Production and Evaluation of Lime Fertilizers with the Addition of Biomass Combustion Waste

Abstract

1. Introduction

2. Materials and Methods

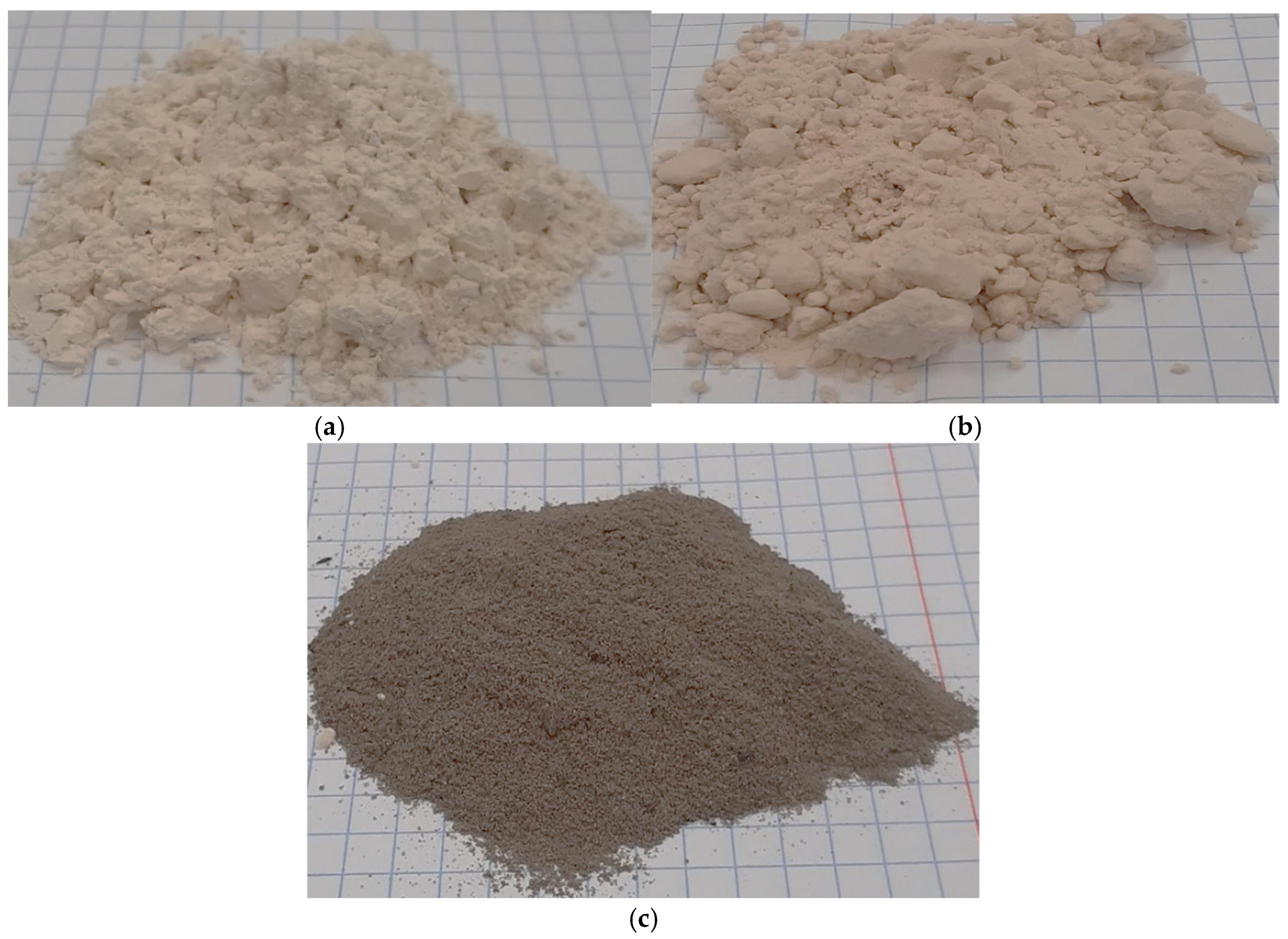

2.1. Materials

- ECO-ZEC (calcium sulfate)—an industrial by-product containing calcium sulfate dihydrate, obtained from a flue gas desulfurization system;

- PPR (post-production residue)—a post-reaction product derived from the semi-dry flue gas desulfurization process in boilers, produced by ENEA Ciepło, Białystok Combined Heat and Power Plant;

- Fly ash—a combustion by-product from biomass, sourced from the same ENEA Ciepło facility.

2.2. Moisture Content Determination

2.3. Particle Size Distribution Analysis

2.4. Bulk Density Determination

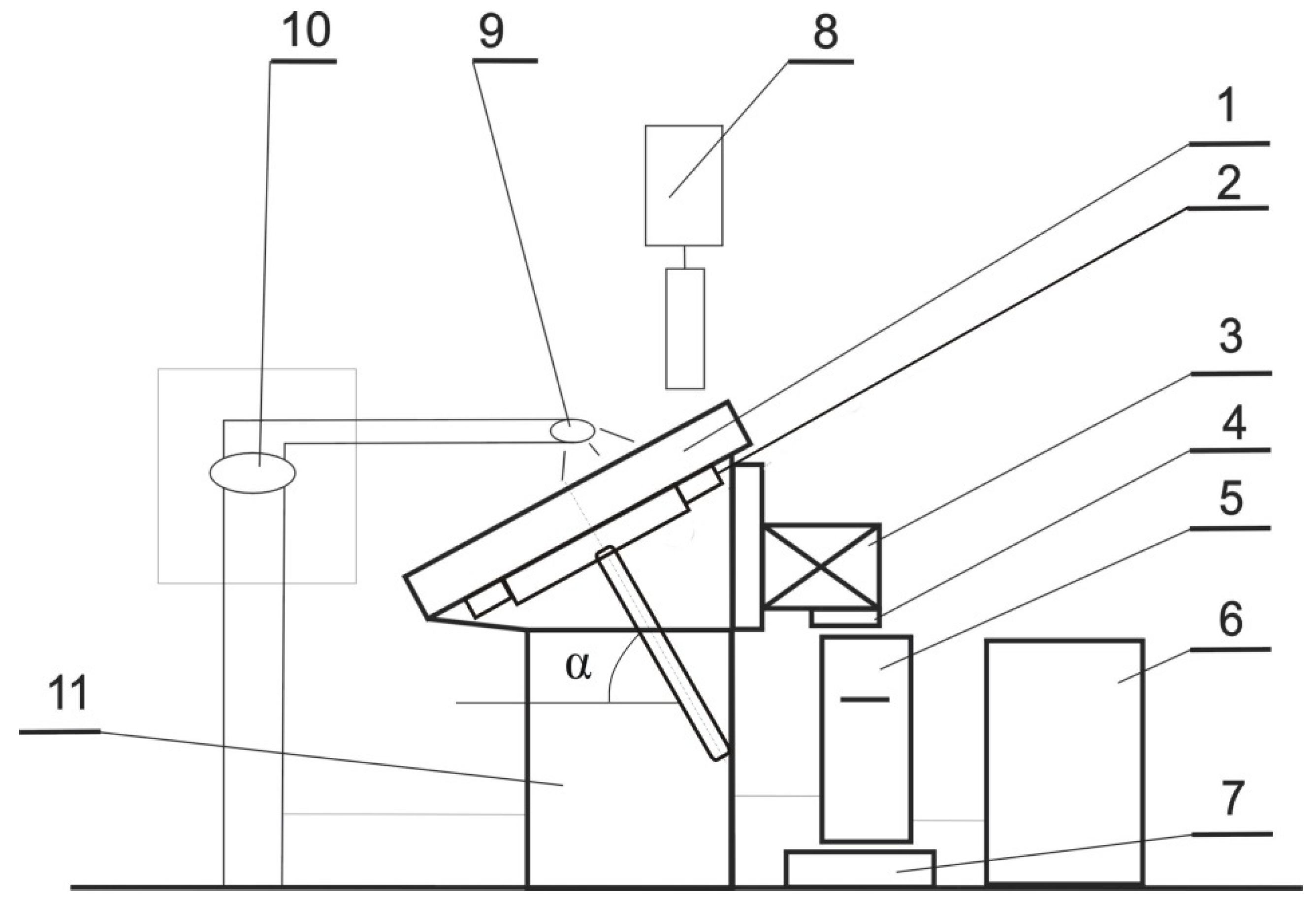

2.5. Fertilizer Production via Non-Pressure Agglomeration

- Granulation plate inclination angle: 65°;

- Blade inclination angle within the plate granulator: 45°.

- Granulation plate rotational speed: 8 rpm;

- Material residence time in the granulator: 9 min;

- Granulation liquid droplet size: mist (fine spray).

2.6. Determination of Macroelements

2.7. Determination of Microelements and Heavy Metals

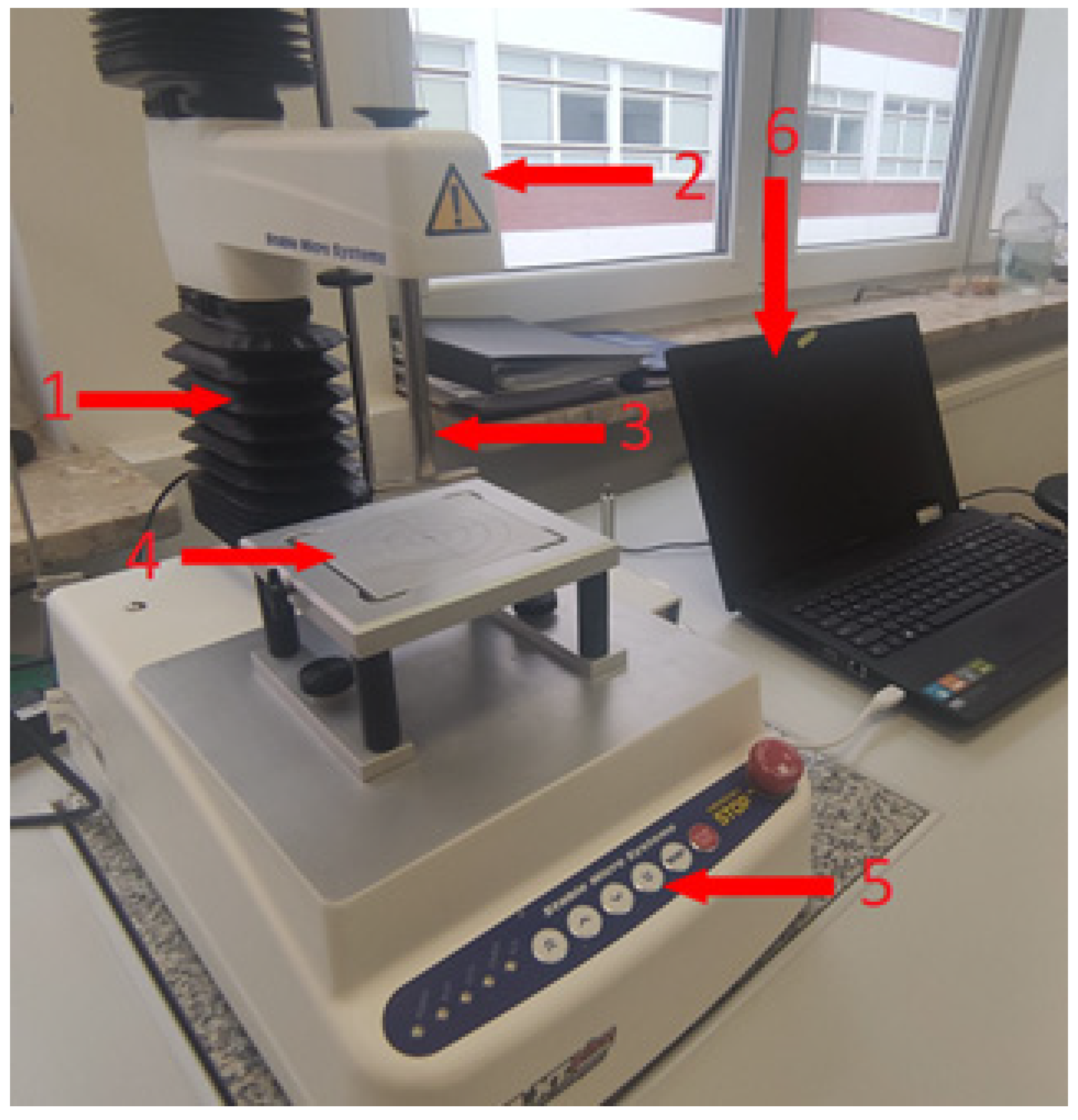

2.8. Determination of Granule Crushing Strength

- Mode: Return to Start;

- Pre-Test Speed: 10 mm·s−1;

- Test Speed: 0.5 mm·s−1;

- Post-Test Speed: 10.0 mm·s−1;

- Distance: 2 mm;

- Tools: Measuring tip for granulate testing, Heavy Duty Platform (HDP/90).

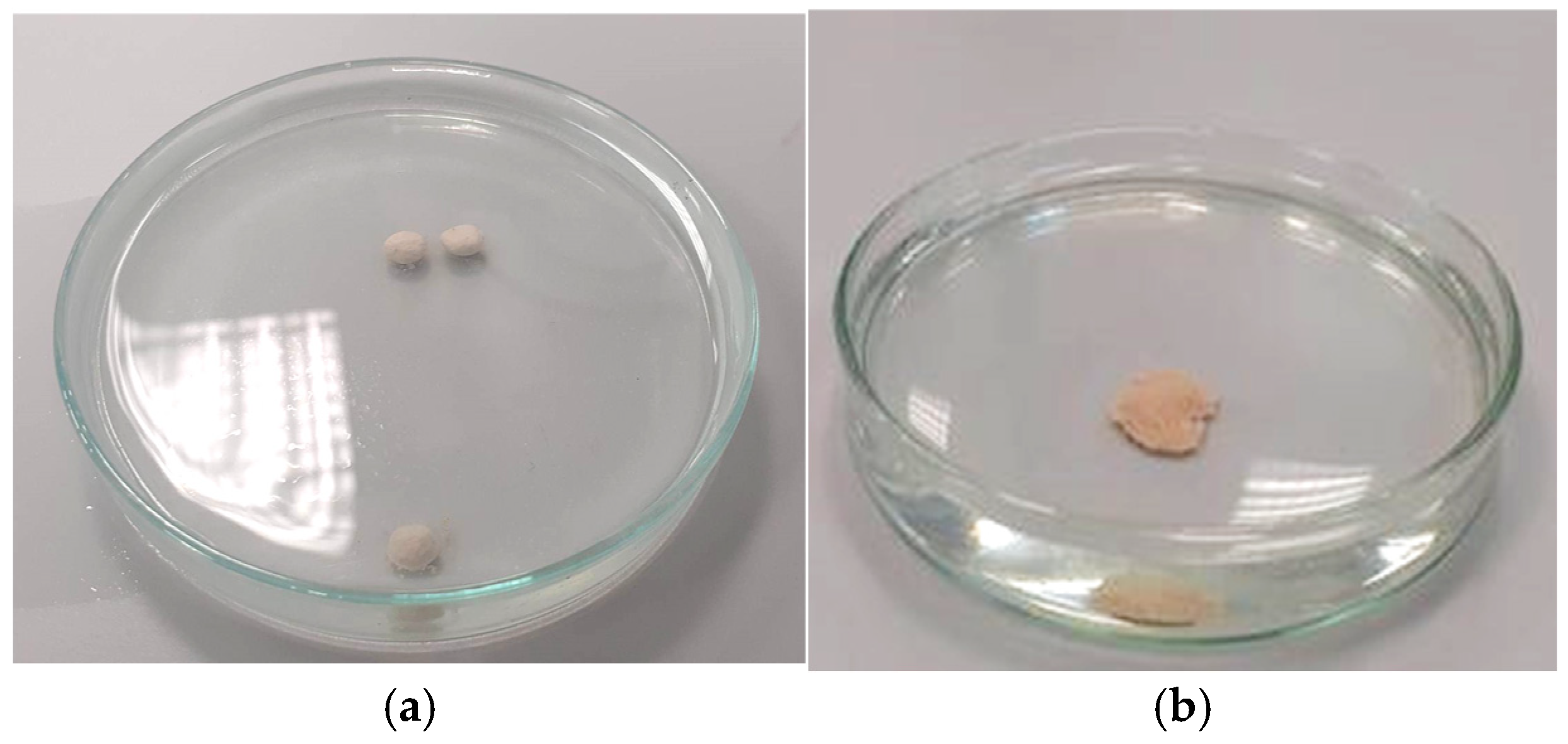

2.9. Determination of the Disintegration Time of Fertilizer Granules in Water

2.10. Determination of pH Value

2.11. Statistical Analysis

3. Results and Discussion

3.1. Moisture Content of Tested Materials

3.2. Granulometric Distribution of Tested Materials

3.3. Macroelement Content

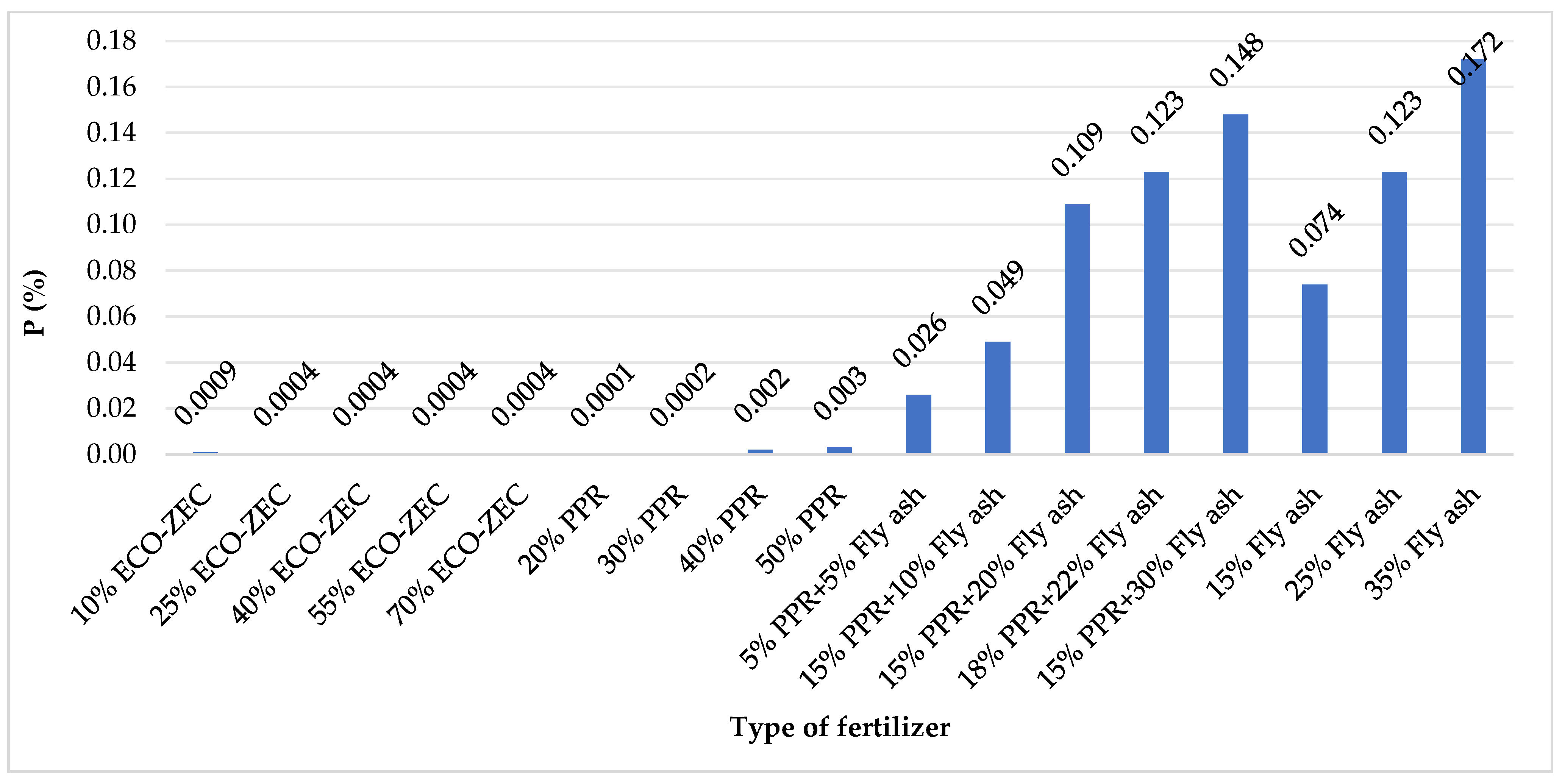

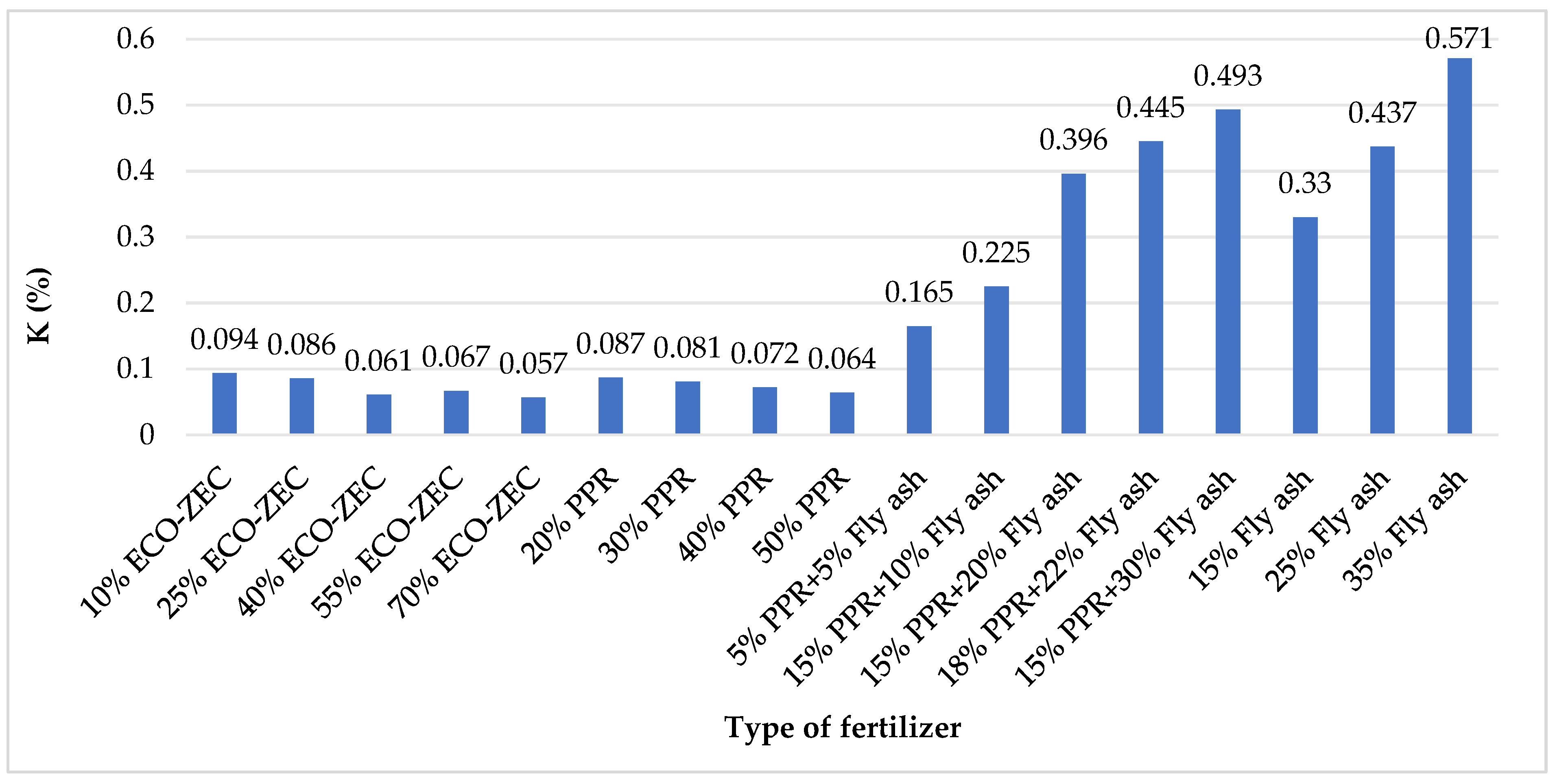

3.4. Microelement Content and Heavy Metals

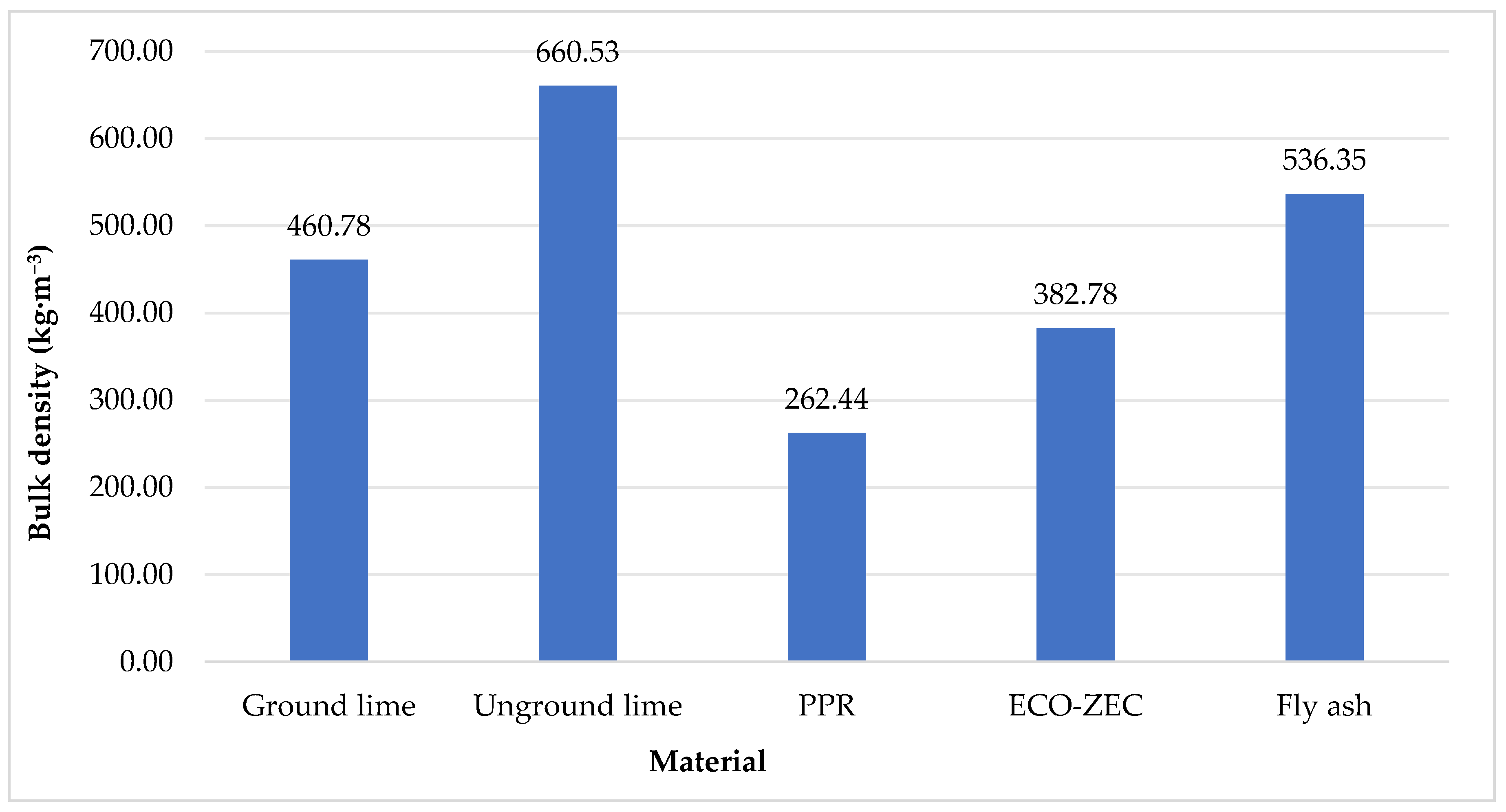

3.5. Bulk Density of Tested Materials

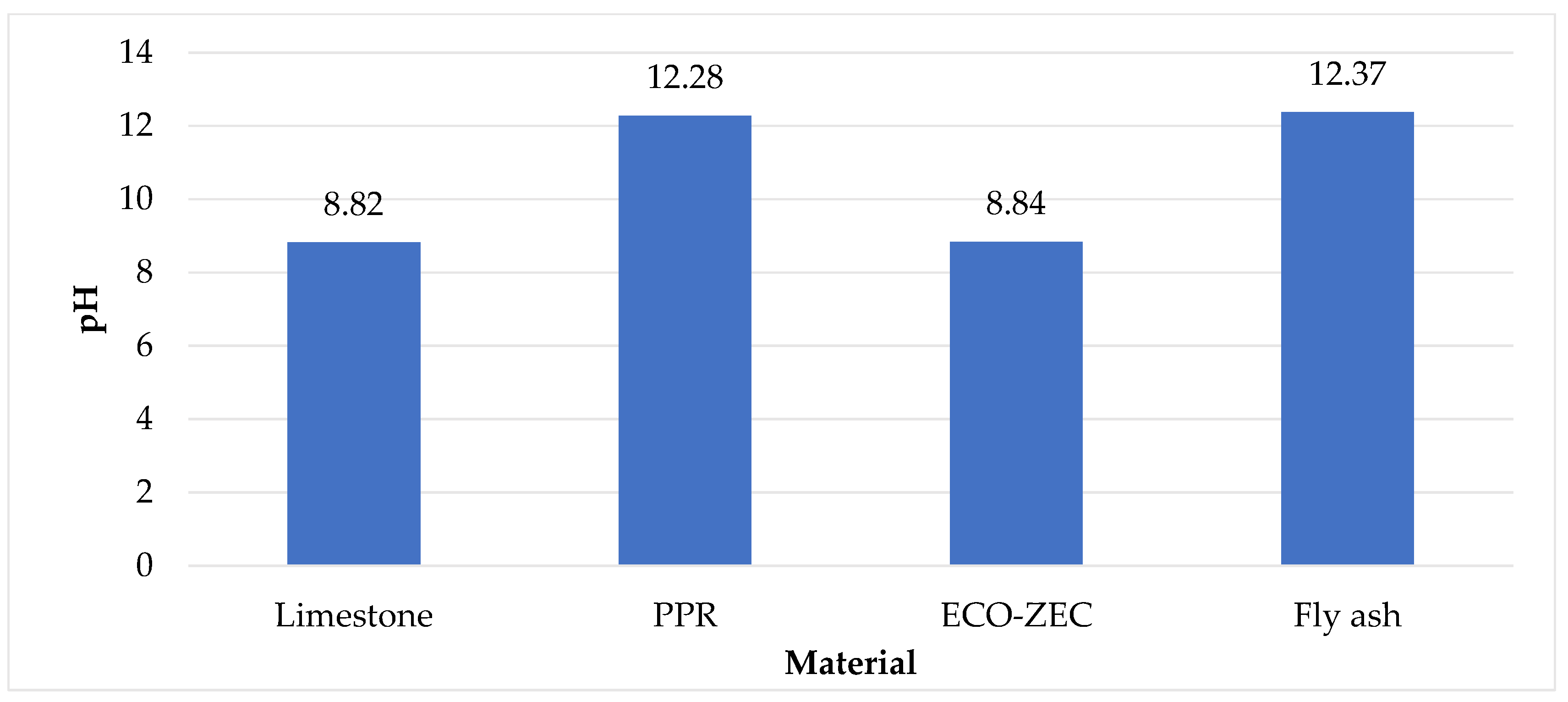

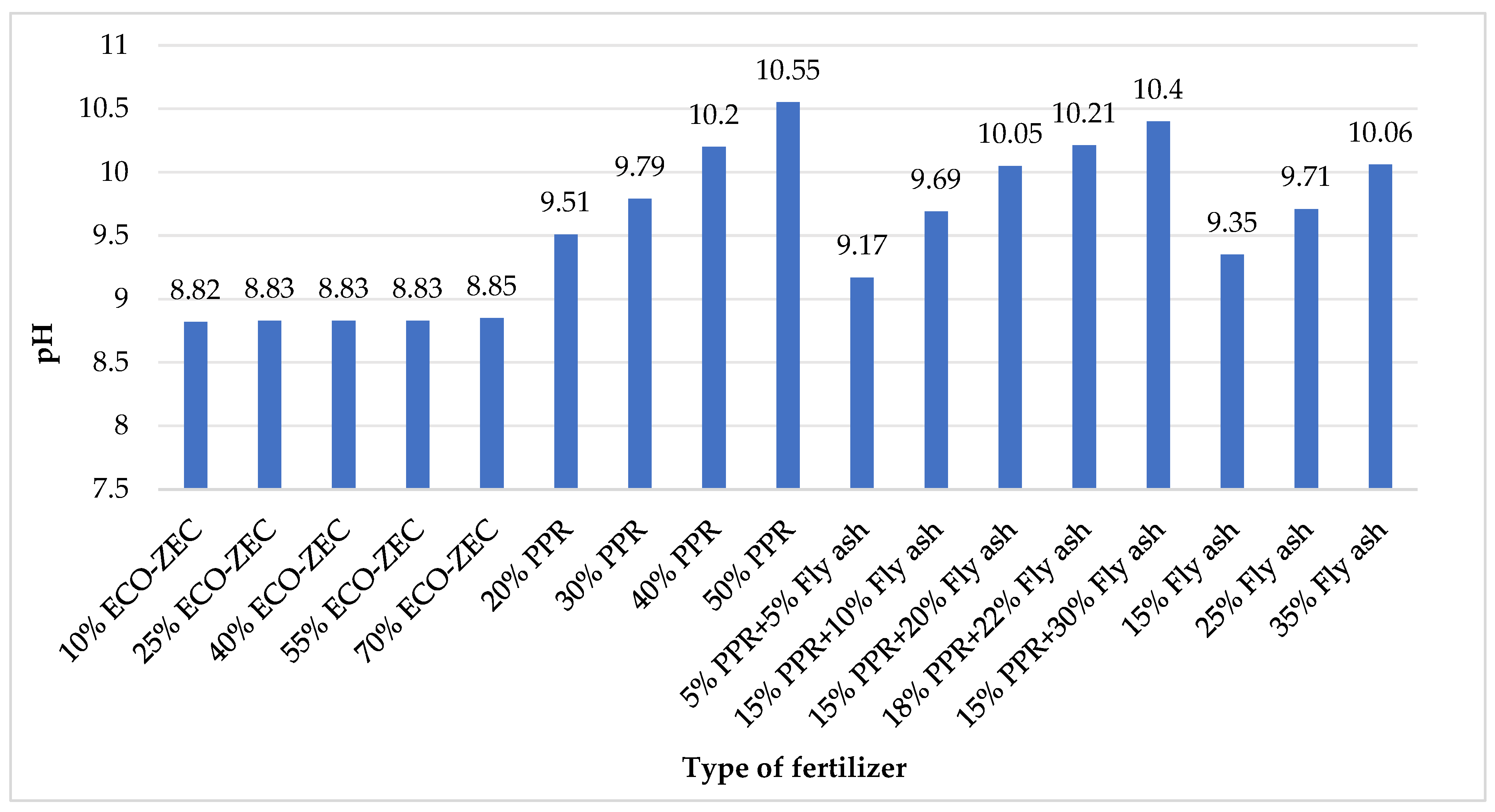

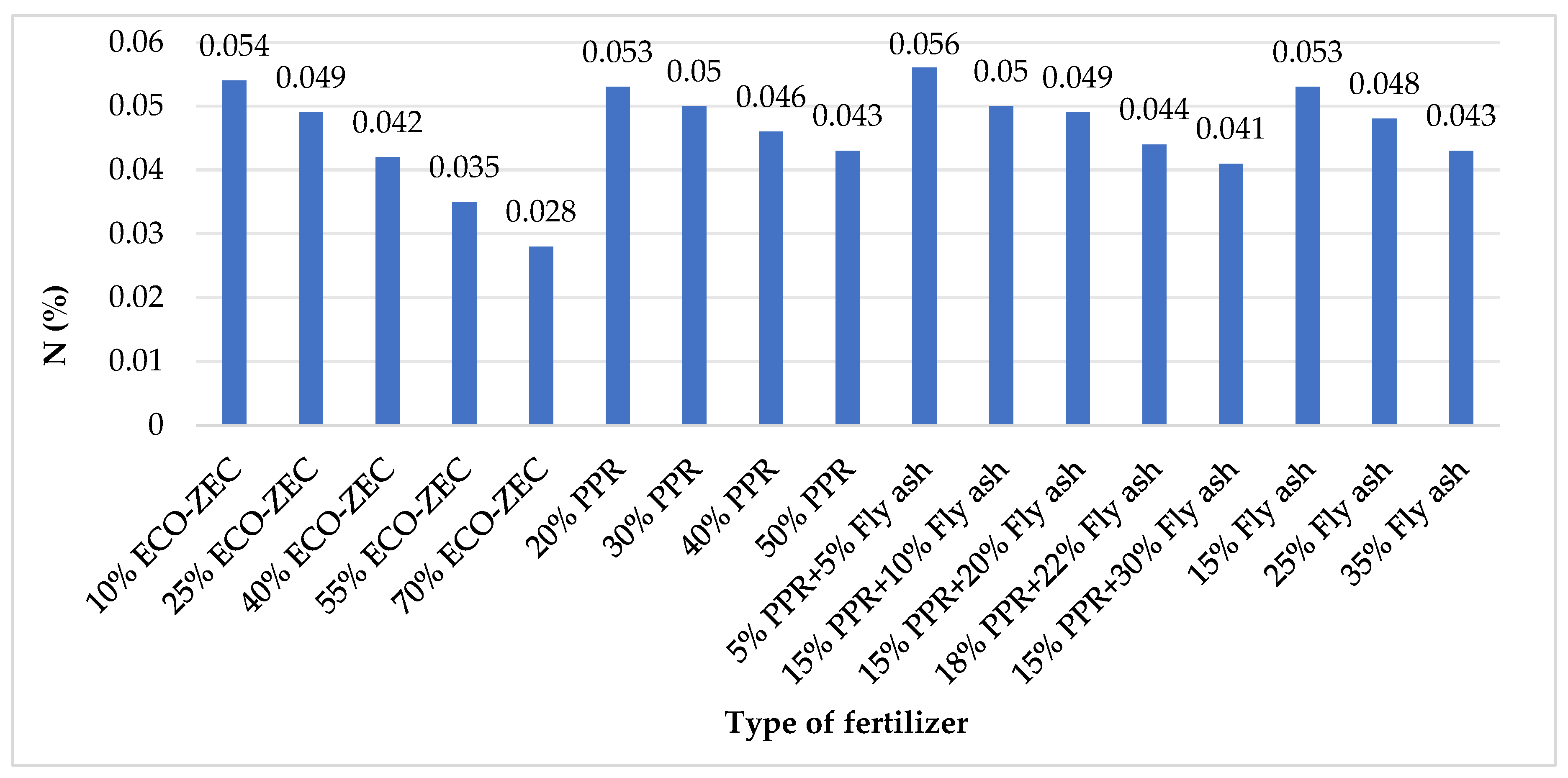

3.6. Fertilizing Properties of the Produced Granulates

3.7. The Results of the Research on the Non-Pressure Agglomeration Process

3.7.1. Granulate Compressive Strength

3.7.2. Bulk Density of Granulate

3.7.3. Granulometric Distribution of Fertilizer Granules

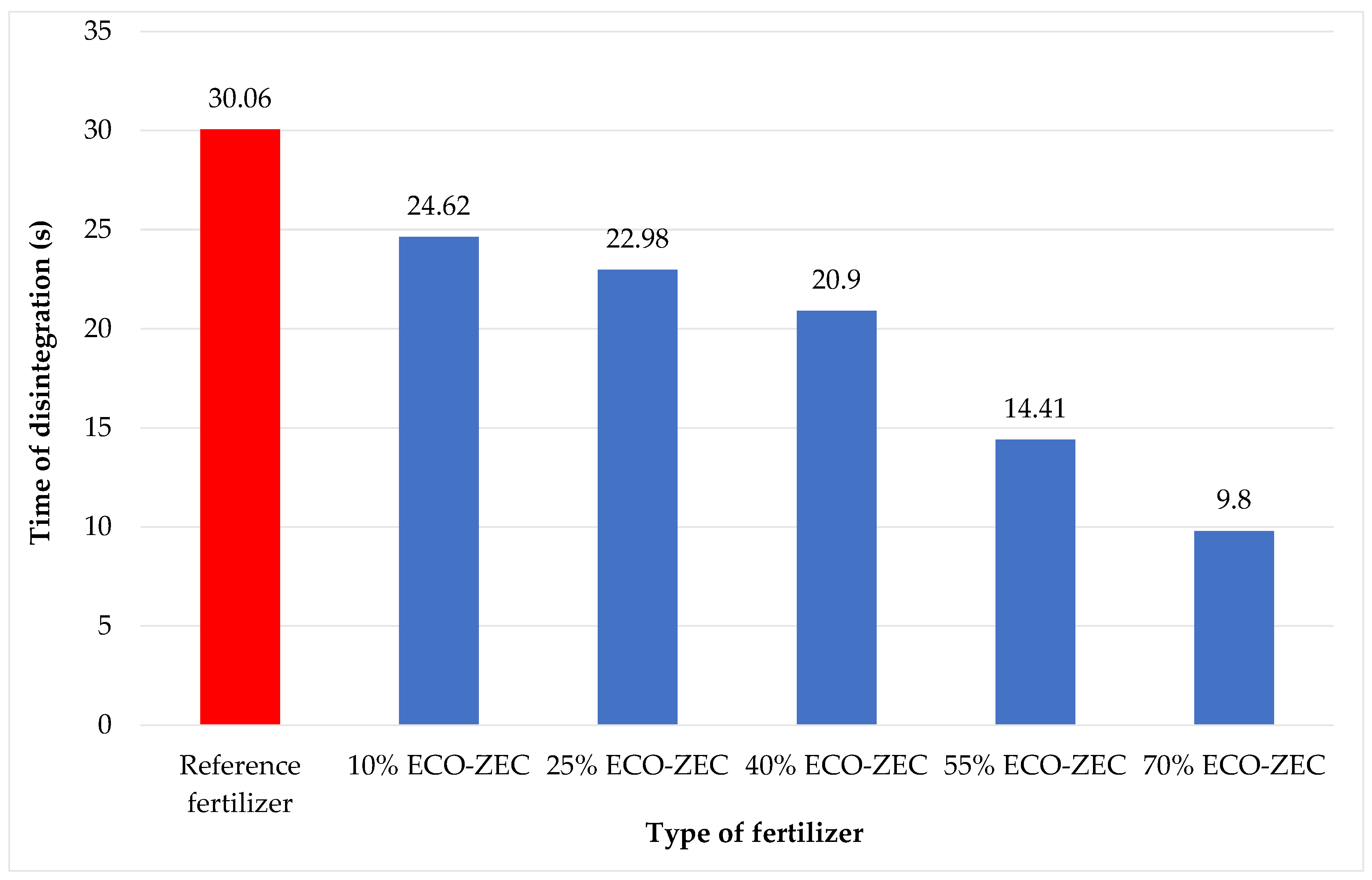

3.8. Disintegration Time of Fertilizer Granules in Water

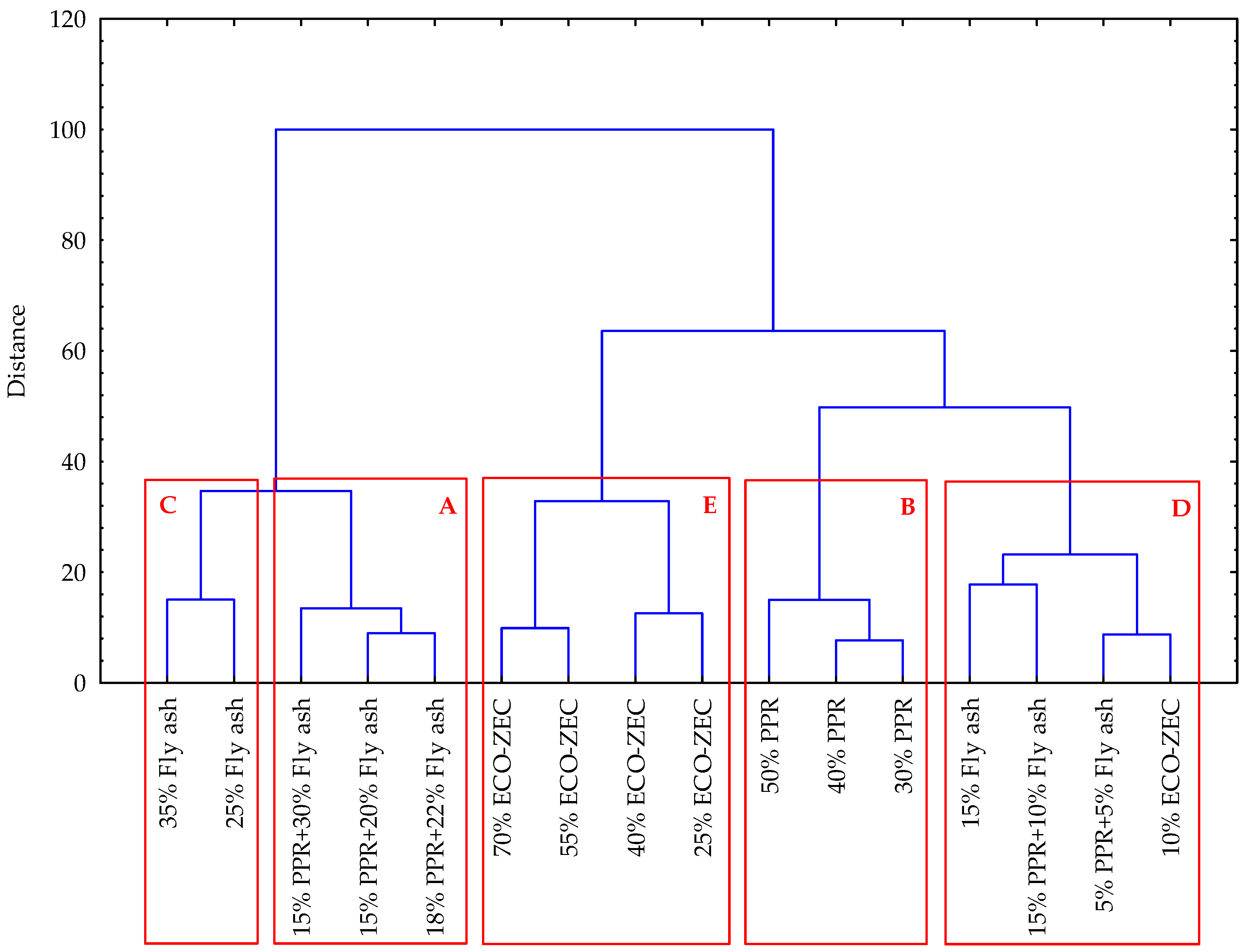

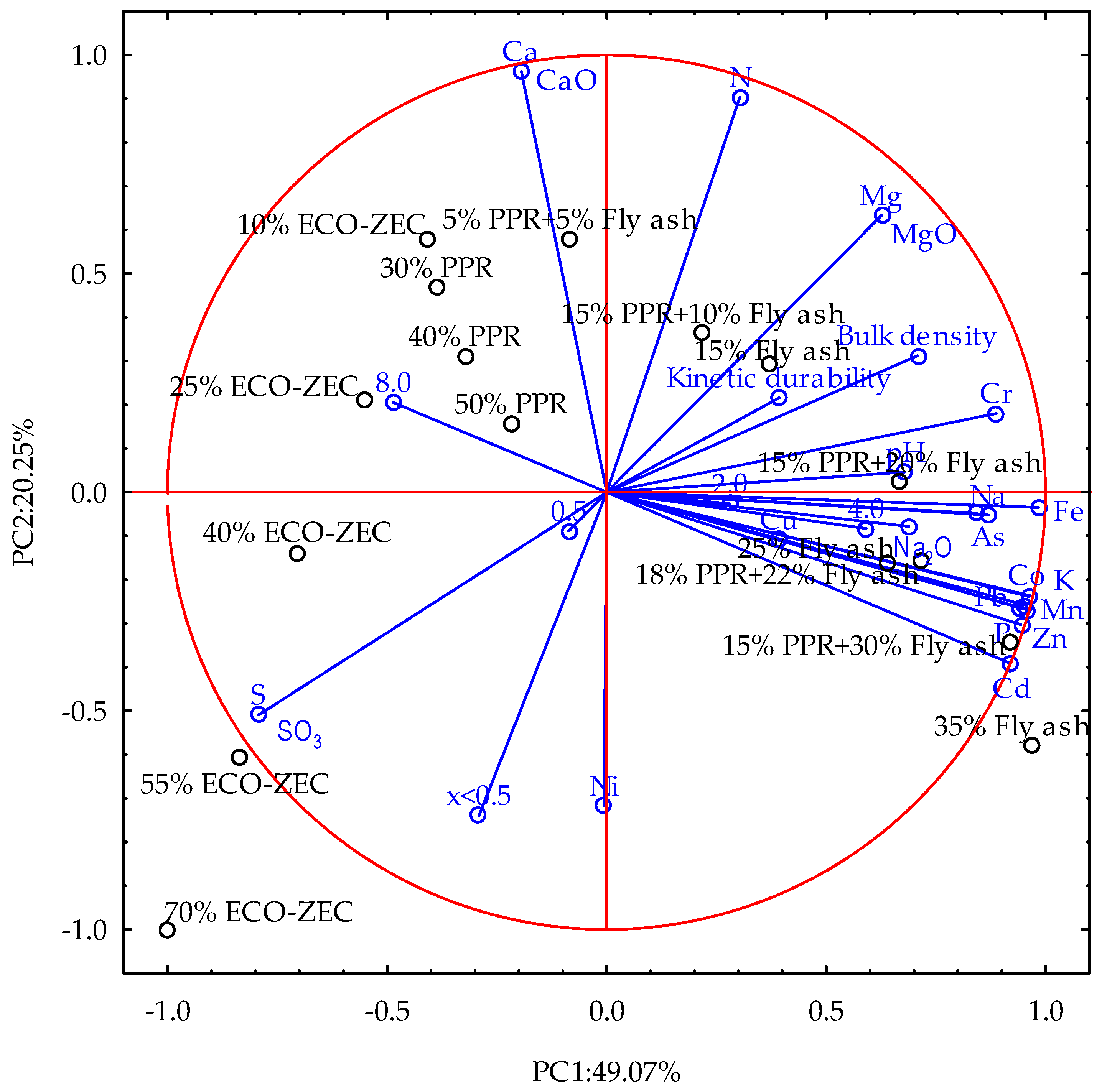

3.9. Statistical Analysis of Obtained Results

4. Conclusions

- The raw materials, including carbonate limestone and the waste additives ECO-ZEC, PPR, and fly ash supplied by ROLPOL, displayed relatively low moisture content. Specifically, unground lime had a moisture content of 0.36%, while fly ash and PPR additives exhibited slightly higher moisture values (0.40% and 1.82%, respectively), with ECO-ZEC lime showing the highest moisture content of 8.17%.

- In terms of particle size distribution, ground lime had a significant proportion of fine particles, with 58.31% in the 0.25 mm fraction and 27.03% in the 0.125 mm fraction. Unground lime, on the other hand, contained larger particles, with 42.05% in the 1.00 mm fraction and approximately 19.39% in the 0.50 mm fraction.

- The waste additives ECO-ZEC, PPR, and fly ash exhibited very fine particles, resulting in partial agglomeration during the sieving process, which could affect their incorporation into the final granules. These fine particles contributed to the unique characteristics of the granules produced.

- When comparing bulk density values, unground lime exhibited a significantly higher bulk density (660.53 kg·m−3) than ground lime (460.78 kg·m−3). Among the waste additives, fly ash had the highest bulk density (536.35 kg·m−3), followed by ECO-ZEC lime (382.78 kg·m−3), and PPR, which had the lowest bulk density (262.44 kg·m−3).

- Regarding chemical composition, fly ash exhibited the highest sodium content, while ECO-ZEC lime had the lowest. Magnesium content was highest in carbonate limestone, with fly ash containing approximately half as much and ECO-ZEC having the least. The calcium content in PPR was around 7% lower than in carbonate limestone, while ECO-ZEC and fly ash had 20% and over 30% less calcium, respectively.

- The granules produced from the mixtures of carbonate limestone and waste materials ECO-ZEC, PPR, and fly ash showed CaO content ranging from 34% to 52%, indicating their potential for use as lime-based fertilizers. However, due to their low magnesium oxide (MgO) content, these granules cannot be classified as magnesium-containing lime fertilizers.

- The granules exhibited low sodium content, with the highest levels found in the mixtures containing fly ash and the lowest in the ECO-ZEC mixtures. Additionally, the heavy metal content in the granules was within permissible limits, with fly ash mixtures exhibiting the highest concentrations of cadmium and lead.

- The waste materials tested, ECO-ZEC, PPR, and fly ash, were highly alkaline, with pH values ranging from 12.37 for fly ash to 8.82 for the provided carbonate limestone. This alkaline nature indicates that the granules, when applied to soil, will not cause a reduction in soil pH, thus preventing potential acidification.

- The addition of waste materials such as fly ash and PPR increased the potassium oxide (K2O) content, while the phosphorus pentoxide (P2O5) content remained moderate, and nitrogen content was relatively low. These changes in nutrient content could have an impact on the fertilizer’s suitability for various soil types and plant requirements.

- The granules with 30% PPR exhibited comparable crushing strength (10.60 N) to the standard granule, while the addition of 50% PPR significantly increased the crushing strength to 14.00 N. The addition of ECO-ZEC lime to ground limestone caused a slight decrease in crushing strength, with values lower than those of the standard granule. However, the addition of fly ash resulted in a marked reduction in crushing strength, which could affect the granule’s durability.

- Granules containing fly ash and PPR (above 10%) did not show disintegration during dissolution tests, indicating that these could be classified as slow-release fertilizers, potentially useful in applications where gradual nutrient release is required.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Directive—1999/31—EN—EUR-Lex. Available online: https://eur-lex.europa.eu/eli/dir/1999/31/oj/eng (accessed on 14 April 2025).

- Act of 14 December 2012 on Waste. Dz. U. 2013 Poz. 21. Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=wdu20130000021 (accessed on 14 April 2025).

- Stępień, M.; Białecka, B. Inwentaryzacja Innowacyjnych Technologii Odzysku Odpadów Energetycznych. Syst. Wspomag. Inż. Prod. 2017, 6, 108–123. [Google Scholar]

- GUS Rocznik Statystyczny Przemysłu 2019. Available online: https://stat.gov.pl/obszary-tematyczne/roczniki-statystyczne/roczniki-statystyczne/rocznik-statystyczny-przemyslu-2019,5,13.html (accessed on 16 April 2025).

- Vassilev, S.V.; Vassileva, C.G.; Baxter, D. Trace Element Concentrations and Associations in Some Biomass Ashes. Fuel 2014, 129, 292–313. [Google Scholar] [CrossRef]

- Al-Fakih, A.; Mohammed, B.S.; Liew, M.S.; Nikbakht, E. Incorporation of Waste Materials in the Manufacture of Masonry Bricks: An Update Review. J. Build. Eng. 2019, 21, 37–54. [Google Scholar] [CrossRef]

- Mukhtar, A.; Qazi, A.U.; Khan, Q.S.; Munir, M.J.; Kazmi, S.M.S.; Hameed, A. Feasibility of Using Coal Ash for the Production of Sustainable Bricks. Sustainability 2022, 14, 6692. [Google Scholar] [CrossRef]

- EN 450-1:2012; Fly Ash for Concrete—Part 1: Definition, Specifications and Conformity Criteria. European Committee for Standardization: Brussels, Belgium, 2012.

- Zdunek, A.; Borowik, M.; Biskupski, A. Nawozy z Popiołów. In Chemia Przemysłowa; 2/2018; Kierunek Chemia: Warsaw, Poland, 2018. [Google Scholar]

- Belviso, C. State-of-the-Art Applications of Fly Ash from Coal and Biomass: A Focus on Zeolite Synthesis Processes and Issues. Prog. Energy Combust. Sci. 2018, 65, 109–135. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An Overview of the Composition and Application of Biomass Ash. Part 1. Phase–Mineral and Chemical Composition and Classification. Fuel 2013, 105, 40–76. [Google Scholar] [CrossRef]

- Yao, X.; Xu, K.; Li, Y. Physicochemical Properties and Possible Applications of Waste Corncob Fly Ash from Biomass Gasification Industries of China. BioResources 2016, 11, 3783–3798. [Google Scholar] [CrossRef]

- Wójcik, M.; Stachowicz, F.; Masłoń, A. The Use of Wood Biomass Ash in Sewage Sludge Treatment in Terms of Its Agricultural Utilization. Waste Biomass Valoriz. 2020, 11, 753–768. [Google Scholar] [CrossRef]

- Zhai, J.; Burke, I.T.; Mayes, W.M.; Stewart, D.I. New Insights into Biomass Combustion Ash Categorisation: A Phylogenetic Analysis. Fuel 2021, 287, 119469. [Google Scholar] [CrossRef]

- Mercl, F.; Tejnecký, V.; Száková, J.; Tlustoš, P. Nutrient Dynamics in Soil Solution and Wheat Response after Biomass Ash Amendments. Agron. J. 2016, 108, 2222–2234. [Google Scholar] [CrossRef]

- Ochecová, P.; Mercl, F.; Košnář, Z.; Tlustoš, P. Fertilization Efficiency of Wood Ash Pellets Amended by Gypsum and Superphosphate in the Ryegrass Growth Original Paper. Plant Soil Environ. 2017, 63, 47–54. [Google Scholar] [CrossRef]

- Huygens, D.; Saveyn, H.; Tonini, D.; Eder, P.; Delgado Sancho, L. Technical Proposals for Selected New Fertilising Materials under the Fertilising Products Regulation (Regulation (EU) 2019/1009). FeHPO CaHPO 2019, 4. [Google Scholar] [CrossRef]

- Zhai, J.; Burke, I.T.; Stewart, D.I. Potential Reuse Options for Biomass Combustion Ash as Affected by the Persistent Organic Pollutants (POPs) Content. J. Hazard. Mater. Adv. 2022, 5, 100038. [Google Scholar] [CrossRef]

- Rutkowska, G.; Wiśniewski, K.; Chalecki, M.; Górecka, M.; Miłosek, K. Influence of Fly-Ashes on Properties of Ordinary Concretes. Ann. Wars. Univ. Life Sci. Land Reclam. 2016, 48, 79–94. [Google Scholar] [CrossRef]

- Skels, P.; Haritonovs, V.; Pavlovskis, E. Wood Fly Ash Stabilized Road Base Layers with High Recycled Asphalt Pavement Content. Balt. J. Road Bridge Eng. 2021, 16, 1–15. [Google Scholar] [CrossRef]

- Kuźnia, M.; Zygmunt-Kowalska, B.; Szajding, A.; Magiera, A.; Stanik, R.; Gude, M. Comparative Study on Selected Properties of Modified Polyurethane Foam with Fly Ash. Int. J. Mol. Sci. 2022, 23, 9725. [Google Scholar] [CrossRef]

- Kalembasa, S.; Godlewska, A.; Wysokinski, A. Sklad Chemiczny Popiolow z Wegla Brunatnego i Kamiennego w Aspekcie Ich Rolniczego Zagospodarowania. Rocz. Glebozn. 2008, 59, 93–97. [Google Scholar]

- Łabętowicz, J.; Rutkowska, B.; Sosulski, T.; Stępień, W.; Szara, E.; Szulc, W.; Szymańska, M. Nawozy z Odpadów Jako Źródło Składników Pokarmowych w Nawożeniu Roślin Uprawnych. Rolnicze Wykorzystanie Odpadów i Produktów Ubocznych Jako Ogniwo Gospodarki Obiegu Zamkniętego; Wydawnictwo SGGW: Warsaw, Poland; Fundacja “Pro Civis”: Kielce, Poland, 2020. [Google Scholar]

- Cruz, N.C.; Silva, F.C.; Tarelho, L.A.; Rodrigues, S.M. Critical Review of Key Variables Affecting Potential Recycling Applications of Ash Produced at Large-Scale Biomass Combustion Plants. Resour. Conserv. Recycl. 2019, 150, 104427. [Google Scholar] [CrossRef]

- Trivedi, N.S.; Mandavgane, S.A.; Mehetre, S.; Kulkarni, B.D. Characterization and Valorization of Biomass Ashes. Environ. Sci. Pollut. Res. 2016, 23, 20243–20256. [Google Scholar] [CrossRef]

- Kohli, S.J.; Goyal, D. Effect of Fly Ash Application on Some Soil Physical Properties and Microbial Activities. Acta Agrophys. 2010, 16, 327–335. [Google Scholar]

- Huotari, N.; Tillman-Sutela, E.; Moilanen, M.; Laiho, R. Recycling of Ash–For the Good of the Environment? For. Ecol. Manag. 2015, 348, 226–240. [Google Scholar] [CrossRef]

- Shi, R.; Li, J.; Jiang, J.; Mehmood, K.; Liu, Y.; Xu, R.; Qian, W. Characteristics of Biomass Ashes from Different Materials and Their Ameliorative Effects on Acid Soils. J. Environ. Sci. 2017, 55, 294–302. [Google Scholar] [CrossRef] [PubMed]

- Paul, S.C. Use of Fly Ash in Agriculture. In Sustainable Agriculture; Apple Academic Press: Palm Bay, FL, USA, 2020; pp. 319–334. [Google Scholar]

- Manisha Basu, M.B.; Mahapatra, S.C.; Bhadoria, P.B.S. Exploiting Fly Ash as Soil Ameliorant to Improve Productivity of Sabai Grass (Eulaliopsis binata (Retz.) CE Hubb) under Acid Lateritic Soil of India. Asian J. Plant Sci. 2006, 5, 1027–1030. [Google Scholar]

- Usmani, Z.; Kumar, V.; Gupta, P.; Gupta, G.; Rani, R.; Chandra, A. Enhanced Soil Fertility, Plant Growth Promotion and Microbial Enzymatic Activities of Vermicomposted Fly Ash. Sci. Rep. 2019, 9, 10455. [Google Scholar] [CrossRef]

- Szostek, M.; Szpunar-Krok, E.; Jańczak-Pieniążek, M.; Ilek, A. Short-Term Effect of Fly Ash from Biomass Combustion on Spring Rape Plants Growth, Nutrient, and Trace Elements Accumulation, and Soil Properties. Int. J. Environ. Res. Public Health 2022, 20, 455. [Google Scholar] [CrossRef]

- Mieldažys, R.; Jotautienė, E.; Jasinskas, A. The Opportunities of Sustainable Biomass Ashes and Poultry Manure Recycling for Granulated Fertilizers. Sustainability 2019, 11, 4466. [Google Scholar] [CrossRef]

- Kurzemann, F.R.; Fernandez-Delgado Juarez, M.; Probst, M.; Gómez-Brandón, M.; Spiegel, H.; Resch, R.; Insam, H.; Pötsch, E.M. Biomass Ash as a Substitute for Lime and Its Impact on Grassland Soil, Forage, and Soil Microbiota. Agronomy 2024, 14, 1568. [Google Scholar] [CrossRef]

- Paleckienė, R.; Sviklas, A.M.; Šlinkšienė, R.; Štreimikis, V. Processing of Rape Straw Ash into Compound Fertilizers Using Sugar Factory Waste. Pol. J. Environ. Stud. 2012, 21, 993–999. [Google Scholar]

- Cruz, N.; Avellan, A.; Ruivo, L.; Silva, F.C.; Römkens, P.; Tarelho, L.A.C.; Rodrigues, S.M. Biomass Ash-Based Soil Improvers: Impact of Formulation and Stabilization Conditions on Materials’ Properties. J. Clean. Prod. 2023, 391, 136049. [Google Scholar] [CrossRef]

- Drapanauskaitė, D.; Bunevičienė, K.; Repšienė, R.; Karčauskienė, D.; Mažeika, R.; Baltrusaitis, J. The Effect of Pelletized Lime Kiln Dust Combined with Biomass Combustion Ash on Soil Properties and Plant Yield in a Three-Year Field Study. Land 2022, 11, 521. [Google Scholar] [CrossRef]

- Buneviciene, K.; Drapanauskaite, D.; Mazeika, R.; Tilvikiene, V.; Baltrusaitis, J. Granulated Biofuel Ash as a Sustainable Source of Plant Nutrients. Waste Manag. Res. J. Sustain. Circ. Econ. 2021, 39, 806–817. [Google Scholar] [CrossRef] [PubMed]

- Pesonen, J.; Kuokkanen, V.; Kuokkanen, T.; Illikainen, M. Co-Granulation of Bio-Ash with Sewage Sludge and Lime for Fertilizer Use. J. Environ. Chem. Eng. 2016, 4, 4817–4821. [Google Scholar] [CrossRef]

- Siuda, R.; Kwiatek, J.; Szufa, S.; Obraniak, A.; Piersa, P.; Adrian, Ł.; Modrzewski, R.; Ławińska, K.; Siczek, K.; Olejnik, T.P. Industrial Verification and Research Development of Lime–Gypsum Fertilizer Granulation Method. Minerals 2021, 11, 119. [Google Scholar] [CrossRef]

- Bondarenko, A.; Tverda, O.; Repin, M.; Tkachuk, K.; Kofanov, O.; Kofanova, O. The Use of Waste from the Production of Gravel as Fertilizer for Cultivation of Technical Energy Crops. Technol. Audit Prod. Reserv. 2021, 3, 56–58. [Google Scholar] [CrossRef]

- Paleckienė, R.; Sviklas, A.M.; Šlinkšienė, R. The Role of Sugar Factory Lime on Compound Fertilizer Properties. Pol. J. Environ. Stud. 2007, 16, 423–426. [Google Scholar]

- Ławińska, K.; Szufa, S.; Modrzewski, R.; Obraniak, A.; Wężyk, T.; Rostocki, A.; Olejnik, T.P. Obtaining Granules from Waste Tannery Shavings and Mineral Additives by Wet Pulp Granulation. Molecules 2020, 25, 5419. [Google Scholar] [CrossRef]

- Obraniak, A.; Gluba, T.; Ławińska, K.; Derbiszewski, B. Minimisation of Environmental Effects Related with Storing Fly Ash from Combustion of Hard Coal. Environ. Prot. Eng. 2018, 44, 177–189. [Google Scholar] [CrossRef]

- Gluba, T.W.; Obraniak, A.Z.; Siuda, R.D.; Kwiatek, J.J. Sposób Wytwarzania Granulowanego Nawozu Wapniowego i/Lub Wapniowo-Magnezowego Pojedynczego Lub Wieloskładnikowego. Polish Patent PL231027, 2018. [Google Scholar]

- Gluba, T.W.; Obraniak, A.Z.; Siuda, R.D.; Kwiatek, J.J.; Olejnik, T.P.; Jabłoński, A.; Marszałek-Gubiec, A.K.; Pietrasik, T. Sposób Wytwarzania Granulowanego Nawozu Wapniowego i/Lub Wapniowo-Magnezowego Pojedynczego Lub Wieloskładnikowego. Polish Patent PL236495, 2020. [Google Scholar]

- Nastaj, S. Sposób granulacji aglomeracyjnej materiałów pylistych, zwłaszcza nawozów. Polish Patent PL207307, 2010. [Google Scholar]

- Corbett, D.; Lynch, B.; Wall, D.P.; Tuohy, P. The Response of Finely Textured and Organic Soils to Lime and Phosphorus Application: Results from an Incubation Experiment. Soil Use Manag. 2023, 39, 368–384. [Google Scholar] [CrossRef]

- PN-EN ISO 18134-3:2023-12; Solid Biofuels—Determination of Moisture Content—Part 3: Moisture in the Sample for General Analysis. Polish Committee for Standardization: Warsaw, Poland, 2023.

- PN-R-64798:2009; Feedstuffs. Determination of Fineness. Polish Committee for Standardization: Warsaw, Poland, 2009.

- PN-EN ISO 17830:2016-07; Solid Biofuels—Grain Composition of Crushed Pellets. Polish Committee for Standardization: Warsaw, Poland, 2016.

- Odzijewicz, J.I.; Wołejko, E.; Wydro, U.; Wasil, M.; Jabłońska-Trypuć, A. Utilization of Ashes from Biomass Combustion. Energies 2022, 15, 9653. [Google Scholar] [CrossRef]

- Czech, T.; Krupa, A.; Sobczyk, A.; Marchewicz, A. Properties of fly ash derived from burning of industrial and medical waste and their impact on the environment. Inż. Ekol. 2017, 18, 1–13. [Google Scholar] [CrossRef]

- Rosik-Dulewska: Podstawy Gospodarki Odpadami—Google Scholar. Available online: https://scholar.google.com/scholar_lookup?title=Podstawy+Gospodarki+Odpadami&author=Rosik-Dulewska,+C.&publication_year=2015 (accessed on 16 April 2025).

- Jarosz-Krzemińska, E.; Poluszyńska, J. Repurposing Fly Ash Derived from Biomass Combustion in Fluidized Bed Boilers in Large Energy Power Plants as a Mineral Soil Amendment. Energies 2020, 13, 4805. [Google Scholar] [CrossRef]

- Regulation of the Minister of Economy of 8 September 2010 on the Method of Packaging Mineral Fertilizers, Placing Information on Fertilizer Components on Such Packaging, the Method of Testing Mineral Fertilizers and Types of Agricultural Lime. Available online: https://dziennikustaw.gov.pl/DU/2010/s/183/1229 (accessed on 16 April 2025).

- Regulation of the Minister of Agriculture and Rural Development of 18 June 2008 on the Implementation of Certain Provisions of the Act on Fertilizers and Fertilization. Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=wdu20081190765 (accessed on 3 June 2025).

- Smołka-Danielowska, D.; Jabłońska, M. Chemical and Mineral Composition of Ashes from Wood Biomass Combustion in Domestic Wood-Fired Furnaces. Int. J. Environ. Sci. Technol. 2022, 19, 5359–5372. [Google Scholar] [CrossRef]

- Jukić, M.; Ćurković, L.; Šabarić, J.; Kerolli-Mustafa, M. Fractionation of Heavy Metals in Fly Ash from Wood Biomass Using the BCR Sequential Extraction Procedure. Bull. Environ. Contam. Toxicol. 2017, 99, 524–529. [Google Scholar] [CrossRef] [PubMed]

- Stankowski, S.; Chajduk, E.; Osińska, B.; Gibczyńska, M. Biomass Ash as a Potential Raw Material for the Production of Mineral Fertilisers. Agron. Res. 2021, 19, 1999–2012. [Google Scholar]

- Balcarik, L.; Simackova, B.; Shaghaghi, S.; Syrova, L. Effect of Ash from Biomass Combustion on Tailings pH. Eng. Proc. 2023, 57, 24. [Google Scholar]

- Feng, C.; Cheng, M.; Gao, X.; Qiao, Y.; Xu, M. Occurrence Forms and Leachability of Inorganic Species in Ash Residues from Self-Sustaining Smouldering Combustion of Sewage Sludge. Proc. Combust. Inst. 2021, 38, 4327–4334. [Google Scholar] [CrossRef]

- Gondal, A.H.; Hussain, I.; Ijaz, A.B.; Zafar, A.; Ch, B.I.; Zafar, H.; Sohail, M.D.; Niazi, H.; Touseef, M.; Khan, A.A. Influence of Soil pH and Microbes on Mineral Solubility and Plant Nutrition: A Review. Int. J. Agric. Biol. Sci. 2021, 5, 71–81. [Google Scholar]

- Barrow, N.J.; Hartemink, A.E. The Effects of pH on Nutrient Availability Depend on Both Soils and Plants. Plant Soil 2023, 487, 21–37. [Google Scholar] [CrossRef]

- Naz, M.; Dai, Z.; Hussain, S.; Tariq, M.; Danish, S.; Khan, I.U.; Qi, S.; Du, D. The Soil pH and Heavy Metals Revealed Their Impact on Soil Microbial Community. J. Environ. Manag. 2022, 321, 115770. [Google Scholar] [CrossRef]

- Pandey, B.; Chen, L. Technologies to Recover Nitrogen from Livestock Manure-A Review. Sci. Total Environ. 2021, 784, 147098. [Google Scholar] [CrossRef]

- Cwalina, P.; Obidziński, S.; Sienkiewicz, A.; Kowczyk-Sadowy, M.; Piekut, J.; Bagińska, E.; Mazur, J. Production and Quality Assessment of Fertilizer Pellets from Compost with Sewage Sludge Ash (SSA) Addition. Materials 2025, 18, 1145. [Google Scholar] [CrossRef] [PubMed]

- Gondek, K.; Kopec, M. Zawartość Wybranych Makro i Mikroelementów w Przekompostowanych Komunalnych Odpadach Biodegradowalnych. Acta Agrophys. 2012, 19, 527–538. [Google Scholar]

- Wierzbowska, J.; Sienkiewicz, S.; Żarczyński, P.; Krzebietke, S. Environmental Application of Ash from Incinerated Biomass. Agronomy 2020, 10, 482. [Google Scholar] [CrossRef]

- Latosińska, J. Risk Assessment of Soil Contamination with Heavy Metals from Sewage Sludge and Ash after Its Incineration. Desalin. Water Treat. 2020, 199, 297–306. [Google Scholar] [CrossRef]

- Miastkowski, K.; Leszczuk, T.; Bakier, S. Zastosowanie Zawiesin Wodnych Bentonitu i Gliny Do Granulacji Bezciśnieniowej Nawozów Rolniczych. Inż. Apar. Chem. 2013, 52, 14–16. [Google Scholar]

- Malinowski, P.; Olech, M.; Sas, J.; Wantuch, W.; Biskupski, A.; Urbańczyk, L.; Borowik, M.; Kotowicz, J. Production of Compound Mineral Fertilizers as a Method of Utilization of Waste Products in Chemical Company Alwernia S.A. PJCT 2010, 12, 6–9. [Google Scholar] [CrossRef]

- Mudryk, K.; Wrobel, M.; Jewiarz, M.; Niemiec, M. Possibility of Using Chalk in Production of Mineral-Organic Fertilizers. In Proceedings of the 17th International Scientific Conference “Engineering for Rural Development”, Jelgava, Latvia, 23–25 May 2018. [Google Scholar]

- Balla, Z.; Tamás, A.; Vántus, A.; Hagymássy, Z. Determining the Main Physical Characteristics of Fertilisers. Columella 2017, 4, 305–308. [Google Scholar]

- Mudryk, K.; Frączek, J.; Wróbel, M.; Jewiarz, M.; Dziedzic, K. Agglomeration of Ash-Based Fertilizer Mixtures from Biomass Combustion and Digestate. In Renewable Energy Sources: Engineering, Technology, Innovation; Springer Proceedings in Energy; Mudryk, K., Werle, S., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 823–834. ISBN 978-3-319-72370-9. [Google Scholar]

- Marchuk, S.; Tait, S.; Sinha, P.; Harris, P.; Antille, D.L.; McCabe, B.K. Biosolids-Derived Fertilisers: A Review of Challenges and Opportunities. Sci. Total Environ. 2023, 875, 162555. [Google Scholar] [CrossRef]

- Antille, D.L.; Gallar, L.; Miller, P.C.; Godwin, R.J. An Investigation into the Fertilizerparticle Dynamics Off-the-Disc. Appl. Eng. Agric. 2015, 31, 49–60. [Google Scholar]

- Vistoso, E.; Iraira, S.; Sandaña, P. Effects of Phosphorus Fertilizer Solubility on Pastures Yield and Quality in Andisols. J. Soil Sci. Plant Nutr. 2020, 20, 637–647. [Google Scholar] [CrossRef]

- Błaszczyk, M.; Zakrzewska, M. Rola Inżynierii Chemicznej i Procesowej w Agrotechnice. In Proceedings of the VII Seminarium Studenckie Bezpieczeństwo w Inżynierii Procesowej, Tkaczew, Poland, 21 April 2017; Wydawnictwo Politechniki Łódzkiej: Łódź, Poland, 2017. ISBN 978-83-7283-891-9. [Google Scholar]

| Fertilizer Composition (%) | ||||

|---|---|---|---|---|

| Limestone | ECO-ZEC | PPR | Fly Ash | |

| 10% ECO-ZEC | 90 | 10 | n/a | n/a |

| 25% ECO-ZEC | 75 | 25 | n/a | n/a |

| 40% ECO-ZEC | 60 | 40 | n/a | n/a |

| 55% ECO-ZEC | 45 | 55 | n/a | n/a |

| 70% ECO-ZEC | 30 | 70 | n/a | n/a |

| 30% PPR | 70 | n/a | 30 | n/a |

| 40% PPR | 60 | n/a | 40 | n/a |

| 50% PPR | 50 | n/a | 50 | n/a |

| 5% PPR + 5% Fly ash | 90 | n/a | 5 | 5 |

| 18% PPR + 22% Fly ash | 60 | n/a | 18 | 22 |

| 15% PPR + 10% Fly ash | 75 | n/a | 15 | 10 |

| 15% PPR + 20% Fly ash | 65 | n/a | 15 | 20 |

| 15% PPR + 30% Fly ash | 55 | n/a | 15 | 30 |

| 15% Fly ash | 85 | n/a | n/a | 15 |

| 25% Fly ash | 75 | n/a | n/a | 25 |

| 35% Fly ash | 65 | n/a | n/a | 35 |

| Material | Moisture ± SD (%) |

|---|---|

| Ground lime | 0.39 ± 0.02 |

| Unground lime | 0.36 ± 0.01 |

| Fly ash | 0.40 ± 0.01 |

| PPR | 1.82 ± 0.02 |

| ECO-ZEC | 8.17 ± 0.11 |

| Share of Fraction (%) | ||||||

|---|---|---|---|---|---|---|

| Material | 2.00 | 1.00 | 0.50 | 0.25 | 0.125 | 0.063 |

| Ground lime | 0.63 | 1.30 | 5.29 | 58.31 | 27.03 | 7.44 |

| Unground lime | 11.03 | 42.05 | 19.39 | 8.32 | 12.42 | 6.79 |

| PPR | 2.12 | 2.74 | 63.06 | 29.14 | 2.94 | 0.00 |

| ECO-ZEC | 20.70 | 26.50 | 52.79 | 0.00 | 0.00 | 0.00 |

| Fly ash | 0.00 | 0.06 | 0.52 | 48.14 | 31.32 | 19.96 |

| Material | Content of Macroelements, Sulfur, and Their Oxides (%) | |||||||

|---|---|---|---|---|---|---|---|---|

| Na | Mg | Ca | S | Na2O | MgO | CaO | SO3 | |

| Limestone | 0.0130 | 1.1624 | 38.4384 | 0.0002 | 0.0172 | 1.9273 | 53.7753 | 0.0005 |

| PPR | 0.0926 | 0.1653 | 31.8823 | 15.2571 | 0.1228 | 0.2740 | 44.6033 | 38.1428 |

| ECO-ZEC | 0.0095 | 0.0360 | 18.2031 | 20.8159 | 0.0126 | 0.0597 | 25.4661 | 52.0398 |

| Fly ash | 0.1580 | 0.6787 | 3.2328 | 0.0251 | 0.2096 | 1.1253 | 4.5226 | 0.0628 |

| Fertilizer Type | Content of Macroelements, Sulfur, and Their Oxides (%) | Fertilizer Variety | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Na | Mg | Ca | S | Na2O | MgO | CaO | SO3 | ||

| 10% ECO-ZEC | 0.0127 | 1.0498 | 36.4149 | 2.0818 | 0.0168 | 1.7405 | 50.9444 | 5.2044 | 05 |

| 25% ECO-ZEC | 0.0121 | 0.8808 | 33.3796 | 5.2041 | 0.0161 | 1.4604 | 46.6980 | 13.0103 | 05 |

| 40% ECO-ZEC | 0.0116 | 0.7118 | 30.3443 | 8.3265 | 0.0154 | 1.1802 | 42.4516 | 20.8162 | 05 |

| 55% ECO-ZEC | 0.0111 | 0.5429 | 27.3090 | 11.4488 | 0.0147 | 0.9001 | 38.2053 | 28.6221 | 06 |

| 70% ECO-ZEC | 0.0106 | 0.3739 | 24.2737 | 14.5712 | 0.0140 | 0.6200 | 33.9589 | 36.4280 | 07, D.1. |

| 20% PPR | 0.0289 | 0.9630 | 37.1272 | 3.0516 | 0.0384 | 1.5966 | 51.9409 | 7.6290 | 05 |

| 30% PPR | 0.0369 | 0.8633 | 36.4716 | 4.5773 | 0.0489 | 1.4313 | 51.0237 | 11.4432 | 05 |

| 40% PPR | 0.0449 | 0.7635 | 35.8160 | 6.1030 | 0.0595 | 1.2660 | 50.1065 | 15.2574 | 05 |

| 50% PPR | 0.0528 | 0.6638 | 35.1603 | 7.6287 | 0.0700 | 1.1006 | 49.1893 | 19.0716 | 05 |

| 5% PPR + 5% Fly ash | 0.0242 | 1.0884 | 36.3503 | 0.7643 | 0.1447 | 1.8045 | 50.8541 | 1.9107 | 05 |

| 18% PPR + 22% Fly ash | 0.0592 | 0.8765 | 29.5131 | 2.7519 | 0.4380 | 1.4532 | 41.2888 | 6.8798 | 05 |

| 15% PPR + 10% Fly ash | 0.0395 | 0.9645 | 33.9344 | 2.2912 | 0.2294 | 1.5991 | 47.4743 | 5.7281 | 05 |

| 15% PPR + 20% Fly ash | 0.0540 | 0.9161 | 30.4139 | 2.2937 | 0.4039 | 1.5189 | 42.5490 | 5.7343 | 05 |

| 15% PPR + 30% Fly ash | 0.0685 | 0.8677 | 26.8933 | 2.2962 | 0.5785 | 1.4387 | 37.6237 | 5.7405 | 06 |

| 15% Fly ash | 0.0348 | 1.0898 | 33.1576 | 0.0039 | 0.0461 | 1.8070 | 46.3874 | 0.0098 | 05 |

| 25% Fly ash | 0.0493 | 1.0415 | 29.6370 | 0.0064 | 0.0653 | 1.7268 | 41.4622 | 0.0161 | 05 |

| 35% Fly ash | 0.0638 | 0.9931 | 26.1164 | 0.0089 | 0.0846 | 1.6466 | 36.5369 | 0.0223 | 06 |

| Fertilizer Type | Microelement and Heavy Metal Content (%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Cr | Mn | Fe | Co | Ni | Cu | Zn | As | Cd | Pb | |

| 10% ECO-ZEC | 1.14 × 10−3 | 9.27 × 10−3 | 1.20 × 10−1 | 5.63 × 10−6 | 5.56 × 10−4 | 1.01 × 10−3 | 2.51 × 10−3 | 2.46 × 10−6 | 1.81 × 10−5 | 1.56 × 10−4 |

| 25% ECO-ZEC | 9.95 × 10−4 | 8.16 × 10−3 | 1.07 × 10−1 | 5.13 × 10−6 | 5.99 × 10−4 | 1.10 × 10−3 | 2.47 × 10−3 | 2.30 × 10−6 | 2.03 × 10−5 | 1.79 × 10−4 |

| 40% ECO-ZEC | 8.32 × 10−4 | 6.88 × 10−3 | 9.14 × 10−2 | 4.54 × 10−6 | 6.48 × 10−4 | 1.20 × 10−3 | 2.43 × 10−3 | 2.12 × 10−6 | 2.29 × 10−5 | 2.05 × 10−4 |

| 55% ECO-ZEC | 6.70 × 10−4 | 5.59 × 10−3 | 7.62 × 10−2 | 3.96 × 10−6 | 6.98 × 10−4 | 1.30 × 10−3 | 2.38 × 10−3 | 1.94 × 10−6 | 2.55 × 10−5 | 2.31 × 10−4 |

| 70% ECO-ZEC | 5.07 × 10−4 | 4.31 × 10−3 | 6.09 × 10−2 | 3.37 × 10−6 | 7.47 × 10−4 | 1.40 × 10−3 | 2.34 × 10−3 | 1.76 × 10−6 | 2.80 × 10−5 | 2.57 × 10−4 |

| 20% PPR | 1.05 × 10−3 | 9.91 × 10−3 | 1.61 × 10−1 | 9.98 × 10−6 | 4.11 × 10−4 | 1.69 × 10−3 | 3.99 × 10−3 | 4.39 × 10−5 | 2.29 × 10−5 | 4.28 × 10−4 |

| 30% PPR | 9.57 × 10−4 | 9.91 × 10−3 | 1.61 × 10−1 | 9.98 × 10−6 | 4.11 × 10−4 | 1.69 × 10−3 | 3.99 × 10−3 | 4.39 × 10−5 | 2.29 × 10−5 | 4.28 × 10−4 |

| 40% PPR | 8.24 × 10−4 | 9.74 × 10−3 | 1.73 × 10−1 | 1.16 × 10−5 | 3.65 × 10−4 | 2.01 × 10−3 | 4.61 × 10−3 | 6.16 × 10−5 | 2.59 × 10−5 | 5.54 × 10−4 |

| 50% PPR | 7.13 × 10−4 | 9.60 × 10−3 | 1.84 × 10−1 | 1.30 × 10−5 | 3.27 × 10−4 | 2.28 × 10−3 | 5.13 × 10−3 | 7.63 × 10−5 | 2.83 × 10−5 | 6.59 × 10−4 |

| 5% PPR + 5% Fly ash | 1.26 × 10−3 | 1.81 × 10−2 | 1.66 × 10−1 | 2.01 × 10−5 | 5.22 × 10−4 | 1.17 × 10−3 | 4.45 × 10−3 | 2.18 × 10−5 | 2.73 × 10−5 | 3.78 × 10−4 |

| 18% PPR + 22% Fly ash | 1.28 × 10−3 | 4.46 × 10−2 | 2.76 × 10−1 | 6.71 × 10−5 | 5.55 × 10−4 | 1.86 × 10−3 | 1.07 × 10−2 | 8.13 × 10−5 | 6.49 × 10−5 | 1.16 × 10−3 |

| 15% PPR + 10% Fly ash | 1.13 × 10−3 | 2.53 × 10−2 | 1.98 × 10−1 | 3.45 × 10−5 | 4.83 × 10−4 | 1.49 × 10−3 | 6.48 × 10−3 | 4.83 × 10−5 | 3.91 × 10−5 | 6.66 × 10−4 |

| 15% PPR + 20% Fly ash | 1.29 × 10−3 | 4.46 × 10−2 | 2.76 × 10−1 | 6.71 × 10−5 | 5.55 × 10−4 | 1.86 × 10−3 | 1.07 × 10−2 | 8.13 × 10−5 | 6.49 × 10−5 | 1.16 × 10−3 |

| 15% PPR + 30% Fly ash | 1.38 × 10−3 | 5.72 × 10−2 | 3.19 × 10−1 | 8.79 × 10−5 | 6.05 × 10−4 | 1.94 × 10−3 | 1.32 × 10−2 | 9.58 × 10−5 | 8.04 × 10−5 | 1.43 × 10−3 |

| 15% Fly ash | 1.41 × 10−3 | 3.38 × 10−2 | 2.18 × 10−1 | 4.60 × 10−5 | 5.90 × 10−4 | 1.24 × 10−3 | 7.48 × 10−3 | 3.82 × 10−5 | 4.63 × 10−5 | 7.06 × 10−4 |

| 25% Fly ash | 1.50 × 10−3 | 4.95 × 10−2 | 2.75 × 10−1 | 7.26 × 10−5 | 6.38 × 10−4 | 1.44 × 10−3 | 1.08 × 10−2 | 6.19 × 10−5 | 6.66 × 10−5 | 1.09 × 10−3 |

| 35% Fly ash | 1.60 × 10−3 | 6.52 × 10−2 | 3.32 × 10−1 | 9.92 × 10−5 | 6.87 × 10−4 | 1.64 × 10−3 | 1.40 × 10−2 | 8.56 × 10−5 | 8.68 × 10−5 | 1.47 × 10−3 |

| Type and Amount of Supplement | Compressive Strength (N) | Bulk Density (kg·m−3) | Granule Disintegration Time (s) | Granulometric Distribution (%) | |||||

|---|---|---|---|---|---|---|---|---|---|

| Sieve Size (mm) | |||||||||

| 8 | 4 | 2 | 0.5 | x < 0.5 Quantity of Non-Granulated Fraction | Quantity of Granulated Fractions | ||||

| Mixtures with ground lime | |||||||||

| Reference fertilizer | 10.60 | 1210.78 | 30.06 | x | x | x | x | x | x |

| 10% ECO-ZEC | 5.11 | 1108.84 | 24.62 | 58.97 | 30.44 | 7.44 | 0.52 | 2.63 | 97.37 |

| 25% ECO-ZEC | 4.99 | 1102.92 | 22.98 | 55.62 | 22.66 | 9.66 | 9.20 | 2.86 | 97.14 |

| 40% ECO-ZEC | 4.85 | 1090.65 | 20.90 | 65.94 | 20.80 | 5.96 | 3.65 | 3.65 | 96.35 |

| 55% ECO-ZEC | 4.76 | 1053.12 | 14.41 | 52.37 | 37.57 | 1.39 | 0.14 | 8.53 | 91.47 |

| 70% ECO-ZEC | 4.65 | 1047.07 | 9.80 | 59.99 | 24.08 | 4.02 | 1.05 | 10.86 | 89.14 |

| 30% PPR | 9.25 | 1054.74 | x | 93.18 | 5.34 | 0.25 | 0.19 | 1.04 | 98.96 |

| 40% PPR | 10.76 | 1068.00 | x | 83.45 | 11.75 | 1.83 | 1.27 | 1.70 | 98.30 |

| 50% PPR | 14.00 | 1084.00 | x | 60.24 | 31.30 | 4.23 | 1.75 | 2.47 | 97.52 |

| 5% PPR + 5% Fly ash | 5.77 | 1129.77 | 912.67 | 54.21 | 39.91 | 2.01 | 0.45 | 3.43 | 96.58 |

| 18% PPR + 22% Fly ash | 13.21 | 1137.77 | x | 38.48 | 49.44 | 10.58 | 0.62 | 0.87 | 99.12 |

| 15% PPR + 10% Fly ash | 12.94 | 1162.38 | x | 40.95 | 56.22 | 2.47 | 0.22 | 0.14 | 99.86 |

| 15% PPR + 20% Fly ash | 12.82 | 1172.43 | x | 59.74 | 38.64 | 1.42 | 0.00 | 0.20 | 99.80 |

| 15% PPR + 30% Fly ash | 12.78 | 1159.72 | x | 70.79 | 28.11 | 0.14 | 0.10 | 0.86 | 99.14 |

| 15% Fly ash | 5.57 | 1148.12 | x | 18.74 | 55.67 | 22.24 | 1.55 | 1.80 | 98.20 |

| 25% Fly ash | 4.79 | 1112.19 | x | 26.46 | 59.75 | 5.04 | 1.94 | 6.81 | 93.19 |

| 35% Fly ash | 4.60 | 1089.65 | x | 23.58 | 45.80 | 15.96 | 5.59 | 9.07 | 90.93 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Obidziński, S.; Cwalina, P.; Sienkiewicz, A.; Kowczyk-Sadowy, M.; Piekut, J.; Mazur, J.; Panasewicz, M. Production and Evaluation of Lime Fertilizers with the Addition of Biomass Combustion Waste. Materials 2025, 18, 2732. https://doi.org/10.3390/ma18122732

Obidziński S, Cwalina P, Sienkiewicz A, Kowczyk-Sadowy M, Piekut J, Mazur J, Panasewicz M. Production and Evaluation of Lime Fertilizers with the Addition of Biomass Combustion Waste. Materials. 2025; 18(12):2732. https://doi.org/10.3390/ma18122732

Chicago/Turabian StyleObidziński, Sławomir, Paweł Cwalina, Aneta Sienkiewicz, Małgorzata Kowczyk-Sadowy, Jolanta Piekut, Jacek Mazur, and Michał Panasewicz. 2025. "Production and Evaluation of Lime Fertilizers with the Addition of Biomass Combustion Waste" Materials 18, no. 12: 2732. https://doi.org/10.3390/ma18122732

APA StyleObidziński, S., Cwalina, P., Sienkiewicz, A., Kowczyk-Sadowy, M., Piekut, J., Mazur, J., & Panasewicz, M. (2025). Production and Evaluation of Lime Fertilizers with the Addition of Biomass Combustion Waste. Materials, 18(12), 2732. https://doi.org/10.3390/ma18122732