Abstract

The rapid progress in additive manufacturing (AM) has unlocked significant possibilities for producing 316/316L stainless steel components, particularly in industries requiring high precision, enhanced mechanical properties, and intricate geometries. However, the widespread adoption of AM—specifically Directed energy deposition (DED), selective laser melting (SLM), and electron beam melting (EBM) remains challenged by inherent process-related defects such as residual stresses, porosity, anisotropy, and surface roughness. This review critically examines these AM techniques, focusing on optimizing key manufacturing parameters, mitigating defects, and implementing effective post-processing treatments. This review highlights how process parameters including laser power, energy density, scanning strategy, layer thickness, build orientation, and preheating conditions directly affect microstructural evolution, mechanical properties, and defect formation in AM-fabricated 316/316L stainless steel. Comparative analysis reveals that SLM excels in achieving refined microstructures and high precision, although it is prone to residual stress accumulation and porosity. DED, on the other hand, offers flexibility for large-scale manufacturing but struggles with surface finish and mechanical property consistency. EBM effectively reduces thermal-induced residual stresses due to its sustained high preheating temperatures (typically maintained between 700 °C and 850 °C throughout the build process) and vacuum environment, but it faces limitations related to resolution, cost-effectiveness, and material applicability. Additionally, this review aligns AM techniques with specific defect reduction strategies, emphasizing the importance of post-processing methods such as heat treatment and hot isostatic pressing (HIP). These approaches enhance structural integrity by refining microstructure, reducing residual stresses, and minimizing porosity. By providing a comprehensive framework that connects AM techniques optimization strategies, this review serves as a valuable resource for academic and industry professionals. It underscores the necessity of process standardization and real-time monitoring to improve the reliability and consistency of AM-produced 316/316L stainless steel components. A targeted approach to these challenges will be crucial in advancing AM technologies to meet the stringent performance requirements of various high-value industrial applications.

1. Introduction

In recent years, significant advancements in stainless steel materials have improved its adaptability for demanding industries such as biomedical, molding, packaging, automotive, and aerospace. Researchers have examined the evolving composition and mechanical behavior of various stainless steel grades—duplex, ferritic, and austenitic—highlighting their effectiveness in diverse environments. Among these, AISI 316/316L, an austenitic stainless steel, stands out for its exceptional corrosion resistance and mechanical properties. Its composition typically includes elements such as carbon, silicon, manganese, chromium, molybdenum, nickel, phosphorus, and nitrogen, making it particularly suitable for high-performance applications in challenging environments [1,2].

Stainless steel, particularly grade 316, plays a critical role in high-precision applications due to its exceptional strength, corrosion resistance, and durability. In high-performance environments, stainless steel tools must not only exhibit superior mechanical properties but also withstand demanding conditions without compromising performance. Manufacturing processes such as injection molding, cutting, drilling, and milling involve high mechanical loads, thermal cycling, and dynamic forces, requiring materials like 316/316L stainless steel that can maintain precise dimensional tolerances and structural integrity under such demanding conditions. The overall quality of stainless steel components is heavily influenced by factors such as surface roughness, porosity, and residual stresses, all of which impact functionality and longevity. To meet these stringent requirements, both conventional manufacturing methods and additive manufacturing (AM) are employed. AM offers significant advantages, including the ability to create intricate designs and enhance material versatility. However, it also presents challenges, such as thermal stresses, surface irregularities, and residual stresses. These issues are particularly critical in 316 stainless steel, where achieving a high-quality surface finish and optimal mechanical strength is essential for reliable performance in demanding applications [3]. In contrast to traditional manufacturing, AM directly builds complex products from raw materials without relying on multiple processes like forging, casting, rolling, machining, or extrusion. AM is also more adaptable with the types of materials it uses, and leftover powder can be recycled, making it a more economical and complex shape-friendly method [4,5,6,7,8,9,10,11,12]. According to ASTM, additive manufacturing (AM) involves creating prototypes and repairing components based on specific design parameters [13]. Unlike conventional manufacturing, which depends on tools such as cutters and dies (which are often product specific and have limited lifespans), resulting in significant material waste and higher costs, AM utilizes only the required feedstock materials. This leads to more efficient material usage, reduced waste, and cost-effective production. Additionally, AM provides a high degree of design flexibility, enabling the fabrication of intricate shapes and complex structures that traditional methods struggle to achieve due to excessive material wastage and manufacturing constraints. AM techniques are categorized based on the heat source and fusion approach, including directed energy deposition (DED), powder bed fusion (PBF), material extrusion (MEX), and material jetting (MJT). Each of these methods employs different raw feedstock forms, such as wire, powder, chips, or foil, which are selected according to process requirements and intended applications [4,13,14,15]. Among these techniques, AM has gained significant recognition for its effectiveness in metallic material fabrication, with DED, selective laser melting (SLM), and electron beam melting (EBM) being the most employed methods, and Table 1 presents why these are better over other AM techniques. For this reason, this paper presents a comparative analysis of 316/316L stainless steel components produced using SLM, EBM, and DED processes [4,5,8].

In the AM of 316L stainless steel, process parameters play a crucial role in determining the mechanical properties and overall quality of the final component. For instance, in DED, laser power directly influences melt pool behavior, bonding strength, and material density, while layer height affects surface smoothness, structural uniformity, and heat distribution. Optimizing these parameters is essential for enhancing component performance and achieving superior results [16]. Similarly, in SLM, energy density is a critical factor in achieving high part density and minimizing defects. Key parameters such as hatch distance, laser power, scanning speed, and rotation angle significantly influence melt pool overlap and structural integrity [17,18]. While DED, EBM, and SLM provide substantial flexibility in creating complex geometries and minimizing material waste, they also introduce challenges that can impact the overall performance of the manufactured parts. Issues such as surface roughness, porosity, and residual stresses can degrade mechanical properties, making it essential to fine-tune AM-specific parameters such as layer thickness, laser power, scanning speed, and build orientation to ensure high-quality outcomes [19]. The impact of these parameters on additively manufactured stainless steel is significant. Poor control over layer deposition and cooling rates can lead to uneven surfaces, internal voids, and stress concentrations, all of which compromise the durability and fatigue resistance of the final component. These imperfections are particularly concerning in applications demanding high precision and structural reliability, as they increase susceptibility to fractures and mechanical failure. Therefore, understanding and optimizing AM process parameters is crucial to enhancing the performance and longevity of 316L stainless steel components in advanced engineering applications [19,20,21,22].

The primary objective of this study is to analyze the impact of additive manufacturing (AM) process parameters on the properties of 316/316L stainless steel. It critically examines the influence of specific processing parameters in direct energy deposition (DED), selective laser melting (SLM), and electron beam melting (EBM) on mechanical properties. Additionally, this review explores post-processing techniques and investigates defects such as porosity, surface roughness, and residual stresses, which collectively shape the final characteristics of stainless steel components [23]. Addressing these issues involves post-processing treatments and surface treatments to enhance wear resistance, corrosion resistance, and surface smoothness. Post-processing, particularly heat treatments, can mitigate AM’s adverse effects on stainless steel by refining microstructure, reducing residual stresses, and improving surface quality. Treatments like annealing, tempering, and solution treatment can restore strength, enhance ductility, and smooth surface irregularities, making the material more suitable for demanding applications. Thus, while AM opens new possibilities for stainless steel manufacturing, careful control of process parameters and effective post-processing steps are essential to achieving the desired properties and ensuring long-term performance [24,25,26].

In addition to parameter optimization and control from the academic literature, industry developments and patents are playing an increasingly important role in advancing additive manufacturing (AM) for 316/316L stainless steel. For instance, patented systems such as US10596626B2 detail enhanced laser-based AM systems designed to optimize melt pool characteristics and improve microstructural uniformity during processing [27]. These technologies underscore how industrial innovation complements academic optimization studies. Furthermore, process management strategies outlined in US20230211561A1 propose digital control methods to fine-tune mechanical anisotropy, ensuring more predictable performance in critical applications [28]. These contributions provide practical, real-world insight into defect mitigation and parameter selection beyond laboratory settings.

Table 1.

Comparative analysis of additive manufacturing processes by advantages, disadvantages (including material limitations), and industrial preference [29,30,31].

Table 1.

Comparative analysis of additive manufacturing processes by advantages, disadvantages (including material limitations), and industrial preference [29,30,31].

| AM Process | Advantages | Disadvantages | Why DED, SLM, and EBM Are Often Preferred |

|---|---|---|---|

| Directed Energy Deposition (DED) |

|

|

|

| Selective Laser Melting |

|

|

|

| Electron Beam Melting (EBM) |

|

|

|

| Fused Deposition Modeling (FDM) |

|

|

|

| Vat Photopolymerization (SLA/DLP) |

|

|

|

| Binder Jetting |

|

|

|

| Material Jetting |

|

|

|

| Sheet Lamination |

|

|

|

In contrast to broader reviews on metal additive manufacturing, this paper emphasizes the use of specific AM techniques—DED, SLM, and EBM—for processing 316/316L stainless steel, providing a targeted examination of their capabilities and challenges. It evaluates the relationship between process parameters, defect formation, and post-processing strategies, assessing their combined impact on microstructures, and mechanical properties in high-performance engineering applications. The key focus areas include the following:

- Optimization and influence of process parameters: We investigate how AM process factors—such as laser power, scanning speed, layer thickness, etc.—affect mechanical attributes like hardness, tensile strength, and fatigue resistance. This study further examines parameter optimization and evaluates the suitability of each AM technique based on its application-specific strengths and constraints.

- Defects and their consequences: We identify typical defects in AM-produced 316/316L stainless steel, including residual stresses, porosity, and surface inconsistencies. These issues can weaken material integrity, necessitating targeted mitigation strategies to meet rigorous engineering requirements.

- Post-processing methods: We explore post-processing techniques such as heat treatment, hot isostatic pressing (HIP), and stress-relief processes, which are essential for improving microstructure, enhancing mechanical properties, and minimizing defects. These treatments contribute to superior dimensional accuracy and surface finish, making AM-fabricated stainless steel viable for applications requiring high precision and reliability.

By establishing this interconnection between process control, defect management, and post-processing optimization, this study provides a comprehensive framework for advancing AM techniques in critical engineering sectors such as aerospace, biomedical, and automotive industries.

2. DED, SLM, and EBM Process Parameter Effects and Optimization

Before proceeding with in-depth research, it is essential to understand the reasons why DED, SLM, and EBM are considered superior to other standard additive manufacturing (AM) processes. Table 1 outlines a detailed comparison highlighting their advantages, material limitations, and industrial relevance.

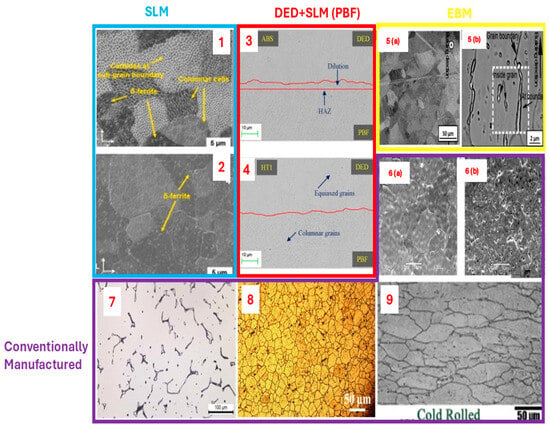

The mechanical properties of 316/316L stainless steel are highly influenced by the selected additive manufacturing (AM) technique and its process parameters. This section compares selective laser melting (SLM), Directed energy deposition (DED), and electron beam melting (EBM), emphasizing the distinct characteristics of each method. It provides a detailed assessment of how their unique operational parameters shape the microstructure and overall performance of stainless steel alloys, offering valuable insights into their suitability for various applications [16]. This comparative analysis highlights key differences in process conditions, powder delivery methods, and preheating requirements, while also addressing defect mitigation through post-processing strategies—factors that play a crucial role in determining the final material properties. Each of the AM techniques operates differently, utilizing distinct energy sources—DED and SLM rely on lasers, while EBM uses an electron beam. Their power capacities also vary significantly, with DED operating at around 500 W, SLM at a lower 120 W, and EBM reaching up to 3500 W. Additionally, the beam sizes differ across these methods, affecting precision and material deposition. DED has a broader beam range of 660 to 900 µm, SLM features a much finer beam of 30 to 250 µm, and EBM falls between 200 and 1000 µm. Another key difference lies in preheating requirements, which play a crucial role in material properties and defect mitigation. DED requires the build plate to be heated between 200 °C and 500 °C, whereas SLM operates at lower preheating temperatures of around 100–200 °C. In contrast, EBM demands significantly higher preheating, typically around 700 °C, which helps in reducing residual stresses. Scanning speed also varies among these techniques—DED operates at a slower rate of 0.001 to 0.04 m/s, while SLM moves at a moderate pace of 0.3 to 1 m/s. EBM, however, achieves much higher speeds, often exceeding 1000 m/s, making it ideal for applications requiring rapid production. The thickness of each deposited layer further differentiates these processes. DED builds thicker layers ranging from 200 to 1000 µm, whereas SLM achieves finer layer deposition between 20 and 100 µm, and EBM falls in between, with layer thicknesses from 50 to 200 µm [32,33,34,35,36,37,38,39,40].

Post-processing is an essential step in ensuring the final product meets quality and performance standards. In DED, post-processing requirements vary based on application, as stress relief may be necessary in some cases. SLM, on the other hand, generally requires post-processing treatments such as hot isostatic pressing (HIP) to enhance mechanical properties and eliminate residual stresses. In contrast, EBM usually requires minimal post-processing, as its high-temperature preheating helps mitigate internal stresses during fabrication. The mechanical properties of components also depend on the AM method used. Both DED and SLM tend to exhibit lower ductility but maintain or even surpass the yield strength of conventionally manufactured materials. EBM, however, produces mechanical properties comparable to traditional manufacturing techniques, offering a balance between strength and stability. Surface quality is another factor that differentiates these techniques. DED often results in rougher surfaces, with roughness values ranging from 20 to 50 µm, depending on the laser beam size. In comparison, SLM produces a much smoother finish, often below 10 µm, making it ideal for precision applications. EBM falls in between, with surface roughness ranging from 10 to 50 µm. Additionally, residual stress accumulation varies among these methods. Both DED and SLM generate high residual stresses due to rapid thermal cycles, often necessitating post-processing for stress relief. In contrast, EBM minimizes residual stress formation thanks to its higher preheating temperatures, which create a more uniform thermal distribution throughout the build. These differences in processing techniques make each AM method suitable for specific applications and materials. DED is widely used in aerospace, medical, dental, tooling, and high-tech industries for fabricating direct metal components. It is compatible with materials such as stainless steel, titanium alloys, cobalt-chromium, tool steels, nickel-based alloys, and aluminum alloys. SLM is preferred for its precision and is commonly employed in aerospace, medical, automotive, and tooling applications, working well with materials like titanium alloys (Ti, Ti6Al4V), cobalt–chromium, and nickel-based superalloys. Meanwhile, EBM is often utilized in the energy, aerospace, medical device, automotive, tooling, and defense industries, supporting materials such as tool steels, stainless steels, titanium alloys, and nickel-based alloys. By understanding the unique characteristics of each AM process, industries can select the most suitable method for their specific needs, balancing factors such as precision, mechanical properties, surface quality, and production efficiency. This comparison highlights how advancements in AM technology continue to push the boundaries of material fabrication, making it a critical solution for high-performance applications [4,34,41,42,43,44].

There are different manufacturers providing equipment for industrial and laboratory applications, such as DED manufactured by Optomec [45], SLM manufactured by Realizer GmbH [46], and EBM manufactured by Arcam EBM S12 [47]. DED, as employed by the Optomec LENS 750 system, is widely used in the aerospace and defense sectors for repairing and rebuilding high-value metal components such as turbine blades, engine parts, and structural brackets, with users including GE Aviation, NASA, and United Technologies. For instance, GE Aviation uses DED to repair aircraft engine components, and NASA has utilized LENS systems for rebuilding rocket engine nozzles. DED is also applied in the oil and gas industry for refurbishing large metal parts like valves and drill heads and in tooling/molds industries for adding material to worn molds [45]. The Realizer SLM 50, a high-precision metal printer, is especially prevalent in the medical/dental, aerospace, and automotive industries. In dental laboratories, the SLM 50 is used to manufacture custom crowns, bridges, and orthodontic devices using cobalt–chrome and titanium alloys. Airbus employs SLM technology for lightweight, topologically optimized aircraft brackets, while BMW and Bugatti use it for complex, high-performance engine parts and brake calipers. Its high resolution makes it ideal for jewelry prototyping as well [46]. The Arcam EBM S12 is a key technology in the orthopedic medical and aerospace industries. EBM is used by companies like Exactech and LimaCorporate to manufacture hip implants, spinal cages, and other porous titanium orthopedic implants, taking advantage of EBM’s ability to create controlled porosity for bone ingrowth. In aerospace, Boeing and Avio Aero (GE Aviation) use Arcam systems to print lightweight, high-strength titanium parts that withstand extreme conditions, such as engine brackets and support structures [47]. Based on this discussion, the comparative analysis of DED (Optomec 750 [45]), SLM (Realizer SLM50 [46]), and EBM (Arcam EBM S12 [47]) has been summarized in Table 2.

Table 2.

Comparative analysis of additive manufacturing techniques: DED, SLM, and EBM (sourced from publisher under permission) [34,35,36].

2.1. Direct Energy Deposition (DED)

The mechanical properties of 316L stainless steel are significantly influenced by build orientation during additive manufacturing. For example, components fabricated in a horizontal orientation (0-degree build angle) generally exhibit higher tensile and yield strengths compared to those produced in a vertical orientation (90-degree build angle). This difference arises because, in the 0-degree orientation, the applied load is parallel to the build layers, whereas in the 90-degree orientation, it is perpendicular. As a result, variations in interlayer bonding and material anisotropy directly impact overall mechanical performance. The cited study further investigated the mechanical behavior of 316L stainless steel fabricated at both 0-degree and 90-degree build orientations [48].

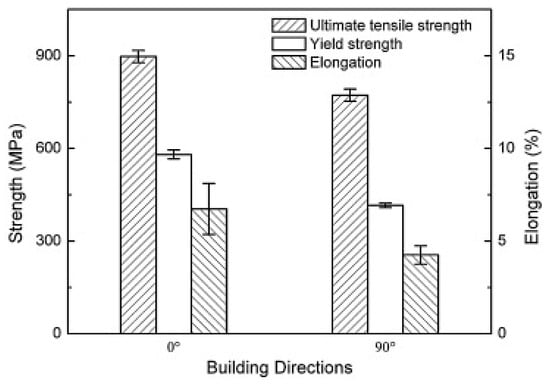

The results indicate that specimens in the 0-degree orientation—where the load is applied along the layers—consistently demonstrate superior tensile properties compared to those in the 90-degree orientation, where the load is applied across the layers (see Figure 1). This trend is consistent with findings from other studies, which report that the zero-degree orientation typically achieves higher ultimate tensile strength (UTS). Accordingly, this build direction is often preferred in applications requiring enhanced tensile performance as shown in Figure 2 [49].

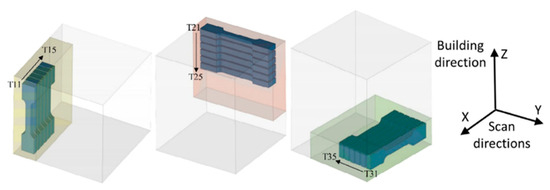

Figure 1.

DED-processed 316L stainless steel cubic component with test specimens oriented in three different directions (sourced from publisher under permission) [48].

Figure 2.

The mechanical properties of DED-fabricated 316L stainless steel alloy are analyzed at both 0° and 90° orientations (sourced from publisher under permission) [49].

While build orientation significantly influences mechanical properties, the deposition pattern is another crucial factor in optimizing part performance and minimizing defects. Common deposition strategies, such as raster, bi-directional, offset, and fractal patterns, impact the final properties of the manufactured part. Selecting an optimal pattern is essential for reducing residual stresses and mitigating thermal distortion. For instance, the offset pattern has been shown to reduce out-of-plane distortion by nearly one-third compared to the bi-directional pattern. Meanwhile, the raster pattern offers versatility, making it suitable for products of varying shapes, thereby enhancing manufacturing flexibility. Additionally, aligning deposition lines at 90 degrees to the longer axis of the substrate can help minimize part deflection, ultimately improving dimensional accuracy [50,51,52,53].

Both infill density and nozzle diameter, typically in the ranges of 15–25% and 0.20–0.40 mm, respectively, play a crucial role in determining the tensile strength of 316L stainless steel fabricated using the DED process. An increase in infill density generally leads to an improvement in tensile strength. Specifically, for a 0.40 mm nozzle diameter, tensile strength showed an enhancement of 20–30%. However, an unexpected trend was observed, where samples with 15% infill density exhibited higher tensile strength compared to those with 20–25% infill. A similar pattern was noted for a 0.2 mm nozzle diameter, with tensile strength consistently improving as infill density increased [54].

Lower laser power combined with high traverse speed reduces energy input at the upper section of the sample, leading to finer microstructures due to accelerated cooling. Conversely, when traverse speed is decreased, and laser power is increased, the cooling rate slows down, promoting the development of coarser microstructures [55,56,57,58]. Research suggests that a higher energy density typically improves the compressive stiffness of 316L stainless steel. However, defining a direct correlation between energy density and porosity in the DED process remains complex. Additionally, as the build height increases, porosity tends to decrease due to a reduction in cooling rates in the upper layers. Among key process variables—such as laser power, scan speed, and feed rate—laser power exerts the greatest influence on the alloy’s mechanical properties [59]. In a separate study, adjusting the scan speed within the range of 960 mm/min to 1200 mm/min had minimal impact on yield strength and elongation. However, variations in laser power were found to significantly influence these mechanical properties [60].

Another experiment revealed that lower laser power (around 400 W), combined with a high scan speed (up to 10 mm/s) and a feed rate of 10 g/min, relative to other DED parameters values, significantly improved the mechanical properties, microhardness, friction behavior, and modulus of 316L stainless steel [61]. A low feed rate ensures complete melting of the material, improving mechanical properties. However, it increases processing time. In contrast, a higher feed rate speeds up production but may lead to defects such as porosity and lack of fusion, reducing tensile strength. Therefore, an optimized feed rate is essential to balance mechanical properties and processing efficiency [62,63,64].

During a DED experiment involving 316L stainless steel, single tracks were deposited onto the base plate at different preheating temperatures—25 °C, 200 °C, 300 °C, 400 °C, and 500 °C. The findings revealed that as the preheating temperature increased, grain size also grew. This grain enlargement contributed to reducing residual stress and enhancing fatigue resistance, ultimately improving the material’s overall mechanical performance [65]. A recent study compared 316L stainless steel samples deposited on both preheated and cold substrates. It was observed that preheated substrates resulted in lower thermal gradients and cooling rates, which further decreased as the layer height increased. In contrast, samples deposited on cold substrates exhibited higher tensile strength and hardness. However, the cold substrate samples showed more non-metallic inclusions within the microstructure, while the slower cooling rate in preheated samples led to reduced formation of δ-ferrite content [66]. Another study found similar trends, showing that different preheating temperatures (room temperature vs. 300 °C) resulted in comparable residual stress and hardness values. However, samples preheated at 300 °C exhibited fewer defects, likely due to improved thermal stability and reduced cooling rates during the DED process [67]. Preheating has been shown to reduce defects in DED processes. Researchers have implemented a preheating technique using a laser-based moving heat source on the substrate, integrated into a Dmg Mori Lt 65 Ded Hybrid Machine, enhancing the quality of the deposition [68].

Studies have shown that increasing the shielding gas flow rate from 5 L/min to 25 L/min, specifically using argon or argon with 3% nitrogen, reduces the oxygen content in the melt pool during the DED process, thereby influencing the formation of oxides and affecting mechanical properties such as strength and ductility [69,70]. Research on Directed energy deposition (DED) of 316-grade stainless steel highlights the crucial role of shielding gas mixtures in influencing the final properties of materials. An argon-based mixture with 3% nitrogen was found to offer superior results, delivering higher tensile strength with significantly less variability. This improvement is linked to a refined microstructure and reduced defect formation. On the other hand, using He-Ar-CO2 or Ar-CO2 mixtures led to a drop in tensile strength and an increase in porosity. The increased porosity and scatter in mechanical properties for these mixtures are mainly due to the stabilization of δ-ferrite during solidification, which compromises the overall material performance [71]. The discussion highlights key DED process parameters and their influence on the mechanical properties of 316L stainless steel. Table 3 summarizes the optimized parameters based on the above discussion and their corresponding effects.

Table 3.

Optimized DED process parameters and their impact on the mechanical properties of 316L/316 stainless steel alloy.

2.2. Selective Laser Melting (SLM)

Several parameters discussed in this section significantly influence material properties. Among these, build orientation is particularly critical in selective laser melting (SLM) fabrication, where a 45-degree orientation demonstrates higher tensile strength, while a 90-degree orientation exhibits greater elongation before failure. Additionally, the fatigue limit at 3 × 105 cycles indicates that the 45-degree orientation has superior fatigue resistance compared to the 90-degree orientation [72]. SLM-fabricated 316L stainless steel parts exhibit distinct mechanical properties based on build orientation. Horizontally built dog-bone specimens show higher ductility, while vertically built ones demonstrate greater strength, emphasizing the critical role of build direction in mechanical performance [73,74]. The referenced study selected a 90-degree build orientation for one of the experiments due to its lower crack density compared to 0-degree and 45-degree orientations [75]. Research showed that hardness is highest at a 90-degree orientation, where reduced layer thickness results in the formation of fine crystalline structures [76].

Meanwhile, electron backscatter diffraction (EBSD) analysis of scanning strategies for 316-grade stainless steel revealed the formation of ⟨100⟩-oriented grains, with ±45° inclined cells adopting a ⟨101⟩ orientation. This structural development plays a crucial role in enhancing mechanical properties. Applying scan rotation removed the ⟨001⟩-oriented grains and increased the frequency of high-angle boundaries. Scanning at 45° and 67° rotations resulted in an increased presence of high-angle grain boundaries. Samples fabricated without scan rotation exhibited a tensile strength of 527 ± 5.4 MPa, a yield strength of 449 ± 2.4 MPa, and a ductility of 58 ± 1.3%. When a 67° scan rotation was applied, tensile strength decreased to 485 ± 4.8 MPa, yield strength dropped to 427 ± 5.4 MPa, and ductility was measured at 50 ± 1.3% [77].

A study found that a strong ⟨110⟩ texture along the build direction enhances ductility through twinning, while the 90-degree orientation exhibits lower ductility but higher strength [78]. Also, the scanning strategy, along with process parameters like hatching patterns (alternate, cross, one direction), beam passes (single, double, etc.), and scan paths, significantly influence the material properties. Variations in hatching and scanning strategies help in controlling the mechanical properties. The rectangular and hexagonal scanning patterns demonstrated epitaxial grain growth without layer rotation, but the application of rotation disrupted this growth. A 47-degree rotation produced finer grains and enhanced mechanical properties compared to the 90-degree rotation. Furthermore, the rectangular scan pattern resulted in greater hardness than the hexagonal pattern [79]. Reducing hatch spacing enhances overlap between melt pools, which decreases porosity and increases microhardness. Wider hatch spacing, while reducing processing time, can result in poor fusion and increased defects, negatively impacting mechanical properties. Achieving an optimal balance in hatch spacing is vital for ensuring uniform melting and improving part quality in SLM-fabricated 316L stainless steel [80]. In addition to this, high scanning speeds can increase tensile strength by refining the microstructure but may result in reduced density due to incomplete melting and higher porosity. Conversely, lower scanning speeds allow for thorough melting, resulting in deeper melt pools, improved fusion, and reduced porosity. An optimal scanning speed is essential to balance tensile strength and ductility, preventing defects like microcracks and ensuring stable microstructural formation [81,82].

Studies indicate that a 60 µm layer thickness reduces hardness variation, though the hardness value itself may be slightly lower. In contrast, 30 µm, 80 µm, and 100 µm thicknesses show better hardness but lead to higher surface roughness, increasing the risk of defects [83]. Layer thicknesses in the range of 30 µm to 50 µm lead to variations in the internal microstructure, significantly altering the properties of 316L stainless steel [84]. Increasing the layer thickness reduces both relative density and hardness due to limited laser penetration. This results in less effective melting, weaker interlayer bonding, and increased defects, ultimately compromising the mechanical properties [80].

Optimizing other parameters such as energy density is crucial as it can enhance mechanical properties by minimizing porosity. Increasing energy density improves densification and microhardness by reducing defects and strengthening layer bonding. Hardness increases linearly with energy density from 50 to 125 J/mm3, but exceeding this range can cause coarsening of the cellular microstructure, reducing hardness and diminishing resistance to local deformation [85,86,87]. While higher laser power generally enhances fusion, boosting tensile strength and density, excessive energy input may cause material vaporization, leading to issues such as keyhole porosity (laser-induced void) and grain coarsening, which deteriorate hardness and mechanical strength. Further, excessive power can also lead to spatter, compromising surface quality. High-power lasers achieve similar densities to low-power ones but tend to form wider and shallower melt pools, resulting in a coarser microstructure and increased cracking due to thermal gradients. In contrast, lower power produces deeper and narrower melt pools, promoting finer grain structures, which contribute to better hardness and enhanced mechanical properties [72,75,80,82,88]. Moreover, smaller laser spot sizes focus energy more effectively, resulting in a finer-grain microstructure with higher resolution [82].

Preheating the build plate to 150 °C helped form an equiaxed microstructure while reducing porosity due to lower cooling rates. This modification increased ductility by 14% and produced a more uniform structure, potentially improving fatigue performance [89]. Preheat-treated specimens exhibited a 62% increase in fatigue life and a 12.35% reduction in cyclic softening compared to the without-preheat-treatment (WHT) specimens. The preheated specimens also showed fewer pores and improved material fusion, contributing to their overall superior fatigue resistance [90]. Studies have indicated that preheating the build platform in SLM reduces residual stresses, enhances strength, and improves hardness [91]. Studies indicate that powder bed preheating in SLM reduces thermal stresses in tool steel materials and results in a more uniform microstructure. Preheated samples exhibit superior mechanical properties, including higher hardness and tensile strength, compared to non-preheated samples [92].

Similarly, at a low shielding gas flow of 500 L/min, inadequate removal of by-products causes defects such as porosity and poor interlayer fusion. Increasing the flow rate to 550–600 L/min significantly enhances the removal of contaminants, reduces powder bed pollution, and improves bonding, leading to better tensile strength and uniform material properties [93]. Flow rates below 500 L/min risk oxidation and powder erosion, leading to defects such as porosity and poor layer bonding [94]. Studies indicate that argon gas effectively minimizes oxidation and enhances toughness. In contrast, nitrogen can form nitrides, increasing hardness but potentially reducing ductility. The use of Helium in SLM reduces the interaction between the laser energy and the powder bed. This leads to obstruction of the laser beam by a large plasma plume, limiting effective energy transfer. As a result, the mechanical properties of the 316L stainless steel alloy are compromised, with increased porosity and lower part density [95].

Balancing these process parameters is essential for minimizing defects and optimizing mechanical properties. Optimizing process parameters such as laser power, scanning speed, and energy density enhances densification, microhardness, and mechanical performance, ensuring superior reliability and durability in SLM-fabricated 316L stainless steel components [96]. Table 4 summarizes the optimized SLM process parameters discussed above, along with their recommended ranges and corresponding effects on mechanical properties, to guide parameter selection for achieving desired material performance.

Table 4.

Optimization of selective laser melting (SLM) process parameters and their impact on mechanical properties.

2.3. Electron Beam Melting (EBM)

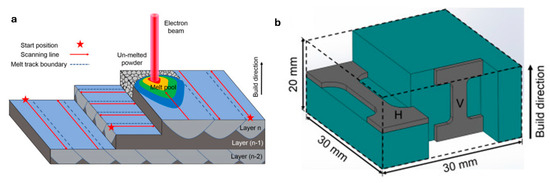

To optimize the mechanical properties of the fabricated components, electron beam melting (EBM) was employed using a distinct three-layer scanning pattern. The scanning pattern is depicted in Figure 3, where red arrows indicate the specific scanning strategy implemented. To investigate the influence of build direction on material properties, samples were fabricated in two different orientations, as illustrated.

Figure 3.

Electron beam melting (EBM) scanning strategy (a) and build orientations for 316L stainless steel: horizontal and vertical build directions (b) (sourced from publisher under permission) [97].

- Horizontal-build-direction samples are built with layers oriented parallel to the build plate.

- Vertical-build-direction samples are built with layers oriented perpendicular to the build plate.

This approach allowed for a comparative analysis of the tensile properties, particularly tensile strength, of the 316L stainless steel samples. The tensile tests were performed on both horizontally and vertically fabricated samples to assess the anisotropy in mechanical properties resulting from the layer-wise build process and scanning strategy [97].

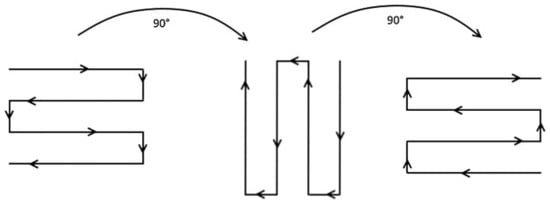

In the tensile testing of EBM-manufactured SS316L samples, the results showed greater tensile strength compared to conventional cast and wrought 316L stainless steel, but the ductility was notably lower. The EBM-fabricated SS316L samples also exhibited strong anisotropic tensile properties. It was observed that the samples had better tensile strength in the vertical orientation as compared to the horizontal orientation. During the experiment, the build plate was preheated to temperatures up to 850 °C, where microstructural and fractographic analyses revealed a significant amount of sigma (σ) phase precipitating at the grain boundaries, especially at higher build temperatures. The presence of this phase was found to be more pronounced under conditions of lower scanning factor (SF) and larger focus offset (FO), which contributed to a reduction in tensile properties, particularly for samples built in the horizontal direction. In the build direction, near the top of the EBM-fabricated sample, intragranular cellular sub grains were observed. Similar microstructural features have also been reported in other studies using both SLM and EBM processes, indicating consistent results across different additive manufacturing methods [39,97,98,99,100,101,102]. To further investigate the effect of scanning strategy and preheating, the scan pattern was rotated by 90 degrees (Figure 4), and the build plate was preheated to a temperature range of 800 to 820 °C. This modification resulted in significantly improved mechanical properties, demonstrating superior performance compared to powder metallurgy methods such as hot isostatic pressing (HIP) [100].

Figure 4.

Illustration of the modified scan pattern, rotated by 90 degrees, and the corresponding preheating conditions (800–820 °C) used in the EBM process for 316L stainless steel. These adjustments contributed to enhanced material properties and better consolidation (sourced from publisher under permission) [100].

Studies also verified and showed that preheating the build plate at higher temperatures reduces defects such as residual stresses for metallic materials [91,103,104]. Similarly, narrower hatch spacing improves part density by promoting effective overlap, while wider spacing increases porosity due to unmelted regions and high scanning speeds often result in insufficient melting, reducing the density of the part. In contrast, lower scanning speeds deliver more energy per unit area, enhancing material consolidation, but can lead to defects if combined with high laser power. Additionally, while volumetric energy density (VED) is a useful metric for assessing porosity and unfused powder, studies indicate that it does not reliably predict final part density, hardness, or microstructural changes in 316L stainless steel [100]. Instead, optimizing scanning speed, beam spot size, and hatch spacing plays a more direct role in controlling these properties [105].

Moreover, typical ranges for EBM include beam speeds around 4350 mm/s, beam currents between 1 and 50 mA, and layer thicknesses around 70 μm. These parameters are critical for achieving dense components without cracks or deformations. Fine-tuning these settings is necessary to optimize tensile strength and mechanical properties [106,107]. An investigation into optimal parameters for 316L stainless steel highlighted the importance of controlling beam spot size, scanning speed, and hatch spacing. The study identified optimal process parameters that resulted in a maximum tensile strength of 1491.51 MPa at an energy density of 64.28 J/mm3. These parameters included a line offset of 0.1 mm, a layer thickness of 50 μm, a scanning speed of 2800 mm/s, and a beam current of 15 mA, all of which contributed to enhancing the material’s mechanical performance. These parameters provided the best balance between density, microstructure, and mechanical strength [108]. The beam spot size was found to significantly affect the melt pool width, influencing microstructural consistency and melt pool overlap. A smaller beam spot size promotes better control of the melt pool, leading to consistent microstructural evolution and enhanced part quality [105]. Energy input in EBM is governed by multiple factors, including beam voltage, scanning speed, beam current, and track offset distance. Studies have shown that adjusting these parameters within an intermediate range results in the best mechanical properties. Fine-tuning these settings is essential to achieving maximum tensile strength, as demonstrated in maraging steel under optimized process conditions [109].

In addition to process parameters, for electron beam melting (EBM), operating in a vacuum environment is essential to minimize electron beam attenuation and ensure efficient energy deposition. However, this vacuum can lead to the evaporation of volatile elements in the alloy due to their high vapor pressures. Increasing the helium (He) pressure within the vacuum chamber can enhance the thermodynamic stability of these elements, reducing their tendency to evaporate. Monte Carlo simulations and thermal experiments indicate that increasing He pressure from 10−3 mbar to 10−2 mbar results in less than a 1.5% decrease in energy deposition efficiency. These findings suggest that controlled gas pressures can be strategically employed to process alloys with volatile elements while maintaining EBM process efficiency [110].

Table 5 presents the optimized process parameters (based on the above discussion) for electron beam melting (EBM) of 316L stainless steel, including recommended values for each parameter and their corresponding effects on mechanical properties. The provided ranges help researchers select optimal conditions to enhance material strength, reduce defects, and improve overall part quality.

Table 5.

Optimized electron beam melting (EBM) process parameters and their impact on mechanical properties.

2.4. Process Parameters and Thermodynamic Phase Evolution

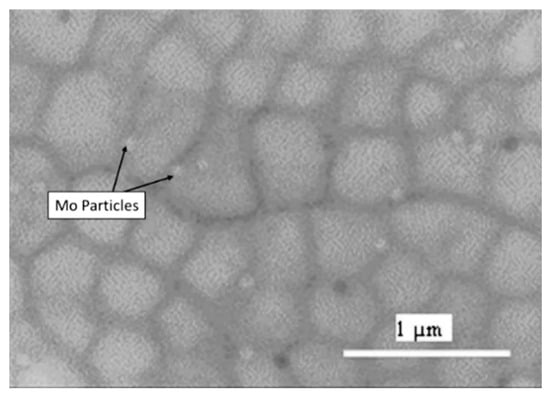

Although the influence of thermal gradients and cooling rates has been extensively discussed in Section 4, a deeper thermodynamic analysis of phase evolution during additive manufacturing (AM) of 316/316L stainless steel is crucial before getting into further details relevant to microstructural analysis. The rapid thermal cycling and localized heat input inherent to AM significantly influence the formation and stability of various phases, including δ-ferrite, sigma (σ) phase, and carbides, which can alter mechanical, corrosion, and long-term performance properties.

- δ-Ferrite Formation

During solidification, particularly under high cooling rates or elevated energy input, 316/316L stainless steel can deviate from the equilibrium austenitic solidification pathway and form δ-ferrite as a residual high-temperature phase. This is especially pronounced in techniques like DED and EBM where slower cooling allows for ferritic solidification modes. The formation of δ-ferrite is influenced by Creq/Nieq ratios (see Equations (1) and (2) [111]; if ratio ≥ 1.5, it is more likely to form primarily ferrite; if ratio is 1.3–1.5, then austenite + δ-ferrite will be present; and if ratio ≤ 1.3, then fully austenite will be formed) [112] and local composition shifts due to segregation during melting. While δ-ferrite can enhance hot cracking resistance, its presence beyond 5–10% may reduce toughness and corrosion resistance [66,71].

Cr equivalent = %Cr + 1.4 × %Mo + 1.5 × %Si + 0.5 × %Nb + 2%Ti

Ni equivalent = %Ni + 30 × %(C + N) + 0.5 × %M

Studies have shown that the use of argon–nitrogen shielding gas in DED leads to δ-ferrite stabilization due to altered solidification dynamics, while preheated builds promote more uniform austenitic structures by reducing thermal gradients and facilitating diffusion-driven phase transformation [66,71].

- Sigma (σ) Phase Precipitation

The sigma phase is an intermetallic compound rich in chromium and molybdenum that forms between 600 °C and 900 °C temperatures that are relevant during slow cooling or prolonged exposure in EBM and post-processing heat treatments. In AM, σ-phase formation is more likely in regions experiencing intermediate reheating, such as overlapping scan zones or during high-temperature preheating in EBM (>800 °C). For example, cited study [97] reports σ-phase precipitation along grain boundaries in EBM-built 316L samples, correlating with reduced ductility in horizontally fabricated parts.

The sigma phase is known to embrittle the material, reduce toughness, and degrade pitting corrosion resistance by depleting Cr and Mo from the matrix. Its suppression typically requires rapid cooling or solution heat treatment above 1050 °C, followed by water quenching [100,103].

- Carbide Precipitation

Carbide formation, particularly chromium-rich M23C6 at grain boundaries, is another key transformation observed in 316/316L stainless steel when exposed to sensitization temperatures (500–800 °C). While 316L’s low carbon content reduces this risk, repeated thermal cycling in AM or inadequate post-processing may promote carbide precipitation. This can lead to intergranular corrosion susceptibility.

High scan speeds and lower energy input in SLM typically avoid prolonged exposure to sensitization ranges, minimizing carbide formation. However, in DED and EBM, the slower solidification or thermal accumulation in thick parts may promote carbide segregation, especially without controlled cooling [100].

- Influence of Important Process Parameters on Phase Stability

- (1)

- High energy density promotes remelting and homogenization, reducing segregation that fosters δ-ferrite or σ-phase formation.

- (2)

- Low scan speeds and high preheating temperatures (especially in EBM) may increase the likelihood of σ-phase and coarse carbide precipitation unless countered by optimized beam parameters [97,100,106].

- (3)

- Post-processing treatments such as solution annealing (>1050 °C) followed by rapid quenching can dissolve the σ-phase and carbides, restoring full austenitic structure and improving corrosion resistance and ductility [103,104].

However, phase evolution in AM-fabricated 316/316L stainless steel is essential for predicting alloy performance under thermal or corrosive service. δ-ferrite, σ-phase, and carbides can be beneficial or detrimental depending on their quantity, morphology, and distribution each of which is process-dependent. Future studies should integrate thermodynamic simulations with in situ thermal monitoring to predict and control phase transformations more precisely.

2.5. Process Optimization Strategies for Cyclic Thermal and Corrosive Environments

When additive manufacturing (AM) components are intended for cyclic thermal or corrosive service environments such as those in the aerospace, marine, or chemical industries traditional process optimization must be extended to address long-term degradation mechanisms, particularly thermal fatigue, corrosion, and environmental stress cracking. Each AM technique, directed energy deposition (DED), selective laser melting (SLM), and electron beam melting (EBM), requires tailored strategies for such demanding conditions.

In DED, large melt pools and slower cooling rates often lead to coarse grain structures and high residual stresses, increasing vulnerability to crack initiation under thermal cycling [113]. To mitigate this, substrate preheating, use of optimized deposition patterns, and incorporation of interlayer dwell times are critical for reducing thermal gradients and associated stress buildup. Furthermore, post-build heat treatment refines grain boundaries and improves dimensional stability under repeated heating and cooling [66,114,115,116]. In corrosive environments, DED parts exhibit higher surface roughness and elevated porosity, making them more susceptible to pitting and stress corrosion cracking. Optimizing the shielding gas composition such as using argon with nitrogen additions can reduce oxide formation and enhance mechanical and electrochemical performance. Post-processing methods like electropolishing or laser remelting further minimize surface irregularities that act as corrosion nucleation sites [114,117,118,119]. In SLM, the optimization must address high thermal gradients that generate significant residual stresses and columnar grains. These issues are especially problematic under thermal cycling, where microcrack formation can propagate through weak interlayer bonds. Preheating the build platform, refining scan strategies, and applying heat treatment can improve ductility and reduce fatigue failure risks [99,114,118,120]. For corrosive resistance, dense microstructures, low porosity, and smooth surfaces are crucial. This can be achieved through optimized energy density, reduced hatch spacing, and argon-based shielding gas flow, followed by surface passivation or polishing [87,94,114,121,122]. On the other side, EBM, with its high preheating temperatures and vacuum operation, inherently minimizes residual stress accumulation and oxidation. However, coarse surface morphology, layer thickness, and limited resolution can still contribute to thermal fatigue under cyclic loads. Rotating scan strategies and optimized beam parameters are essential to ensure fine microstructure and uniform energy distribution. For corrosion-critical applications, EBM’s vacuum environment reduces contamination, but post-build finishing remains necessary to smooth surface roughness and eliminate subsurface pores [16,97,123].

However, optimizing AM processes for cyclic or corrosive environments requires a multi-objective approach, targeting not only mechanical strength but also microstructural stability, residual stress control, porosity reduction, and surface refinement. By integrating thermal management, strategic deposition planning, gas control, and post-processing, each AM technique can be adapted to meet the stringent durability requirements of real-world operating conditions.

2.6. AI/ML in Optimizing Parameters and Predictions of Defects and Properties

Machine learning (ML) and artificial intelligence (AI) have become central to addressing key challenges in additive manufacturing (AM), especially for 316/316L stainless steel. These include optimizing process parameters, predicting mechanical properties, and enabling real-time process monitoring. Recent studies [124,125,126,127,128,129] emphasize the effectiveness of supervised learning techniques, including artificial neural networks (ANNs), random forest, Gaussian process regression (GPR), and SVM, for process parameter optimization in laser powder bed fusion (LPBF) and directed energy deposition (DED) processes. These models correlate critical parameters—like laser power, scan speed, layer thickness, and hatch spacing—with part quality metrics such as density and surface roughness. For example, ref. [130] developed a universal predictor-based ML model using volumetric energy density to enhance model transferability across different machines and materials, achieving up to 80% prediction accuracy for relative density and surface finish even with small datasets.

AI-driven systems also enhance real-time monitoring by integrating in situ sensor data. The cited study [131] demonstrated a computer vision algorithm for LPBF machines that can classify powder bed anomalies during the recoating process, potentially enabling closed-loop control systems to correct deviations as they arise. Researchers also reviewed how digital twins, virtual replicas of the build process, can use ML algorithms to monitor and adjust builds in real time, improving part quality and minimizing defects [130].

ML also facilitates predictive modeling of mechanical outcomes such as yield strength, tensile strength, and hardness. Researchers developed a vertically integrated modeling framework for DED, which combines powder flow, molten pool dynamics, and residual stress analysis to predict microstructure and mechanical behavior with high fidelity. These models significantly reduce reliance on trial-and-error experimentation by enabling virtual testing environments and process optimization based on predefined property targets [32].

Researchers noted that AI techniques are essential for scaling AM across industries, allowing data-driven decisions for material selection, process settings, and post-processing strategies. Integration of AI with sensor-rich environments supports Industry 4.0 objectives, reducing waste, improving quality, and enabling sustainable manufacturing practices. AI and ML are no longer supplementary but core technologies in AM. Their ability to optimize parameters, predict mechanical properties, and enable real-time feedback mechanisms is reshaping how high-performance materials like 316L stainless steel are manufactured [132,133].

2.7. Critical Evaluation and Comparison of Mechanical Properties

Qualitative and Quantitative Framework

To determine the most effective additive manufacturing process for 316/316L stainless steel, a comparative critique of directed energy deposition (DED), selective laser melting (SLM), and electron beam melting (EBM) has been conducted. Each process presents unique advantages and limitations, influencing its suitability for specific industrial applications—for example, DED allows for large-scale component repair but suffers from poor surface finish; SLM offers high precision and excellent mechanical properties but is limited by build size and high residual stresses; whereas EBM minimizes residual stress through high preheating but is constrained by lower resolution and material compatibility. A critical evaluation of mechanical strength, microstructural integrity, porosity, and residual stress formation is essential for making an informed selection.

- Directed Energy Deposition (DED)

DED is often chosen for large-scale component fabrication due to its high deposition rates. It allows for rapid prototyping and cost-effective material usage, particularly in applications where modifying or repairing existing parts is necessary. The flexibility in feedstock types, including wire and powder, further enhances its adaptability. However, the process lacks precision compared to other additive manufacturing techniques, as it produces coarser surface finishes, requiring extensive post-processing. This limitation makes DED less suitable for applications demanding intricate geometries. A major drawback of DED is the formation of residual stresses due to rapid cooling. These stresses contribute to structural distortion, necessitating stress-relief treatments. Additionally, the presence of porosity and fusion defects undermines mechanical integrity, making it unsuitable for applications requiring high fatigue resistance. Preheating the build plate (200–500 °C) has been shown to reduce residual stress formation and porosity, but this does not completely eliminate anisotropy in mechanical properties. The cited studies showed components printed in vertical orientations tend to exhibit higher tensile and yield strengths compared to those fabricated in horizontal orientations. However, the uneven cooling rates characteristic of DED makes it difficult to achieve uniform material properties across the entire part. While DED is advantageous for large components and repair applications, its lack of precision and high residual stress levels makes it a less favorable choice for industries requiring fine feature resolution and high structural reliability [48,61,63,65].

- Selective Laser Melting (SLM)

SLM is widely regarded as the most precise additive manufacturing technique for stainless steel, allowing for the production of intricate geometries with high part density. The fine microstructure achieved in SLM results in enhanced mechanical strength, making it an attractive choice for aerospace, biomedical, and high-performance engineering applications. However, the process is highly sensitive to parameters selection. Factors such as energy density, scanning speed, and hatch spacing must be precisely regulated to prevent defects such as porosity and keyholing. Failure to optimize these parameters can lead to a significant decrease in mechanical performance. High residual stresses are another concern, as they can lead to part warping and cracking, especially for larger builds. Unlike DED, SLM is limited by build size constraints, restricting its use in applications requiring large-scale manufacturing. Moreover, operational costs are significantly higher due to the need for strict environmental control and post-processing to achieve the desired surface quality. Thermo-mechanical behavior in SLM is primarily governed by energy density, which directly influences part density and hardness. Preheating the build plate to approximately 150 °C mitigates residual stresses but does not fully resolve them. The choice of layer thickness is another critical factor—while thinner layers enhance part density, they increase surface roughness, requiring additional finishing processes. SLM is the preferred choice for applications requiring high precision, strength, and fine microstructures, but it is not ideal for large-scale manufacturing due to size limitations, and the high costs associated with maintaining strict process parameters [72,85,87,91].

- Electron Beam Melting (EBM)

EBM offers a unique advantage over DED and SLM by operating in a vacuum environment, preventing oxidation and enhancing material purity. This makes it an excellent choice for applications requiring high-performance components with minimal contamination. One of the most significant benefits of EBM is its ability to preheat materials to approximately 850 °C, effectively reducing residual stresses and minimizing part distortion. This aspect makes EBM particularly suited for manufacturing components that require high structural stability, such as those in the aerospace and medical industries. However, EBM has notable drawbacks. The process has a lower resolution compared to SLM due to larger beam spot sizes and thicker layers, making it unsuitable for applications requiring fine feature details. Additionally, material compatibility is limited because of the vacuum environment, restricting the range of alloys that can be effectively processed. EBM also suffers from high setup and operational costs, making it a less economical choice for industries that do not specifically require its unique advantages. Thermo-mechanical effects in EBM are heavily influenced by preheating, which significantly reduces residual stresses and improves thermal stability. Build orientation plays a crucial role in anisotropy, with vertical builds generally exhibiting higher tensile strength. However, excessive energy input can lead to sigma phase precipitation at grain boundaries, reducing ductility and potentially compromising mechanical performance. While EBM is the most effective process for residual stress reduction and maintaining material purity, its lower resolution, limited material compatibility, and high costs make it a specialized rather than a widely applicable additive manufacturing technique [91,97,106].

- Which Process is the Best for 316/316L SS?

The choice between DED, SLM, and EBM depends on the specific requirements of the application. For large-scale components where deposition speed is a priority, DED is the most suitable choice, despite its limitations in precision and surface finish. For applications requiring high precision, fine microstructures, and superior mechanical strength, SLM is the optimal choice, provided that the limitations in build size and residual stresses are managed. For industries prioritizing stress reduction and material purity, EBM is the best option, though its high costs and lower resolution limit its use to specialized applications. However, EBM effectively reduces residual stresses but lacks the resolution and material flexibility of SLM and DED. Each of these additive manufacturing processes has distinct strengths and weaknesses, making it crucial to align process selection with specific engineering requirements. For researchers and engineers selecting an additive manufacturing process for 316/316L stainless steel, SLM remains the best overall choice for achieving optimal mechanical properties and part quality, provided that the challenges of residual stress and cost are addressed through effective process control and post-processing techniques [48,61,63,65,72,85,87,91,97,106].

- Mechanical Properties Comparison (AM vs. Conventional)

Table 6 presents a comprehensive comparison of process parameters and their impact on the mechanical properties of 316/316L stainless steel across different manufacturing techniques. These techniques include directed energy deposition (DED), selective laser melting (SLM), electron beam melting (EBM), and conventional processing methods such as wrought and cast production. The comparison focuses on critical parameters such as build orientation, energy input, scanning speed, and preheating conditions, evaluating their effects on ultimate tensile strength, yield strength, elongation, and hardness. By incorporating the technique (orientation) column, the table provides a clearer understanding of how specific processing conditions influence material behavior.

Table 6.

Mechanical properties of 316/316L stainless steel based on additive manufacturing process parameters—comparison of DED, SLM, EBM, and conventional methods (wrought, cast).

Table 6.

Mechanical properties of 316/316L stainless steel based on additive manufacturing process parameters—comparison of DED, SLM, EBM, and conventional methods (wrought, cast).

| Technique and Build Orientation | UTS (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HV) | Process Parameters | Refs. |

|---|---|---|---|---|---|---|

| DED (X) | 776 | 576 | 33% | 289 | Laser power: 400 W, V: 15 (mm/s) | [134] |

| DED (Y) | 703 | 479 | 46% | 272 | Laser power: 400 W, V: 15 (mm/s) | [134] |

| DED (90°) Overlap in X: 50%, Z: 25% | 469 ± 6 | 649 ± 2 | 23 ± 3 | - | Laser power: 900 W, V: 15 (mm/s) | [135] |

| DED (67°) Overlap in X: 50%, Z: 25% | 469 ± 10 | 624 ± 10 | 17 ± 3 | - | Power (P): 900 W, speed (υ): 15 mm/s | [135] |

| SLM (X) | 666–738 | 653–718 | 20–36% | 235 | Laser power: 200 W; V: 1000 (mm/s), spot size: 80–300 μm, layer thickness; 30–100 μm | [136] |

| SLM (Y) | 653–680 | 541–668 | 30–33% | 235 | - | [136] |

| SLM (Z) | 555–608 | 508–577 | 40–47% | 235 | - | [136] |

| EBM (X) | 571.8 ± 19.3 | 334.2 ± 15.5 | 29.3 ± 5.2 | - | Layer thickness: 50 μm, plate temperature: 850 °C | [97] |

| EBM (X) Another sample | 436.5 ± 23.2 | 342.9 ± 22.8 | 9.6 ± 2.3 | - | - | [97] |

| EBM (Y) | 580.2 ± 6.8 | 315.7 ± 10.0 | 35.2 ± 2.3 | - | - | [97] |

| EBM (Y) Another sample | 651.7 ± 8.5 | 395.8 ± 9.0 | 30.6 ± 3.0 | - | - | [97] |

| Wrought (316) | 586 | 234 | 50 | 160–200 | - | [55] |

| Wrought (316L) | 480 | 170 | 40 | 140–190 | - | [55] |

| Cast (316) | 485–585 | 240–290 | 30–35 | 150–180 | - | [137,138,139] |

| Cast (316L) | 450–550 | 200–250 | 30–35 | 140–170 | - | [137,138,139] |

- Process Parameters with the Highest Reported Variability in Mechanical Properties

Across the reviewed studies as discussed above, laser power emerged as the process parameter associated with the highest variability in mechanical property outcomes for 316/316L stainless steel components manufactured using DED, SLM, and EBM. In DED, changes in laser power—from as low as 400 W to 900 W—resulted in substantial variation in tensile strength (469–776 MPa) and elongation (17–46%), indicating a strong influence on melt pool behavior, grain morphology, and porosity. Similarly, in SLM, even moderate adjustments in laser power (e.g., 200–220 W) significantly affected yield strength (508–718 Mpa) and elongation (20–47%), particularly when interacting with build orientation and scanning strategies. In EBM, beam current (functionally equivalent to laser power) directly influenced density, grain coarsening, and defect formation, thus impacting tensile and ductile responses. While other parameters like scan speed and hatch spacing contributed to mechanical differences, the reviewed data consistently showed laser power as the dominant factor contributing to variability in mechanical performance across additive manufacturing processes.

- Decision Matrix and Performance Index to synthesize mechanical, economic, and processing feasibility of DED, SLM, and EBM

To reinforce the comparative findings presented in this review, a decision-support tool was developed by introducing a multi-criteria decision matrix and corresponding performance index (PI). This framework synthesizes mechanical, economic, and process-related factors, offering a consolidated view of how directed energy deposition (DED), selective laser melting (SLM), and electron beam melting (EBM) perform when applied to 316/316L stainless steel fabrication.

Each AM process (DED, SLM, and EBM) was scored across eight evaluation criteria using a 1–5 scale, where 5 represents the best observed performance. These scores were drawn directly from Table 1, Table 2, Table 3, Table 4, Table 5, Table 6, Table 7 and Table 8 and the discussion sections of this review, which compare process parameters, microstructural outcomes, post-processing needs, and mechanical behavior. The matrix was built using a weighted sum model, a common method in engineering design and materials selection decision-making, as Equation (3) explains [140,141].

where

PIj is the performance index of AM process j.

ω is the weight of criterion i.

Sij is the score of process j for criterion i.

To reflect scenarios where mechanical strength and surface quality are especially critical, such as in aerospace, biomedical, and precision tooling applications, the evaluation criteria were reweighted accordingly.

The table below integrates the evaluation criteria, their assigned weights, rationales, and the comparative scores of directed energy deposition (DED), selective laser melting (SLM), and electron beam melting (EBM) across each criterion. The scores are derived from detailed analysis in this review, and the weights reflect their importance in high-performance applications. The performance index (PI) is calculated using a weighted sum model, providing a single score for each method.

Table 7.

Integrated decision matrix with weighted criteria, rationales, and performance index for additive manufacturing methods applied to 316/316L stainless steel.

Table 7.

Integrated decision matrix with weighted criteria, rationales, and performance index for additive manufacturing methods applied to 316/316L stainless steel.

| Criterion | Weight | Rationale | DED | SLM | EBM |

|---|---|---|---|---|---|

| Mechanical Strength | 0.25 | High-priority for structural reliability | 3 | 5 | 4 |

| Surface Finish | 0.15 | Crucial for fatigue, sealing, and part interfaces | 2 | 5 | 3 |

| Porosity/Defect Control | 0.10 | Key for part integrity and fatigue resistance | 3 | 4 | 5 |

| Residual Stress Reduction | 0.05 | Supports dimensional stability, but less critical when post-processed | 3 | 2 | 5 |

| Build Speed | 0.10 | Relevant in high-throughput production | 4 | 2 | 4 |

| Dimensional Accuracy | 0.10 | Required in assembly-critical or complex geometry applications | 2 | 5 | 3 |

| Post-Processing Requirements | 0.10 | Affects lead time, cost, and workflow complexity | 3 | 2 | 5 |

| Economic and Operational Cost | 0.15 | Important for adoption in manufacturing environments | 4 | 2 | 3 |

| Performance Index (PI) | - | - | 3.00 | 3.70 | 3.85 |

Despite the marginally higher overall PI for EBM, this outcome primarily reflects its superior performance in stress mitigation and defect reduction. However, in contexts where mechanical performance and surface precision are prioritized, SLM achieves nearly equivalent performance (PI = 3.70) and remains the most favorable technique due to its exceptional strength-to-weight ratio, fine resolution, and refined microstructure. This is consistent with the earlier qualitative conclusion identifying SLM as the optimal method for applications demanding tight tolerances and mechanical integrity. DED, with a lower PI of 3.00, offers value in scenarios prioritizing scalability, repair, and cost-efficiency, though with trade-offs in precision and defect sensitivity.

3. Defects

3.1. Porosity

AISI 316L stainless steel was produced using the directed energy deposition (DED) method to analyze porosity on an S235JR mild steel substrate. The study focused on four specific regions: the top and bottom zones in both the YZ and XZ planes. Porosity was categorized into two ranges: (i) 0.0–20.0 μm and (ii) 21.0–40.0 μm. While all examined areas demonstrated a high material density exceeding 99.80%, hardness variations were observed due to differences in grain size, with lower hardness near the fusion line and higher hardness within the track body. The primary causes of defects were attributed to air entrapment, moisture evaporation, and incomplete melting [142].

Compared to traditional manufacturing techniques, selective laser melting (SLM) achieves higher densification (~99.97%) [143] and improved mechanical performance in 316L stainless steel. An optimized SLM sample processed with specific parameters (P = 170 W, h = 0.08 mm, v = 1000 mm/s) demonstrated the greatest yield strength (421 MPa), hardness (245 HV), and elongation (42%). However, certain defects, such as weak bonding, were linked to low energy density, which limited the penetration of molten metal into previously solidified layers. These irregular defects were primarily caused by insufficient energy input, while spherical gas porosities observed at higher energy densities likely resulted from gas entrapment during atomization or within the processing environment. Additionally, the rapid cooling rates in SLM impeded gas bubble escape from the molten pool, causing their entrapment during solidification [143,144]. These process-induced defects underscore the critical importance of optimizing parameters to mitigate challenges [145,146], while laser power and scanning speed variations in SLM significantly affect the morphology of solidified melt pools, thereby influencing porosity formation in 316L stainless steel. For instance, maintaining consistent energy density while reducing laser power and scanning speed effectively decreased porosity levels. Optimized SLM processes can yield periodic, overlapping melt pools, resulting in samples with minimal porosity. While porosity had a limited impact on strength, ductility demonstrated greater sensitivity. Samples processed at 135 W and 750 mm/s exhibited low porosity and an approximate 10% improvement in ductility, highlighting the necessity for precise parameter control to enhance the mechanical performance of SLM 316L stainless steel [147].

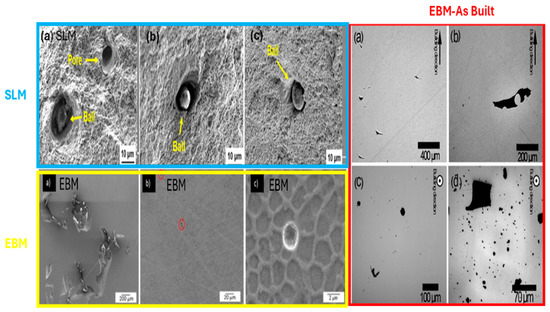

The electron beam melting (EBM) technique used to fabricate 316L stainless steel with thicker layers (200 μm) resulted in increased defects and slightly reduced density and hardness compared to thinner layers (100 μm). This emphasizes the need for parameter optimization for thicker layers to improve material quality. Investigating the effect of layer thickness on fatigue performance is particularly critical for applications involving significant temperature variations and cyclic thermal stresses [96]. Furthermore, an EBM-fabricated SS316L component revealed micron and submicron pores alongside larger crescent-shaped pores up to 200 μm, indicating insufficient energy input and challenges with melt pool overlap. The edges of the sample exhibited higher porosity and lower density compared to the inner regions, with a calculated cross-sectional density of 99.8%. These findings highlight the necessity of optimizing process parameters to improve edge density and overall material quality [39]. The porosity defects associated with various additive manufacturing processes concerning process parameters are summarized in Figure 5.

Figure 5.

{Selective laser melting (SLM, highlighted blue area) analysis indicates the presence of various defect types influenced by processing conditions. At a laser power of 120 W and a scan speed of 100 mm/s, all samples exhibited pores and balling defects: (a) SLM—as built, (b) HT-SLM, (c) HIP-SLM [143]}. {Electron beam melting (EBM, yellow highlighted area) with a 200 μm layer thickness presents various defects, as observed in SEM images. These include (a–c) unmelted and partially melted powder particles, cracks, voids, macro-level porosity, and encapsulated gas bubbles. Such defects emphasize the challenges associated with this specific parameter setting [100]}. {Electron beam melting (EBM) of SS316L: The red-highlighted regions illustrate structural characteristics of the as-built component along the designated build direction. (a,b) The side view exposes the internal structure, along with a noticeable large defect. (c,d) The cross-sectional view reveals internal flaws, including porosity clusters near the sample edges. All examined areas exhibit voids, porosity, and structural inconsistencies [39]}. (Images reproduced with permission from publisher).

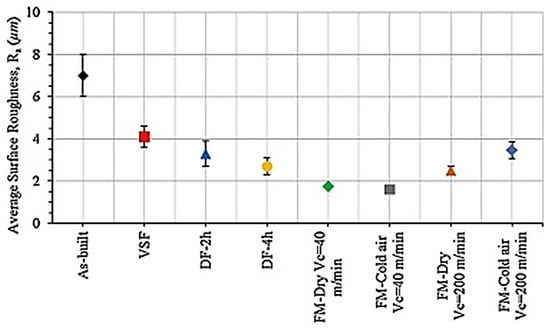

3.2. Surface Roughness