powder bed fusion IN718: Power density effects and feature maps. J. Manuf. Process. 2025, 135, 240–252. [Google Scholar] [CrossRef]

- Wang, K.; Du, D.; Liu, G.; Pu, Z.; Chang, B.; Ju, J. A study on the additive manufacturing of a high chromium Nickel-based superalloy by extreme high-speed laser metal deposition. Opt. Laser Technol. 2021, 133, 106504. [Google Scholar] [CrossRef]

- Svetlizky, D.; Das, M.; Zheng, B.; Vyatskikh, A.L.; Bose, S.; Bandyopadhyay, A.; Schoenung, J.M.; Lavernia, E.J.; Eliaz, N. Directed energy deposition (DED) additive manufacturing: Physical characteristics, defects, challenges and applications. Mater. Today 2021, 49, 271–295. [Google Scholar] [CrossRef]

- Panwisawas, C.; Gong, Y.; Tang, Y.T.; Reed, R.C.; Shinjo, J. Additive manufacturability of superalloys: Process-induced porosity, cooling rate and metal vapour. Addit. Manuf. 2021, 47, 102339. [Google Scholar] [CrossRef]

- Mostafaei, A.; Ghiaasiaan, R.; Ho, I.T.; Strayer, S.; Chang, K.-C.; Shamsaei, N.; Shao, S.; Paul, S.; Yeh, A.-C.; Tin, S.; et al. Additive manufacturing of nickel-based superalloys: A state-of-the-art review on process-structure-defect-property relationship. Prog. Mater. Sci. 2023, 136, 101108. [Google Scholar] [CrossRef]

- King, W.E.; Barth, H.D.; Castillo, V.M.; Gallegos, G.F.; Gibbs, J.W.; Hahn, D.E.; Kamath, C.; Rubenchik, A.M. Observation of keyhole-mode laser melting in laser powder-bed fusion additive manufacturing. J. Mater. Process. Technol. 2014, 214, 2915–2925. [Google Scholar] [CrossRef]

- Zhu, G.; Pan, W.; Wang, R.; Wang, D.; Shu, D.; Zhang, L.; Dong, A.; Sun, B. Microstructures and mechanical properties of GTD222 superalloy fabricated by selective laser melting. Mater. Sci. Eng. A 2021, 807, 140668. [Google Scholar] [CrossRef]

- Chauvet, E.; Kontis, P.; Jägle, E.A.; Gault, B.; Raabe, D.; Tassin, C.; Blandin, J.-J.; Dendievel, R.; Vayre, B.; Abed, S.; et al. Hot cracking mechanism affecting a non-weldable Ni-based superalloy produced by selective electron Beam Melting. Acta Mater. 2018, 142, 82–94. [Google Scholar] [CrossRef]

- Platl, J.; Bodner, S.; Hofer, C.; Landefeld, A.; Leitner, H.; Turk, C.; Nielsen, M.-A.; Demir, A.G.; Previtali, B.; Keckes, J.; et al. Cracking mechanism in a laser powder bed fused cold-work tool steel: The role of residual stresses, microstructure and local elemental concentrations. Acta Mater. 2022, 225, 117570. [Google Scholar] [CrossRef]

- Caruso, M.; Frame, L. Ductility dip cracking mechanisms and characterization: A review. J. Mater. Sci. 2024, 59, 16789–16814. [Google Scholar] [CrossRef]

- Wu, B.; Liang, J.-J.; Yang, Y.-H.; Li, J.-G.; Zhou, Y.-Z. Phase constitution, microstructure and mechanical properties of a Ni-based superalloy specially designed for additive manufacturing. China Foundry 2021, 18, 397–408. [Google Scholar] [CrossRef]

- Zhou, Z.; Huang, L.; Shang, Y.; Li, Y.; Jiang, L.; Lei, Q. Causes analysis on cracks in nickel-based single crystal superalloy fabricated by laser powder deposition additive manufacturing. Mater. Des. 2018, 160, 1238–1249. [Google Scholar] [CrossRef]

- Guo, B.; Zhang, Y.; Yang, Z.; Cui, D.; He, F.; Li, J.; Wang, Z.; Lin, X.; Wang, J. Cracking mechanism of Hastelloy X superalloy during directed energy deposition additive manufacturing. Addit. Manuf. 2022, 55, 102792. [Google Scholar] [CrossRef]

- Griffiths, S.; Ghasemi Tabasi, H.; Ivas, T.; Maeder, X.; De Luca, A.; Zweiacker, K.; Wróbel, R.; Jhabvala, J.; Logé, R.E.; Leinenbach, C. Combining alloy and process modification for micro-crack mitigation in an additively manufactured Ni-base superalloy. Addit. Manuf. 2020, 36, 101443. [Google Scholar] [CrossRef]

- Eshkabilov, S.; Ara, I.; Azarmi, F. A comprehensive investigation on application of machine learning for optimization of process parameters of laser powder bed fusion-processed 316L stainless steel. Int. J. Adv. Manuf. Technol. 2022, 123, 2733–2756. [Google Scholar] [CrossRef]

- Zhou, Z.; Lei, Q.; Yan, Z.; Wang, Z.; Shang, Y.; Li, Y.; Qi, H.; Jiang, L.; Liu, Y.; Huang, L. Effects of process parameters on microstructure and cracking susceptibility of a single crystal superalloy fabricated by directed energy deposition. Mater. Des. 2021, 198, 109296. [Google Scholar] [CrossRef]

- Li, K.; Zhan, J.; Wang, Y.; Qin, Y.; Gong, N.; Zhang, D.Z.; Tan, S.; Murr, L.E.; Liu, Z. Application of data-driven methods for laser powder bed fusion of Ni-based superalloys: A review. J. Manuf. Process. 2025, 133, 285–321. [Google Scholar] [CrossRef]

- Adegoke, O.; Andersson, J.; Brodin, H.; Pederson, R. Influence of Laser Powder Bed Fusion Process Parameters on Voids, Cracks, and Microhardness of Nickel-Based Superalloy Alloy 247LC. Materials 2020, 13, 3770. [Google Scholar] [CrossRef]

- Ghoussoub, J.N.; Tang, Y.T.; Panwisawas, C.; Németh, A.; Reed, R.C. On the Influence of Alloy Chemistry and Processing Conditions on Additive Manufacturability of Ni-Based Superalloys. In Superalloys 2020; Springer: Cham, Switzerland, 2020; ISBN 978-3-030-51834-9. [Google Scholar] [CrossRef]

- Yu, Y.; Yan, W.; Lin, F. Understanding the formation process of shrinkage pores with a 3D dendrite growth model: From casting to additive manufacturing. Comput. Mech. 2022, 69, 133–149. [Google Scholar] [CrossRef]

- Frieden Templeton, W.; Hinnebusch, S.; Strayer, S.T.; To, A.C.; Pistorius, P.C.; Narra, S.P. A mechanistic explanation of shrinkage porosity in laser powder bed fusion additive manufacturing. Acta Mater. 2024, 266, 119632. [Google Scholar] [CrossRef]

- Guo, C.; Li, G.; Li, S.; Hu, X.; Lu, H.; Li, X.; Xu, Z.; Chen, Y.; Li, Q.; Lu, J.; et al. Additive manufacturing of Ni-based superalloys: Residual stress, mechanisms of crack formation and strategies for crack inhibition. Nano Mater. Sci. 2023, 5, 53–77. [Google Scholar] [CrossRef]

- Liang, Y.-J.; Cheng, X.; Li, J.; Wang, H.-M. Microstructural control during laser additive manufacturing of single-crystal nickel-base superalloys: New processing–microstructure maps involving powder feeding. Mater. Des. 2017, 130, 197–207. [Google Scholar] [CrossRef]

- Segerstark, A.; Andersson, J.; Svensson, L.-E.; Ojo, O. Effect of Process Parameters on the Crack Formation in Laser Metal Powder Deposition of Alloy 718. Metall. Mater. Trans. A 2018, 49, 5042–5050. [Google Scholar] [CrossRef]

- Cloots, M.; Uggowitzer, P.J.; Wegener, K. Investigations on the microstructure and crack formation of IN738LC samples processed by selective laser melting using Gaussian and doughnut profiles. Mater. Des. 2016, 89, 770–784. [Google Scholar] [CrossRef]

- Xu, J.; Ding, Y.; Gao, Y.; Wang, H.; Hu, Y.; Zhang, D. Grain refinement and crack inhibition of hard-to-weld Inconel 738 alloy by altering the scanning strategy during selective laser melting. Mater. Des. 2021, 209, 109940. [Google Scholar] [CrossRef]

| Element | Ni | Co | Cr | Mo + W | Nb | Al + Ti | Hf | C + B + Zr | Si |

|---|---|---|---|---|---|---|---|---|---|

| wt.% | Bal. | 25.75 | 13.00 | 7.94 | 0.93 | 7.1 | 0.19 | 0.098 | 0.048 |

| Condition No. | Power (W) | Scanning Speed (mm/min) | Powder Feeding Rate (rpm) | Hatching Space (mm) | Linear Energy Density (J/mm) |

|---|---|---|---|---|---|

| 1 | 500 | 400 | 0.4 | 0.5 | 75 |

| 2 | 600 | 600 | 0.7 | 0.7 | 60 |

| 3 | 700 | 800 | 0.5 | 0.65 | 52.5 |

| 4 | 800 | 500 | 0.8 | 0.6 | 96 |

| 5 | 900 | 700 | 0.6 | 0.55 | 77.14 |

| 6 | 500 | 500 | 0.5 | 0.55 | 60 |

| 7 | 600 | 700 | 0.8 | 0.5 | 51.43 |

| 8 | 700 | 400 | 0.6 | 0.7 | 105 |

| 9 | 800 | 600 | 0.4 | 0.65 | 80 |

| 10 | 900 | 800 | 0.7 | 0.6 | 67.5 |

| 11 | 500 | 600 | 0.6 | 0.6 | 50 |

| 12 | 600 | 800 | 0.4 | 0.55 | 45 |

| 13 | 700 | 500 | 0.7 | 0.5 | 84 |

| 14 | 800 | 700 | 0.5 | 0.7 | 68.57 |

| 15 | 900 | 400 | 0.8 | 0.65 | 135 |

| 16 | 500 | 700 | 0.7 | 0.65 | 42.86 |

| 17 | 600 | 400 | 0.5 | 0.6 | 90 |

| 18 | 700 | 600 | 0.8 | 0.55 | 70 |

| 19 | 800 | 800 | 0.6 | 0.5 | 60 |

| 20 | 900 | 500 | 0.4 | 0.7 | 108 |

| 21 | 500 | 800 | 0.8 | 0.7 | 37.5 |

| 22 | 600 | 500 | 0.6 | 0.65 | 72 |

| 23 | 700 | 700 | 0.4 | 0.6 | 60 |

| 24 | 800 | 400 | 0.7 | 0.55 | 120 |

| 25 | 900 | 600 | 0.5 | 0.5 | 90 |

| Condition No. | Void Content (%) | Crack Count Density (pieces/mm2) | Crack Length Density (mm/mm2) |

|---|---|---|---|

| 1 | 1.18 | 0.60 | 0.07 |

| 2 | 1.14 | 0.12 | 0.01 |

| 3 | 0.80 | 0.65 | 0.09 |

| 4 | 0.20 | 1.13 | 0.17 |

| 5 | 0.22 | 1.96 | 0.28 |

| 6 | 0.75 | 0.00 | 0.00 |

| 7 | 0.77 | 0.00 | 0.00 |

| 8 | 0.38 | 1.49 | 0.34 |

| 9 | 0.56 | 0.60 | 0.50 |

| 10 | 0.27 | 0.77 | 0.15 |

| 11 | 1.15 | 0.83 | 0.10 |

| 12 | 1.14 | 1.25 | 0.25 |

| 13 | 0.20 | 0.60 | 0.13 |

| 14 | 0.26 | 0.42 | 0.04 |

| 15 | 0.41 | 1.01 | 0.22 |

| 16 | 1.23 | 0.77 | 0.14 |

| 17 | 0.38 | 0.12 | 0.00 |

| 18 | 0.59 | 0.36 | 0.04 |

| 19 | 0.32 | 0.54 | 0.08 |

| 20 | 0.19 | 2.08 | 0.55 |

| 21 | 0.65 | 0.48 | 0.05 |

| 22 | 0.43 | 0.60 | 0.04 |

| 23 | 0.21 | 1.55 | 0.33 |

| 24 | 0.13 | 0.60 | 0.35 |

| 25 | 0.49 | 1.96 | 0.14 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, W.-T.; Zhou, J.-C.; Ruan, J.-J.; Zhang, H.; Zhou, X.; Jiang, L.; Zhu, L.-L. Effects of Process Parameters on Defect Formation in Laser Additive Manufacturing of a Novel Ni-Based Superalloy. Materials 2025, 18, 3102. https://doi.org/10.3390/ma18133102

Liu W-T, Zhou J-C, Ruan J-J, Zhang H, Zhou X, Jiang L, Zhu L-L. Effects of Process Parameters on Defect Formation in Laser Additive Manufacturing of a Novel Ni-Based Superalloy. Materials. 2025; 18(13):3102. https://doi.org/10.3390/ma18133102

Chicago/Turabian StyleLiu, Wen-Tao, Jing-Cheng Zhou, Jing-Jing Ruan, Hua Zhang, Xin Zhou, Liang Jiang, and Li-Long Zhu. 2025. "Effects of Process Parameters on Defect Formation in Laser Additive Manufacturing of a Novel Ni-Based Superalloy" Materials 18, no. 13: 3102. https://doi.org/10.3390/ma18133102

APA StyleLiu, W.-T., Zhou, J.-C., Ruan, J.-J., Zhang, H., Zhou, X., Jiang, L., & Zhu, L.-L. (2025). Effects of Process Parameters on Defect Formation in Laser Additive Manufacturing of a Novel Ni-Based Superalloy. Materials, 18(13), 3102. https://doi.org/10.3390/ma18133102