Physico-Mechanical and Sorption Properties of Wood Treated with Cellulose Nanofibers

Abstract

1. Introduction

2. Materials and Methods

2.1. Wood Material

2.2. Wood Surface Treatment

2.3. Attenuated Total Reflectance Fourier Transform Infrared Spectroscopy (ATR-FTIR)

2.4. Scanning Electron Microscopy (SEM)

2.5. Contact Angle Measurement

2.6. Sorption Experiments

2.7. Sorption Isotherm Modeling

2.8. Color Change Measurement

2.9. Static Bending Strength

2.10. Statistical Analysis

3. Results and Discussion

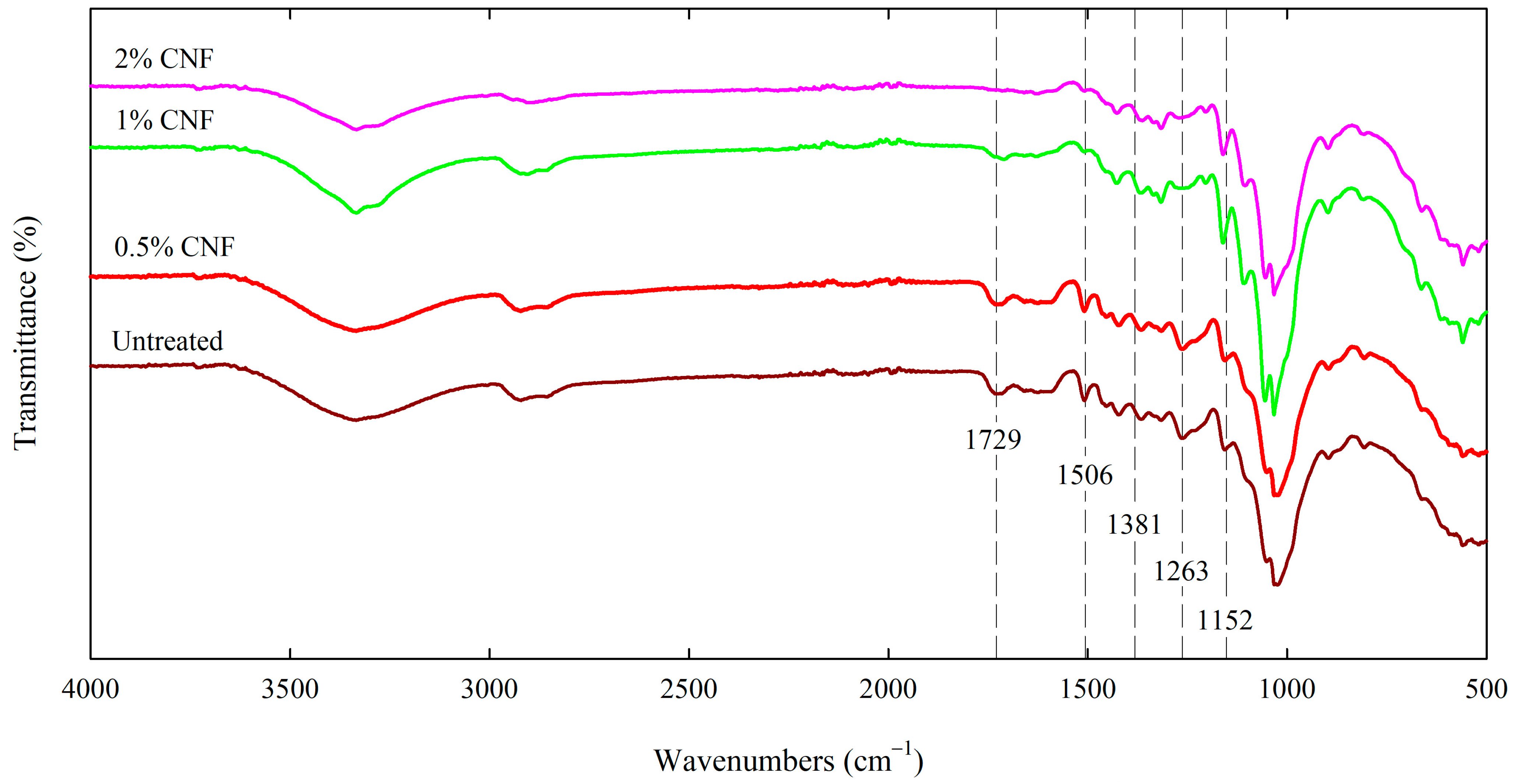

3.1. Structural and Morphological Characterization of CNF-Treated Wood

3.2. Wettability Analysis

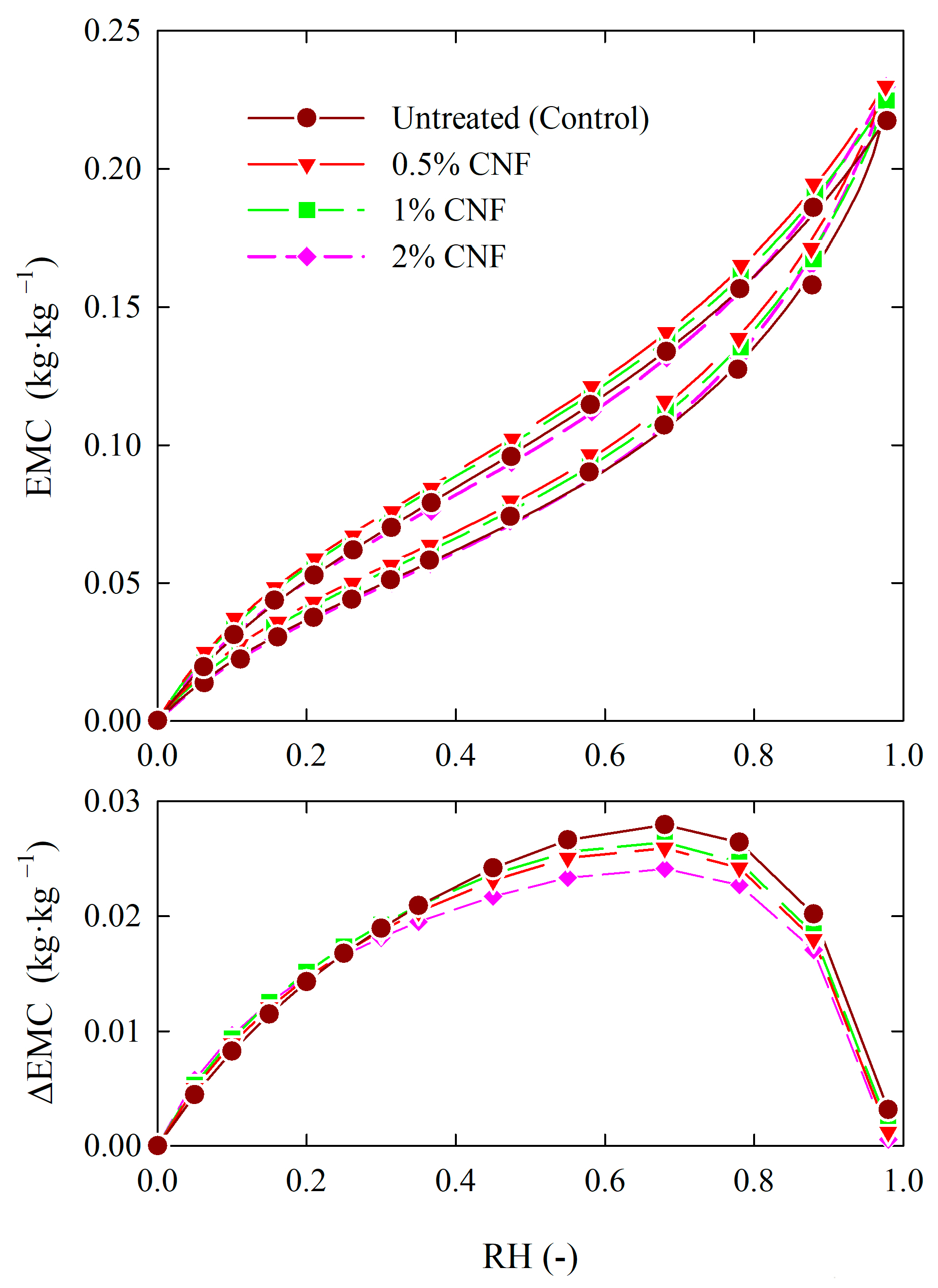

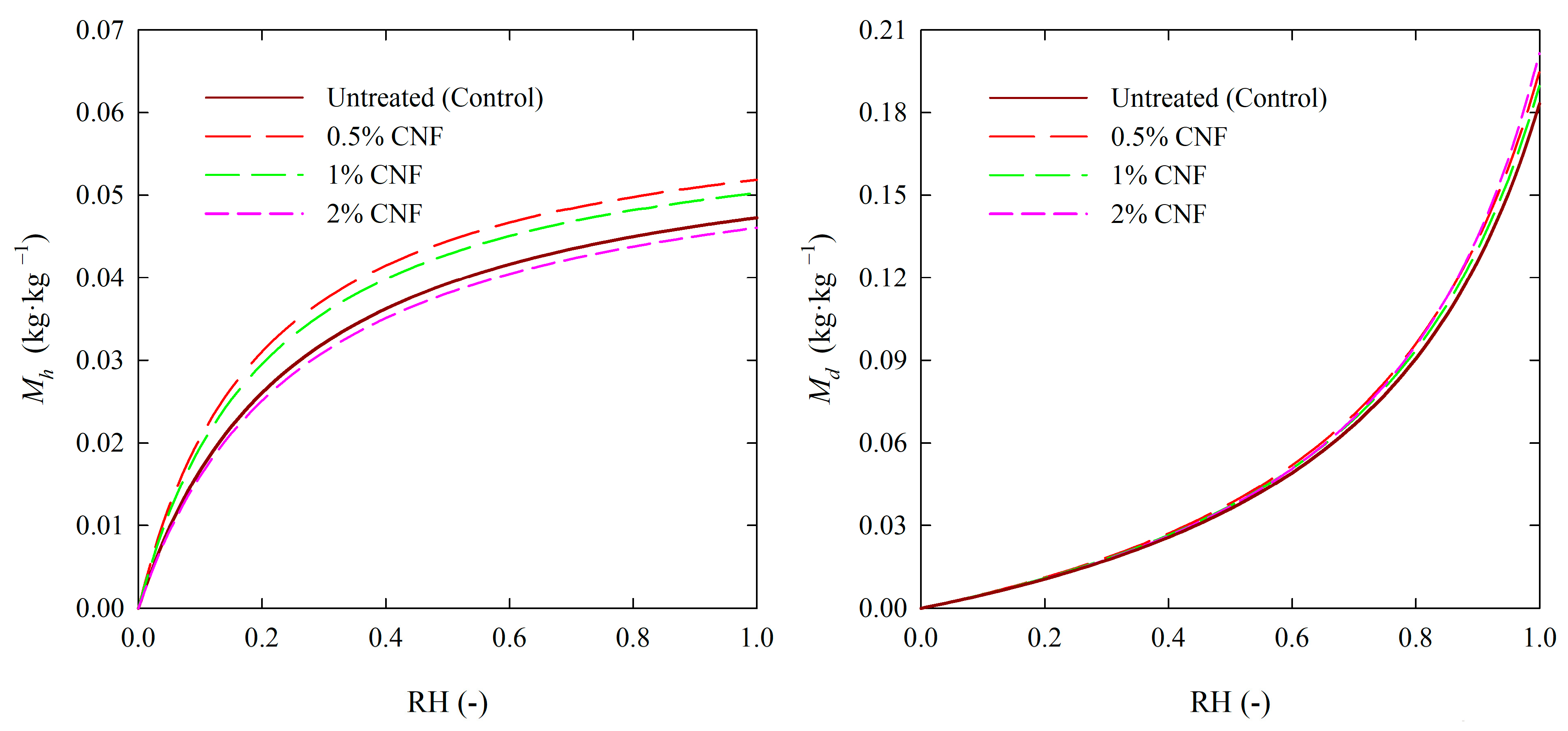

3.3. Sorption Behavior

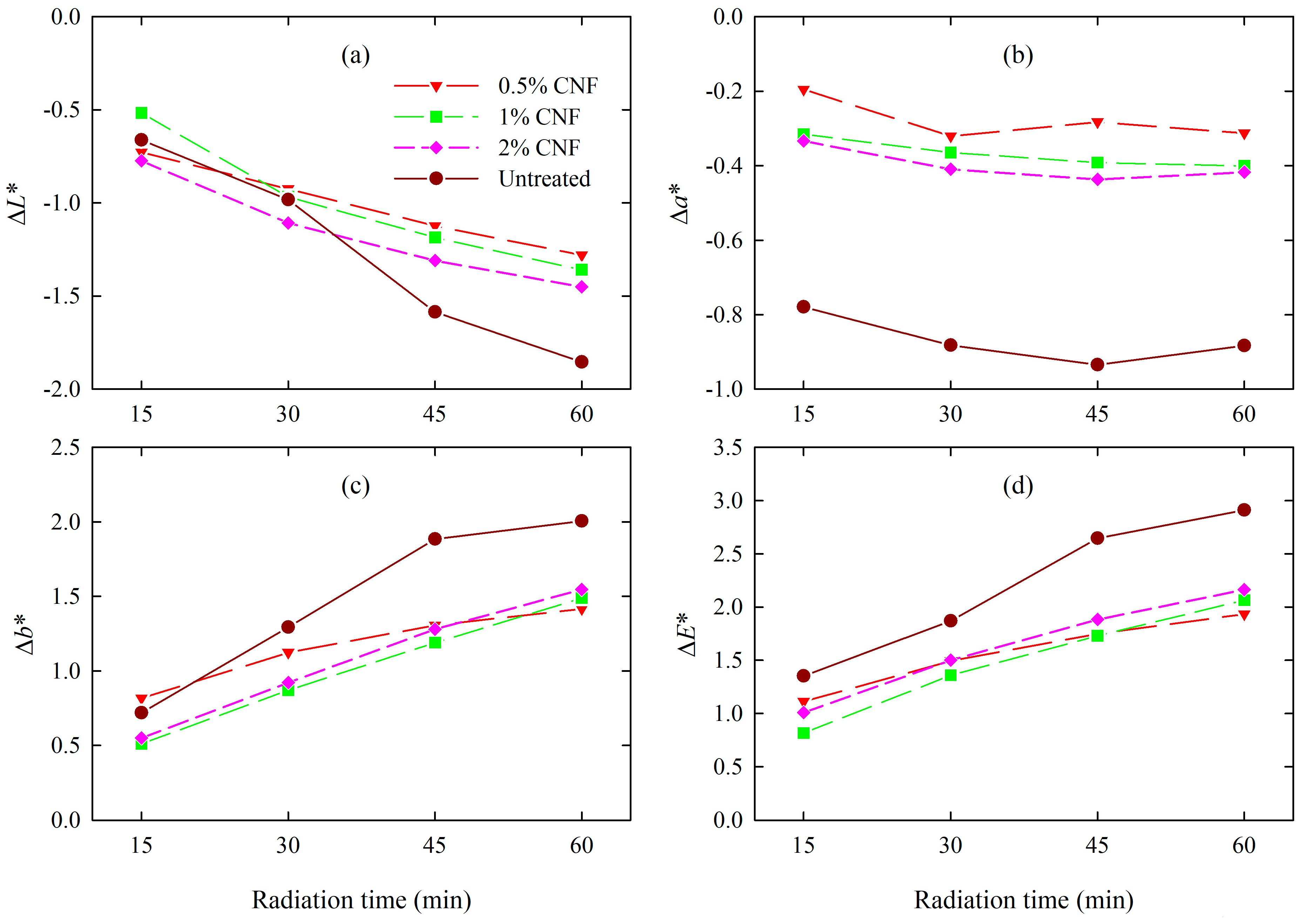

3.4. Color Measurements

3.5. Mechanical Parameters

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rajput, H.; Rajan, P.; Li, S.; Stratton, G.W.; Murray, G.; He, Q. Development of Wood Preservatives to Prevent Biodeterioration. J. Wood Chem. Technol. 2023, 43, 371–389. [Google Scholar] [CrossRef]

- Hill, C.; Kymäläinen, M.; Rautkari, L. Review of the Use of Solid Wood as an External Cladding Material in the Built Environment. J. Mater. Sci. 2022, 57, 9031–9076. [Google Scholar] [CrossRef]

- Zelinka, S.L.; Altgen, M.; Emmerich, L.; Guigo, N.; Keplinger, T.; Kymäläinen, M.; Thybring, E.E.; Thygesen, L.G. Review of Wood Modification and Wood Functionalization Technologies. Forests 2022, 13, 1004. [Google Scholar] [CrossRef]

- Changotra, R.; Rajput, H.; Liu, B.; Murray, G.; He, Q. Occurrence, Fate, and Potential Impacts of Wood Preservatives in the Environment: Challenges and Environmentally Friendly Solutions. Chemosphere 2024, 352, 141291. [Google Scholar] [CrossRef]

- Athulya, R.; Nandini, J.; Bhoi, T.K.; Sundararaj, R. Recent Advances of Nanotechnology in Wood Protection: A Comprehensive Review. Wood Mater. Sci. Eng. 2023, 19, 279–290. [Google Scholar] [CrossRef]

- Bansal, R.; Barshilia, H.C.; Pandey, K.K. Nanotechnology in Wood Science: Innovations and Applications. Int. J. Biol. Macromol. 2024, 262, 130025. [Google Scholar] [CrossRef]

- Papadopoulos, A.N.; Bikiaris, D.N.; Mitropoulos, A.C.; Kyzas, G.Z. Nanomaterials and Chemical Modifications for Enhanced Key Wood Properties: A Review. Nanomaterials 2019, 9, 607. [Google Scholar] [CrossRef] [PubMed]

- Bi, W.; Li, H.; Hui, D.; Gaff, M.; Lorenzo, R.; Corbi, I.; Corbi, O.; Ashraf, M. Effects of Chemical Modification and Nanotechnology on Wood Properties. Nanotechnol. Rev. 2021, 10, 978–1008. [Google Scholar] [CrossRef]

- Woźniak, M. Antifungal Agents in Wood Protection—A Review. Molecules 2022, 27, 6392. [Google Scholar] [CrossRef]

- Terzi, E.; Kartal, S.N.; Yilgör, N.; Rautkari, L.; Yoshimura, T. Role of Various Nano-Particles in Prevention of Fungal Decay, Mold Growth and Termite Attack in Wood, and Their Effect on Weathering Properties and Water Repellency. Int. Biodeterior. Biodegrad. 2016, 107, 77–87. [Google Scholar] [CrossRef]

- Xu, E.; Zhang, Y.; Lin, L. Improvement of Mechanical, Hydrophobicity and Thermal Properties of Chinese Fir Wood by Impregnation of Nano Silica Sol. Polymers 2020, 12, 1632. [Google Scholar] [CrossRef] [PubMed]

- Cristea, M.V.; Riedl, B.; Blanchet, P. Effect of Addition of Nanosized UV Absorbers on the Physico-Mechanical and Thermal Properties of an Exterior Waterborne Stain for Wood. Prog. Org. Coat. 2011, 72, 755–762. [Google Scholar] [CrossRef]

- Hu, X.; Sun, Z. Nano CaAlCO3-Layered Double Hydroxide-Doped Intumescent Fire-Retardant Coating for Mitigating Wood Fire Hazards. J. Build. Eng. 2021, 44, 102987. [Google Scholar] [CrossRef]

- El-Kady, M.M.; Ansari, I.; Arora, C.; Rai, N.; Soni, S.; Verma, D.K.; Singh, P.; Mahmoud, A.E.D. Nanomaterials: A Comprehensive Review of Applications, Toxicity, Impact, and Fate to Environment. J. Mol. Liq. 2023, 370, 121046. [Google Scholar] [CrossRef]

- Jasmani, L.; Rusli, R.; Khadiran, T.; Jalil, R.; Adnan, S. Application of Nanotechnology in Wood-Based Products Industry: A Review. Nanoscale Res. Lett. 2020, 15, 207. [Google Scholar] [CrossRef]

- Dhali, K.; Ghasemlou, M.; Daver, F.; Cass, P.; Adhikari, B. A Review of Nanocellulose as a New Material towards Environmental Sustainability. Sci. Total Environ. 2021, 775, 145871. [Google Scholar] [CrossRef] [PubMed]

- Noremylia, M.B.; Hassan, M.Z.; Ismail, Z. Recent Advancement in Isolation, Processing, Characterization and Applications of Emerging Nanocellulose: A Review. Int. J. Biol. Macromol. 2022, 206, 954–976. [Google Scholar] [CrossRef] [PubMed]

- Babicka, M.; Woźniak, M.; Bartkowiak, M.; Peplińska, B.; Waliszewska, H.; Zborowska, M.; Borysiak, S.; Ratajczak, I. Miscanthus and Sorghum as Sustainable Biomass Sources for Nanocellulose Production. Ind. Crops Prod. 2022, 186, 115177. [Google Scholar] [CrossRef]

- Tong, J.; Hu, W.; Qin, Y.; Liu, Y. Deep Eutectic Solvent Pretreatment for Green Preparation of Nanocellulose. Cellulose 2023, 30, 4773–4792. [Google Scholar] [CrossRef]

- Joshi, G.; Chauhan, S.S. Synthesis and Characterization of Cellulose Nanofibers from Waste Paper and Their Utilization in Wood Adhesion. Polym. Compos. 2024, 45, 9103–9118. [Google Scholar] [CrossRef]

- Markets and Markets. Nanocellulose Market Size, Share & Trends Analysis Report by Type (Cellulose Nanofibers, Bacterial Cellulose, Crystalline Nanocellulose), by Application, by Region, and Segment Forecasts, 2023–2030; Markets and Markets: Northbrook, IL, USA, 2024. [Google Scholar]

- Kluge, M.; Veigel, S.; Pinkl, S.; Henniges, U.; Zollfrank, C.; Rössler, A.; Gindl-Altmutter, W. Nanocellulosic Fillers for Waterborne Wood Coatings: Reinforcement Effect on Free-Standing Coating Films. Wood Sci. Technol. 2017, 51, 601–613. [Google Scholar] [CrossRef]

- Hossain, R.; Tajvidi, M. Cellulose Nanofibrils as a Bio-Based Binder for Wood Fiber Composite Insulation Panels with Enhanced Thermo-Mechanical Properties for Structural Wall Sheathing Applications. Carbohydr. Polym. Technol. Appl. 2024, 7, 100429. [Google Scholar] [CrossRef]

- Kawalerczyk, J.; Dziurka, D.; Dukarska, D.; Woźniak, M.; Walkiewicz, J.; Mirski, R. The Effect of Urea-Formaldehyde Adhesive Modification with Diisocyanate-Functionalized Nanocellulose on the Properties of Particleboard. Int. J. Adhes. Adhes. 2024, 135, 103850. [Google Scholar] [CrossRef]

- Kryg, P.; Mazela, B.; Perdoch, W.; Broda, M. Challenges and Prospects of Applying Nanocellulose for the Conservation of Wooden Cultural Heritage—A Review. Forests 2024, 15, 1174. [Google Scholar] [CrossRef]

- Song, X.; Zhu, Z.; Tang, S.; Chi, X.; Han, G.; Cheng, W. Efficient Extraction of Nanocellulose from Lignocellulose Using Aqueous Butanediol Fractionation to Improve the Performance of Waterborne Wood Coating. Carbohydr. Polym. 2023, 322, 121347. [Google Scholar] [CrossRef]

- Janiszewska-Latterini, D.; Hochmańska-Kaniewska, P.; Kwaśniewska-Sip, P.; Czajka, M.; Pędzik, M. Effect of Wood Adhesive Modification with Liquefied Lignocellulosic Biomass and Nanocellulose on the Formaldehyde and Volatile Organic Compounds Emissions of Particleboards. Wood Mater. Sci. Eng. 2024, 19, 451–461. [Google Scholar] [CrossRef]

- Kawalerczyk, J.; Dziurka, D.; Mirski, R.; Siuda, J. The Reduction of Adhesive Application in Plywood Manufacturing by Using Nanocellulose-Reinforced Urea-Formaldehyde Resin. J. Appl. Polym. Sci. 2021, 138, 49834. [Google Scholar] [CrossRef]

- Basile, R.; Bergamonti, L.; Fernandez, F.; Graiff, C.; Haghighi, A.; Isca, C.; Lottici, P.P.; Pizzo, B.; Predieri, G. Bio-Inspired Consolidants Derived from Crystalline Nanocellulose for Decayed Wood. Carbohydr. Polym. 2018, 202, 164–171. [Google Scholar] [CrossRef]

- Joshi, G.; Chauhan, S.S. Cellulose Nanofibers-Based UV Resistant and Hydrophobic Wood Coatings. Surf. Interfaces 2024, 54, 105259. [Google Scholar] [CrossRef]

- Fukuzumi, H.; Saito, T.; Iwata, T.; Kumamoto, Y.; Isogai, A. Transparent and High Gas Barrier Films of Cellulose Nanofibers Prepared by TEMPO-Mediated Oxidation. Biomacromolecules 2009, 10, 162–165. [Google Scholar] [CrossRef]

- Clauser, N.M.; Felissia, F.F.; Area, M.C.; Vallejos, M.E. Technological and Economic Barriers of Industrial-Scale Production of Nanocellulose. In Green Nanomaterials for Industrial Applications; Elsevier: Amsterdam, The Netherlands, 2022; pp. 21–39. [Google Scholar] [CrossRef]

- ISO 13061-2:2014; Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens—Part 2: Determination of Density for Physical and Mechanical Tests. International Organization for Standarization: Geneva, Switzerland, 2014.

- ISO 13061-1:2014; Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens—Part 1: Determination of Moisture Content for Physical and Mechanical Tests. International Organization for Standarization: Geneva, Switzerland, 2014.

- EN 828; Adhesives—Wettability—Determination by Measurement of Contact Angle and Surface. CEN, European Committee for Standarization: Brussels, Belgium, 2013.

- Hailwood, A.J.; Horrobin, S. Absorption of Water by Polymers: Analysis in Terms of a Simple Model. Trans. Faraday Soc. 1946, 42, B084–B092. [Google Scholar] [CrossRef]

- Skaar, C. Hygroexpansion in Wood; Springer: Berlin/Heidelberg, Germany, 1988; Volume 76, pp. 122–176. [Google Scholar] [CrossRef]

- Furmaniak, S.; Terzyk, A.P.; Gauden, P.A. The General Mechanism of Water Sorption on Foodstuffs—Importance of the Multitemperature Fitting of Data and the Hierarchy of Models. J. Food Eng. 2007, 82, 528–535. [Google Scholar] [CrossRef]

- Furmaniak, S.; Terzyk, A.P.; Gauden, P.A.; Rychlicki, G. Applicability of the Generalised D’Arcy and Watt Model to Description of Water Sorption on Pineapple and Other Foodstuffs. J. Food Eng. 2007, 79, 718–723. [Google Scholar] [CrossRef]

- Furmaniak, S.; Terzyk, A.P.; Gołembiewski, R.; Gauden, P.A.; Czepirski, L. Searching the Most Optimal Model of Water Sorption on Foodstuffs in the Whole Range of Relative Humidity. Food Res. Int. 2009, 42, 1203–1214. [Google Scholar] [CrossRef]

- Furmaniak, S.; Terzyk, A.P.; Gauden, P.A. Some Remarks on the Classification of Water Vapor Sorption Isotherms and Blahovec and Yanniotis Isotherm Equation. Dry. Technol. 2011, 29, 984–991. [Google Scholar] [CrossRef]

- Furmaniak, S. The Alternative Model of Water Vapour Sorption in Porous Building Materials. Transp. Porous Media 2012, 95, 21–23. [Google Scholar] [CrossRef]

- Papadopoulos, A.N.; Hill, C.A.S. The Sorption of Water Vapour by Anhydride Modified Softwood. Wood Sci. Technol. 2003, 37, 221–231. [Google Scholar] [CrossRef]

- Papadopoulos, A.N. Moisture Adsorption Isotherms of Two Esterified Greek Hardwoods. Holz Roh Werkst. 2005, 63, 123–128. [Google Scholar] [CrossRef]

- Papadopoulos, A.N.; Avramidis, S.; Elustondo, D. The Sorption of Water Vapour by Chemically Modified Softwood: Analysis Using Various Sorption Models. Wood Sci. Technol. 2005, 39, 99–111. [Google Scholar] [CrossRef]

- Papadopoulos, A.N.; Foti, D.; Kyzas, G.Z. Sorption Behavior of Water Vapor of Wood Treated by Chitosan Polymer. Eur. J. Wood Wood Prod. 2020, 78, 483–491. [Google Scholar] [CrossRef]

- Han, L.; Xi, G.; Dai, W.; Zhou, Q.; Sun, S.; Han, X.; Guo, H. Influence of Natural Aging on the Moisture Sorption Behaviour of Wooden Structural Components. Molecules 2023, 28, 1946. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Chai, Y.; Liu, J.; Zhu, J.Y. The Viscoelastic and Hygroscopicity Behavior of Delignified and Densified Poplar Wood. Forests 2023, 14, 1721. [Google Scholar] [CrossRef]

- Furmaniak, S.; Terzyk, A.P.; Gauden, P.A. Interrelation between Steam Sorption by Wood and Temperature. Drew.-Wood 2008, 51, 15–29. [Google Scholar]

- Olek, W.; Majka, J.; Czajkowski, Ł. Sorption Isotherms of Thermally Modified Wood. Holzforschung 2013, 67, 183–191. [Google Scholar] [CrossRef]

- Majka, J.; Babiński, L.; Olek, W. Sorption Isotherms of Waterlogged Subfossil Scots Pine Wood Impregnated with a Lactitol and Trehalose Mixture. Holzforschung 2017, 71, 813–819. [Google Scholar] [CrossRef]

- Majka, J.; Czajkowski, Ł.; Olek, W. Sorption Hysteresis of Spruce. BioResources 2016, 11, 5265–5275. [Google Scholar]

- Lis, B.; Woźniak, M.; Krystofiak, T.; Ratajczak, I. Effect of Accelerated Aging on the Color Changes of Wood Treated with Eco-Friendly Formulations Based on Propolis and Silicon Compounds. BioResources 2020, 15, 3667–3677. [Google Scholar] [CrossRef]

- PN-77/D-04103; Wood. Determination of Static Bending Strength. Polish Committee for Standarization: Warsaw, Poland, 1977.

- PN-63/D-04117; Physical and Mechanical Properties of Wood. Determination of the Elasticity Coefficient for Static Bending. Polish Committee for Standarization: Warsaw, Poland, 1963.

- Durmaz, S.; Özgenç, Ö.; Boyaci, I.H.; Yildiz, Ü.C.; Erişir, E. Examination of the Chemical Changes in Spruce Wood Degraded by Brown-Rot Fungi Using FT-IR and FT-Raman Spectroscopy. Vib. Spectrosc. 2016, 85, 202–207. [Google Scholar] [CrossRef]

- Traoré, M.; Kaal, J.; Martínez Cortizas, A. Differentiation between Pine Woods According to Species and Growing Location Using FTIR-ATR. Wood Sci. Technol. 2018, 52, 487–504. [Google Scholar] [CrossRef]

- Ozgenc, O.; Durmaz, S.; Hakki Boyaci, I.; Eksi-Kocak, H. ATR-FTIR Spectroscopic Analysis of Thermally Modified Wood Degraded by Rot Fungi. Wood 2018, 61, 201. [Google Scholar] [CrossRef]

- Fornari, A.; Rocco, D.; Mattiello, L.; Bortolami, M.; Rossi, M.; Bergamonti, L.; Graiff, C.; Bani, S.; Morresi, F.; Pandolfi, F. Comparative Studies on Nanocellulose as a Bio-Based Consolidating Agent for Ancient Wood. Appl. Sci. 2024, 14, 7964. [Google Scholar] [CrossRef]

- Santoni, I.; Pizzo, B. Effect of Surface Conditions Related to Machining and Air Exposure on Wettability of Different Mediterranean Wood Species. Int. J. Adhes. Adhes. 2011, 31, 743–753. [Google Scholar] [CrossRef]

- Huang, S.; Wang, D. A Simple Nanocellulose Coating for Self-Cleaning upon Water Action: Molecular Sesign of Stable Surface Hydrophilicity. Angew. Chem. Int. Ed. 2017, 56, 9053–9057. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Moser, C.; Lindström, M.E.; Henriksson, G.; Li, J. Cellulose Nanofibers from Softwood, Hardwood, and Tunicate: Preparation-Structure-Film Performance Interrelation. ACS Appl. Mater. Interfaces 2017, 9, 13508–13519. [Google Scholar] [CrossRef]

- Jusic, J.; Tamantini, S.; Romagnoli, M.; Vinciguerra, V.; Di Mattia, E.; Zikeli, F.; Cavalera, M.; Mugnozza, G.S. Improving Sustainability in Wood Coating: Testing Lignin and Cellulose Nanocrystals as Additives to Commercial Acrylic Wood Coatings for Bio-Building. iForest—Biogeosci. For. 2021, 14, 499. [Google Scholar] [CrossRef]

- Solhi, L.; Guccini, V.; Heise, K.; Solala, I.; Niinivaara, E.; Xu, W.; Mihhels, K.; Kröger, M.; Meng, Z.; Wohlert, J.; et al. Understanding Nanocellulose-Water Interactions: Turning a Detriment into an Asset. Chem. Rev. 2023, 123, 1925–2015. [Google Scholar] [CrossRef]

- Hang, J.; Yan, X.; Li, J. A Review on the Effect of Wood Surface Modification on Paint Film Adhesion Properties. Coatings 2024, 14, 1313. [Google Scholar] [CrossRef]

- Simpson, W. Sorption Theories Applied To Wood. Wood Fiber Sci. 1980, 12, 183–195. [Google Scholar]

- Cataldi, A.; Esposito Corcione, C.; Frigione, M.; Pegoretti, A. Photocurable Resin/Nanocellulose Composite Coatings for Wood Protection. Prog. Org. Coat. 2017, 106, 128–136. [Google Scholar] [CrossRef]

- Hamed, S.A.A.K.M.; Hassan, M.L. A New Mixture of Hydroxypropyl Cellulose and Nanocellulose for Wood Consolidation. J. Cult. Herit. 2019, 35, 140–144. [Google Scholar] [CrossRef]

- Marcuello, C.; Foulon, L.; Chabbert, B.; Molinari, M.; Aguié-Béghin, V. Langmuir-Blodgett Procedure to Precisely Control the Coverage of Functionalized AFM Cantilevers for SMFS Measurements: Application with Cellulose Nanocrystals. Langmuir 2018, 34, 9376–9386. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.; Wu, Q.; Zhang, X.; Ren, S.; Lei, T.; Li, W.; Xu, G.; Zhang, Q. Nanocellulose Films with Combined Cellulose Nanofibers and Nanocrystals: Tailored Thermal, Optical and Mechanical Properties. Cellulose 2018, 25, 1103–1115. [Google Scholar] [CrossRef]

- Claro, P.; de Campos, A.; Corrêa, A.; Rodrigues, V.; Luchesi, B.; Silva, L.; Tonoli, G.; Mattoso, L.; Marconcini, J. Curaua and Eucalyptus Nanofiber Films by Continuous Casting: Mixture of Cellulose Nanocrystals and Nanofibrils. Cellulose 2019, 26, 2453–2470. [Google Scholar] [CrossRef]

| Variability Range | Color Difference |

|---|---|

| 0 < ∆E* < 1 | invisible |

| 1 < ∆E* ≤ 2 | very small and recognizable only by an experienced observer |

| 2 < ∆E* ≤ 3.5 | average and recognizable by an inexperienced observer |

| 3.5 < ∆E* ≤ 5 | clearly |

| ∆E* > 5 | distinctly |

| Sample Description | Θ (degrees) |

|---|---|

| 0.5% CNF | 24.3 c ± 5.8 |

| 1% CNF | 31.7 c ± 8.1 |

| 2% CNF | 56.3 b ± 7.9 |

| Untreated wood | 98.3 a ± 12.1 |

| Sample Description | Sorption Phase | k1 | k2 | w (kg·kmol−1) | R2 | Mh (kg·kg−1) | Md (kg·kg−1) |

|---|---|---|---|---|---|---|---|

| 0.5% CNF | Adsorption | 6.546 | 0.7574 | 288.6 | 0.9997 | 0.0519 | 0.1947 |

| Desorption | 7.023 | 0.6485 | 198.2 | 0.9998 | 0.0745 | 0.1676 | |

| 1% CNF | Adsorption | 6.214 | 0.7565 | 295.0 | 0.9996 | 0.0503 | 0.1896 |

| Desorption | 6.901 | 0.6441 | 200.3 | 0.9999 | 0.0734 | 0.1626 | |

| 2% CNF | Adsorption | 4.904 | 0.7761 | 309.6 | 0.9996 | 0.0460 | 0.2016 |

| Desorption | 6.396 | 0.6861 | 223.0 | 0.9999 | 0.0657 | 0.1764 | |

| Untreated (control) | Adsorption | 5.195 | 0.7554 | 303.5 | 0.9989 | 0.0473 | 0.1832 |

| Desorption | 5.442 | 0.6273 | 194.2 | 0.9998 | 0.0717 | 0.1560 |

| Sample Description | Sorption Phase | mGDW (kg·kg−1) | KGDW | kGDW | wGDW | R2 |

|---|---|---|---|---|---|---|

| 0.5% CNF | Adsorption | 0.0833 | 3.947 | 0.7753 | 0.7911 | 0.9997 |

| Desorption | 0.0837 | 6.330 | 0.5964 | 1.5732 | 0.9999 | |

| 1% CNF | Adsorption | 0.0903 | 3.274 | 0.7853 | 0.6835 | 0.9997 |

| Desorption | 0.0853 | 5.904 | 0.5978 | 1.4917 | 0.9999 | |

| 2% CNF | Adsorption | 0.1151 | 1.934 | 0.8207 | 0.5058 | 0.9998 |

| Desorption | 0.0941 | 4.336 | 0.6877 | 0.9846 | 0.9999 | |

| Untreated (control) | Adsorption | 0.1620 | 1.318 | 0.8468 | 0.2858 | 0.9998 |

| Desorption | 0.0890 | 4.557 | 0.5803 | 1.5206 | 0.9999 |

| Sample Description | H (Arb. Units) | ΔEMCmax (kg·kg−1) | RH (-) |

|---|---|---|---|

| 0.5% CNF | 0.0181 | 0.026 | 0.66 |

| 1% CNF | 0.0186 | 0.027 | 0.66 |

| 2% CNF | 0.0173 | 0.024 | 0.66 |

| Untreated (control) | 0.0191 | 0.028 | 0.67 |

| Color Parameters | Exposure Times (min) | Sample Description | |||

|---|---|---|---|---|---|

| Untreated | 0.5% CNF | 1% CNF | 2% CNF | ||

| L* | 0 | 92.2 ± 1.5 | 92.0 ± 0.9 | 92.4 ± 0.7 | 92.2 ± 0.9 |

| 15 | 91.6 ± 1.4 | 91.3 ± 0.9 | 91.8 ± 0.7 | 91.4 ± 1.0 | |

| 30 | 91.3 ± 1.2 | 91.1 ± 0.9 | 91.4 ± 0.7 | 91.0 ± 0.9 | |

| 45 | 90.7 ± 1.2 | 90.9 ± 0.9 | 91.2 ± 0.7 | 91.2 ± 2.0 | |

| 60 | 90.4 ± 1.4 | 90.8 ± 1.0 | 91.0 ± 0.7 | 90.7 ± 1.0 | |

| a* | 0 | 6.3 a ± 0.7 | 5.4 b ± 0.5 | 5.3 b ± 0.3 | 5.3 b ± 0.4 |

| 15 | 5.5 a ± 0.5 | 5.2 b ± 0.5 | 5.0 b ± 0.3 | 5.0 b ± 0.4 | |

| 30 | 5.4 a ± 0.6 | 5.1 b ± 0.4 | 4.9 b ± 0.3 | 4.9 b ± 0.4 | |

| 45 | 5.4 a ± 0.6 | 5.1 ab ± 0.5 | 4.9 b ±0.3 | 4.9 b ± 0.4 | |

| 60 | 5.4 a ± 0.6 | 5.1 ab ± 0.5 | 4.9 b ± 0.3 | 4.9 b ± 0.4 | |

| b* | 0 | 19.6 a ± 1.4 | 16.5 b ± 0.9 | 16.2 b ± 0.6 | 16.5 b ± 0.6 |

| 15 | 20.3 a ± 1.4 | 17.3 b ± 0.9 | 16.7 b ± 0.5 | 17.1 b ± 0.6 | |

| 30 | 20.9 a ± 1.3 | 17.6 b ± 0.8 | 17.0 b ± 0.5 | 17.4 b ± 0.6 | |

| 45 | 21.5 a ± 1.2 | 17.8 b ± 0.9 | 17.3 b ± 0.5 | 17.8 b ± 0.6 | |

| 60 | 21.6 a ± 1.3 | 17.9 b ± 0.9 | 17.6 b ± 0.4 | 18.1 b ± 0.5 | |

| Sample Description | MC (kg·kg−1) | WD (kg·m−3) | MOE (GPa) | MOR (MPa) |

|---|---|---|---|---|

| 0.5% CNF | 0.062 b ± 0.001 | 546 ± 29 | 10.9 ± 1.3 | 107.6 ± 23.5 |

| 1% CNF | 0.062 b ± 0.001 | 546 ± 27 | 11.4 ± 1.6 | 110.0 ± 17.1 |

| 2% CNF | 0.062 b ± 0.001 | 538 ± 26 | 10.6 ± 1.4 | 104.2 ± 13.8 |

| Untreated wood | 0.072 a ± 0.001 | 551 ± 42 | 10.7 ± 1.7 | 96.1 ± 17.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Woźniak, M.; Majka, J.; Krystofiak, T.; Lis, B.; Roszyk, E.; Ratajczak, I. Physico-Mechanical and Sorption Properties of Wood Treated with Cellulose Nanofibers. Materials 2025, 18, 2762. https://doi.org/10.3390/ma18122762

Woźniak M, Majka J, Krystofiak T, Lis B, Roszyk E, Ratajczak I. Physico-Mechanical and Sorption Properties of Wood Treated with Cellulose Nanofibers. Materials. 2025; 18(12):2762. https://doi.org/10.3390/ma18122762

Chicago/Turabian StyleWoźniak, Magdalena, Jerzy Majka, Tomasz Krystofiak, Barbara Lis, Edward Roszyk, and Izabela Ratajczak. 2025. "Physico-Mechanical and Sorption Properties of Wood Treated with Cellulose Nanofibers" Materials 18, no. 12: 2762. https://doi.org/10.3390/ma18122762

APA StyleWoźniak, M., Majka, J., Krystofiak, T., Lis, B., Roszyk, E., & Ratajczak, I. (2025). Physico-Mechanical and Sorption Properties of Wood Treated with Cellulose Nanofibers. Materials, 18(12), 2762. https://doi.org/10.3390/ma18122762