Potential of Graphene Doping Towards Superlubric Performance of Additively Manufactured Structures

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Fused Deposition Modeling (FDM)

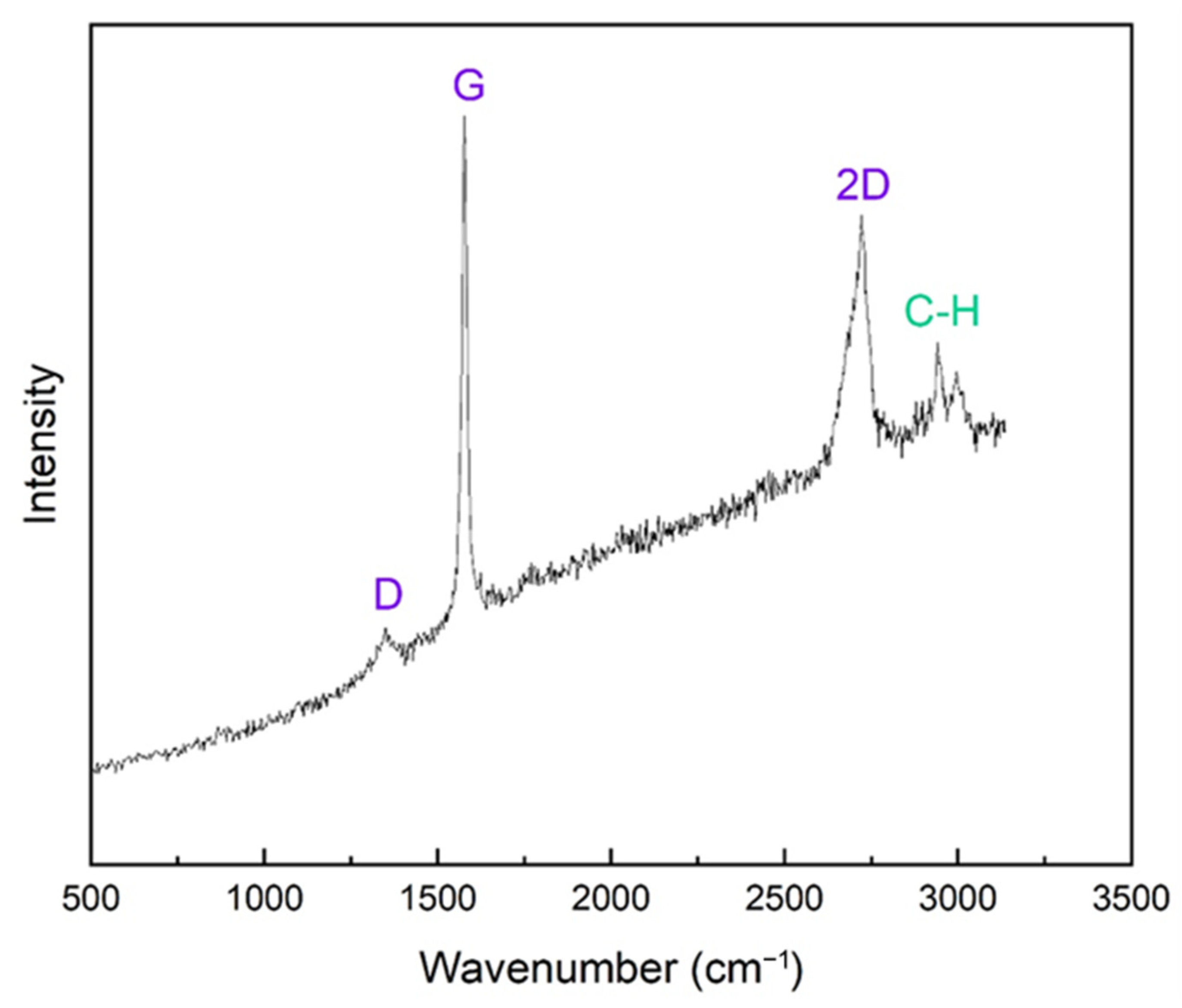

2.3. Spectroscopic and Morphological Characterization

2.4. Mechanical Testing

2.5. Tribometry

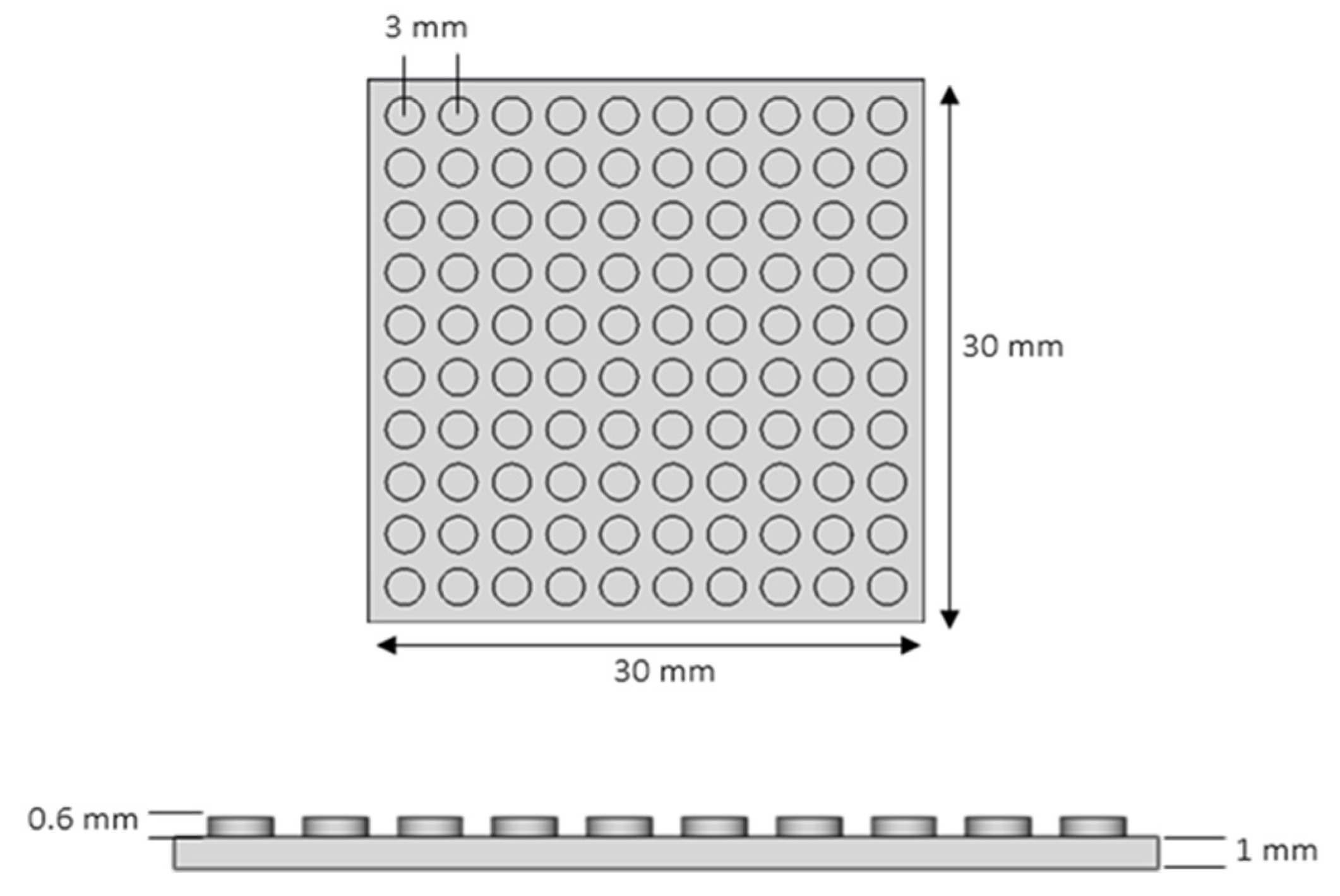

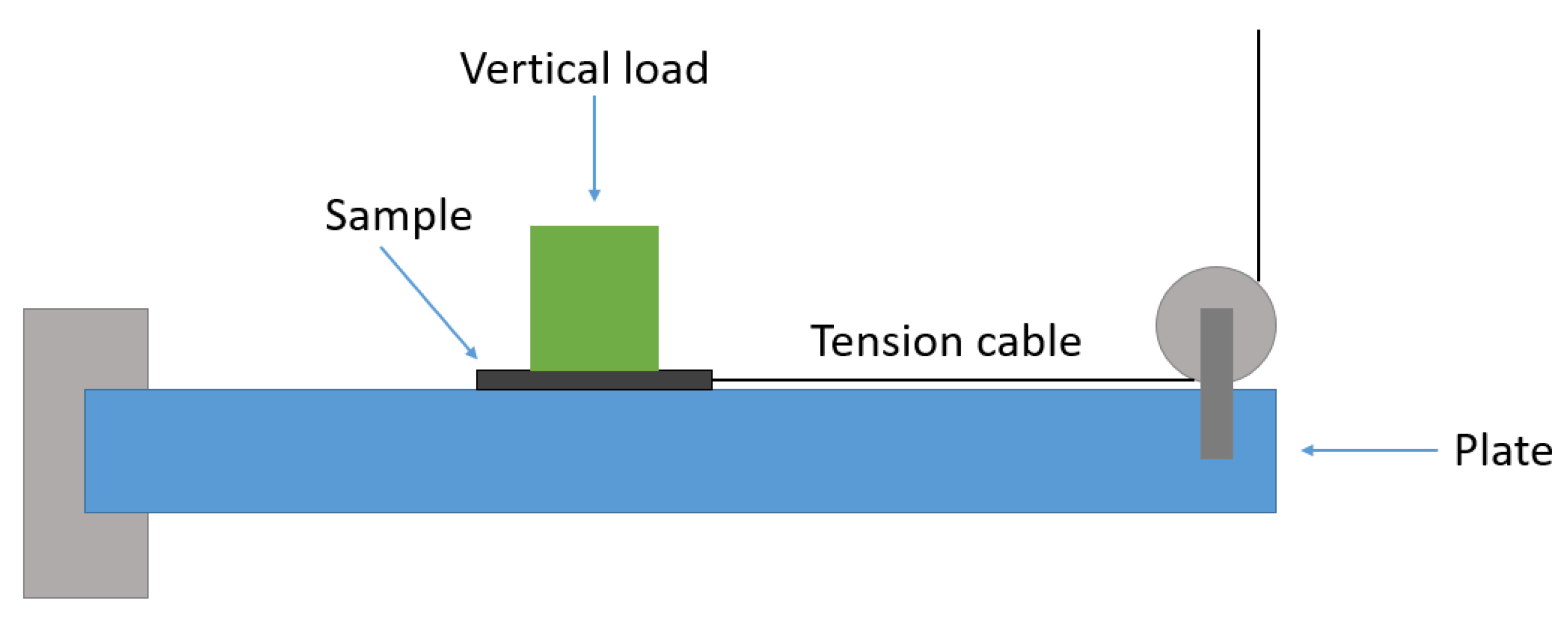

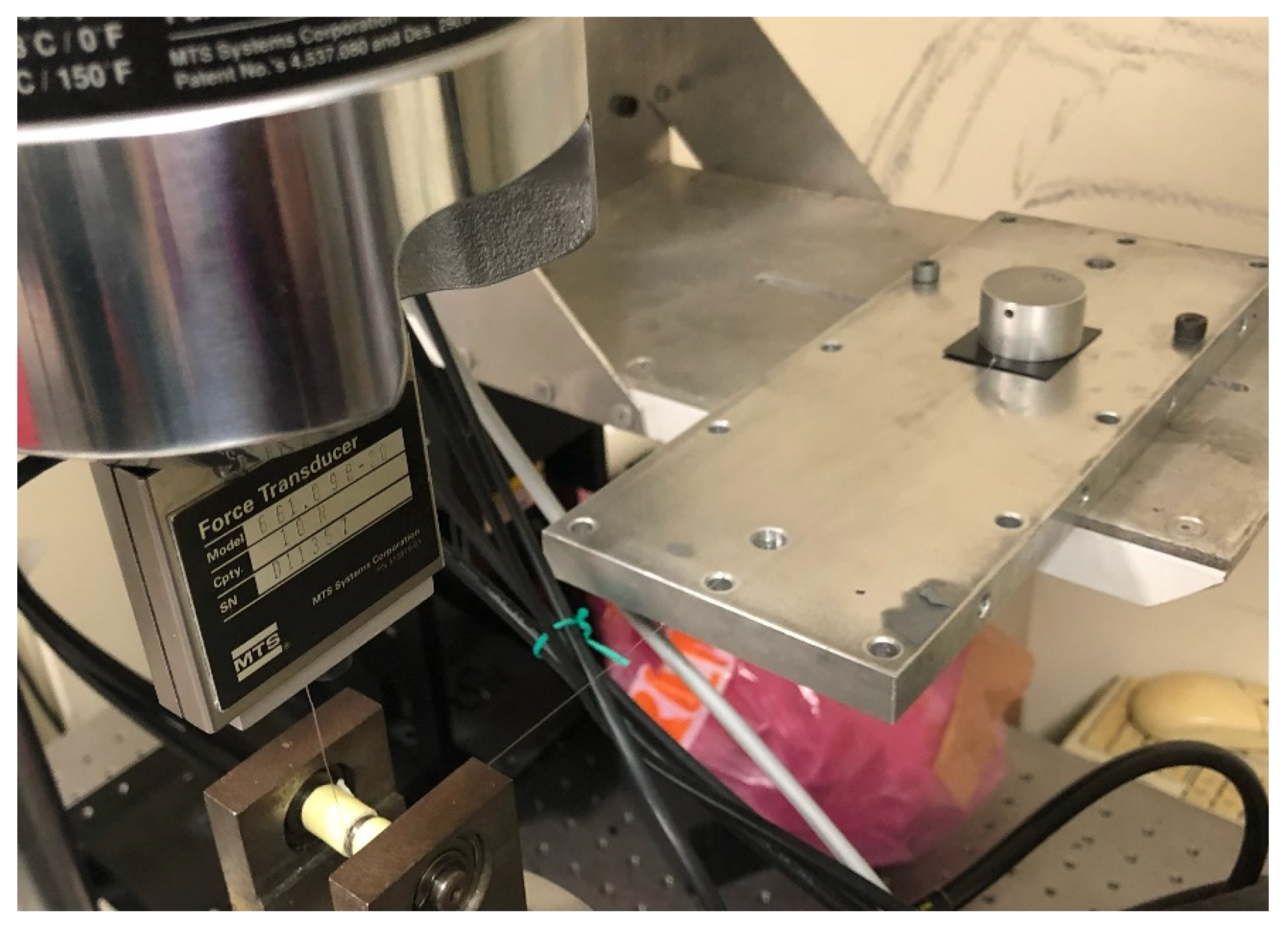

2.5.1. Purpose-Built Conceptual Tribometer

2.5.2. Ball-on-Disk Tribometer

3. Results and Discussion

3.1. Spectroscopic Characterization

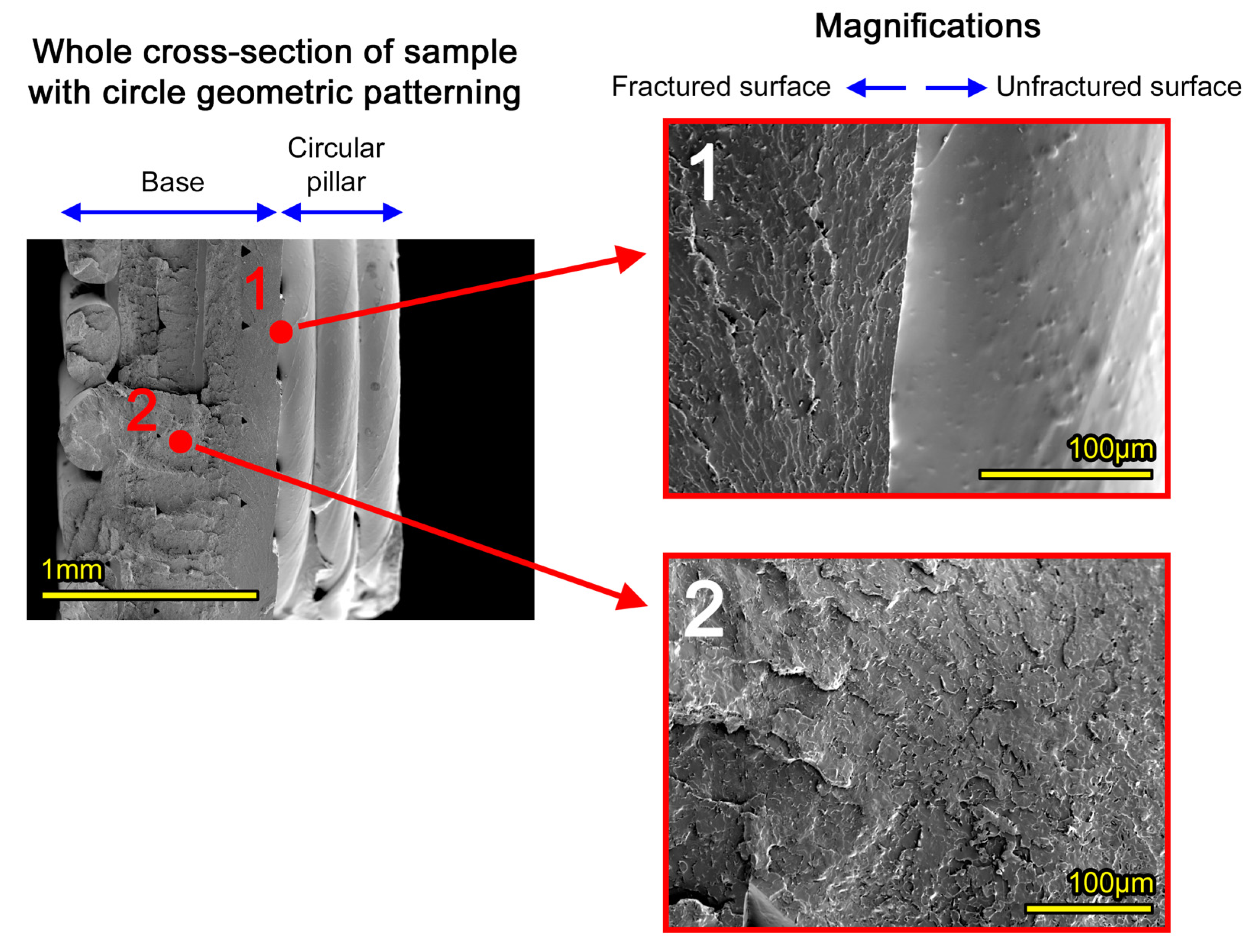

3.2. Microstructure

3.3. Mechanical Testing

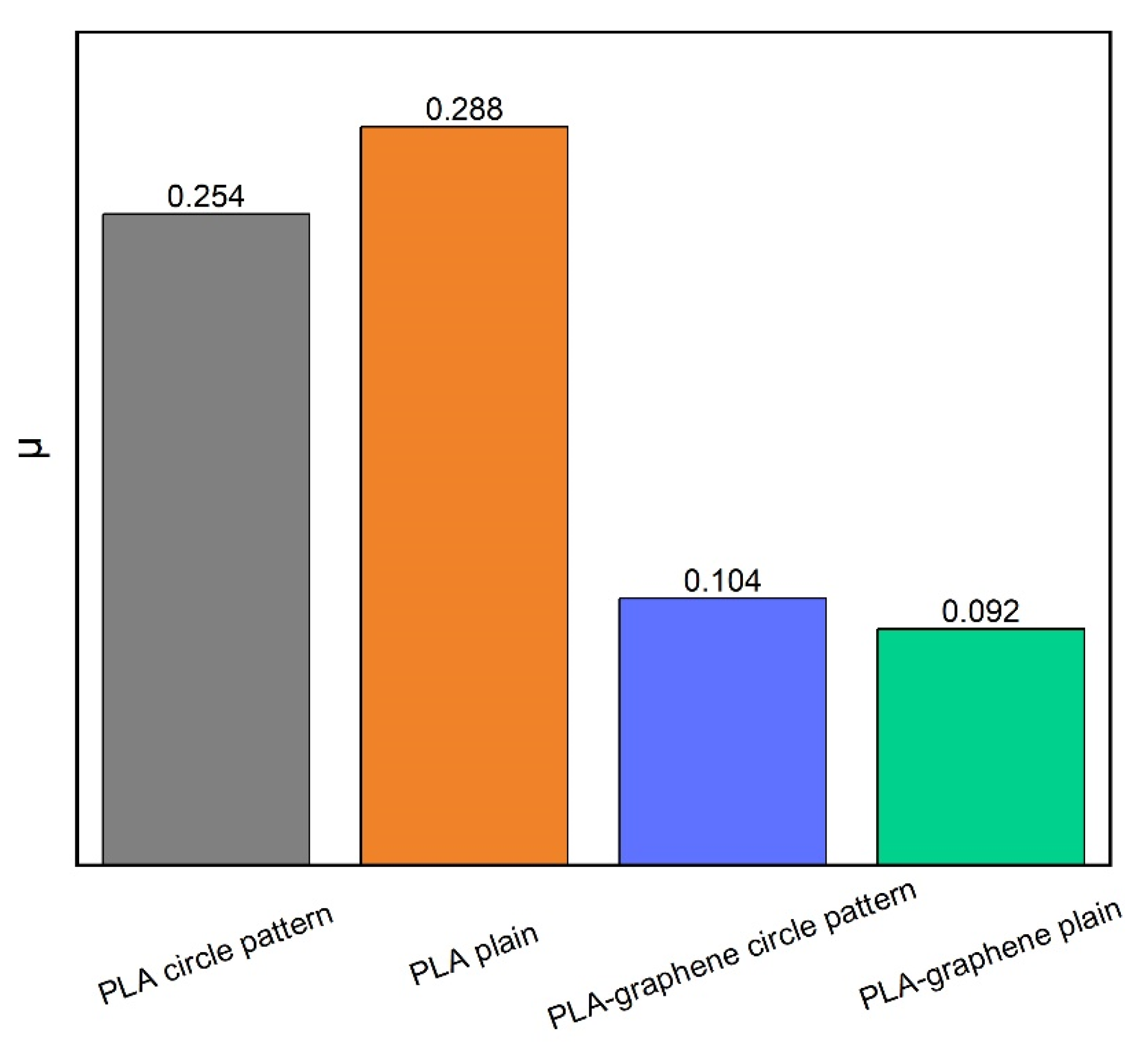

3.4. Tribometry

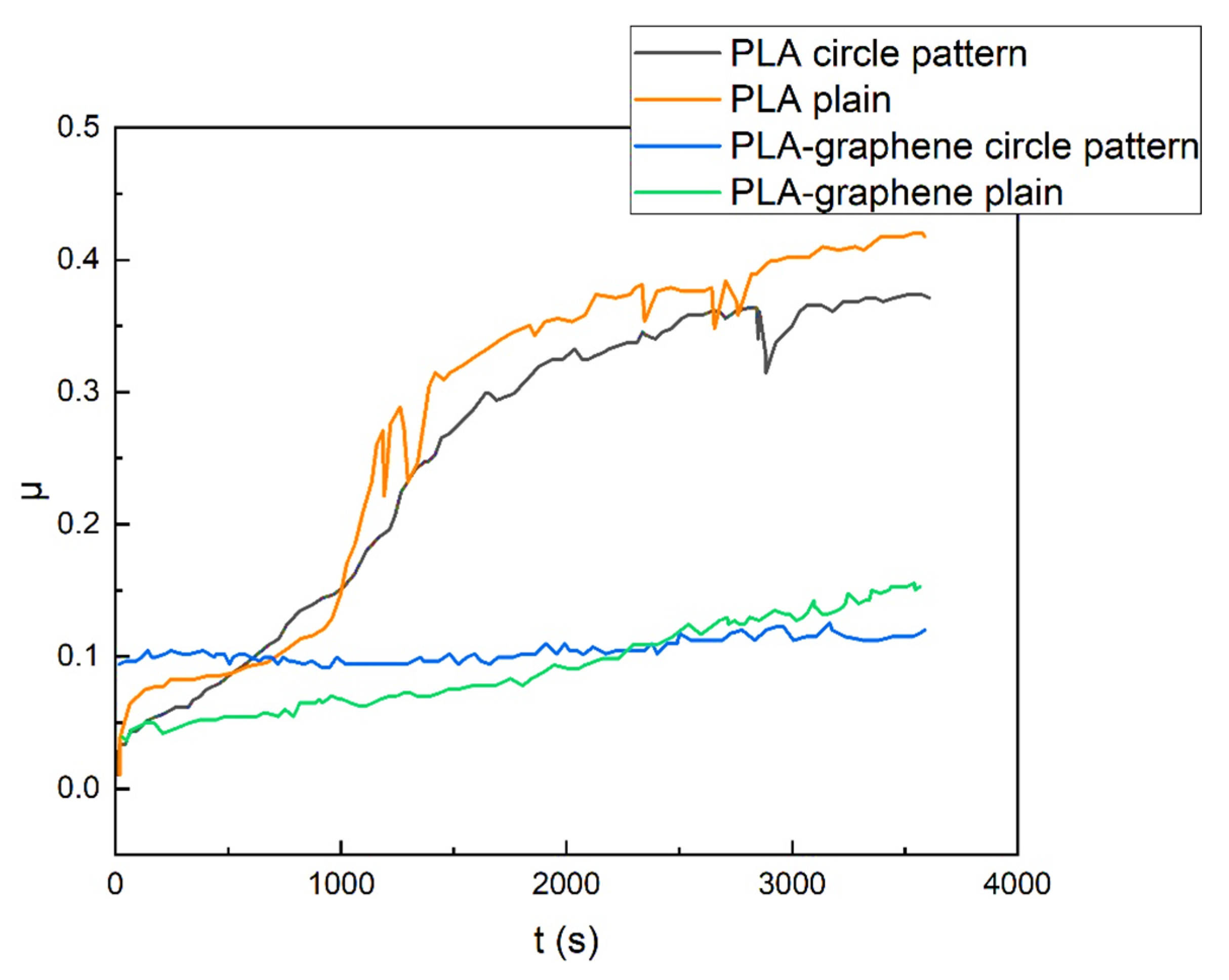

3.4.1. Purpose-Built Conceptual Tribometer

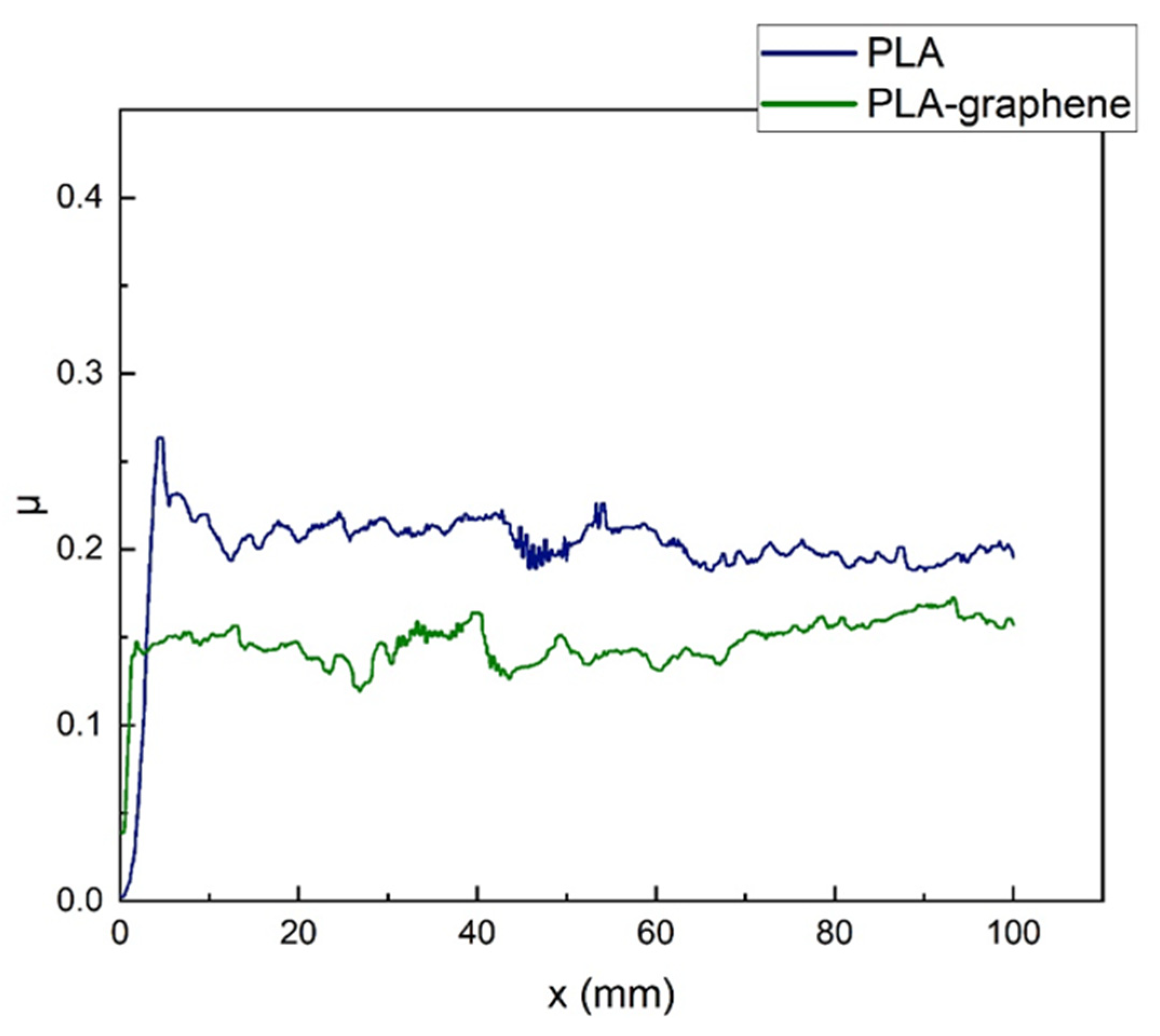

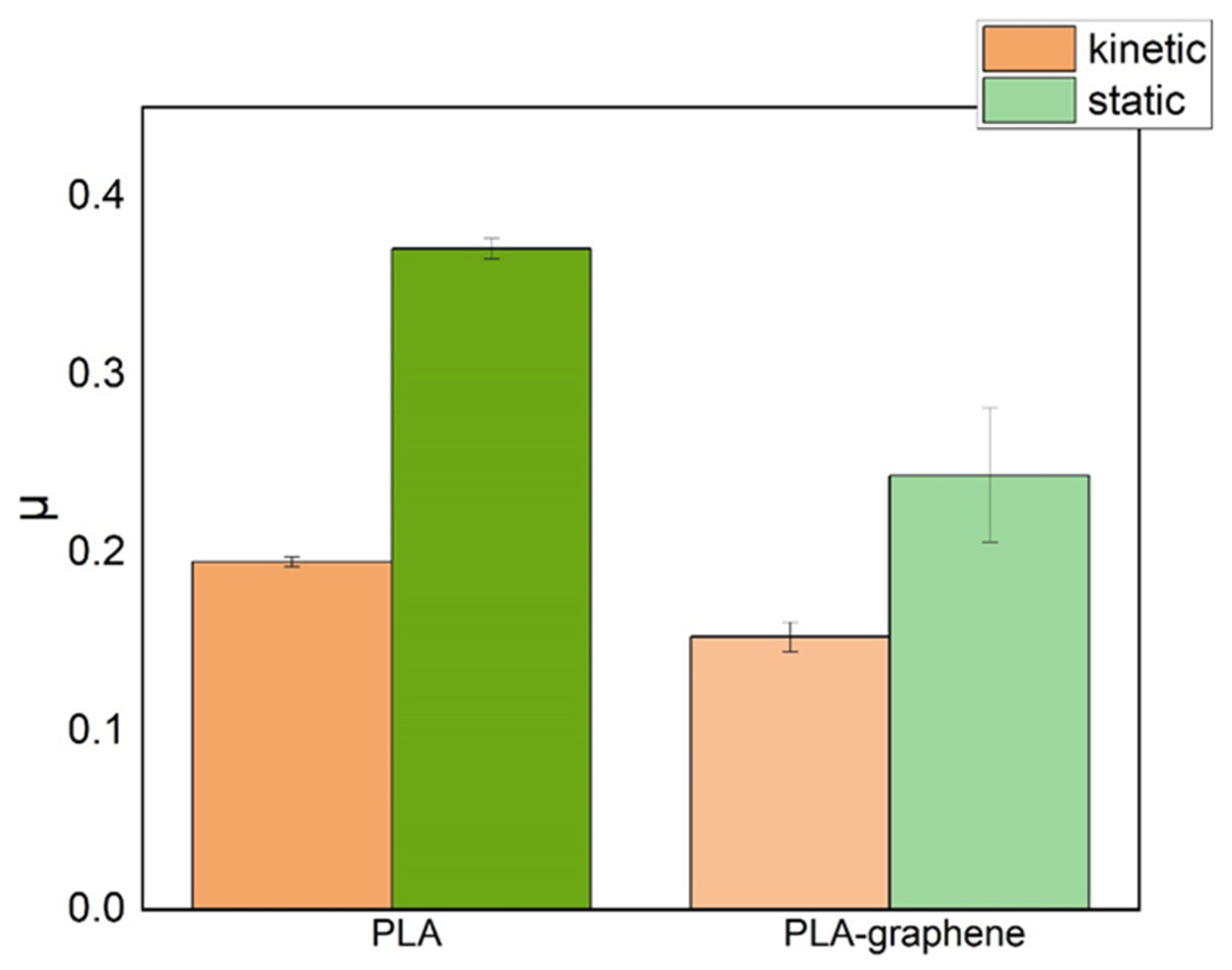

3.4.2. Ball-on-Disk Tribometer

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| 3D | three-dimensional |

| GNP | graphene nanoplatelets |

| PLA | polylactic acid |

| DLP | digital light processing |

| FDM | fused deposition modelling |

| SLM | selective laser melting |

| IJP | inkjet printing |

| LVDT | linear variable differential transformer |

References

- Holmberg, K.; Erdemir, A. Influence of tribology on global energy consumption, costs and emissions. Friction 2017, 5, 263–284. [Google Scholar] [CrossRef]

- Nowak, P.; Kucharska, K.; Kaminski, M. Ecological and Health Effects of Lubricant Oils Emitted into the Environment. Int. J. Environ. Res. Public Health 2019, 16, 3002. [Google Scholar] [CrossRef]

- Ramezani, M.; Ripin, Z.M.; Jiang, C.-P.; Pasang, T. Superlubricity of Materials: Progress, Potential, and Challenges. Materials 2023, 16, 5145. [Google Scholar] [CrossRef]

- Hirano, M.; Shinjo, K. Superlubricity and frictional anisotropy. Wear 1993, 168, 121–125. [Google Scholar] [CrossRef]

- Shekhar, H.; Dumpala, R. Overcoming friction and steps towards superlubricity: A review of underlying mechanisms. Appl. Surf. Sci. Adv. 2021, 6, 100175. [Google Scholar] [CrossRef]

- Jang, S.; Kim, S.H. Distinct effects of endogenous hydrogen content and exogenous hydrogen supply on superlubricity of diamond-like carbon. Carbon 2023, 202, 61–69. [Google Scholar] [CrossRef]

- Buzio, R.; Gerbi, A.; Bernini, C.; Repetto, L.; Vanossi, A. Graphite superlubricity enabled by triboinduced nanocontacts. Carbon 2021, 184, 875–890. [Google Scholar] [CrossRef]

- Wang, R.; Zhang, F.; Yang, K.; Xiong, Y.; Tang, J.; Chen, H.; Duan, M.; Li, Z.; Zhang, H.; Xiong, B. Review of two-dimensional nanomaterials in tribology: Recent developments, challenges and prospects. Adv. Colloid Interface Sci. 2023, 321, 103004. [Google Scholar] [CrossRef]

- Miura, K.; Ishikawa, M. C60 Intercalated Graphite as Nanolubricants. Materials 2010, 3, 4510–4517. [Google Scholar] [CrossRef]

- Zhang, J.; Osloub, E.; Siddiqui, F.; Zhang, W.; Ragab, T.; Basaran, C. Anisotropy of Graphene Nanoflake Diamond Interface Frictional Properties. Materials 2019, 12, 1425. [Google Scholar] [CrossRef]

- Ge, X.; Chai, Z.; Shi, Q.; Liu, Y.; Tang, J.; Wang, W. Liquid Superlubricity Enabled by the Synergy Effect of Graphene Oxide and Lithium Salts. Materials 2022, 15, 3546. [Google Scholar] [CrossRef] [PubMed]

- Romanov, R.I.; Fominski, D.V.; Demin, M.V.; Gritskevich, M.D.; Doroshina, N.V.; Volkov, V.S.; Fominski, V.Y. Tribological Properties of WS2 Thin Films Containing Graphite-like Carbon and Ni Interlayers. Materials 2023, 16, 282. [Google Scholar] [CrossRef] [PubMed]

- Bustillos, J.; Montero, D.; Nautiyal, P.; Loganathan, A.; Boesl, B.; Agarwal, A. Integration of graphene in poly(lactic) acid by 3D printing to develop creep and wear-resistant hierarchical nanocomposites. Polym. Compos. 2018, 39, 3877–3888. [Google Scholar] [CrossRef]

- Gkougkousi, K.; Karantzalis, A.E.; Nikolakopoulos, P.G.; Dassios, K.G. Synergistic Effect of Carbon Micro/Nano-Fillers and Surface Patterning on the Superlubric Performance of 3D-Printed Structures. Materials 2024, 17, 1215. [Google Scholar] [CrossRef]

- Rosenkranz, A.; Costa, H.L.; Baykara, M.Z.; Martini, A. Synergetic effects of surface texturing and solid lubricants to tailor friction and wear—A review. Tribol. Int. 2021, 155, 106792. [Google Scholar] [CrossRef]

- Zhao, Y.; Mei, H.; Chang, P.; Chen, C.; Cheng, L.; Konstantinos, G. Dassios. ACS Nano 2021, 15, 240–257. [Google Scholar] [CrossRef]

- Lin, N.; Li, D.; Zou, J.; Xie, R.; Wang, Z.; Tang, B. Surface Texture-Based Surface Treatments on Ti6Al4V Titanium Alloys for Tribological and Biological Applications: A Mini Review. Materials 2018, 11, 487. [Google Scholar] [CrossRef]

- ASTM Standard D638-02; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2002.

- ASTM Standard D1894-14; Standard Test Method for Static and Kinetic Coefficients of Friction of Plastic Film and Sheeting. ASTM International: West Conshohocken, PA, USA, 2023. Available online: https://www.astm.org/d1894-14.html (accessed on 3 March 2025).

- Ahmad, A.F.; Aziz, S.A.; Abbas, Z.; Obaiys, S.J.; Matori, K.A.; Zaid, M.H.M.; Raad, H.K.; Aliyu, U.S. Chemically reduced graphene oxide-reinforced poly (lactic acid)/poly (ethylene glycol) nanocomposites: Preparation, characterization, and applications in electromagnetic interference shielding. Polymers 2019, 11, 661. [Google Scholar] [CrossRef]

- Butt, J.; Bhaskar, R.; Mohaghegh, V. Non-destructive and destructive testing to analyse the effects of processing parameters on the tensile and flexural properties of FFF-printed graphene-enhanced PLA. J. Compos. Sci. 2022, 6, 148. [Google Scholar] [CrossRef]

- Laraba, S.R.; Rezzoug, A.; Avcu, E.; Luo, W.; Halimi, R.; Wei, J.; Li, Y. Enhancing the tribological performance of PLA-based biocomposites reinforced with graphene oxide. Biomed. Mater. 2023, 148, 106224. [Google Scholar] [CrossRef]

- Wu, F.-B.; Zhou, S.-J.; Ouyang, J.-H.; Wang, S.-Q.; Chen, L. Structural Superlubricity of Two-Dimensional Materials: Mechanisms, Properties, Influencing Factors, and Applications. Lubricants 2024, 12, 138. [Google Scholar] [CrossRef]

- Cardoso, P.H.M.; de Oliveira, M.F.L.; de Oliveira, M.G.; Thire, R.M.d.S.M. 3D Printed Parts of Polylactic Acid Reinforced with Carbon Black and Alumina Nanofillers for Tribological Applications. Macromol. Symp. 2020, 394, 2000155. [Google Scholar] [CrossRef]

- Stoimenova, N.; Kandevab, M.; Zagorskib, M.; Paneva, P. Static and Kinetic Friction of 3D Printed Polymers and Composites. Tribol. Ind. 2024, 46, 97–106. [Google Scholar] [CrossRef]

| Material | Manufacturing Method | Young’s Modulus (MPa) | Yield Strength (MPa) | Tensile Stress at Break (MPa) |

|---|---|---|---|---|

| Pure PLA | 3D-printed | 1446.1 ± 198.5 | 35.07 ± 5.31 | 32.31 ± 0.19 |

| Hot-pressed | 1632.5 ± 102.2 | 41.59 ± 0.62 | 32.85 ± 2.89 | |

| PLA–graphene | 3D-printed | 1895.4 ± 200.1 | 34.74 ± 4.69 | 32.45 ± 3.82 |

| Hot-pressed | 2195.9 ± 91.0 | 34.47 ± 1.60 | 33.56 ± 2.34 |

| Material | Micropattern Orientation | Friction Coefficient | |

|---|---|---|---|

| Kinetic | Static | ||

| Pure PLA | [45°, 135°] | 0.195 ± 0.002 | 0.341 ± 0.035 |

| [0°, 90°] | 0.191 ± 0.002 | 0.331 ± 0.097 | |

| [90°, 180°] | 0.218 ± 0.015 | 0.276 ± 0.006 | |

| PLA–graphene | [45°, 135°] | 0.183 ± 0.007 | 0.271 ± 0.055 |

| [0°, 90°] | 0.231 ± 0.004 | 0.326 ± 0.085 | |

| [90°, 180°] | 0.243 ± 0.023 | 0.306 ± 0.013 | |

| Material | Kinetic Friction Coefficient | Static Friction Coefficient |

|---|---|---|

| Pure PLA | 0.195 ± 0.003 | 0.371 ± 0.006 |

| PLA–graphene | 0.153 ± 0.008 | 0.243 ± 0.038 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Katsivardi, P.; Koutroumanis, N.; Karantzalis, A.E.; Nikolakopoulos, P.G.; Dassios, K.G. Potential of Graphene Doping Towards Superlubric Performance of Additively Manufactured Structures. Materials 2025, 18, 2730. https://doi.org/10.3390/ma18122730

Katsivardi P, Koutroumanis N, Karantzalis AE, Nikolakopoulos PG, Dassios KG. Potential of Graphene Doping Towards Superlubric Performance of Additively Manufactured Structures. Materials. 2025; 18(12):2730. https://doi.org/10.3390/ma18122730

Chicago/Turabian StyleKatsivardi, Pinelopi, Nikolaos Koutroumanis, Alexandros E. Karantzalis, Pantelis G. Nikolakopoulos, and Konstantinos G. Dassios. 2025. "Potential of Graphene Doping Towards Superlubric Performance of Additively Manufactured Structures" Materials 18, no. 12: 2730. https://doi.org/10.3390/ma18122730

APA StyleKatsivardi, P., Koutroumanis, N., Karantzalis, A. E., Nikolakopoulos, P. G., & Dassios, K. G. (2025). Potential of Graphene Doping Towards Superlubric Performance of Additively Manufactured Structures. Materials, 18(12), 2730. https://doi.org/10.3390/ma18122730