Direct Measurement of Transverse Compressive Properties of Polyacrylonitrile-Based Single Carbon Fibers

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Specimen Preparation

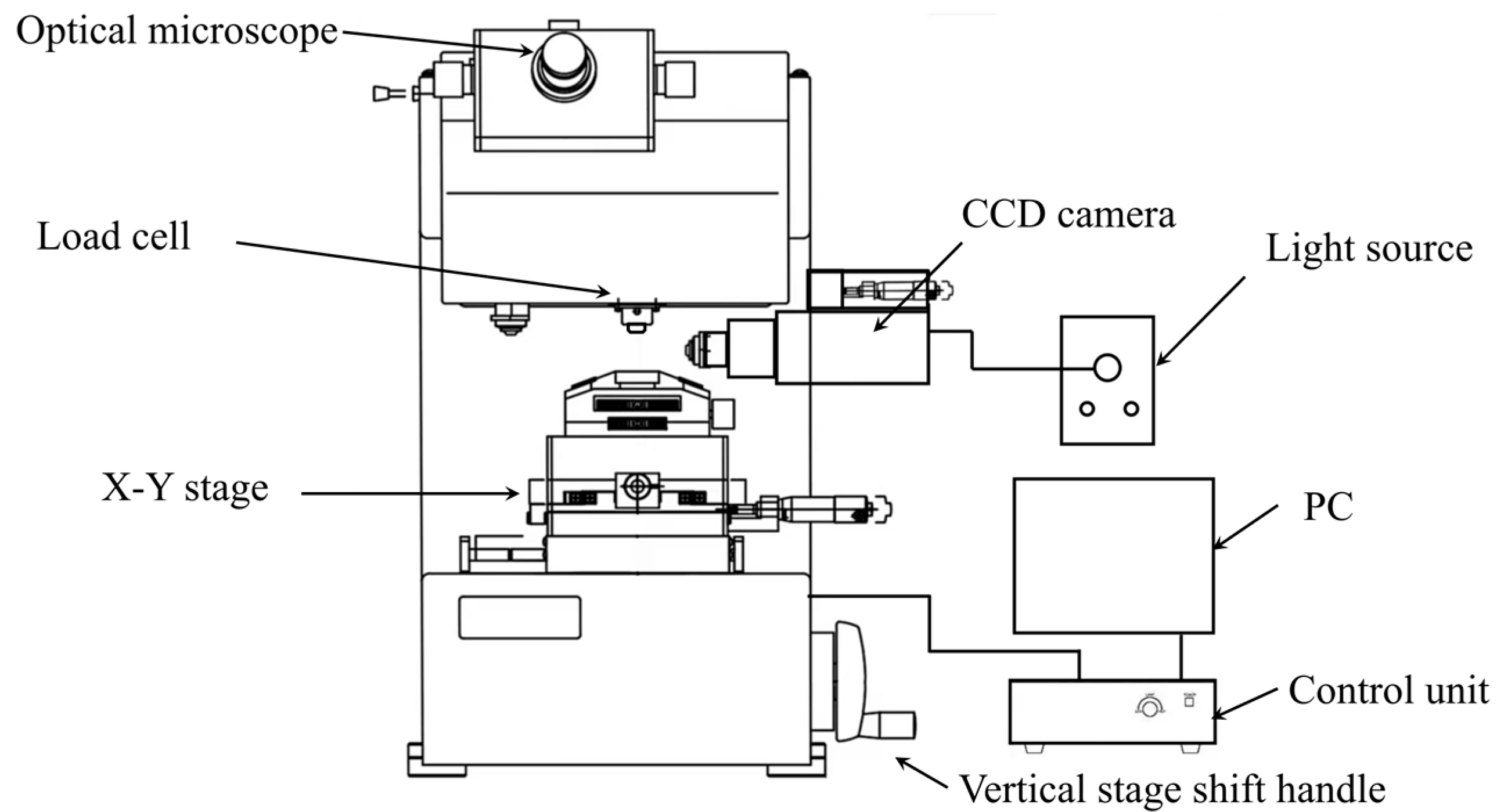

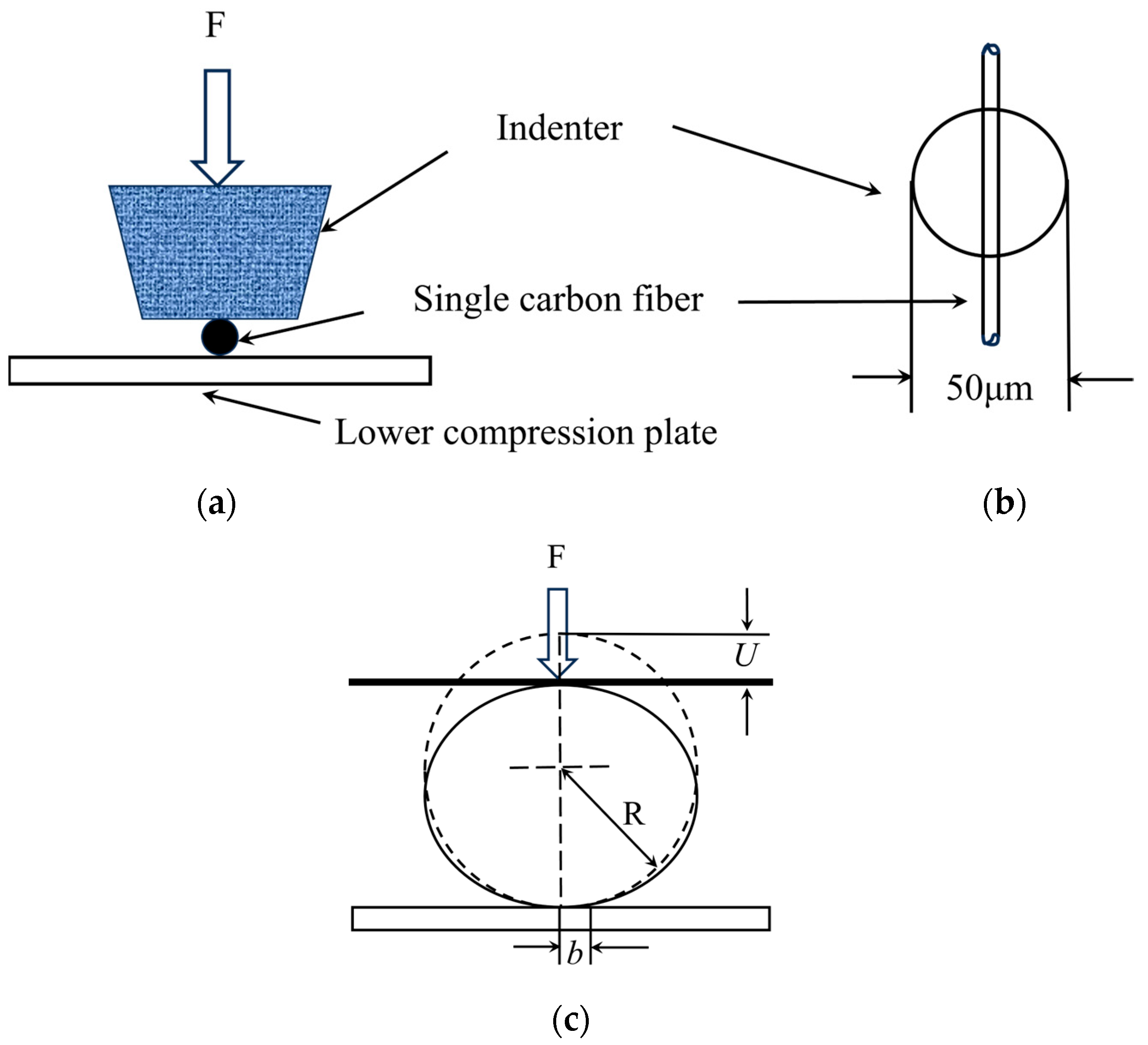

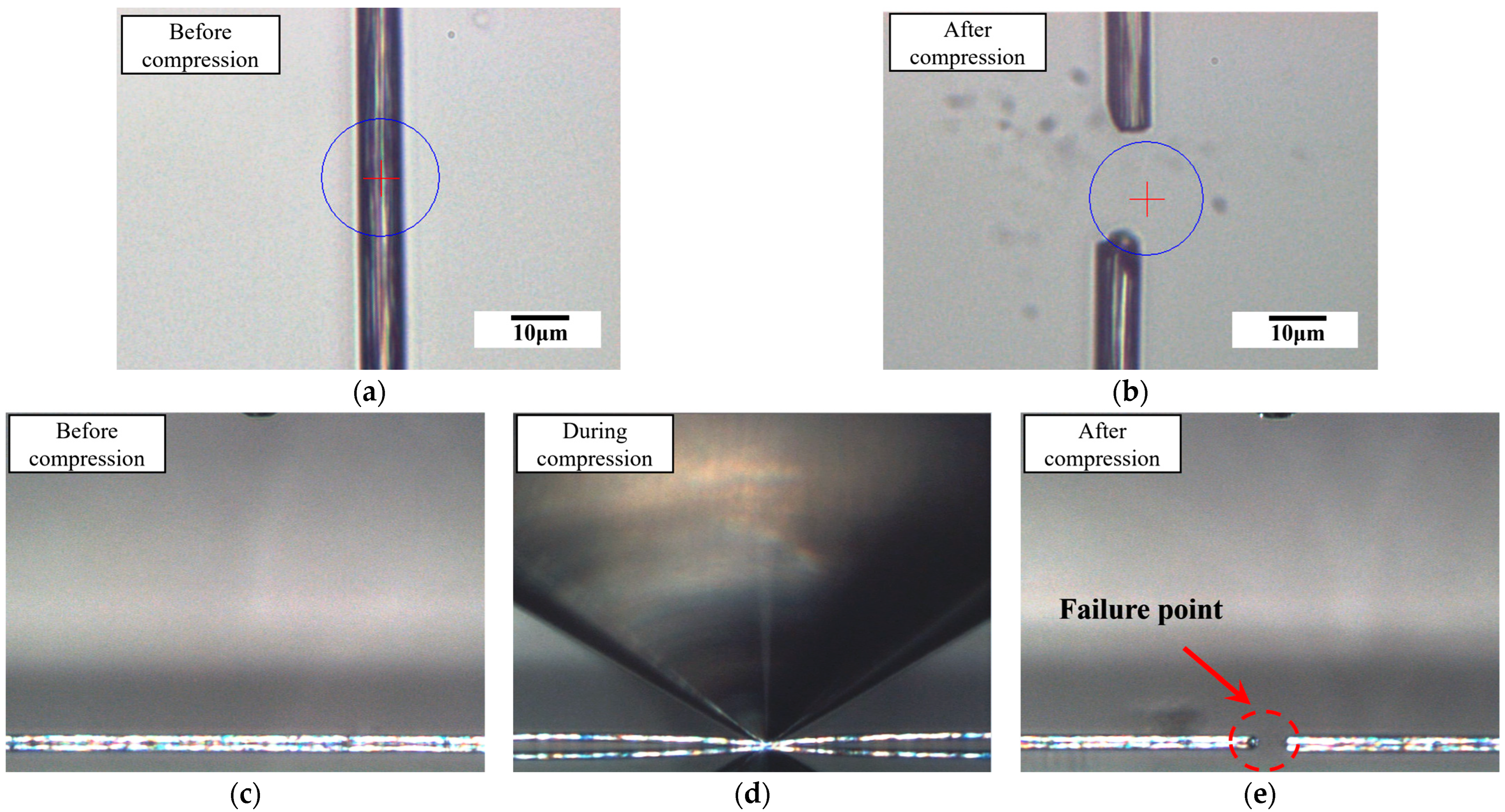

2.3. Transverse Compression Tests

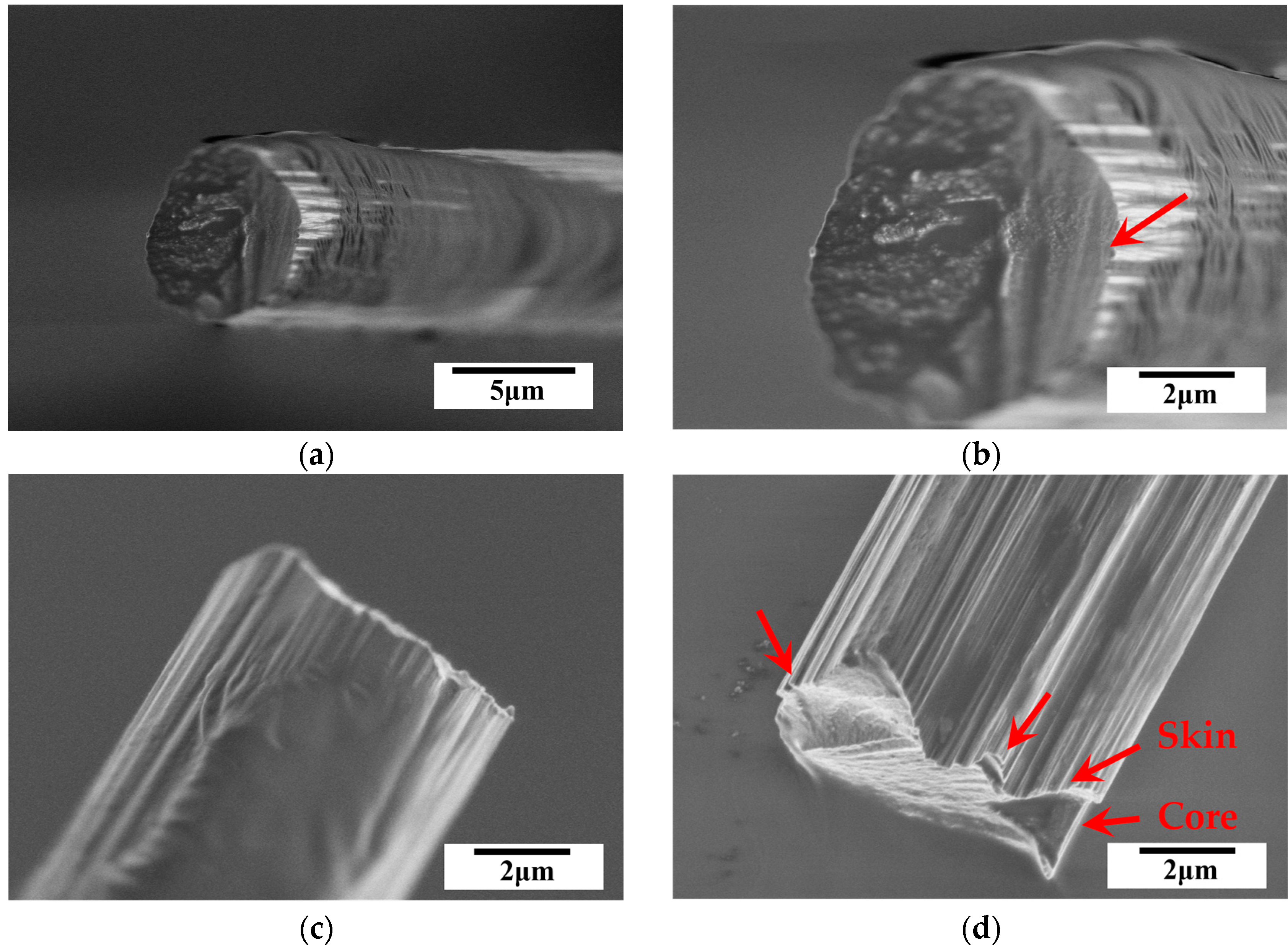

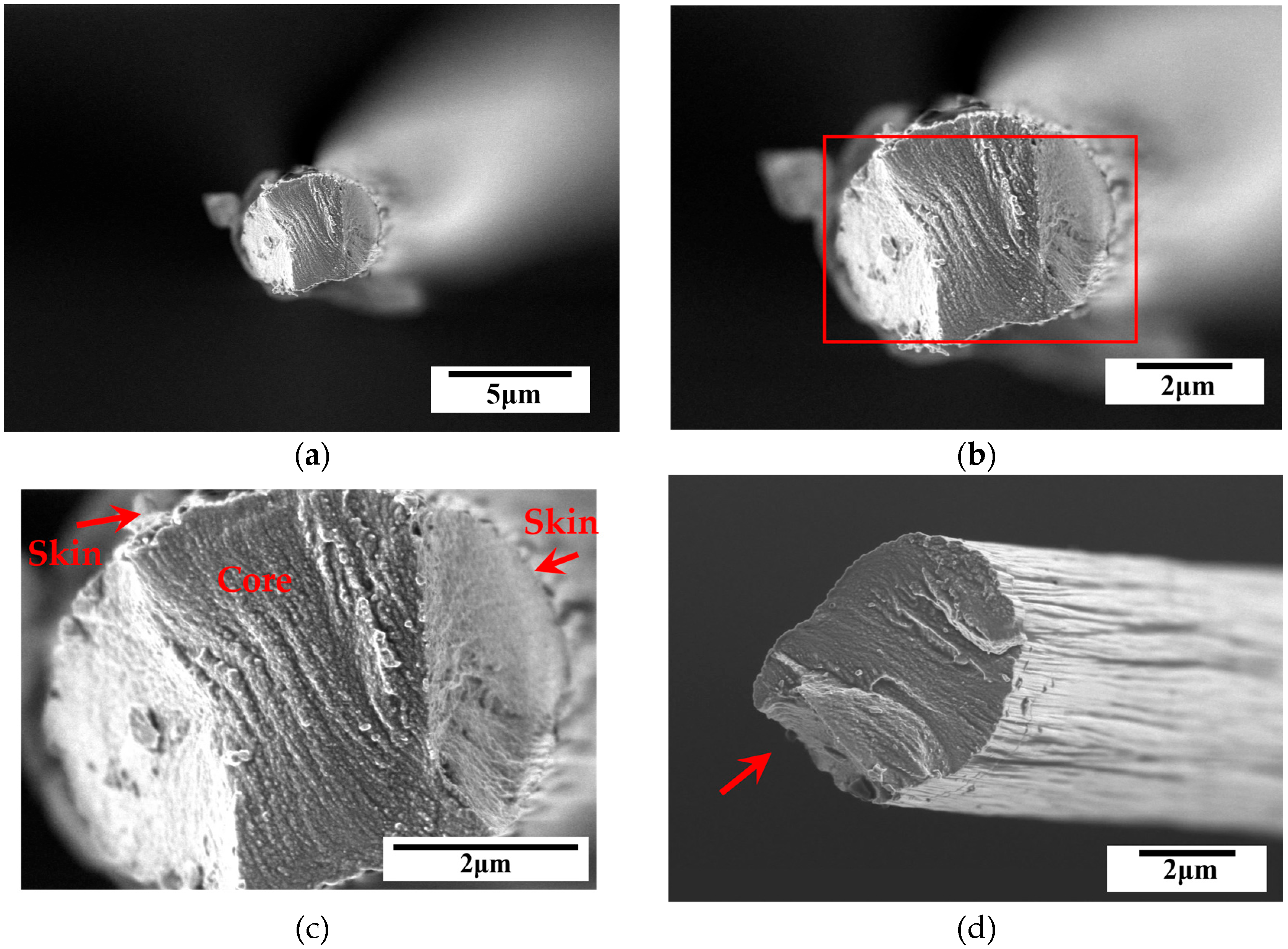

2.4. Characterization of Failure Mode

3. Results and Discussions

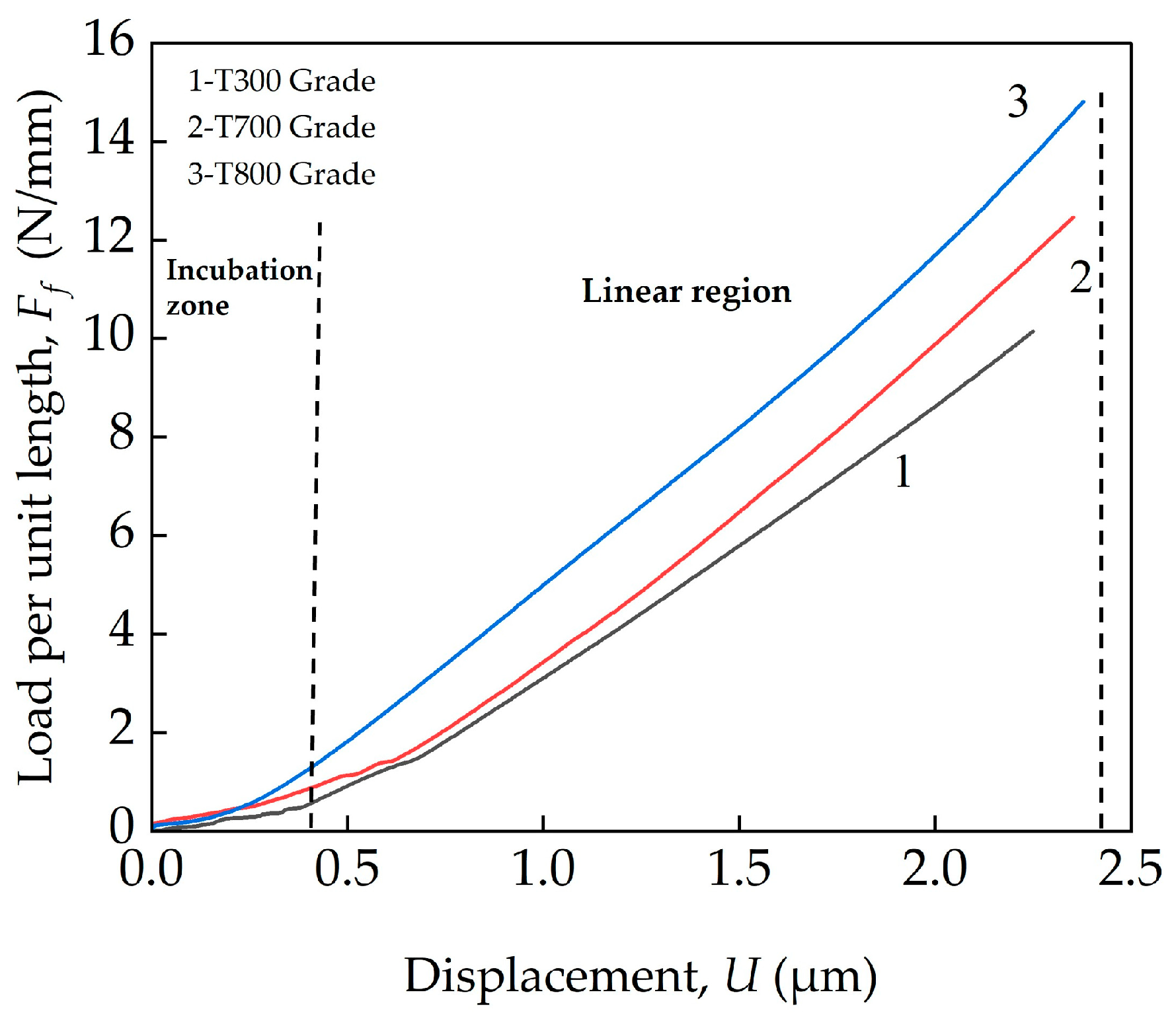

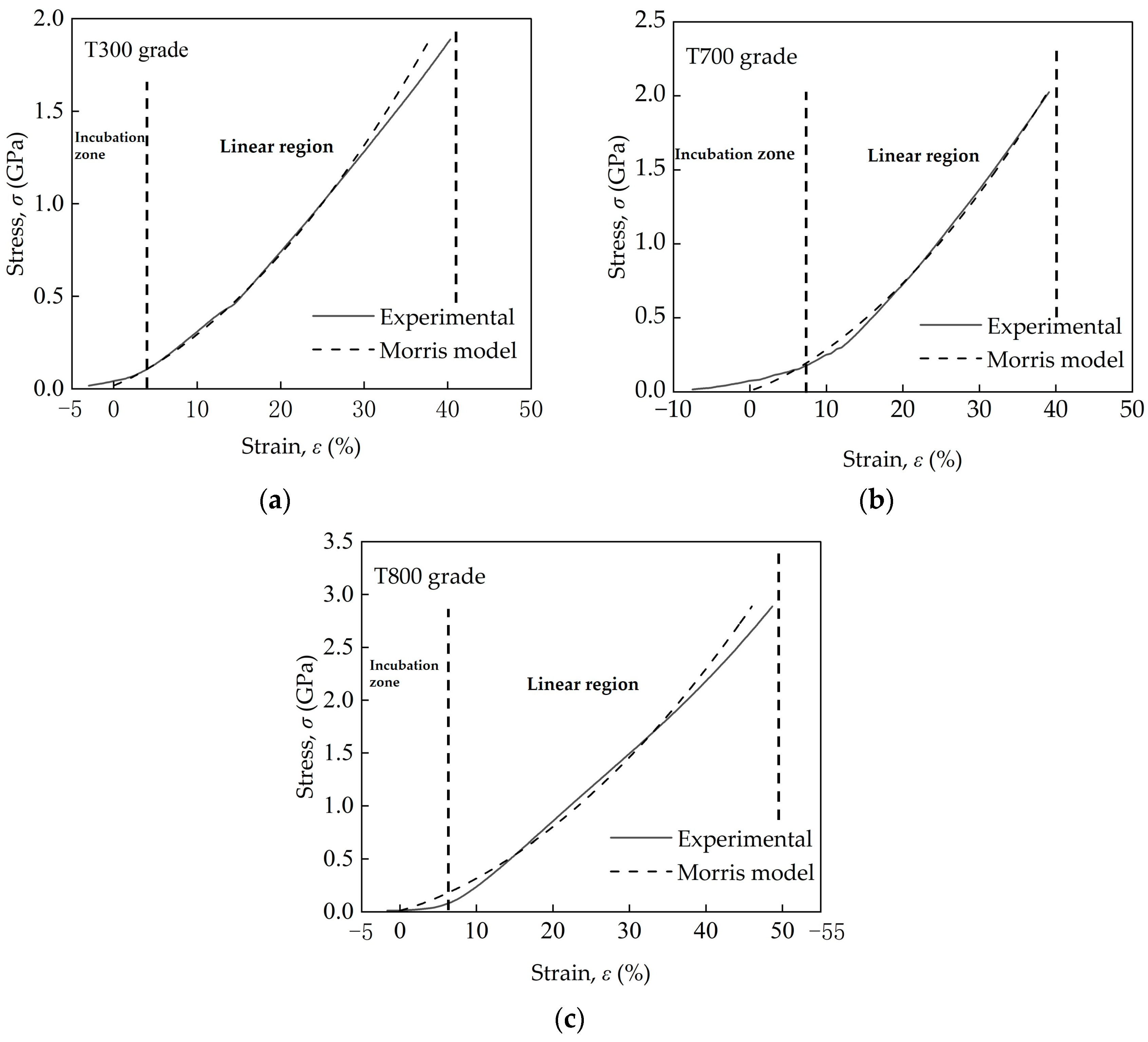

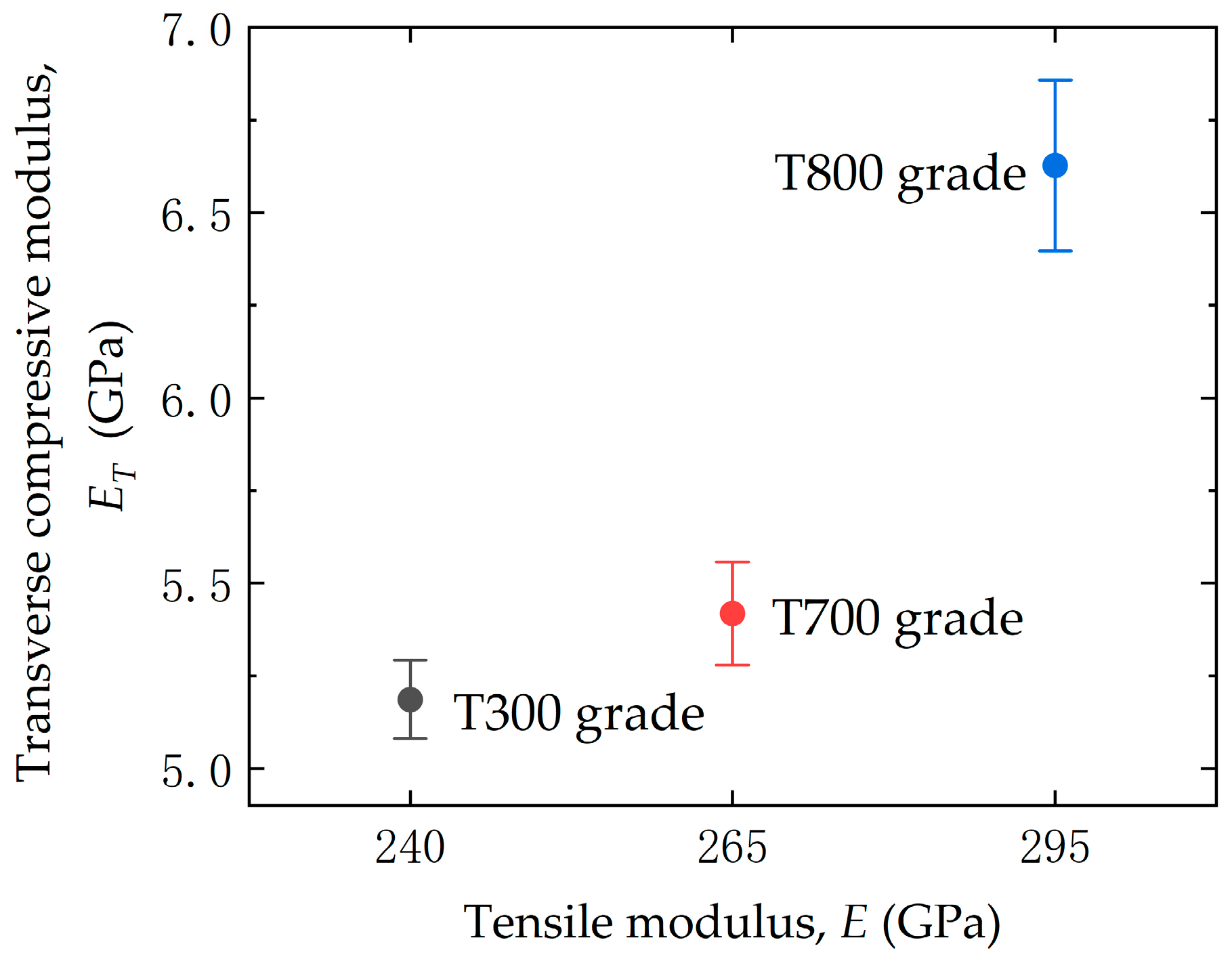

3.1. Transverse Compressive Modulus

3.2. Transverse Compressive Strength

3.3. Failure Mode

4. Conclusions

- The transverse compressive moduli, , for the T300, T700, and T800 grades are 5.19 GPa, 5.42 GPa and 6.63 GPa, respectively. For the three domestic PAN-based carbon fibers, the transverse compressive modulus increases with the increases in tensile modulus.

- The transverse compressive strengths, , for the T300, T700, and T800 grades are 2.35 GPa, 2.65 GPa and 2.82 GPa, respectively. For the three domestic PAN-based carbon fibers, the transverse compressive strength increases with the increases in transverse compressive modulus, and it reduces to ~50% of tensile strength.

- Two regions were found on the compression curves. In the initial incubation region, the fiber aligned between the indenter and sample stage, and the load increased slowly and non-linearly with displacement. In the second region, where the displacement increased linearly with load, and in this region the curve was well-fit by the Morris model.

- The high-strength PAN-based carbon fibers show a brittle failure mode during transverse compression, coincident with the microstructure observations.

- The quantified and values provide critical inputs for multi-scale composite modeling, including the development of a meso-mechanical model for carbon fiber-reinforced polymer (CFRP) composites to investigate the influence of carbon fiber properties and carbon fiber-resin interface characteristics on the performance of composites in resisting impact damage. This framework thus explores the underlying mechanisms and establishes correlations between the impact damage resistance of laminated plates and fiber performance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Skoczylas, J.; Samborski, S.; Kłonica, M. The application of composite materials in the aerospace industry. J. Technol. Exploit. Mech. Eng. 2019, 5, 1–6. [Google Scholar] [CrossRef]

- Mrázová, M. Advanced composite materials of the future in aerospace industry. Incas Bull. 2013, 5, 139–150. [Google Scholar] [CrossRef]

- Parveez, B.; Kittur, M.I.; Badruddin, I.A.; Kamangar, S.; Hussien, M.; Umarfarooq, M.A. Scientific Advancements in Composite Materials for Aircraft Applications: A Review. Polymers. 2022, 14, 5007. [Google Scholar] [CrossRef]

- Fitzer, E. PAN-based carbon fibers—Present state and trend of the technology from the viewpoint of possibilities and limits to influence and to control the fiber properties by the process parameters. Carbon. 1989, 27, 621–645. [Google Scholar] [CrossRef]

- Zhang, J.; Lin, G.; Vaidya, U.; Wang, H. Past, present and future prospective of global carbon fibre composite developments and applications. Compos. Part B Eng. 2023, 250, 110463. [Google Scholar] [CrossRef]

- VinÇon, I.; Allix, O.; Sigety, P.; Auvray, M.H. Compressive performance of carbon fibres: Experiment and analysis. Compos. Sci. Technol. 1998, 58, 1649–1658. [Google Scholar] [CrossRef]

- Oya, N.; Johnson, D.J. Longitudinal compressive behaviour and microstructure of PAN-based carbon fibres. Carbon 2001, 39, 635–645. [Google Scholar] [CrossRef]

- Kumar, I.P.; Mohite, P.; Kamle, S. Axial compressive strength testing of single carbon fibres. Arch. Mech. 2013, 65, 27–43. [Google Scholar]

- Zhang, N.; Huang, D.; Quan, H.; Ye, C.; Peng, C.; Tao, L.; Zhu, S.; Fan, Z.; Shi, K.; Qian, F.; et al. Unveiling the microscopic compression failure behavior of mesophase-pitch-based carbon fibers for improving the compressive strength of their polymer composites. Compos. Part B Eng. 2024, 283, 111658. [Google Scholar] [CrossRef]

- Lu, J.; Lin, G.; Wang, Z.; Xiao, S. Reduction of compressive strength of concrete due to triaxial compressive loading history. Mag. Concr. Res. 2004, 56, 139–149. [Google Scholar] [CrossRef]

- Mrse, A.M.; Piggott, M. Compressive properties of unidirectional carbon fibre laminates: II. The effects of unintentional and intentional fibre misalignments. Compos. Sci. Technol. 1993, 46, 219–227. [Google Scholar] [CrossRef]

- Bouvet, C.; Rivallant, S. 2–Damage tolerance of composite structures under low-velocity impact. In Dynamic Deformation, Damage and Fracture in Composite Materials and Structures, 2nd ed.; Silberschmidt, V., Ed.; Woodhead Publishing: Cambridge, UK, 2023; pp. 3–28. [Google Scholar]

- Zhang, X. Impact damage in composite aircraft structures-experimental testing and numerical simulation. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 1998, 212, 245–259. [Google Scholar] [CrossRef]

- Feraboli, P.; Miller, M. Damage resistance and tolerance of carbon/epoxy composite coupons subjected to simulated lightning strike. Compos. Part A Appl. Sci. Manuf. 2009, 40, 954–967. [Google Scholar] [CrossRef]

- Shabani, P.; Li, L.; Laliberte, J.; Qi, G. Compression after impact (CAI) failure mechanisms and damage evolution in large composite laminates: High-fidelity simulation and experimental study. Compos. Struct. 2024, 339, 118143. [Google Scholar] [CrossRef]

- Opelt, C.V.; Cândido, G.M.; Rezende, M.C. Compressive failure of fiber reinforced polymer composites–A fractographic study of the compression failure modes. Mater. Today Commun. 2018, 15, 218–227. [Google Scholar] [CrossRef]

- Tuo, H.; Lu, Z.; Ma, X.; Xing, J.; Zhang, C. Damage and failure mechanism of thin composite laminates under low-velocity impact and compression-after-impact loading conditions. Compos. Part B Eng. 2019, 163, 642–654. [Google Scholar] [CrossRef]

- Hadley, D.W.; Ward, I.M.; Ward, J. The Transverse Compression of Anisotropic Fibre Monofilaments. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1965, 285, 275–286. [Google Scholar]

- Oya, N.; Johnson, D.J. Direct measurement of longitudinal compressive strength in carbon fibres. Carbon 1999, 37, 1539–1544. [Google Scholar] [CrossRef]

- Cheng, M.; Chen, W.; Weerasooriya, T. Experimental investigation of the transverse mechanical properties of a single Kevlar® KM2 fiber. Int. J. Solids Struct. 2004, 41, 6215–6232. [Google Scholar] [CrossRef]

- Lim, J.; Zheng, J.Q.; Masters, K.; Chen, W.W. Mechanical behavior of A265 single fibers. J. Mater. Sci. 2010, 45, 652–661. [Google Scholar] [CrossRef]

- Naito, K.; Tanaka, Y.; Yang, J.M. Transverse compressive properties of polyacrylonitrile (PAN)-based and pitch-based single carbon fibers. Carbon 2017, 118, 168–183. [Google Scholar] [CrossRef]

- Zhu, J.; Gao, Z.; Mao, Q.; Gao, Y.; Li, Y.; Zhang, X.; Gao, Q.; Jiang, M.; Lee, S.; van Duin, A.C.T. Advances in developing cost-effective carbon fibers by coupling multiscale modeling and experiments: A critical review. Prog. Mater. Sci. 2024, 146, 101329. [Google Scholar] [CrossRef]

- Wu, B.; Zheng, G.; Wang, R.; Zhou, C.; Hu, Y.; Lv, J. Synergistic modification of carbon fiber by electrochemical oxidation and sizing treatment and its effect on the mechanical properties of carbon fiber reinforced composites. J. Appl. Polym. Sci. 2019, 136, 48028. [Google Scholar] [CrossRef]

- Kil, H.-S.; Jang, S.Y.; Ko, S.; Jeon, Y.P.; Kim, H.-C.; Joh, H.-I.; Lee, S. Effects of stabilization variables on mechanical properties of isotropic pitch based carbon fibers. J. Ind. Eng. Chem. 2018, 58, 349–356. [Google Scholar] [CrossRef]

- Shirasu, K.; Goto, K.; Naito, K. Microstructure-elastic property relationships in carbon fibers: A nanoindentation study. Compos. Part B Eng. 2020, 200, 108342. [Google Scholar] [CrossRef]

- Ribas, L.; Cordeiro, G.C.; Toledo Filho, R.D.; Tavares, L.M. Measuring the strength of irregularly-shaped fine particles in a microcompression tester. Miner. Eng. 2014, 65, 149–155. [Google Scholar] [CrossRef]

- Antonyuk, S.; Tomas, J.; Heinrich, S.; Mörl, L. Breakage behaviour of spherical granulates by compression. Chem. Eng. Sci. 2005, 60, 4031–4044. [Google Scholar] [CrossRef]

- Naruhashi, T.; Aoki, D.; Taniguchi, T.; Karatsu, T. Mechanical stability and insulation reliability of polymeric layers constructed by thermal fusion of polymer shell particles heterocoagulated on conductive nickel-plated core particles. J. Appl. Polym. Sci. 2023, 140, e54072. [Google Scholar] [CrossRef]

- Morris, S. The Determination of the Lateral-Compression Modulus of Fibres. J. Text. Inst. 1968, 59, 536–547. [Google Scholar] [CrossRef]

- DIN EN ISO 10548: 2003-12; Carbon Fibre-Determination of Size Content (ISO 10548: 2002); German version EN ISO 10548: 2003. The International Organization for Standardization: Geneva, Switzerland, 2003.

- Yamada, H.; Ogasawara, N.; Shimizu, Y.; Horikawa, K.; Kobayashi, H.; Chen, X. Effect of High Strain Rate on Indentation in Pure Aluminum. J. Eng. Mater. Technol. 2013, 135, 021010. [Google Scholar] [CrossRef]

- Kawabata, S. Measurement of the Transverse Mechanical Properties of High-performance Fibres. J. Text. Inst. 1990, 81, 432–447. [Google Scholar] [CrossRef]

- Guo, Z.; Casem, D.; Hudspeth, M.; Nie, X.; Sun, J.; Chen, W. Transverse compression of two high-performance ballistic fibers. Text. Res. J. 2016, 86, 502–511. [Google Scholar] [CrossRef]

- Tan, T.T.; Wang, C.G.; Jing, M.; Feng, Z.H.; Yang, Y.H.; Chen, Y.; Xie, B. Study on relationship between microstructure and mechanical property of PAN-based carbon fiber. Funct. Mater. 2012, 43, 2226–2230. [Google Scholar]

- Loidl, D.; Paris, O.; Rennhofer, H.; Müller, M.; Peterlik, H. Skin-core structure and bimodal Weibull distribution of the strength of carbon fibers. Carbon 2007, 45, 2801–2805. [Google Scholar] [CrossRef]

- Fidan, S.; Palazotto, A.; Tsai, C.T.; Kumar, S. Compressive properties of high-performance polymeric fibers. Compos. Sci. Technol. 1993, 49, 291–297. [Google Scholar] [CrossRef]

- Mori, T.; Tanaka, K. Average stress in matrix and average elastic energy of materials with misfitting inclusions. Acta Metall. 1973, 21, 571–574. [Google Scholar] [CrossRef]

- Weibull, W. A Statistical Theory of Strength of Materials; Generalstabens Litografiska Anstalts Förlag: Stockholm, Sweeden, 1939. [Google Scholar]

| Fiber | Batch No. | (μm) | (μm) |

|---|---|---|---|

| T300 grade | 300-1 | 50.01 (0.006) | 6.41 (0.211) |

| 300-2 | 50.00 (0.015) | 6.32 (0.339) | |

| 300-3 | 50.01 (0.010) | 6.49 (0.282) | |

| Average | 50.01 (0.006) | 6.41 (0.085) | |

| T700 grade | 700-1 | 50.01 (0.006) | 6.10 (0.643) |

| 700-2 | 50.02 (0.021) | 6.31 (0.811) | |

| 700-3 | 50.01 (0.110) | 6.25 (0.644) | |

| Average | 50.01 (0.006) | 6.22 (0.108) | |

| T800 grade | 800-1 | 50.00 (0.010) | 5.13 (0.271) |

| 800-2 | 50.01 (0.006) | 5.19 (0.347) | |

| 800-3 | 50.01 (0.006) | 6.14 (0.424) | |

| Average | 50.01 (0.006) | 5.49 (0.567) |

| Fiber | Batch No. | Compressive Properties | Tensile Properties | Transverse-to-Tensile Modulus Ratio (%) | Transverse-to-Tensile Strength Ratio (%) | Failure Mode | ||

|---|---|---|---|---|---|---|---|---|

| (GPa) | (GPa) | (GPa) | (GPa) | |||||

| T300 grade | 300-1 | 5.15 (0.183) | 2.31 (0.273) | 240 | 4.1 | 2.2 | 57.3 | Brittle |

| 300-2 | 5.24 (0.075) | 2.38 (0.290) | ||||||

| 300-3 | 5.17 (0.172) | 2.36 (0.247) | ||||||

| Average | 5.19 (0.050) | 2.35 (0.033) | ||||||

| T700 grade | 700-1 | 5.45 (0.255) | 2.66 (0.147) | 265 | 5.0 | 2.1 | 53.0 | Brittle |

| 700-2 | 5.51 (0.120) | 2.68 (0283) | ||||||

| 700-3 | 5.30 (0.137) | 2.60 (0.149) | ||||||

| Average | 5.42 (0.104) | 2.65 (0.041) | ||||||

| T800 grade | 800-1 | 6.49 (0.314) | 2.68 (0.446) | 295 | 5.6 | 2.2 | 50.5 | Brittle |

| 800-2 | 6.67 (0.275) | 2.89 (0.126) | ||||||

| 800-3 | 6.72 (0.353) | 2.90 (0.115) | ||||||

| Average | 6.63 (0.120) | 2.82 (0.121) | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, J.; Ma, H.; Wang, X.; Li, H.; Li, B.; Wei, Q.; Cao, Z. Direct Measurement of Transverse Compressive Properties of Polyacrylonitrile-Based Single Carbon Fibers. Materials 2025, 18, 3018. https://doi.org/10.3390/ma18133018

Yan J, Ma H, Wang X, Li H, Li B, Wei Q, Cao Z. Direct Measurement of Transverse Compressive Properties of Polyacrylonitrile-Based Single Carbon Fibers. Materials. 2025; 18(13):3018. https://doi.org/10.3390/ma18133018

Chicago/Turabian StyleYan, Jin, Hongyi Ma, Xueming Wang, Hongyun Li, Biao Li, Qi Wei, and Zhenghua Cao. 2025. "Direct Measurement of Transverse Compressive Properties of Polyacrylonitrile-Based Single Carbon Fibers" Materials 18, no. 13: 3018. https://doi.org/10.3390/ma18133018

APA StyleYan, J., Ma, H., Wang, X., Li, H., Li, B., Wei, Q., & Cao, Z. (2025). Direct Measurement of Transverse Compressive Properties of Polyacrylonitrile-Based Single Carbon Fibers. Materials, 18(13), 3018. https://doi.org/10.3390/ma18133018