Interface-Engineered RuP2/Mn2P2O7 Heterojunction on N/P Co-Doped Carbon for High-Performance Alkaline Hydrogen Evolution

Abstract

1. Introduction

2. Experimental Procedure

2.1. Chemicals

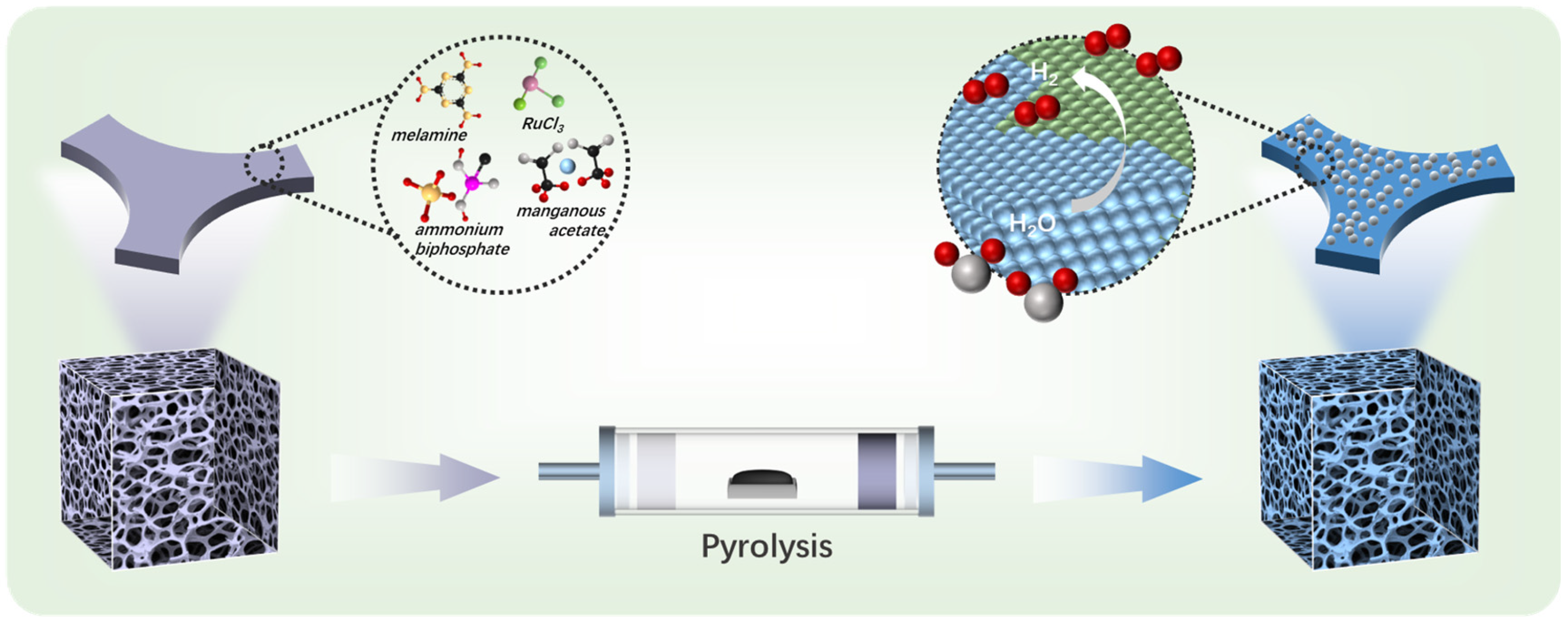

2.2. Synthesis of RuP2/Mn2P2O7/NPC and Control Catalysts

2.3. Characterization

2.4. Electrocatalytic Measurement

3. Results and Discussion

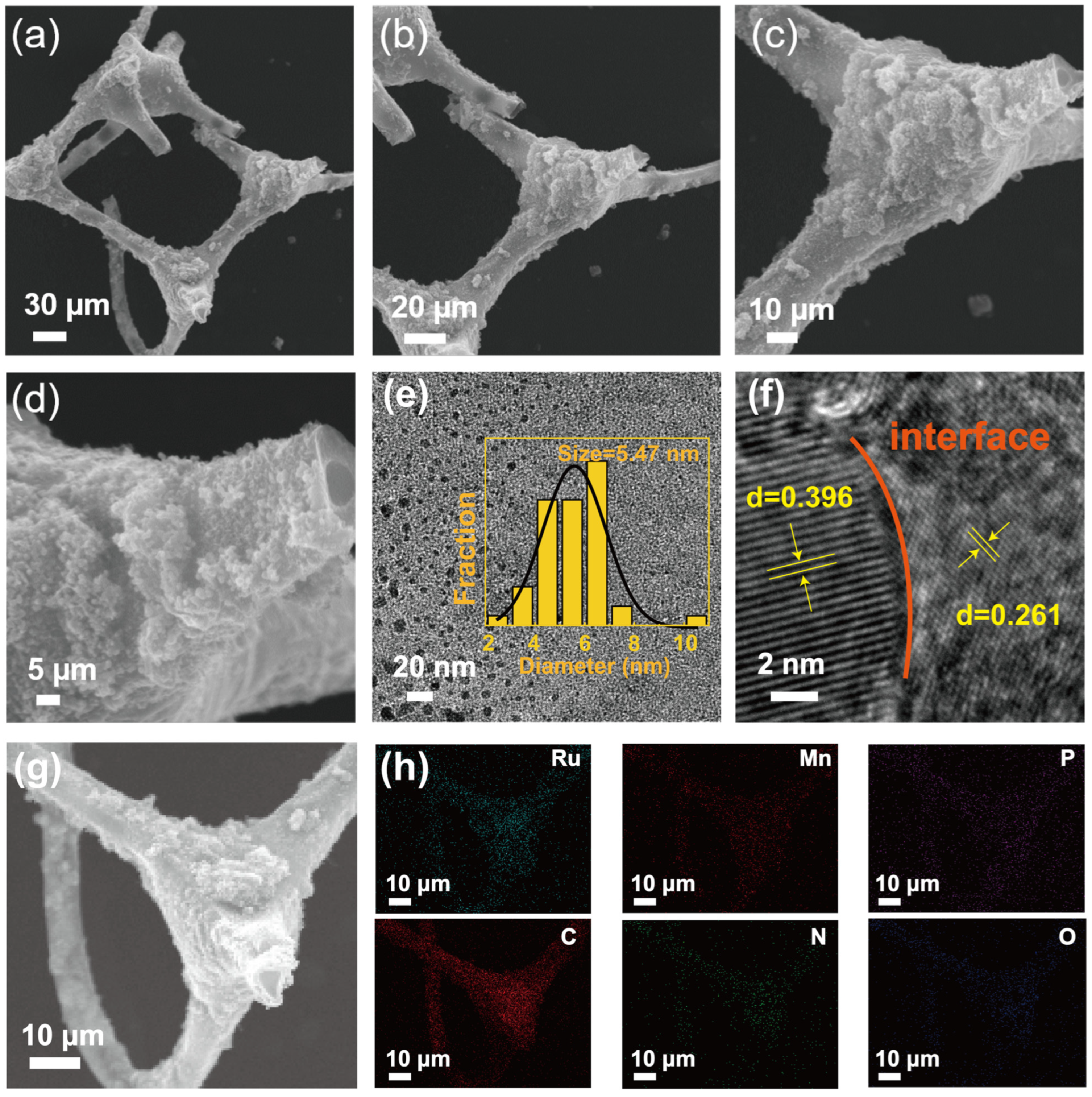

3.1. Synthesis and Characterization of RuP2/Mn2P2O7/NPC Catalyst

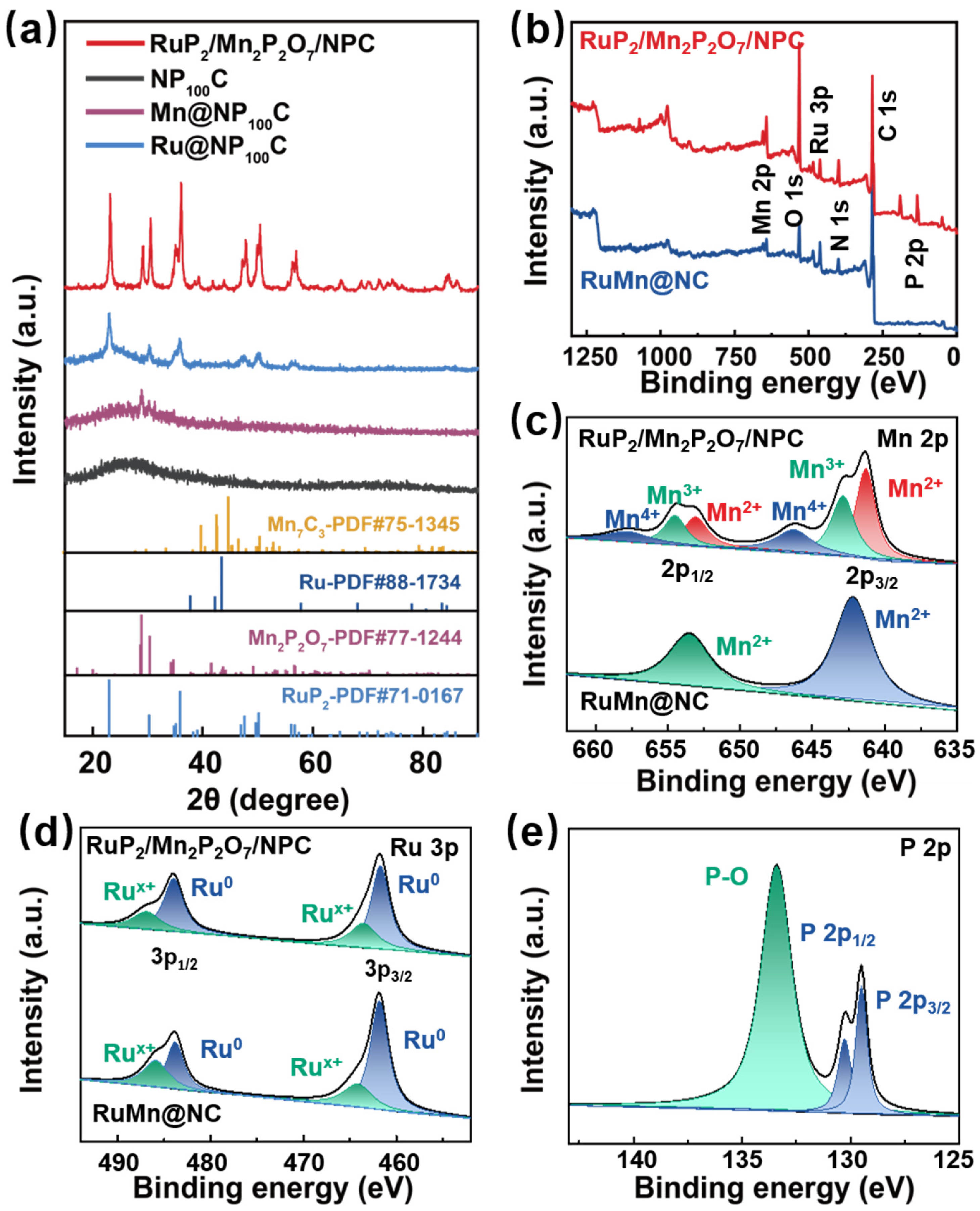

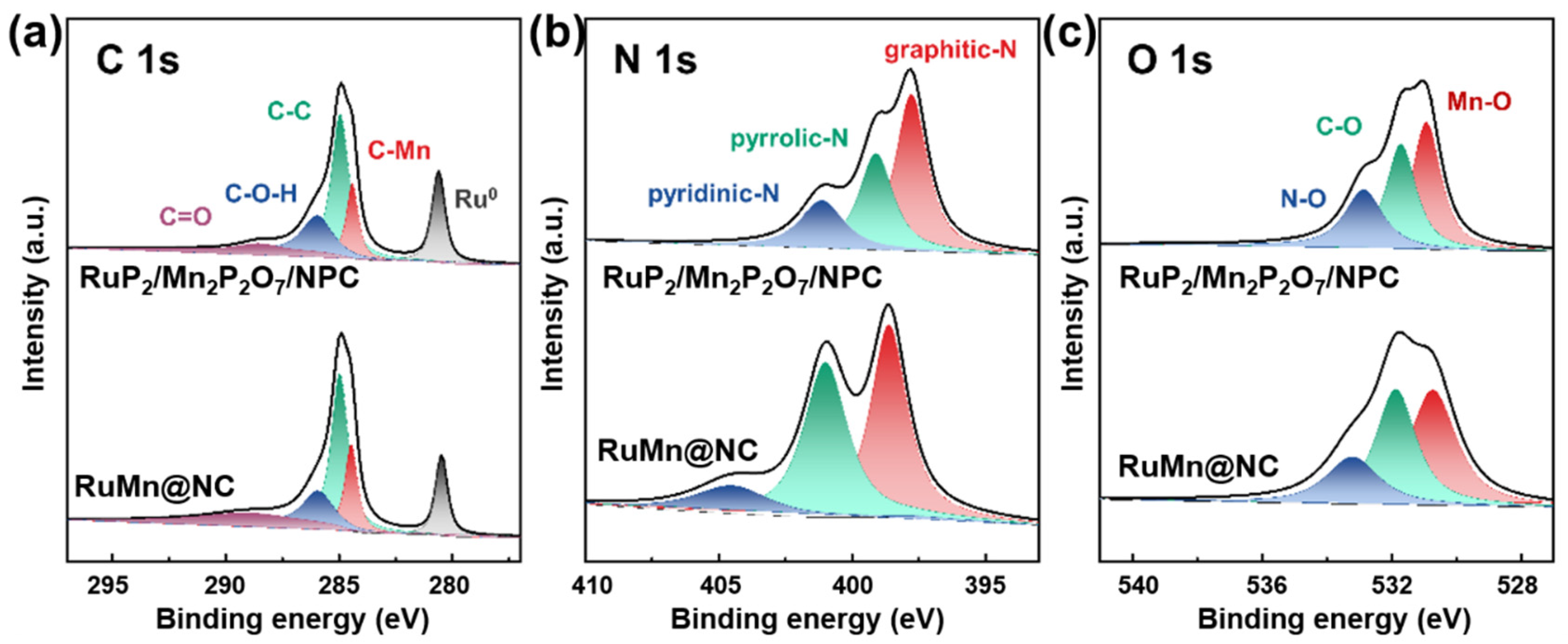

3.2. Structural Analysis of the Materials

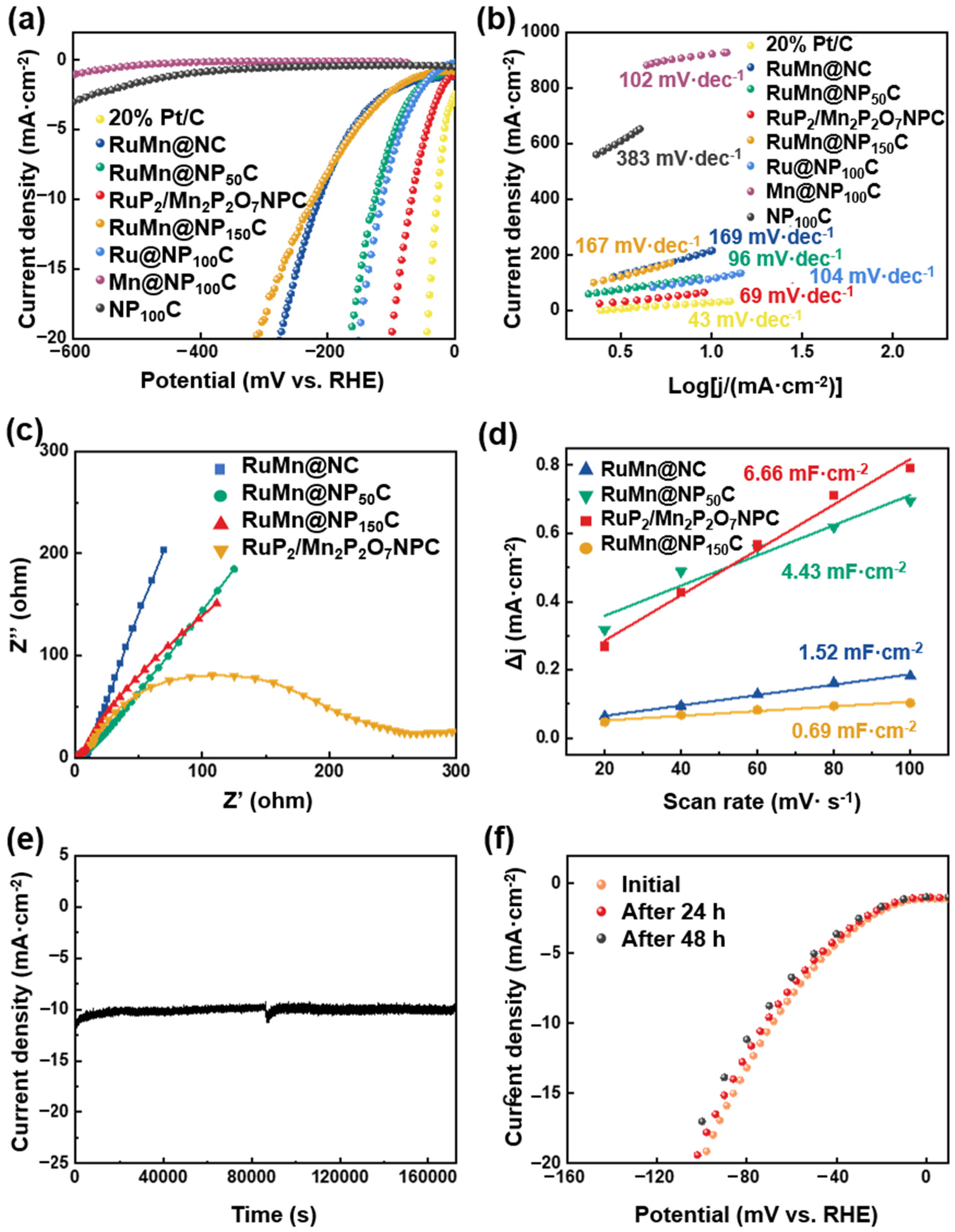

3.3. Electrochemical Performance of the Catalyst for HER

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, D.; Park, E.J.; Zhu, W.; Shi, Q.; Zhou, Y.; Tian, H.; Lin, Y.; Serov, A.; Zulevi, B.; Baca, E.D.; et al. Highly quaternized polystyrene ionomers for high performance anion exchange membrane water electrolysers. Nat. Energy 2020, 5, 378–385. [Google Scholar] [CrossRef]

- Sha, Q.; Wang, S.; Yan, L.; Feng, Y.; Zhang, Z.; Li, S.; Guo, X.; Li, T.; Li, H.; Zhuang, Z.; et al. 10,000-h-stable intermittent alkaline seawater electrolysis. Nature 2025, 639, 360–367. [Google Scholar] [CrossRef] [PubMed]

- Cao, L.; Yu, L.; Huang, H.; Gao, C.; Huang, X.; Zhang, X.; Zhang, X.; Du, Z.; He, C. A molecular engineered strategy to remolding architecture of RuP2 nanoclusters for sustainable hydrogen evolution. Adv. Funct. Mater. 2024, 34, 2411111. [Google Scholar] [CrossRef]

- Liu, H.; Xie, R.; Luo, Y.; Cui, Z.; Yu, Q.; Gao, Z.; Zhang, Z.; Yang, F.; Kang, X.; Ge, S.; et al. Dual interfacial engineering of a Chevrel phase electrode material for stable hydrogen evolution at 2500 mA cm−2. Nat. Commun. 2022, 13, 6382. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, Z.; Dastafkan, K.; Shen, Y.; Zhao, C.; Wang, M. Yttrium-doped NiMo-MoO2 heterostructure electrocatalysts for hydrogen production from alkaline seawater. Nat. Commun. 2025, 16, 773. [Google Scholar] [CrossRef]

- Xu, T.; Jiao, D.; Fan, J.; Dong, Y.; Jin, Z.; Zhang, L.; Zhang, W.; Zhao, J.; Zheng, W.; Cui, X. “Similar stacking”-inspired compressive strain of heterogeneous phosphide for efficient hydrogen evolution. Carbon Energy 2025, 7, e668. [Google Scholar] [CrossRef]

- Zhou, Z.; Su, Y.; Tan, H.; Wang, Y.; Huang, Q.; Wang, H.; Wang, J.; Kubo, M.; Ni, Z.; Kong, Y.; et al. Atomically dispersed Co-P moieties via direct thermal exfoliation for alkaline hydrogen electrosynthesis. J. Am. Chem. Soc. 2025, 147, 3994–4004. [Google Scholar] [CrossRef]

- Huang, L.; Yao, R.; Wang, X.; Sun, S.; Zhu, X.; Liu, X.; Kim, M.; Lian, J.; Liu, F.; Li, Y.; et al. In situ phosphating of Zn-doped bimetallic skeletons as a versatile electrocatalyst for water splitting. Energy Environ. Sci. 2022, 15, 2425–2434. [Google Scholar] [CrossRef]

- Jiang, Z.; Song, S.; Zheng, X.; Liang, X.; Li, Z.; Gu, H.; Li, Z.; Wang, Y.; Liu, S.; Chen, W.; et al. Lattice strain and schottky junction dual regulation boosts ultrafine ruthenium nanoparticles anchored on a N-modified carbon catalyst for H2 production. J. Am. Chem. Soc. 2022, 144, 19619–19626. [Google Scholar] [CrossRef]

- Miao, J.; Lang, Z.; Zhang, X.; Kong, W.; Peng, O.; Yang, Y.; Wang, S.; Cheng, J.; He, T.; Amini, A.; et al. Polyoxometalate-derived hexagonal molybdenum nitrides (MXenes) supported by boron, nitrogen codoped carbon nanotubes for efficient electrochemical hydrogen evolution from seawater. Adv. Funct. Mater. 2019, 29, 1805893. [Google Scholar] [CrossRef]

- Wang, Y.; Zhuo, H.; Zhang, X.; Dai, X.; Yu, K.; Luan, C.; Yu, L.; Xiao, Y.; Li, J.; Wang, M.; et al. Synergistic effect between undercoordinated platinum atoms and defective nickel hydroxide on enhanced hydrogen evolution reaction in alkaline solution. Nano Energy 2018, 48, 590–599. [Google Scholar] [CrossRef]

- Zhou, L.; Wan, T.; Zhong, Y.; Liu, W.; Yu, L.; Li, T.; Sun, K.; Waterhouse, G.I.N.; Xu, H.; Kuang, Y.; et al. Ampere-level hydrogen generation via 1000 h stable seawater electrolysis catalyzed by Pt-cluster-loaded NiFeCo phosphide. Small 2024, 20, 2406076. [Google Scholar] [CrossRef] [PubMed]

- Ji, K.; Wang, S.; Yao, S.; Ji, Y.; Li, J.; Wang, X.; Shi, L.; Wang, G.; Ren, W.; Wang, J.; et al. Built-in electric field in Ru/CoP bifunctional electrocatalyst enhances hydrazine-assisted water splitting. Adv. Mater. 2025, 2503182. [Google Scholar] [CrossRef] [PubMed]

- Jiang, K.; Liu, Z.; Wang, Z.; Xie, F.; Yuan, X.; Tan, Y. Manipulating interfacial water via metallic Pt1Co6 sites on self-adaptive metal phosphides to enhance water electrolysis. Adv. Mater. 2025, 37, 2419644. [Google Scholar] [CrossRef]

- Chen, S.; Zhang, Z.; Jiang, W.; Zhang, S.; Zhu, J.; Wang, L.; Ou, H.; Zaman, S.; Tan, L.; Zhu, P.; et al. Engineering water molecules activation center on multisite electrocatalysts for enhanced CO2 methanation. J. Am. Chem. Soc. 2022, 144, 12807–12815. [Google Scholar] [CrossRef]

- Gu, Y.; Xi, B.J.; Wei, R.C.; Fu, Q.; Qain, Y.T.; Xiong, S. Sponge assembled by graphene nanocages with double active sites to accelerate alkaline HER kinetics. Nano Lett. 2020, 20, 8375–8383. [Google Scholar] [CrossRef]

- Bi, M.; Zhang, Y.; Jiang, X.H.; Sun, J.; Wang, X.; Zhu, J.; Fu, Y. Ruthenium-induced activation of molybdenum-cobalt phosphide for high-efficiency water splitting. Adv. Funct. Mater. 2024, 34, 2309330. [Google Scholar] [CrossRef]

- Lei, H.; Zhou, Y.; Huangfu, Z.; Chen, L.; Cao, J.; Yang, X.; Mai, W.; Wang, Z. Noble metal nanoparticles anchored on transition metal phosphides for effective pH-universal hydrogen evolution. Adv. Sci. 2025, 37, 2504462. [Google Scholar] [CrossRef]

- Wang, C.; Guo, W.; Chen, T.; Lu, W.; Song, Z.; Yan, C.; Feng, Y.; Gao, F.; Zhang, X.; Rao, Y.; et al. Advanced noble-metal/transition-metal/metal-free electrocatalysts for hydrogen evolution reaction in water-electrolysis for hydrogen production. Coordin. Chem. Rev. 2024, 514, 215899. [Google Scholar] [CrossRef]

- An, W.; Lu, W.; Ma, L.; Li, W.; Yan, C.; Prova, U.H.; Wang, C.; Huang, G. Heterojunction regulates the function of coral like NiCoP for efficient hydrogen evolution reaction. Int. J. Hydrogen Energy 2023, 48, 35953–35961. [Google Scholar] [CrossRef]

- Chen, Z.; Xu, H.; Chen, T.; Zhang, J.; Zhang, S.; Chen, L.; Pang, H.; Huang, Z. MOF derived phosphide nanocubes with internal heterojunction: A study powered by single entity electrochemistry. Nano Lett. 2025, 25, 4921–4929. [Google Scholar] [CrossRef] [PubMed]

- Du, H.; He, S.; Li, B.; Wang, K.; Zhou, Z.; Li, J.; Wang, T.; Du, Z.; Ai, W.; Huang, W. Cascade reaction enables heterointerfaces-enriched nanoarrays for ampere-level hydrogen production. Angew. Chem. Int. Ed. 2025, 64, e202422393. [Google Scholar] [CrossRef] [PubMed]

- Gao, W.; Wu, Y.; Wan, X.; Gao, J.; Wen, D. Engineering the electronic structure of FeP with rare earth elements to enhance the electrocatalytic hydrogen evolution performance. J. Mater. Chem. A 2023, 11, 18126–18134. [Google Scholar] [CrossRef]

- Jin, M.T.; Zhang, X.; Shi, R.; Lian, Q.; Niu, S.Z.; Peng, O.W.; Wang, Q.; Cheng, C. Hierarchical CoP@Ni2P catalysts for pH-universal hydrogen evolution at high current density. Appl. Catal. B Environ. 2021, 296, 120350. [Google Scholar] [CrossRef]

- Niu, H.; Yan, Y.; Jiang, S.; Liu, T.; Sun, T.; Zhou, W.; Guo, L.; Li, J. Interfaces decrease the alkaline hydrogen-evolution kinetics energy barrier on NiCoP/Ti3C2TX MXene. ACS Nano 2022, 16, 11049–11058. [Google Scholar] [CrossRef]

- Wang, K.; He, S.; Li, B.; Du, H.; Wang, T.; Du, Z.; Xie, L.; Ai, W. Relaying alkaline hydrogen evolution over locally amorphous Ni/Co-based phosphides constructed by diffusion-limited phase-transition. Appl. Catal. B Environ. Energy 2023, 339, 123136. [Google Scholar] [CrossRef]

- Wang, F.; Ju, L.; Wu, B.; Li, S.; Peng, J.; Chen, Y.; Sendeku, M.G.; Wang, K.; Cai, Y.; Yi, J.; et al. Effect of intrinsic ferroelectric phase transition on hydrogen evolution electrocatalysis. Angew. Chem. Int. Ed. 2024, 63, e202402033. [Google Scholar] [CrossRef]

- Wang, X.; Le, J.; Fei, Y.; Gao, R.; Jing, M.; Yuan, W.; Li, C. Self-assembled ultrasmall mixed Co-W phosphide nanoparticles on pristine graphene with remarkable synergistic effects as highly efficient electrocatalysts for hydrogen evolution. J. Mater. Chem. A 2022, 10, 7694–7704. [Google Scholar] [CrossRef]

- Feng, D.; Wang, P.; Ma, B.; Zhao, X.; Chen, Y. MoN@NiO core-shell heterostructure nanorods array for highly efficient electrocatalytic hydrogen evolution reaction. Appl. Catal. B Environ. 2025, 374, 125373. [Google Scholar] [CrossRef]

- Yang, H.; Guo, P.; Wang, R.; Chen, Z.; Xu, H.; Pan, H.; Sun, D.; Fang, F.; Wu, R. Sequential phase conversion-induced phosphides heteronanorod arrays for superior hydrogen evolution performance to Pt in wide pH media. Adv. Mater. 2022, 34, 2107548. [Google Scholar] [CrossRef]

- Zhang, K.; Jia, J.; Yang, E.; Qi, S.; Tian, H.; Chen, J.; Li, J.; Lou, Y.; Guo, Y. Work-function-induced electron rearrangement of in-plane FeP@CoP heterojunction enhances all pH range and alkaline seawater hydrogen evolution reaction. Nano Energy 2023, 114, 108601. [Google Scholar] [CrossRef]

- Zhang, Y.; Guo, P.; Guo, S.; Xin, X.; Wang, Y.; Huang, W.; Wang, M.; Yang, B.; Sobrido, A.J.; Ghasemi, J.B.; et al. Gradient heating epitaxial growth gives well lattice-matched Mo2C-Mo2N heterointerfaces that boost both electrocatalytic hydrogen evolution and water vapor splitting. Angew. Chem. Int. Ed. 2022, 61, e202209703. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Zhang, Z.; Gu, S.; Liu, Y.; Deng, Y.; Li, Y.; Xiao, Z.; Liu, K.; Wu, Z.; Wang, L. The cobalt-based metal organic frameworks array derived CoFeNi-layered double hydroxides anode and CoP/FeNi2P heterojunction cathode for ampere-level seawater overall splitting. J. Colloid Interf. Sci. 2024, 676, 52–60. [Google Scholar] [CrossRef]

- Xu, H.; Wei, J.; Zhang, K.; Yukihide, S.; Du, Y. Hierarchical NiMo phosphide nanosheets strongly anchored on carbon nanotubes as robust electrocatalysts for overall water splitting. ACS Appl. Mater. Interfaces 2018, 10, 29647–29655. [Google Scholar] [CrossRef]

- Cai, J.; Song, Y.; Zang, Y.; Niu, S.; Wu, Y.; Xie, Y.; Zheng, X.; Liu, Y.; Lin, Y.; Qian, Y. N-induced lattice contraction generally boosts the hydrogen evolution catalysis of P-rich metal phosphides. Sci. Adv. 2020, 6, eaaw8113. [Google Scholar] [CrossRef]

- Wang, P.; Zhao, D.; Zhang, P.; Hui, X.; Zhang, Z.; Wang, R.; Wang, C.; Ge, X.; Liu, X.; Li, Y.; et al. P-block element modulated 1 T phase MoS2 with Ru lattice grafting for high-performance Li | |O2 batteries. Nat. Commun. 2025, 16, 1453. [Google Scholar] [CrossRef]

- Shi, S.; Sun, C.; Yin, X.; Shen, L.; Shi, Q.; Zhao, K.; Zhao, Y.; Zhang, J. FeP quantum dots confined in carbon-nanotube-grafted P-doped carbon octahedra for high-rate sodium storage and full-cell applications. Adv. Funct. Mater. 2020, 30, 1909283. [Google Scholar] [CrossRef]

- Zhang, Q.; Ti, Z.; Zhu, Y.; Zhang, Y.; Cao, Y.; Li, S.; Wang, M.; Li, D.; Zou, B.; Hou, Y.; et al. Achieving ultralow lattice thermal conductivity and high thermoelectric performance in GeTe alloys via introducing Cu2Te nanocrystals and resonant level doping. ACS Nano 2021, 15, 19345–19356. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, N.; Chen, L.; Yang, X.; Guo, H.; Wang, Z.; Yuan, M.; Yan, X.; Yang, J.; Li, X.; et al. Ultrawide bandgap diamond/ε-Ga2O3 heterojunction pn diodes with breakdown voltages over 3 kV. Nano Lett. 2025, 25, 537–544. [Google Scholar] [CrossRef]

| Element | RuP2/Mn2P2O7/NPC (Atomic%) | RuMn@NC (Atomic%) |

|---|---|---|

| Ru | 1.91 | 2.19 |

| Mn | 0.79 | 3.31 |

| P | 11.8 | 0 |

| N | 9.71 | 5.66 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, W.; Guo, W.; Liu, Z.; Zhang, C.; Li, A.; Su, C.; Wang, C. Interface-Engineered RuP2/Mn2P2O7 Heterojunction on N/P Co-Doped Carbon for High-Performance Alkaline Hydrogen Evolution. Materials 2025, 18, 3065. https://doi.org/10.3390/ma18133065

Wu W, Guo W, Liu Z, Zhang C, Li A, Su C, Wang C. Interface-Engineered RuP2/Mn2P2O7 Heterojunction on N/P Co-Doped Carbon for High-Performance Alkaline Hydrogen Evolution. Materials. 2025; 18(13):3065. https://doi.org/10.3390/ma18133065

Chicago/Turabian StyleWu, Wenjie, Wenxuan Guo, Zeyang Liu, Chenxi Zhang, Aobing Li, Caihua Su, and Chunxia Wang. 2025. "Interface-Engineered RuP2/Mn2P2O7 Heterojunction on N/P Co-Doped Carbon for High-Performance Alkaline Hydrogen Evolution" Materials 18, no. 13: 3065. https://doi.org/10.3390/ma18133065

APA StyleWu, W., Guo, W., Liu, Z., Zhang, C., Li, A., Su, C., & Wang, C. (2025). Interface-Engineered RuP2/Mn2P2O7 Heterojunction on N/P Co-Doped Carbon for High-Performance Alkaline Hydrogen Evolution. Materials, 18(13), 3065. https://doi.org/10.3390/ma18133065