Temperature-Dependent Charpy Impact Toughness and Deformation Mechanisms of Austenitic Fe-32Mn-0.6C Steel

Abstract

1. Introduction

2. Materials and Methods

3. Results

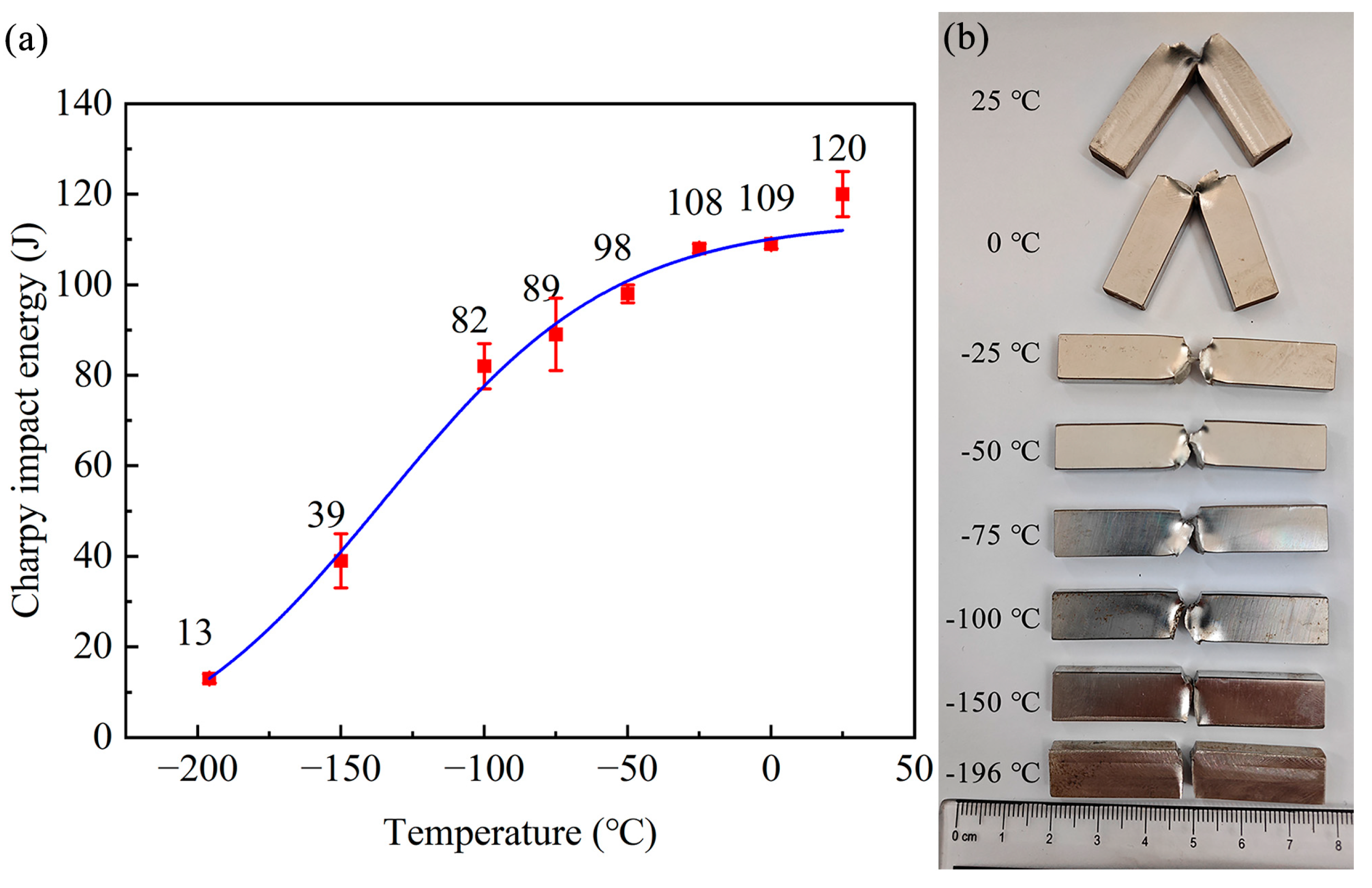

3.1. Effect of Temperature on Charpy Impact Properties

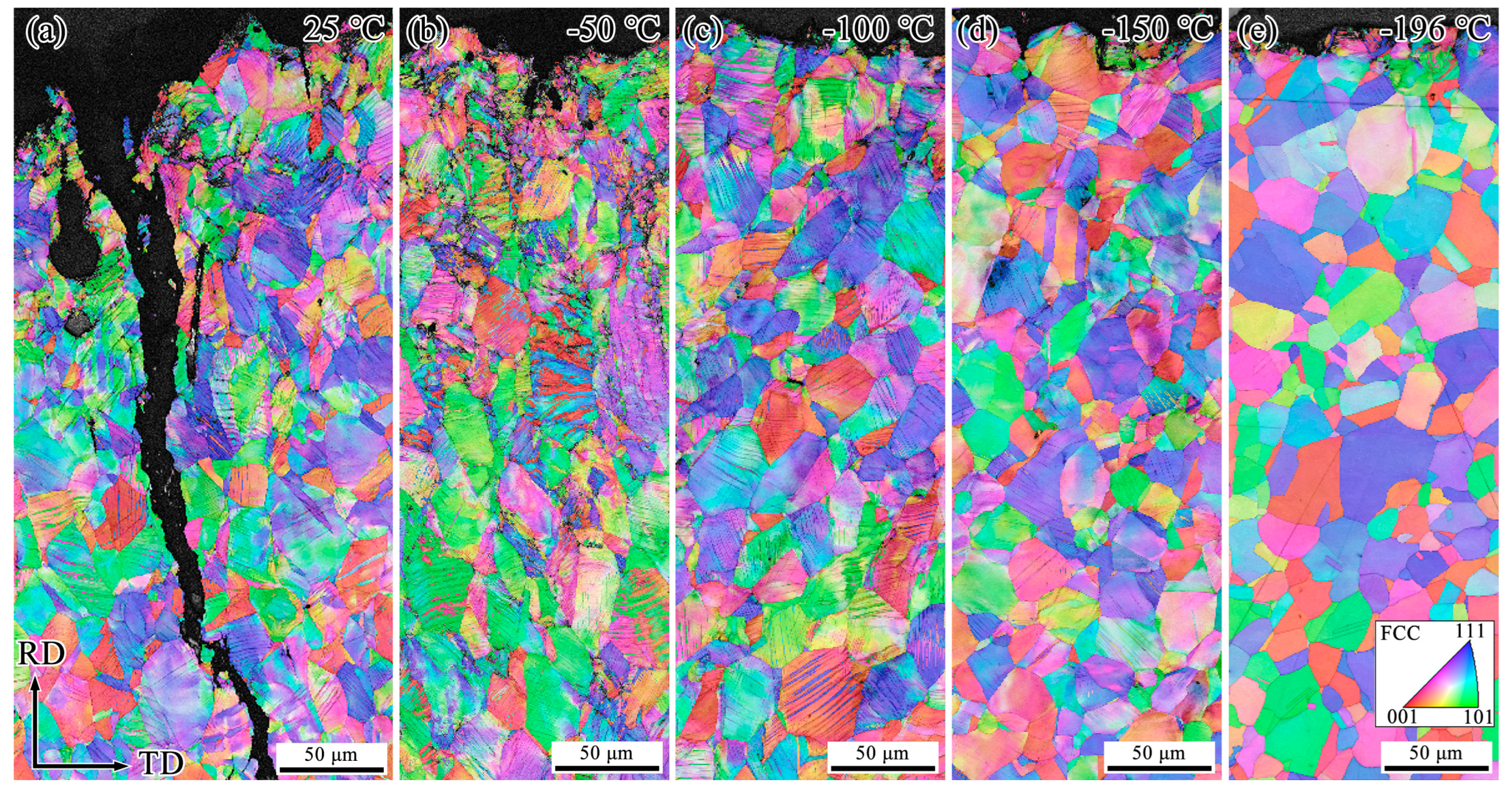

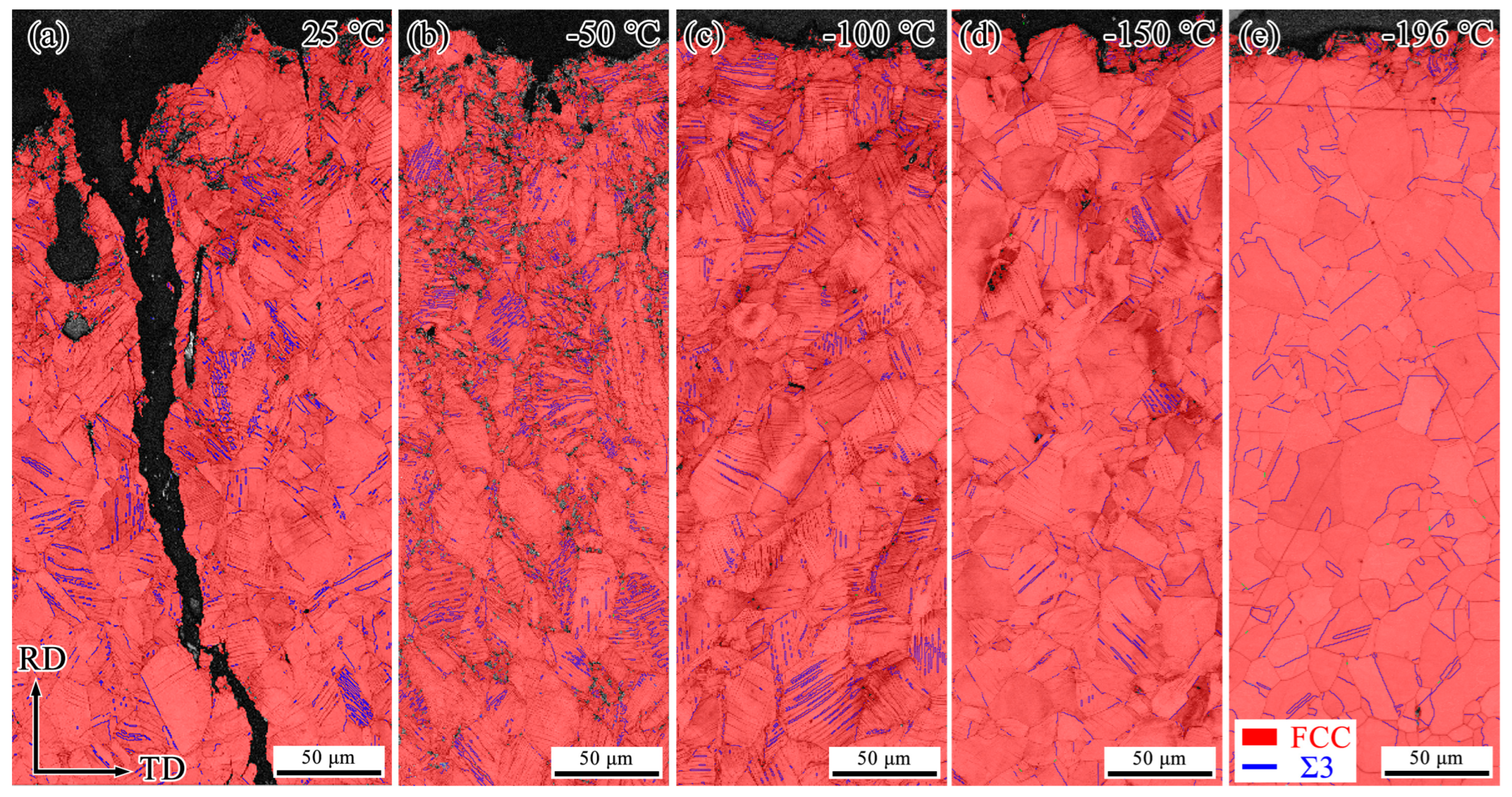

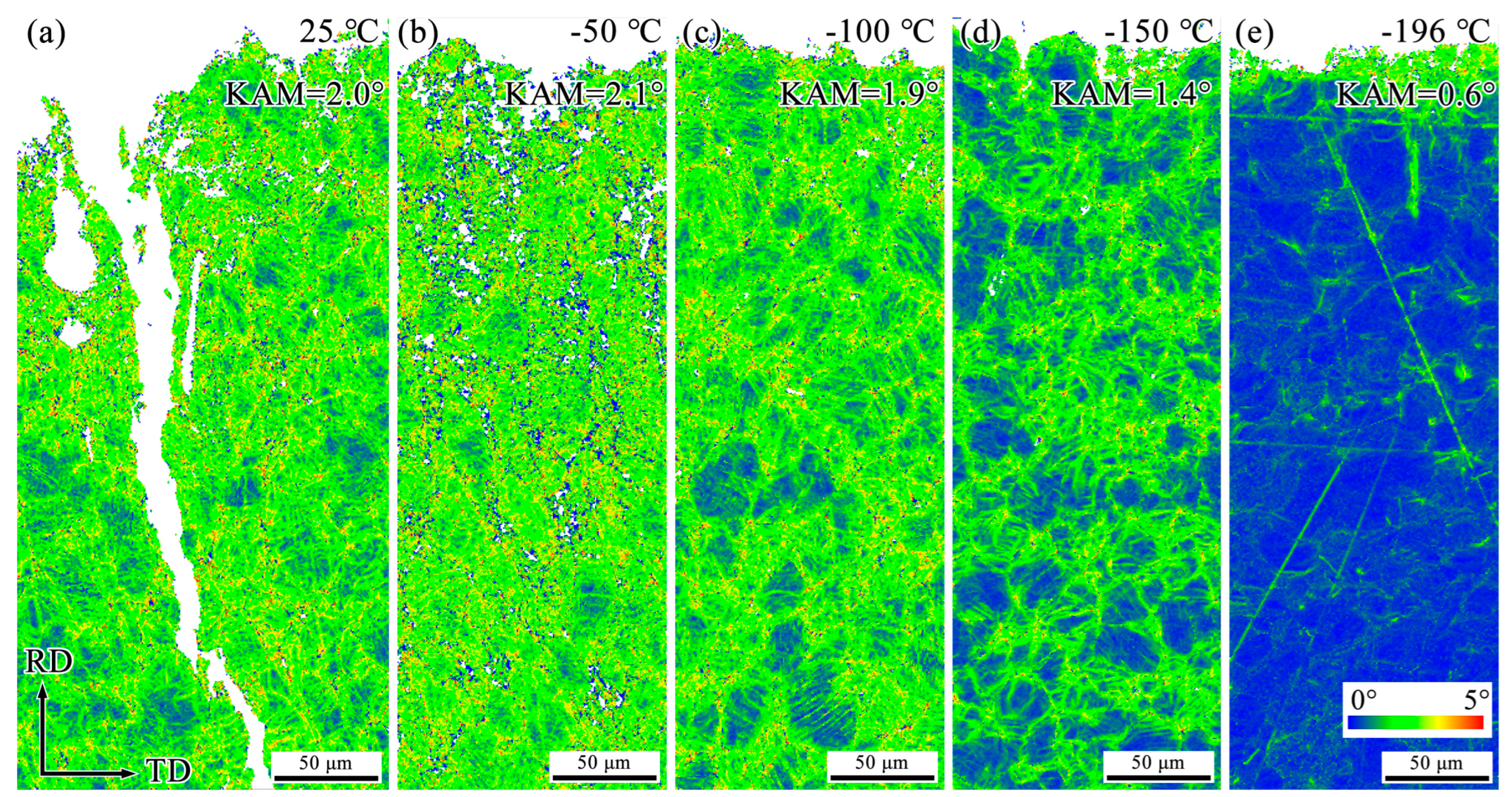

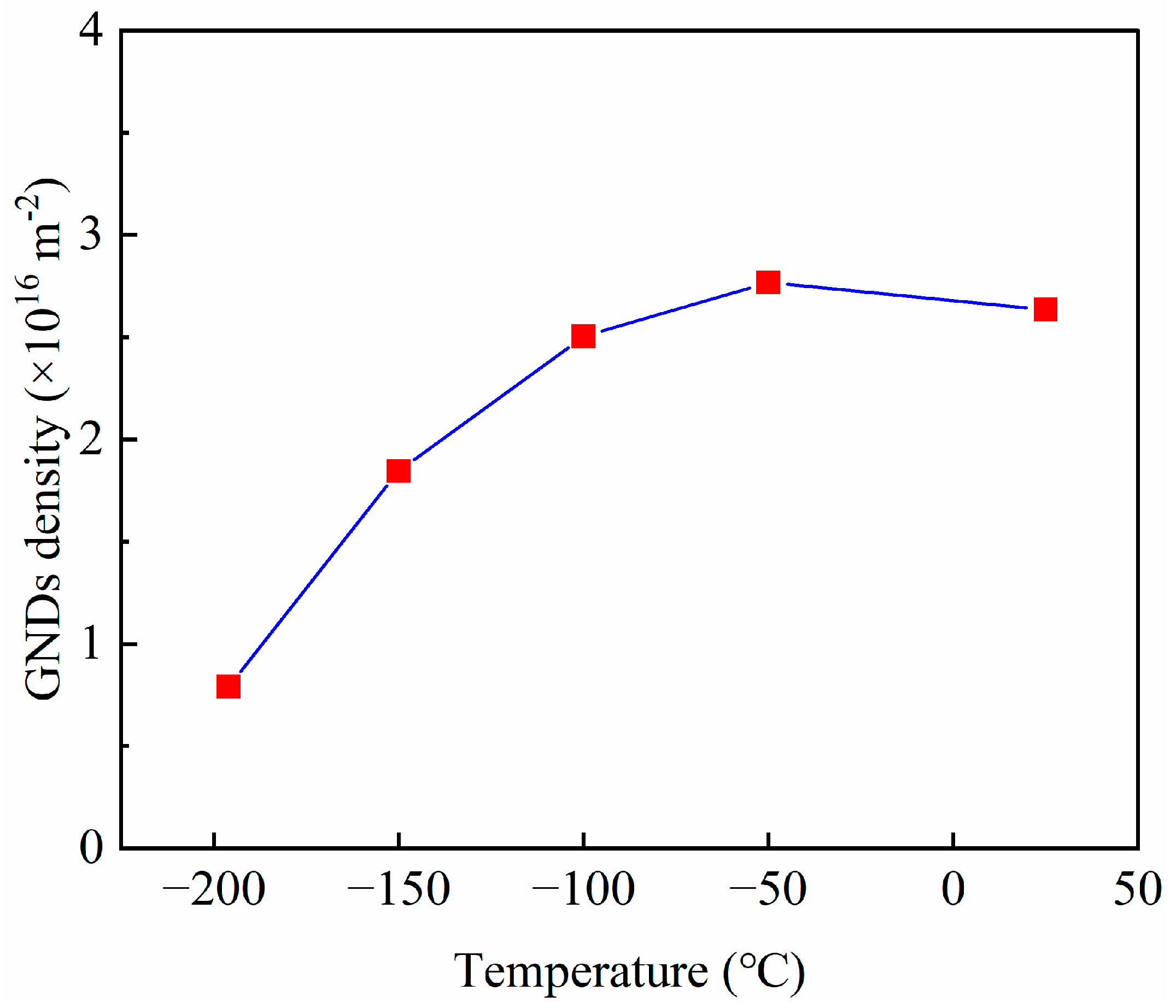

3.2. Effect of Temperature on Charpy Impact Deformation Mechanisms

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sohn, S.S.; Hong, S.; Lee, J.; Suh, B.; Kim, S.; Lee, B.; Kim, N.J.; Lee, S. Effects of Mn and Al contents on cryogenic-temperature tensile and Charpy impact properties in four austenitic high-Mn steels. Acta Metall. 2015, 100, 39–52. [Google Scholar] [CrossRef]

- Bouaziz, O.; Allain, S.; Scott, C.P.; Cugy, P.; Barbier, D. High manganese austenitic twinning induced plasticity steels: A review of the microstructure properties relationships. Curr. Opin. Solid State Mater. Sci. 2011, 15, 141–168. [Google Scholar] [CrossRef]

- Shen, Y.F.; Jia, N.; Misra, R.D.K.; Zuo, L. Softening behavior by excessive twinning and adiabatic heating at high strain rate in a Fe–20Mn–0.6C TWIP steel. Acta Metall. 2016, 103, 229–242. [Google Scholar] [CrossRef]

- Li, Y.; Lu, Y.; Li, W.; Khedr, M.; Liu, H.; Jin, X. Hierarchical microstructure design of a bimodal grained twinning-induced plasticity steel with excellent cryogenic mechanical properties. Acta Metall. 2018, 158, 79–94. [Google Scholar] [CrossRef]

- Liang, X.; McDermid, J.R.; Bouaziz, O.; Wang, X.; Embury, J.D.; Zurob, H.S. Microstructural evolution and strain hardening of Fe–24Mn and Fe–30Mn alloys during tensile deformation. Acta Metall. 2009, 57, 3978–3988. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Y.; Godfrey, A.; Kang, J.; Peng, Y.; Wang, T.; Hansen, N.; Huang, X. Cryogenic toughness in a low-cost austenitic steel. Commun. Mater. 2021, 2, 44. [Google Scholar] [CrossRef]

- Kim, B.; Lee, S.G.; Kim, D.W.; Jo, Y.H.; Bae, J.; Sohn, S.S.; Lee, S. Effects of Ni and Cu addition on cryogenic-temperature tensile and Charpy impact properties in austenitic 22Mn-0.45C–1Al steels. J. Alloys Compd. 2020, 815, 152407. [Google Scholar] [CrossRef]

- Lee, S.G.; Kim, B.; Jo, M.C.; Kim, K.; Lee, J.; Bae, J.; Lee, B.; Sohn, S.S.; Lee, S. Effects of Cr addition on Charpy impact energy in austenitic 0.45C-24Mn-(0,3,6)Cr steels. J. Mater. Sci. Technol. 2020, 50, 21–30. [Google Scholar] [CrossRef]

- Ren, J.; Chen, Q.; Chen, J.; Liu, Z. Enhancing strength and cryogenic toughness of high manganese TWIP steel plate by double strengthened structure design. Mater. Sci. Eng. A 2020, 786, 139397. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, Z.F. Getting tougher in the ultracold. Science 2022, 378, 947–948. [Google Scholar] [CrossRef]

- Song, R.; Ponge, D.; Raabe, D. Mechanical properties of an ultrafine grained C–Mn steel processed by warm deformation and annealing. Acta Metall. 2005, 53, 4881–4892. [Google Scholar] [CrossRef]

- Liu, Z.G.; Gao, X.H.; Xiong, M.; Li, P.; Misra, R.D.K.; Rao, D.Y.; Wang, Y.C. Role of hot rolling procedure and solution treatment process on microstructure, strength and cryogenic toughness of high manganese austenitic steel. Mater. Sci. Eng. A 2021, 807, 140881. [Google Scholar] [CrossRef]

- Kang, Q.; Zhang, Z.; Gao, Z.; Wang, C.; Liang, J.; Liu, Z.; Weng, Y.; Cao, W. Excellent mechanical properties and underlined deformation twinning mechanism of a low-carbon low-density cryogenic steel. Mater. Sci. Eng. A 2025, 923, 147741. [Google Scholar] [CrossRef]

- Shi, Y.; Chen, L.; Cao, T.; Wei, R.; Yang, Z.; Li, Y.; Yang, C.; Wan, X.; Wu, Y.; Jiang, F. Charpy impact behavior and fracture mechanisms in cost-effective ferrous medium-entropy alloy at ambient and cryogenic temperatures. Intermetallics 2025, 178, 108628. [Google Scholar] [CrossRef]

- Park, J.; Lee, K.; Sung, H.; Kim, Y.J.; Kim, S.K.; Kim, S. J-integral fracture toughness of high-Mn steels at room and cryogenic temperatures. Metall. Mater. Trans. A 2019, 50, 2678–2689. [Google Scholar] [CrossRef]

- Xiong, J.; Li, H.; Kong, L.; Zhang, X.; Cao, W.; Wang, Y. Dependence of Charpy impact properties of Fe-30Mn-0.05C steel on microstructure. Crystals 2023, 13, 353. [Google Scholar] [CrossRef]

- Mohammadzadeh, R.; Akbari, A.; Mohammadzadeh, M. Impact toughness properties of nickel- and manganese-free high nitrogen austenitic stainless steels. Metall. Mater. Trans. A 2016, 47, 6032–6041. [Google Scholar] [CrossRef]

- Zheng, C.; Yu, W. Effect of low-temperature on mechanical behavior for an AISI 304 austenitic stainless steel. Mater. Sci. Eng. A 2018, 710, 359–365. [Google Scholar] [CrossRef]

- Xiong, J.; Liu, E.; Zhang, C.; Kong, L.; Yang, H.; Zhang, X.; Wang, Y. Tuning mechanical behavior and deformation mechanisms in high-manganese steels via carbon content modification. Mater. Sci. Eng. A 2023, 881, 145401. [Google Scholar] [CrossRef]

- GB/T 229-2020; Metallic Materials Charpy Pendulum Impact Test Method. TransForyou Co., Ltd.: Beijing, China, 2020; p. 28.

- Yang, M.; Zhou, L.; Wang, C.; Jiang, P.; Yuan, F.; Ma, E.; Wu, X. High impact toughness of CrCoNi medium-entropy alloy at liquid-helium temperature. Scr. Mater. 2019, 172, 66–71. [Google Scholar] [CrossRef]

- Chu, X.; Li, Y.; Xu, C.; Li, W.; Fu, B.; Jia, X. Tri-functional co-nanoprecipitates enhanced cryogenic ductility by inducing structural heterogeneity and refining nano-twins in a low-stacking-fault-energy 17Mn steel. Int. J. Plast. 2024, 178, 104014. [Google Scholar] [CrossRef]

- Xiong, H.; Li, Y.; Xu, C.; Li, W.; Jia, X. Influences of dislocation configuration and texture optimization on obtaining exceptional cryogenic strength-ductility synergy in a dynamic-recovered heterogeneous high-manganese steel. Int. J. Plast. 2025, 185, 104225. [Google Scholar] [CrossRef]

- Zhang, D.D.; Zhang, J.Y.; Kuang, J.; Liu, G.; Sun, J. Superior strength-ductility synergy and strain hardenability of Al/Ta co-doped NiCoCr twinned medium entropy alloy for cryogenic applications. Acta Metall. 2021, 220, 117288. [Google Scholar] [CrossRef]

- Byun, T.; Hashimoto, N.; Farrell, K. Temperature dependence of strain hardening and plastic instability behaviors in austenitic stainless steels. Acta Mater. 2004, 52, 3889–3899. [Google Scholar] [CrossRef]

- Fang, X.; Zhang, L.; Liu, W.; Shu, K.; Fang, Y.; Zeng, Y.; Meng, L.; Liu, J. Cracking in a Fe-25Mn-3Si-3Al steel. Mater. Res. Lett. 2014, 2, 204–208. [Google Scholar] [CrossRef]

- Shen, S.; Xie, P.; Wu, C. Temperature dependence of mechanical properties and deformation mechanism of Fe–25Mn–3Al–3Si alloy at high strain rate. Mater. Sci. Eng. A 2023, 872, 144912. [Google Scholar] [CrossRef]

- Allain, S.; Bouaziz, O.; Chateau, J.P. Thermally activated dislocation dynamics in austenitic FeMnC steels at low homologous temperature. Scr. Mater. 2010, 62, 500–503. [Google Scholar] [CrossRef]

- Wang, Z.; Lu, W.; An, F.; Song, M.; Ponge, D.; Raabe, D.; Li, Z. High stress twinning in a compositionally complex steel of very high stacking fault energy. Nat. Commun. 2022, 13, 3598. [Google Scholar] [CrossRef]

- Gui, Y.; An, D.; Han, F.; Lu, X.; Kang, G.; Zhang, X. Multiple-mechanism and microstructure-based crystal plasticity modeling for cyclic shear deformation of TRIP steel. Int. J. Mech. Sci. 2022, 222, 107269. [Google Scholar] [CrossRef]

- Chang, M.; Fang, T.; Zhu, T.; Lin, J.-W. Effect of manganese on mechanical properties and deformation mechanism of CoCrFeNi high entropy alloys. Mater. Today Commun. 2023, 35, 105844. [Google Scholar] [CrossRef]

| Testing temperature (°C) | 25 | 0 | −25 | −50 | −75 | −100 | −150 | −196 |

| Lateral expansion (mm) | 2.30 ± 0.16 | 1.70 ± 0.13 | 1.68 ± 0.11 | 1.72 ± 0.10 | 1.45 ± 0.10 | 1.43 ± 0.09 | 0.89 ± 0.08 | 0.49 ± 0.09 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiong, J.; Cui, Y.; Wang, X.; Liu, C.; Barella, S.; Belfi, M.; Gruttadauria, A.; Wang, Y.; Peng, Y.; Mapelli, C. Temperature-Dependent Charpy Impact Toughness and Deformation Mechanisms of Austenitic Fe-32Mn-0.6C Steel. Materials 2025, 18, 2845. https://doi.org/10.3390/ma18122845

Xiong J, Cui Y, Wang X, Liu C, Barella S, Belfi M, Gruttadauria A, Wang Y, Peng Y, Mapelli C. Temperature-Dependent Charpy Impact Toughness and Deformation Mechanisms of Austenitic Fe-32Mn-0.6C Steel. Materials. 2025; 18(12):2845. https://doi.org/10.3390/ma18122845

Chicago/Turabian StyleXiong, Jianchao, Yue Cui, Xin Wang, Caiyi Liu, Silvia Barella, Marco Belfi, Andrea Gruttadauria, Yuhui Wang, Yan Peng, and Carlo Mapelli. 2025. "Temperature-Dependent Charpy Impact Toughness and Deformation Mechanisms of Austenitic Fe-32Mn-0.6C Steel" Materials 18, no. 12: 2845. https://doi.org/10.3390/ma18122845

APA StyleXiong, J., Cui, Y., Wang, X., Liu, C., Barella, S., Belfi, M., Gruttadauria, A., Wang, Y., Peng, Y., & Mapelli, C. (2025). Temperature-Dependent Charpy Impact Toughness and Deformation Mechanisms of Austenitic Fe-32Mn-0.6C Steel. Materials, 18(12), 2845. https://doi.org/10.3390/ma18122845