An Experimental Investigation on the Mechanical Performance of Engineered Cementitious Composites with Different Types of Steel Fibers

Abstract

1. Introduction

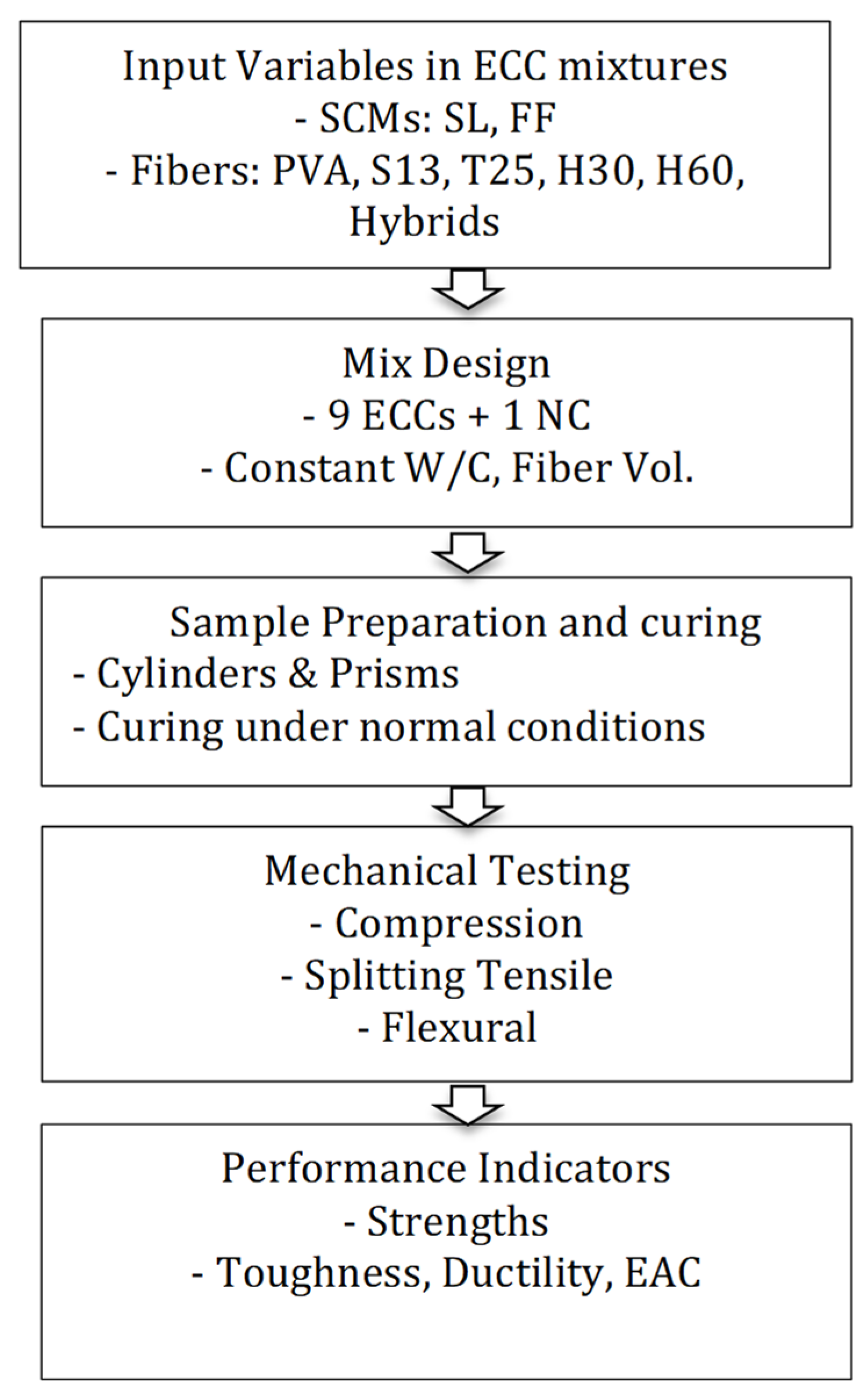

2. Experimental Program

2.1. Materials and Mixture Proportions

2.2. Mechanical Testing

3. Results

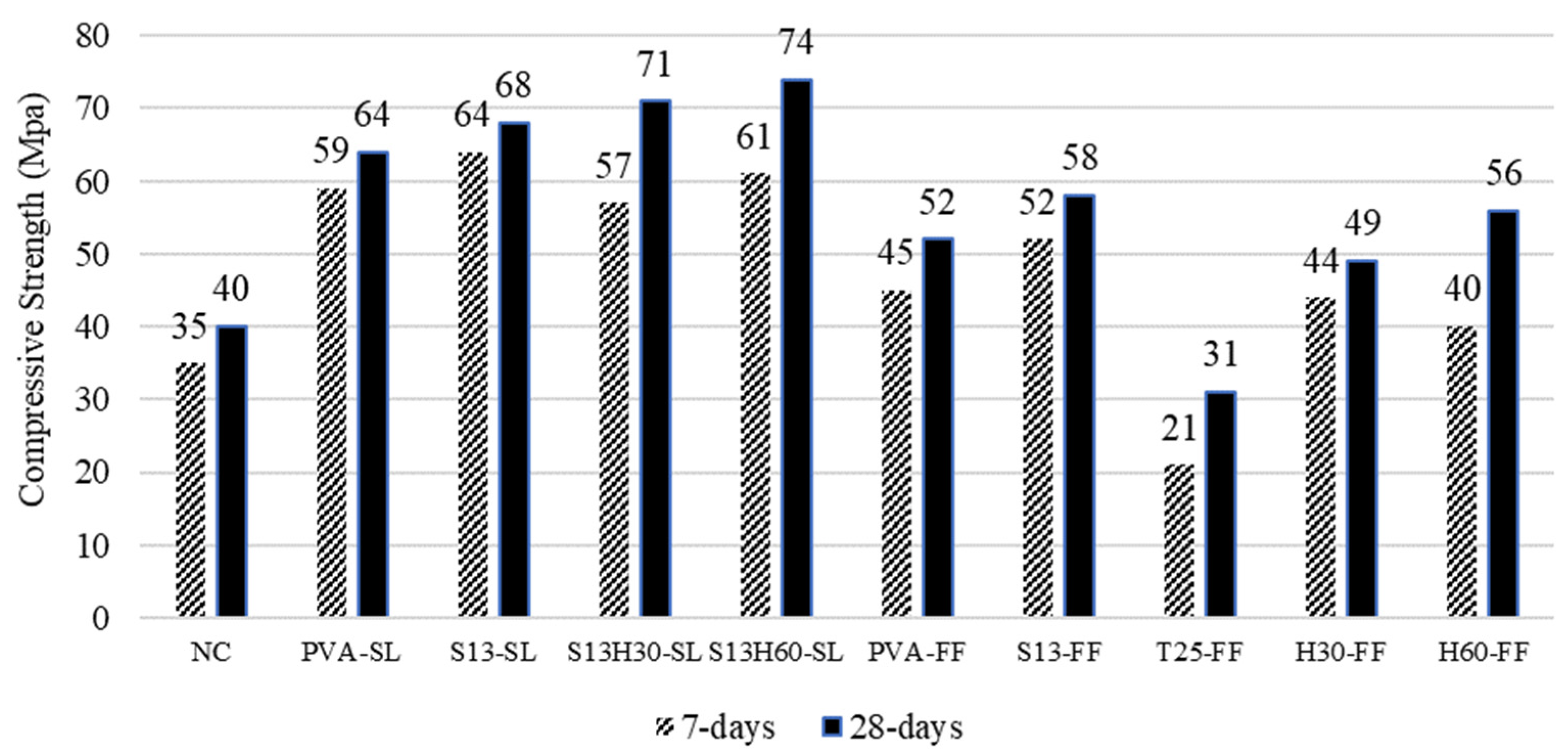

3.1. Compressive Strength

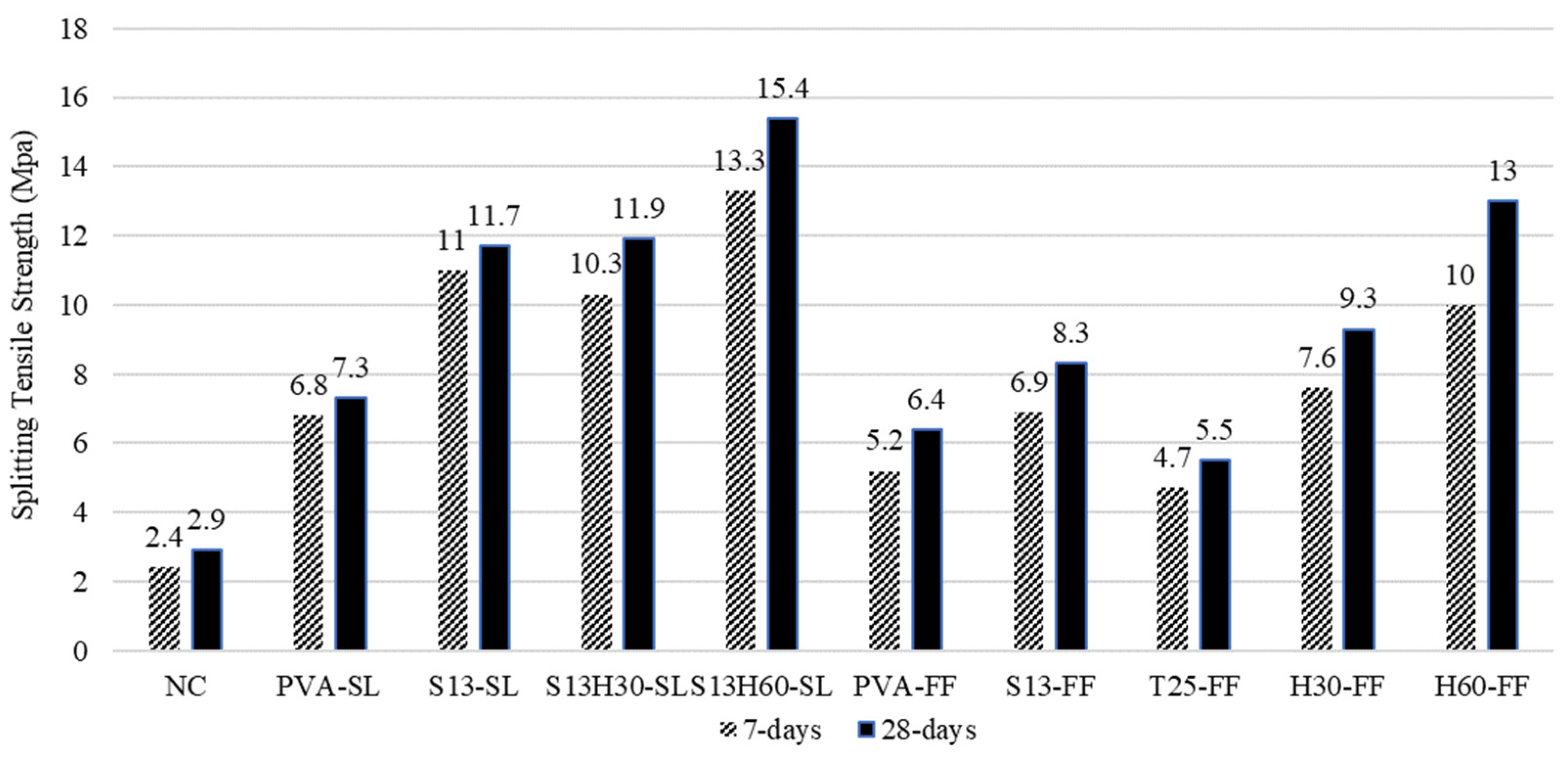

3.2. Splitting Tensile Strength

4. Flexural Behavior

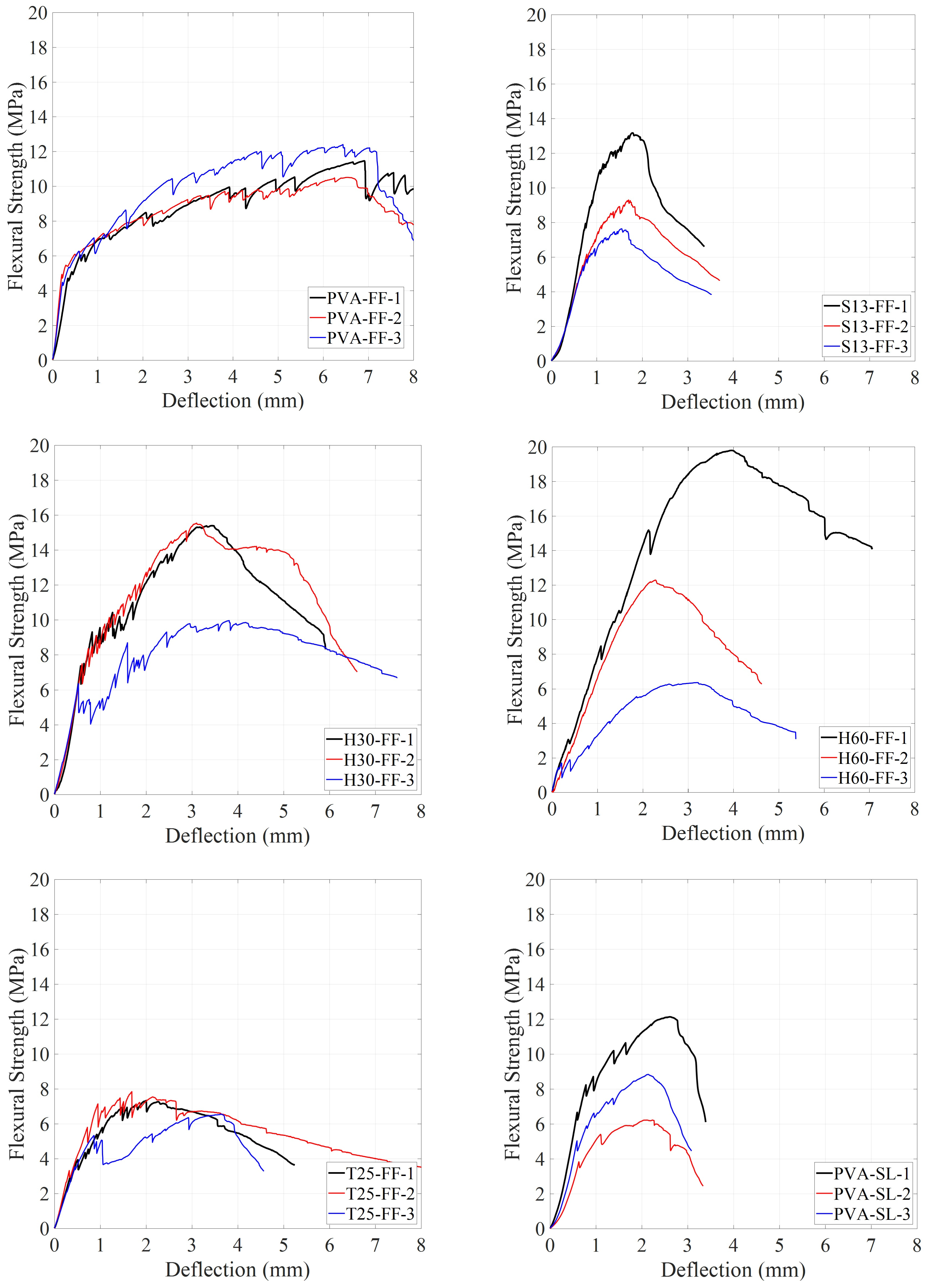

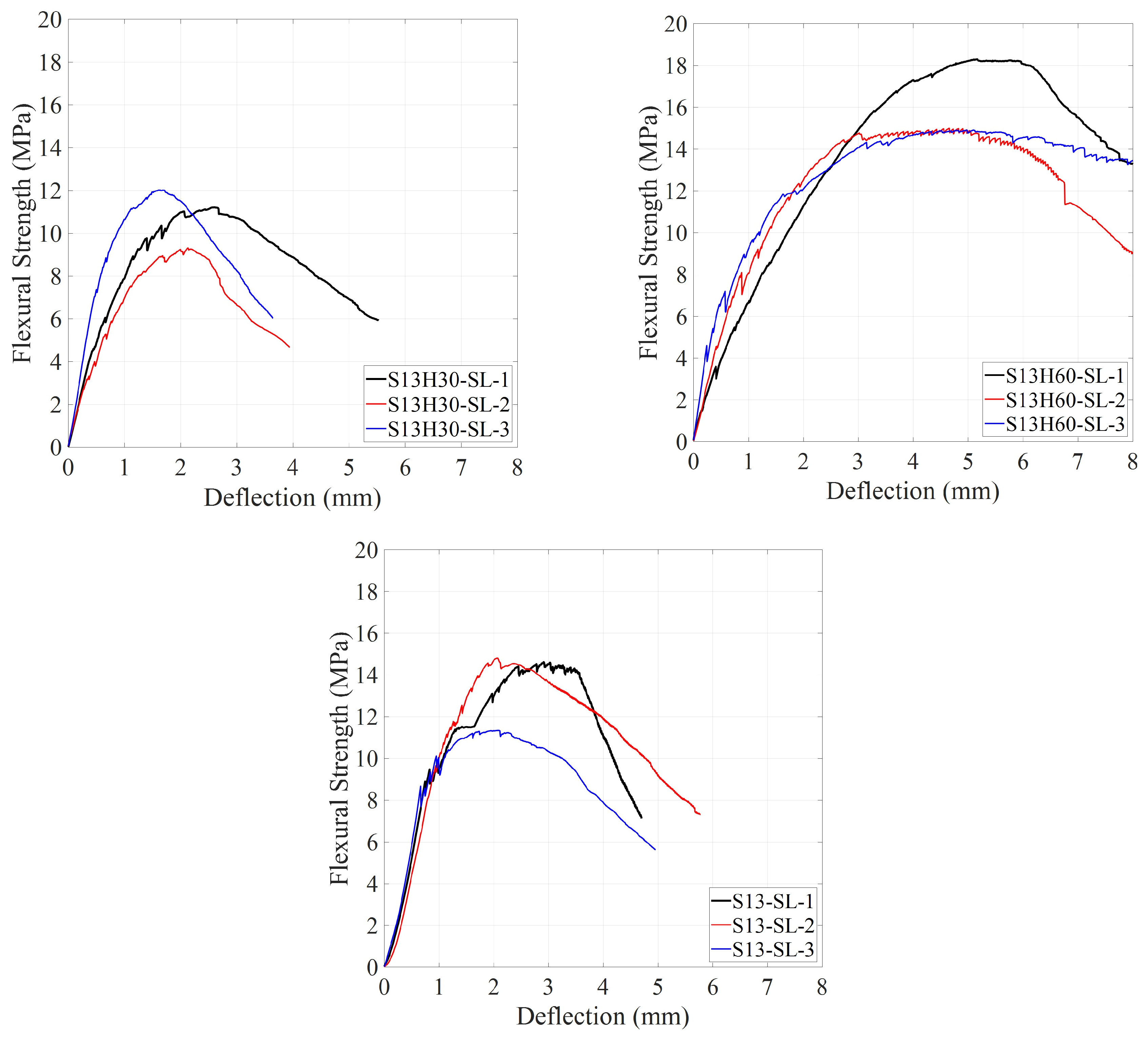

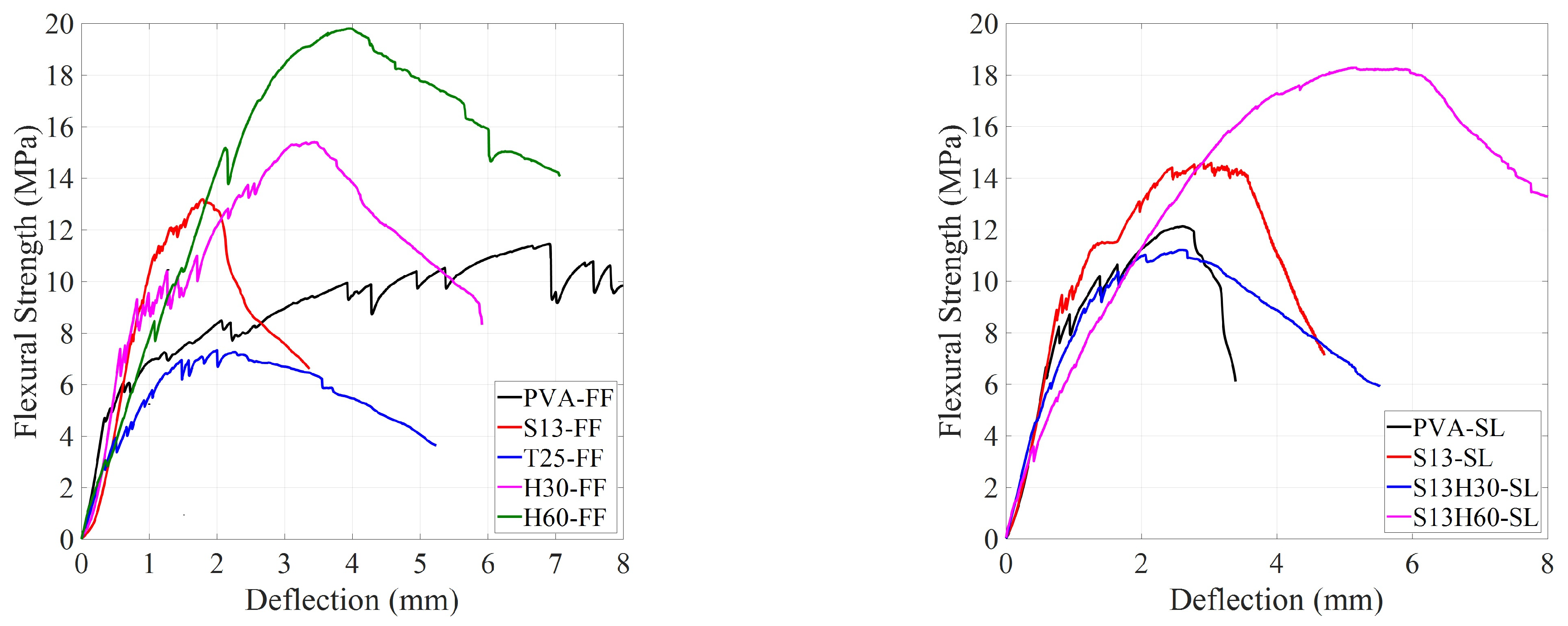

4.1. Load–Deflection Response

4.2. Failure Mode and Micro-Cracking Behavior

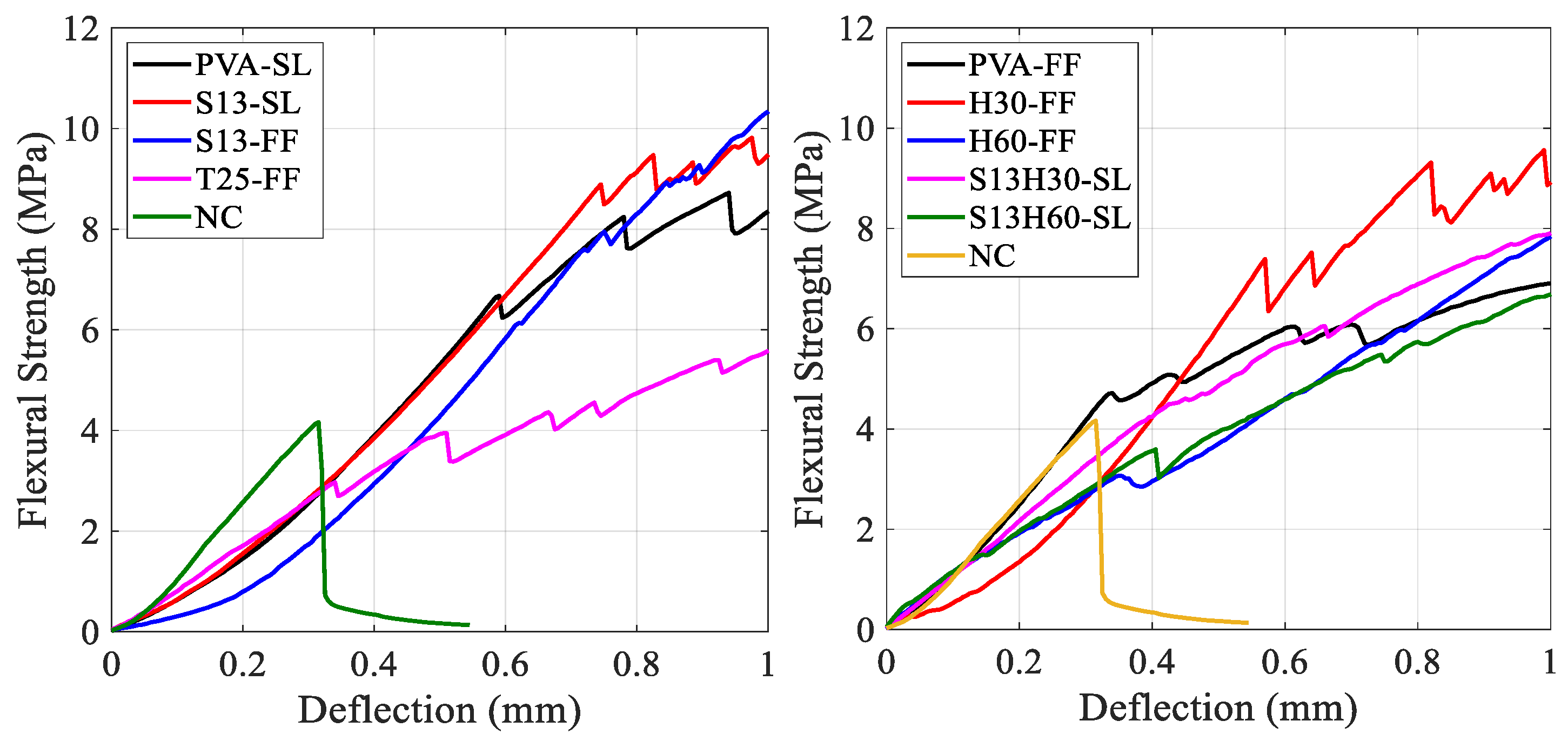

4.3. Initial Stiffness and First-Crack Stress

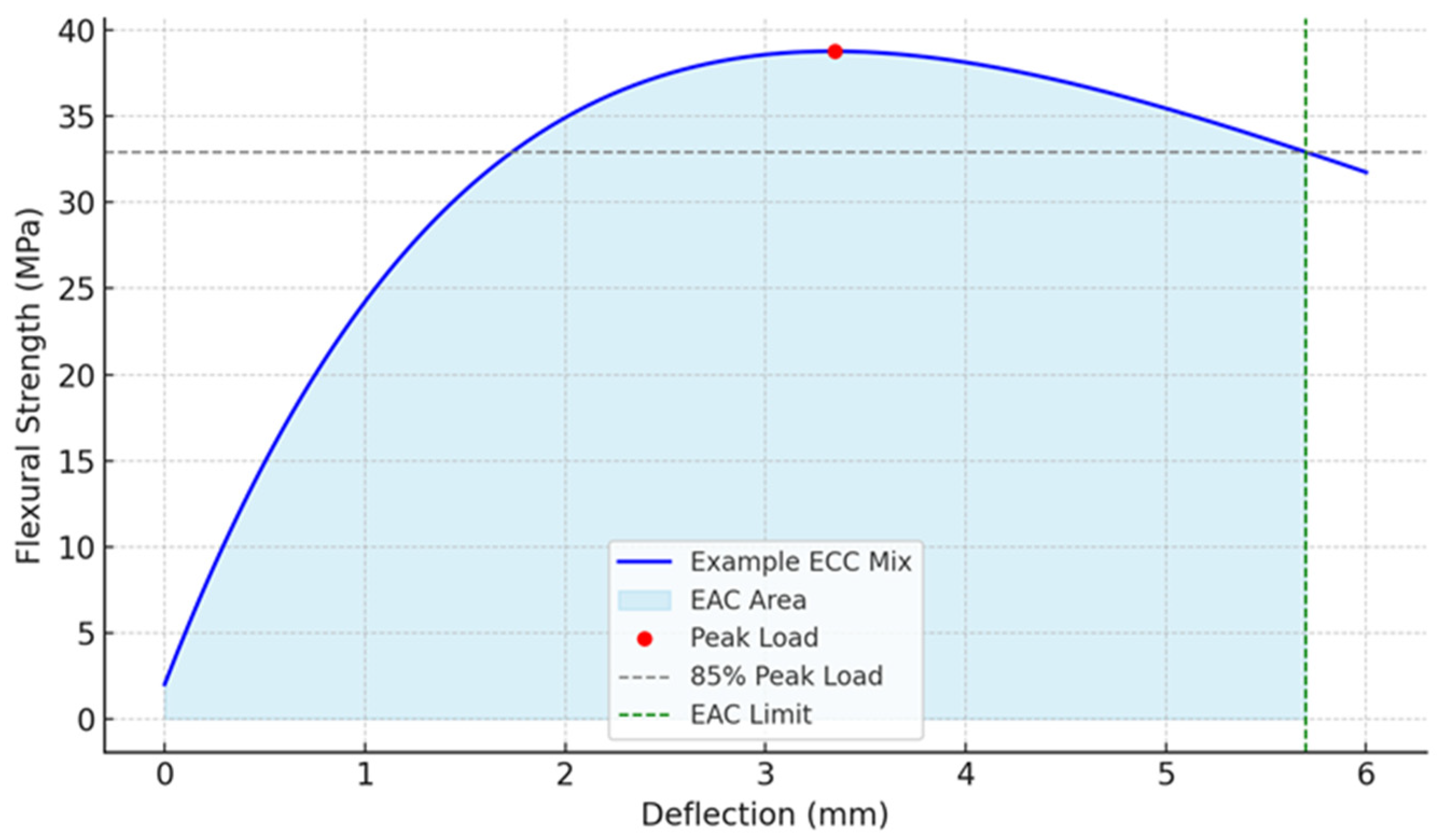

4.4. Toughness, Ductility, and Energy Absorption Capacity

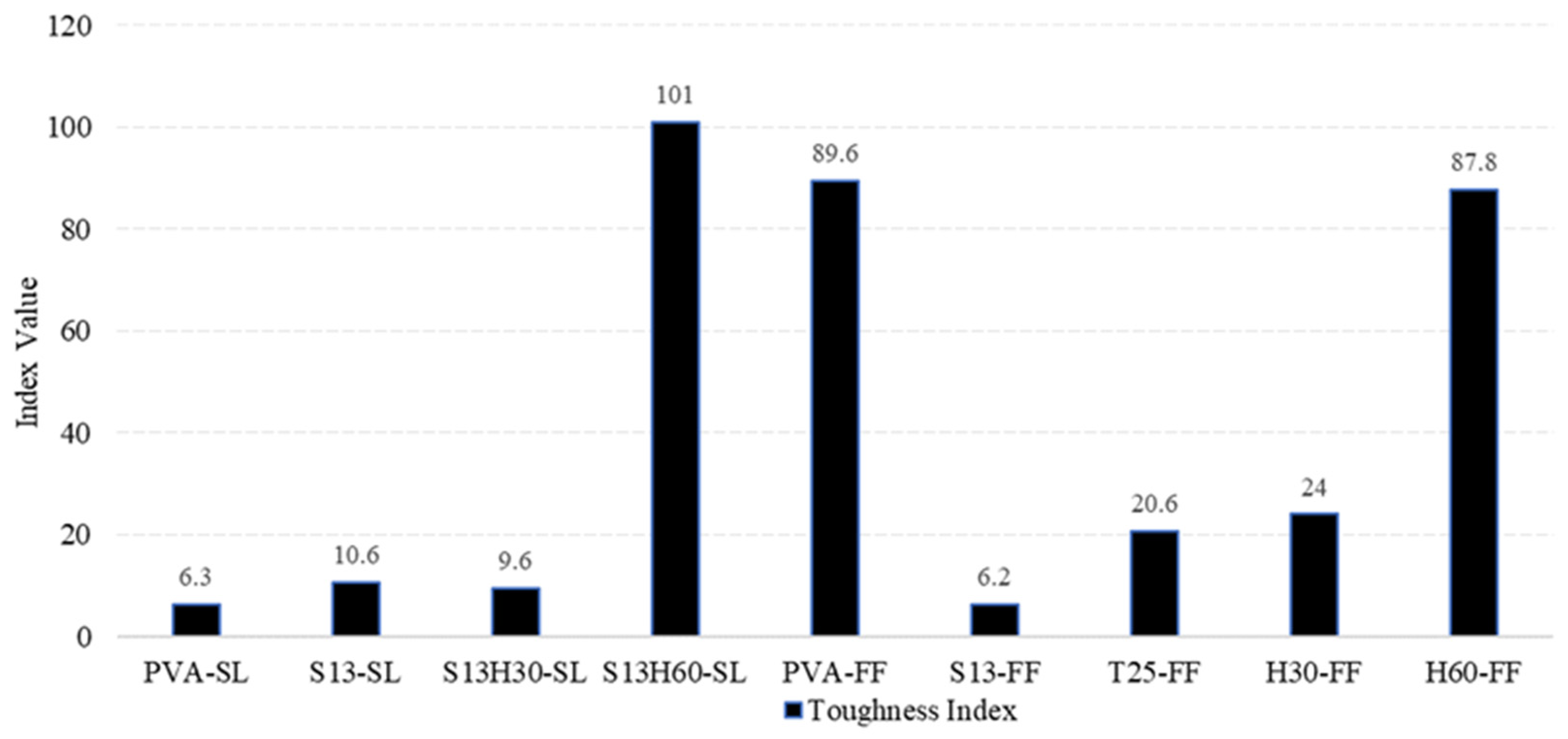

4.4.1. Toughness Index

4.4.2. Ductility Index

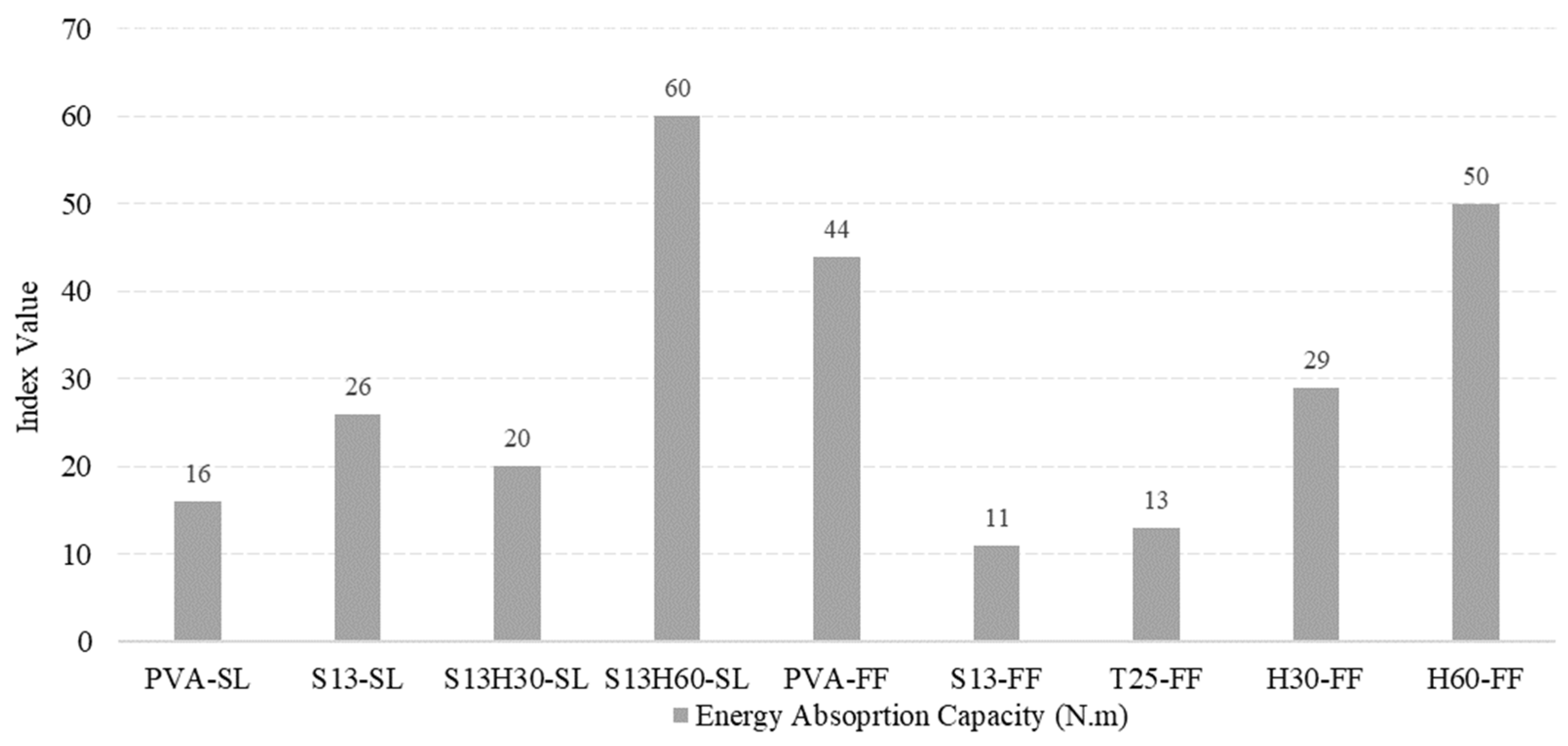

4.4.3. Energy Absorption Capacity

5. Conclusions

- Hybrid compositions achieved the highest compressive and tensile strengths among all tested ECCs, surpassing traditional PVA-ECCs and other steel fiber ECCs.

- ECCs with S13 fibers failed with a single crack without micro-cracking behavior and poor ductility. The high cracking strength, along with A low aspect ratio and straight shape, of S13 fibers resulted in a weaker bond between the fiber and the matrix, resulting in lower fiber bridging strength, which prevented S13-FF and S13-SL from demonstrating the desirable micro-cracking behavior and ductility.

- Single-fiber ECCs with longer steel fibers faced challenges in fiber distribution, leading to reduced performance in compositions such as H30-FF, H60-FF, and T25-FF.

- S13H60-SL demonstrated exceptional toughness, ductility, and energy absorption capacity. The combination of short and long steel fibers resolved the fiber distribution issue and showed multiple micro-cracking behavior with the highest compressive and tensile strengths among all the samples.

- ECCs with PVA fibers exhibited exceptional ductility and multiple micro-cracking behavior, although only the hybrid S13H60-SL composition among the steel fiber ECCs achieved a similar ductility and micro-cracking behavior, making it the most effective steel fiber-reinforced ECC in this study.

- The findings suggest that carefully designed hybrid steel fiber ECCs can outperform traditional ECCs with PVA fibers, providing a more cost-effective and resilient material option for the construction industry.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- De Larrard, F.; Sedran, T. Optimization of ultra-high-performance concrete by the use of a packing model. Cem. Concr. Res. 1994, 24, 997–1009. [Google Scholar] [CrossRef]

- Li, V.C.; Leung, C.K. Steady-state and multiple cracking of short random fiber composites. J. Eng. Mech. 1992, 118, 2246–2264. [Google Scholar] [CrossRef]

- Weinberg, K.; Khosravani, M.R. On the tensile resistance of UHPC at impact. Eur. Phys. J. Spec. Top. 2018, 227, 167–177. [Google Scholar] [CrossRef]

- Li, V.C. Engineered cementitious composites (ECC)-tailored composites through micromechanical modeling. In Fiber Reinforced Concrete: Present and the Future; Canadian Society for Civil Engineering: Montreal, QC, Canada, 1998. [Google Scholar]

- Li, V.C. Advances in ECC research. ACI Spec. Publ. 2002, 206, 373–400. [Google Scholar]

- Li, V.C. On engineered cementitious composites (ECC) a review of the material and its applications. J. Adv. Concr. Technol. 2003, 1, 215–230. [Google Scholar] [CrossRef]

- Li, V.C. Engineered Cementitious Composites (ECC)—Material, Structural, and Durability Performance; University of Michigan: Ann Arbor, MI, USA, 2011. [Google Scholar]

- Mechtcherine, V.; Millon, O.; Butler, M.; Thoma, K. Mechanical behaviour of strain hardening cement-based composites under impact loading. Cem. Concr. Compos. 2011, 33, 1–11. [Google Scholar] [CrossRef]

- Maalej, M.; Quek, S.T.; Ahmed, S.F.U.; Zhang, J.; Lin, V.W.J.; Leong, K.S. Review of potential structural applications of hybrid fiber Engineered Cementitious Composites. Constr. Build. Mater. 2012, 36, 216–227. [Google Scholar] [CrossRef]

- Siad, H.; Lachemi, M.; Sahmaran, M.; Mesbah, H.A.; Hossain, K.A. Advanced engineered cementitious composites with combined self-sensing and self-healing functionalities. Constr. Build. Mater. 2018, 176, 313–322. [Google Scholar] [CrossRef]

- Hooshmand, A.; Kianoush, R.; Siad, H.; Lachemi, M.; Booya, E.; Moslemi, M. Volumetric strain behaviour and self-healing of large scale engineered cementitious composite and normal concrete panels under natural conditions. Constr. Build. Mater. 2021, 308, 125078. [Google Scholar] [CrossRef]

- Li, V.C.; Wang, S.; Wu, C. Tensile strain-hardening behavior of polyvinyl alcohol engineered cementitious composite (PVA-ECC). Mater. J. 2001, 98, 483–492. [Google Scholar]

- Yu, J.; Yao, J.; Lin, X.; Li, H.; Lam, J.Y.; Leung, C.K.; Sham, I.M.; Shih, K. Tensile performance of sustainable Strain-Hardening Cementitious Composites with hybrid PVA and recycled PET fibers. Cem. Concr. Res. 2018, 107, 110–123. [Google Scholar] [CrossRef]

- Liu, D.; Yu, J.; Qin, F.; Zhang, K.; Zhang, Z. Mechanical performance of high-strength engineering cementitious composites (ECC) with hybriding PE and steel fibers. Case Stud. Constr. Mater. 2023, 18, e01961. [Google Scholar] [CrossRef]

- Abd Elmoaty, A.E.M.; Morsy, A.M.; Harraz, A.B. Effect of Fiber Type and Volume Fraction on Fiber Reinforced Concrete and Engineered Cementitious Composite Mechanical Properties. Buildings 2022, 12, 2108. [Google Scholar] [CrossRef]

- Pan, Z.; Wu, C.; Liu, J.; Wang, W.; Liu, J. Study on mechanical properties of cost-effective polyvinyl alcohol engineered cementitious composites (PVA-ECC). Constr. Build. Mater. 2015, 78, 397–404. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, F.; Yu, J.; Dong, F.; Ye, J. Effect of polyethylene fiber content on physical and mechanical properties of engineered cementitious composites. Constr. Build. Mater. 2020, 251, 118917. [Google Scholar] [CrossRef]

- Sasmal, S.; Avinash, G. Investigations on mechanical performance of cementitious composites micro-engineered with poly vinyl alcohol fibers. Constr. Build. Mater. 2016, 128, 136–147. [Google Scholar] [CrossRef]

- Said, S.H.; Razak, H.A.; Othman, I. Flexural behavior of engineered cementitious composite (ECC) slabs with polyvinyl alcohol fibers. Constr. Build. Mater. 2015, 75, 176–188. [Google Scholar] [CrossRef]

- Holschemacher, K.; Mueller, T.; Ribakov, Y. Effect of steel fibres on mechanical properties of high-strength concrete. Mater. Des. 2010, 31, 2604–2615. [Google Scholar] [CrossRef]

- Kim, D.J.; Park, S.H.; Ryu, G.S.; Koh, K.T. Comparative flexural behavior of hybrid ultra high-performance fiber reinforced concrete with different macro fibers. Constr. Build. Mater. 2011, 25, 4144–4155. [Google Scholar] [CrossRef]

- ASTM C150/C150M-19a; Standard Specification for Portland Cement. ASTM International: West Conehohocken, PA, USA, 2019.

- Zokaei, S.; Siad, H.; Lachemi, M.; Mahmoodi, O.; Şahmaran, M. Self-healing capability of engineered cementitious composites with calcium aluminate cement. Constr. Build. Mater. 2023, 403, 133051. [Google Scholar] [CrossRef]

- Ahmadi, A.; Kianoush, M.R.; Moslemi, M.; Lachemi, M.; Siad, H.; Booya, E. Investigation on repair of tension cracks in reinforced concrete panels. Eng. Struct. 2021, 245, 112974. [Google Scholar] [CrossRef]

- Hooshmand, A.; Kianoush, R.; Siad, H.; Lachemi, M.; Moslemi, M. Investigation of leakage and self-healing of direct tension cracks under sustained loading and high-water pressure. Constr. Build. Mater. 2021, 267, 120879. [Google Scholar] [CrossRef]

- ASTM C39/C39M-14; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM C78/C78M-16; Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading). ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM C496/C496M-17; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2017.

- Li, G.; Zhao, X. Properties of concrete incorporating fly ash and ground granulated blast-furnace slag. Cem. Concr. Compos. 2003, 25, 293–299. [Google Scholar] [CrossRef]

- Shumuye, E.D.; Liu, J.; Li, W.; Wang, Z. Eco-friendly, high-ductility slag/fly-ash-based engineered cementitious composite (ECC) reinforced with PE fibers. Polymers 2022, 14, 1760. [Google Scholar] [CrossRef]

- Bentz, D.P. Modeling the influence of limestone filler on cement hydration using CEMHYD3D. Cem. Concr. Compos. 2006, 28, 124–129. [Google Scholar] [CrossRef]

- Bonavetti, V.; Donza, H.; Menendez, G.; Cabrera, O.; Irassar, E.F. Limestone filler cement in low w/c concrete: A rational use of energy. Cem. Concr. Res. 2003, 33, 865–871. [Google Scholar] [CrossRef]

- Ouyang, X.; Koleva, D.A.; Ye, G.; Van Breugel, K. Insights into the mechanisms of nucleation and growth of C–S–H on fillers. Mater. Struct. 2017, 50, 213. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Kang, S.T.; Yoon, Y.S. Effect of fiber length and placement method on flexural behavior, tension-softening curve, and fiber distribution characteristics of UHPFRC. Constr. Build. Mater. 2014, 64, 67–81. [Google Scholar] [CrossRef]

- Prathipati, S.T.; Koniki, S.; Rao, C.B.K.; Kasagani, H. Assessment of fiber distribution characteristics in the hybrid fiber reinforced concrete—An experimental study. Mater. Today Proc. 2021, 38, 2541–2548. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Kim, S. Comparative pullout behavior of half-hooked and commercial steel fibers embedded in UHPC under static and impact loads. Cem. Concr. Compos. 2019, 97, 89–106. [Google Scholar] [CrossRef]

- Baloch, W.L.; Siad, H.; Lachemi, M.; Sahmaran, M. The role of supplementary cementitious materials and fiber reinforcements in enhancing the sulfate attack resistance of SCC/ECC composite systems. Constr. Build. Mater. 2024, 423, 135821. [Google Scholar] [CrossRef]

- Booya, E.; Gorospe, K.; Das, S.; Loh, P. The influence of utilizing slag in lieu of fly ash on the performance of engineered cementitious composites. Constr. Build. Mater. 2020, 256, 119412. [Google Scholar] [CrossRef]

- Turk, K.; Nehdi, M.L. Flexural toughness of sustainable ECC with high-volume substitution of cement and silica sand. Constr. Build. Mater. 2021, 270, 121438. [Google Scholar] [CrossRef]

- Shabakhty, N.; Karimi, H.R.; Bakhtiary, A.Y. Effect of short to long hybrid elastic/hyperelastic (Glass/PP) fibers on high-strength engineered cementitious composites (ECC), along with presenting a constitutive model. J. Build. Eng. 2024, 89, 109215. [Google Scholar] [CrossRef]

- Ding, C.; Guo, L.; Chen, B. Orientation distribution of polyvinyl alcohol fibers and its influence on bridging capacity and mechanical performances for high ductility cementitious composites. Constr. Build. Mater. 2020, 247, 118491. [Google Scholar] [CrossRef]

- Sarmiento, E.V.; Geiker, M.R.; Kanstad, T. Influence of fibre distribution and orientation on the flexural behaviour of beams cast from flowable hybrid polymer–steel FRC. Constr. Build. Mater. 2016, 109, 166–176. [Google Scholar] [CrossRef]

- Hooshmand, A.; Kianoush, R.; Lachemi, M.; Siad, H.; Moslemi, M. Combined effect of pressurized water and sustained load on self-healing of engineered cementitious composite panels. J. Mater. Civ. Eng. 2022, 34, 04021462. [Google Scholar] [CrossRef]

- Baloch, W.L.; Siad, H.; Lachemi, M.; Şahmaran, M. Impact of SCMs and fibres in ECC on the fire resistance of hot-jointed SCC/ECC composites. Mag. Concr. Res. 2023, 76, 330–349. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Shin, W.; Chun, B.; Banthia, N. Assessment of steel fiber corrosion in self-healed ultra-high-performance fiber-reinforced concrete and its effect on tensile performance. Cem. Concr. Res. 2020, 133, 106091. [Google Scholar] [CrossRef]

- Lee, H.J.; Yang, K.H. Compressive and flexural toughness indices of lightweight aggregate concrete reinforced with micro-steel fibers. Constr. Build. Mater. 2023, 401, 132965. [Google Scholar] [CrossRef]

- Qi, J.; Wu, Z.; Ma, Z.J.; Wang, J. Pullout behavior of straight and hooked-end steel fibers in UHPC matrix with various embedded angles. Constr. Build. Mater. 2018, 191, 764–774. [Google Scholar] [CrossRef]

- Liu, W.; Han, J. Fiber Synergy of Polyvinyl Alcohol and Steel Fibers on the Bond Behavior of a Hybrid Fiber-Reinforced Cementitious Composite. Materials 2024, 17, 629. [Google Scholar] [CrossRef] [PubMed]

- Bheel, N.; Mohammed, B.S.; Ali, M.O.A.; Shafiq, N.; Tag-eldin, E.M.; Ahmad, M. Effect of polyvinyl alcohol fiber on the mechanical properties and embodied carbon of engineered cementitious composites. Results Eng. 2023, 20, 101458. [Google Scholar] [CrossRef]

- Feng, H.; Guo, A.; Zhao, J. Ultra-High Ductility Magnesium-Phosphate-Cement-Based Composites (UHDMC); Springer: Singapore, 2024. [Google Scholar]

- Zokaei, S.; Siad, H.; Lachemi, M.; Mahmoodi, O.; Ozcelikci, E.; Şahmaran, M. Engineered cementitious composites with super-sulfated cement: Mechanical, physical, and durability performance. Materials 2024, 17, 2240. [Google Scholar] [CrossRef] [PubMed]

- Shi, J.; Han, J.; Xu, J. Effect of fiber constituent in matrix on cyclic behavior of PVA-Steel hybrid Fiber-Reinforced cementitious composites columns with mild steel rebar. Constr. Build. Mater. 2022, 359, 129514. [Google Scholar] [CrossRef]

- Venkateswarlu, M.; Gunneswara Rao, T.D. Effect of steel and PVA fibres as monofibres on strength and cracking properties of fly ash and slag-based alkali-activated concrete. J. Eng. Appl. Sci. 2023, 70, 100. [Google Scholar] [CrossRef]

- Liu, L.; Wan, S.; Yan, C.; Zheng, X.; Zhao, J.; Dong, X.; Gong, Y.; Liu, J.; Li, J.; Song, Z.; et al. Flexural behavior of ECC reinforced RC beams under secondary load: Experimental, numerical simulation and theoretical analysis. Case Stud. Constr. Mater. 2024, 20, e03340. [Google Scholar] [CrossRef]

- Li, L.; Li, B.; Wang, Z.; Zhang, Z.; Alselwi, O. Effects of hybrid PVA–steel fibers on the mechanical performance of high-ductility cementitious composites. Buildings 2022, 12, 1934. [Google Scholar] [CrossRef]

- Chen, Z.; Fan, H.; Zheng, W.; Zhang, S.; Wu, X.; Fu, T.; Yu, D. Influence of Modified PVA Fiber on Ultra-High-Performance Concrete and Its Enhancing Mechanism. Polymers 2024, 16, 3449. [Google Scholar] [CrossRef]

- da Silva Neto, J.T.; Ribeiro Soares Junior, P.R.; Reis, E.D.; de Souza Maciel, P.; Gomes, P.C.C.; Gouveia, A.M.C.; da Silva Bezerra, A.C. Fiber-reinforced cementitious composites: Recent advances and future perspectives on key properties for high-performance design. Discov. Civ. Eng. 2025, 2, 65. [Google Scholar] [CrossRef]

| Chemical Composition (%) | PC | FF | SL |

|---|---|---|---|

| SiO2 | 19.5 | 57 | 36.8 |

| Al2O3 | 5.1 | 21 | 8.72 |

| Fe2O3 | 2.95 | 4.2 | 0.55 |

| MnO | - | 0.02 | 0.33 |

| MgO | 2.5 | 1.8 | 11 |

| CaO | 61.8 | 9.8 | 38.1 |

| Na2O | 0.3 | 2.2 | 0.21 |

| K2O | 1.11 | 1.5 | 0.31 |

| TiO2 | - | 1.05 | 0.37 |

| SiO2 + Al2O3 + Fe2O3 | 27.5 | 82.2 | 46 |

| Loss on ignition (LOI) | 2.5 | 1.74 | 1.1 |

| Specific gravity (g/cm3) | 3.1 | 2.25 | 3.1 |

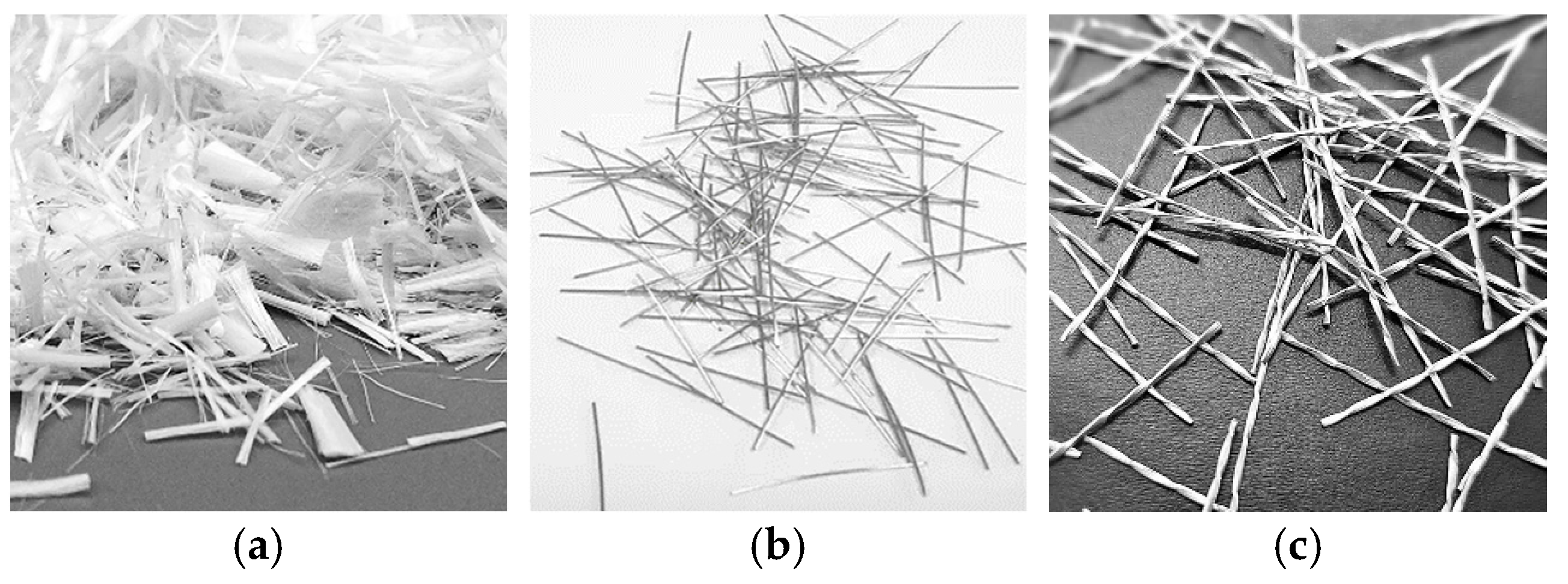

| Type of Fiber | Shape | Length (mm) | Diameter (mm) | Aspect Ratio | Tensile Strength (MPa) |

|---|---|---|---|---|---|

| PVA | straight | 8 | 0.038 | 210 | 1600 |

| S13 | straight | 13 | 0.2 | 65 | 1900 |

| T25 | twisted | 25 | 0.25 | 100 | 1700 |

| H30 | hooked | 30 | 0.38 | 80 | 3070 |

| H60 | hooked | 60 | 0.75 | 80 | 2200 |

| Composition Notation | Fiber | Cement | Silica Sand | Water | Slag | Fly Ash | Fiber (Vol. Fraction) |

|---|---|---|---|---|---|---|---|

| PVA_SL | PVA | 1 | 0.8 | 0.58 | 1.2 | - | 0.02 |

| PVA_FF | PVA | 1 | 0.8 | 0.58 | - | 1.2 | 0.02 |

| S13_SL | 13 mm straight | 1 | 0.8 | 0.58 | 1.2 | - | 0.02 |

| S13_FF | 13 mm straight | 1 | 0.8 | 0.58 | - | 1.2 | 0.02 |

| T25_FF | 25 mm Twisted | 1 | 0.8 | 0.58 | - | 1.2 | 0.02 |

| H30_FF | 30 mm hooked | 1 | 0.8 | 0.58 | - | 1.2 | 0.02 |

| H60_FF | 60 mm hooked | 1 | 0.8 | 0.58 | - | 1.2 | 0.02 |

| S13H30_SL | 13 mm straight 30 mm hooked | 1 | 0.8 | 0.58 | 1.2 | - | 0.02 |

| S13H60_SL | 13 mm straight 60 mm hooked | 1 | 0.8 | 0.58 | 1.2 | - | 0.02 |

| fLOP (MPa) | δLOP (mm) | fMOR (MPa) | δMOR (mm) | Ei (kN/mm) | |

|---|---|---|---|---|---|

| PVA-SL | 6.7 | 0.85 | 12.4 | 2.6 | 9.1 |

| PVA-FF | 4.7 | 0.33 | 11.5 | 6.9 | 10.9 |

| S13-SL | 8.9 | 0.74 | 14.6 | 2.9 | 9.0 |

| S13-FF | 8.0 | 0.75 | 13.2 | 1.8 | 9.1 |

| T25-FF | 3.0 | 0.34 | 7.3 | 2.0 | 5.6 |

| H30-FF | 7.3 | 0.56 | 15.4 | 3.5 | 11.3 |

| H60-FF | 3.1 | 0.35 | 19.8 | 4.0 | 4.9 |

| S13H30-SL | 6.0 | 0.66 | 11.2 | 2.6 | 6.8 |

| S13H60-SL | 3.5 | 0.40 | 18.3 | 5.9 | 5.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maldar, M.; Kianoush, R.; Siad, H.; Lachemi, M. An Experimental Investigation on the Mechanical Performance of Engineered Cementitious Composites with Different Types of Steel Fibers. Materials 2025, 18, 2990. https://doi.org/10.3390/ma18132990

Maldar M, Kianoush R, Siad H, Lachemi M. An Experimental Investigation on the Mechanical Performance of Engineered Cementitious Composites with Different Types of Steel Fibers. Materials. 2025; 18(13):2990. https://doi.org/10.3390/ma18132990

Chicago/Turabian StyleMaldar, Mohammad, Reza Kianoush, Hocine Siad, and Mohamed Lachemi. 2025. "An Experimental Investigation on the Mechanical Performance of Engineered Cementitious Composites with Different Types of Steel Fibers" Materials 18, no. 13: 2990. https://doi.org/10.3390/ma18132990

APA StyleMaldar, M., Kianoush, R., Siad, H., & Lachemi, M. (2025). An Experimental Investigation on the Mechanical Performance of Engineered Cementitious Composites with Different Types of Steel Fibers. Materials, 18(13), 2990. https://doi.org/10.3390/ma18132990