Effects of Lanthanum Element and Heat Treatment on Phase Formation and Magnetic Properties of SmFe10V2 Melt-Spun Ribbons

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

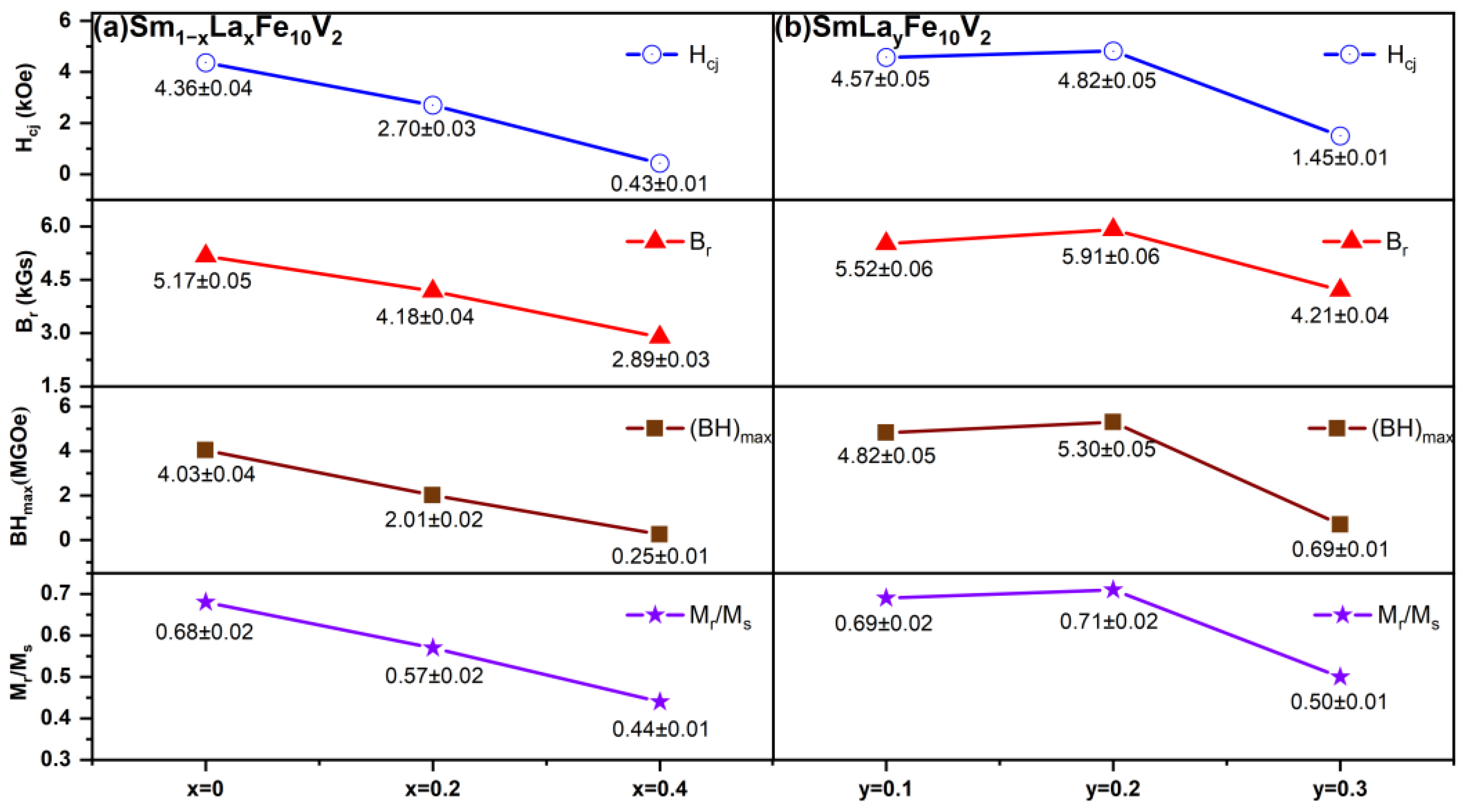

3.1. Sm1−xLaxFe10V2 Ribbons

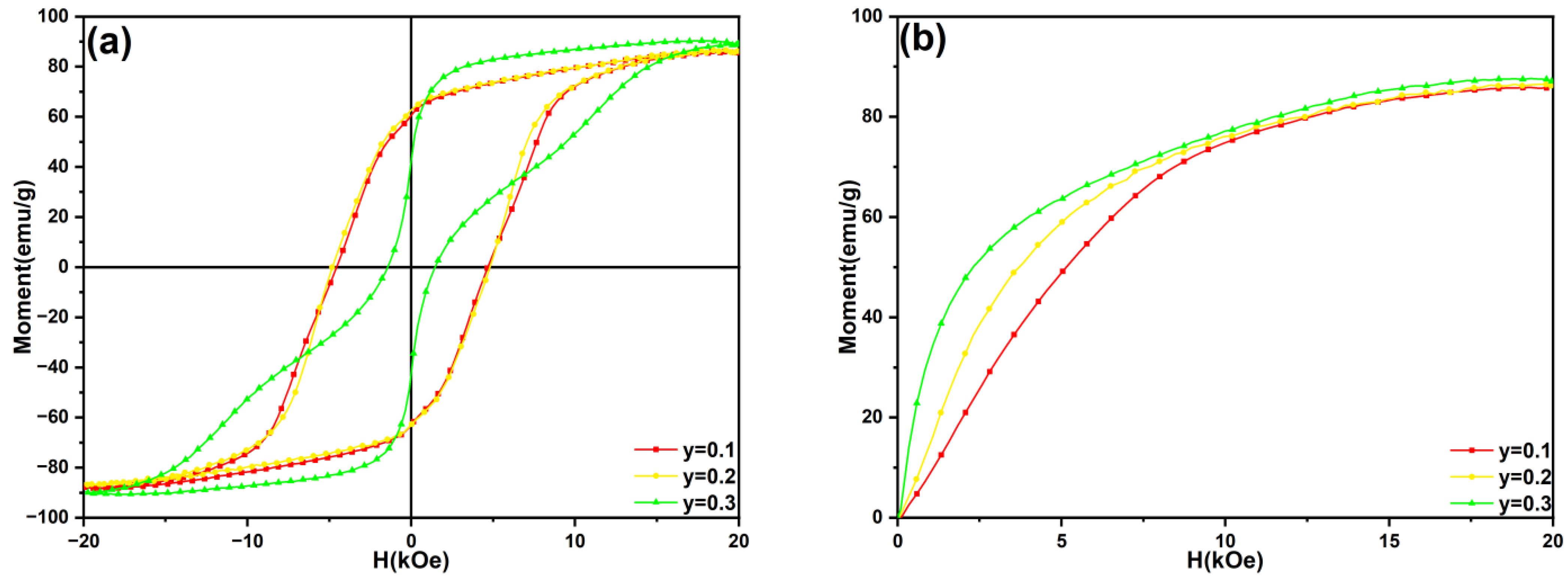

3.2. SmLayFe10V2 Ribbons

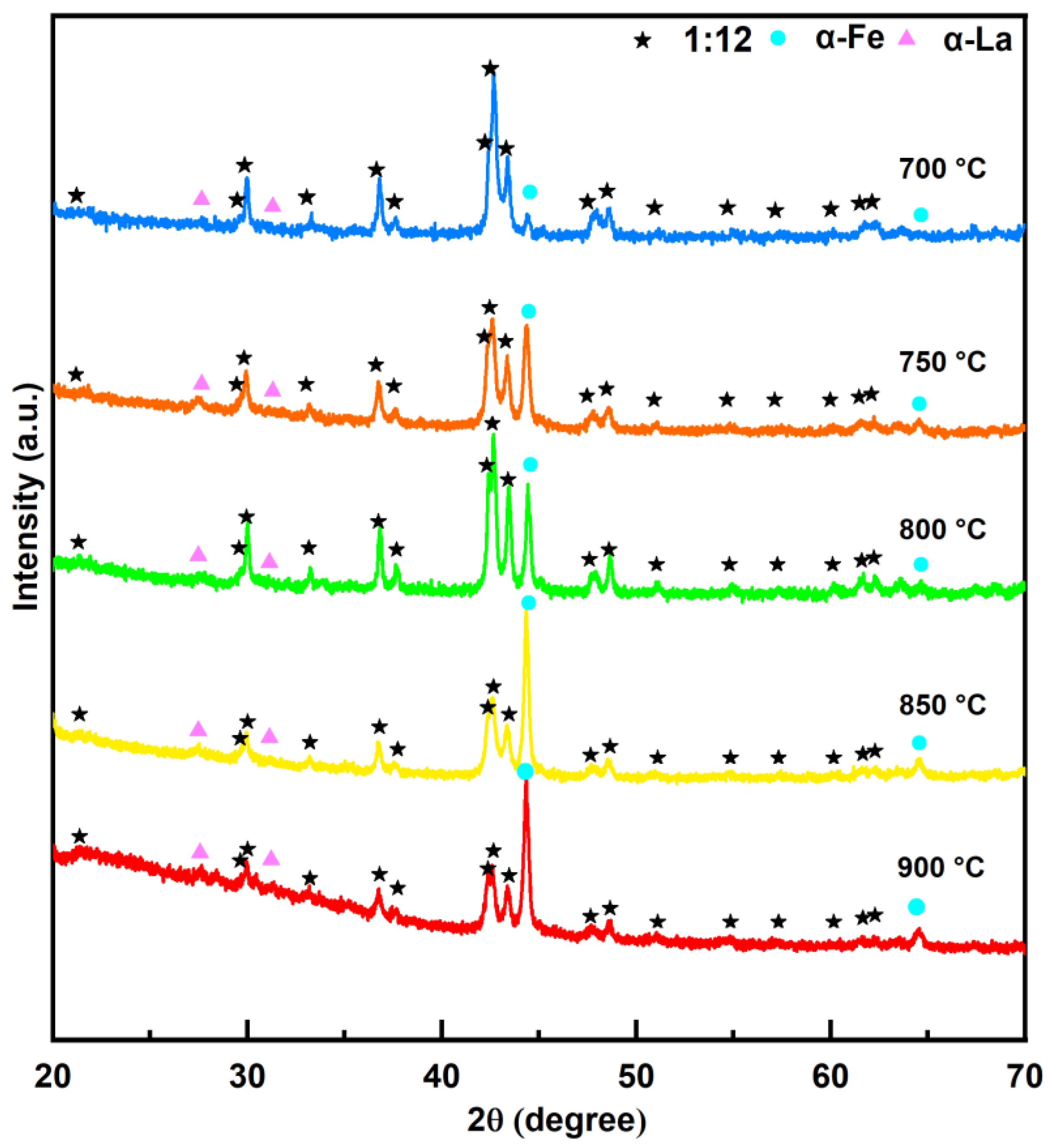

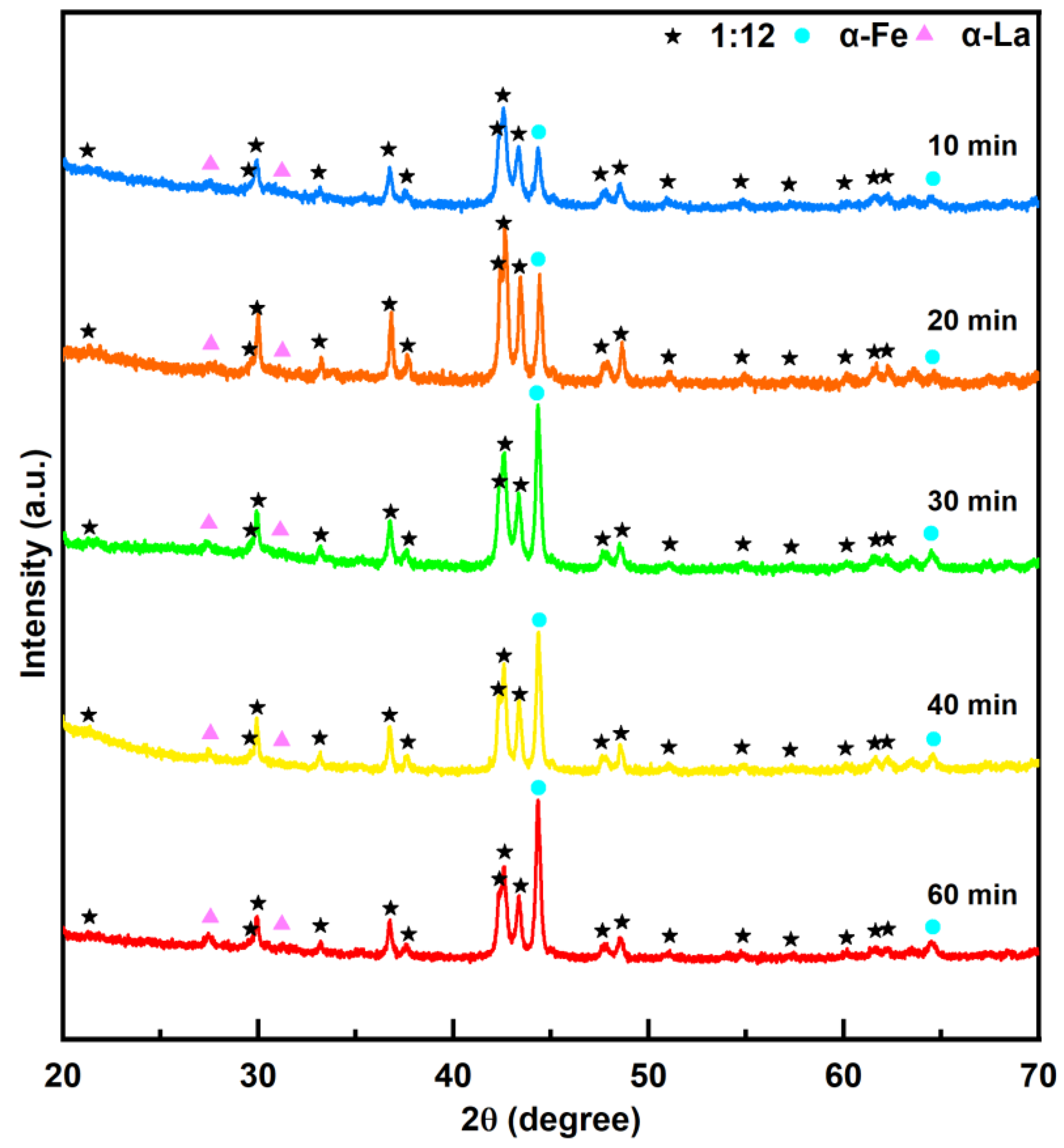

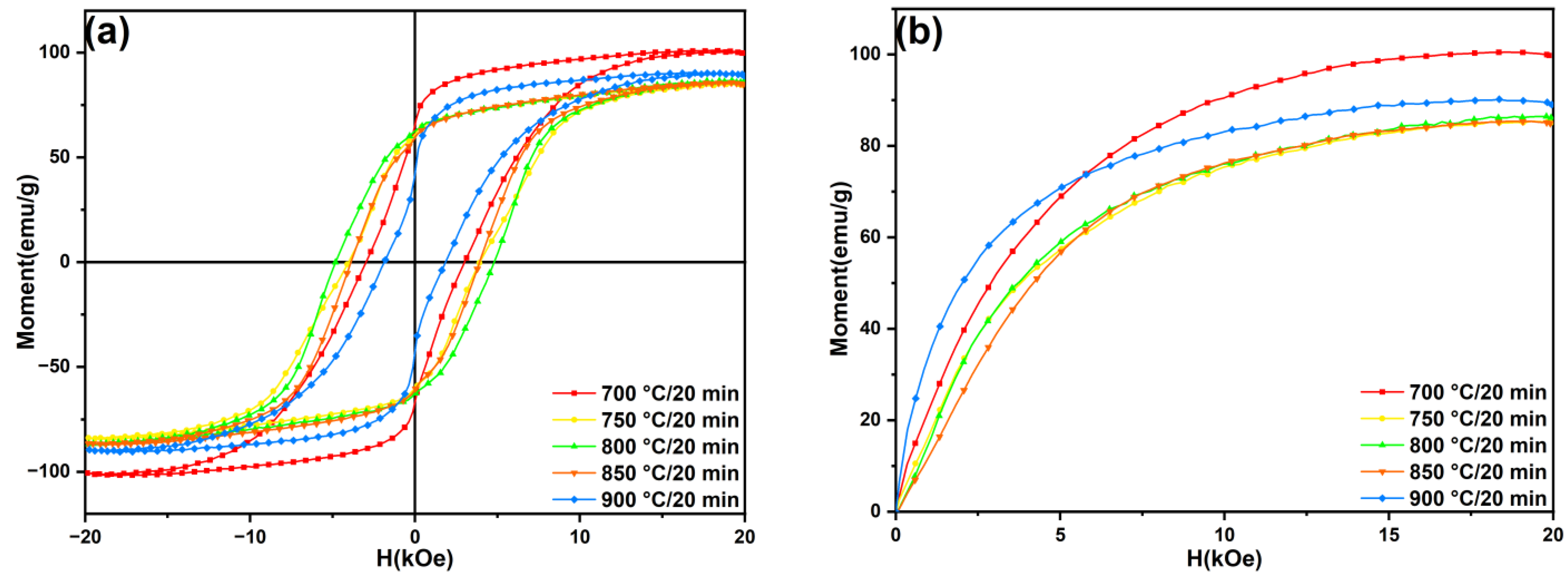

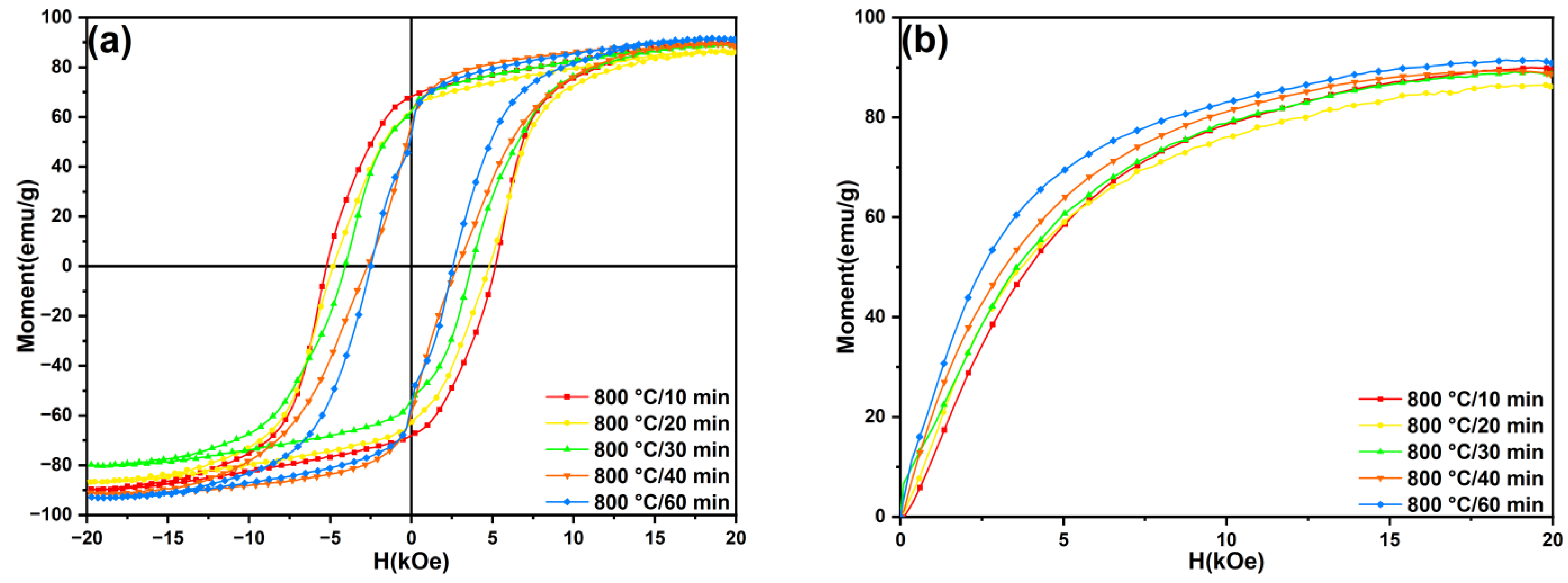

3.3. SmLa0.2Fe10V2 Ribbons

4. Conclusions

- (1)

- The XRD results demonstrate that both Sm1−xLaxFe10V2 (x = 0, 0.2, 0.4) and SmLayFe10V2 (y = 0.1, 0.2, 0.3) ribbons are composed of the 1:12 main phase with a ThMn12-type structure, α-Fe phase and α-La phase. Substituting La for Sm induces a gradual reduction in the phase fraction of the 1:12 main phase and an increase in the α-Fe phase content, thereby leading to the deterioration of the magnetic properties. Minor La addition (y ≤ 0.2) exhibits no significant impact on the formation of the 1:12 main phase in SmLayFe10V2 ribbons.

- (2)

- Heat treatment experiments on SmLa0.2Fe10V2 ribbons reveal that higher annealing temperatures improve the crystallinity of the 1:12 main phase. Excessively high annealing temperatures or prolonged annealing durations promote the precipitation of the α-Fe phase, resulting in the deterioration of the magnetic properties. After annealing at 800 °C for 10 min, the optimal magnetic properties (Hcj = 5.12 kOe, Br = 6.89 kGs, (BH)max = 6.78 MGOe) of the SmLa0.2Fe10V2 ribbon were obtained.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tozman, P.; Sepehri-Amin, H.; Hono, K. Prospects for the development of SmFe12-based permanent magnets with a ThMn12-type phase. Scr. Mater. 2021, 194, 113686. [Google Scholar] [CrossRef]

- Schönhöbel, A.M.; Madugundo, R.; Barandiarán, J.M.; Hadjipanayis, G.C.; Palanisamy, D.; Schwarz, T.; Gault, B.; Raabe, D.; Skokov, K.; Gutfleisch, O.; et al. Schrefl, Nanocrystalline Sm-based 1:12 magnets. Acta Mater. 2020, 200, 652–658. [Google Scholar] [CrossRef]

- Kobayashi, K.; Furusawa, D.; Suzuki, S.; Kuno, T.; Urushibata, K.; Sakuma, N.; Yano, M.; Shoji, T.; Kato, A.; Manabe, A.; et al. High-temperature stability of ThMn12 magnet materials. Mater. Trans. 2018, 59, 1845–1853. [Google Scholar] [CrossRef]

- Takahashi, Y.K.; Sepehri-Amin, H.; Ohkubo, T. Recent advances in SmFe12-based permanent magnets. Sci. Technol. Adv. Mater. 2021, 22, 449–460. [Google Scholar] [CrossRef] [PubMed]

- Ochirkhuyag, T.; Hong, S.C.; Odkhuu, D. Intrinsic hard magnetism and thermal stability of a ThMn12-type permanent magnet. Npj Comput. Materials 2022, 8, 193. [Google Scholar] [CrossRef]

- Harashima, Y.; Terakura, K.; Kino, H.; Lshibashi, S.; Miyake, T. First-principles study on stability and magnetism of NdFe11M and NdFe11MN for M=Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Zn. J. Appl. Phys. 2016, 120, 20394. [Google Scholar] [CrossRef]

- Nguyen, D.; Kino, H.; Miyake, T.; Dam, H. Explainable active learning in investigating structure-stability of SmFe12-α-βXαYβ structures X, Y={Mo, Zn, Co, Cu, Ti, Al, Ga}. MRS Bull. 2023, 48, 31–44. [Google Scholar] [CrossRef]

- Coehoorn, R. Electronic structure and magnetism of transition-metal-stabilized YFe12−xMx intermetallic compounds. Phys. Rev. B 1990, 41, 11790. [Google Scholar] [CrossRef]

- Wang, Y.Z.; Hadjipanayis, G.C. Magnetic properties of Sm-Fe-Ti-V alloys. J. Magn. Magn. Mater. 1990, 87, 375–378. [Google Scholar] [CrossRef]

- Schönhöbel, A.M.; Madugundo, R.; Vekilova, O.Y.; Eriksson, O.; Herper, H.C.; Barandiará, J.M.; Hadjipanayis, G.C. Intrinsic magnetic properties of SmFe12−xVx alloys with reduced V-concentration. J. Alloys Compd. 2019, 786, 969–974. [Google Scholar] [CrossRef]

- Chen, N.X.; Hao, S.Q.; Wu, Y.; Shen, J. Phase stability and site preference of Sm(Fe,T)12. J. Magn. Magn. Mater. 2001, 233, 169–180. [Google Scholar]

- Dirba, I.; Harashima, Y.; Sepehri-Amin, H.; Ohkubo, T.; Miyake, T.; Hirosawa, S.; Hono, K. Thermal decomposition of ThMn12-type phase and its optimum stabilizing elements in SmFe12-based alloys. J. Alloys Compd. 2020, 813, 152224. [Google Scholar] [CrossRef]

- Bosco, R.C.; André, G.F.; Jame, R.R.J.; Cristina, E.B.; Jose, M.P.; Paula, S.G.; Daniel, S. Magnetic properties of tetragonal SmFe12−xMox alloys in bulk and melt-spun ribbons. Phys. Status Solidi (A) 2020, 219, 2100725. [Google Scholar]

- Lin, Z.; Han, J.Z.; Liu, S.; Xing, M.Y.; Yang, Y.B.; Yang, J.B.; Wang, C.S.; Du, H.L.; Yang, Y.C. Phase composition, microstructures and magnetic properties of melt-spun Nd1.2Fe10.5Mo1.5 ribbons and their nitrides. J. Magn. Magn. Mater. 2012, 324, 196–199. [Google Scholar] [CrossRef]

- Qian, H.D.; Lim, J.T.; Kim, J.W.; Yang, Y.; Zhou, T.H.; Jeon, H.K.; Park, J.; Choi, C.J. Physical and magnetic properties of ThMn12-type Sm(Fe0.8Co0.2)10Si2 melt-spun ribbons. Metals 2022, 12, 753. [Google Scholar] [CrossRef]

- Tozman, P.; Sepehri-Amin, H.; Ohkubo, T.; Hono, K. Intrinsic magnetic properties of (Sm,Gd)Fe12-based compounds with minimized addition of Ti. J. Alloys Compd. 2021, 855, 157491. [Google Scholar] [CrossRef]

- Srinithi, A.K.; Tang, X.; Sepehri-Amin, H.; Zhang, J.; Ohkubo, T. Hono, High-coercivity SmFe12-based anisotropic sintered magnets by Cu addition. Acta Mater. 2023, 256, 119111. [Google Scholar] [CrossRef]

- Xu, Y.T.; Han, C.Y.; Ni, C.Y.; Gabay, A.; Hadjipanayis, G.C. Bulk magnetic hardening in Sm(Fe,V)12 alloys. J. Magn. Magn. Mater. 2024, 603, 172223. [Google Scholar] [CrossRef]

- Tozman, P.; Fukazawa, T.; Ogawa, D.; Sepehri-Amin, H.; Bolyachkin, A.; Miyake, T.; Hirosawa, S.; Hono, K.; Takahashi, Y.K. Peculiar behavior of V on the Curie temperature and anisotropy field of SmFe12−xVx compounds. Acta Mater. 2022, 232, 117928. [Google Scholar] [CrossRef]

- Makurenkova, A.; Ogawa, D.; Tozman, P.; Okamoto, S.; Nikitin, S.; Hirosawa, S.; Hono, K.; Takahashi, Y.K. Intrinsic hard magnetic properties of Sm(Fe,Co)12−xTix compound with ThMn12 structure. J. Alloys Compd. 2021, 861, 158477. [Google Scholar] [CrossRef]

- Saito, T.; Watanabe, F.; Nishio-Hamane, D. High-coercivity Sm(Fe,V,Ti)12 bulk magnets. Mater. Res. Bull. 2021, 133, 11060. [Google Scholar] [CrossRef]

- Otsuka, K.; Kamata, M.; Nomura, T.; Iida, H.; Nakamura, H. Coercivities of Sm-Fe-M sintered magnets with ThMn12-type structure (M=Ti, V). Mater. Trans. 2021, 62, 887–891. [Google Scholar] [CrossRef]

- Niarchos, D.; Gjoka, M.; Schönhöbel, A.M.; Aubert, A.; Madugundo, R.; Garitaonandía, J.J.S.; Barandiaran, J.M.L.; Hadjipanayis, G. Intrinsic magnetic properties of (Nd1−xSmx)Fe11Ti. J. Alloys Compd. 2021, 864, 158097. [Google Scholar] [CrossRef]

- Hagiwara, M.; Sanada, N.; Sakurada, S. Structural and magnetic properties of rapidly quenched (Sm,R)(Fe,Co)11.4Ti0. 6(R=Y, Zr) with ThMn12 structure. AIP Adv. 2019, 9, 035036. [Google Scholar] [CrossRef]

- Gabay, A.M.; Cabassi, R.; Fabbrici, S.; Albertini, F.; Hadjipanayis, G.C. Structure and permanent magnet properties of Zr1-xRxFe10Si2 alloys with R=Y, La, Ce, Pr and Sm. J. Alloys Compd. 2016, 683, 271–275. [Google Scholar] [CrossRef]

- Kim, H.T.; Kim, Y.B.; Kim, C.S.; Jin, H. Magnetocrystalline anisotropy of (Sm0.5RE0.5)Fe11Ti compounds (RE Ce, Pr, Nd, Sm, Gd and Tb). J. Magn. Magn. Mater. 1996, 152, 387–390. [Google Scholar] [CrossRef]

- Wuest, H.; Bommer, L.; Huber, A.M.; Goll, D.; Weissgaerber, T.; Kieback, B. Preparation of nanocrystalline Ce1-xSmx(Fe,Co)11Ti by melt spinning and mechanical alloying. J. Magn. Magn. Mater. 2017, 428, 194–197. [Google Scholar] [CrossRef]

- Liu, F.; Feng, H.; Zhao, H.; Sun, X. Magnetic properties and microstructure of Ce and Zr synergetic stabilizing Ti-lean SmFe12-based strip-casting flakes. J. Magn. Magn. Mater. 2024, 599, 172100. [Google Scholar] [CrossRef]

- Kobayashi, K.; Suzuki, S.; Kuno, T.; Urushibata, K.; Sakuma, N.; Yano, M.; Shouji, T.; Kato, A.; Manabe, A. The stability of newly developed (R,Zr)(Fe,Co)12−xTix alloys for permanent magnets. J. Alloys Compd. 2017, 694, 914–920. [Google Scholar] [CrossRef]

- Zhao, L.Z.; Su, R.; Wen, L.; Li, W.; Liu, X.L.; Zhang, Z.H.; Zhao, R.Z.; Han, Y.Y.; Zhang, X.F.; Li, W. Intrinsically high magnetic performance in core-shell structural (Sm, Y)Fe12-based permanent magnets. Adv. Mater. 2022, 34, 2203503. [Google Scholar] [CrossRef]

- Yang, Z.L.; Ying, W.Y.; Liu, X.; Yao, Q.R.; Wang, J. Effect of La on phase formation, microstructure, and magnetic properties of ThMn12-type SmFe11Ti melt-spun ribbons. Phys. Status Solidi (A) 2024, 222, 2400725. [Google Scholar] [CrossRef]

- Zhou, T.H.; Song, Y.; Zhang, B.C.; Zheng, X.; Choi, C.J.; Cho, Y.R.; Park, J. Enhancing coercivity through grain boundary phase modification in SmxFe10V2. J. Mater. Res. Technol. 2024, 30, 3092–3100. [Google Scholar] [CrossRef]

- Hagiwara, M.; Sanada, N.; Sakurada, S. Effect of Y substitution on the structural and magnetic properties of Sm(Fe0.8Co0.2)11.4Ti0.6. J. Magn. Magn. Mater. 2018, 465, 554–558. [Google Scholar] [CrossRef]

- Egorov, D.; Petrov, I.; Pyrhönen, J.J.; Link, J.; Stern, R.; Sergeant, P. Hysteresis loss in NdFeB permanent magnets in a permanent magnet synchronous machine. IEEE Trans. Ind. Electron. 2022, 69, 121–129. [Google Scholar] [CrossRef]

- Duerrschnabel, M.; Yi, M.; Uestuener, K.; Liesegang, M.; Katter, M.; Kleebe, H.J.; Xu, B.; Gutfleisch, O.; Molina-Luna, L. Atomic structure and domain wall pinning in samarium-cobalt-based permanent magnets. Nat. Commun. 2017, 8, 54. [Google Scholar] [CrossRef]

- Chen, C.; Huang, Y.L.; Yao, Y.F.; Fu, X.K.; Li, W.; Hou, Y.H. Effects of thermal annealing on improved magnetic properties and microstructure for SmFe11Ti alloy. J. Magn. Magn. Mater. 2021, 530, 167950. [Google Scholar] [CrossRef]

- Saito, T.; Miyoshi, H.; Nishio-Hamane, D. Magnetic properties of Sm-Fe-Ti nanocomposite magnets with a ThMn12 structure. J. Alloys Compd. 2012, 519, 144–148. [Google Scholar] [CrossRef]

| Ribbon | Hcj (kOe) | Br (kGs) | (BH)max (MGOe) | Mr/Ms |

|---|---|---|---|---|

| SmFe10V2 | 4.36 ± 0.04 | 5.17 ± 0.05 | 4.03 ± 0.04 | 0.68 ± 0.02 |

| Sm0.8La0.2Fe10V2 | 2.70 ± 0.03 | 4.18 ± 0.04 | 2.01 ± 0.02 | 0.57 ± 0.02 |

| Sm0.6La0.4Fe10V2 | 0.43 ± 0.01 | 2.89 ± 0.03 | 0.25 ± 0.01 | 0.44 ± 0.01 |

| SmLa0.1Fe10V2 | 4.57 ± 0.05 | 5.52 ± 0.06 | 4.82 ± 0.05 | 0.69 ± 0.02 |

| SmLa0.2Fe10V2 | 4.82 ± 0.05 | 5.91 ± 0.06 | 5.30 ± 0.05 | 0.71 ± 0.02 |

| SmLa0.3Fe10V2 | 1.45 ± 0.01 | 4.21 ± 0.04 | 0.69 ± 0.01 | 0.50 ± 0.01 |

| Heat Treatment | Hcj (kOe) | Br (kGs) | (BH)max (MGOe) | Mr/Ms |

|---|---|---|---|---|

| 700 °C/20 min | 2.97 ± 0.03 | 5.54 ± 0.05 | 2.86 ± 0.03 | 0.64 ± 0.02 |

| 750 °C/20 min | 4.06 ± 0.04 | 5.71 ± 0.06 | 4.60 ± 0.05 | 0.71 ± 0.02 |

| 800 °C/20 min | 4.82 ± 0.05 | 5.91 ± 0.06 | 5.30 ± 0.05 | 0.71 ± 0.02 |

| 850 °C/20 min | 3.85 ± 0.04 | 5.43 ± 0.05 | 4.32 ± 0.04 | 0.69 ± 0.02 |

| 900 °C/20 min | 1.86 ± 0.02 | 3.98 ± 0.04 | 0.95 ± 0.01 | 0.49 ± 0.01 |

| 800 °C/10 min | 5.12 ± 0.05 | 6.89 ± 0.07 | 6.78 ± 0.07 | 0.75 ± 0.02 |

| 800 °C/30 min | 4.08 ± 0.04 | 5.82 ± 0.06 | 5.17 ± 0.05 | 0.70 ± 0.02 |

| 800 °C/40 min | 2.75 ± 0.03 | 5.20 ± 0.05 | 2.42 ± 0.02 | 0.64 ± 0.02 |

| 800 °C/60 min | 2.44 ± 0.02 | 4.78 ± 0.05 | 2.20 ± 0.02 | 0.58 ± 0.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ying, W.; Yang, Z.; Liu, X.; Yao, Q.; Wang, J. Effects of Lanthanum Element and Heat Treatment on Phase Formation and Magnetic Properties of SmFe10V2 Melt-Spun Ribbons. Materials 2025, 18, 2322. https://doi.org/10.3390/ma18102322

Ying W, Yang Z, Liu X, Yao Q, Wang J. Effects of Lanthanum Element and Heat Treatment on Phase Formation and Magnetic Properties of SmFe10V2 Melt-Spun Ribbons. Materials. 2025; 18(10):2322. https://doi.org/10.3390/ma18102322

Chicago/Turabian StyleYing, Weiyi, Zhengli Yang, Xiang Liu, Qingrong Yao, and Jiang Wang. 2025. "Effects of Lanthanum Element and Heat Treatment on Phase Formation and Magnetic Properties of SmFe10V2 Melt-Spun Ribbons" Materials 18, no. 10: 2322. https://doi.org/10.3390/ma18102322

APA StyleYing, W., Yang, Z., Liu, X., Yao, Q., & Wang, J. (2025). Effects of Lanthanum Element and Heat Treatment on Phase Formation and Magnetic Properties of SmFe10V2 Melt-Spun Ribbons. Materials, 18(10), 2322. https://doi.org/10.3390/ma18102322