Particleboards with Various Biomass Residues

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Materials

2.3. Methods for Characterisation of Different Types of Biomasses

2.3.1. Moisture Content

2.3.2. pH and Acid Buffering Capacity

2.3.3. Fourier-Transform Infrared (FTIR) Spectroscopy

2.3.4. X-Ray Diffraction (XRD) Measurements

2.3.5. Thermogravimetric Analysis (TGA)

2.4. Preparation of Particleboards

2.5. Particleboard Performance Tests

3. Results and Discussion

3.1. Properties of the Urea-Formaldehyde Reins

3.2. Properties of Studying Biomaterials

3.3. FTIR Analysis Results

- Cellulose is rich in compounds with O–H and C–O bonds;

- Hemicelluloses contain more C=O compounds;

- Lignin might be rich in methoxyl—OCH3, C–O–C and C=C (aromatic ring)-containing compounds.

- All materials have fatty acids to some extent;

- Coffee grounds have less cellulose than other materials (considering that cellulose gives any crystallinity to the material, this result is also confirmed by the XRD study below where the coffee ground sample has the lowest crystallinity);

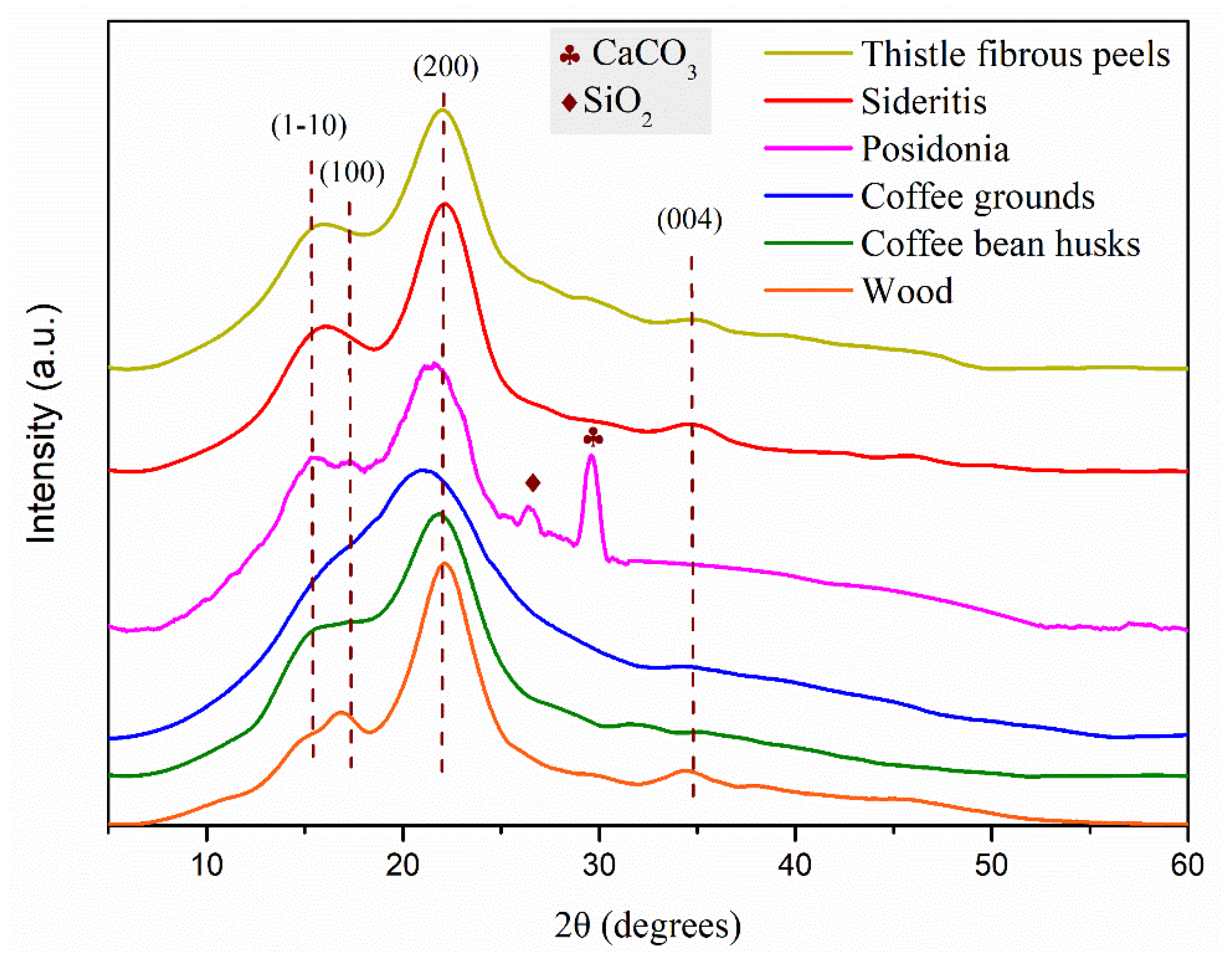

3.4. XRD Analysis

3.5. TGA Study Results

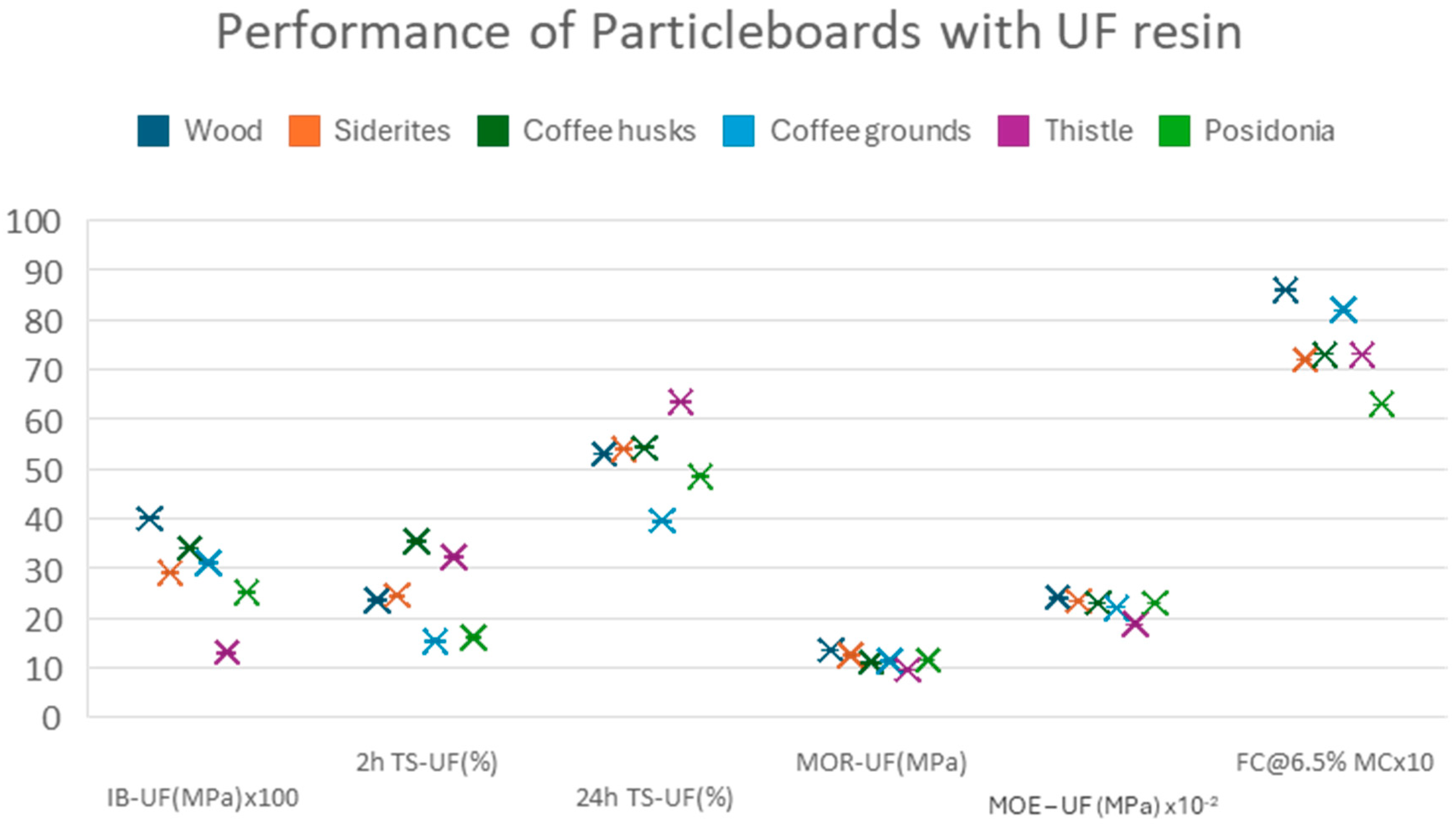

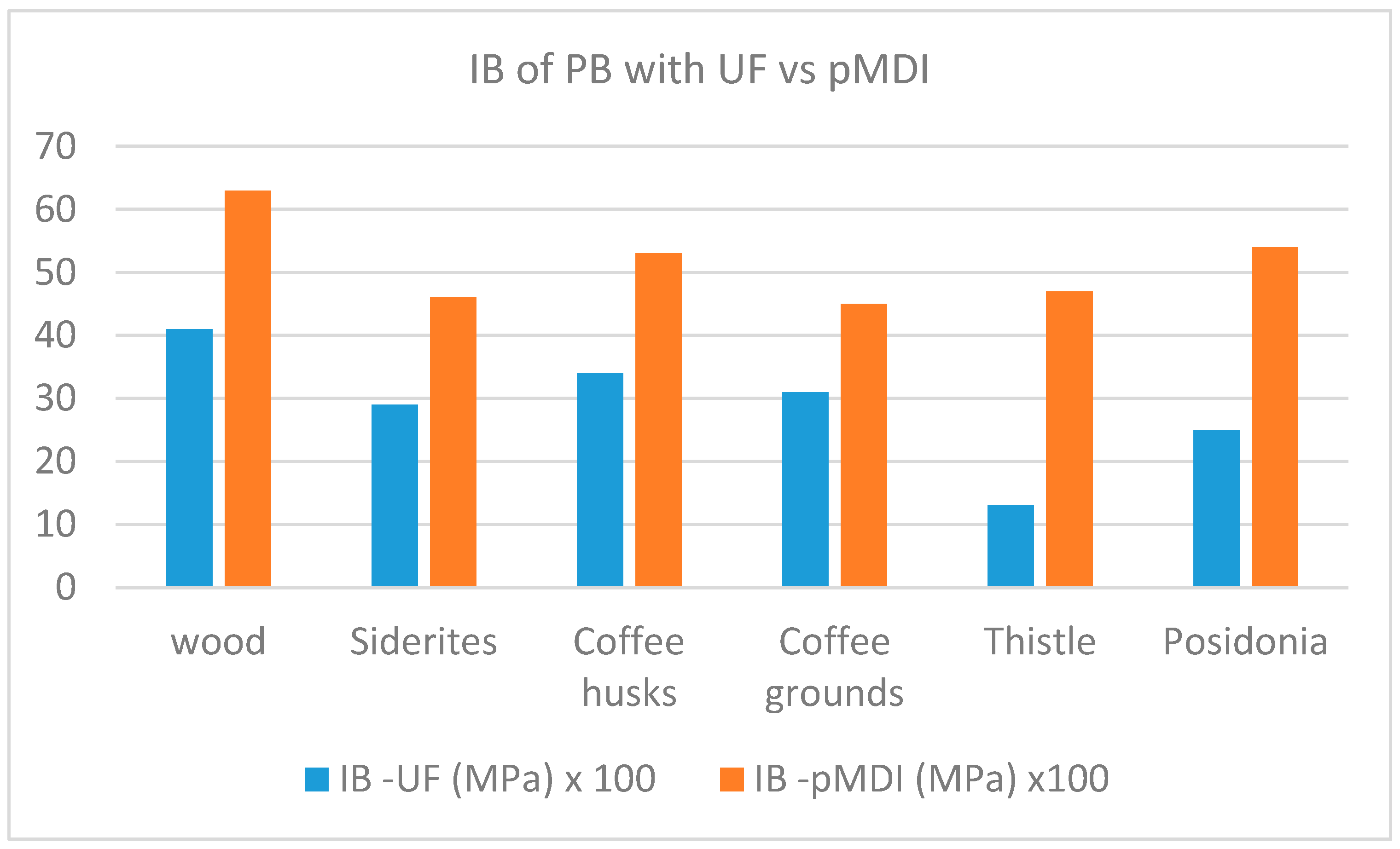

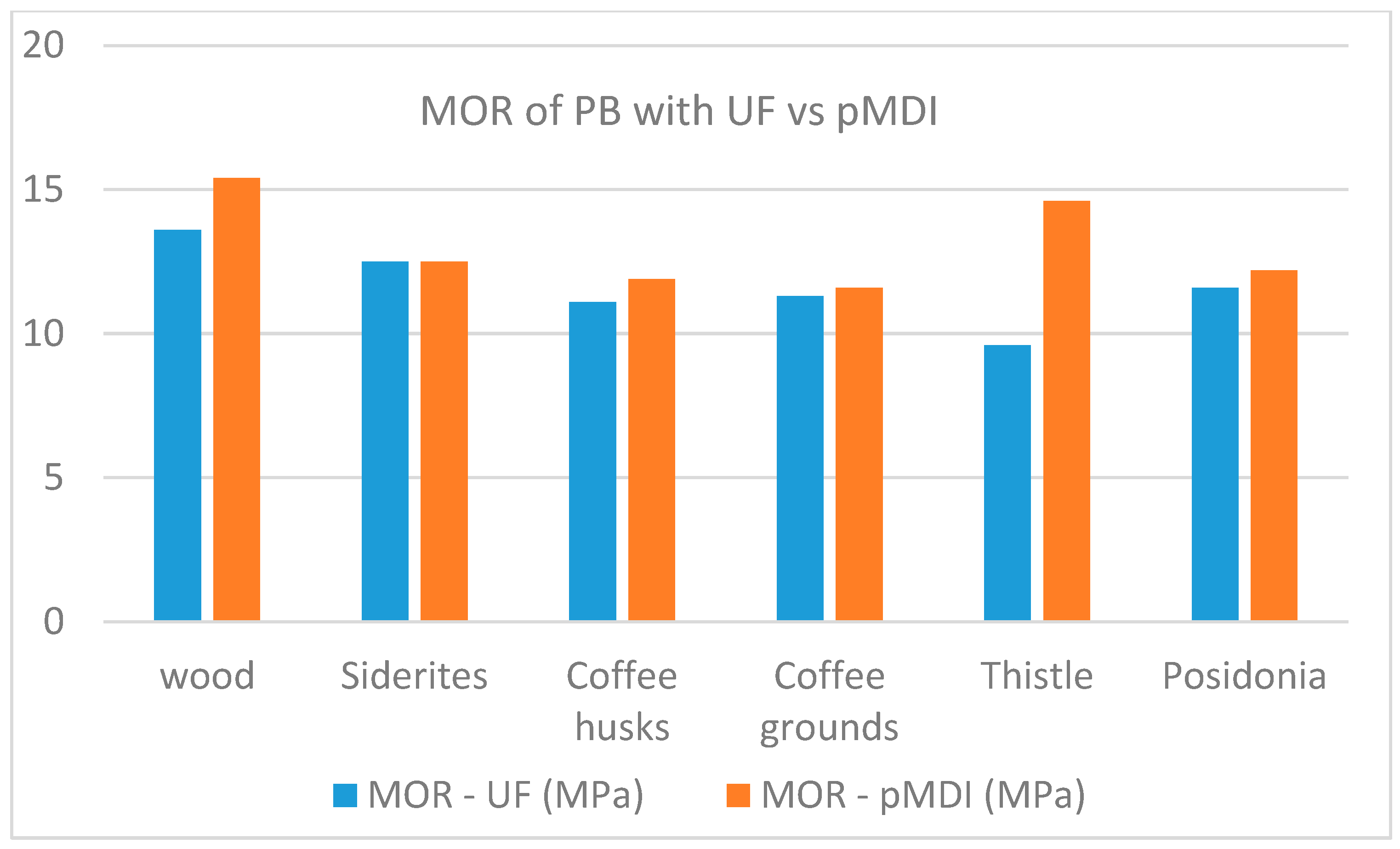

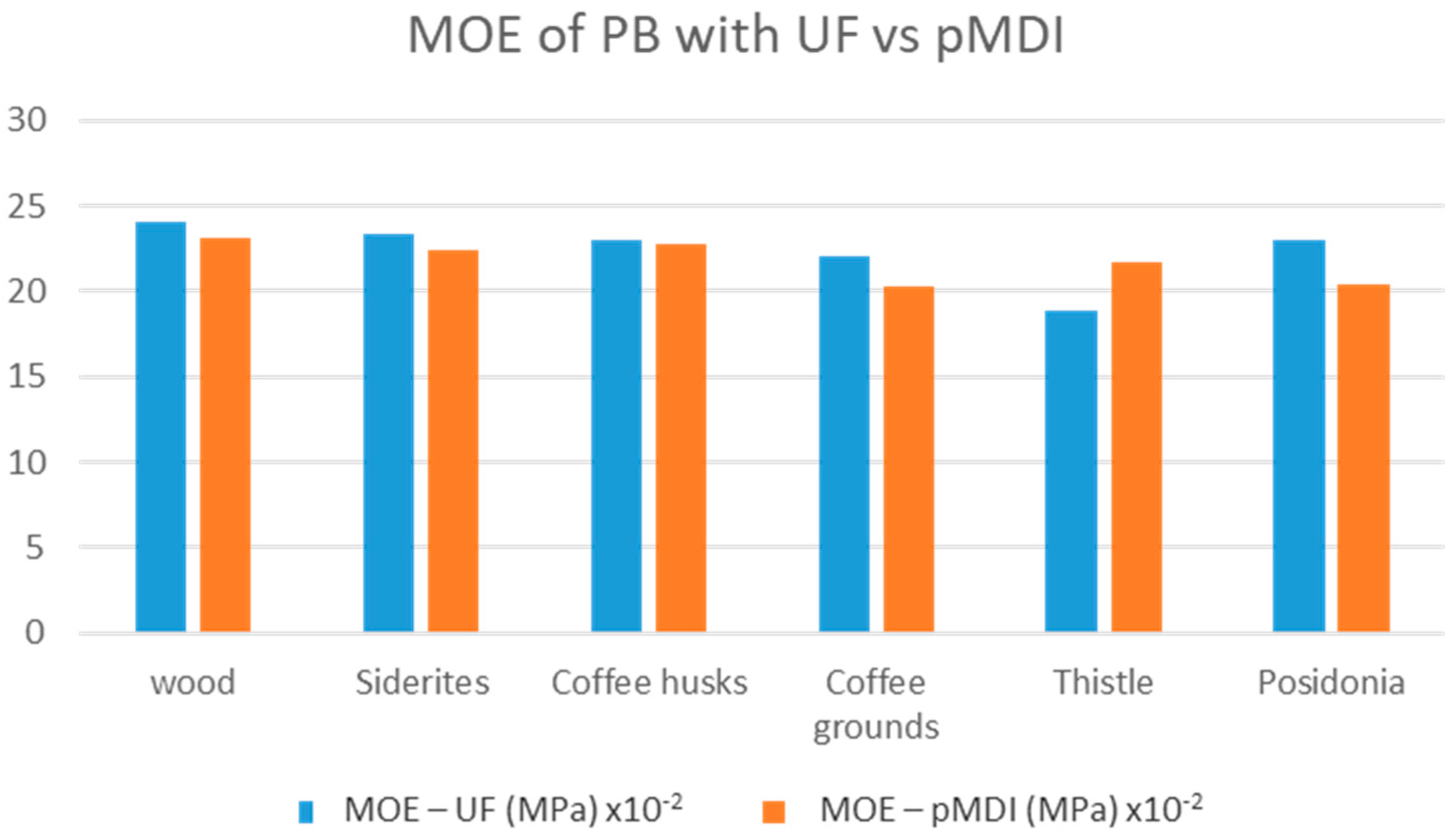

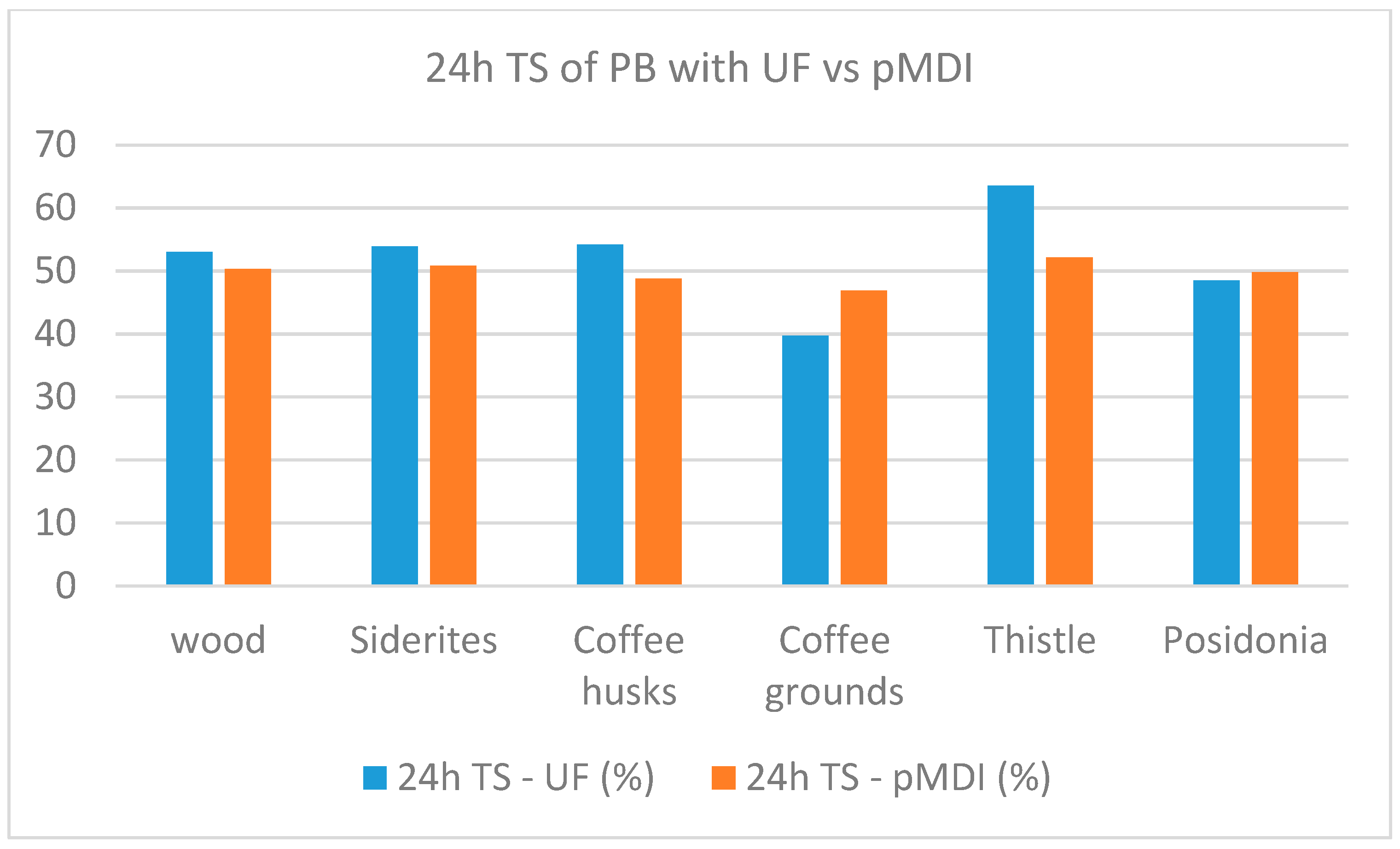

3.6. Properties of Particleboards

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, C.; Zhang, W.; Qiu, X.; Xu, C. Hydrothermal treatment of lignocellulosic biomass towards low-carbon development: Production of high-value-added bioproducts. Energy Chem. 2024, 6, 100133. [Google Scholar] [CrossRef]

- Lee, S.H.; Lum, W.C.; Boon, J.G.; Kristak, L.; Antov, P.; Pędzik, M.; Rogoziński, T.; Taghiyari, H.R. Muhammad Adly Rahandi Lubis, Widya Fatriasari, Sumit Manohar Yadav, Aujchariya Chotikhun, Antonio Pizzi, Particleboard from agricultural biomass and recycled wood waste: A review. J. Mater. Res. Technol. 2022, 20, 4630–4658. [Google Scholar] [CrossRef]

- Nayana, N.P.; Ramya, C.S.; Prajwal, R. Production of Particle Board from Agricultural Residues. Agritech Today 2024, 2, 240204053. Available online: https://www.researchgate.net/publication/382253163 (accessed on 20 September 2024).

- Maulida, C.R.; Mursal; Ismail, I. A Study on the utilization of coffee grounds for particle board. J. Aceh. Phys. Soc. 2021, 10, 49–53. [Google Scholar] [CrossRef]

- Scatolino, M.V.; Costa, A.d.O.; Júnior, J.B.G.; Protásio, T.d.P.; Mendes, R.F.; Mendes, L.M. Eucalyptus wood and coffee parchment for particleboard production: Physical and mechanical properties. Ciênc. E Agrotecnol. 2017, 41, 139–146. [Google Scholar] [CrossRef]

- Nuamsrinuan, N.; Naemchanthara, P.; Limsuwan, P.; Naemchanthara, K. Fabrication and Characterization of Particle Board from Coffee Husk Waste. Appl. Mech. Mater. 2019, 891, 111–116. [Google Scholar] [CrossRef]

- TIS. 876-2547; Flat Pressed Particleboards. Thailand Industrial Standards Institute, Ministry of Industry: Bangkok, Thailand, 2004.

- Rachtanapun, P.; Sattayarak, T.; Ketsamak, N. Correlation of density and properties of particleboard from coffee waste with urea–formaldehyde and polymeric methylene diphenyl diisocyanates. J. Compos. Mater. 2012, 46, 1839–1850. [Google Scholar] [CrossRef]

- Bekalo, S.A.; Reinhardt, H.-W. Fibers of coffee husk and hulls for the production of particleboard. Mater. Struct. 2010, 43, 1049–1060. [Google Scholar] [CrossRef]

- Maciá, A.; Baeza, F.J.; Saval, J.M.; Ivorra, S. Mechanical properties of boards made in biocomposites reinforced with wood and Posidonia oceanica fibers. Compos. Part B Eng. 2016, 104, 1–8. [Google Scholar] [CrossRef]

- Monteiro, S.; Nunes, L.; Martins, J.; Fernão, D. Magalhães and Luísa Carvalho, Low-Density Cardoon (Cynara cardunculus L.) Particleboards Bound with Potato Starch-Based Adhesive. Polymers 2020, 12, 1799. [Google Scholar] [CrossRef]

- CEN/TS 16368:2014; Lightweight Particleboards—Specifications. European Committee for Standardization: Brussels, Belgium, 2014.

- Batiancela, M.A.; Acda, M.N.; Cabangon, R.J. Particleboard from waste tea leaves and wood particles. J. Compos. Mater. 2014, 48, 911–916. [Google Scholar] [CrossRef]

- EN 312-2:1996; Particleboards—Specifications—Part 2: Requirements for General Purpose Boards for Use in Dry Conditions. CEN: Brussels, Belgium, 1996.

- Risnasari, I.; Nuryawan, A.; Siallagan, N.F. Characterization of Particleboard from Waste Tea Leaves (Camellia sinensis L.) and Meranti Wood (Shorea sp.) using Urea-Formaldehyde Adhesive and It’s Formaldehyde Emission. In Proceedings of the International Conference on Natural Resources and Technology, ICONART, Jakarta, Indonesia, 12–13 March 2019; pp. 261–264. [Google Scholar] [CrossRef]

- Zorba, T.; Papadopoulou, E.; Hatjiissaak, A.; Chrissafis, K.M.P.K. Urea-Formaldehyde resins characterization by thermal analysis and FTIR method. J. Therm. Anal. Calorim. 2008, 92, 29–33. [Google Scholar] [CrossRef]

- Hultnäs, M.; Fernandez-Cano, V. Determination of the moisture content in wood chips of Scots pine and Norway spruce using Mantex Desktop Scanner based on dual energy X-ray absorptiometry. J. Wood Sci. 2012, 58, 309–314. [Google Scholar] [CrossRef]

- Marufuzzaman, R.A.; Street, M.; Wooten, J.; Gude, J.; Buchanan, V.G.; Wang, R.H. A comprehensive review on wood chip moisture content assessment and prediction. Renew. Sustain. Energy Rev. 2024, 189 Pt A, 113843. [Google Scholar]

- Govet, R.; Mace, T.; Bowe, S. A Practical Handbook of Basic Information, Definitions, Calculations, Practices and Procedures for Purchasers and Suppliers of Woody Biomass, October 2020. Available online: http://www.tropicaltimber.info/wp-content/uploads/2015/06/A-Practical-Guide-for-Determination-of-Moisture-Content-of-Woody-Biomass-2010GovettR.University-of-WisconsinStevens-Point20-pp.pdf (accessed on 20 September 2024).

- Hernández, V. Radiata pine pH and buffering capacity; effect of age and location in the stem. Maderas. Cienc. Y Tecnol. 2013, 15, 73–78. [Google Scholar] [CrossRef]

- Segal, L.; Creely, J.J.; Martin, A.E.; Conrad, C.M. An Empirical Method for Estimating the Degree of Crystallinity of Native Cellulose Using the X-Ray Diffractometer. Text. Res. J. 1959, 29, 786–794. [Google Scholar] [CrossRef]

- Zhang, S.; Zhu, Q.; Wang, T.; Wang, X.; Sun, X.; Wei, Y.; Luo, L. Contact electrification property controlled by amino modification of cellulose fibers. Cellulose 2022, 29, 3195–3208. [Google Scholar] [CrossRef]

- dos Santos, M.F.N.; Battistelle, R.A.G.; Bezerra, B.S.; Varum, H.S.A. Comparative study of the life cycle assessment of particleboards made of residues from sugarcane bagasse (Saccharum spp.) and pine wood shavings (Pinus elliottii). J. Clean. Prod. 2014, 64, 345–355. [Google Scholar] [CrossRef]

- EN 319:1993; Particleboards and Fibreboards—Determination of Tensile Strength Perpendicular to the Plane of the Board. European Committee for Standardization: Brussels, Belgium, 1993.

- EN 310:1993; Wood-Based Panels—Determination of Modulus of Elasticity in Bending and of Bending Strength. European Committee for Standardization: Brussels, Belgium, 1993.

- EN 317:1993; Particleboards and Fibreboards—Determination of Swelling in Thickness After Immersion in Water. European Committee for Standardization: Brussels, Belgium, 1993.

- EN 120:1992; Wood Based Panels—Determination of Formaldehyde Content—Extraction Method Called the Perforator Method. CEN: Brussels, Belgium, 1992.

- Benito-González, I.; López-Rubio, A.; Martínez-Abad, A.; Ballester, A.-R.; Falcó, I.; González-Candelas, L.; Sánchez, G.; Lozano-Sánchez, J.; Borrás-Linares, I.; Segura-Carretero, A.; et al. In-Depth Characterization of Bioactive Extracts from Posidonia oceanica Waste Biomass. Mar. Drugs 2019, 17, 409. [Google Scholar] [CrossRef]

- Chen, J.; Li, S. Characterization of biofuel production from hydrothermal treatment of hyperaccumulator waste (Pteris vittata L.) in sub- and supercritical water. RSC Adv. 2020, 10, 2160–2169. [Google Scholar] [CrossRef]

- Kurian, J.K.; Gariepy, Y.; Orsat, V.; Raghavan, G.S.V. Microwave-assisted lime treatment and recovery of lignin from hydrothermally treated sweet sorghum bagasse. Biofuels 2015, 6, 341–355. [Google Scholar] [CrossRef]

- Plis, A.; Lasek, J.A.; Zuwała, J.; Yu, C.-C.; Iluk, A. Combustion performance evaluation of Posidonia oceanica using TGA and bubbling fluidized-bed combustor (batch reactor). J. Sustain. Min. 2016, 15, 181–190. [Google Scholar] [CrossRef]

- Lazli, W.; Hellal, A. Biosorption of phenol by modified dead leaves of Posidonia oceanica immobilized in calcium alginate beads: Optimal experimental parameters using central composite design. Water SA 2020, 46, 322–329. [Google Scholar] [CrossRef]

- Torbatinejad, N.M.; Annison, G.; Rutherfurd-Markwick, K.; Sabine, J.R. Structural constituents of the seagrass Posidonia australis. J. Agric. Food Chem. 2007, 55, 4021–4026. [Google Scholar] [CrossRef] [PubMed]

- Zhuang, J.; Li, M.; Pu, Y.; Ragauskas, A.J.; Yoo, C.G. Observation of potential contaminants in processed biomass using fourier transform infrared spectroscopy. Appl. Sci. 2020, 10, 4345. [Google Scholar] [CrossRef]

- Hariyanto, B.; Wardani, D.A.P.; Kurniawati, N.; Har, N.P.; Darmawan, N.; Irzaman. X-Ray Peak Profile Analysis of Silica by Williamson–Hall and Size-Strain Plot Methods. J. Phys. Conf. Ser. 2021, 2019, 012106. [Google Scholar] [CrossRef]

- Li, B.; Xu, W.; Kronlund, D.; Eriksson, J.-E.; Määttänen, A.; Willför, S.; Xu, C. Comparable Characterization of Nanocellulose Extracted from Bleached Softwood and Hardwood Pulps. Pap. Biomater. 2018, 3, 35–44. [Google Scholar] [CrossRef]

- Zuluaga, R.; Hoyos, C.G.; Velásquez-Cock, J.; Vélez-Acosta, L.; Valencia, I.P.; Torres, J.A.R.; Rojo, P.G. Exploring Spent Coffee Grounds: Comprehensive Morphological Analysis and Chemical Characterization for Potential Uses. Molecules 2024, 29, 5866. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, M.; Su, J.; Hu, H.; Yang, M.; Huang, Z.; Chen, D.; Wu, J.; Feng, Z. Overcoming biomass recalcitrance by synergistic pretreatment of mechanical activation and metal salt for enhancing enzymatic conversion of lignocellulose. Biotechnol. Biofuels 2019, 12, 12. [Google Scholar] [CrossRef]

- Silva, J.; Teixeira, S.; Teixeira, J. A Review of Biomass Thermal Analysis, Kinetics and Product Distribution for Combustion Modeling: From the Micro to Macro Perspective. Energies 2023, 16, 6705. [Google Scholar] [CrossRef]

- Popescu, M.A.; Isopescu, R.; Matei, C.; Fagarasan, G.; Plesu, V. Thermal decomposition of calcium carbonate polymorphs precipitated in the presence of ammonia and alkylamines. Adv. Powder Technol. 2014, 25, 500–507. [Google Scholar] [CrossRef]

- Benbow, M.E.; Merritt, R.W. Road Salt. In Water Encyclopedia; John Wiley & Sons: Hoboken, NJ, USA, 2005. [Google Scholar] [CrossRef]

- Yao, X.; Xu, K.; Yan, F.; Liang, Y. The influence of ashing temperature on ash foulinq and slagging characteristics during combustion of biomass fuels. BioResources 2017, 12, 1593–1610. [Google Scholar] [CrossRef]

- Yao, X.; Zhao, Z.; Chen, S.; Zhou, H.; Xu, K. Migration and transformation behaviours of ash residues from a typical fixed-bed gasification station for biomass syngas production in China. Energy 2020, 201, 117646. [Google Scholar] [CrossRef]

- EN 312:2010; Particleboards—Specifications. European Committee for Standardization: Brussels, Belgium, 2010.

| Type of Resin | UF |

|---|---|

| Solids, % | 65.02 |

| pH at 25 °C, [ ] | 7.91 |

| Viscosity at 25 °C, cP | 250 |

| Water Tolerance, mL/mL | 1/4 |

| Gel time at 100 °C, s | 55.00 |

| Buffer Capacity, % | 9.0 |

| Name of Material | Moisture Content, % | pH, [ ] | Buffer Capacity, mL |

|---|---|---|---|

| Sideritis | 11.74 | 5.34 | 33 |

| Coffee bean husks | 6.18 | 5.60 | 60 |

| Coffee grounds | 19.25 | 5.70 | 15 |

| Thistle fibrous peels | 14.84 | 6.11 | 23 |

| Posidonia | 20.81 | 7.38 | 16 |

| wood | 12.50 | 5.32 | 6 |

| Material | Degree of Crystallinity |

|---|---|

| Wood | 64.7% |

| Sideritis | 62.4% |

| Thistle | 57.8% |

| Coffee husks | 53.5% |

| Posidonia leaves | 48.8% |

| Spent coffee grounds | 45.7% |

| Sample | Dehydration Stage | Devolatilization | Char and Mineral Combustion | Ash (Residual Mass %) | |||

|---|---|---|---|---|---|---|---|

| T-Range (°C) | Mass (%) | T-Range (°C) | Mass (%) | T-Range (°C) | Mass (%) | ||

| Wood | 25–190 | 7 | 190–375 | 62 | 375–700 | 30.95 | 0.05 |

| Sideritis | 25–160 | 7 | 160–378 | 46 | 378–1200 | 27.8 | 19.2 |

| Thistle | 25–160 | 9 | 160–385 | 63 | 385–600 | 23.4 | 4.6 |

| Coffee bean husks | 25–155 | 6 | 155–386 | 56 | 386–700 | 34.6 | 3.4 |

| Coffee grounds | 25–150 | 10 | 150–387 | 58 | 387–700 | 29 | 3 |

| Posidonia | 25–200 | 13 | 200–406 | 33 | 406–1200 | 37 | 17 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Papadopoulou, E.; Moutousidis, D.; Achelonoudis, C.; Tsompanidis, S.; Kyriakou-Tziamtzi, C.; Chrissafis, K.; Bikiaris, D.N. Particleboards with Various Biomass Residues. Materials 2025, 18, 2632. https://doi.org/10.3390/ma18112632

Papadopoulou E, Moutousidis D, Achelonoudis C, Tsompanidis S, Kyriakou-Tziamtzi C, Chrissafis K, Bikiaris DN. Particleboards with Various Biomass Residues. Materials. 2025; 18(11):2632. https://doi.org/10.3390/ma18112632

Chicago/Turabian StylePapadopoulou, Electra, Dimitrios Moutousidis, Christos Achelonoudis, Stavros Tsompanidis, Christina Kyriakou-Tziamtzi, Konstantinos Chrissafis, and Dimitrios N. Bikiaris. 2025. "Particleboards with Various Biomass Residues" Materials 18, no. 11: 2632. https://doi.org/10.3390/ma18112632

APA StylePapadopoulou, E., Moutousidis, D., Achelonoudis, C., Tsompanidis, S., Kyriakou-Tziamtzi, C., Chrissafis, K., & Bikiaris, D. N. (2025). Particleboards with Various Biomass Residues. Materials, 18(11), 2632. https://doi.org/10.3390/ma18112632