Modeling and Analysis of Torsional Stiffness in Rehabilitation Robot Joints Using Fractal Theory

Abstract

1. Introduction

2. Force Analysis of the Joint Traction Drive System

3. Modeling of Tangential Stiffness of Contact Pairs Based on Fractal Theory

- 1.

- The contact between two rough surfaces is simplified to that between an equivalent rough surface and an ideally rigid flat;

- 2.

- The surface roughness is statistically isotropic;

- 3.

- All micro-asperities share a common base plane, which is assumed to be fixed and does not shift with the applied normal load. As the normal load increases, the contact plane moves toward the base plane;

- 4.

- Work hardening and interactions between deforming micro-asperities are neglected during the deformation process.

4. Modeling the Torsional Stiffness of the Joint Traction System

5. Discussion

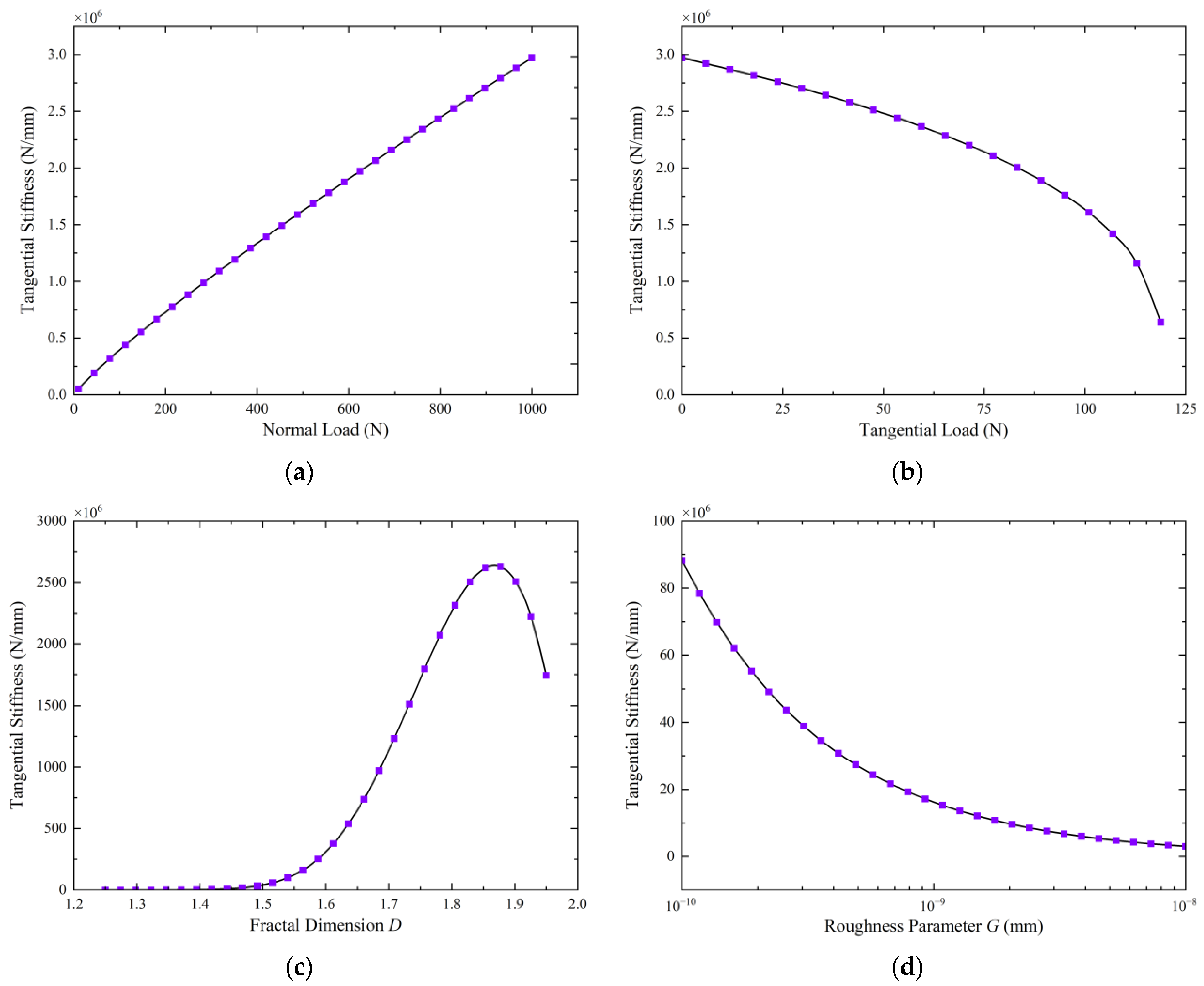

5.1. Analysis of Factors Affecting the Tangential Stiffness of a Single Roller Contact Pair

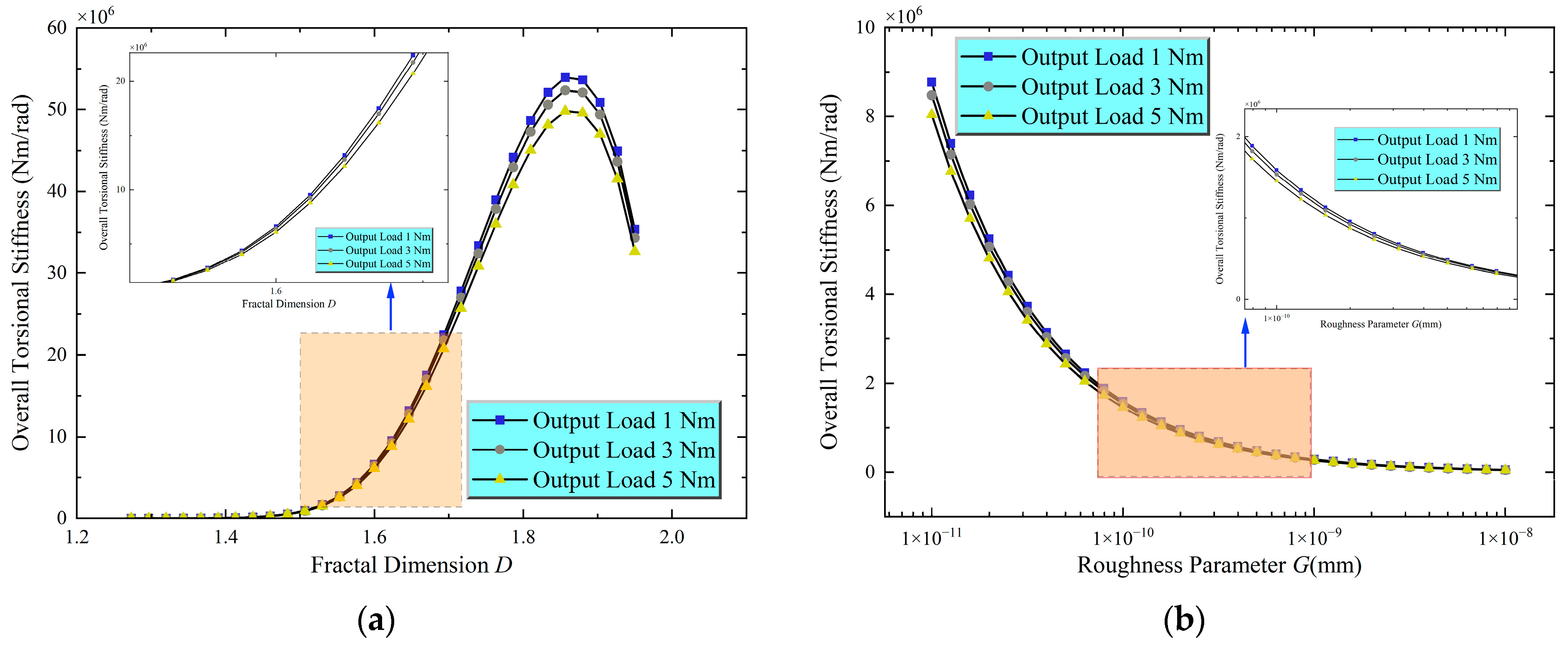

5.2. Analysis of Torsional Stiffness in the Rehabilitation Robot Joint Traction Drive System

6. Conclusions

- Contact Pair Torsional Stiffness Characteristics: The tangential stiffness of the contact pair increases non-linearly with the normal load and decreases non-linearly with the tangential load. Once the tangential load exceeds a critical value, the stiffness rapidly drops to zero, and macroscopic sliding occurs. The influence of the fractal dimension on tangential stiffness follows a non-monotonic pattern, initially increasing and then decreasing, with a peak observed around 1.85. An increase in the roughness parameter leads to a gradual reduction in tangential stiffness. An increase in both contact length and roller radius non-linearly enhances tangential stiffness, although their relative influence is limited;

- Relationship between Overall Torsional Stiffness and Fractal Geometric Parameters: The overall system torsional stiffness also exhibits a non-monotonic dependence on the fractal dimension , showing an initial increase followed by a decrease, consistent with the trend observed for contact pair tangential stiffness. An increase in the roughness parameter leads to a gradual reduction in overall system torsional stiffness. Increases in the effective contact length and roller radius significantly enhance the overall system torsional stiffness;

- Effect of Output Load on Overall Torsional Stiffness: Under conditions of a sufficiently high initial preload, the overall system torsional stiffness exhibits a slight decrease as the output load increases. This trend is mainly due to the combined effect of a relatively small increase in normal load compared with the initial preload and a relatively large increase in tangential load relative to the initial tangential load;

- Effect of Friction Coefficient on Overall Torsional Stiffness: The influence of the friction coefficient () on the overall system torsional stiffness is non-monotonic. As the friction coefficient increases, the torsional stiffness initially increases gradually. However, once the friction coefficient reaches a certain threshold, its effect on enhancing torsional stiffness reduces and tends toward saturation. This behavior is related to the transition between sliding and sticking states at the contact interface.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| PTD | Planetary traction drive |

References

- Shah, M.F.; Hussain, S.; Goecke, R.; Jamwal, P.K. Mechanism design and control of shoulder rehabilitation robots: A Review. IEEE Trans. Med. Robot. Bionics 2023, 5, 780–792. [Google Scholar] [CrossRef]

- Zhang, Z.; Calderon, A.D.; Huang, X.; Huang, A. Research status and prospect of finger rehabilitation machinery. J. Med. Devices Evid. Res. 2024, 17, 1–22. [Google Scholar] [CrossRef] [PubMed]

- Kok, C.L.; Dai, Y.; Lee, T.K.; Koh, Y.Y.; Teo, T.H.; Chai, J.P. A Novel Low-Cost Capacitance Sensor Solution for Real-Time Bubble Monitoring in Medical Infusion Devices. Electronics 2024, 13, 1111. [Google Scholar] [CrossRef]

- Kok, C.L.; Ho, C.K.; Dai, Y.; Lee, T.K.; Koh, Y.Y.; Chai, J.P. A Novel and Self-Calibrating Weighing Sensor with Intelligent Peristaltic Pump Control for Real-Time Closed-Loop Infusion Monitoring in IoT-Enabled Sustainable Medical Devices. Electronics 2024, 13, 1724. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, H.; Liu, Y. Intelligent sensors for rehabilitation robots: A comprehensive review. Sensors 2024, 24, 1234. [Google Scholar] [CrossRef]

- Chen, X.; Li, M.; Zhou, K. Upper limb rehabilitation robots: Current trends and future directions. J. NeuroEngineering Rehabil. 2024, 21, 45. [Google Scholar]

- Rodriguez, A.; Smith, J.; Brown, P. Advances in lower limb exoskeleton technology for gait rehabilitation. IEEE Trans. Neural Syst. Rehabil. Eng. 2024, 32, 123–134. [Google Scholar]

- Zha, Q.; Xu, Z.; Yang, H.; Zhang, G.; Cai, X.; Zhang, W.; Liu, Y.; Shen, X.; Li, Y. Development of a robot-assisted reduction and rehabilitation system for distal radius fractures. Front. Bioeng. Biotechnol. 2024, 11, 1342229. [Google Scholar] [CrossRef]

- Loewenthal, S.H.; Zaretsky, E.V. Design of traction drives. NASA Ref. Publ. 1985, 1154, 1–196. [Google Scholar]

- Abdallah, I.B.; Bouteraa, Y.; Rekik, C. Design of smart robot for wrist rehabilitation. Int. J. Smart Sens. Intell. Syst. 2016, 9, 1029–1053. [Google Scholar] [CrossRef]

- Ai, X. Development of zero-spin planetary traction drive transmission: Part 1—Design and principles of performance calculation. J. Tribol. 2002, 124, 386–391. [Google Scholar] [CrossRef]

- Rohn, D.A.; Loewenthal, S.H. An analysis of traction drive torsional stiffness. J. Mech. Des. 1985, 107, 573–581. [Google Scholar] [CrossRef]

- Gu, J.; Tong, T.; Huang, D.; Wang, S.; Wang, F.; Wang, Z. Study on torsional vibration of a harmonic driver based on time-varying stiffness caused by manufacturing error. J. Vibroengineering 2021, 23, 588–601. [Google Scholar] [CrossRef]

- Zou, Y.; Wu, X.; Zhang, B.; Zhang, S.; Zeng, Z.; Ma, L. Stiffness analysis of parallel cable-driven upper limb rehabilitation robot. Micromachines 2022, 13, 253. [Google Scholar] [CrossRef]

- Huang, T.H.; Kuan, J.Y.; Huang, H.P. Design of a new variable stiffness actuator and application for assistive exercise control. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems, San Francisco, CA, USA, 25–30 September 2011; pp. 372–377. [Google Scholar]

- Johnson, K.L. Contact Mechanics, 1st ed.; Cambridge University Press: Cambridge, UK, 1985; pp. 1–452. [Google Scholar]

- Zhang, S.; Li, D.; Liu, Y. Friction behavior of rough surfaces on the basis of contact mechanics: A Review and Prospects. Micromachines 2022, 13, 1907. [Google Scholar] [CrossRef]

- Shi, X.; Polycarpou, A.A. Measurement and modeling of normal contact stiffness and contact damping at the mesoscale. J. Vib. Acoust. 2005, 127, 52–60. [Google Scholar] [CrossRef]

- Greenwood, J.A.; Johnson, K.L.; Matsubara, E. A surface roughness parameter in Hertz contact. Wear 1984, 100, 47–57. [Google Scholar] [CrossRef]

- Maaboudallah, F.; Najah, M.; Atalla, N. A review on the contact mechanics modeling of rough surfaces in the elastic regime: Fundamentals, theories, and numerical implementations. In Tribology of Machine Elements; IntechOpen: London, UK, 2022. [Google Scholar]

- Borodich, F.M.; Gao, Z.; Jin, X. Fractal models in tribology: A critical review. Friction 2024, 13, 9440945. [Google Scholar] [CrossRef]

- Mandelbrot, B.B. The Fractal Geometry of Nature, 1st ed.; W.H. Freeman and Company: New York, NY, USA, 1982; pp. 1–468. [Google Scholar]

- Cheng Bin, Z. Fractal characteristics of surface roughness and its effect on laminar flow in microchannels. Acta Phys. Sin. 2009, 58, 7050–7056. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, C.; Shi, M.; Yang, Y. Role of surface roughness characterized by fractal geometry on laminar flow in microchannels. Phys. Rev. E 2009, 80, 026301. [Google Scholar] [CrossRef]

- Wang, S.; Liu, K.; Chen, M. Fractal theory applications in tribology: A decade review. Tribol. Int. 2023, 180, 108234. [Google Scholar]

- Yu, H.; Zhang, Q.; Li, F. Multi-scale surface topography characterization using fractal geometry. Surf. Topogr. Metrol. Prop. 2023, 11, 025001. [Google Scholar]

- Jackson, R.L.; Green, I. A finite element study of elasto-plastic hemispherical contact against a rigid flat. J. Tribol. 2005, 127, 343–354. [Google Scholar] [CrossRef]

- Sahoo, P.; Ghosh, N. Finite element contact analysis of fractal surfaces. J. Phys. D Appl. Phys. 2007, 40, 4245–4252. [Google Scholar] [CrossRef]

- Li, H.; Liu, Y.; Wang, Y.; Wang, Z. Estimation method of ideal fractal parameters for multi-scale Measurement of Polished Surface Topography. Fractal Fract. 2023, 7, 17. [Google Scholar] [CrossRef]

- Majumdar, A.; Bhushan, B. Fractal model of elastic-plastic contact between rough surfaces. J. Tribol. Trans. ASME 1991, 113, 1–11. [Google Scholar] [CrossRef]

- Hu, Q.; Li, H.; Wang, G.; Zhang, J. Research on torsional stiffness of flexspline-flexible bearing contact pair in harmonic drive based on macro-micro scale modeling. Front. Mater. 2023, 10, 1169889. [Google Scholar] [CrossRef]

- Guo, Z.; Li, S.; Wu, W.; Zhang, L. Quasi-static load sharing characteristics of a planetary gear set with planet journal bearings. Appl. Sci. 2020, 10, 1113. [Google Scholar] [CrossRef]

- Loewenthal, S.H.; Rohn, D.A.; Anderson, N.E. Evaluation of a high performance fixed-ratio traction drive. J. Mech. Des. 1981, 103, 410–417. [Google Scholar] [CrossRef]

- Kumar, A.; Patel, V.; Singh, R. Advanced contact models for gear tooth stiffness calculation. Mech. Mach. Theory 2023, 185, 105321. [Google Scholar]

- Thompson, M.; Davis, L.; Wilson, K. Contact stiffness modeling in rolling element bearings. J. Sound Vib. 2023, 556, 117722. [Google Scholar]

- Xue, S.; Entwistle, R.; Mazhar, I.; Howard, I. The torsional stiffness of involute spur planetary gears. In Proceedings of the 9th IFToMM International Conference on Rotor Dynamics; Pennacchi, P., Ed.; Springer International Publishing: Cham, Switzerland, 2015; pp. 243–252. [Google Scholar]

- Yu, X.; Sun, Y.; Zhao, D.; Wu, T. A revised contact stiffness model of rough curved surfaces based on the length scale. Tribol. Int. 2021, 164, 107206. [Google Scholar] [CrossRef]

- Shi, J.; Cao, X.; Zhu, H. Tangential contact stiffness of rough cylindrical faying surfaces based on the fractal theory. J. Tribol. 2014, 136, 041401. [Google Scholar] [CrossRef]

- Xiong, Y.; Zhou, Z.; Huang, K.; Zuo, Z.; Guo, J. An improved fractal model for tangential contact damping of high contact ratio gear considering friction effect. Chaos Solitons Fractals 2021, 153, 111510. [Google Scholar] [CrossRef]

- Wang, R.; Zhu, L.; Zhu, C. Research on fractal model of normal contact stiffness for mechanical joint considering asperity interaction. Int. J. Mech. Sci. 2017, 134, 357–369. [Google Scholar] [CrossRef]

- Mindlin, R.D. Compliance of elastic bodies in contact. J. Appl. Mech. 1949, 16, 259–268. [Google Scholar] [CrossRef]

- Xue, S.; Entwistle, R.; Mazhar, I.; Howard, I. The spur planetary gear torsional stiffness and its crack sensitivity under quasi-static conditions. Eng. Fail. Anal. 2016, 63, 106–120. [Google Scholar] [CrossRef]

| Cases | Fn (N) | T (N) | D | G (mm) | R1/R2 (mm) | L (mm) | σ (MPa) |

|---|---|---|---|---|---|---|---|

| case a | 0~1000 | 0 | 1.4 | 1×10−8 | 10/20 | 5 | 450 |

| case b | 1000 | 0~119 | 1.4 | 1×10−8 | 10/20 | 5 | 450 |

| case c | 1000 | 0 | 1.3~1.95 | 1×10−8 | 10/20 | 5 | 450 |

| case d | 1000 | 0 | 1.4 | 1×10−10~1×10−8 | 10/20 | 5 | 450 |

| case e | 1000 | 0 | 1.4 | 1×10−8 | 10/10~10/50 | 5 | 450 |

| case f | 1000 | 0 | 1.4 | 1×10−8 | 10/20 | 5~30 | 450 |

| Parameter | Sun Roller—Planet Roller | Planet Roller—Load Roller | Load Roller—Outer Ring |

|---|---|---|---|

| yield strength (MPa) | 450 | 450 | 450 |

| contact Radii (mm) | 4/13.5 | 13.5/5 | 5/40 |

| contact line length (mm) | 5 | 5 | 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zou, S.; Yan, W.; Xie, G.; Yang, R.; Xu, H.; Sun, F. Modeling and Analysis of Torsional Stiffness in Rehabilitation Robot Joints Using Fractal Theory. Materials 2025, 18, 2866. https://doi.org/10.3390/ma18122866

Zou S, Yan W, Xie G, Yang R, Xu H, Sun F. Modeling and Analysis of Torsional Stiffness in Rehabilitation Robot Joints Using Fractal Theory. Materials. 2025; 18(12):2866. https://doi.org/10.3390/ma18122866

Chicago/Turabian StyleZou, Shuaidong, Wenjie Yan, Guanghui Xie, Renqiang Yang, Huachao Xu, and Fanwei Sun. 2025. "Modeling and Analysis of Torsional Stiffness in Rehabilitation Robot Joints Using Fractal Theory" Materials 18, no. 12: 2866. https://doi.org/10.3390/ma18122866

APA StyleZou, S., Yan, W., Xie, G., Yang, R., Xu, H., & Sun, F. (2025). Modeling and Analysis of Torsional Stiffness in Rehabilitation Robot Joints Using Fractal Theory. Materials, 18(12), 2866. https://doi.org/10.3390/ma18122866