Compressive Strength Tests of Concrete Core Samples with the Addition of Recycled Aggregate

Abstract

1. Introduction

2. Materials and Methods

- Cement CEM II/B-V 32.5R, 2.95 kg/dm3;

- Pure natural aggregate with a grain size of 0–2 mm (river sand), 2.67 kg/dm3;

- Pure natural aggregate with a grain size of 0–16 mm (mine gravel), 2.67 kg/dm3;

- Recycled aggregate with a grain size of 4–16 mm (crushed standard cubic particles of concrete containing natural aggregate: sand and gravel), 2.40 kg/dm3;

- Potable water taken from the municipal water supply, 1.0 kg/dm3;

- FK-88 plasticizer was added to the mixing water during the preparation of concrete mix, 1.18 kg/dm3.

2.1. Description of the Experiment

- I.

- The compressive strength of the produced concrete was checked in accordance with EN 12390-3 [45] on standard cubic samples with a side length of 150 mm. The samples were prepared in accordance with EN 12390-1 [46] and then tested according to standard EN 12390-3 [45] on a Toni Technik compression testing machine (with a rate of loading of 0.5 MPa/s).

- II.

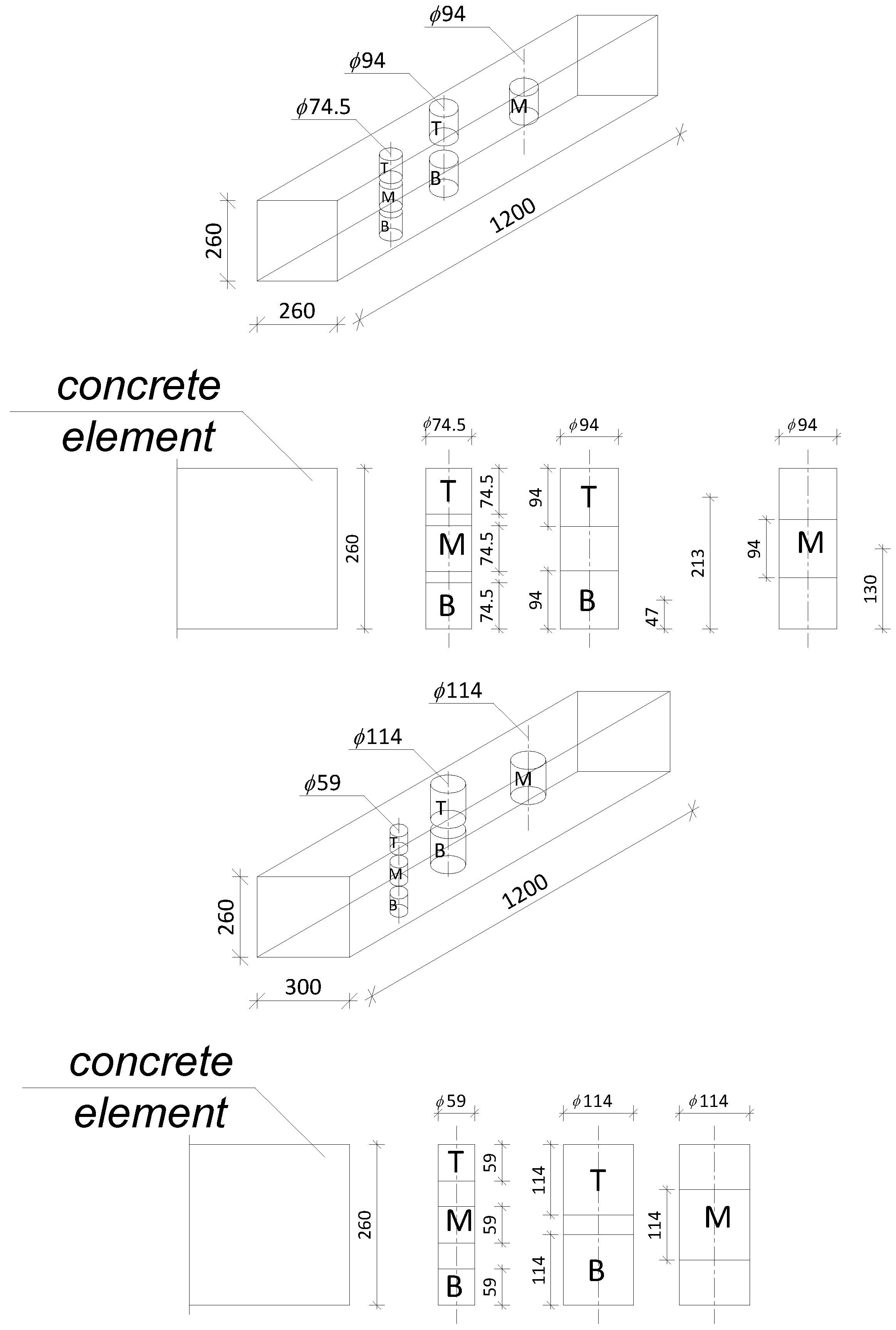

- Concrete elements with a thickness of 260 mm were prepared. They were compacted for 5 min with the use of a ϕ 38 mm deep vibrator (with a frequency of 300 Hz).

- III.

- Core samples with a height-to-diameter ratio equal to 1 were cut from cores taken along the direction of concreting (Figure 1) and then tested. Core samples were taken in such a way that half of the sample’s height was placed as low as possible to the bottom layer, the other half was as high as possible to the top layer, and the middle of the sample was halfway up the thickness of the element. Core samples of the diameters 94 mm and 114 mm were taken from two cores to obtain a height-to-diameter ratio equal to 1. Core samples from the top and bottom layers were taken from the first core, and core samples from the middle layer were taken from the second core (Figure 2). According to research [28], the designed compressive strength is for a sample taken in the middle of the height of a concrete cylinder. The concrete elements, after removal from the mold, were stored at a temperature of 20 ± 2 °C and a humidity of 50 ± 15% until the cores were taken. The cores were cut into the core samples. After cutting, the core samples were stored for 30 days at a temperature of 20 ± 2 °C and a humidity of 50 ± 15% until their compressive strength was tested. The core samples were tested 90 days after concreting.

2.2. Processing of the Research Results

2.3. Statistics

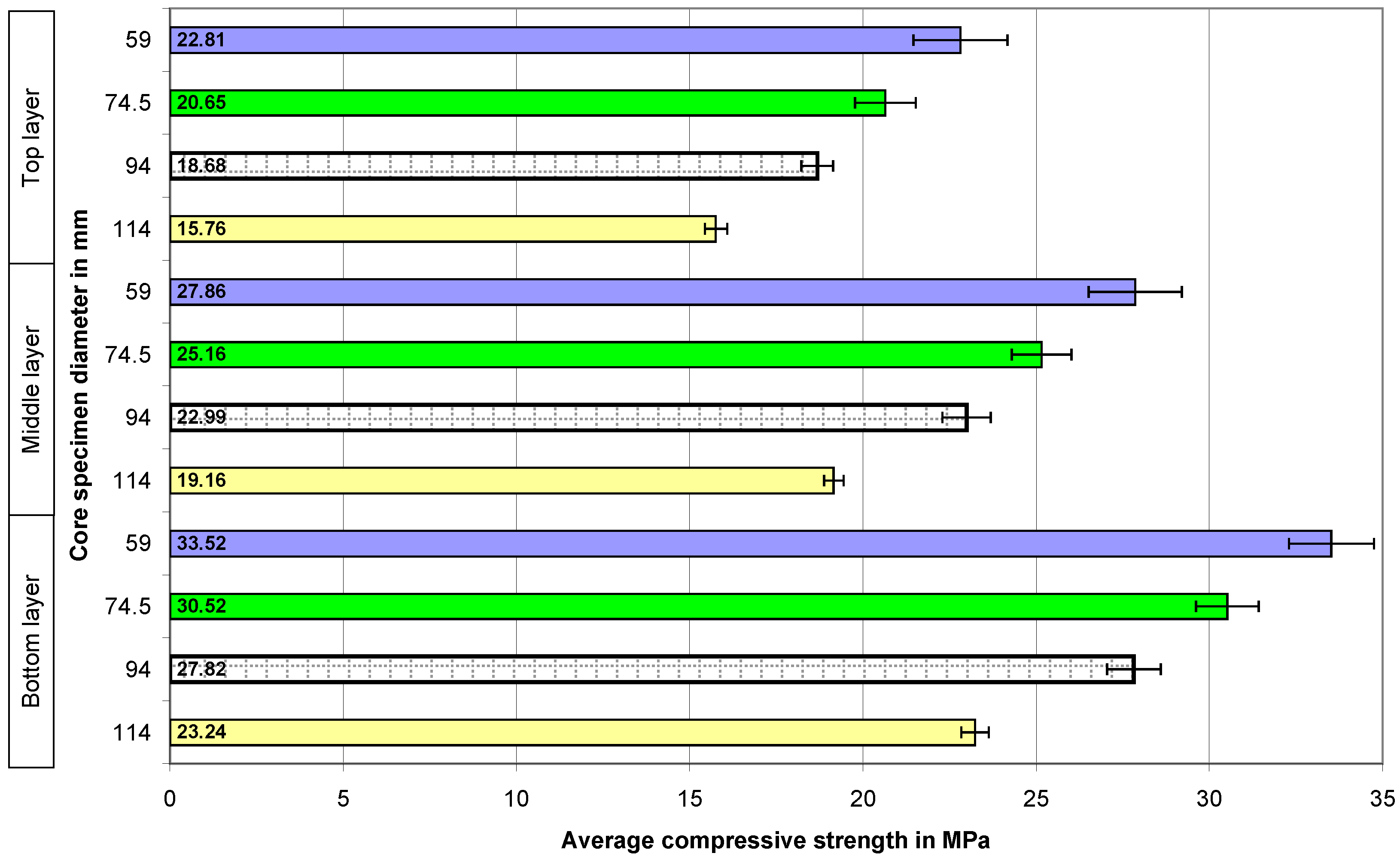

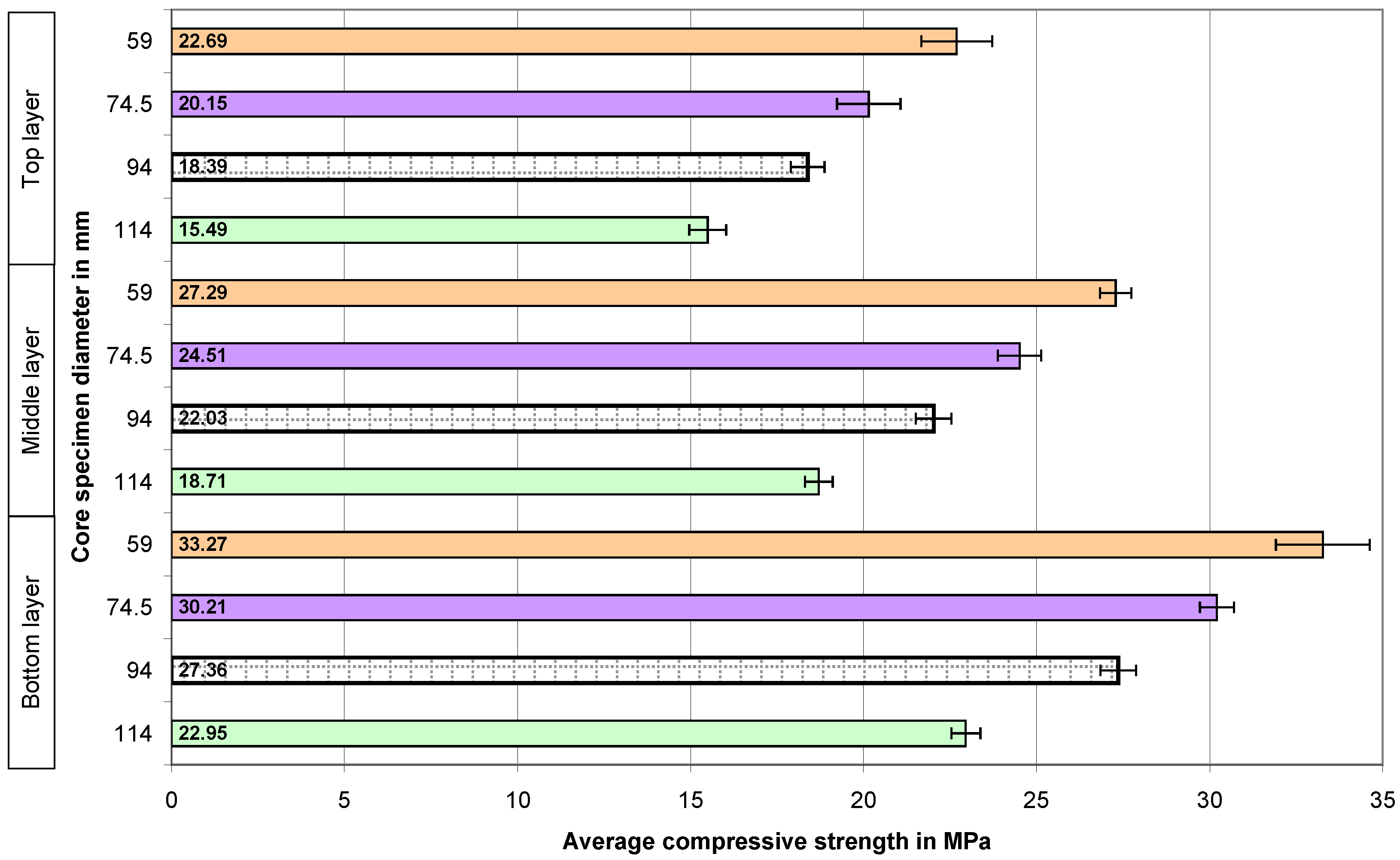

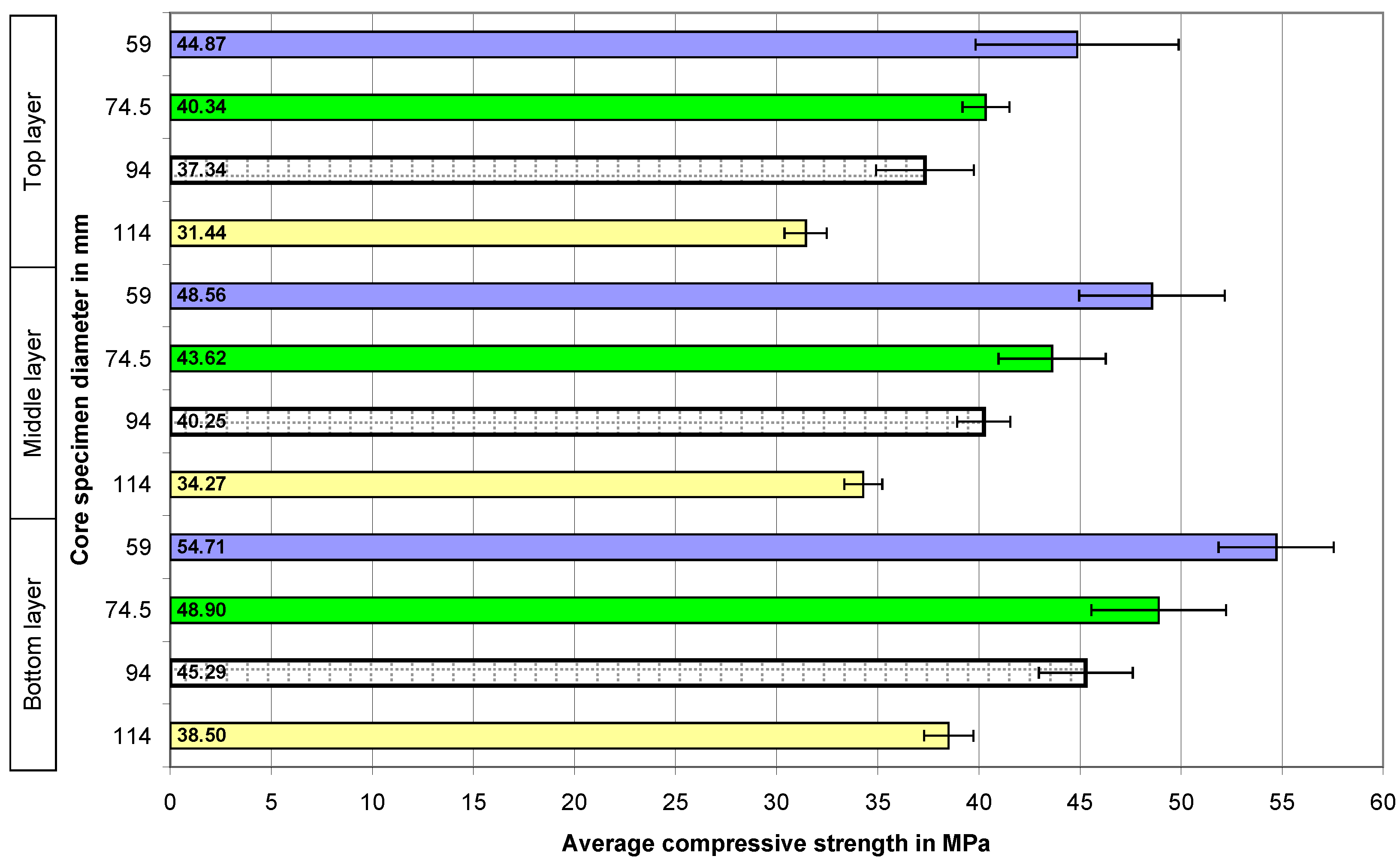

3. Results

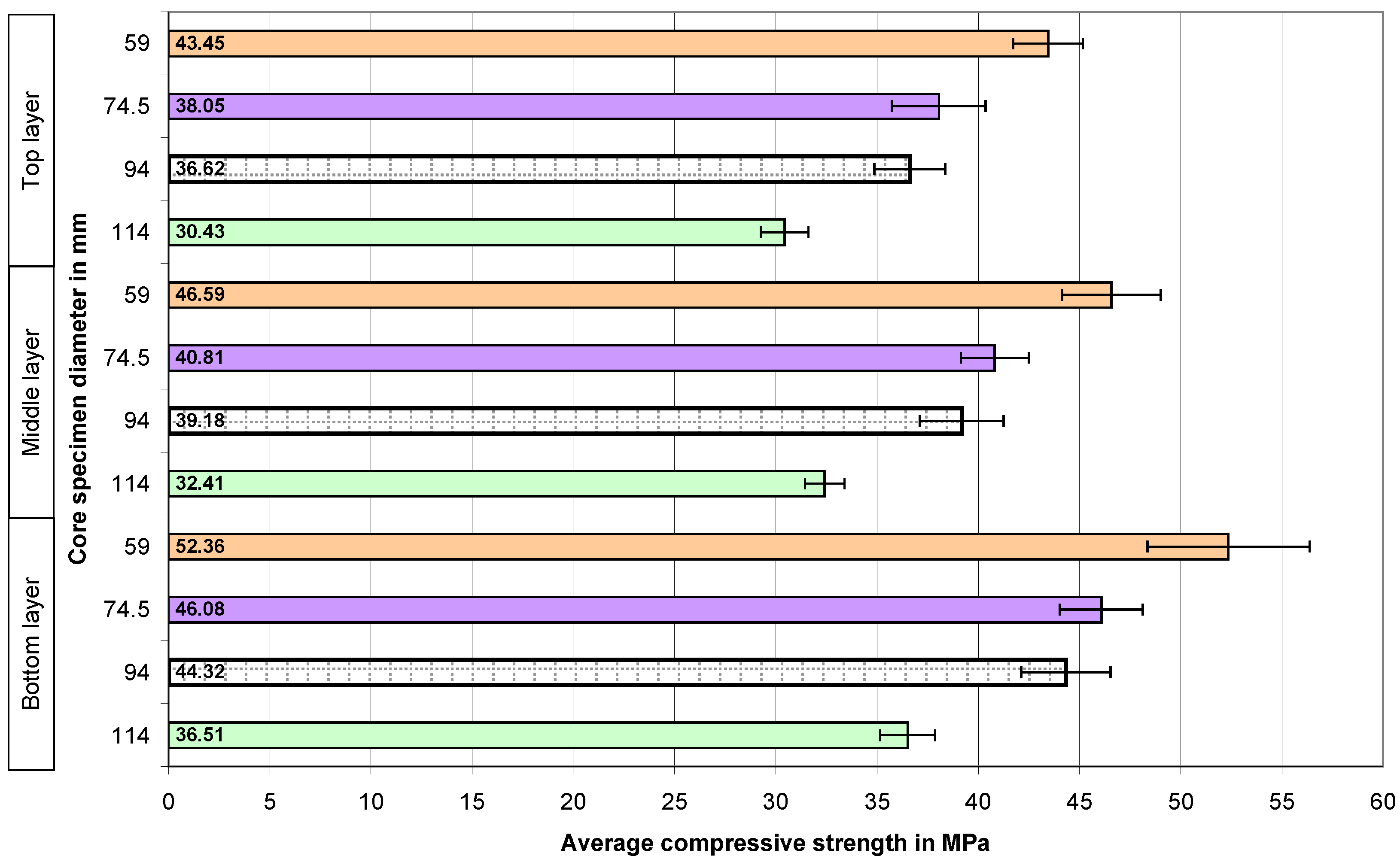

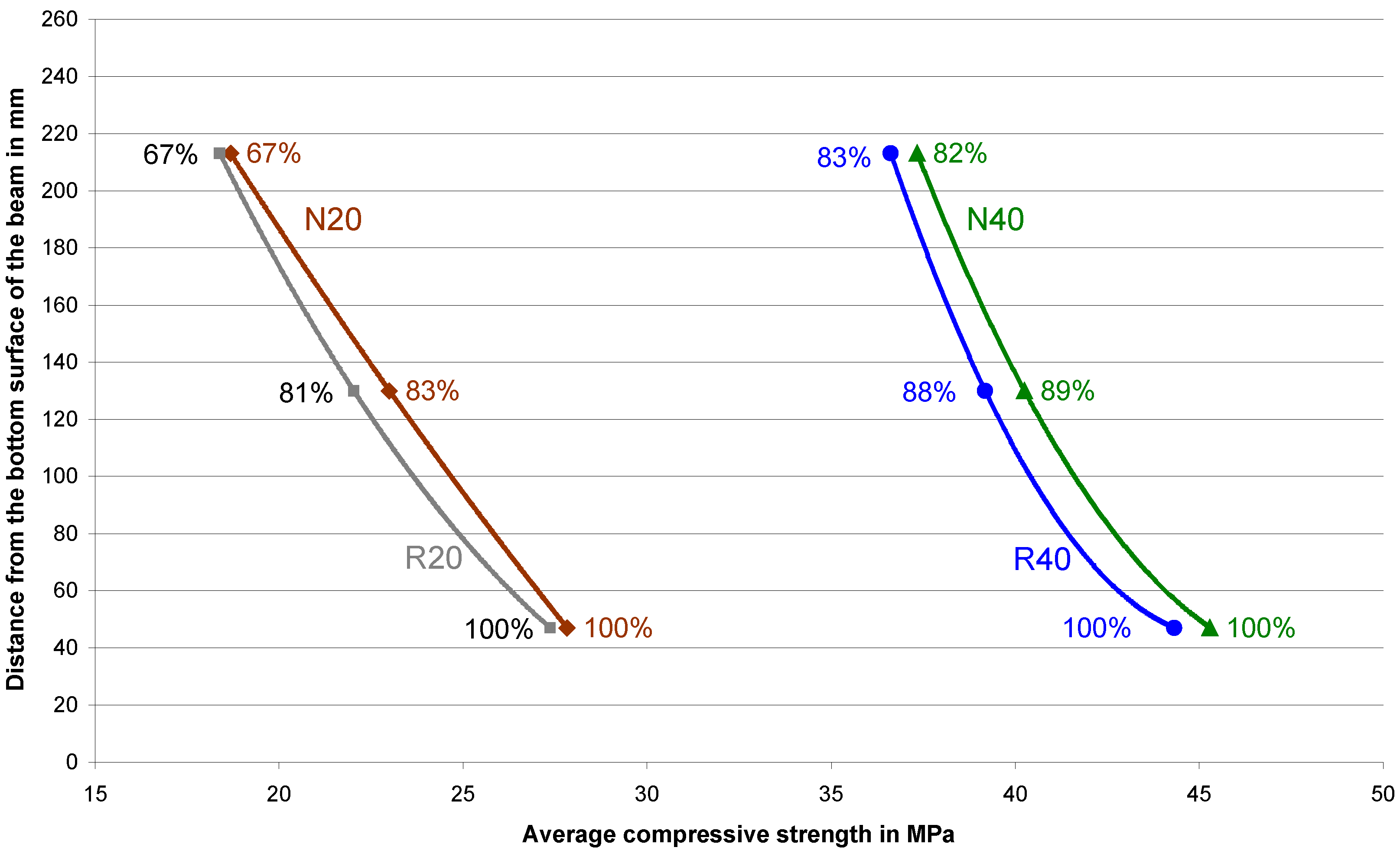

3.1. Compressive Strength

3.2. Compressive Strength Statistics

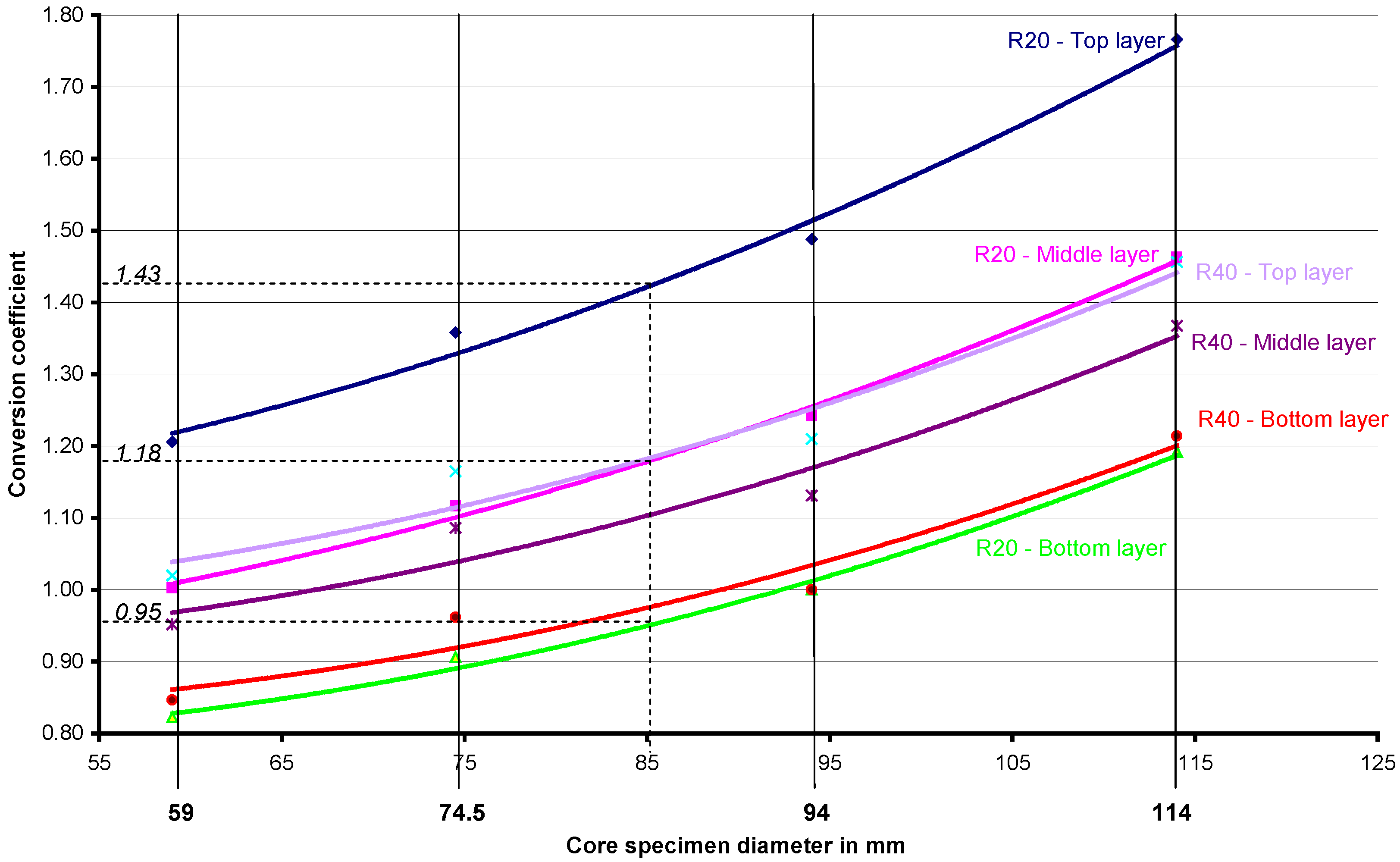

3.3. Conversion Coefficients

3.4. Recommendation

4. Discussion

5. Conclusions

- The compressive strength of the core samples of concrete with pure natural aggregate and with the addition of recycled aggregate from the top layers was about 17% lower (17.1% for the concrete with pure natural aggregate, 17.8% for the concrete with the addition of recycled aggregate) than the strength of the core samples from the bottom layer. This relationship corresponds to the designed compressive strength of the concrete equal to 40 MPa.

- The compressive strength of the core samples of concrete with pure natural aggregate and with the addition of recycled aggregate from the top layers was about 33% lower (33.3% for the concrete with pure natural aggregate, 33.6% for the concrete with the addition of recycled aggregate) than the strength of the core samples from the bottom layer. This relationship corresponds to the designed compressive strength of the concrete equal to 20 MPa.

- When determining the compressive strength of concrete in a structure, the variation in compressive strength across the thickness of the concrete element should be taken into account.

- Thin concrete elements must be carefully formed by the contractors. The contractors must have experience in pouring and compacting concrete mixtures of various structural elements.

- The quality of the concrete made or the technical condition of the building must be determined on the basis of the compressive strength of core samples taken from different layers (there is compression) of horizontally formed concrete elements.

- The conclusion coefficients are held if the height-to-diameter ratio is equal to 1 and if the concrete slab thickness is up to 260 mm.

- The conversion coefficients that enable the compressive strength of the concrete tested on core samples of various dimensions to be converted onto the normative compressive strength after 28 days.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Alam, M.S.; Huda, S.B. Mechanical behavior of three generations of 100% repeated recycled coarse aggregate, concrete. Constr. Build. Mater. 2014, 65, 574–582. [Google Scholar]

- Li, J.; Nguyen, B.T.; Saberian, M.; Wang, G. Permanent deformation behaviour of pavement base and subbase containing recycle concrete aggregate, coarse and fine crumb rubber. Constr. Build. Mater. 2018, 178, 51–58. [Google Scholar]

- Li, J.; Nguyen, B.T.; Saberian, M. Effect of crumb rubber on the mechanical properties of crushed recycled pavement materials. J. Environ. Manag. 2018, 218, 291–299. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Sata, V.; Wonsan, A.; Zaetang, Y. Properties of pervious concrete containing recycled concrete block aggregate and recycled concrete aggregate. Constr. Build. Mater. 2016, 111, 15–21. [Google Scholar]

- Brito, J.; Chastre, C.; Evangelista, L.; Pacheco, J. Experimental investigation on the variability of the main mechanical properties of concrete produced with coarse recycled concrete aggregates. Constr. Build. Mater. 2019, 201, 110–120. [Google Scholar]

- Brito, J.; Chastre, C.; Evangelista, L.; Pacheco, J.N. Probabilistic conversion of the compressive strength of cubes to cylinders of natural and recycled aggregate concrete specimens. Materials 2019, 12, 280. [Google Scholar] [CrossRef]

- Chen, X.; Du, H.; Hitch, M.; Huang, M.; Li, J.; Li, Y.; Ni, W.; Song, X.; Yang, D. Performance assessment of all-solid-waste high-strength concrete prepared from waste rock aggregates. Materials 2025, 18, 624. [Google Scholar]

- Li, J.; Wang, C.; Ni, W.; Zhu, S.; Mao, S.; Jiang, F.; Zeng, H.; Sun, X.; Huang, B.; Hitch, M. Orthogonal test design for the optimisation of preparation of steel slag-based carbonated building materials with ultramafic tailings as fine aggregates. Minerals 2022, 12, 246. [Google Scholar] [CrossRef]

- Bouzar, B.; Mamindy-Pajany, Y. Manufacture and characterization of carbonated lightweight aggregates from waste paper fly ash. Powder Technol. 2022, 406, 117583. [Google Scholar] [CrossRef]

- Li, Y.; Pan, X.; Poon, C.-S.; Shi, C.; Xie, Z.; Zhang, J. Influence of carbonated recycled concrete aggregate on properties of cement mortar. Constr. Build. Mater. 2015, 98, 1–7. [Google Scholar]

- Tam, V.W.Y.; Tam, C.M.; Wang, Y. Optimization on proportion for recycled aggregate in concrete using twostage mixing approach. Constr. Build. Mater. 2017, 21, 1928–1939. [Google Scholar] [CrossRef]

- Guo, L.; Yang, Y.; Zhong, L.; Zhong, J. Effect of Aggregate Characteristics and Distribution on the Mechanical Characteristics of Recycled Concrete. In Arabian Journal for Science and Engineering; Springer: Berlin/Heidelberg, Germany, 2024. [Google Scholar] [CrossRef]

- Bravo, M.; Cantero, B.; De Brito, J. Water transport and shrinkage in concrete made with ground recycled concrete-additioned cement and mixed recycled aggregate. Cem. Concr. Compos. 2021, 118, 103957. [Google Scholar]

- Bungey, J.H.; Grantham, M.G.; Millard, S.G. Testing of Concrete in Structures, 4th ed.; Taylor and Francis Group: London, UK, 2006; p. 352. [Google Scholar]

- Aggarwal, P.K.; Naval, S.; Sharma, S. Experimental study of core diameter varying H/D on concrete. Int. J. Eng. Res. Technol. 2013, 2, 1–15. [Google Scholar]

- Alizadeh, A.M.; Madandoust, R. Assessing the effective parameters on normal strength concrete by core testing. J. Automot. Appl. Mech. 2015, 3, 17–21. [Google Scholar]

- Javadein, S.I.; Madandoust, R.; Mirhosseini, S.M. In Situ Strength Assessment of Concrete Using Recycled Aggregates by Means of Small Diameter Cores. J. Rehabil. Civ. Eng. 2020, 8, 158–170. [Google Scholar]

- Li, M.; Hao, H.; Shi, Y. Specimen shape and size effects on the concrete compressive strength under static and dynamic tests. Constr. Build. Mater. 2018, 161, 84–93. [Google Scholar] [CrossRef]

- Ahmed, M.H.M.; Elrazek, M.A.; Rashwan, M.M. Experimental Study for the Comparison between Core, Schmidt and Cubic Concrete Compressive Strength After Durability Test. Mater. Sci. Eng. 2022, 1269, 012005. [Google Scholar]

- Kazemi, M.; Madandoust, R.; Brito, J. Compressive strength assessment of recycled aggregate concrete using Schmidt rebound hammer and core testing. Constr. Build. Mater. 2019, 224, 630–638. [Google Scholar] [CrossRef]

- Loo, Y.H.; Tam, C.T.; Tan, C.W. Effects of embedded reinforcement on measured strength of concrete cylinders. Mag. Concr. Res. 1989, 41, 11–18. [Google Scholar] [CrossRef]

- Chen, J.; Yin, F.; Zhou, Y. A Practical Equation for the Elastic Modulus of Recycled Aggregate Concrete. Buildings 2022, 12, 187. [Google Scholar] [CrossRef]

- Carrazedo, R.; Felix, E.F.; Possan, E. A New Formulation to Estimate the Elastic Modulus of Recycled Concrete Based on Regression and ANN. Sustainability 2021, 13, 8561. [Google Scholar] [CrossRef]

- Ashiq, S.Z.; Kazmi, S.M.S.; Lin, X.; Munir, M.J.; Wu, Y.-F. Development of unified elastic modulus model of natural and recycled aggregate concrete for structural applications. Casa Stud. Constr. Mater. 2023, 18, e01873. [Google Scholar]

- Liu, X.; Yan, P.; Zhang, X. Prediction model for elastic modulus of recycled concrete based on properties of recycled coarse aggregate and cementations materials. Casa Stud. Constr. Mater. 2024, 21, e04058. [Google Scholar]

- Ahmad, M.R.; Kazmi, S.M.S.; Lin, X.; Munir, M.J.; Wu, Y.-F. Axial Stress-Strain Performance of Recycled Aggregate Concrete Reinforced with Macro-Polypropylene Fibres. Sustainability 2021, 13, 5741. [Google Scholar]

- Kazmi, S.M.S.; Munir, M.J.; Patnaikuni, I.; Wu, Y.-F.; Xing, F.; Zhou, Y. Axial stress-strain behavior of macro-synthetic fiber reinforced recycled aggregate concrete. Cem. Concr. Compos. 2019, 97, 341–356. [Google Scholar] [CrossRef]

- Stawiski, B. Ultrasonic Testing Concrete and Mortar with Using Point Heads; Oficyna Wydawnicza Politechniki Wrocławskiej: Wroclaw, Poland, 2009; Volume 39, p. 154. [Google Scholar]

- Stawiski, B.; Szpetulski, J. Changes in the compressive strength of concrete in thin horizontally formed slabs. Materials 2020, 13, 5671. [Google Scholar] [CrossRef]

- Szpetulski, J. Testing the compressive strength of concrete in the construction. Przeg. Bud. 2016, 3, 21–24. [Google Scholar]

- Brunarski, L. Research Methods Used in the Assessment of Building Structures-Estimation of Concrete Compressive Strength In Situ; Diagnostyka i wzmacnianie konstrukcji żelbetowych: Warsaw, Poland, 1994; Volume 2–3, pp. 106–107. [Google Scholar]

- Drobiec, Ł.; Jasiński, R.; Piekarczyk, A. Diagnostics of Reinforced Concrete Structures. Methodology, Field Tests, Laboratory Tests of Concrete and Steel; Wydawnictwo Naukowe PWN: Warsaw, Poland, 2010. [Google Scholar]

- Schabowicz, K. Non-Destructive Testing of Materials in Civil Engineering. Materials 2019, 12, 3237. [Google Scholar] [CrossRef]

- Sobolewski, M. Uncertainty of measurement results of concrete compressive strength tests of core samples. ACTA Sci. Pol. Arch. 2013, 12, 93–108. [Google Scholar]

- EN 13791; Assessment of In-Situ Compressive Strength in Structures and Pre-Cast Concrete Components. European Committee for Standardization: Brussels, Belgium, 2007.

- Jaskulski, R.; Koper, A.; Kubissa, W.; Szpetulski, J. Properties of concretes with natural aggregate improved by RCA addition. Procedia Eng. 2015, 108, 30–38. [Google Scholar]

- Jaskulski, R.; Koper, A.; Kubissa, W.; Supera, M. High performance concrete with SCM and recycled aggregate. Eng. Mater. 2016, 677, 233–240. [Google Scholar]

- Kania, T.; Stawiski, B. Examining the distribution of strength across the thickness of reinforced concrete elements subject to sulphate corrosion using the ultrasonic method. Materials 2019, 12, 2519. [Google Scholar] [CrossRef]

- Kania, T.; Stawiski, B. Tests of concrete strength across the thickness of industrial floor using the ultrasonic method with exponential spot heads. Materials 2020, 13, 2118. [Google Scholar] [CrossRef]

- Malhotra, V.M. Concrete strength requirements-Cores versus in-situ evaluation. J. Amer. Concr. Inst. 1977, 74, 163–172. [Google Scholar]

- Mlaker, P.F. Acoustic Emission Behavior of Concrete, In-Situ/Nondestructive Testing of Concrete; Malhotra, V.M., Ed.; American Concr. Institute SP-82: Detroit, MI, USA, 1984; pp. 619–628. [Google Scholar]

- Neville, A.M. A general relation for strengths of concrete specimens of different shapes and sizes. J. Amer. Concr. Inst. 1966, 63, 1095–1109. [Google Scholar]

- Neville, A.M. Core test: Easy to perform, Not easy to interpret. Concr. Int. 2001, 23, 59–68. [Google Scholar]

- Petersons, N. Should standard cube test specimens be replaced by test specimens taken from structures? Mater. Struct. 1968, 1, 425–435. [Google Scholar] [CrossRef]

- EN 12390-3; Testing Hardened Concrete. Compressive Strength of Test Specimens. European Committee for Standardization: Brussels, Belgium, 2019.

- EN 12390-1; Testing Hardened Concrete. Shape, Dimensions and Other Requirements for Specimens and Moulds. European Committee for Standardization: Brussels, Belgium, 2012.

- EN 206; Concrete. Specification, Performance, Production and Conformity. European Committee for Standardization: Brussels, Belgium, 2016.

- EN 12350-5; Testing fresh concrete. Flow table test. European Committee for Standardization: Brussels, Belgium, 2019.

- EN 12350-2; Testing fresh concrete. Slump test. European Committee for Standardization: Brussels, Belgium, 2019.

- ASTM C 1231/C1231M-00; Standard Practice for Use of Unbonded Caps in Determination of Compressive Strength of Hardened Concrete Cylinders. ASTM International: West Conshohocken, PA, USA, 2000.

- EN 12504-1; Testing Concrete in Structures. Cored Specimens. Taking, Examining and Testing in Compression. European Committee for Standardization: Brussels, Belgium, 2019.

- Haavisto, J.; Husso, A.; Laaksonen, A. Compressive strength of core specimens drilled from concrete test cylinders. Structural Concrete 2020, 1–13. [Google Scholar] [CrossRef]

- Hansen, K.; Kielland, A.; Nielsen, K.E.C.; Thaulow, S. Compressive strength of concrete-cube or cylinder? RILEM Bull. 1962, 17, 23–30. [Google Scholar]

- Kania, T.; Stawiski, B. Determination of the influence of cylindrical samples dimensions on the evaluation of concrete and wall mortar strength using ultrasound method. Procedia Eng. 2013, 57, 1078–1085. [Google Scholar]

- Stawiski, B. Research on the influence of the dimensions of cylindrical samples on the assessment of concrete strength using the ultrasound method. In Proceedings of the 39 Krajowa Konferencja Badan Nieniszczacych, Szczyrk, Poland, 25–28 October 2010; Volume 4, pp. 1–9. [Google Scholar]

| fcm | Concrete Series | Components of the Concrete Mix | Mass of Components per 1 m3 [kg] |

|---|---|---|---|

| 20 MPa | N20 | Cement | 275.0 |

| Sand | 784.7 | ||

| Gravel | 1083.7 | ||

| Water | 206.3 | ||

| R20 | Cement | 275.0 | |

| Sand | 784.7 | ||

| Gravel | 541.7 | ||

| Recycled aggregate | 490.7 | ||

| Water | 206.3 | ||

| 40 MPa | N40 | Cement | 300.0 |

| Sand | 636.6 | ||

| Gravel | 1352.7 | ||

| Water | 150.0 | ||

| Plasticizer | 3.0 | ||

| R40 | Cement | 300.0 | |

| Sand | 636.2 | ||

| Gravel | 676.0 | ||

| Recycled aggregate | 611.2 | ||

| Water | 150.0 | ||

| Plasticizer | 3.5 |

| Concrete Series | U [MPa] | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ϕ 59 mm | ϕ 74.5 mm | ϕ 94 mm | ϕ 114 mm | |||||||||

| Bottom Layer | Middle Layer | Top Layer | Bottom Layer | Middle Layer | Top Layer | Bottom Layer | Middle Layer | Top Layer | Bottom Layer | Middle Layer | Top Layer | |

| N20 | 1.23 | 1.34 | 1.36 | 0.91 | 0.86 | 0.88 | 0.78 | 0.70 | 0.46 | 0.40 | 0.27 | 0.32 |

| R20 | 1.36 | 0.46 | 1.02 | 0.50 | 0.63 | 0.93 | 0.51 | 0.51 | 0.49 | 0.42 | 0.40 | 0.54 |

| N40 | 2.84 | 3.60 | 5.02 | 3.33 | 2.64 | 1.17 | 2.33 | 1.31 | 2.42 | 1.22 | 0.94 | 1.04 |

| R40 | 4.00 | 2.44 | 1.73 | 2.05 | 1.68 | 2.31 | 2.20 | 2.08 | 1.75 | 1.37 | 0.98 | 1.17 |

| Dimensions in mm | Conversion Coefficient | |||

|---|---|---|---|---|

| Bottom Layer | Middle Layer | Top Layer | ||

| N20 | ϕ 59 × 59 | 0.83 | 1.00 | 1.22 |

| ϕ 74.5 × 74.5 | 0.91 | 1.11 | 1.35 | |

| ϕ 114 × 114 | 1.20 | 1.45 | 1.77 | |

| R20 | ϕ 59 × 59 | 0.83 | 0.93 | 1.01 |

| ϕ 74.5 × 74.5 | 0.93 | 1.04 | 1.12 | |

| ϕ 114 × 114 | 1.18 | 1.32 | 1.44 | |

| Dimensions in mm | Conversion Coefficient | |||

|---|---|---|---|---|

| Bottom Layer | Middle Layer | Top Layer | ||

| N40 | ϕ 59 × 59 | 0.82 | 1.00 | 1.21 |

| ϕ 74.5 × 74.5 | 0.91 | 1.12 | 1.36 | |

| ϕ 114 × 114 | 1.19 | 1.46 | 1.77 | |

| R40 | ϕ 59 × 59 | 0.85 | 0.95 | 1.02 |

| ϕ 74.5 × 74.5 | 0.96 | 1.09 | 1.16 | |

| ϕ 114 × 114 | 1.21 | 1.37 | 1.46 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szpetulski, J.; Sadowski, G.; Stawiski, B. Compressive Strength Tests of Concrete Core Samples with the Addition of Recycled Aggregate. Materials 2025, 18, 2631. https://doi.org/10.3390/ma18112631

Szpetulski J, Sadowski G, Stawiski B. Compressive Strength Tests of Concrete Core Samples with the Addition of Recycled Aggregate. Materials. 2025; 18(11):2631. https://doi.org/10.3390/ma18112631

Chicago/Turabian StyleSzpetulski, Jacek, Grzegorz Sadowski, and Bohdan Stawiski. 2025. "Compressive Strength Tests of Concrete Core Samples with the Addition of Recycled Aggregate" Materials 18, no. 11: 2631. https://doi.org/10.3390/ma18112631

APA StyleSzpetulski, J., Sadowski, G., & Stawiski, B. (2025). Compressive Strength Tests of Concrete Core Samples with the Addition of Recycled Aggregate. Materials, 18(11), 2631. https://doi.org/10.3390/ma18112631