LCA of Cement with Alternative Additives: Pathways to Sustainable Production

Abstract

1. Introduction

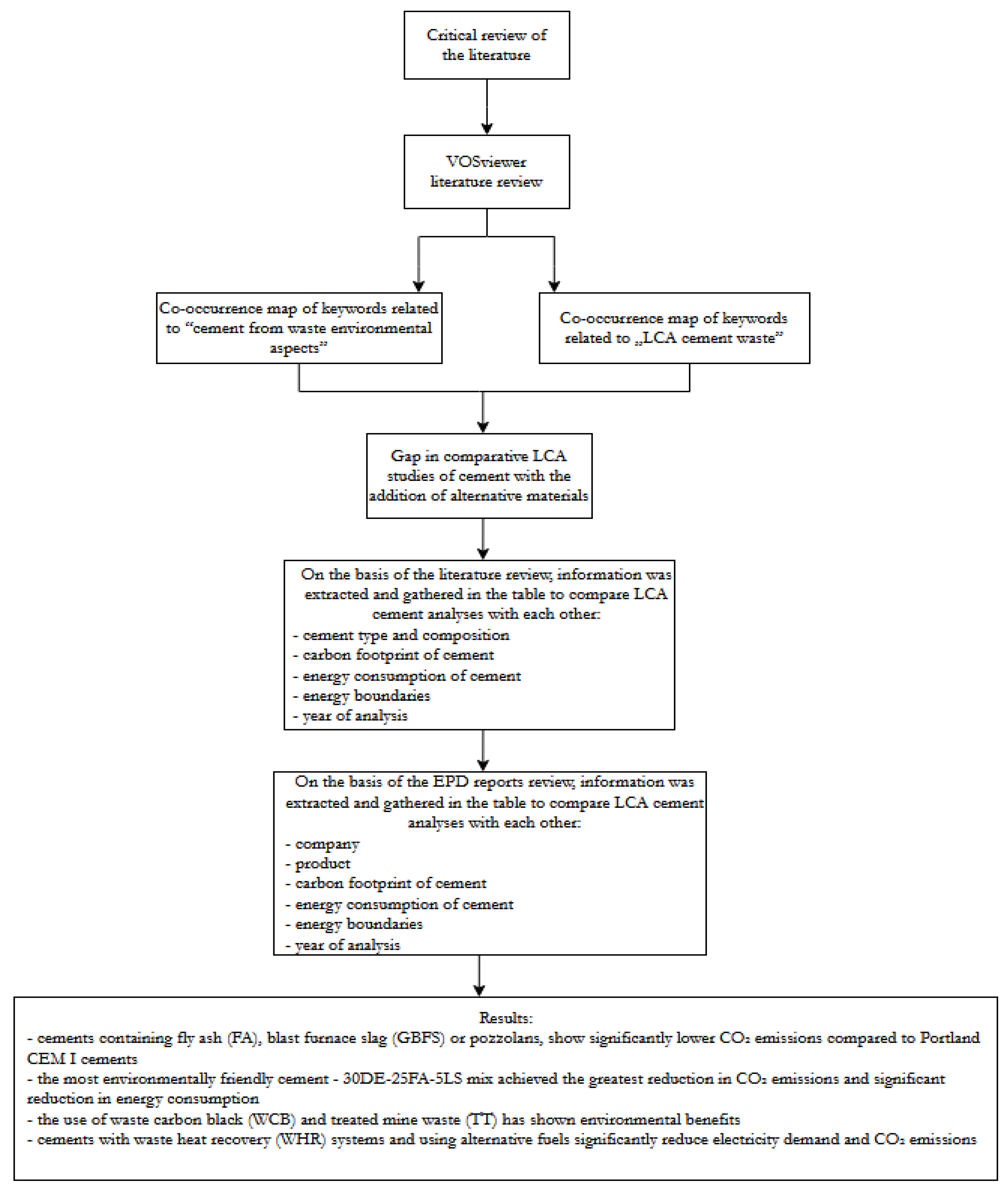

2. Materials and Methods

- -

- “cement production”, resulting in 13,317 articles across databases;

- -

- “clinker production”, resulting in 1165 articles across databases;

- -

- “environmental aspects of cement”, resulting in 1014 articles across databases;

- -

- “environmental aspects of clinker”, result in 39 articles across databases;

- -

- “waste from cement production”, resulting in 3680 articles across databases.

- Blue cluster: This cluster focuses on the mechanical properties and durability of concrete. The main terms are mechanical properties, durability, fine aggregate, replacement, and cement mortar. This cluster reflects the technical aspects of using alternative materials in concrete mixtures.

- Red cluster: This cluster focuses on waste and environmental aspects. Prominent terms include waste, stabilization, adsorption, removal, immobilization, sewage sludge, and heavy metals. This cluster indicates research on the potential use of industrial and municipal waste in cement technology and its impact on the environment.

- Green cluster: This cluster is related to recycling and alternative sources of raw material, including recycled aggregate, sustainable development, red mud, steel slag, and biomass. It includes issues related to the circular economy and the replacement of natural resources with waste.

- Yellow cluster: This cluster deals with material properties and hydration processes. Common words are strength, hydration, behavior, resistance, porosity, and supplementary cementitious materials. This shows interest in the effects of mineral additives on strength and structural properties.

- Turquoise cluster: This cluster contains words related to concrete mix design and aspects of optimization and additives, such as optimization, shrinkage, blended cement, and fly ash.

- Red cluster (LCA and waste management): The main keywords are life cycle assessment, waste management, management, incineration, energy recovery, and impact assessment. This cluster focuses on the environmental aspects of systemic waste management and their evaluation from an LCA perspective, often in relation to incineration and energy recovery processes.

- Green cluster (alternative materials and mechanical properties): This cluster includes terms such as fly ash, geopolymer, compressive strength, metakaolin, silica fume, slag, and alkali activation. This area is concerned with the use of mineral wastes as additives to cement and concrete and the study of their physical and chemical properties.

- Blue cluster (cement, concrete, and their environmental assessment): This cluster contains central buzzwords such as cement, concrete, environmental impact, recycling, and greenhouse gas. This cluster bridges the gap between materials technology and the environmental assessment of building materials.

- Yellow cluster (recycled aggregate and the circular economy): This cluster includes terms like recycled aggregate, construction and demolition waste, structural concrete, and sustainable concrete. It focuses on aspects of the recovery and reuse of aggregates from building demolition.

- Purple cluster (emissions and carbon footprint): This cluster includes words such as carbon footprint, carbon emissions, GHG emissions, soil, capture, cement production, and carbonation. It focuses on emission analysis and mitigation strategies in the cement industry.

3. Results

- Cements containing a high proportion of mineral additives—in particular, cements containing fly ash (FA), granulated blast furnace slag (GBFS), or pozzolans, which show significantly lower CO2 emissions compared to Portland CEM I cements.

- The most environmentally friendly cement—30DE-25FA-5LS mix achieved the greatest reduction in CO2 emissions (60%) and a significant reduction in energy consumption (50%) while maintaining high mechanical strength.

- Cements with industrial waste—the use of waste carbon black (WCB) and treated mine waste (TT) has shown environmental benefits, but their effectiveness depends on the level of cement substitution and additional energy consumption in processing these materials.

- Energy efficiency—cements with waste heat recovery (WHR) systems and using alternative fuels significantly reduce electricity demand and CO2 emissions.

4. Discussion

5. Conclusions

- Policy support is essential to accelerate the shift. Instruments such as carbon pricing, green procurement, and mandatory EPDs can enable broader adoption of sustainable cement technologies [23].

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| AS | Alternative scenario including the use of dried sewage sludge |

| CCS | Carbon capture and storage |

| DE | Diatomite |

| EPD | Environmental Product Declaration |

| FA | Fly ash |

| FA1 | Ash from a fluidized circulation boiler (clean wood and cocoa shells) |

| FA2 | Ash from a wood pellet boiler |

| FA3 | Ash from a bubbling boiler (paper sludge and waste wood) |

| GBFS | Ground granulated blast furnace slag |

| GWP | Global Warming Potential |

| LCA | Life Cycle Assessment |

| LS | Limestone |

| MK | Metakaolin |

| OPC | Ordinary Portland cement |

| PC | Portland cement |

| SCMs | Supplementary cementitious materials |

| TT | Treated tailing |

| WCB | Waste ceramic byproducts |

| WHR | Waste heat recovery system |

References

- Gao, P.; Zha, W.; Chu, Y.; Yu, Y.; Zhan, B.; Yu, Q.; Xie, F.; Lu, H. Calculation model for CO2 emissions of blended cement production. J. Clean. Prod. 2025, 489, 144646. [Google Scholar] [CrossRef]

- Lin, C.; Zhao, Z.; Tao, J.; Ye, T.; Yao, L.; Ji, C.; Duan, Z. Properties of cement-based materials made with sediment and calcined sediment: A critical review. J. Build. Eng. 2025, 106, 112609. [Google Scholar] [CrossRef]

- Miller, S.A.; Habert, G.; Myers, R.J.; Harvey, J.T. Achieving net zero greenhouse gas emissions in the cement industry via value chain mitigation strategies. One Earth 2021, 4, 1398–1411. [Google Scholar] [CrossRef]

- Nikolakopoulos, A.; Steriotis, T.; Charalambopoulou, G.; Karagiannakis, G.; Dimitrakis, D.; Michalis, V.; Katsiotis, M. Reducing carbon emissions in cement production through solarization of the calcination process and thermochemical energy storage. Comput. Chem. Eng. 2024, 180, 108506. [Google Scholar] [CrossRef]

- Guo, Y.; Luo, L.; Liu, T.; Hao, L.; Li, Y.; Liu, P.; Zhu, T. A review of low-carbon technologies and projects for the global cement industry. J. Environ. Sci. 2024, 136, 682–697. [Google Scholar] [CrossRef] [PubMed]

- Khalil, E.; AbouZeid, M. A global assessment tool for cement plants improvement measures for the reduction of CO2 emissions. Results Eng. 2025, 26, 104767. [Google Scholar] [CrossRef]

- Feng, W.; Yu, Z.; Bao, R.; Xiong, J.; Yan, K.; Liu, R.; Zhang, R.; Lu, X. From waste to resource: Advanced activation techniques for tailings in sustainable cement production. J. Build. Eng. 2024, 97, 110780. [Google Scholar] [CrossRef]

- Dacić, A.; Mester-Szabó, E.; Fenyvesi, O.; Szalay, Z. Life cycle assessment of concrete incorporating all concrete recycling products. Case Stud. Constr. Mater. 2024, 21, e03910. [Google Scholar] [CrossRef]

- Qiao, L.; Tang, Y.; Li, Y.; Liu, M.; Yuan, X.; Wang, Q.; Ma, Q. Life cycle assessment of three typical recycled products from construction and demolition waste. J. Clean. Prod. 2022, 376, 134139. [Google Scholar] [CrossRef]

- Sousa, V.; Bogas, J.A. Comparison of energy consumption and carbon emissions from clinker and recycled cement production. J. Clean. Prod. 2021, 306, 127277. [Google Scholar] [CrossRef]

- Clark, G.; Davis, M.; Kumar, A. The development of a framework to compare carbon capture and storage technologies as a means of decarbonizing cement production. Renew. Sustain. Energy Rev. 2025, 214, 115556. [Google Scholar] [CrossRef]

- Andrade Neto, J.S.; Carvalho, I.C.; Monteiro, P.J.M.; de Matos, P.R.; Kirchheim, A.P. Unveiling the key factors for clinker reactivity and cement performance: A physic-chemical and performance investigation of 40 industrial clinkers. Cem. Concr. Res. 2025, 187, 107717. [Google Scholar] [CrossRef]

- Kampai, C.; Chindasiriphan, P.; Jongvivatsakul, P.; Miao, P.; Tangchirapat, W. Durability properties of high-strength concrete with high-volume bottom ash as a substitute for cement and fine aggregate. Constr. Build. Mater. 2024, 457, 139401. [Google Scholar] [CrossRef]

- Akintayo, B.D.; Olanrewaju, O.A.; Olanrewaju, O.I. Life Cycle Assessment of Ordinary Portland Cement Production in South Africa: Mid-Point and End-Point Approaches. Sustainability 2024, 16, 3001. [Google Scholar] [CrossRef]

- Vargas, F.; Lopez, M.; Rigamonti, L. Environmental impacts evaluation of treated copper tailings as supplementary cementitious materials. Resour. Conserv. Recycl. 2020, 160, 104890. [Google Scholar] [CrossRef]

- Caldas, L.R.; Da Gloria, M.Y.R.; Pittau, F.; Andreola, V.M.; Habert, G.; Toledo Filho, R.D. Environmental impact assessment of wood bio-concretes: Evaluation of the influence of different supplementary cementitious materials. Constr. Build. Mater. 2021, 268, 121146. [Google Scholar] [CrossRef]

- Irshidat, M.R.; Al-Nuaimi, N.; Ahmed, W.; Rabie, M. Feasibility of recycling waste carbon black in cement mortar production: Environmental life cycle assessment and performance evaluation. Constr. Build. Mater. 2021, 296, 123740. [Google Scholar] [CrossRef]

- Li, J.; Zhang, W.; Li, C.; Monteiro, P.J.M. Eco-friendly mortar with high-volume diatomite and fly ash: Performance and life-cycle assessment with regional variability. J. Clean. Prod. 2020, 261, 121224. [Google Scholar] [CrossRef]

- Tosti, L.; van Zomeren, A.; Pels, J.R.; Damgaard, A.; Comans, R.N.J. Life cycle assessment of the reuse of fly ash from biomass combustion as secondary cementitious material in cement products. J. Clean. Prod. 2020, 245, 118937. [Google Scholar] [CrossRef]

- VOSviewer. VOSviewer—Visualizing Scientific Landscapes. Available online: https://www.vosviewer.com// (accessed on 14 May 2025).

- Vargas, F.; Rigamonti, L. Environmental evaluation of treated tailing as Supplementary Cementitious Material. Procedia CIRP 2020, 90, 280–284. [Google Scholar] [CrossRef]

- Huseien, G.F.; Shah, K.W. Durability and life cycle evaluation of self-compacting concrete containing fly ash as GBFS replacement with alkali activation. Constr. Build. Mater. 2020, 235, 117458. [Google Scholar] [CrossRef]

- Çankaya, S.; Pekey, B. A comparative life cycle assessment for sustainable cement production in Turkey. J. Environ. Manag. 2019, 249, 109362. [Google Scholar] [CrossRef] [PubMed]

- NEPD-6369-5628_AB-Sydsten-Fabriksbetong-C30-37.pdf. Available online: https://www.epd-norge.no/getfile.php/13189396-1741687372/EPDer/Byggevarer/Ferdig%20betong/NEPD-6369-5628_AB-Sydsten-Fabriksbetong-C30-37.pdf (accessed on 6 May 2025).

- EPD Colacem Gubbio.pdf. Available online: https://www.colacem.com/downloads/3739/1627/EPD%20Colacem%20Gubbio.pdf (accessed on 6 May 2025).

- EPD Colacem Rassina.pdf. Available online: https://www.colacem.com/downloads/3739/1628/EPD%20Colacem%20Rassina.pdf (accessed on 6 May 2025).

- EPD Ragusa Cementi di Ragusa.pdf. Available online: https://www.colacem.com/downloads/3739/1633/EPD%20Ragusa%20Cementi%20di%20Ragusa.pdf (accessed on 6 May 2025).

- Knauf. AQUAPANEL® Cement Board Rooftop 6. Available online: https://knauf.com/de-DE/p/produkt/aquapanel-r-cement-board-rooftop-6-18652_0010 (accessed on 6 May 2025).

- Process Data Set: Airium Cement-Based Insulation Foam (en)—OEKOBAU.DAT. Available online: https://oekobaudat.de/OEKOBAU.DAT/datasetdetail/process.xhtml?lang=en&uuid=fd6ae0fa-4d2d-4005-9759-909e508751ab&version=00.01.000 (accessed on 6 May 2025).

- AQUAPANEL Cement Board Outdoor—Site Volos. Available online: https://www.oekobaudat.de/OEKOBAU.DAT/resource/sources/6e187615-0b36-4fb5-acbc-082cddd781c9/AQUAPANEL_Cement_Board_Outdoor_-_Site_Volos_15647.pdf?version=00.01.000 (accessed on 6 May 2025).

- Cemcor. EPD-Cemcor-CEM-I-52.5-N-4-02-23-EPDIE-22-94.pdf. Available online: https://www.igbc.ie/wp-content/uploads/2023/01/EPD-Cemcor-CEM-I-525-N-4-02-23-EPDIE-22-94.pdf (accessed on 6 May 2025).

- Cemcor. EPD-Cemcor-CEM-IIA-L-42.5-R-4-01-2023-EPDIE-22-95.pdf. Available online: https://www.igbc.ie/wp-content/uploads/2023/01/EPD-Cemcor-CEM-IIA-L-425-R-4-01-2023-EPDIE-22-95.pdf (accessed on 6 May 2025).

- GreenBook Live: Klasse Group Ltd. Available online: https://www.greenbooklive.com/search/scheme.jsp?id=417 (accessed on 6 May 2025).

- DAP-004-2024-SECIL_EN.pdf. Available online: https://daphabitat.pt/assets/Uploads/dap/pdfs/40d8b17ad6/DAP-004-2024-SECIL_EN.pdf (accessed on 6 May 2025).

- DAP-014-2024_EN_SECIL.pdf. Available online: https://daphabitat.pt/assets/Uploads/dap/pdfs/c4381accfe/DAP-014-2024_EN_SECIL.pdf (accessed on 6 May 2025).

- CEM I 52.5 R Cement—Milieu Relevante Product Informatie. Available online: https://www.mrpi.nl/epd/cem-i-52-5-r-cement/ (accessed on 6 May 2025).

- Baumit GmbH—3 Cement Data Sets—2024—Ecoinvent. Available online: https://www.bau-epd.at/en/epd/data/baumit-gmbh-3-cement-data-sets-2024-ecoinvent (accessed on 6 May 2025).

- ECO PORTAL—Eco Platform en. Available online: https://www.eco-platform.org/epd-data.html (accessed on 6 May 2025).

| Cement Type | Carbon Footprint | Energy Consumption | System Boundaries | Source |

|---|---|---|---|---|

| Portland Cement produced in South Africa | 772 kg CO2-eq/t cement | - | Cradle-to-gate A1–A3 | [14] |

| 1 OPC (without additives, BC-34) | 380.3 kg CO2/t cement | 836 kWh/t TT | Cradle-to-gate A1–A3 | [15] |

| 1 Cement with TT (OP1-34) | 320.97 kg CO2/t cement | 836 kWh/t cement | ||

| 1 Cement with TT (LS5-34) | 357.66 kg CO2/t cement | 951 kWh/t cement | ||

| 1 Cement (BC-41, maximum strength) | 455.2 kg CO2/t cement | - | ||

| 1 Cement with TT (OP1-41) | 337.72 kg CO2/t cement | 836 kWh/t cement | ||

| 1 Cement with TT (LS5-37) | 364.57 kg CO2/t cement | 951 kWh/t cement | ||

| 1 TTs (treated tailings)—processed copper mining waste used as a substitute material for cement. TT energy consumption includes grinding and calcination processes. System boundaries include the full production process up to the concrete plant exit, excluding use and end of life phases. | ||||

| 2 100% CEM | 415 kg CO2-eq/m3 WBC | 836 kWh/m3 WBC | Cradle-to-gate A1–A3 | [16] |

| 2 40% MK | 320.97 kg CO2-eq/m3 WBC | 951 kWh/m3 WBC | ||

| 2 30% MK-10% FA | 337.72 kg CO2-eq/m3 WBC | 836 kWh/m3 WBC | ||

| 2 20% MK-20% FA | 364.57 kg CO2-eq/m3 WBC | 951 kWh/m3 WBC | ||

| 2 40% MK-10% FA | Lowest: −39 to 41 (depending on fuel) kg CO2-eq/m3 WBC | 1014 kWh/m3 WBC | ||

| 2 30% MK-20% FA | 100 kg CO2-eq/m3 WBC | 1014 kWh/m3 WBC | ||

| 2 25% MK-25% FA | −39 (lowest, using wood chips) kg CO2-eq/m3 WBC | 1014 kWh/m3 WBC | ||

| 2 SCM: supplementary cementitious materials (metakaolin—MK; fly ash—FA). Lowest climate impact: the 25 MK-25 FA blend achieved −39 kg CO2-eq/m3 due to CO2 sequestration in wood (scenario using wood chips as fuel for kaolin calcination). | ||||

| 3 0%(control) | 659 kg CO2-eq/m3 | 2520 MJ/m3 | Cradle-to-gate A1–A3 | [17] |

| 3 5% WCB | 632 kg CO2-eq/m3 | 2430 MJ/m3 | ||

| 3 10% WCB | 600 kg CO2-eq/m3 | 2340 MJ/m3 | ||

| 3 20% WCB | 527 kg CO2-eq/m3 | 2150 MJ/m3 | ||

| 3 30% WCB | 472 kg CO2-eq/m3 | 2010 MJ/m3 | ||

| 3 40% WCB | 422 kg CO2-eq/m3 | 1900 MJ/m3 | ||

| 3 WCB: waste carbon black—waste carbon black from the aluminum industry. System boundaries: stages from raw material acquisition (A1) and transportation (A2) to cement mortar production (A3). LCA methodology: the CML 2016 method was used, with analysis of impact categories GWP, AP, EP, and ADP. Best compromise: a mix with 10% WCB, which provided a 9% reduction in CO2 emissions while maintaining comparable strength to the control mix. | ||||

| 4 BC-34 (bez TT) | 659 kg CO2-eq/m3 | 700 kWh/m3 | Cradle-to-gate A1–A3 | [21] |

| 4 OP-34 (OP1 TT, 27,8%) | 580 kg CO2-eq/m3 | 836 kWh/m3 | ||

| 4 LS-34 (LS5 TT, 14,4%) | 612 kg CO2-eq/m3 | 951 kWh/m3 | ||

| 4 BC-41 (without TT) | 720 kg CO2-eq/m3 | 750 kWh/m3 | ||

| 4 OP-41 (OP1 TT, 20%) | 610 kg CO2-eq/m3 | 836 kWh/m3 | ||

| 4 BC-20 (without TT) | 410 kg CO2-eq/m3 | 650 kWh/m3 | ||

| 4 OP-20 (OP1 TT, 43,9%) | 430 kg CO2-eq/m3 | 1014 kWh/m3 | ||

| 4 LS-20 (LS5 TT, 40%) | 460 kg CO2-eq/m3 | 1014 kWh/m3 | ||

| 4 TTs (treated tailings): copper mine waste after mechanical and heat treatment. OP1: waste from an operating mine (calcination at 600 °C). LS5: waste from a deposited mine (calcination at 700 °C). | ||||

| 5 100% GBFS (SCAAC1) | 73.6 kg CO2-eq/m3 | 1.15 GJ/m3 | Cradle-to-gate A1–A3 | [22] |

| 5 30% FA-70% GBFS (SCAAC2) | 60.4 kg CO2-eq/m3 | 0.83 GJ/m3 | ||

| 5 40% FA-60% GBFS (SCAAC3) | 53.2 kg CO2-eq/m3 | 0.72 GJ/m3 | ||

| 5 50% FA-50% GBFS (SCAAC4) | 43.9 kg CO2-eq/m3 | 0.61 GJ/m3 | ||

| 5 60% FA-40% GBFS (SCAAC5) | 33.8 kg CO2-eq/m3 | 0.50 GJ/m3 | ||

| 5 70% FA-30% GBFS (SCAAC6) | 26.1 kg CO2-eq/m3 | 0.39 GJ/m3 | ||

| 5 FA (fly ash): fly ash as a substitute for blast furnace slag (GBFS). GBFS (ground granulated blast furnace slag): ground blast furnace slag. | ||||

| 6 100% PC (control) | 2836 kg CO2-eq/m3 | 2836 MJ/m3 | Cradle-to-gate A1–A3 | [18] |

| [18] 6 30FA | 2020 kg CO2-eq/m3 | 1970 MJ/m3 | ||

| 6 30DE | 1900 kg CO2-eq/m3 | 1830 MJ/m3 | ||

| 6 30DE-15FA | 1700 kg CO2-eq/m3 | 1650 MJ/m3 | ||

| 6 30DE-10LS | 1600 kg CO2-eq/m3 | 1500 MJ/m3 | ||

| 6 30DE-20FA-10LS | 1190 kg CO2-eq/m3 | 1344 MJ/m3 | ||

| 6 30DE-25FA-5LS | 1135 kg CO2-eq/m3 | 1418 MJ/m3 | ||

| 6 PC: Portland cement; DE: diatomite; FA: fly ash; LS: limestone. | ||||

| 7 OPC (reference) | 850 kg CO2-eq/t cement | 3600 MJ/t cement | Cradle-to-gate A1–A3 | [19] |

| 7 20_FA1 | 705 kg CO2-eq/t cement | 3150 MJ/t cement | ||

| 7 40_FA1 | 650 kg CO2-eq/t cement | 3000 MJ/t cement | ||

| 7 20_FA2 | 755 kg CO2-eq/t cement | 3300 MJ/t cement | ||

| 7 40_FA2 | 722 kg CO2-eq/t cement | 3180 MJ/t cement | ||

| 7 20_FA3 | 725 kg CO2-eq/t cement | 3250 MJ/t cement | ||

| 7 40_FA3 | 630 kg CO2-eq/t cement | 2900 MJ/t cement | ||

| 7 FA1: ash from a fluidized circulation boiler (clean wood and cocoa shells); FA2: ash from a wood pellet boiler; FA3: ash from a bubbling boiler (paper sludge and waste wood). | ||||

| 8 CEM I (TS) | 850 kg CO2-eq/t cement | 10,985 kWh/t cement | Cradle-to-gate (A1–A3) | [23] |

| 8 CEM I (AS) | 838 kg CO2-eq/t cement | 11,467 kWh/t cement | ||

| 8 CEM II (TS) | 766 kg CO2-eq/t cement | - | ||

| 8 CEM II (AS) | 721 kg CO2-eq/t cement | - | ||

| 8 CEM IV (TS) | 666 kg CO2-eq/t cement | - | ||

| 8 CEM IV (AS) | 529 kg CO2-eq/t cement | - | ||

| 8 OWC (TS) | 841 kg CO2-eq/t cement | - | ||

| 8 OWC (AS) | 864 kg CO2-eq/t cement | - | ||

| 8 Alternative scenario (AS): the use of dried sewage sludge, RDF, and waste oil as alternative fuels, as well as a waste heat recovery (WHR) system. | ||||

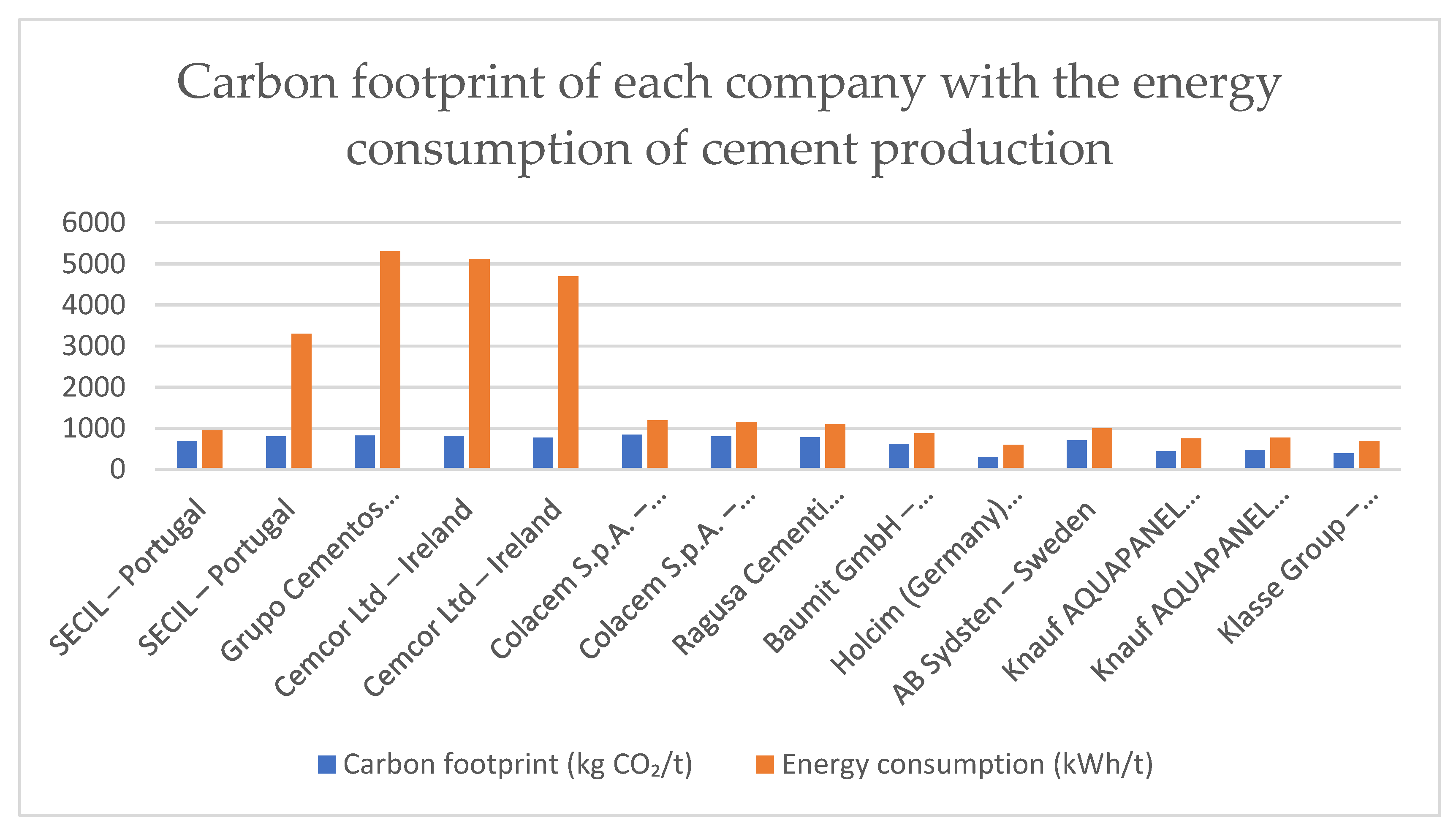

| Company Name | Product Name/Type of Cement | Carbon Footprint (kg CO2/t) | (kWh/t) | Boundaries of the System | Report Year | Source (Report Name) |

|---|---|---|---|---|---|---|

| AB Sydsten—Sweden (Stockholm) | Betong med Anläggningscement FA | 710 | 1000 | Cradle-to-gate (A1–A3) | 2020 | [24] |

| Colacem S.p.A.—Italy (Gubbio) | CEM I 52.5 R | 850 | 1200 | Cradle-to-gate (A1–A3) | 2021 | [25] |

| Colacem S.p.A.—Italy (Rassina) | CEM II/B-LL 32.5 R | 810 | 1150 | Cradle-to-gate (A1–A3) | 2021 | [26] |

| Ragusa Cementi S.p.A.—Italy (Ragusa) | CEM IV/A(P) 42.5 R–SR | 790 | 1100 | Cradle-to-gate (A1–A3) | 2021 | [27] |

| Knauf AQUAPANEL GmbH—Germany (Iserlohn) | AQUAPANEL® Cement Board Rooftop 6 mm | 450 | 750 | Cradle-to-gate (A1–A3) | 2021 | [28] |

| Holcim GmbH—Germany (Hamburg) | Airium™ Spray (cement-based insulation foam) | 300 | 600 | Cradle-to-gate (A1–A3) | 2022 | [29] |

| Knauf AQUAPANEL GmbH—Greece (Thessaloniki) | AQUAPANEL® Cement Board Outdoor 12.5 mm | 480 | 770 | Cradle-to-gate (A1–A3) | 2022 | [30] |

| Cemcor Ltd.—Ireland (Cookstown) | CEM I 52.5 N Bulk Cement | 819 | 5100 | Cradle-to-gate (A1–A3) | 2023 | [31] |

| Cemcor Ltd.—Ireland (Cookstown) | CEM II/A-L 42.5 R Bulk Cement | 770 | 4700 | Cradle-to-gate (A1–A3) | 2023 | [32] |

| Klasse Group—UK (Swansea) | S-Board (calcium silicate board) | 390 | 690 | Cradle-to-gate (A1–A3) | 2023 | [33] |

| SECIL—Portugal (Leiria) | CEM II/B-M (V-L) 42.5R (Maceira-Liz) | 680 | 950 | Cradle-to-gate (A1–A3) | 2024 | [34] |

| SECIL—Portugal (Leiria) | CEM I 52.5R Portland Cement (Outão) | 807 | 3300 | Cradle-to-gate (A1–A3) | 2024 | [35] |

| Grupo Cementos Portland Valderrivas—Spain (Barcelona) | CEM I 52.5 R Cement (Sevilla) | 825 | 5300 | Cradle-to-gate (A1–A3) | 2024 | [36] |

| Baumit GmbH—Austria (Vienna) | CEM II/C-M (S-LL) 42.5 N | 620 | 880 | Cradle-to-gate (A1–A3) | 2024 | [37] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Generowicz-Caba, N.; Kulczycka, J. LCA of Cement with Alternative Additives: Pathways to Sustainable Production. Materials 2025, 18, 3057. https://doi.org/10.3390/ma18133057

Generowicz-Caba N, Kulczycka J. LCA of Cement with Alternative Additives: Pathways to Sustainable Production. Materials. 2025; 18(13):3057. https://doi.org/10.3390/ma18133057

Chicago/Turabian StyleGenerowicz-Caba, Natalia, and Joanna Kulczycka. 2025. "LCA of Cement with Alternative Additives: Pathways to Sustainable Production" Materials 18, no. 13: 3057. https://doi.org/10.3390/ma18133057

APA StyleGenerowicz-Caba, N., & Kulczycka, J. (2025). LCA of Cement with Alternative Additives: Pathways to Sustainable Production. Materials, 18(13), 3057. https://doi.org/10.3390/ma18133057