Assessment of Premature Failures in Concrete Railway Ties: A Case Study from Brazil

Abstract

1. Introduction

2. Experimental Program

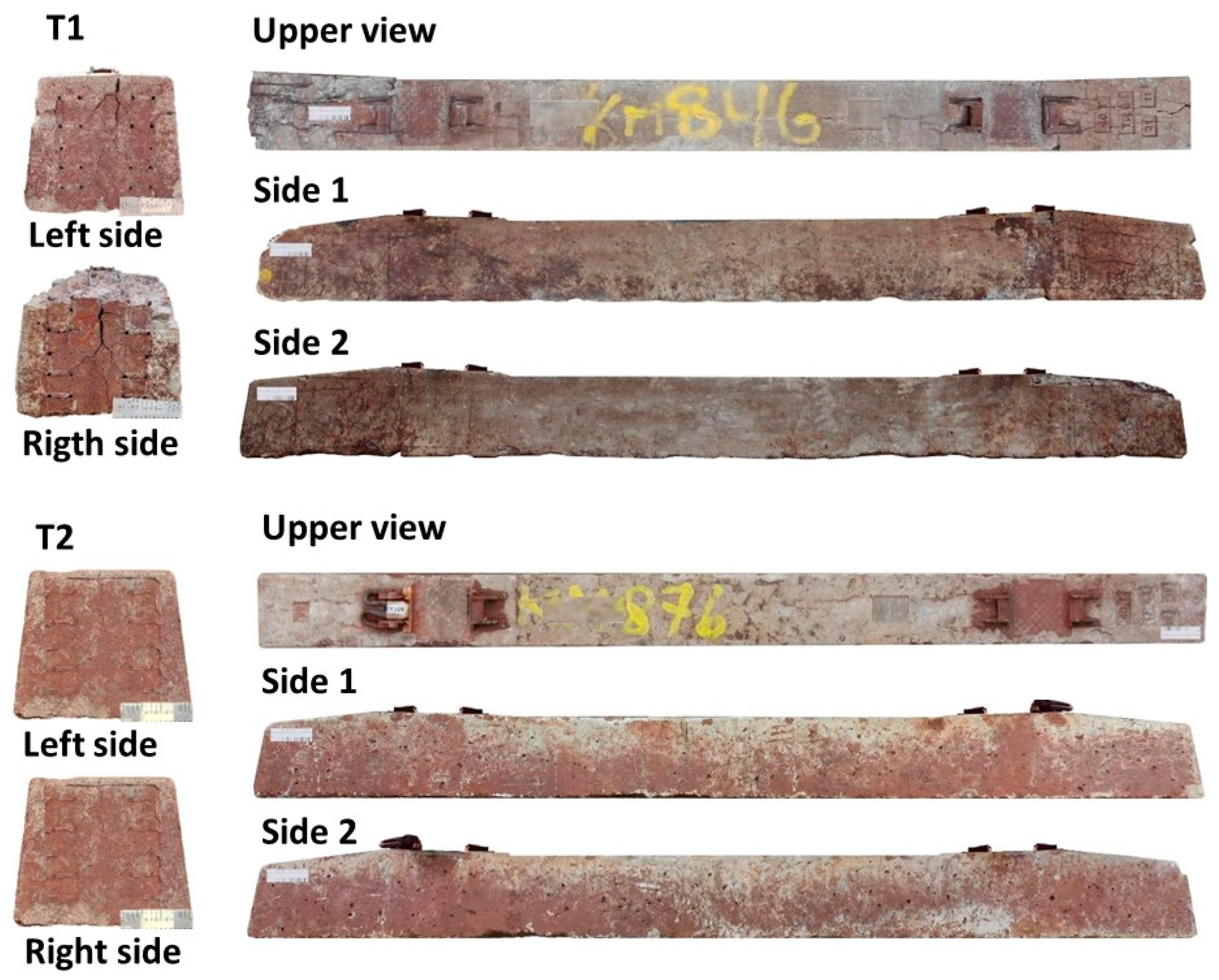

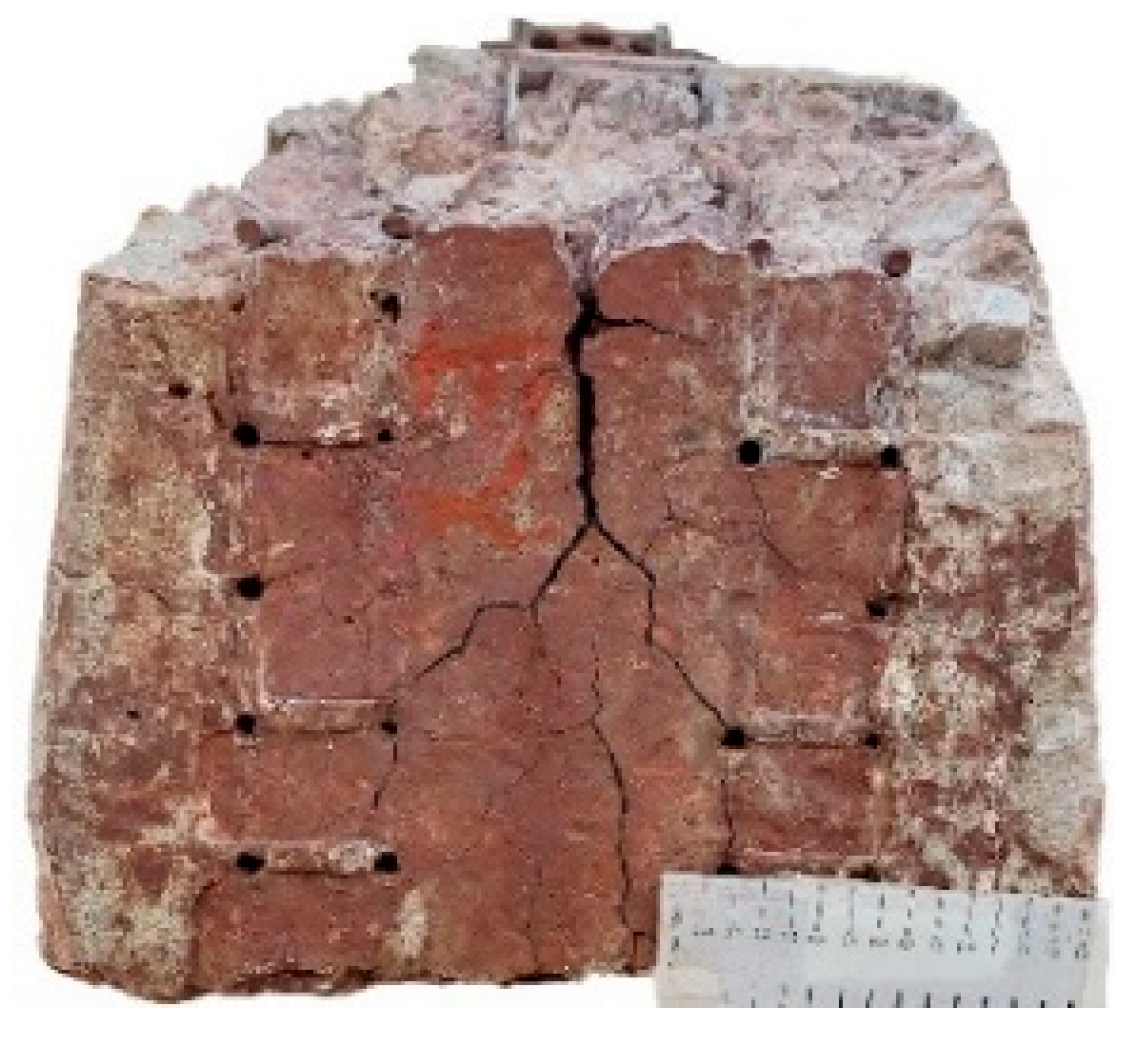

2.1. Preliminary Inspection

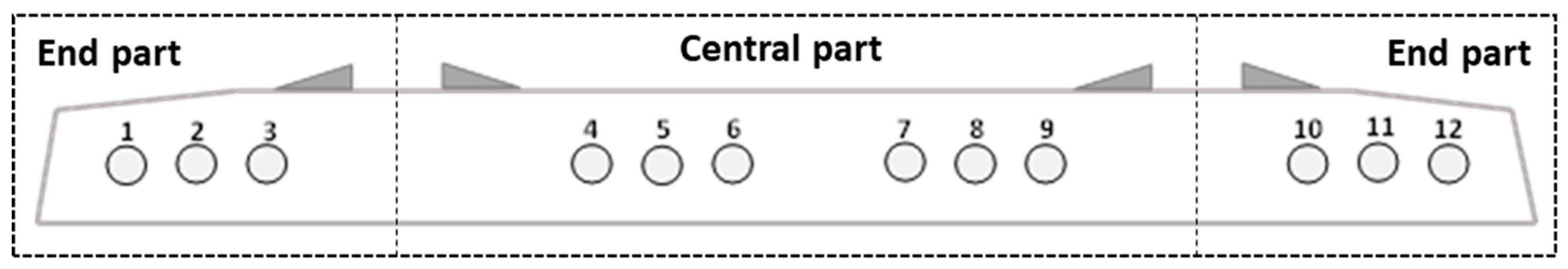

2.2. Mechanical Tests

2.3. Determination of Soluble Salts, Sulfates, and Chlorides

2.4. Water and Chloride Transport Properties

2.5. Microstructural Analysis

3. Results and Discussion

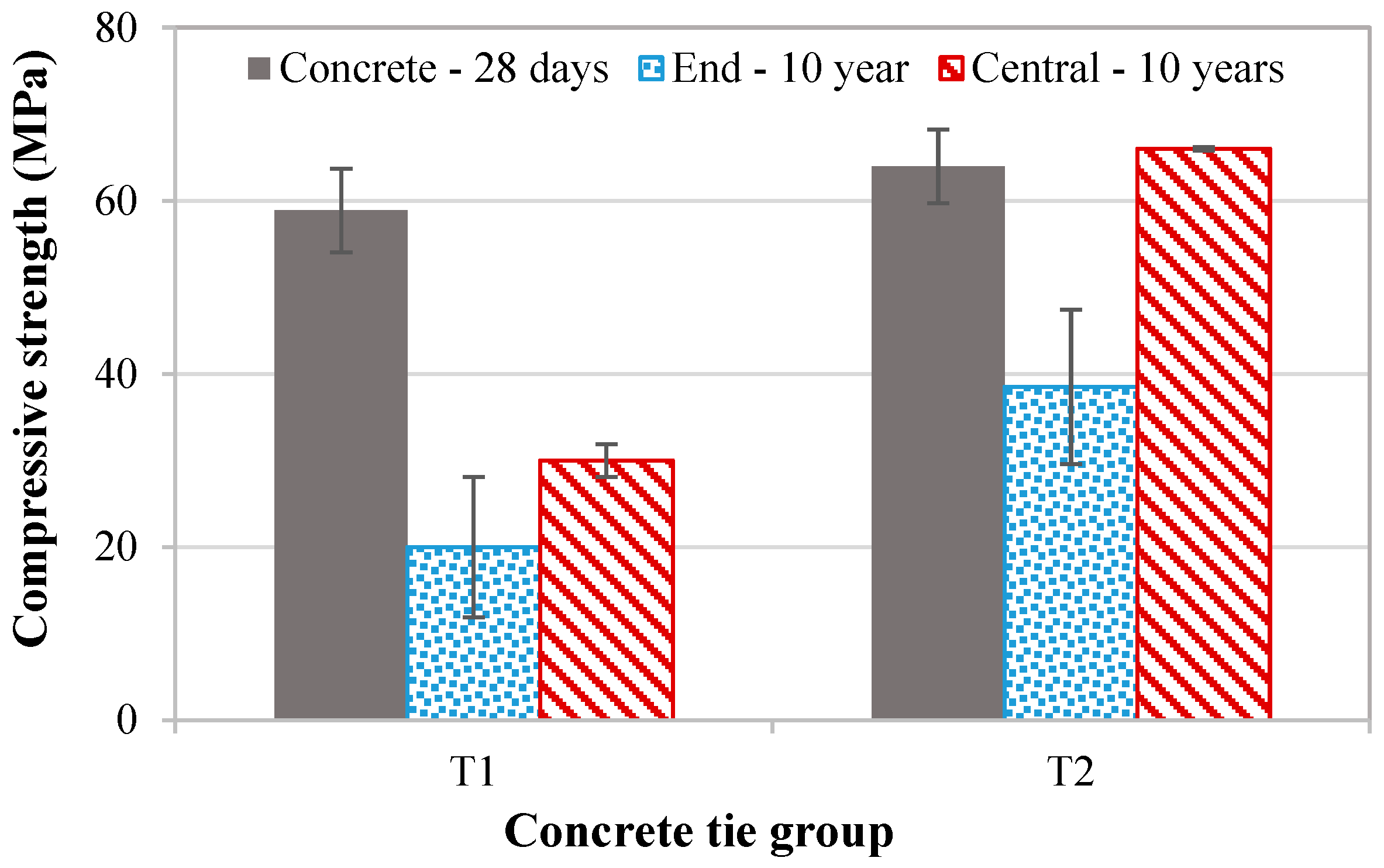

3.1. Mechanical Properties

3.2. Concentration of Soluble Salts, Sulfates, and Chlorides

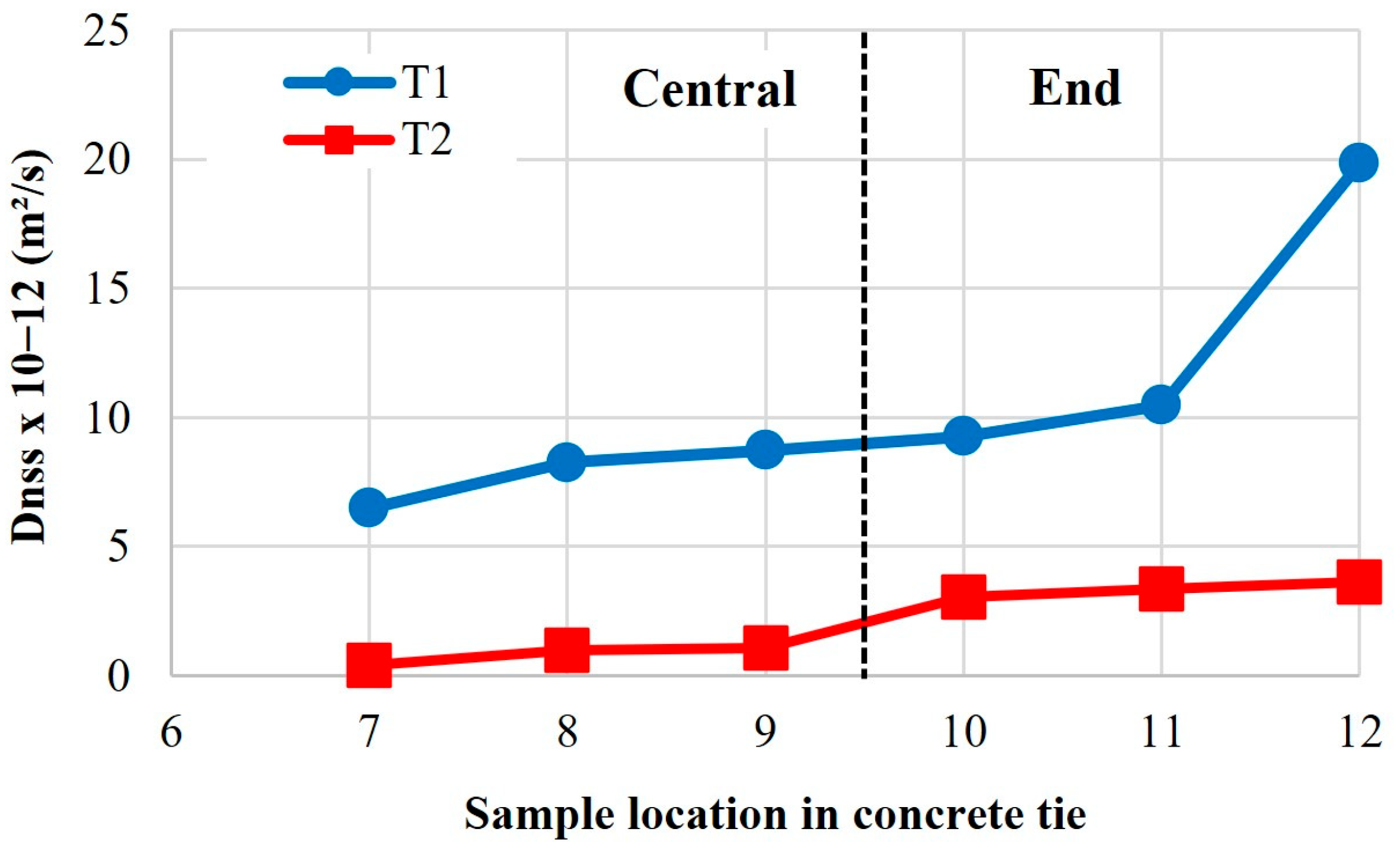

3.3. Evaluation of Water and Chloride Transport Properties

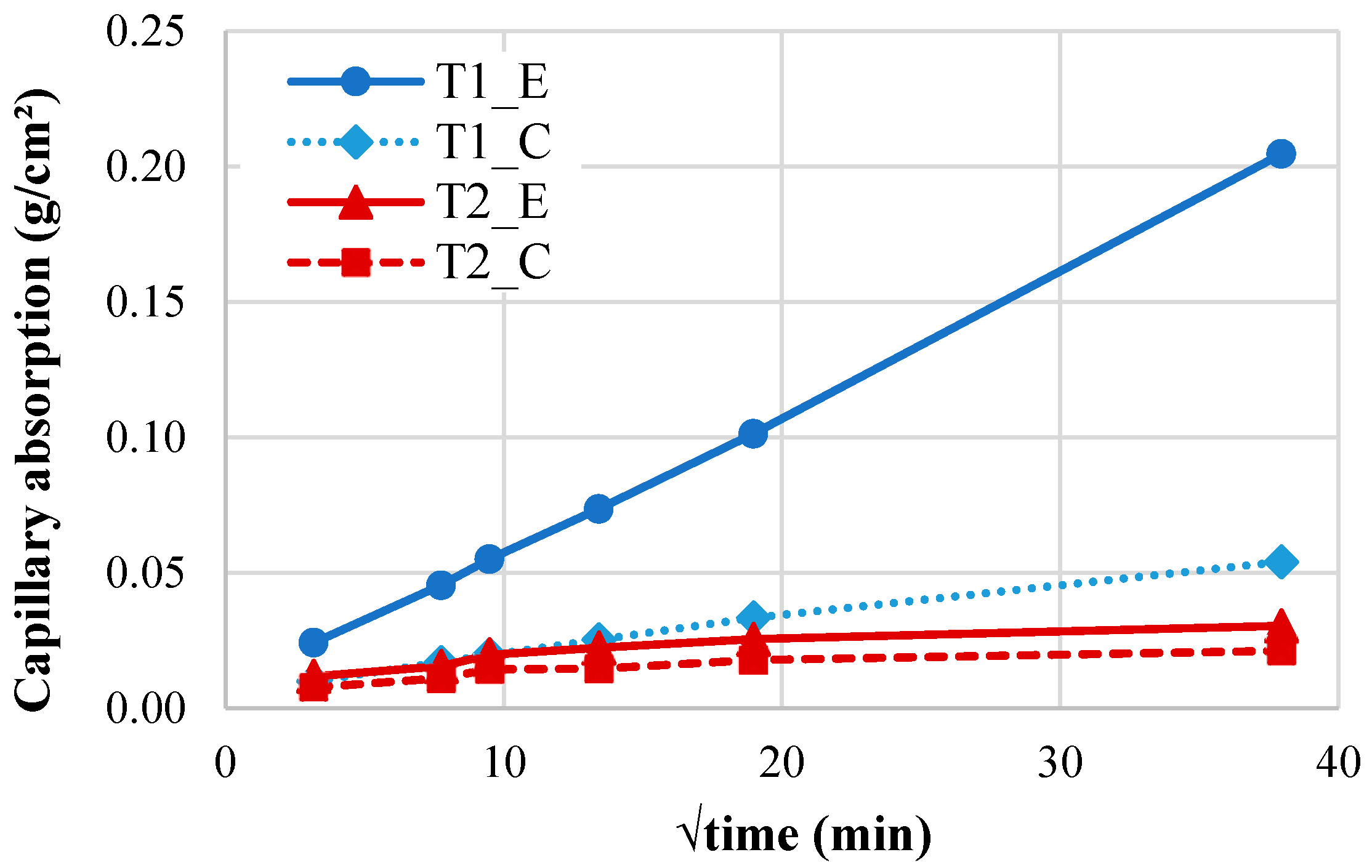

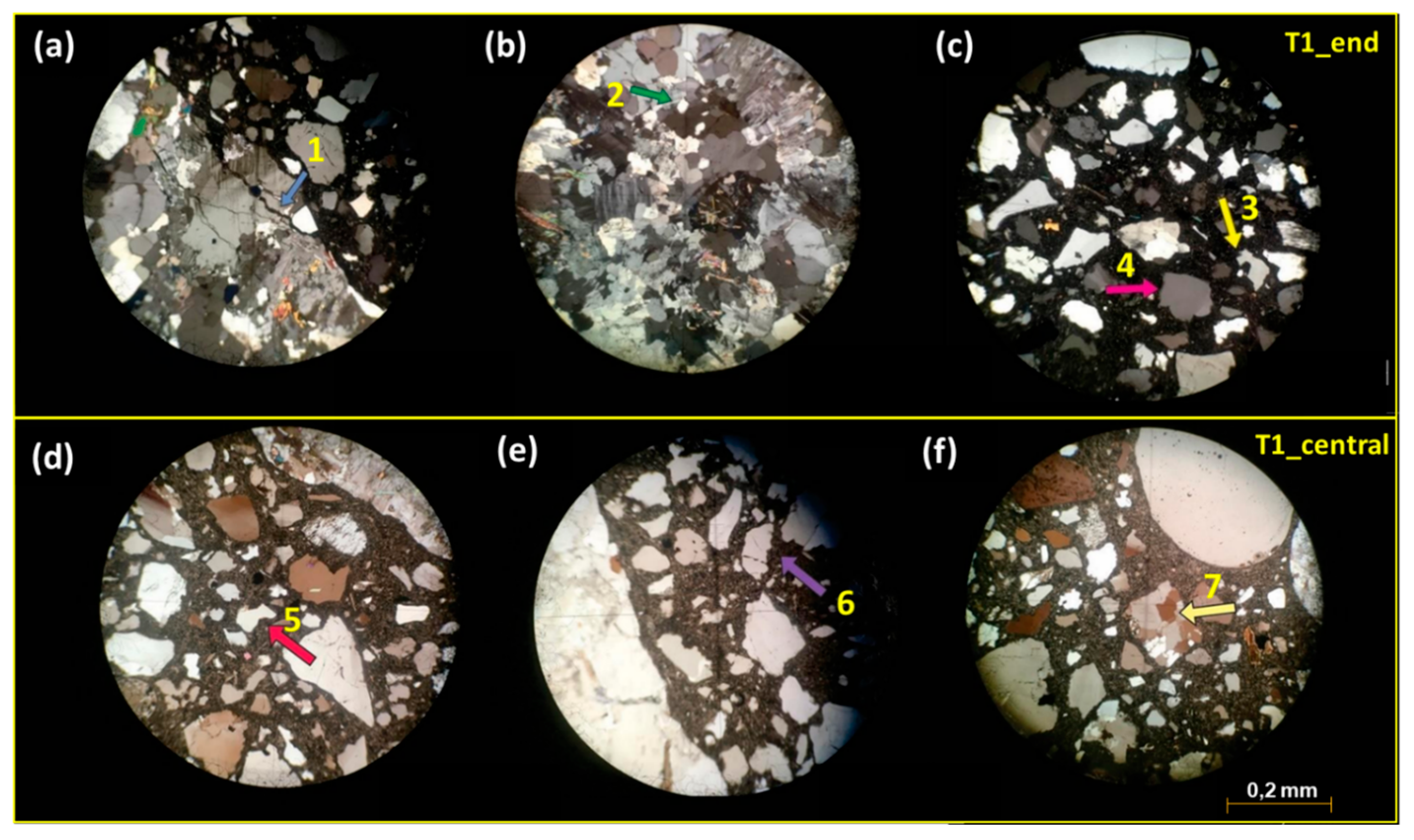

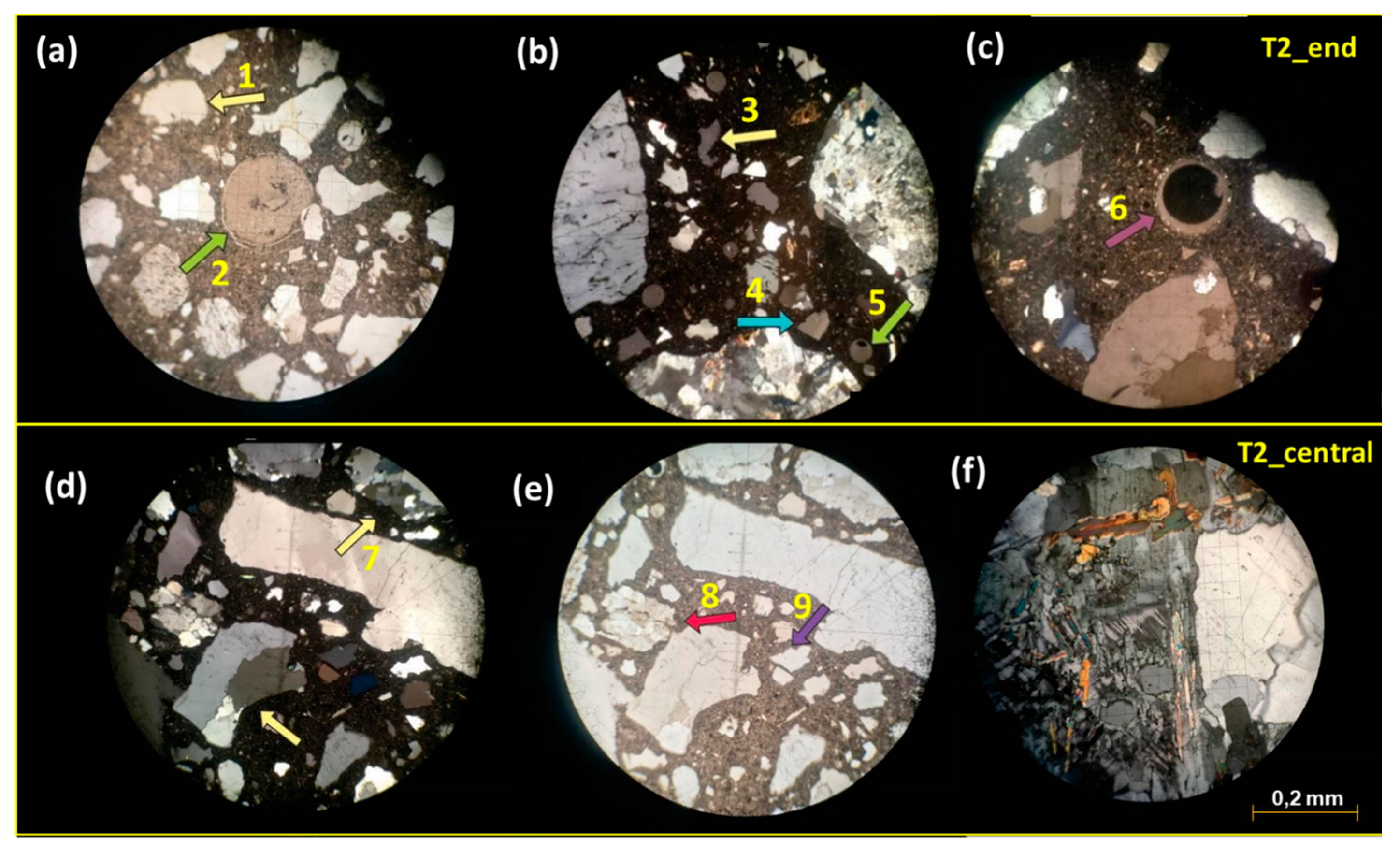

3.4. Petrographical Examination

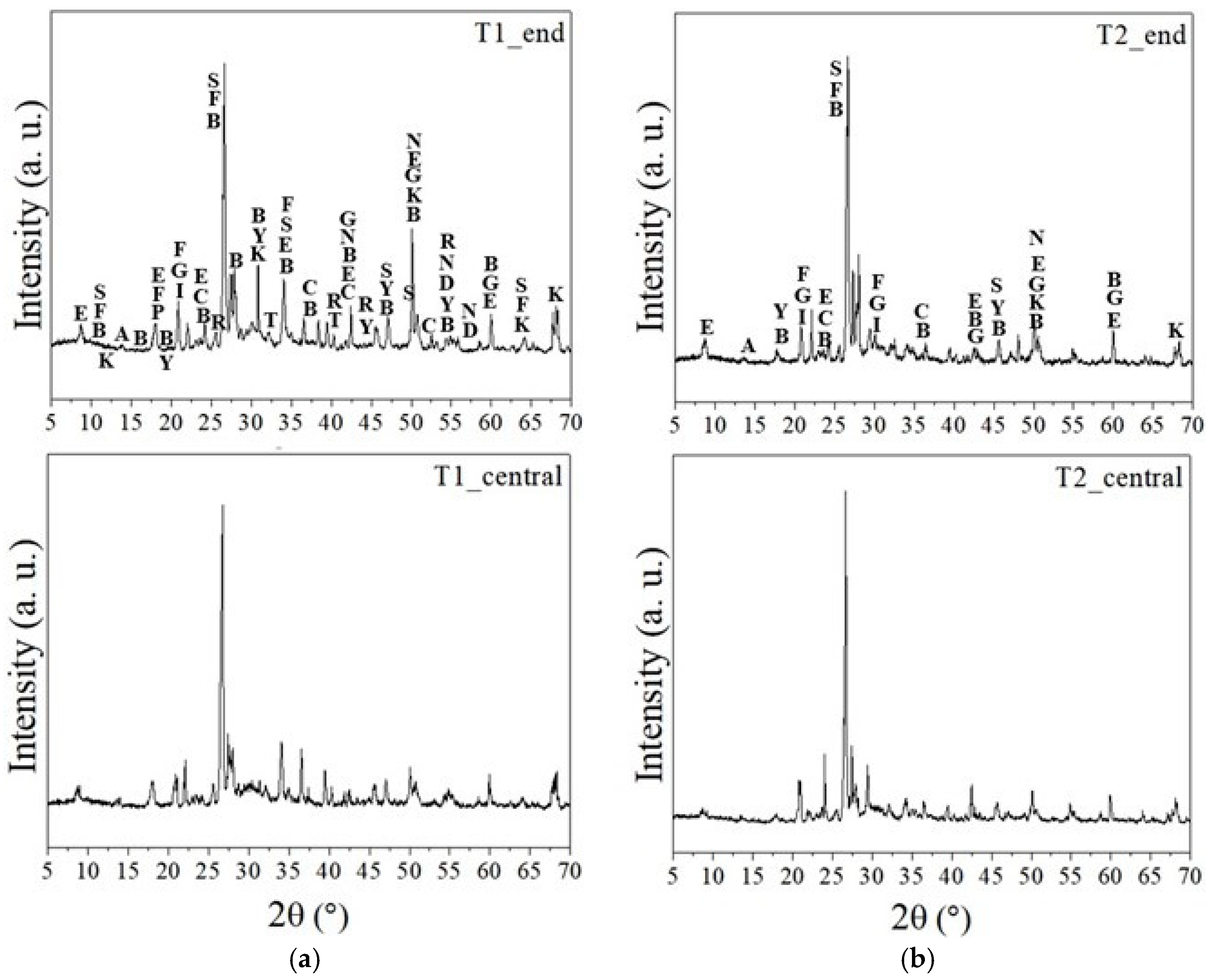

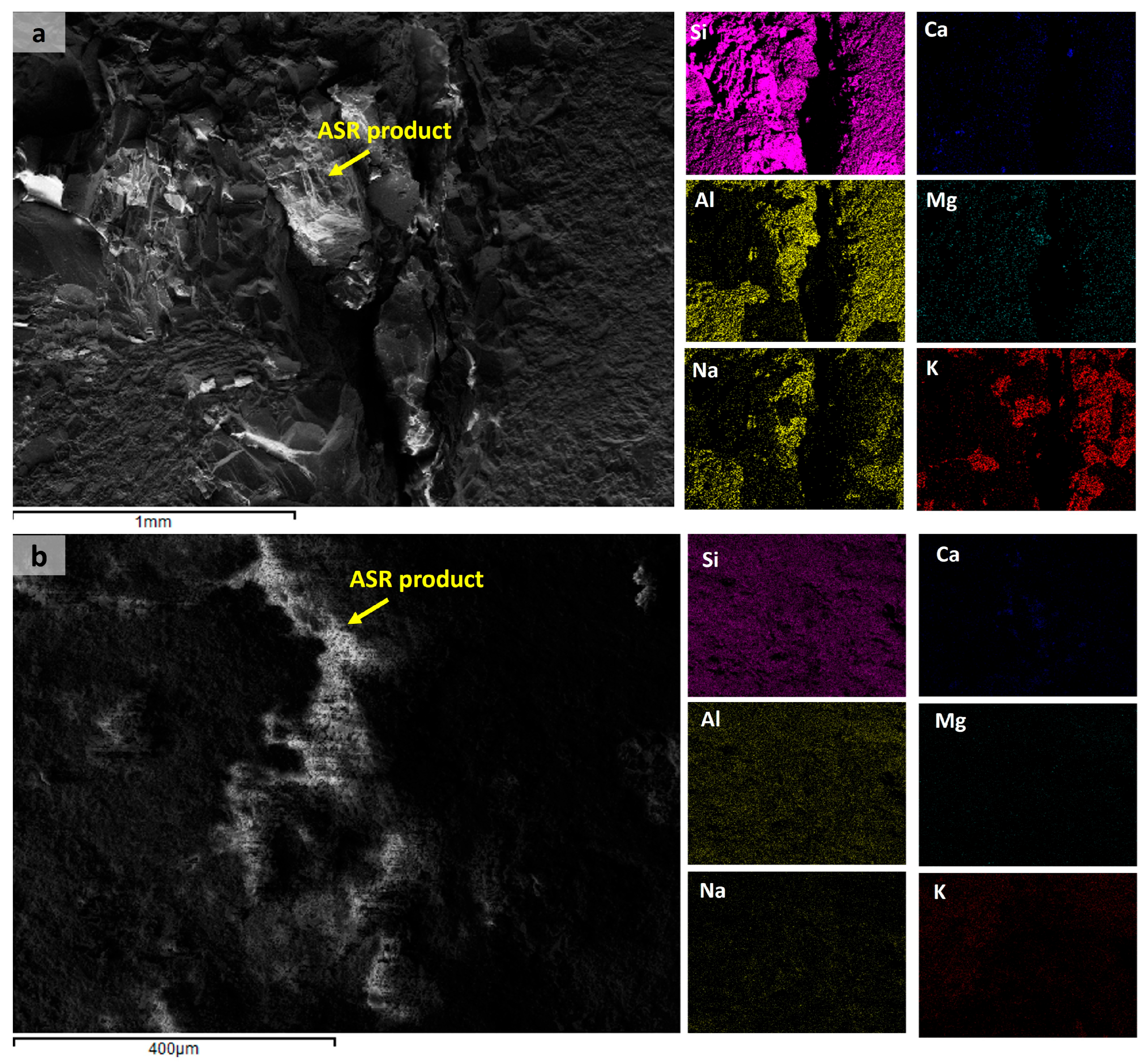

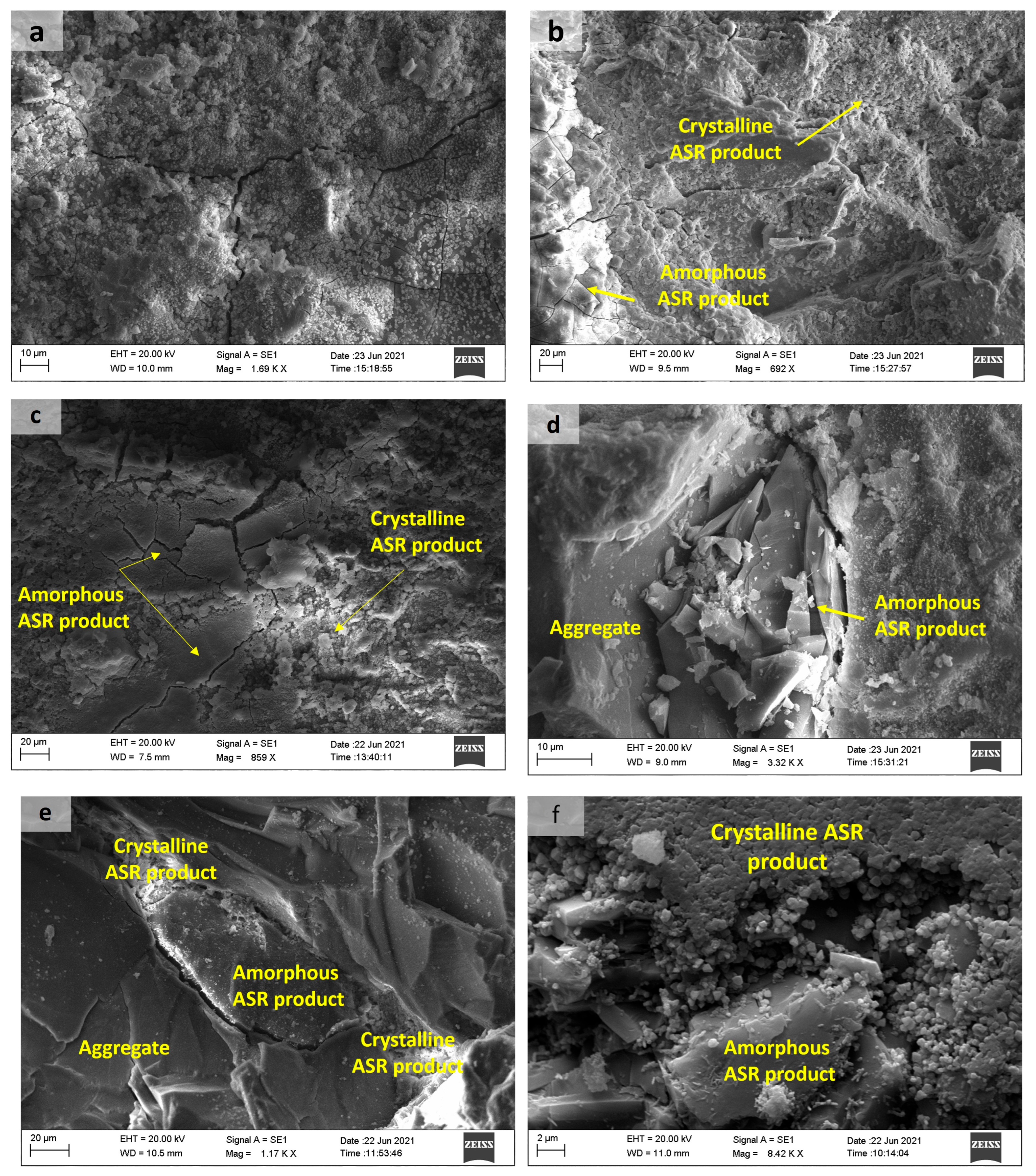

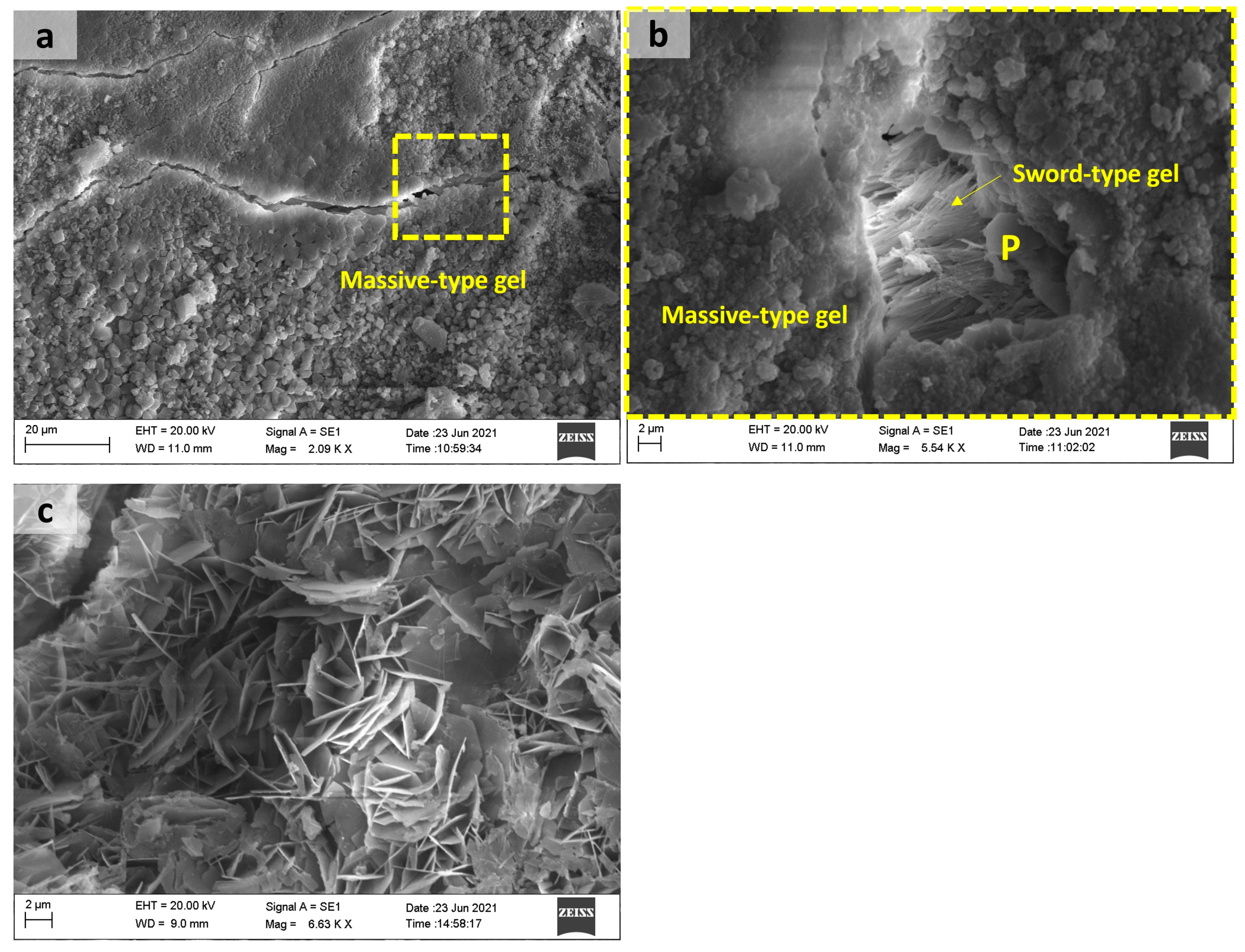

3.5. XRD/SEM-EDS Analysis

3.6. A Predictive Model of ASR Damage: Integrating Expansion Kinetics and Transport Properties

3.7. Practical Recommendations and Future Research

- (1)

- Material optimization: Use non-reactive aggregates with low-alkali cement and supplementary cementitious materials to mitigate ASR/DEF risks by controlling reactive species availability;

- (2)

- Design improvements: Implement optimized prestress distribution focusing on vulnerable end regions to improve stress resistance;

- (3)

- Drainage system: Install properly graded drainage systems to minimize water retention and associated deterioration mechanisms;

- (4)

- Monitoring protocol: Establish regular visual inspections and non-destructive testing (NDT) programs, prioritizing examination of rail seats and tie ends for early deterioration detection.

4. Conclusions

- Both groups showed a reduction in compressive strength compared to the 28-day benchmark. Specimens taken from the tie ends exhibited lower strength than those from the center. T1 samples showed a strength reduction of up to 66%, while T2 samples decreased by approximately 40%.

- T1 samples exhibited significantly higher capillary absorption and chloride migration coefficients (Dnss) than T2, indicating increased permeability. This facilitated the ingress of aggressive agents, leading to higher concentrations of soluble salts and an accelerated deterioration process.

- Petrographic analysis revealed that both coarse and fine aggregates in T1 and T2 were found to be potentially reactive. Microcracking and voids filled with gel and cryptocrystalline materials were observed. T1 samples from the ends showed advanced carbonation, while central samples exhibited carbonation primarily around aggregate boundaries.

- XRD analysis identified ettringite in T1 ends and T2 centers, with SEM images showing ettringite in air voids and on aggregate surfaces. This phase in the cement paste is linked to secondary ettringite formation, contributing to expansion and cracking.

- ASR products were identified both at aggregate–paste interfaces and within aggregates, pores, and microcracks. All specimens contained boggsite, characteristic of (N,C)ASH gel development. Furthermore, T1 displayed thermonatrite and natron, which are typical carbonation products of sodium. Massive crystals with a sword-type morphology and rosette-type reaction products associated with a more advanced stage of ASR were found in T1 samples.

- The level of deterioration in T1 ties is more severe than in T2, likely due to increased moisture exposure and drying cycles. The superior performance of T2 ties underscores the critical role of drainage design in durability.

- The key determinant of performance variation between T1 and T2 ties is their differing microenvironmental moisture exposure, interacting critically with prestress distribution effects. The synergistic combination of (1) terrain-induced moisture accumulation disparities and (2) stress confinement patterns create the significant durability gap observed in field performance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ASR | Alkali–Silica Reaction |

| CAGR | Compound Annual Growth Rate |

| DEF | Delay Ettringite Formation |

| EDS | Energy Dispersive Spectroscopy |

| RSD | Rail-Seat Deterioration |

| SEM | Scanning Electron Microscopy |

| XRD | X-Ray Diffraction (XRD) |

Appendix A

| Compounds | Chemical Formula | T1 | T2 | ||

|---|---|---|---|---|---|

| End | Central | End | Central | ||

| Quartz | P | P | P | P | |

| C-S-H | - | P | P | P | P |

| C-A-S-H | - | P | P | P | P |

| Portlandite | P | P | P | P | |

| AFm | P | P | P | P | |

| Ettringite | P | P | P | P | |

| Gypsum | P | P | P | P | |

| Calcite | P | P | P | P | |

| Dolomite | P | P | P | P | |

| Thermonadrite | P | P | P | n.d | |

| Natron | P | P | n.d | n.d | |

| Boggsite | P | P | P | P | |

| Aluminum sulfate | P | P | P | P | |

| Nordstrandite | P | P | P | P | |

| Ye’elimite | P | P | P | P | |

| Arcanite | P | P | P | P | |

| Misenite | P | P | P | P | |

| Goergeyite | P | P | P | P | |

References

- Industry Research. Global Railway Sleepers Market Research Report. Industry Research. Available online: https://www.industryresearch.biz/global-railway-sleepers-market-27001892 (accessed on 14 March 2024).

- Ferdous, W.; Manalo, A.; Van Erp, G.; Aravinthan, T.; Kaewunruen, S.; Remennikov, A. Composite railway sleepers–Recent developments, challenges and future prospects. Compos. Struct. 2015, 134, 158–168. [Google Scholar] [CrossRef]

- Li, D.; Kaewunruen, S.; Remennikov, A.; You, R. Diagnostics and management methods for concrete sleepers. In Rail Infrastructure Resilience: A Best-Practices Handbook; Calçada, R., Kaewunruen, S., Eds.; Elsevier: London, UK, 2022; pp. 271–294. [Google Scholar]

- Dolci, G.; Rigamonti, L.; Grosso, M. Potential for improving the environmental performance of railway sleepers with an outer shell made of recycled materials. Transp. Res. Interdiscip. Perspect. 2020, 6, 100160. [Google Scholar] [CrossRef]

- Pang, Y.; Lingamanaik, N.; Chen, B.K.; Yu, S.F. Measurement of deformation of the concrete sleepers under different support conditions using non-contact laser speckle imaging sensor. Eng. Struct. 2020, 205, 110054. [Google Scholar] [CrossRef]

- Palomo, A.; Fernández-Jimenéz, A.; López-Hombrandos, C.; Lleyda, J.L. Railway sleepers made of alkali activated fly ash concrete. Rev. Ing. Constr. 2007, 22, 75–80. [Google Scholar] [CrossRef]

- Rail Suply. The Cause of the Regional Train Catastrophe in Burgrein on 3 June 2022, Was an Infrastructure Failure. 27 June 2023. Available online: https://www.railway.supply/en/the-cause-of-the-regional-train-catastrophe-in-burgrein-on-june-3-2022-was-an-infrastructure-failure (accessed on 6 March 2025).

- Awasthi, A.; Matsumoto, K.; Nagai, K.; Asamoto, S.; Goto, S. Investigation on possible causes of expansion damages in concrete. J. Asian Concr. Fed. 2017, 3, 49–66. [Google Scholar] [CrossRef]

- Valdes, A. Renovator MATISA Reached More Than 1 Million Replacement Concrete Ties. In Brazilian Association of Railway Industry. 29 July 2021. Available online: https://abifer.org.br/renovadora-matisa-alcancou-mais-de-1-milhao-de-dormentes-substituidos (accessed on 6 March 2025).

- Railway Gazette International. Interim Report Finds Faulty Sleepers Caused Garmisch Derailment. Infrastructure. 27 June 2023. Available online: https://www.railwaygazette.com/infrastructure/interim-report-finds-faulty-sleepers-caused-garmisch-derailment/64391.article (accessed on 6 March 2025).

- Riedel, A. Stars and Stripes. Fatal German Train Derailment Last Year Caused by Faulty Concrete Ties, Investigators Say. 1 June 2023. Available online: https://www.stripes.com/theaters/europe/2023-06-01/train-derailment-caused-by-faulty-rail-ties-10301622.html (accessed on 6 March 2025).

- DieSachsen News. Line Closure Due to Replacement of Concrete Sleepers Between Leipzig and Chemnitz. 15 April 2024. Available online: https://www.diesachsen.de/en/economy/line-closure-due-to-replacement-of-concrete-sleepers-between-leipzig-and-chemnitz-2921476 (accessed on 12 December 2024).

- Ferdous, W.; Manalo, A. Failures of mainline railway sleepers and suggested remedies–Review of current practice. Eng. Fail. Anal. 2014, 44, 17–35. [Google Scholar] [CrossRef]

- Greve, M.; Dersch, M.S.; Riley, J.E.; Barkan, C.P.L.; Mediavilla, J.; Wilson, B.M. Analysis of the Relationship Between Rail Seat Load Distribution and Rail Seat Deterioration in Concrete Crossties. In Proceedings of the 2014 Joint Rail Conference, Colorado Springs, CO, USA, 2–4 April 2014; American Society of Mechanical Engineers: Colorado Springs, CO, USA, 2014. [Google Scholar]

- Qinhua, J.; Min, D.; Sufen, A. Investigation of deteriorated concrete railway ties. Cem. Concr. Res. 1996, 26, 999–1006. [Google Scholar] [CrossRef]

- Suresh Kumar, A.; Muthukannan, M. An Examination on Performance of Railway Sleepers. Int. J. Recent Technol. Eng. 2019, 8, 37–44. [Google Scholar]

- Jeon, D.; Yu, J.; Kim, J.; Yoon, S.; Bae, Y.; Oh, J.E. Synergetic Influence of Microcrystalline Quartz and Alkali Content in Aggregate on Deterioration of Concrete Railroad Ties Used for 15 Years in High-Speed Railways. Int. J. Concr. Struct. Mater. 2022, 16, 57. [Google Scholar] [CrossRef]

- Thaulow, N.; Sahu, S. Mechanism of concrete deterioration due to salt crystallization. Mater. Charact. 2004, 53, 123–127. [Google Scholar] [CrossRef]

- Fernández-Jiménez, A.; Puertas, F. The alkali–silica reaction in alkali-activated granulated slag mortars with reactive aggregate. Cem. Concr. Res. 2002, 32, 1019–1024. [Google Scholar] [CrossRef]

- Lindgård, J.; Sellevold, E.J.; Thomas, M.D.A.; Pedersen, B.; Justnes, H.; Rønning, T.F. Alkali–silica reaction (ASR)—Performance testing: Influence of specimen pre-treatment, exposure conditions and prism size on concrete porosity, moisture state and transport properties. Cem. Concr. Res. 2013, 53, 145–167. [Google Scholar] [CrossRef]

- Bouzabata, H.; Multon, S.; Sellier, A.; Houari, H. Swellings due to alkali-silica reaction and delayed ettringite formation: Characterisation of expansion isotropy and effect of moisture conditions. Cem. Concr. Compos. 2012, 34, 349–356. [Google Scholar] [CrossRef]

- Wang, H.L.; Dai, J.G.; Sun, X.Y.; Zhang, X.L. Characteristics of concrete cracks and their influence on chloride penetration. Constr. Build. Mater. 2016, 107, 216–225. [Google Scholar] [CrossRef]

- ABNT NBR 5733; High Early Strength Portland Cement. ABNT: Rio de Janeiro, Brazil, 1991.

- ABNT NBR 7680; Concrete: Sampling, Preparing and Testing Concrete Cores. ABNT: Rio de Janeiro, Brazil, 2015.

- ABNT NBR 5739; Concrete: Compression Test of Cylindrical Specimens. ABNT: Rio de Janeiro, Brazil, 2018.

- ABNT NBR 8802; Hardened Concrete–Determination of Ultrasonic Wave Transmission Velocity. ABNT: Rio de Janeiro, Brazil, 2019.

- ABNT NBR 9917; Aggregates for Concrete–Determination of Soluble Salts, Chlorides and Sulphates. ABNT: Rio de Janeiro, Brazil, 2022.

- EN ISO 15148; European Standard. Higrothermal Performance of Building Materials and Products–Determination of Water Coefficient by Partial Immersion. International Organization for Standardization: London, UK, 2002.

- NT Build 492; Chloride Migration Coefficient from Non-Steady-State Migration Experiments. Nordtest Method. NORDTEST: Espoo, Finland, 1999.

- ASTM C856M-20; American Society for Testing and Materials. Standard Practice for Petrographic Examination of Hardened Concrete. ABNT: Rio de Janeiro, Brazil, 2025.

- ABNT NBR 15577-3; Aggregates–Alkali Aggregate Reactivity Part 3: Petrographic Analysis for Evaluation of the Potential Reactivity of Aggregates with Alkali Compounds from Concrete. ABNT: Rio de Janeiro, Brazil, 2018.

- Thun, H.; Utsi, S.; Elfgren, L. Load carrying capacity of cracked concrete railway sleepers. Struct. Concr. 2008, 9, 153–161. [Google Scholar]

- Scherer, G.W. Stress from crystallization of salt. Cem. Concr. Res. 2004, 34, 1613–1624. [Google Scholar] [CrossRef]

- Flatt, R.; Mohamed, N.A.; Caruso, F.; Derluyn, H.; Desarnaud, J.; Lubelli, B.; Marzal, R.M.E.; Pel, L.; Rodriguez-Navarro, C.; Scherer, G.W.; et al. Predicting salt damage in practice: A theoretical insight into laboratory tests. RILEM Tech. Lett. 2017, 2, 108–118. [Google Scholar] [CrossRef]

- Saelensminde, J.; Samindi, S.M.; Samarakoon, M.K. Deterioration of concrete structures due to salt crystallization-Influence of salt types and relative humidity. In Proceedings pro 112 on International RILEM Conference on Materials, Systems and Structures in Civil Engineering Conference Segment on Moisture in Materials and Structures; Hansen, K.K., Rode, C., Nilsson, L., Eds.; RILEM: Lyngby, Denmark, 2016; pp. 120–127. [Google Scholar]

- Heidari, M.; Momeni, A.A.; Naseri, F. New weathering classifications for granitic rocks based on geomechanical parameters. Eng. Geol. 2013, 166, 65–73. [Google Scholar] [CrossRef]

- Yuguchi, T.; Izumino, Y.; Sasao, E. Genesis and development processes of fractures in granite: Petrographic indicators of hydrothermal alteration. PLoS ONE 2021, 16, e0251198. [Google Scholar] [CrossRef]

- Ali, A.; Sajid, M.; Ali, L.; Usman, M. Petrographic study of coarse aggregate to evaluate their susceptibility to Alkali Silica Reactivity in different rocks of District Shangla, Swat, Pakistan. J. Himal. Earth Sci. 2014, 47, 125–139. [Google Scholar]

- Kuchařová, A.; Götze, J.; Šachlová, Š.; Pertold, Z.; Přikryl, R. Microscopy and Cathodoluminescence Spectroscopy Characterization of Quartz Exhibiting Different Alkali–Silica Reaction Potential. Microsc. Microanal. 2016, 22, 189–198. [Google Scholar] [CrossRef] [PubMed]

- Antolik, A.; Jóźwiak-Niedźwiedzka, D. Assessment of the alkali-silica reactivity potential in granitic rocks. Constr. Build. Mater. 2021, 295, 123690. [Google Scholar] [CrossRef]

- Poole, A.B.; Sims, I. Concrete Petrography: A Handbook of Investigative Techniques, 2nd ed.; CRC Press: London, UK, 2016. [Google Scholar]

- L’Hôpital, E.; Lothenbach, B.; Scrivener, K.; Kulik, D.A. Alkali uptake in calcium alumina silicate hydrate (C-A-S-H). Cem. Concr. Res. 2016, 85, 122–136. [Google Scholar] [CrossRef]

- Shi, Z.; Lothenbach, B. The combined effect of potassium, sodium and calcium on the formation of alkali-silica reaction products. Cem. Concr. Res. 2010, 127, 105914. [Google Scholar] [CrossRef]

- Leemann, A.; Shi, Z.; Lindgård, J. Characterization of amorphous and crystalline ASR products formed in concrete aggregates. Cem. Concr. Res. 2020, 137, 106190. [Google Scholar] [CrossRef]

- Leemann, A.; Münch, B. The addition of caesium to concrete with alkali-silica reaction: Implications on product identification and recognition of the reaction sequence. Cem. Concr. Res. 2019, 120, 27–35. [Google Scholar] [CrossRef]

- Shi, Z.; Leemann, A.; Rentsch, D.; Lothenbach, B. Synthesis of alkali-silica reaction product structurally identical to that formed in field concrete. Mater. Des. 2020, 190, 108562. [Google Scholar] [CrossRef]

- Penttala, V. Causes and mechanisms of deterioration in reinforced concrete. In Failure, Distress and Repair of Concrete Structures; Dellate, N., Ed.; Woodhead Publishing Series in Civil and Structural Engineering; CRC Press: Cambridge, UK, 2009; pp. 3–31. [Google Scholar]

- Wang, K.; Guo, J.; Yang, L.; Zhang, P.; Xu, H. Multiphysical damage characteristics of concrete exposed to external sulphate attack: Elucidating effect of drying–wetting cycles. Constr. Build. Mater. 2022, 329, 127143. [Google Scholar] [CrossRef]

- Yuan, J.; Liu, Y.; Tan, Z.; Zhang, B. Investigating the failure process of concrete under the coupled actions between sulphate attack and drying–wetting cycles by using X-ray CT. Constr. Build. Mater. 2016, 108, 129–138. [Google Scholar] [CrossRef]

- Larive, C. Apports Combinés de L’expérimentation et de la Modélisation à la Compréhension de L’alcali-Réaction et de ses Effets Mécaniques. Ph.D. Thesis, École Nationale des Ponts et Chaussées, Paris, France, 1997. [Google Scholar]

- Multon, S.; Toutlemonde, F. Effect of applied stresses on alkali–silica reaction-induced expansions. Cem. Concr. Res. 2006, 36, 912–920. [Google Scholar] [CrossRef]

- Maalouf, J.; Cagnon, H.; Verdier, J.; Multon, S.; Jabbour, J.; Bouhjiti, D. Impact of alkali-silica reaction and delayed ettringite formation-induced cracking on air permeability and water diffusivity in concrete. Case Stud. Constr. Mater. 2025, 22, e04183. [Google Scholar] [CrossRef]

| Characteristics of Concrete Ties | T1 | T2 | |

|---|---|---|---|

| Slump (cm) | 4.21 ± 1.24 | 3.66 ± 1.50 | |

| Variation in time of curing (h) | 5 to 9 | 5:30 to 15 | |

| Average time of curing (h) | 6.45 | 6.44 | |

| Compressive strength 1 (MPa) at | 3 days | 45.3 ± 3.9 | 50.5 ± 4.2 |

| 7 days | 52.2 ± 4.6 | 57.0 ± 3.9 | |

| 28 days | 58.9 ± 4.8 | 64.0 ± 4.2 | |

| 3 point-flexural tensile strength 2 (MPa) at 28 days | 7.9 ± 0.9 | 6.3 ± 0.5 | |

| T1_End | T1_Central | T2_End | T2_Central | |

|---|---|---|---|---|

| Compressive strength (MPa) | 20.0 ± 8.1 | 30.0 ± 1.9 | 38.5 ± 8.9 | 66.0 ± 0.2 |

| Dynamic elastic modulus (GPa) | 28.8 ± 5.4 | 40.8 ± 4.4 | 32.9 ± 8.6 | 47.0 ± 4.8 |

| T1_End | T1_Central | T2_End | T2_Central | |

|---|---|---|---|---|

| Soluble salt (%) | 2.17 ± 0.01 | 2.19 ± 0.01 | 1.26 ± 0.07 | 0.96 ± 0.02 |

| Sulfates (%) | 0.10 ± 0.00 | 0.10 ± 0.00 | 0.11 ± 0.01 | 0.05 ± 0.01 |

| Chloride (%) | <0.0062 | <0.0062 | <0.0062 | <0.0062 |

| Parameter | T1_End | T1_Central | T2_End | T2_Central | |

|---|---|---|---|---|---|

| Coarse aggregate | Rock type | granite | granite | granitoid | granite |

| Particle size | 5–25 mm | 5–25 mm | 5–25 mm | 5–25 mm | |

| Microcracks | punctual | occasional | occasional | occasional | |

| Reactivity | potentially | potentially | potentially | potentially | |

| Reaction edges | incipient | incipient | incipient | incipient | |

| Gel | thin film | thin film | thin film | thin film | |

| Fine aggregate | Mineralogy | quartz | quartz | quartz | quartz |

| Microcracks | no detected | no detected | no detected | no detected | |

| Reaction edges | sinous | sinous | sinous | sinous | |

| Gel | present | present | present | present | |

| Cement paste | Color | uniform | uniform | uniform | uniform |

| Voids | partially filled | partially filled | partially filled | partially filled | |

| Gel | present | present | present | present | |

| Carbonation | advanced | restricted | no detected | no detected | |

| Concrete | ASR | present | present | present | present |

| Region | Initial fc (MPa) | 10-Year fc (MPa) | Strength Loss (%) | ASR Severity |

|---|---|---|---|---|

| T1_end | 58.9 | 20.0 ± 8.1 | ~66% | Severe (low prestress) |

| T1_central | 58.9 | 30.0 ± 1.9 | ~49% | Moderate (partial σ inhibition) |

| T2_end | 64.0 | 38.5 ± 8.9 | ~40% | Moderate |

| T2_central | 64.0 | 66.0 ± 0.2 | ~0% | Negligible (high σ) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Costa, E.B.C.; Coutinho, M.E.G.; Ferreira, R.A.D.R.; Dos Santos, A.C.; Oliveira, L. Assessment of Premature Failures in Concrete Railway Ties: A Case Study from Brazil. Materials 2025, 18, 2994. https://doi.org/10.3390/ma18132994

Costa EBC, Coutinho MEG, Ferreira RADR, Dos Santos AC, Oliveira L. Assessment of Premature Failures in Concrete Railway Ties: A Case Study from Brazil. Materials. 2025; 18(13):2994. https://doi.org/10.3390/ma18132994

Chicago/Turabian StyleCosta, Eliane Betânia Carvalho, Maria Eduarda Guedes Coutinho, Rondinele Alberto Dos Reis Ferreira, Antonio Carlos Dos Santos, and Luciano Oliveira. 2025. "Assessment of Premature Failures in Concrete Railway Ties: A Case Study from Brazil" Materials 18, no. 13: 2994. https://doi.org/10.3390/ma18132994

APA StyleCosta, E. B. C., Coutinho, M. E. G., Ferreira, R. A. D. R., Dos Santos, A. C., & Oliveira, L. (2025). Assessment of Premature Failures in Concrete Railway Ties: A Case Study from Brazil. Materials, 18(13), 2994. https://doi.org/10.3390/ma18132994