Non-Destructive Integrity Assessment of Austenitic Stainless-Steel Membranes via Magnetic Property Measurements

Abstract

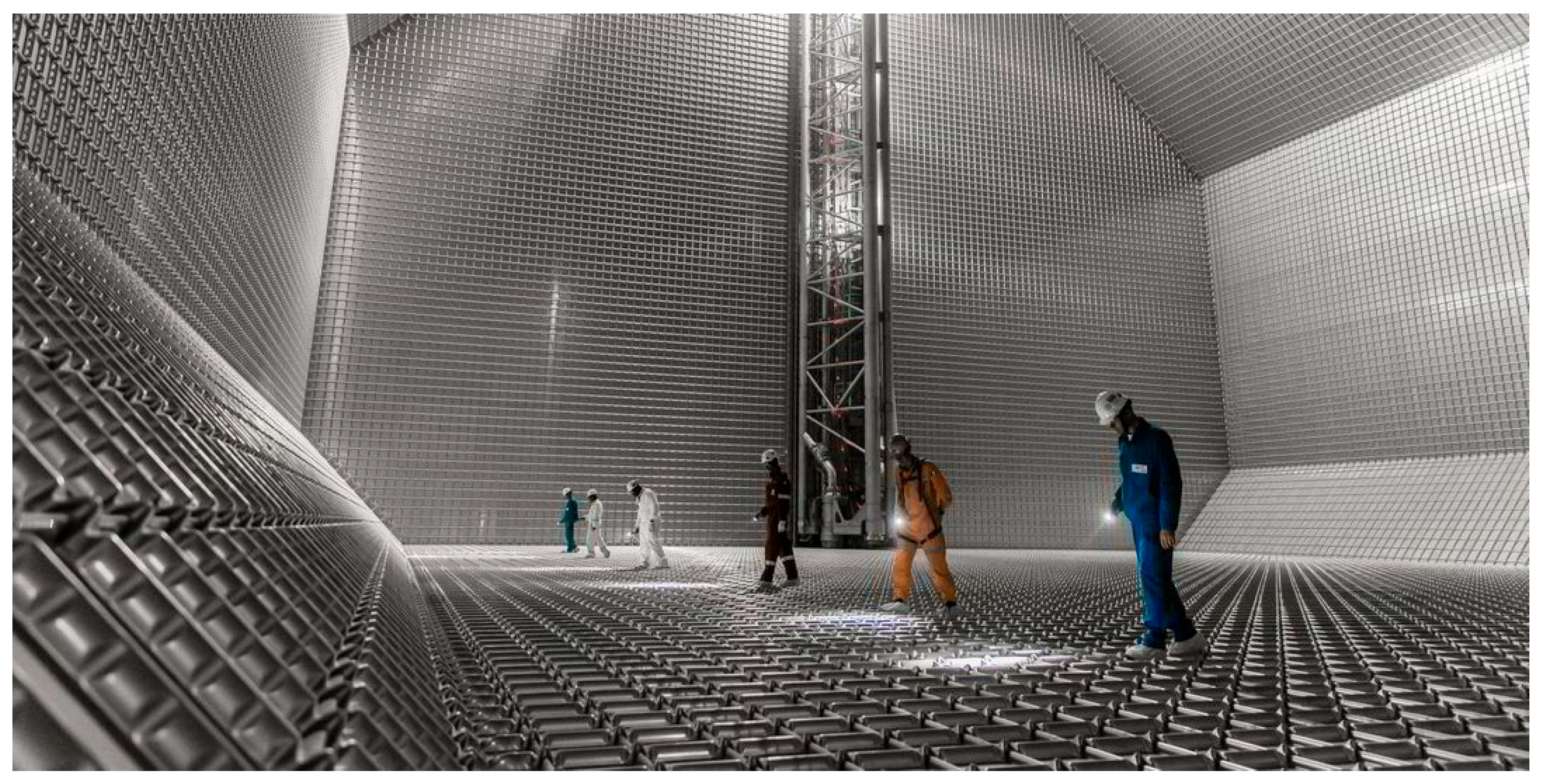

1. Introduction

| Material | SIMT Kinetics | References |

|---|---|---|

| SUS 304 | Biaxial tension > uniaxial tension | [21,22] |

| SUS 301LN | Biaxial tension ≈ uniaxial tension | [23] |

| Biaxial tension < uniaxial tension | [24] | |

| SUS 201 | Biaxial tension < uniaxial tension | [25] |

2. Materials and Methods

2.1. Material

2.2. Mechanical Test

2.2.1. Uniaxial Tensile Test

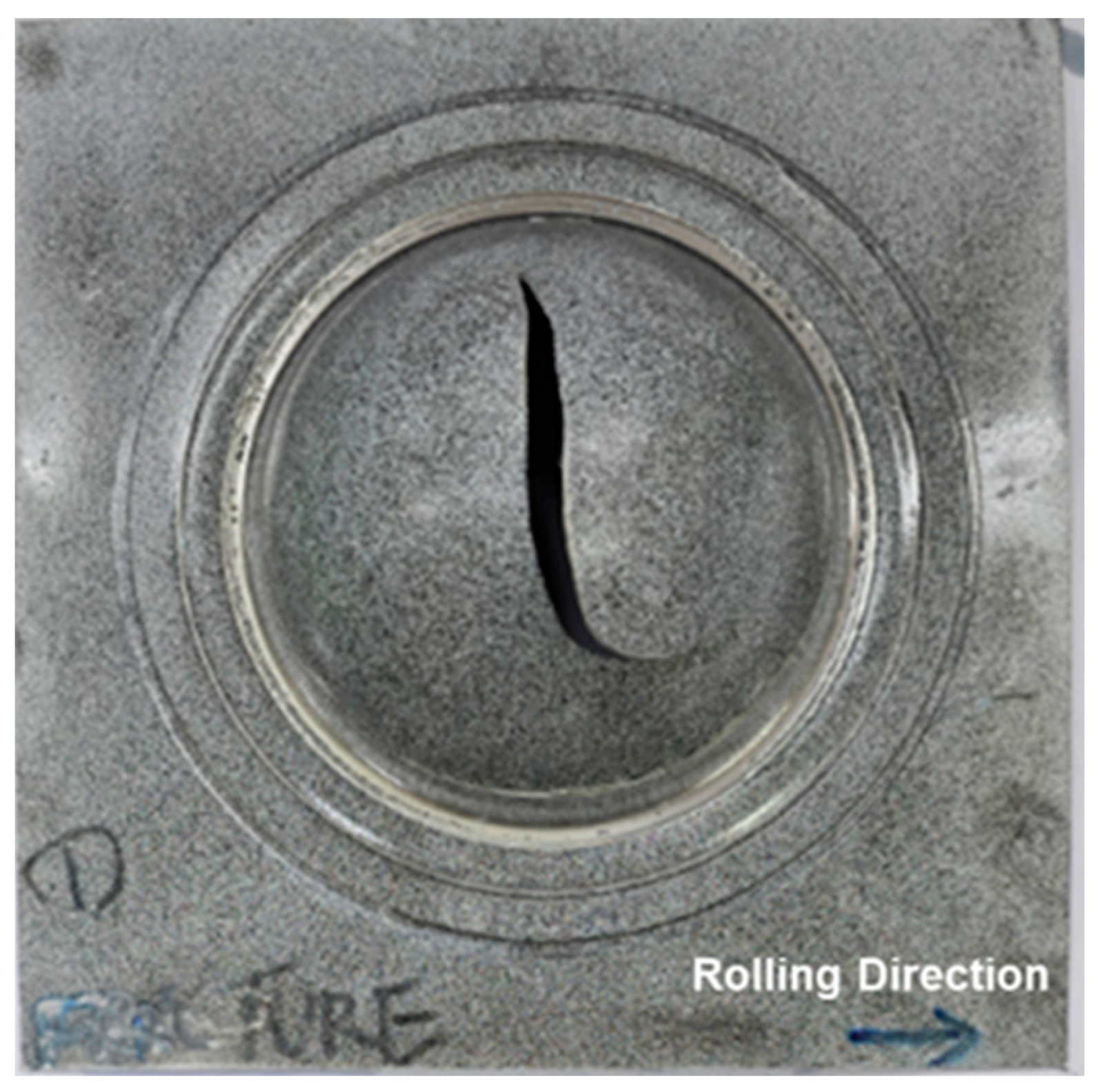

2.2.2. Hydraulic Bulge Test

2.3. Microstructural Analysis

2.3.1. Magnetic Permeability Measurement

2.3.2. X-Ray Diffraction Measurement

2.3.3. EBSD Measurement

3. Results

3.1. Mechanical Property

3.2. Quantitative Measurement of X-Ray Diffraction

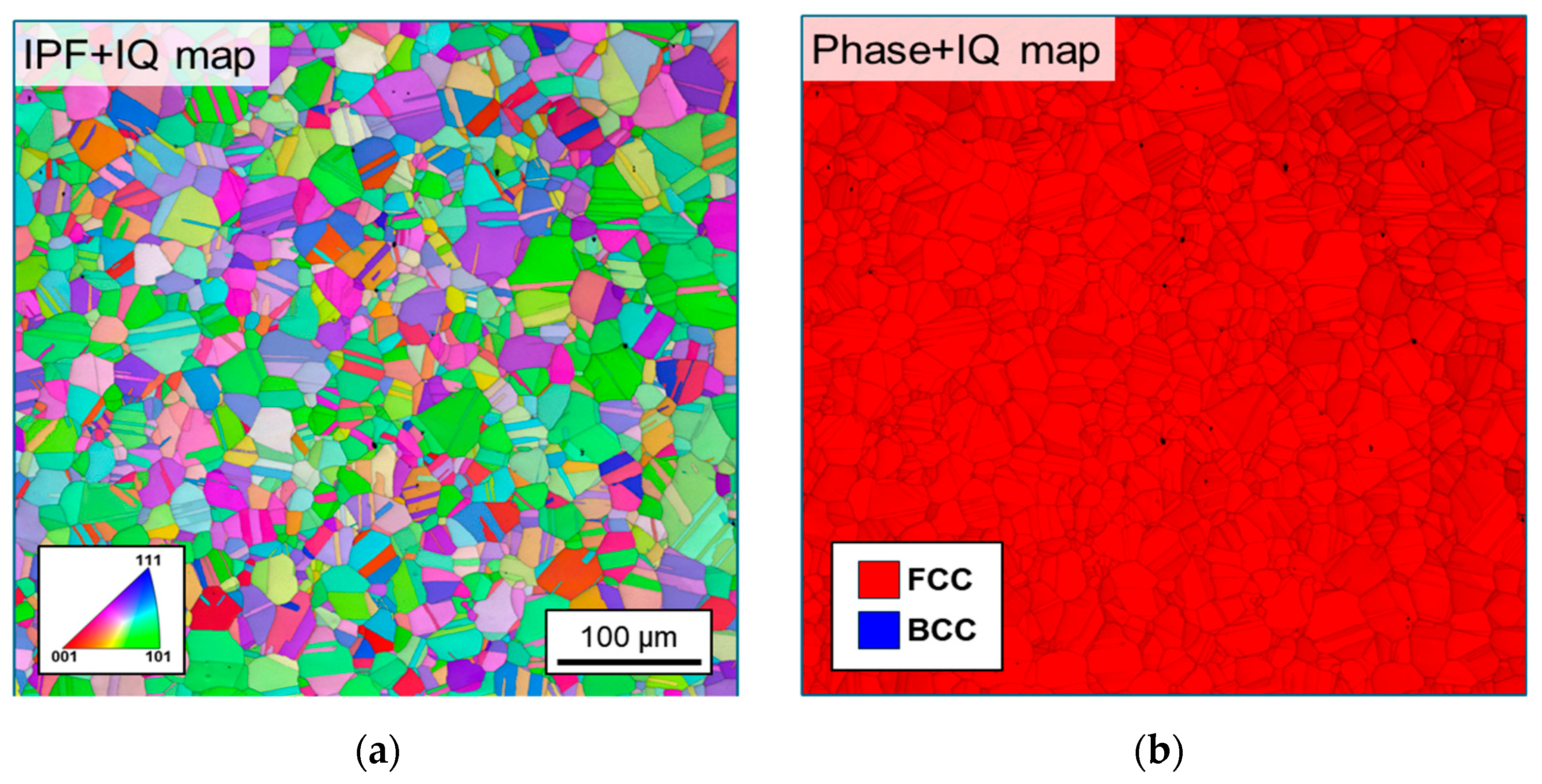

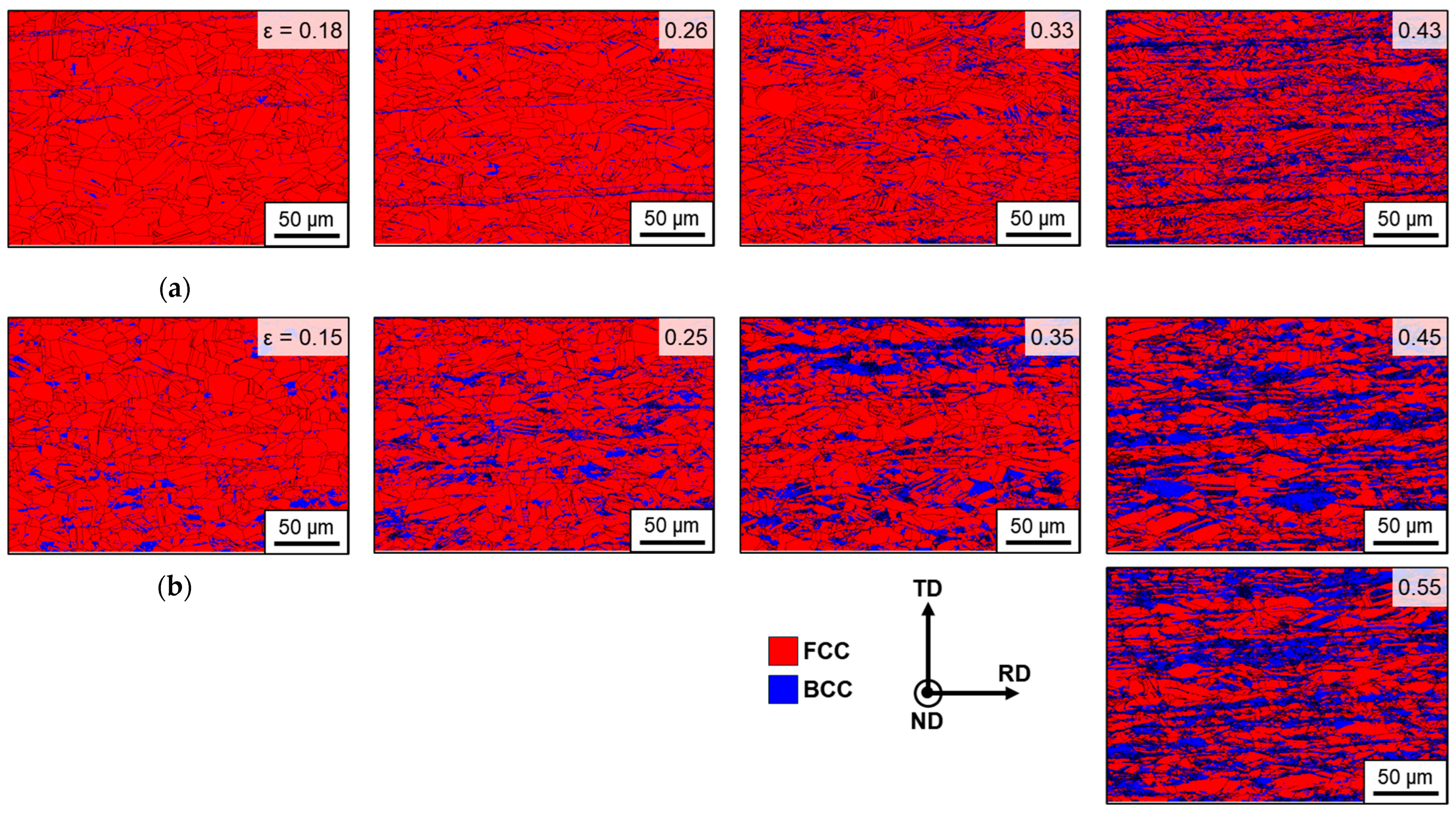

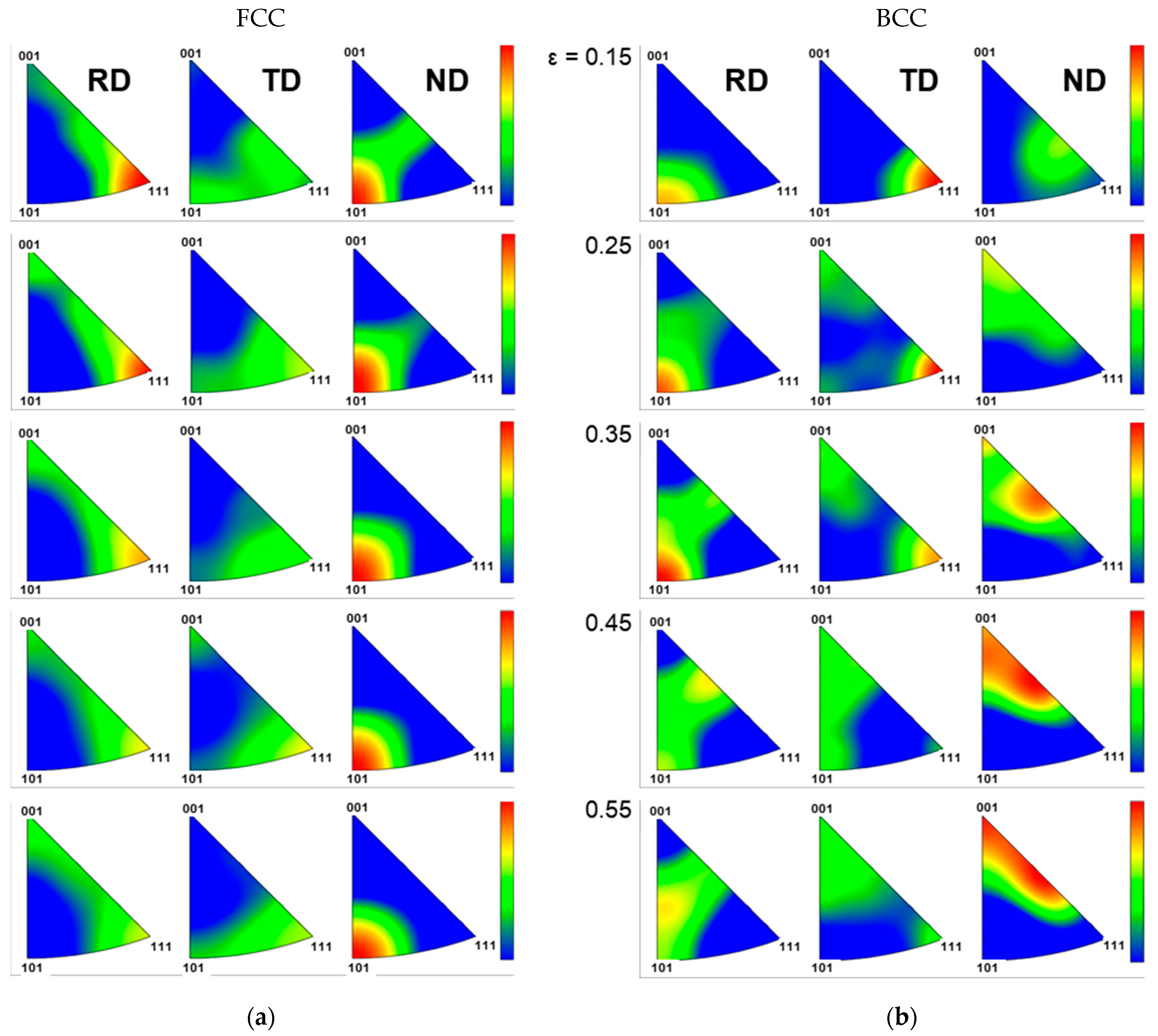

3.3. Quantitative Measurement of EBSD

3.4. Quantitative Measurement of Feritscope

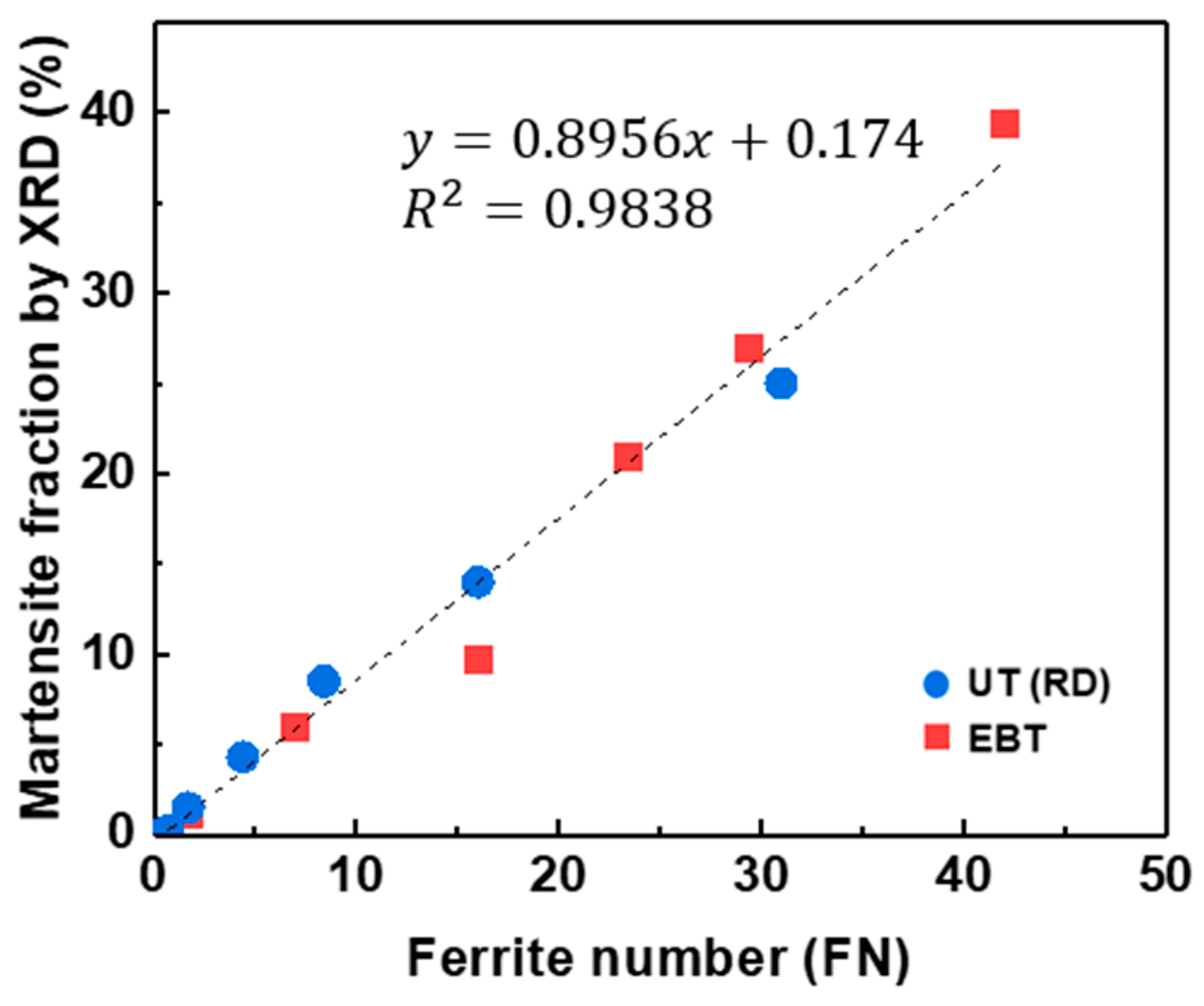

3.5. XRD-Based Calibration of the Feritscope

- Case 1: Cold rolled material, Cr Kα radiation:

- Case 2: Cold rolled material, Co Kα radiation:

- Case 3: Tensile strained material, Cr Kα radiation:

4. Discussion

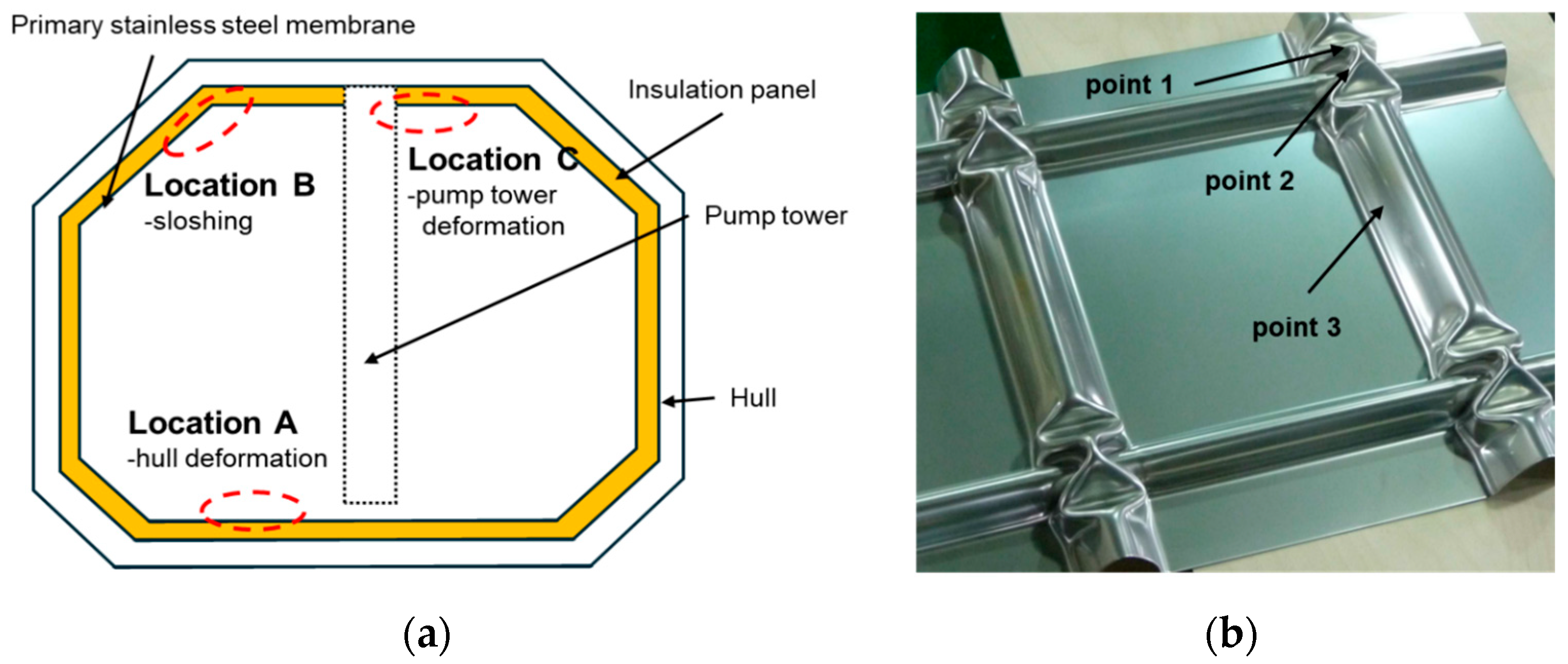

4.1. Proposal of Inspection Methodology Based on Magnetic Permeability

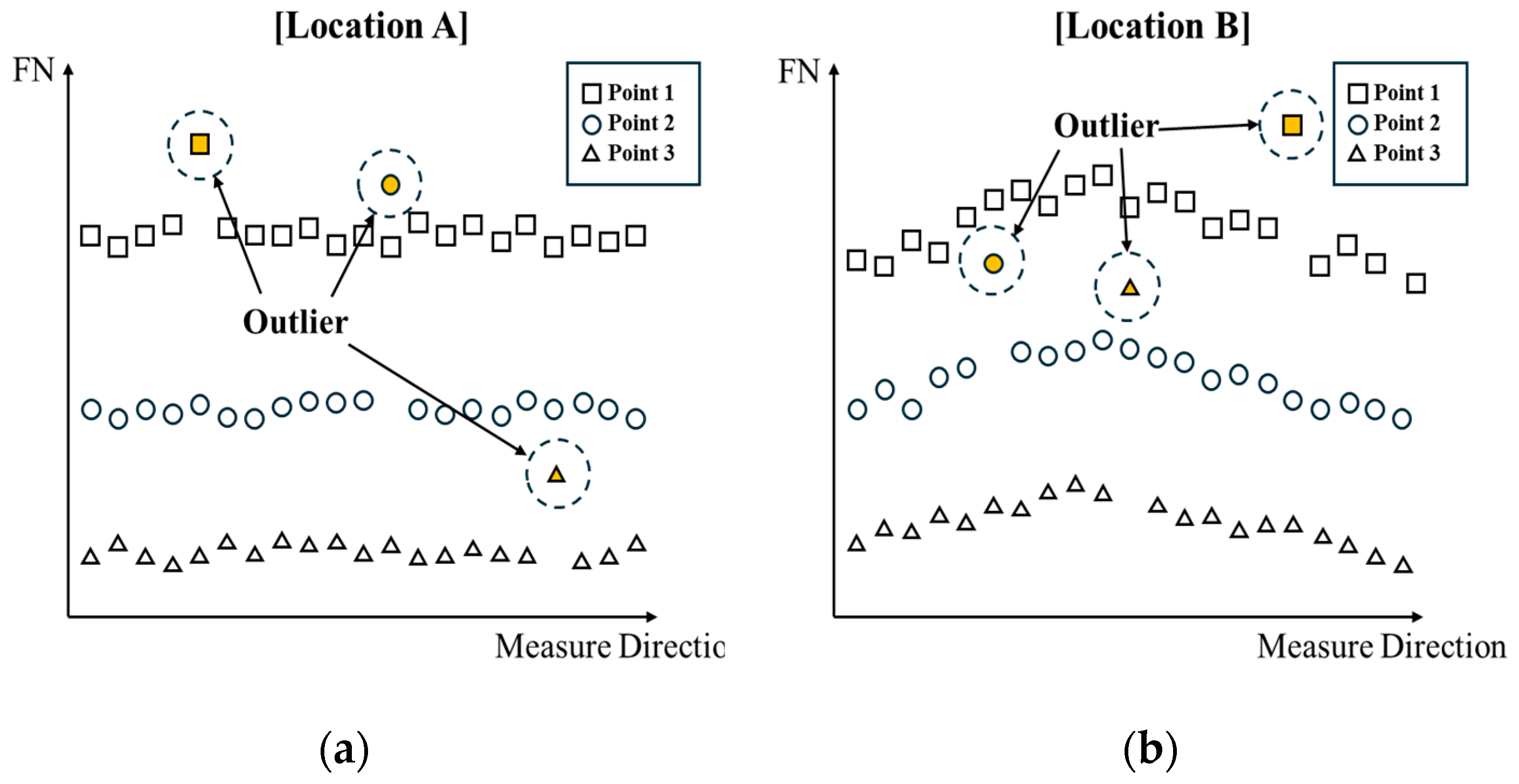

- Outlier detection: This method identifies regions exhibiting abnormally high FN values by conducting a relative comparison within periodic structural patterns subjected to similar loading conditions.

- Quantitative damaged area analysis: This approach quantitatively assesses the extent of damage in a suspected area by comparing its FN values with those of the surrounding regions, thereby aiding in determining the optimal repair scope.

- Time-series analysis: By performing regular Feritscope measurements, this method monitors cumulative damage progression over time, enabling predictive assessments of the structure’s remaining service life.

4.1.1. Outlier Detection

4.1.2. Quantitative Damaged Area Analysis

4.1.3. Time-Series Analysis

- Rate of FN increase: This parameter quantifies the increase in FN between consecutive inspection cycles and is categorized into three levels: Low, Mid, and High. It serves as an indicator of the current damage progression rate relative to previous inspection results. Initially, a relative criterion (e.g., percentage increase compared to the previous inspection) can be applied, and as data accumulates, more precise and quantitative threshold values (e.g., a specific FN increase) can be established.

- Temporal pattern of FN increase: This parameter classifies FN variation trends over multiple inspection cycles into three categories: stabilization, linear increase, and accelerated increase. It serves as an indicator of cumulative damage progression over time, capturing not only the instantaneous rate of FN increase but also the long-term trend, thereby enabling a more comprehensive assessment of the structural risk level.

5. Conclusions

- Outlier Detection: This approach leverages the repetitive structural features of the membrane and uses statistical methods to identify regions with abnormally high FN values, thus enabling early detection of potential defect locations.

- Quantitative Damaged Area Analysis: This involves detailed FN measurements around a suspected defect area to quantitatively assess the extent of damage and guide repair scope decisions.

- Time-Series Analysis: This entails periodic FN measurements to track the cumulative damage progression over time, predict the remaining useful life, and inform risk-based maintenance strategies.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

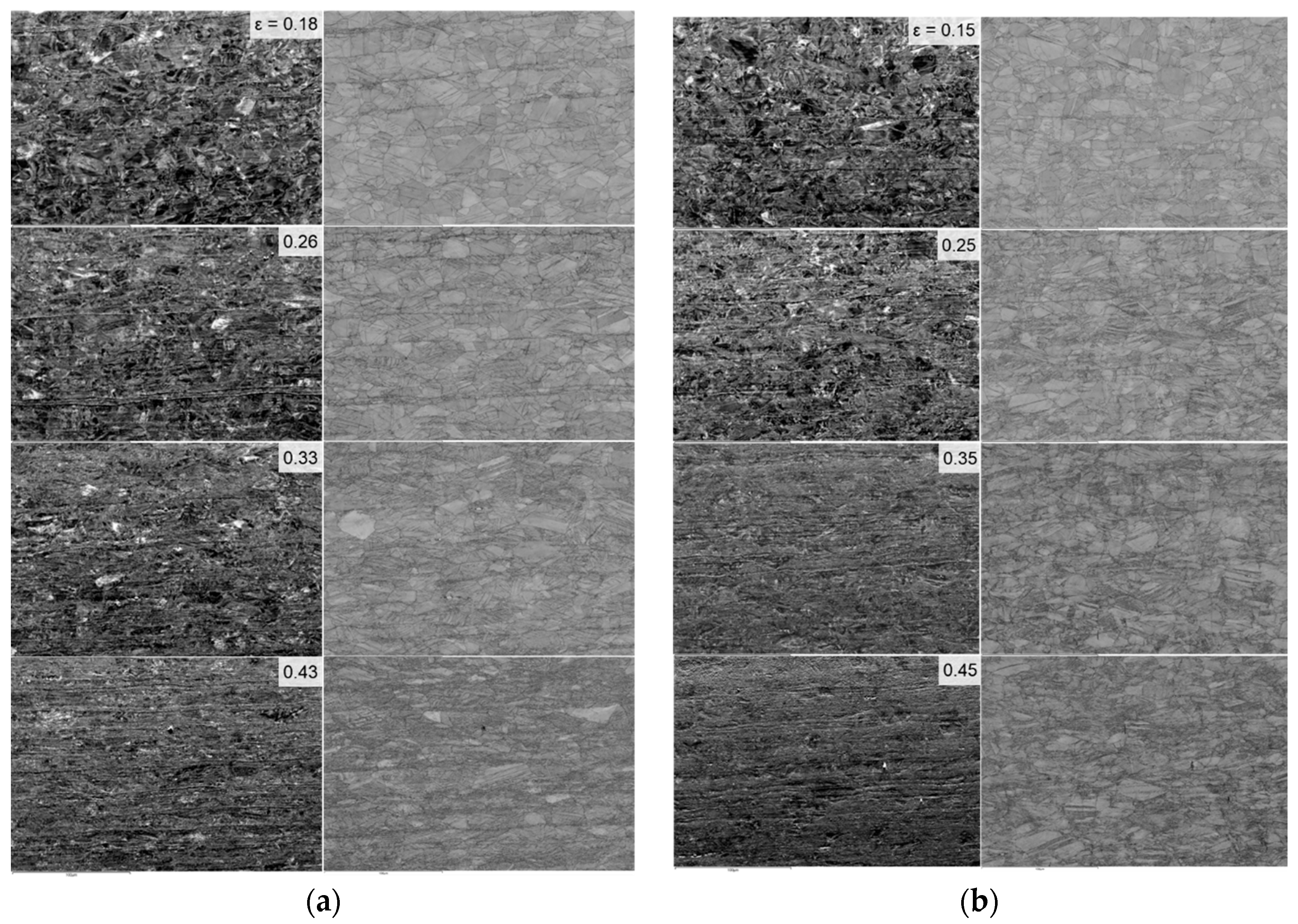

Appendix A.1. Detailed EBSD Analysis: Grain Morphology and Refinement

References

- Oh, D.J.; Kim, N.K.; Song, S.W.; Kim, Y.D.; Kim, M.H. Investigation of Fatigue Performance for New Membrane-Type LNG CCS at Cryogenic Temperature. Mar. Struct. 2018, 62, 90–105. [Google Scholar] [CrossRef]

- Kim, B.C.; Yoon, S.H.; Lee, D.G. Pressure Resistance of the Corrugated Stainless Steel Membranes of LNG Carriers. Ocean Eng. 2011, 38, 592–608. [Google Scholar] [CrossRef]

- Bos, R.W.; Van Der Eijk, M.; Den Besten, J.H.; Wellens, P.R. A Reduced Order Model for FSI of Tank Walls Subject To Wave Impacts During Sloshing. Int. Shipbuild. Prog. 2022, 69, 119–138. [Google Scholar] [CrossRef]

- Thome, M.; el Moctar, O.; Schellin, T.E. Hydroelastic Effects on Hydrodynamic Loads on an LNG Pump Tower Structure. Ocean Eng. 2024, 307, 118224. [Google Scholar] [CrossRef]

- Korean Register. Guidance for Strength Assessment of Membrane-Type LNG Tanks Under Sloshing Loads; Korean Register of Shipping: Busan, Republic of Korea, 2022. [Google Scholar]

- Lin, B.; Dong, X. Ship Hull Inspection: A Survey. Ocean Eng. 2023, 289, 116281. [Google Scholar] [CrossRef]

- Tu, W.; Zhong, S.; Shen, Y.; Incecik, A. Nondestructive Testing of Marine Protective Coatings Using Terahertz Waves with Stationary Wavelet Transform. Ocean Eng. 2016, 111, 582–592. [Google Scholar] [CrossRef]

- Veruz, E.G.; Silva, A.J.; Michalski, M.A.d.C.; da Silva, R.F.; de Souza, G.F.M.; Oshiro, A.T. A Framework for Planning Underwater Hull Inspections Based on Computer Vision and Degradation Assessment. Ocean Eng. 2025, 317, 120053. [Google Scholar] [CrossRef]

- Andersen, R.E.; Boukas, E. Domain Adapted Probabilistic Inspection Using Deep Probabilistic Segmentation. Ocean Eng. 2023, 270, 113568. [Google Scholar] [CrossRef]

- Vázquez, K.; Rodríguez, R.R.; Esteban, M.D. Proposal for a Programme of Periodic Inspections for Preventive Maintenance of Offshore Monopiles. Ocean Eng. 2023, 277, 114262. [Google Scholar] [CrossRef]

- Alizadeh, A.; Daghigh, M.; Bali, M.; Golpour, H.; Kazeminezhad, M.H. A Framework for Implementing Structural Integrity Management of an Aging Fixed Offshore Platform Using Wave Modeling for Risk-Based Underwater Inspection Provision. Ocean Eng. 2024, 309, 118368. [Google Scholar] [CrossRef]

- Jurkovič, M.; Neslušan, M.; Čep, R.; Minárik, P.; Trojan, K.; Čapek, J.; Kalina, T. Magnetic Non-Destructive Monitoring of a Ship’s Propeller Blade after Long-Term Operation. Ocean Eng. 2024, 291, 116470. [Google Scholar] [CrossRef]

- Ryoo, D.Y.; Kang, N.; Kang, C.Y. Effect of Ni Content on the Tensile Properties and Strain-Induced Martensite Transformation for 304 Stainless Steel. Mater. Sci. Eng. A 2011, 528, 2277–2281. [Google Scholar] [CrossRef]

- Sunil, S.; Kapoor, R. Effect of Strain Rate on the Formation of Strain-Induced Martensite in AISI 304L Stainless Steel. Metall. Mater. Trans. A 2020, 51, 5667–5676. [Google Scholar] [CrossRef]

- Egels, G.; Bussmann, M.; Benito, S.; Weber, S. On the Temperature-Dependence of Deformation-Induced Martensite Formation in AISI 304L Type Stefel. Metall. Mater. Trans. A 2023, 54, 4222–4232. [Google Scholar] [CrossRef]

- Kim, H.; Lee, J.; Barlat, F.; Kim, D.; Lee, M.G. Experiment and Modeling to Investigate the Effect of Stress State, Strain and Temperature on Martensitic Phase Transformation in TRIP-Assisted Steel. Acta Mater. 2015, 97, 435–444. [Google Scholar] [CrossRef]

- Beese, A.M.; Mohr, D. Effect of Stress Triaxiality and Lode Angle on the Kinetics of Strain-Induced Austenite-to-Martensite Transformation. Acta Mater. 2011, 59, 2552–2565. [Google Scholar] [CrossRef]

- Sohrabi, M.J.; Naghizadeh, M.; Mirzadeh, H. Deformation-Induced Martensite in Austenitic Stainless Steels: A Review. Arch. Civ. Mech. Eng. 2020, 20, 124. [Google Scholar] [CrossRef]

- Kim, M.S.; Kim, J.H.; Kim, S.K.; Lee, J.M. Experimental Investigation of Structural Response of Corrugated Steel Sheet Subjected to Repeated Impact Loading: Performance of LNG Cargo Containment System. Appl. Sci. 2019, 9, 1558. [Google Scholar] [CrossRef]

- Jeon, S.G.; Kim, J.H.; Kim, J.D.; Jeong, Y.J.; Kim, H.T.; Kim, S.K.; Lee, J.M. Impact Failure Characteristics of LNG Carrier Cargo Containment System. Int. J. Mech. Sci. 2023, 240, 107938. [Google Scholar] [CrossRef]

- Hecker, S.S.; Stout, M.G.; Staudhammer, K.P.; Smith, J.L. Effects of Strain State and Strain Rate on Deformation-Induced Transformation in 304 Stainless Steel: Part I. Magnetic Measurements and Mechanical Behavior. Metall. Trans. A 1982, 13, 619–626. [Google Scholar] [CrossRef]

- Murr, L.E.; Staudhammer, K.P.; Hecker, S.S. Effects of Strain State and Strain Rate on Deformation-Induced Transformation in 304 Stainless Steel: Part II. Microstructural Study. Metall. Trans. A 1982, 13, 627–634. [Google Scholar] [CrossRef]

- Nanga, S.; Pineau, A.; Tanguy, B.; Le Gallo, T. Plasticity and Strain Induced Martensitic Transformation in Two Austenitic Stainless Steels. Procedia Mater. Sci. 2009, 1, 159–162. [Google Scholar] [CrossRef]

- Beese, A.M.; Mohr, D. Identification of the Direction-Dependency of the Martensitic Transformation in Stainless Steel Using In Situ Magnetic Permeability Measurements. Exp. Mech. 2011, 51, 667–676. [Google Scholar] [CrossRef]

- Hsu, W. Deformation-Induced Martensitic Transformation Under Multiaxial Loading. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2019. [Google Scholar]

- ASTM A751-21; Standard Test Methods and Practices for Chemical Analysis of Steel Products. ASTM: West Conshohocken, PA, USA, 2021.

- Costa, D.C.T.; Cardoso, M.C.; Fonseca, G.S.; Moreira, L.P.; Martiny, M.; Mercier, S. Strain-Induced Martensite Formation of AISI 304L Steel Sheet: Experiments and Modeling. Mater. Sci. Forum 2016, 869, 490–496. [Google Scholar] [CrossRef]

- ASTM E8; Standard Test Methods for Tension Testing of Metallic Materials. ASTM: West Conshohocken, PA, USA, 2024.

- Bentley, A.P.; Smith, G.C. Phase Transformation of Austenitic Stainless Steels as a Result of Cathodic Hydrogen Charging. Metall. Trans. A 1986, 17, 1593–1600. [Google Scholar] [CrossRef]

- Olson, G.B.; Cohen, M. Kinetics of Strain-Induced Martensitic Nucleation. Metall. Trans. A 1975, 6, 791–795. [Google Scholar] [CrossRef]

- Dastur, P.; Zarei-Hanzaki, A.; Pishbin, M.H.; Moallemi, M.; Abedi, H.R. Transformation and Twinning Induced Plasticity in an Advanced High Mn Austenitic Steel Processed by Martensite Reversion Treatment. Mater. Sci. Eng. A 2017, 688, 281–292. [Google Scholar] [CrossRef]

- Raghavan, K.; Jefferies, G.T.; Gibson, M.A. A Comparison of Different Measurement Methods to Evaluate Strain-Induced Martensite Formation in a Metastable Austenitic Stainless Steel. Metall. Mater. Trans. A 2014, 45, 4557–4565. [Google Scholar]

- Shirdel, M.; Mirzadeh, H.; Parsa, M.H. Estimation of the Kinetics of Martensitic Transformation in Austenitic Stainless Steels by Conventional and Novel Approaches. Mater. Sci. Eng. A 2015, 624, 256–260. [Google Scholar] [CrossRef]

- Yang, W.; Shen, Y.; Chen, S.; Wang, X.; Shu, D.; Wang, H. Study of the Constitutive Equations of Austenitic Stainless Steels under High Strain Rate Loading Considering Phase Transformation Effects. JOM, 2025; in press. [Google Scholar] [CrossRef]

- Tian, Y.; Xu, J.; Peng, R.L.; Calmunger, M.; Moverare, J.J. Enhanced Fatigue Resistance from Metastable Phase Transformation in Cold Drawn Austenitic Stainless Steel 316L. Mater. Sci. Eng. A 2025, 924, 147848. [Google Scholar] [CrossRef]

- Park, T.M.; Jeong, M.S.; Jung, C.; Choi, W.S.; Choi, P.P.; Han, J. Improved Strength of a Medium-Mn Steel by V Addition without Sacrificing Ductility. Mater. Sci. Eng. A 2021, 804, 140683. [Google Scholar] [CrossRef]

- Daniel, T.; Smaga, M. Cyclic Deformation Behavior of Metastable Austenitic Stainless Steel AISI 347 in the VHCF Regime at Ambient Temperature and 300 °C. Int. J. Fatigue 2022, 160, 106886. [Google Scholar] [CrossRef]

- Zheng, C.; Hu, L.; Zhen, Q.; Tang, Y.; Wang, Y.; Li, N.; Jiang, H. Low Temperature Mechanical Behavior of Fine- and Ultrafine-Grained 304 Austenitic Stainless Steel Fabricated by Cryogenic-Rolling and Annealing. Mater. Charact. 2022, 192, 112196. [Google Scholar] [CrossRef]

- Talonen, J.; Aspegren, P.; Hänninen, H. Comparison of Different Methods for Measuring Strain Induced α′-Martensite Content in Austenitic Steels. Mater. Sci. Technol. 2004, 20, 1506–1512. [Google Scholar] [CrossRef]

- Park, J.; Hou, Y.; Min, J.; Hou, Z.; Han, H.N.; He, B.; Lee, M.G. Understanding Plasticity in Multiphase Quenching & Partitioning Steels: Insights from Crystal Plasticity with Stress State-Dependent Martensitic Transformation. Int. J. Plast. 2024, 180, 104075. [Google Scholar] [CrossRef]

- Huang, C.X.; Yang, G.; Gao, Y.L.; Wu, S.D.; Li, S.X. Investigation on the Nucleation Mechanism of Deformation-Induced Martensite in an Austenitic Stainless Steel under Severe Plastic Deformation. J. Mater. Res. 2007, 22, 724–729. [Google Scholar] [CrossRef]

| Material | Chemical Composition | |||||||

|---|---|---|---|---|---|---|---|---|

| SUS304L | Ni | C | Si | Mn | S | P | Cu | Cr |

| 9.2 | 0.016 | 0.62 | 1.2 | 0.003 | 0.014 | 0.11 | 18.1 | |

| Parameter | Value |

|---|---|

| Drawing force | 80 tonF |

| Blank holding force | 80 tonF |

| Drawing speed | 0.02 mm/s |

| Bulge diameter | 100 mm |

| Specimen thickness | 1.2 mm |

| Strain measurement | ARAMIS DIC system |

| Parameter | Value |

|---|---|

| Acceleration voltage | 20 kV |

| Magnification | ×500 |

| Scan area | 260 × 180 μm2 |

| Step size | 0.2 μm |

| Indexing rate | 99.2% |

| 0.2% Yield Stress (MPa) | Ultimate Tensile Strength (MPa) | Uniform Elongation (%) | Total Elongation (%) | R-Value (ε = 15%) | |

|---|---|---|---|---|---|

| RD | 262 | 641 | 51.3 | 59 | 0.90 |

| DD | 253 | 593 | 57 | 64 | 1.26 |

| TD | 254 | 611 | 58 | 66 | 0.80 |

| True Strain | UT (FCC) | UT (BCC) | EBT (FCC) | EBT (BCC) |

|---|---|---|---|---|

| 0.18/0.15 | 12.2 ± 4.2 | 1.8 ± 0.5 | 10.1 ± 3.5 | 4.5 ± 1.2 |

| 0.26/0.25 | 11.3 ± 3.7 | 2.1 ± 0.6 | 9.2 ± 2.9 | 3.5 ± 0.9 |

| 0.33/0.35 | 10.0 ± 3.1 | 1.9 ± 0.5 | 8.8 ± 2.6 | 4.2 ± 1.1 |

| 0.43/0.45 | 6.8 ± 2.0 | 2.1 ± 0.6 | 7.8 ± 2.1 | 5.0 ± 1.1 |

| 0.55 | - | - | 7.6 ± 1.9 | 3.9 ± 1.0 |

| UT (True Strain %) | 0.18 | 0.26 | 0.33 | 0.43 |

| FCC | 97.1 | 91.7 | 85.4 | 67.6 |

| BCC | 2.2 | 5.5 | 10.9 | 29.4 |

| Zero solution | 0.7 | 2.8 | 3.7 | 3.0 |

| EBT (True Strain %) | 0.15 | 0.25 | 0.35 | 0.45 |

| FCC | 91.1 | 79.7 | 70.4 | 54.8 |

| BCC | 8.1 | 17.4 | 24.9 | 34.4 |

| Zero solution | 0.8 | 2.9 | 4.7 | 10.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Heo, H.S.; Park, J.; You, J.; Rhee, S.H.; Lee, M.-G. Non-Destructive Integrity Assessment of Austenitic Stainless-Steel Membranes via Magnetic Property Measurements. Materials 2025, 18, 2898. https://doi.org/10.3390/ma18122898

Heo HS, Park J, You J, Rhee SH, Lee M-G. Non-Destructive Integrity Assessment of Austenitic Stainless-Steel Membranes via Magnetic Property Measurements. Materials. 2025; 18(12):2898. https://doi.org/10.3390/ma18122898

Chicago/Turabian StyleHeo, Haeng Sung, Jinheung Park, Jehyun You, Shin Hyung Rhee, and Myoung-Gyu Lee. 2025. "Non-Destructive Integrity Assessment of Austenitic Stainless-Steel Membranes via Magnetic Property Measurements" Materials 18, no. 12: 2898. https://doi.org/10.3390/ma18122898

APA StyleHeo, H. S., Park, J., You, J., Rhee, S. H., & Lee, M.-G. (2025). Non-Destructive Integrity Assessment of Austenitic Stainless-Steel Membranes via Magnetic Property Measurements. Materials, 18(12), 2898. https://doi.org/10.3390/ma18122898