Alumina-Based Cutting Tools—A Review of Recent Progress

Abstract

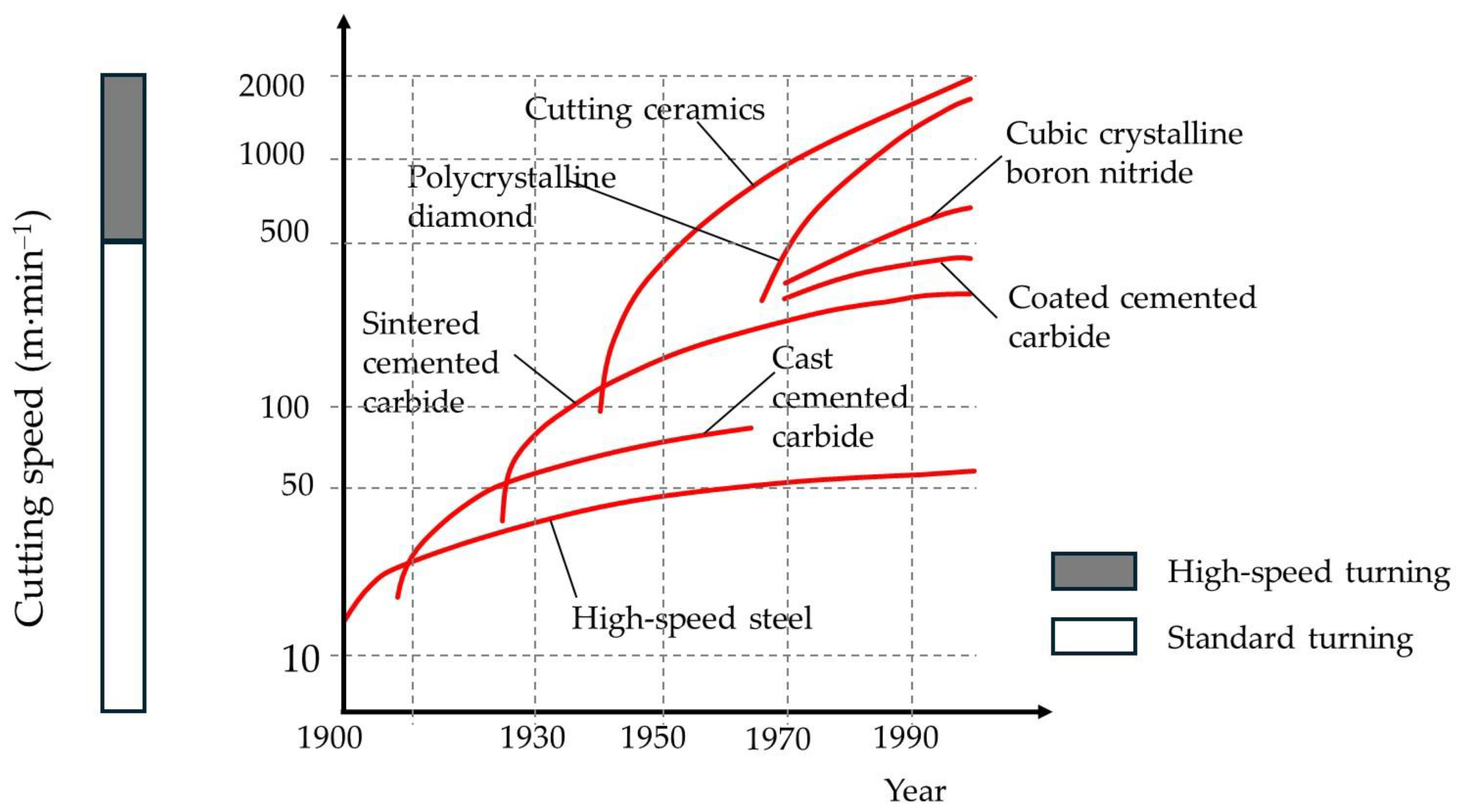

1. Introduction

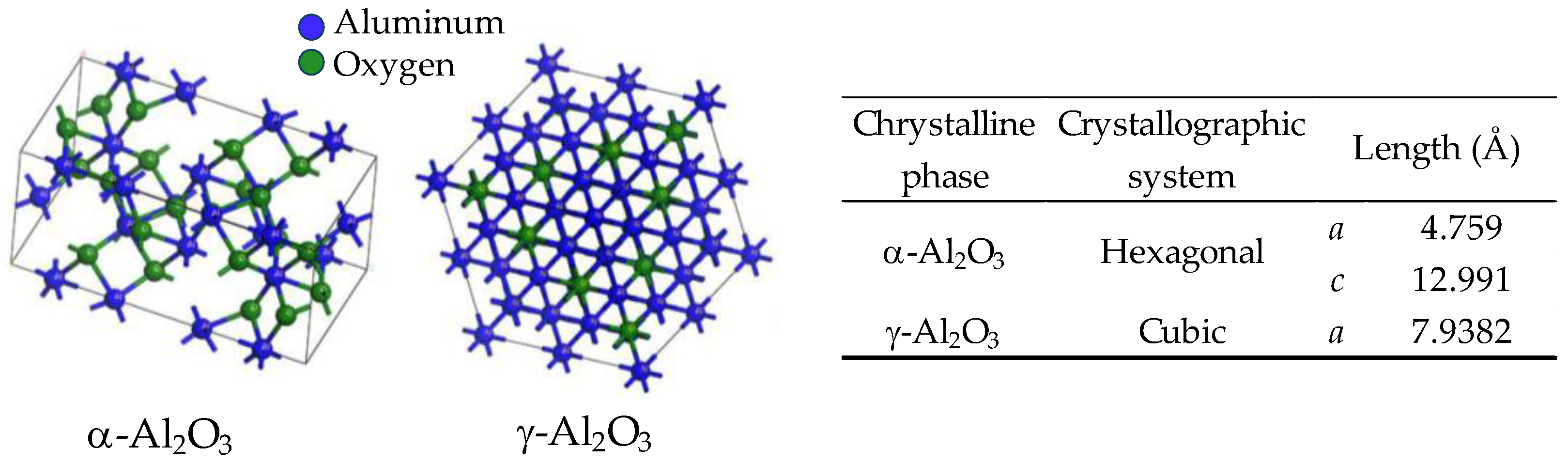

2. Alumina as Cutting Tool Inserts

2.1. Doped vs. Composite Ceramics—Not to Be Confused with CMCs

2.2. Doped Alumina for Cutting Inserts

2.2.1. Doping Alumina with Titania

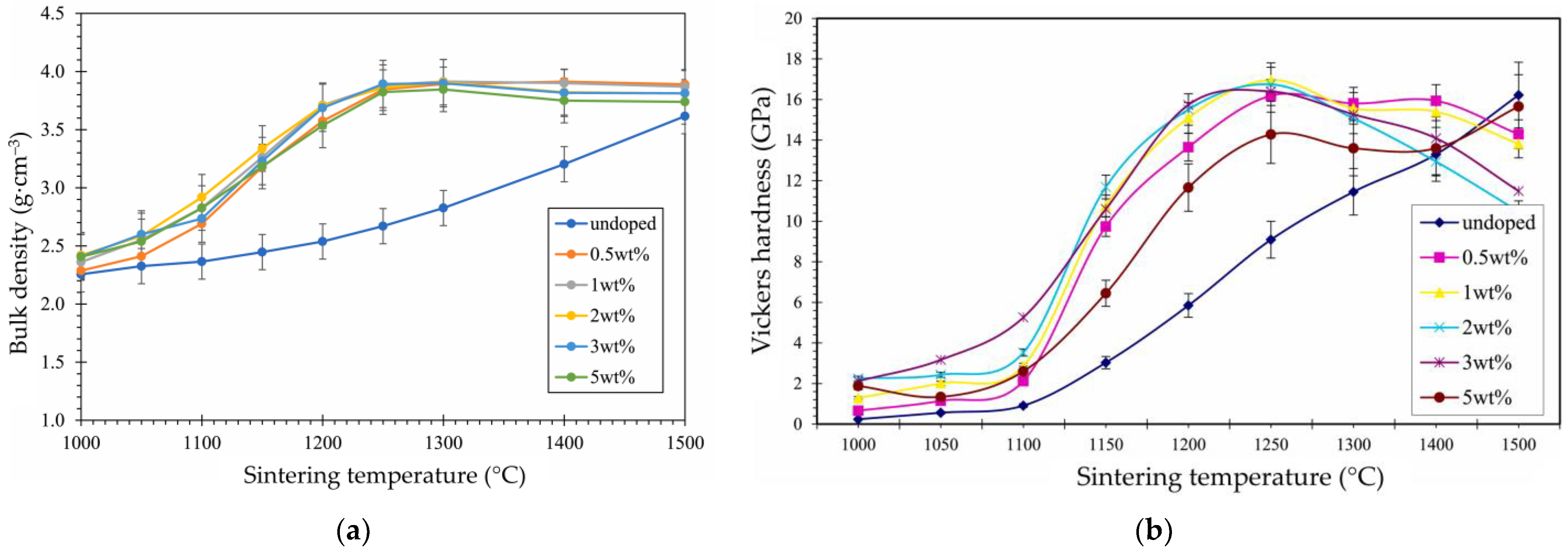

2.2.2. Manganese Oxide Doped Alumina

2.3. Zirconia-Toughened Alumina (ZTA)

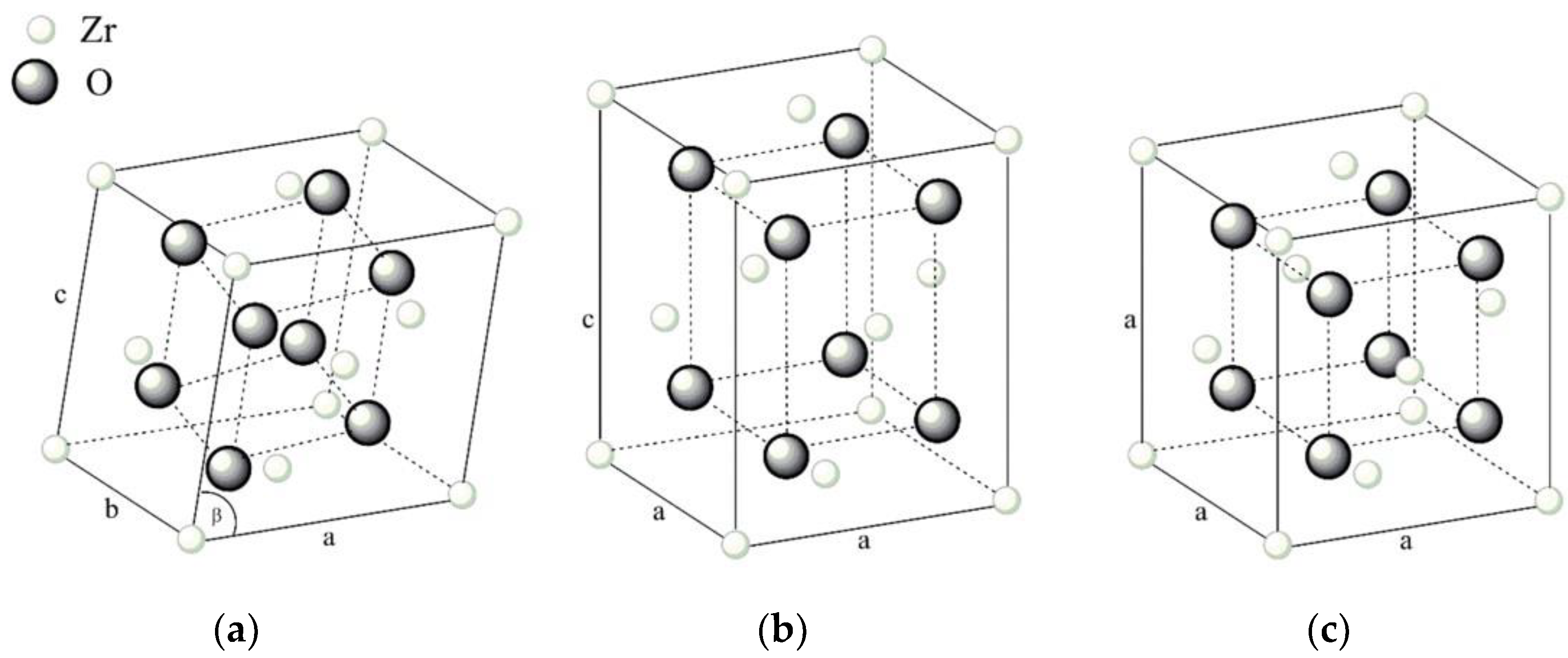

2.3.1. Yttria Tetragonal Stabilized Zirconia for ZTA

2.3.2. Magnesia Tetragonal Stabilized Zirconia for ZTA

2.4. Molybdenum Reinforced Zirconia-Toughened Alumina

2.5. Strontium Reinforced Zirconia-Toughened Alumina

2.6. Multi-Walled Carbon Nanotubes (MWCNTs)-Alumina Hybrid Composites

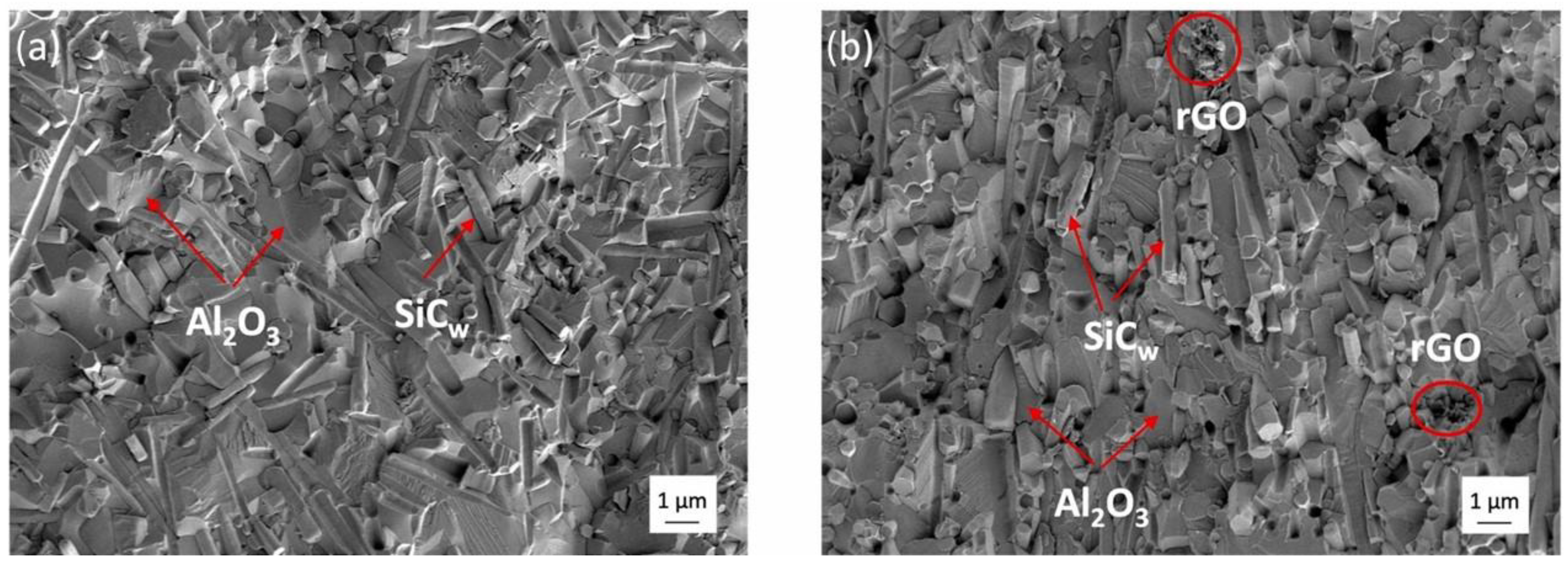

2.7. Ceramic Matrix Composite with SiC Whiskers

2.8. Other Composite Alumina Ceramics

3. Advanced Sintering Techniques

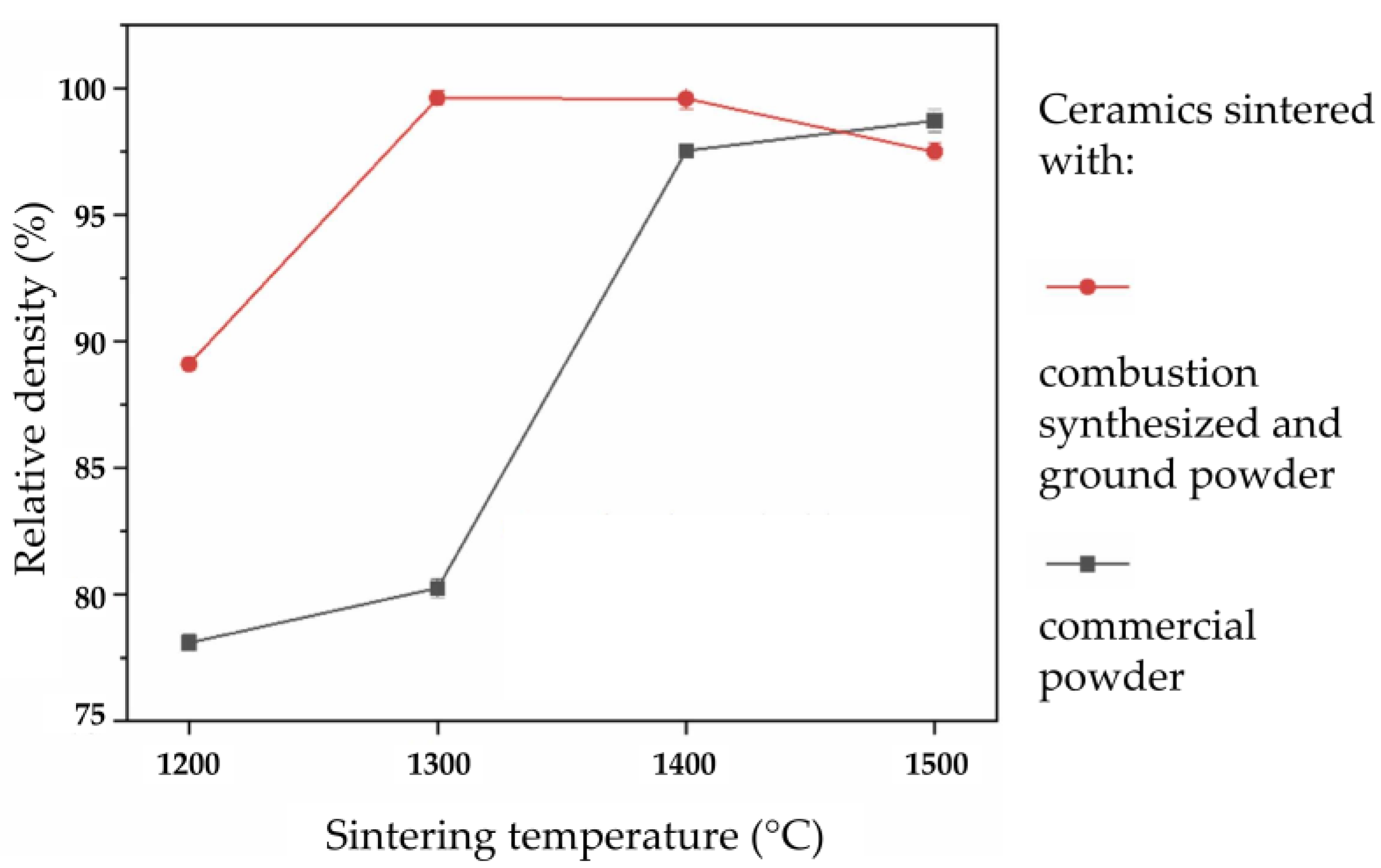

3.1. Two-Step Sintering Using Nanoparticles

3.2. Spark Plasma Sintering Using Co-Precipitated Powders

3.3. Cold Sintering

3.4. Low Temperature Sintering

3.5. Microwave Sintering Using Nanoparticles

3.6. Electron Beam Powder Bed Sintering

4. Discussion

5. Conclusions, Sustainability and Perspective

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| 3Y-TZP | 3% Yttria-Tetragonal Zirconia Polycrystal |

| CFRP | Carbon Fiber Reinforced Composites |

| CMC | Ceramic Matrix Composites |

| CRM | Critical Raw Materials |

| CSP | Cold Sintering Process |

| EB-PBF | Electron Beam Powder Bed Fusion |

| EBM | Electron Beam Melting |

| EDM | Electrical Discharge Machining |

| FESEM | Field Emission Scanning Electron Microscopy |

| GO | Graphene Oxide |

| MMC | Metal Matrix Composites |

| MQL | Minimum Quantity Lubrication |

| MW | Microwave |

| MWCNT | Multi-Walled Carbon Nanotubes |

| PcBN | Polycrystalline Cubic Boron Nitride |

| rGO | Reduced Graphene Oxide |

| PCD | Polycrystalline Diamond |

| SDG | Sustainable Development Goals |

| SEM | Scanning Electron Microscopy |

| SiCw | Silicon Carbide Whiskers |

| SPS | Spark Plasma Sintering |

| TEM | Transmission Electron Microscopy |

| TZP | Tetragonal Zirconia Polycrystal |

| YSZ | Yttria-Stabilized Zirconia |

| ZTA | Zirconia-Toughened Alumina |

References

- Shokrani, A.; Arrazola, P.J.; Biermann, D.; Mativenga, P.; Jawahir, I.S. Sustainable Machining: Recent Technological Advances. CIRP Ann. 2024, 73, 483–508. [Google Scholar] [CrossRef]

- Wegener, K.; Kuster, F.; Weikert, S.; Weiss, L.; Stirnimann, J. Success Story Cutting. Procedia CIRP 2016, 46, 512–524. [Google Scholar] [CrossRef]

- Seleznev, A.; Pinargote, N.W.S.; Smirnov, A. Ceramic Cutting Materials and Tools Suitable for Machining High-Temperature Nickel-Based Alloys: A Review. Metals 2021, 11, 1385. [Google Scholar] [CrossRef]

- Senthil Kumar, A.; Raja Durai, A.; Sornakumar, T. Machinability of Hardened Steel Using Alumina Based Ceramic Cutting Tools. Int. J. Refract. Metals Hard Mater. 2003, 21, 109–117. [Google Scholar] [CrossRef]

- Jianxin, D.; Xing, A. Wear Behavior and Mechanisms of Alumina-Based Ceramic Tools in Machining of Ferrous and Non-Ferrous Alloys. Tribol. Int. 1997, 30, 807–813. [Google Scholar] [CrossRef]

- Thakur, T.; Heinen, S.; Ehrle, B.; Blugan, G. Optimizing Woodcutting with Zirconia-Toughened Alumina: Processing, Performance, and Industrial Insights. Heliyon 2025, 11, e41785. [Google Scholar] [CrossRef] [PubMed]

- Sun, N.; Cheng, Y.; Zhu, T.; Pan, L.; Liao, N.; Wang, H.; Li, Y.; Dai, J.; Xie, Z.; Sang, S. Mechanical Properties of Binderless Tungsten Carbide Enhanced via the Addition of ZrO2-20 wt% Al2O3 Composite Powder and Graphene Nanosheets. Ceram. Int. 2023, 49, 22853–22860. [Google Scholar] [CrossRef]

- Sun, N.; Cheng, Y.; Zhu, T.; Wang, H.; Pan, L.; Liao, N.; Li, Y.; Xie, Z. Tribological Properties and Wear Resistance Mechanism of WC-ZrO2-Al2O3 Ceramics. J. Alloys Compd. 2023, 960, 171069. [Google Scholar] [CrossRef]

- Sun, N.; Zhu, T.; Liang, X.; Pan, L.; Li, Y.; Wang, H.; Xie, Z.; Sang, S.; Dai, J. Improved Comprehensive Mechanical Properties of Oscillatory Pressure Sintered WC–ZrO2–Al2O3 Ceramics with VC/Cr3C2 Addition. Ceram. Int. 2023, 49, 11494–11503. [Google Scholar] [CrossRef]

- Memarianpour, M.; Niknam, S.A.; Turenne, S.; Balazinski, M. Study of the Effects of Initial Cutting Conditions and Transition Period on Ultimate Tool Life When Machining Inconel 718. Materials 2021, 14, 592. [Google Scholar] [CrossRef]

- Zou, Q.; Dong, P.; Li, Y.; Li, S.; Dai, L.; Wu, D.; Luo, Y. Effect of Sintering Temperature on Microstructure and Properties of PcBN Composites. J. Mater. Eng. Perform. 2024, 34, 4494–4501. [Google Scholar] [CrossRef]

- Yue, Y.; Zhu, Y.; Li, Z. Preparation and Cutting Performance Study of YSZ-Toughened PcBN Superhard Tools. RSC Adv. 2023, 13, 15616–15623. [Google Scholar] [CrossRef] [PubMed]

- Peicheng, M.; Chao, C.; Guang, J.; Jiarong, C.; Delong, X.; Leyin, X.; Xiaoyi, P.; Feng, L. Effect of Tungsten Content on Microstructure and Mechanical Properties of PCBN Synthesized in CBN-Ti-Al-W System. Int. J. Refract. Metals Hard Mater. 2020, 87, 105138. [Google Scholar] [CrossRef]

- Klymenko, S.; Zhang, H.; Savchenko, D.; Chumak, A.; Klymenko, S.; Melniychuk, Y.; Manokhin, A.; Kremenytskyi, V.V.; Novichenko, V.M. Bi-Layer CBN-Based Composites Reinforced with Oxide and Non-Oxide Microfibers of Refractory Compounds. Sci. Rep. 2024, 14, 10050. [Google Scholar] [CrossRef]

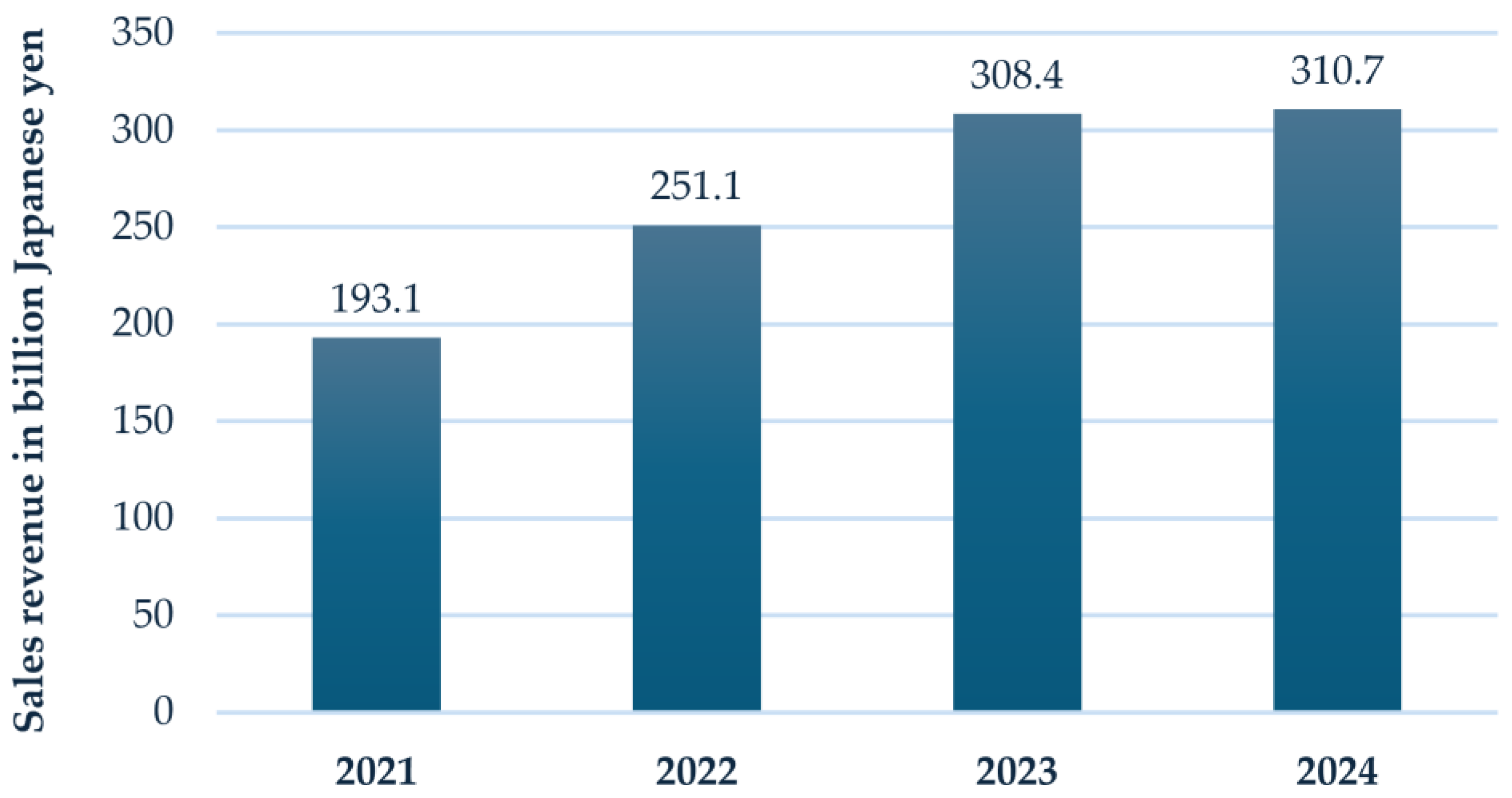

- Sales Revenue of Kyocera Corporation’s Industrial Tools Segment from Fiscal Year 2021 to 2024 (in Billion Japanese Yen) [Graph]. Available online: https://www-statista-com.ezproxy.nsk.hr/statistics/1311791/kyocera-industrial-tools-segment-sales-revenue/ (accessed on 10 March 2025).

- Schultheiss, F.; Zhou, J.; Gröntoft, E.; Ståhl, J.-E. Sustainable Machining through Increasing the Cutting Tool Utilization. J. Clean. Prod. 2013, 59, 298–307. [Google Scholar] [CrossRef]

- The 17 Goals—Sustainable Development. Available online: https://sdgs.un.org/goals (accessed on 14 February 2025).

- Publications Office of the European Union. Tackling the Challenges in Commodity Markets and on Raw Materials. Available online: https://op.europa.eu/s/z4sY (accessed on 17 February 2025).

- Rizzo, A.; Goel, S.; Luisa Grilli, M.; Iglesias, R.; Jaworska, L.; Lapkovskis, V.; Novak, P.; Postolnyi, B.O.; Valerini, D. The Critical Raw Materials in Cutting Tools for Machining Applications: A Review. Materials 2020, 13, 1377. [Google Scholar] [CrossRef]

- Publications Office of the European Union. Critical Raw Materials Resilience: Charting a Path Towards Greater Security and Sustainability. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52020DC0474 (accessed on 15 February 2025).

- Peng, Y.; Chen, Z.; Sun, X.; Zhou, Y.; Ou, X. Properties, Treatment and Resource Utilization of Bauxite Tailings: A Review. Sustainability 2024, 16, 6948. [Google Scholar] [CrossRef]

- Ćećez, M.; Šahinagić-Isović, M. Fresh and Hardened Concrete Properties Containing Red Mud and Silica Fume. J. Croat. Assoc. Civ. Eng. 2023, 75, 439–449. [Google Scholar] [CrossRef]

- Muñoz-Vélez, M.F.; Salazar-Serna, K.; Escobar-Torres, D.; Rojas-Manzano, M.A.; Gómez-Gómez, A.; Maury-Ramírez, A. Circular Economy: Adding Value to the Post-Industrial Waste through the Transformation of Aluminum Dross for Cement Matrix Applications. Sustainability 2023, 15, 13952. [Google Scholar] [CrossRef]

- Denkena, B.; Breidenstein, B.; Krödel, A.; Bergmann, B.; Picker, T.; Wolters, P. Suitability of Natural Rocks as Materials for Cutting Tools. SN Appl. Sci. 2022, 4, 2. [Google Scholar] [CrossRef]

- Breidenstein, B.; Denkena, B.; Bergmann, B.; Picker, T.; Wolters, P. Tool Wear When Using Natural Rocks as Cutting Material for the Turning of Aluminum Alloys and Plastics. Prod. Eng. 2023, 17, 425–435. [Google Scholar] [CrossRef]

- Breidenstein, B.; Denkena, B.; Wolters, P.; Keitel, M.; Tillmann, W.; Stangier, D.; Lopes Dias, N.F. A Novel Development of Sustainable Cutting Inserts Based on PVD-Coated Natural Rocks. Mater. Today Sustain. 2023, 24, 100507. [Google Scholar] [CrossRef]

- Xing, Y.; Luo, C.; Zhu, M.; Zhao, Y.; Ehmann, K.; Wu, Z.; Liu, L. Assessment of Self-Lubricating Coated Cutting Tools Fabricated by Laser Additive Manufacturing Technology for Friction-Reduction. J. Mater. Process Technol. 2023, 318, 118010. [Google Scholar] [CrossRef]

- Li, Y.; Chen, H.; Zhang, J.; Xiao, G.; Yi, M.; Chen, Z.; Xu, C. Synergetic Lubrication between Self-Lubricating Ceramic Tools and Nanofluids: Advancing the Application of Self-Lubricating Ceramic Cutting Tools. Int. J. Refract. Metals Hard Mater. 2024, 120, 106622. [Google Scholar] [CrossRef]

- Feng, C.; Huang, S. The Analysis of Key Technologies for Sustainable Machine Tools Design. Appl. Sci. 2020, 10, 731. [Google Scholar] [CrossRef]

- Kim, D.M.; Kim, H.I.; Park, H.W. Tool Wear, Economic Costs, and CO2 Emissions Analysis in Cryogenic Assisted Hard-Turning Process of AISI 52100 Steel. Sustain. Mater. Technol. 2021, 30, e00349. [Google Scholar] [CrossRef]

- Mativenga, P.; Schoop, J.; Jawahir, I.S.; Biermann, D.; Kipp, M.; Kilic, Z.M.; Özel, T.; Wertheim, R.; Arrazola, P.; Boing, D. Engineered Design of Cutting Tool Material, Geometry, and Coating for Optimal Performance and Customized Applications: A Review. CIRP J. Manuf. Sci. Technol. 2024, 52, 212–228. [Google Scholar] [CrossRef]

- O’Hara, J.; Fang, F.-Z. Design and Fabrication of an Aluminium Oxide Cutting Insert with an Internal Cooling Channel. Adv. Manuf. 2024, 12, 619–641. [Google Scholar] [CrossRef]

- Kelliger, T.; Meurer, M.; Bergs, T. Potentials of Additive Manufacturing for Cutting Tools: A Review of Scientific and Industrial Applications. Metals 2024, 14, 982. [Google Scholar] [CrossRef]

- Gupta, P.K.; Yadav, N.P. Numerical Investigation Into Convective Heat Transfer Coefficient of the Grinding Fluid Used in a Deep Grinding Process. Trans. FAMENA 2024, 48, 129–144. [Google Scholar] [CrossRef]

- Agapiou, J.; Stephenson, D.A. Cutting Tool Wear and Failure Mechanisms. In Encyclopedia of Tribology; Springer: Boston, MA, USA, 2013; pp. 661–677. [Google Scholar]

- Volosova, M.A.; Okunkova, A.A.; Fedorov, S.V.; Hamdy, K.; Mikhailova, M.A. Electrical Discharge Machining Non-Conductive Ceramics: Combination of Materials. Technologies 2020, 8, 32. [Google Scholar] [CrossRef]

- Huang, Y.; Peng, X.; Chen, X.-Q. The Mechanism of θ- to α-Al2O3 Phase Transformation. J. Alloys Compd. 2021, 863, 158666. [Google Scholar] [CrossRef]

- Kaunisto, K.; Lagerbom, J.; Honkanen, M.; Varis, T.; Lambai, A.; Mohanty, G.; Levänen, E.; Kivikytö-Reponen, P.; Frankberg, E. Evolution of Alumina Phase Structure in Thermal Plasma Processing. Ceram. Int. 2023, 49, 21346–21354. [Google Scholar] [CrossRef]

- Lamouri, S.; Hamidouche, M.; Bouaouadja, N.; Belhouchet, H.; Garnier, V.; Fantozzi, G.; Trelkat, J.F. Control of the γ-Alumina to α-Alumina Phase Transformation for an Optimized Alumina Densification. Boletín Soc. Esp. Cerám. Vidrio 2017, 56, 47–54. [Google Scholar] [CrossRef]

- Hao, Z.; Wu, B.; Wu, T. Preparation of Alumina Ceramic by κ-Al2O3. Ceram. Int. 2018, 44, 7963–7966. [Google Scholar] [CrossRef]

- Zhou, H.; Ji, Y.; Wang, Y.; Feng, K.; Luan, B.; Zhang, X.; Chen, L.-Q. First-Principles Lattice Dynamics and Thermodynamic Properties of α-, θ-, κ- and γ-Al2O3 and Solid State Temperature-Pressure Phase Diagram. Acta Mater. 2024, 263, 119513. [Google Scholar] [CrossRef]

- Silva-Holguín, P.N.; Ruíz-Baltazar, Á.d.J.; Medellín-Castillo, N.A.; Labrada-Delgado, G.J.; Reyes-López, S.Y. Synthesis and Characterization of α-Al2O3/Ba-β-Al2O3 Spheres for Cadmium Ions Removal from Aqueous Solutions. Materials 2022, 15, 6809. [Google Scholar] [CrossRef]

- Sato, B.K.; Lopes, J.C.; Rodriguez, R.L.; Garcia, M.V.; Mia, M.; Ribeiro, F.S.F.; Sanchez, L.E.D.A.; Aguiar, P.R.; Bianchi, E.C. Novel Comparison Concept between CBN and Al2O3 Grinding Process for Eco-Friendly Production. J. Clean. Prod. 2022, 330, 129673. [Google Scholar] [CrossRef]

- Sreejith, P.S.; Ngoi, B.K.A. Dry Machining: Machining of the Future. J. Mater. Process Technol. 2000, 101, 287–291. [Google Scholar] [CrossRef]

- Adam, A.A.; Bakar, H.A.; Amani, U.A.; Paijan, L.H.; Wahab, N.A.; Mamat, M.F.; Ali, M.B.; Herawan, S.G.; Ahmad, Z. Effect of Sintering Parameters on the Mechanical Properties and Wear Performance of Alumina Inserts. Lubricants 2022, 10, 325. [Google Scholar] [CrossRef]

- Klimov, A.; Bakeev, I.; Dolgova, A.; Oks, E.; Tran, V.T.; Zenin, A. Electron-Beam Sintering of Al2O3-Cr-Based Composites Using a Forevacuum Electron Source. Ceramics 2022, 5, 748–760. [Google Scholar] [CrossRef]

- Boldin, M.S.; Popov, A.A.; Lantsev, E.A.; Nokhrin, A.V.; Chuvil’deev, V.N. Investigation of the Densification Behavior of Alumina during Spark Plasma Sintering. Materials 2022, 15, 2167. [Google Scholar] [CrossRef] [PubMed]

- Patel, K.; Blair, V.; Douglas, J.; Dai, Q.; Liu, Y.; Ren, S.; Brennan, R. Structural Effects of Lanthanide Dopants on Alumina. Sci. Rep. 2017, 7, 39946. [Google Scholar] [CrossRef] [PubMed]

- Sungur, Ş. Titanium Dioxide Nanoparticles. In Handbook of Nanomaterials and Nanocomposites for Energy and Environmental Applications; Springer International Publishing: Cham, Switzerland, 2020; pp. 1–18. [Google Scholar]

- Zhao, H.; Bresme, F. Melting Point and Crystal Growth Kinetics of Metals and Metal Oxides Using Reactive Force Fields: The Case of Aluminum and Alumina. J. Chem. Theory Comput. 2024, 20, 8190–8201. [Google Scholar] [CrossRef]

- Ramachandran, K.; Selvarajan, V.; Ananthapadmanabhan, P.V.; Sreekumar, K.P. Microstructure, Adhesion, Microhardness, Abrasive Wear Resistance and Electrical Resistivity of the Plasma Sprayed Alumina and Alumina–Titania Coatings. Thin Solid Films 1998, 315, 144–152. [Google Scholar] [CrossRef]

- Qian, C.; Hu, K.; Shen, Z.; Wang, Q.; Li, P.; Lu, Z. Effect of Sintering Aids on Mechanical Properties and Microstructure of Alumina Ceramic via Stereolithography. Ceram. Int. 2023, 49, 17506–17523. [Google Scholar] [CrossRef]

- Oladijo, O.P.; Popoola, A.P.I.; Booi, M.; Fayomi, J.; Collieus, L.L. Corrosion and Mechanical Behaviour of Al2O3.TiO2 Composites Produced by Spark Plasma Sintering. S. Afr. J. Chem. Eng. 2020, 33, 58–66. [Google Scholar] [CrossRef]

- Muniyappan, A.; Muthuvel, P.A. Taguchi Optimisation of Friction and Wear Properties of Ti6Al4V Alloy Coated with TiAlN for Orthopaedic Applications. Trans. FAMENA 2024, 48, 17–32. [Google Scholar] [CrossRef]

- Haldar, P.; Bhattacharya, T.K.; Modak, N. Tribological Behavior of Alumina Ceramics with Nano-TiO2 as a Sintering Aid in Non-Conformal Contact. J. Tribol. 2022, 144, 061703. [Google Scholar] [CrossRef]

- Han, J.-C.; Wang, B.-L. Thermal Shock Resistance of Ceramics with Temperature-Dependent Material Properties at Elevated Temperature. Acta Mater. 2011, 59, 1373–1382. [Google Scholar] [CrossRef]

- Çelik, A.; Turan, S. Si-Al-O-N Ceramics, Structure and Properties. In Encyclopedia of Materials: Technical Ceramics and Glasses; Pomeroy, M., Ed.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 128–143. [Google Scholar]

- Zhao, J.; Ai, X.; Huang, X.P. Relationship between the Thermal Shock Behavior and the Cutting Performance of a Functionally Gradient Ceramic Tool. J. Mater. Process Technol. 2002, 129, 161–166. [Google Scholar] [CrossRef]

- Zhou, N.; Li, C.; Wumaier, N.; Luo, Q.; Hu, L.; Ma, J.; Zou, Y. Effect of TiO2 Addition on the Microstructure and Electrical Properties of Al2O3 Ceramics. Ceram. Int. 2024, 50, 2836–2844. [Google Scholar] [CrossRef]

- Obolkina, T.O.; Kotelnikov, N.L.; Goldberg, M.A.; Khayrutdinova, D.R.; Smirnov, S.V.; Utkin, D.A.; Antonova, O.S.; Egorov, A.A.; Ogarkov, A.I.; Mosolov, A.N.; et al. Adding MnO to Improve the Characteristics of Zirconia-Toughened Alumina Ceramic Parts Made Using the Digital Light Processing Method. Minerals 2024, 15, 10. [Google Scholar] [CrossRef]

- Svoboda, J.; Drdlíková, K.; Drdlík, D.; Kroupa, A.; Michalicka, J.; Maca, K. Doping of Alumina Ceramics by Manganese—Thermodynamical and Experimental Approach. Process. Appl. Ceram. 2022, 16, 13–21. [Google Scholar] [CrossRef]

- Mottye, J.; Ratzker, B.; Kalabukhov, S.; Favelukis, B.; Hayun, S.; Frage, N. Effect of Mn Doping on the Densification and Properties of Transparent Alumina by High-Pressure Spark Plasma Sintering. Ceram. Int. 2023, 49, 28369–28375. [Google Scholar] [CrossRef]

- Gnanasagaran, C.L.; Ramachandran, K.; Ramesh, S.; Ubenthiran, S.; Jamadon, N.H. Effect of Co-Doping Manganese Oxide and Titania on Sintering Behaviour and Mechanical Properties of Alumina. Ceram. Int. 2023, 49, 5110–5118. [Google Scholar] [CrossRef]

- Cheng, D.; Xia, Y.; Yao, D.; Zhu, M.; Zhao, J.; Zeng, Y.-P. Quasi-Static and Dynamic Mechanical Properties of Interpenetrating Zirconia-Toughened Alumina-Aluminum Alloy Composite Material. Mater. Today Commun. 2024, 41, 110929. [Google Scholar] [CrossRef]

- Arab, A.; Sktani, Z.; Zhou, Q.; Ahmad, Z.; Chen, P. Effect of MgO Addition on the Mechanical and Dynamic Properties of Zirconia Toughened Alumina (ZTA) Ceramics. Materials 2019, 12, 2440. [Google Scholar] [CrossRef]

- Rashid, A.B.; Haque, M.; Islam, S.M.M.; Uddin Labib, K.M.R.; Chowdhury, P. Breaking Boundaries with Ceramic Matrix Composites: A Comprehensive Overview of Materials, Manufacturing Techniques, Transformative Applications, Recent Advancements, and Future Prospects. Adv. Mater. Sci. Eng. 2024, 2024, 2112358. [Google Scholar] [CrossRef]

- Bódis, E.; Károly, Z. Zirconia-Toughened Alumina (ZTA) Nanoceramics with a Gradient Microstructure: A Comparative Study of ZTA Ceramics with Fibrous and Granular Morphology. Micromachines 2023, 14, 1681. [Google Scholar] [CrossRef]

- Li, S.; Zhu, Y.; Chai, J.; Liu, Y.; Niu, L.; Gao, X.; Jin, P.; Shen, T.; Cui, M.; Wang, Z.; et al. Effects of ZrC Content on the Microstructure and Mechanical Property of ZrC/ZTA Composites Consolidated by Hot Pressing. J. Alloys Compd. 2021, 860, 158402. [Google Scholar] [CrossRef]

- Li, S.; Niu, L.; Zhu, Y.; Chai, J.; Wang, Z.; Xie, E. Mechanical and Thermal Properties of ZrC/ZTA Composites Prepared by Spark Plasma Sintering. Ceram. Int. 2022, 48, 6453–6460. [Google Scholar] [CrossRef]

- Akhtar, S.S.; Waqar, T.; Hakeem, A.S.; Arif, A.F.M.; Al-Athel, K.S. Design and Development of Hybrid Al2O3 Based Composites with Toughening and Self-Lubricating Second-Phase Inclusions. Materials 2019, 12, 2378. [Google Scholar] [CrossRef] [PubMed]

- Fathalian, M.; Postek, E.; Tahani, M.; Sadowski, T. A Comprehensive Study of Al2O3 Mechanical Behavior Using Density Functional Theory and Molecular Dynamics. Molecules 2024, 29, 1165. [Google Scholar] [CrossRef]

- Kern, F.; Lawitzki, R. Properties of Alumina 10 Vol% Zirconia Composites—The Role of Zirconia Starting Powders. J. Eur. Ceram. Soc. 2022, 42, 534–542. [Google Scholar] [CrossRef]

- Song, X.; Ding, Y.; Zhang, J.; Jiang, C.; Liu, Z.; Lin, C.; Zheng, W.; Zeng, Y. Thermophysical and Mechanical Properties of Cubic, Tetragonal and Monoclinic ZrO2. J. Mater. Res. Technol. 2023, 23, 648–655. [Google Scholar] [CrossRef]

- Zhao, Y.; Deng, J.; Li, W.; Liu, J.; Yuan, W. Grain Growth Behavior of Alumina in Zirconia-Toughened Alumina (ZTA) Ceramics During Pressureless Sintering. Crystals 2025, 15, 89. [Google Scholar] [CrossRef]

- Zadorozhnaya, O.Y.; Khabas, T.A.; Tiunova, O.V.; Malykhin, S.E. Effect of Grain Size and Amount of Zirconia on the Physical and Mechanical Properties and the Wear Resistance of Zirconia-Toughened Alumina. Ceram. Int. 2020, 46, 9263–9270. [Google Scholar] [CrossRef]

- Sun, S.; Xu, Q. Fabricating a Novel Intragranular Microstructure for Al2O3/GdAlO3 Ceramic Composites. Materials 2018, 11, 1879. [Google Scholar] [CrossRef]

- Verma, V.; Kumar, U.; Ghosh, S.; Gurnani, L.; Mukhopadhyay, A. Developing Intragranular Zirconia-reinforced Alumina Possessing Vastly Improved Mechanical and Tribological Properties. J. Am. Ceram. Soc. 2024, 107, 760–776. [Google Scholar] [CrossRef]

- Bakhtierkhalzi, M.; Wahedul Islam, M.; Suzauddin, M.; Nurul Islam, M.; Mahmood, A. Al Effect of TiO2 as Sintering Additive on Microstructural, Physical, and Mechanical Properties of CeO2 Doped Zirconia Toughened Alumina Ceramic Composite. Ceram. Int. 2023, 49, 6666–6670. [Google Scholar] [CrossRef]

- Sun, Y.; Li, Y.; Zhang, L.; Shen, Y.; Yan, M.; Ma, C.; Sun, J. Formation Mechanism and Controllable Preparation of Ti(C,N) in Al–TiO2–Al2O3 Composite at 1673 K in Flowing N2. Mater. Chem. Phys. 2020, 239, 122128. [Google Scholar] [CrossRef]

- Kuntz, M.; Krüger, R. The Effect of Microstructure and Chromia Content on the Properties of Zirconia Toughened Alumina. Ceram. Int. 2018, 44, 2011–2020. [Google Scholar] [CrossRef]

- Sui, Y.; Yuan, Y.; Tan, P.; Jiang, Y.; Han, L. Correlation between Microstructure and Mechanical Properties of ZTA–TiO2–Nb2O5 Ceramics Sintered by SPS. J. Mater. Sci. 2023, 58, 707–717. [Google Scholar] [CrossRef]

- Seong, W.-K.; Ahn, B.-M.; Min, Y.; Hwang, G.-T.; Choi, J.-J.; Choi, J.-H.; Hahn, B.-D.; Cho, Y.-R.; Ahn, C.-W. An Easy Approach to Manufacture High Quality Zirconia-Toughed Alumina. Mater. Sci. Eng. A 2020, 784, 139328. [Google Scholar] [CrossRef]

- Ismail, H.; Mohamad, H. Effects of CaCO3 Additive on the Phase, Physical, Mechanical, and Microstructural Properties of Zirconia-Toughened Alumina-CeO2-Nb2O5 Ceramics. Ceram. Int. 2023, 49, 36850–36856. [Google Scholar] [CrossRef]

- Wang, X.; Zhao, J.; Cui, E.; Liu, H.; Dong, Y.; Sun, Z. Effects of Sintering Parameters on Microstructure, Graphene Structure Stability and Mechanical Properties of Graphene Reinforced Al2O3-Based Composite Ceramic Tool Material. Ceram. Int. 2019, 45, 23384–23392. [Google Scholar] [CrossRef]

- Sorrentino, R.; Navarra, C.O.; Di Lenarda, R.; Breschi, L.; Zarone, F.; Cadenaro, M.; Spagnuolo, G. Effects of Finish Line Design and Fatigue Cyclic Loading on Phase Transformation of Zirconia Dental Ceramics: A Qualitative Micro-Raman Spectroscopic Analysis. Materials 2019, 12, 863. [Google Scholar] [CrossRef]

- Benali, B.; Huntz, A.M.; Andrieux, M.; Ignat, M.; Poissonnet, S. Internal Stresses and Stability of the Tetragonal Phase in Zirconia Thin Layers Deposited by OMCVD. Appl. Surf. Sci. 2008, 254, 5807–5813. [Google Scholar] [CrossRef]

- Jin, X.-J. Martensitic Transformation in Zirconia Containing Ceramics and Its Applications. Curr. Opin. Solid State Mater. Sci. 2005, 9, 313–318. [Google Scholar] [CrossRef]

- Moradkhani, A.; Baharvandi, H. Effects of Additive Amount, Testing Method, Fabrication Process and Sintering Temperature on the Mechanical Properties of Al2O3/3Y-TZP Composites. Eng. Fract. Mech. 2018, 191, 446–460. [Google Scholar] [CrossRef]

- Casellas, D.; Cumbrera, F.L.; Sánchez-Bajo, F.; Forsling, W.; Llanes, L.; Anglada, M. On the Transformation Toughening of Y–ZrO2 Ceramics with Mixed Y–TZP/PSZ Microstructures. J. Eur. Ceram. Soc. 2001, 21, 765–777. [Google Scholar] [CrossRef]

- Žmak, I.; Ćorić, D.; Mandić, V.; Ćurković, L. Hardness and Indentation Fracture Toughness of Slip Cast Alumina and Alumina-Zirconia Ceramics. Materials 2019, 13, 122. [Google Scholar] [CrossRef] [PubMed]

- Basu, B.; Vleugels, J.; Van Der Biest, O. ZrO2–Al2O3 Composites with Tailored Toughness. J. Alloys Compd. 2004, 372, 278–284. [Google Scholar] [CrossRef]

- Hadzley, A.B.; Norfauzi, T.; Umar, U.A.A.; Afuza, A.A.; Faiz, M.M.; Naim, M.F. Effect of Sintering Temperature on Density, Hardness and Tool Wear for Alumina-Zirconia Cutting Tool. J. Mech. Eng. Sci. 2019, 13, 4648–4660. [Google Scholar] [CrossRef]

- Singh, B.K.; Goswami, S.; Ghosh, K.; Roy, H.; Mandal, N. Performance Evaluation of Self Lubricating CuO Added ZTA Ceramic Inserts in Dry Turning Application. Int. J. Refract. Metals Hard Mater. 2021, 98, 105551. [Google Scholar] [CrossRef]

- Ghosh, K.; Mazumder, S.; Kumar Singh, B.; Hirani, H.; Roy, P.; Mandal, N. Tribological Property Investigation of Self-Lubricating Molybdenum-Based Zirconia Ceramic Composite Operational at Elevated Temperature. J. Tribol. 2020, 142, 021704. [Google Scholar] [CrossRef]

- Li, H.; Wu, H.; Han, Y.; Liu, X.; Wan, D.; Bao, Y. Enhanced High Temperature Properties of ZTA Prestressed Ceramics Reinforced by Cordierite Coating. Int. J. Appl. Ceram. Technol. 2024, 21, 855–860. [Google Scholar] [CrossRef]

- Ghosh, K.; Goswami, S.; Roy, P.; Mandal, N. High Temperature Tribological Performance of Molybdenum Reinforced Zirconia Toughened Alumina Composites Prepared by Pressure-Less Sintering. Ceram. Int. 2022, 48, 28013–28022. [Google Scholar] [CrossRef]

- Qi, Y.; Zhang, Y.-S.; Hu, L.-T. High-Temperature Self-Lubricated Properties of Al2O3/Mo Laminated Composites. Wear 2012, 280–281, 1–4. [Google Scholar] [CrossRef]

- Ghosh, K.; Goswami, S.; Prajapati, P.K.; Roy, P.; Mandal, N. Pressure-Less Sintering of Molybdenum-Reinforced Ceramic Cutting Inserts with Improved Tool Life. Int. J. Refract. Metals Hard Mater. 2024, 120, 106619. [Google Scholar] [CrossRef]

- Afshani, J.; Delgado, T.; Paveliuc, G.; Hagemann, H. Luminescence Spectroscopy of CaAl12O19:Eu3+ and SrAl12O19:Eu3+ Nanoparticles. J. Lumin. 2022, 246, 118805. [Google Scholar] [CrossRef]

- Prajapati, P.K.; Bapanapalle, C.O.; Biswas, P.; Sadhu, K.K.; Sahoo, R.R.; Mandal, N. Cutting Performance, Failure Mechanisms and Tribological Properties of MWCNT-Reinforced ZTA-MgO Ceramic Inserts in High-Speed Machining of Hardened AISI-4340 Steel. Diam. Relat. Mater. 2025, 153, 112094. [Google Scholar] [CrossRef]

- Toor, Z.S.; Shifa, M. Effect of Multiwalled Carbon Nanotubes (MWCNTs) Distribution on Physiomechancal Characteristics of Alumina (Al2O3) Matrix Nanocomposite. Diam. Relat. Mater. 2023, 136, 109975. [Google Scholar] [CrossRef]

- Prajapati, P.K.; Biswas, P.; Singh, B.K.; Bapanapalle, C.O.; Ghosh, R.; Mandal, N. Reinforcing Potential of MWCNTs on Mechanical and Machining Performance of Hot-Pressed ZTA-MgO Ceramic Cutting Inserts. Diam. Relat. Mater. 2023, 138, 110202. [Google Scholar] [CrossRef]

- Sallakhniknezhad, R.; Ahmadian, H.; Zhou, T.; Weijia, G.; Anantharajan, S.K.; Sadoun, A.M.; Abdelfattah, W.M.; Fathy, A. Recent Advances and Applications of Carbon Nanotubes (CNTs) in Machining Processes: A Review. J. Manuf. Mater. Process. 2024, 8, 282. [Google Scholar] [CrossRef]

- Dennison, M.S.; Jebabalan, S.K.; Barik, D. Applicability of Nano-Cutting Fluids for Enhanced Cooling, Low Tool Wear, and High Tribological Performance during Machining—A Review. Discov. Appl. Sci. 2024, 6, 663. [Google Scholar] [CrossRef]

- Liu, B.; Sun, J.; Zhao, J.; Yun, X. Hybrid Graphene and Carbon Nanotube–Reinforced Composites: Polymer, Metal, and Ceramic Matrices. Adv. Compos. Hybrid. Mater. 2025, 8, 1. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Fedorov, S.V.; Hamdy, K. Materials, Properties, Manufacturing Methods and Cutting Performance of Innovative Ceramic Cutting Tools—A Review. Manuf. Rev. 2019, 6, 19. [Google Scholar] [CrossRef]

- Smirnov, A.; Peretyagin, P.; Solís Pinargote, N.W.; Gershman, I.; Bartolomé, J.F. Wear Behavior of Graphene-Reinforced Alumina–Silicon Carbide Whisker Nanocomposite. Nanomaterials 2019, 9, 151. [Google Scholar] [CrossRef]

- Suárez, M.; Benavente, R.; Borrell, A.; Pérez-Mas, A.M.; Menéndez, R.; Gutiérrez, C.F.; Fernández, A. Enhancing Cutting Tool Durability: Exploration of Al2O3-SiCw-Graphene Composites Fabricated by SPS for Improved Mechanical and Scratch Resistance. Ceram. Int. 2024, 50, 35421–35429. [Google Scholar] [CrossRef]

- Chai, J.; Zhu, Y.; Gao, X.; Shen, T.; Niu, L.; Li, S.; Jin, P.; Cui, M.; Wang, Z. Effects of Residual Stress and Intragranular Particles on Mechanical Properties of Hot-Pressed Al2O3/SiC Ceramic Composites. Ceram. Int. 2022, 48, 23258–23265. [Google Scholar] [CrossRef]

- Grigoriev, S.; Volosova, M.; Peretyagin, P.; Seleznev, A.; Okunkova, A.; Smirnov, A. The Effect of TiC Additive on Mechanical and Electrical Properties of Al2O3 Ceramic. Appl. Sci. 2018, 8, 2385. [Google Scholar] [CrossRef]

- Cygan, T.; Wozniak, J.; Kostecki, M.; Petrus, M.; Jastrzębska, A.; Ziemkowska, W.; Olszyna, A. Mechanical Properties of Graphene Oxide Reinforced Alumina Matrix Composites. Ceram. Int. 2017, 43, 6180–6186. [Google Scholar] [CrossRef]

- Zhang, J.; Xiao, G.; Zhang, J.; Yi, M.; Chen, Z.; Zhang, W.; Xu, C. Al2O3/WB2 Composite Ceramic Tool Material Reinforced with Graphene Oxide Self-Assembly Coated Silicon Nitride. Int. J. Refract. Metals Hard Mater. 2019, 81, 173–182. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, H.; Xiao, G.; Yi, M.; Zhang, J.; Chen, Z.; Lin, Q.; Xu, C. Alumina Ceramic Tool Material with Enhanced Properties through the Addition of Bionic Prepared Nano SiC@graphene. Ceram. Int. 2023, 49, 19753–19765. [Google Scholar] [CrossRef]

- Paredes-Goyes, B.; Venkatesh, A.M.; Jauffres, D.; Martin, C.L. Two-Step Sintering of Alumina Nano-Powders: A Discrete Element Study. J. Eur. Ceram. Soc. 2023, 43, 501–509. [Google Scholar] [CrossRef]

- Lóh, N.J.; Simão, L.; Jiusti, J.; Arcaro, S.; Raupp-Pereira, F.; De Noni, A.; Montedo, O.R.K. Densified Alumina Obtained by Two-Step Sintering: Impact of the Microstructure on Mechanical Properties. Ceram. Int. 2020, 46, 12740–12743. [Google Scholar] [CrossRef]

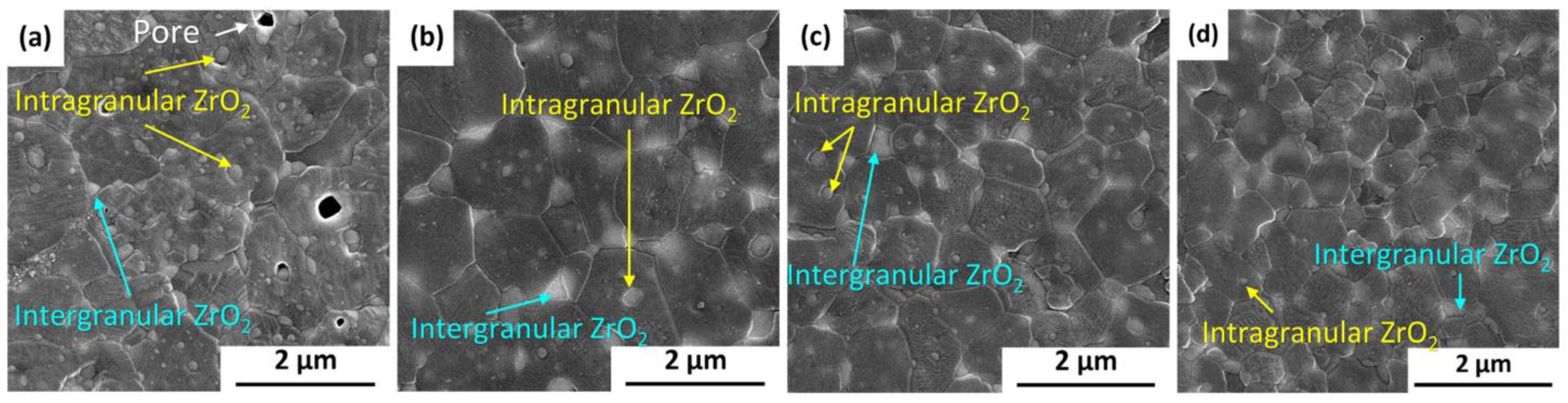

- Li, J.; Cai, Q.; Luo, G.; Zhong, X.; Shen, Q.; Tu, R.; Guo, X.; Ding, R. Zirconia Toughened Alumina Ceramics via Forming Intragranular Structure. Materials 2024, 17, 1309. [Google Scholar] [CrossRef]

- Wang, Z.; Yi, M.; Zheng, K.; Chen, Z.; Xiao, G.; Xu, C. Synthesis and Characterization of Al2O3-TiC-ZrO ceramics with Intragranular Nanostructure by Spark Plasma Sintering. Int. J. Appl. Ceram. Technol. 2023, 20, 2281–2288. [Google Scholar] [CrossRef]

- Wang, Z.; Zheng, K.; Yi, M.; Chen, H.; Zhou, T.; Xu, C. Spark Plasma Sintering Mechanism of Al2O3-Based Ceramics Granulation Powder. Open Ceram. 2022, 12, 100310. [Google Scholar] [CrossRef]

- Szutkowska, M.; Podsiadło, M.; Sadowski, T.; Figiel, P.; Boniecki, M.; Pietras, D.; Polczyk, T. A Novel Approach by Spark Plasma Sintering to the Improvement of Mechanical Properties of Titanium Carbonitride-Reinforced Alumina Ceramics. Molecules 2021, 26, 1344. [Google Scholar] [CrossRef] [PubMed]

- Kang, S.; Zhao, X.; Guo, J.; Liang, J.; Sun, J.; Yang, Y.; Yang, L.; Liao, R.; Randall, C.A. Thermal-Assisted Cold Sintering Study of Al2O3 Ceramics: Enabled with a Soluble γ-Al2O3 Intermediate Phase. J. Eur. Ceram. Soc. 2023, 43, 478–485. [Google Scholar] [CrossRef]

- Kholodkova, A.A.; Kornyushin, M.V.; Pakhomov, M.A.; Smirnov, A.V.; Ivakin, Y.D. Water-Assisted Cold Sintering of Alumina Ceramics in SPS Conditions. Ceramics 2023, 6, 1113–1128. [Google Scholar] [CrossRef]

- Xudong, L.; Yuchen, Y.; Renjie, W.; Shiyang, Z.; Yuelei, B.; Canqing, F.; Ce, C.; Yongting, Z. Low Temperature Sintering of High Performance Al2O3/ZrO2 Ceramics with Ultra-Fine Nanoparticles Strengthening. J. Alloys Compd. 2024, 971, 172405. [Google Scholar] [CrossRef]

- Ćurković, L.; Veseli, R.; Gabelica, I.; Žmak, I.; Ropuš, I.; Vukšić, M. A Review of Microwave-Assisted Sintering Technique. Trans. FAMENA 2021, 45, 1–16. [Google Scholar] [CrossRef]

- Khalile, N.; Petit, C.; Meunier, C.; Valdivieso, F. Microwave Sintering of Zirconia Toughened Alumina—Influence of the Type and Content of Doping in Zirconia. Ceram. Int. 2023, 49, 36218–36224. [Google Scholar] [CrossRef]

- Du, W.; Ai, Y.; He, W.; Chen, W.; Liang, B.; Lv, C. Formation and Control of “Intragranular” ZrO2 Strengthened and Toughened Al2O3 Ceramics. Ceram. Int. 2020, 46, 8452–8461. [Google Scholar] [CrossRef]

- Sjöström, W.; Botero, C.; Jimenez-Piqueo, E. Melting Ceramic Al2O3 Powder by Electron Beam Powder Bed Fusion. Prog. Addit. Manuf. 2024, 9, 1523–1535. [Google Scholar] [CrossRef]

- Klimov, A.; Bakeev, I.; Oks, E.; Zenin, A. Electron Beam Sintering of Composite Al2O3-ZrO2 Ceramics in the Forevacuum Pressure Range. Coatings 2022, 12, 278. [Google Scholar] [CrossRef]

- Han, Y.; Li, S.; Zhu, T.; Wu, W.; An, D.; Xie, Z. Enhanced Properties of Pure Alumina Ceramics by Oscillatory Pressure Sintering. Ceram. Int. 2018, 44, 5238–5241. [Google Scholar] [CrossRef]

- Sharma, N.; Syed, A.N.; Ray, B.C.; Yadav, S.; Biswas, K. Alumina–MWCNT Composites: Microstructural Characterization and Mechanical Properties. J. Asian Ceram. Soc. 2019, 7, 1–19. [Google Scholar] [CrossRef]

- Zhang, D.; Yu, R.; Feng, X.; Guo, X.; Yang, Y.; Xu, X. Enhanced Mechanical Properties of Al2O3 Nanoceramics via Low Temperature Spark Plasma Sintering of Amorphous Powders. Materials 2023, 16, 5652. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.-Y.; Cropsey, L.C.G.; Tyszka, B.R.; Case, E.D. Grain Size, Density, and Mechanical Properties of Alumina Batch-Processed in a Single-Mode Microwave Cavity. Mater. Res. Bull. 1997, 32, 287–295. [Google Scholar] [CrossRef]

- Liu, W.; Wu, H.; Xu, Y.; Lin, L.; Li, Y.; Wu, S. Cutting Performance and Wear Mechanism of Zirconia Toughened Alumina Ceramic Cutting Tools Formed by Vat Photopolymerization-Based 3D Printing. Ceram. Int. 2023, 49, 23238–23247. [Google Scholar] [CrossRef]

- Liu, X.; Yuan, Y.; Wang, R.; Zhu, S.; Bai, Y.; Fang, C.; Li, J.; Chen, C.; Zheng, Y. Pressureless Sintering Behaviour of Al2O3/ZrO2 Amorphous/Solid Solution Powder with Ultra-Fine ZrO2 Nanoparticle Precipitation. Ceram. Int. 2023, 49, 39886–39897. [Google Scholar] [CrossRef]

- Kumar, S.; Tamilselvan, P.; Feroskhan, M.; Doss, A.S.A.; Sasikumar, M.; Elango, M.; Sivarajan, S. Hard Turning of AISI D2 Steel with Cubic Boron Nitride Cutting Inserts. Mater. Today Proc. 2023, 72, 2002–2006. [Google Scholar] [CrossRef]

- Gutema, E.M.; Lemu, H.G. Conventional Machining of Metal Matrix Composites towards Sustainable Manufacturing—Present Scenario and Future Prospects. J. Compos. Sci. 2024, 8, 356. [Google Scholar] [CrossRef]

- Matos, F.; Silva, T.E.F.; Sousa, V.F.C.; Marques, F.; Figueiredo, D.; Silva, F.J.G.; Jesus, A.M.P. de On the Influence of Binder Material in PCBN Cutting Tools for Turning Operations of Inconel 718. Metals 2023, 13, 934. [Google Scholar] [CrossRef]

- Guo, S.; Zhu, F.; Xiu, Z.; Zhang, M.; Sun, X. Enhanced Performance in Si3N4 Ceramics Cutting Tool Materials by Tailoring of Phase Composition and Hot-Pressing Temperature. Coatings 2023, 13, 475. [Google Scholar] [CrossRef]

- Zhou, Y.; Lao, Z.-Y.; Guo, W.-M.; Luo, S.-C.; Lin, H.-T. Effects of (Ta0.2W0.2Nb0.2Mo0.2V0.2)C High-Entropy Carbide Content on the Microstructure and Properties of Ti(C0.7N0.3)-Based Cermet. Ceram. Int. 2023, 49, 10280–10286. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, H.; Huang, C.; Ji, L.; Wang, L.; Yuan, Y.; Liu, Q.; Han, Q. Study on Crack Healing Performance of Al2O3/SiCw/TiSi2 New Ceramic Tool Material. Ceram. Int. 2023, 49, 13790–13798. [Google Scholar] [CrossRef]

| Density (g·cm−3) | Melting Point (°C) | Flexural Strength (MPa) | Vickers Hardness (GPa) | Fracture Toughness (MPa·√m) | Thermal Conductivity (W·m−1·K−1) | Thermal Expansion Coefficient (10−6·K−1) | |

|---|---|---|---|---|---|---|---|

| Al2O3 | 3.8–4.0 | 2044 | 300–350 | 19–21 | 3.0–3.5 | 25–30 | 8.0–9.0 |

| ZrO2 | 6.0–6.05 | 2715 | 750–1050 | 12–13 | 8.0–10.0 | 2–3 | 10.0–11.0 |

| Si3N4 | 2.37–3.25 | 1900 | 650–800 | 16–19.6 | 6.5–7.2 | 10–43 | 1.4–3.7 |

| Content of SrAl12O19 | 0 wt.% | 2.5 wt.% | 5.0 wt.% | 7.5 wt.% |

|---|---|---|---|---|

| Density after HIP (%) | 100 | 99.77 | 100 | 99.76 |

| Density after Sintering (%) | 99.77 | 99.53 | 99.77 | 99.29 |

| Young’s Modulus (GPa) | 362.7 | 358.44 | 362.64 | 353.45 |

| Vickers Hardness (GPa) | 19.85 | 20.12 | 21.04 | 18.53 |

| Composition | Flexural Strength (MPa) | Fracture Toughness (MPa·√m) | Hardness * (GPa) |

|---|---|---|---|

| Al2O3 | 750 | 9.5 | 10.6 |

| Al2O3-17%SiCw | 750 | 9.52 | 28.8 |

| Al2O3-17%SiCw/0.5%Graphene | 919 | 10.55 | 29.9 |

| Sintering Process | Temperature (°C) | Flexural Strength (MPa) | Hardness (GPa) | Young’s Modulus (GPa) | Fracture Toughness (MPa·√m) | Lit. Ref. |

|---|---|---|---|---|---|---|

| Conventional | 1650 | 353 | 16.8 | 323 | 2.6–2.8 | [128,129] |

| Two-step | 1550; 1450 | 303 | 17.5 | 303 | 4.35 | [115] |

| Spark plasma | 1500 | 710 | 21.3 | - | 2.9 | [130] |

| Thermal- assisted cold | 1350 | - | 14 | 335 | - | [122] |

| Microwave | 1500 | - | 16.19 | 365.4 | 2.7 | [131] |

| Material | Benefits * | Drawbacks * | Applications |

|---|---|---|---|

| Al2O3 | High hardness and wear resistance | Low fracture toughness and thermal shock resistance | High-speed cutting of cast iron and steel |

| Al2O3 + ZrO2 | Higher thermal stability, higher toughness | Increased price | Interrupted cutting |

| Al2O3 + ZrO2 + MgO | MgO (0.2 wt.%) increases dynamic compressive strength | Too much MgO decreases dynamic compressive strength | Higher cutting-edge stability |

| Al2O3 + ZrO2 + Mo | Higher electrical conductivity | Reduced oxidation resistance at high temperatures | Tool shaping by EDM (electrical discharge machining) |

| Al2O3 + MnO | Less porosity, higher wear resistance, and compressive strength | Decrease in Young’s modulus | Finishing operations of hardened steels |

| Al2O3 + TiO2 | Less porosity, higher wear resistance, and toughness | Decrease in bending strength if more than 0.5% TiO2 | Cutting hard or abrasive materials |

| Al2O3 + ZrO2 + SrCO3 | Finer and more uniform grain structure | Too much SrCO3: formation of secondary phase or porosity | Tools with tailored dielectric properties |

| Al2O3 + WB2 | Much higher hardness and melting point | Lower toughness and thermal shock resistance | Precision cutting tools |

| Al2O3 + ZrO2 + MgO + MWCNTs | Significant improvement in wear resistance | Difficult processing due to MWCNTs | Low feed rates and shallow cutting depths |

| Al2O3 + SiCw | Improved toughness compared to Al2O3 | Difficult to manufacture and more expensive | Superalloys cutting |

| Al2O3 + SiCw + GO | GO improves toughness, thermal and electric conductivity | Difficult processing due to GO | Intermittent cutting, tool shaping by EDM |

| Cemented carbide (WC + Co) | Lower hardness, more versatile, lower cost | Lower chemical stability, shorter tool life due to lower hardness | Wet and dry cutting, various materials |

| Cermets (no WC + Co) | Sharper edges, good crater wear resistance, lower cost | Lower hardness, i.e., shorter tool life | Good for finishing |

| Si3N4 | Good thermal shock resistance and toughness | Lower hardness, more expensive | Intermittent cutting, superalloys |

| PcBN | Extreme hardness, long tool life | Difficult to machine, expensive | Machining hard and abrasive materials, hard turning |

| PCD | Extreme hardness, long tool life | Reacts with iron at high temperatures | Machining aluminum alloys, MMC, and CFRPs |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Žmak, I.; Jozić, S.; Ćurković, L.; Filetin, T. Alumina-Based Cutting Tools—A Review of Recent Progress. Materials 2025, 18, 2813. https://doi.org/10.3390/ma18122813

Žmak I, Jozić S, Ćurković L, Filetin T. Alumina-Based Cutting Tools—A Review of Recent Progress. Materials. 2025; 18(12):2813. https://doi.org/10.3390/ma18122813

Chicago/Turabian StyleŽmak, Irena, Sonja Jozić, Lidija Ćurković, and Tomislav Filetin. 2025. "Alumina-Based Cutting Tools—A Review of Recent Progress" Materials 18, no. 12: 2813. https://doi.org/10.3390/ma18122813

APA StyleŽmak, I., Jozić, S., Ćurković, L., & Filetin, T. (2025). Alumina-Based Cutting Tools—A Review of Recent Progress. Materials, 18(12), 2813. https://doi.org/10.3390/ma18122813