The Influence of Fibre and Fly Ash Additions on the Properties of Self-Compacting Concrete

Abstract

1. Introduction

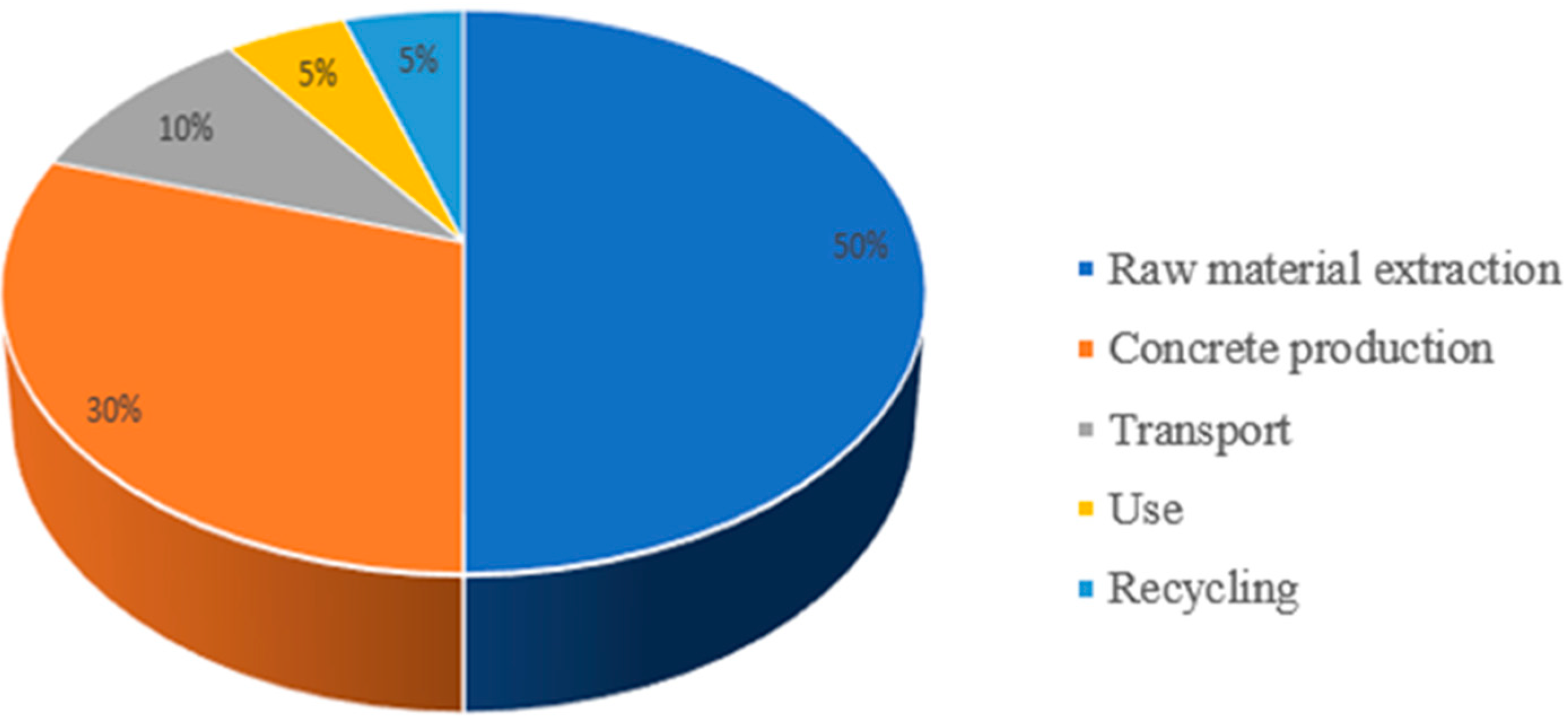

- Increasing energy efficiency—modernisation of cement plants and the use of new technologies, including alternative fuels, e.g., biomass, can significantly reduce CO2 emissions. According to the European Cement Manufacturers Association (CEMBUREAU), such actions can reduce emissions by up to 30% [17].

- Reducing the share of clinker in cement—clinker is the most carbon-intensive part of cement. Replacing it with supplementary materials, such as fly ash or blast furnace slag, can reduce CO2 emissions by up to 40%, while also enhancing the mechanical properties of concrete [18].

- Using CCS (Carbon Capture and Storage) technology—capturing and storing CO2 directly from the production process has the potential to reduce emissions by up to 85–95%. However, implementing this technology requires substantial investment and international cooperation [18].

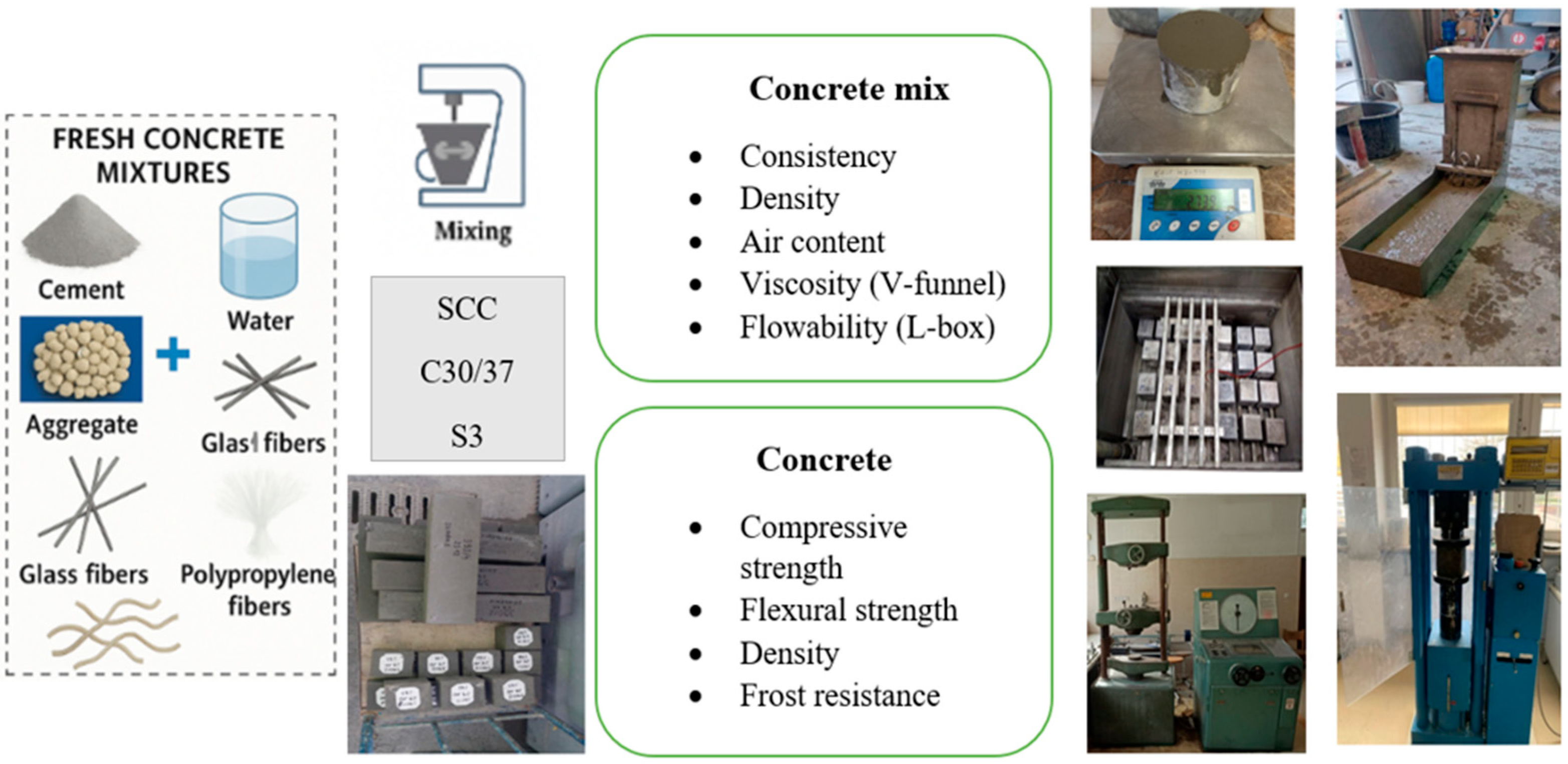

2. Materials and Methods

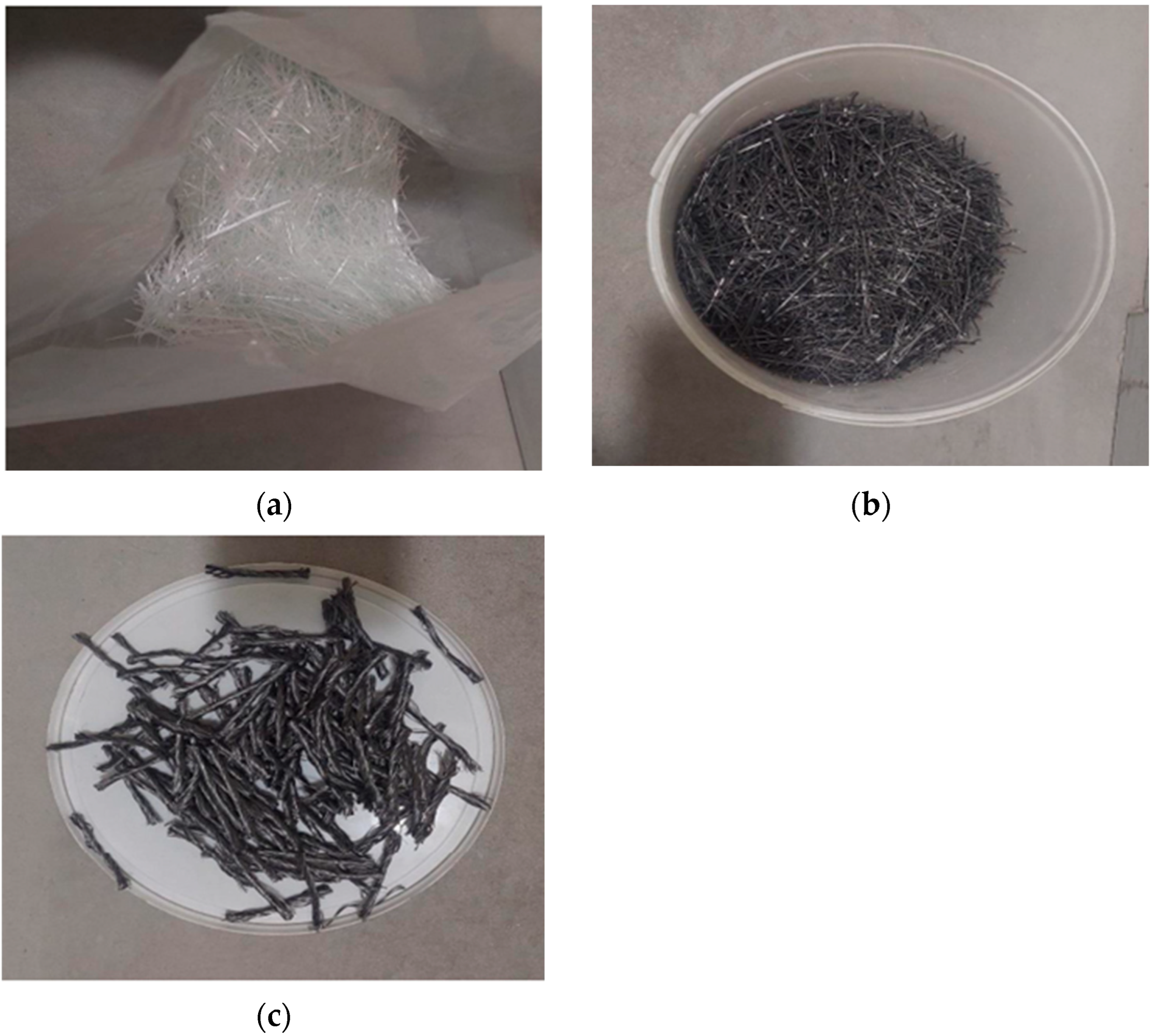

- BZ—reference concrete without added fibres;

- WPO—concrete with added polypropylene fibres;

- WSZ—concrete with added glass fibres;

- WST—concrete with added steel fibres.

- Consistency, according to EN 12350-2:2019-08, using the flow table method [46];

- Density, according to EN 12350-6:2019-08 [47];

- Air content, according to EN 12350-7:2019-08, using the pressure method [48];

- Viscosity using a V-funnel according to EN 12350-9:2012 [49];

- Flowability using an L-box according to EN 12350-10:2012 [50].

- Compressive strength, according to EN 12390-3:2019-07, on samples of dimensions 10 × 10 × 10 cm (after 3 samples) [51];

- Flexural strength according to EN on samples with dimensions of 10 × 10 × 40 cm (3 samples each) PN-EN 12390-5 [52];

- Density, according to EN 12390-7:2019-08 on samples with dimensions of 10 × 10 × 10 cm (3 samples each) [53];

- Frost resistance, according to PN-88/B-06250 on samples with dimensions of 10 × 10 × 10 cm (12 samples each) [54];

- Water absorption according to PN-88/B-06250 on samples with dimensions of 10 × 10 × 10 cm (3 samples each) [54].

3. Test Results and Their Analysis

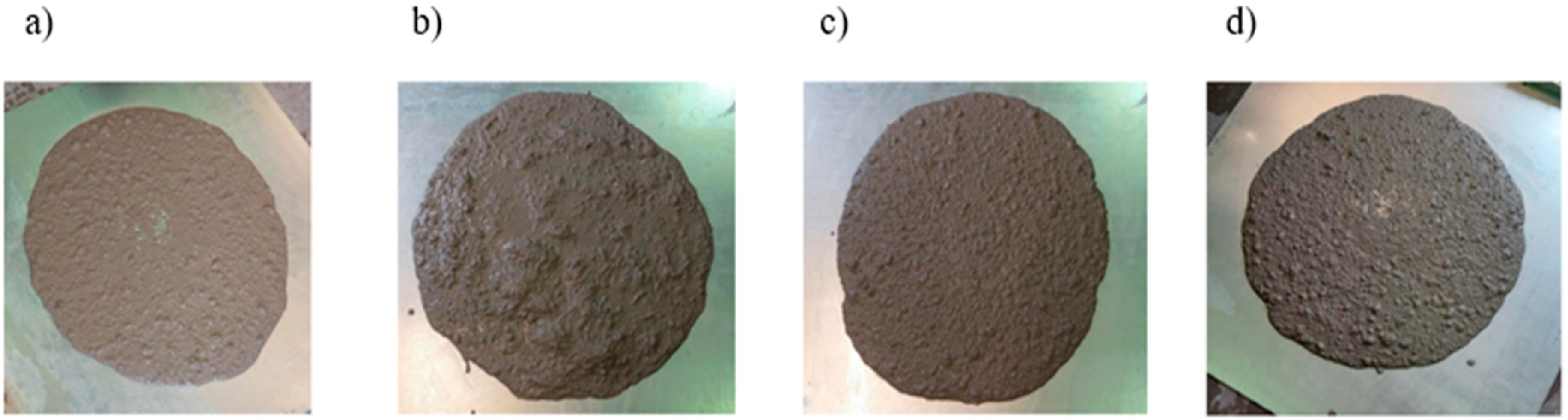

3.1. Concrete Mix

3.2. Mature Concrete

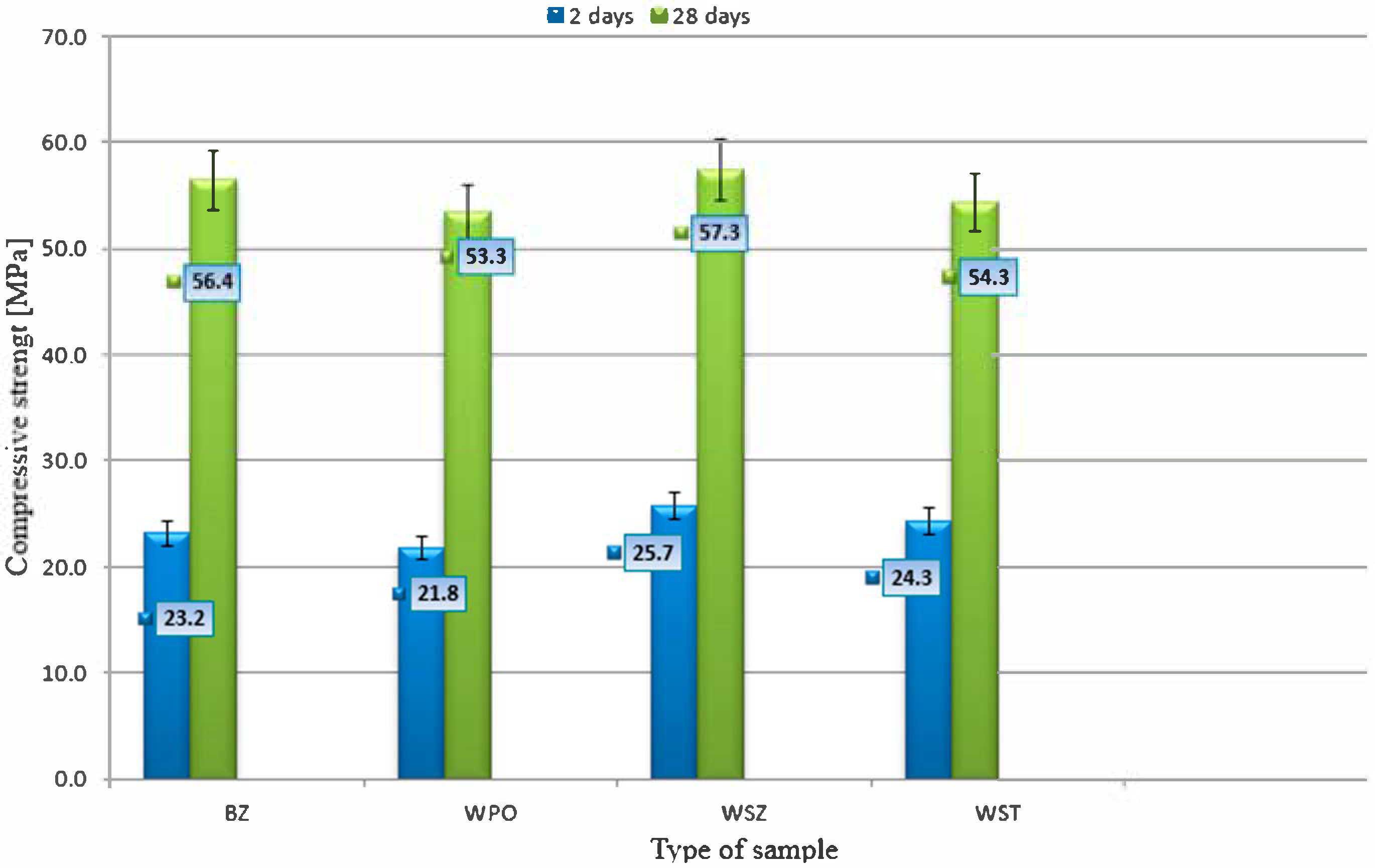

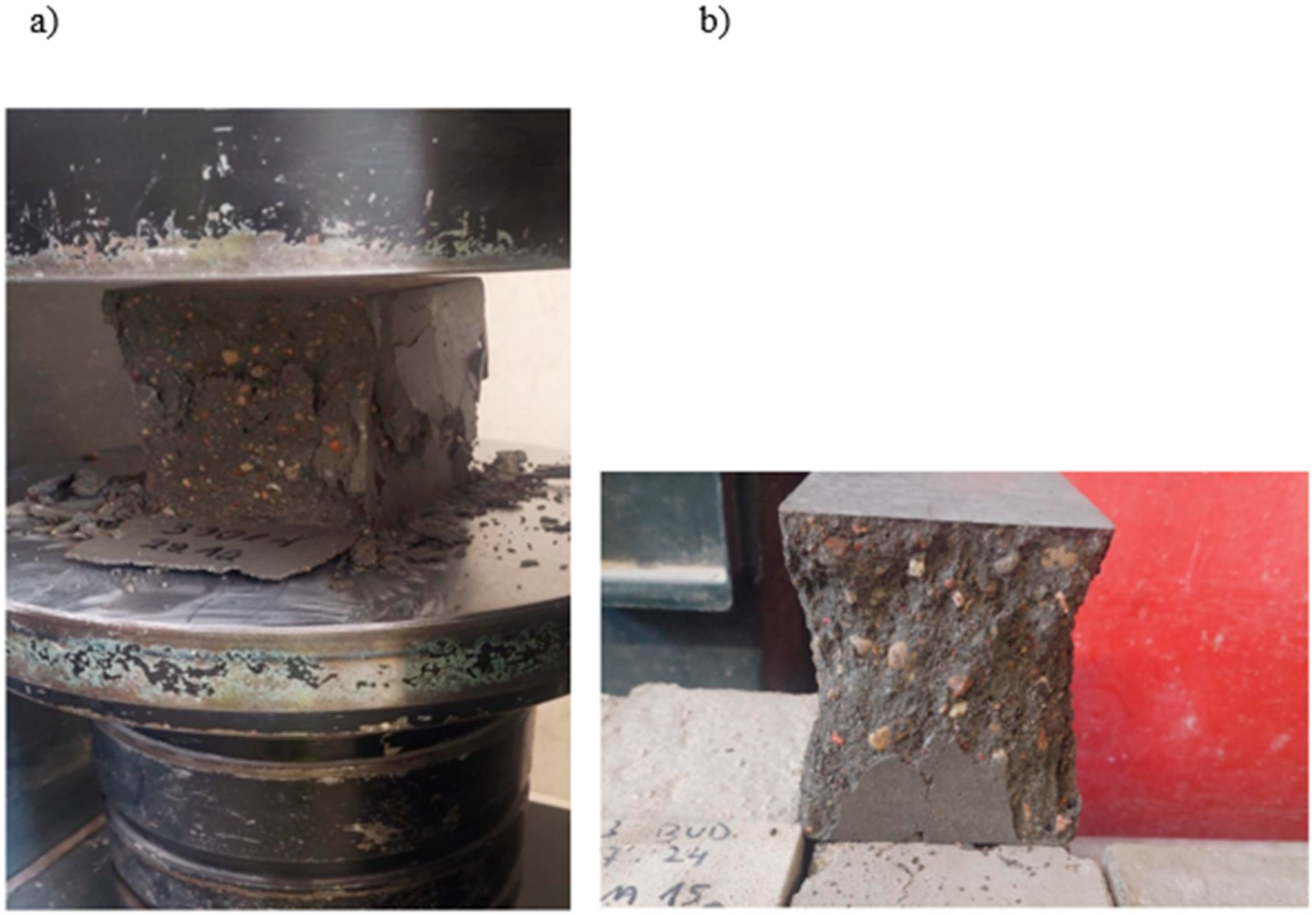

3.2.1. Compressive Strength

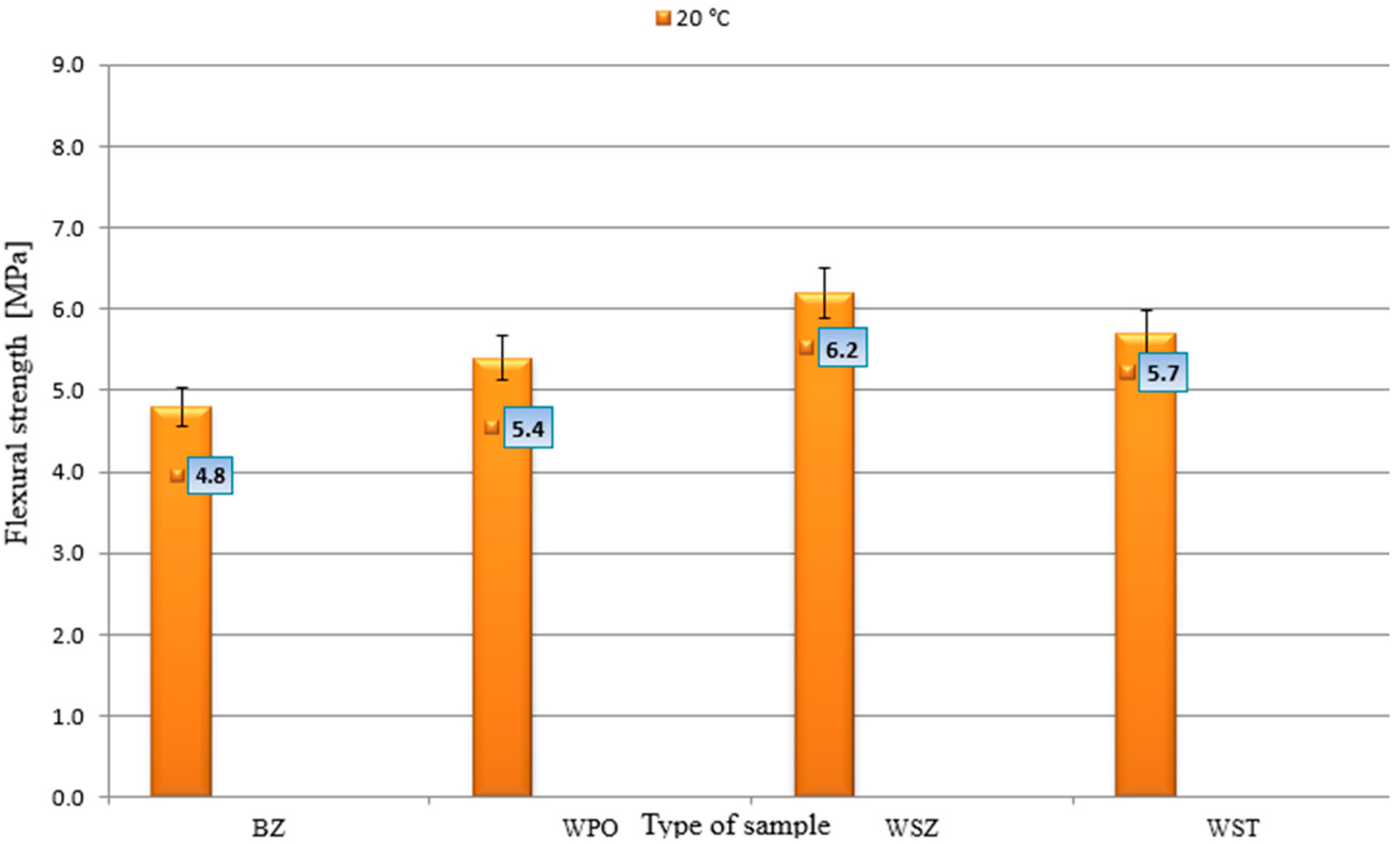

3.2.2. Flexural Strength

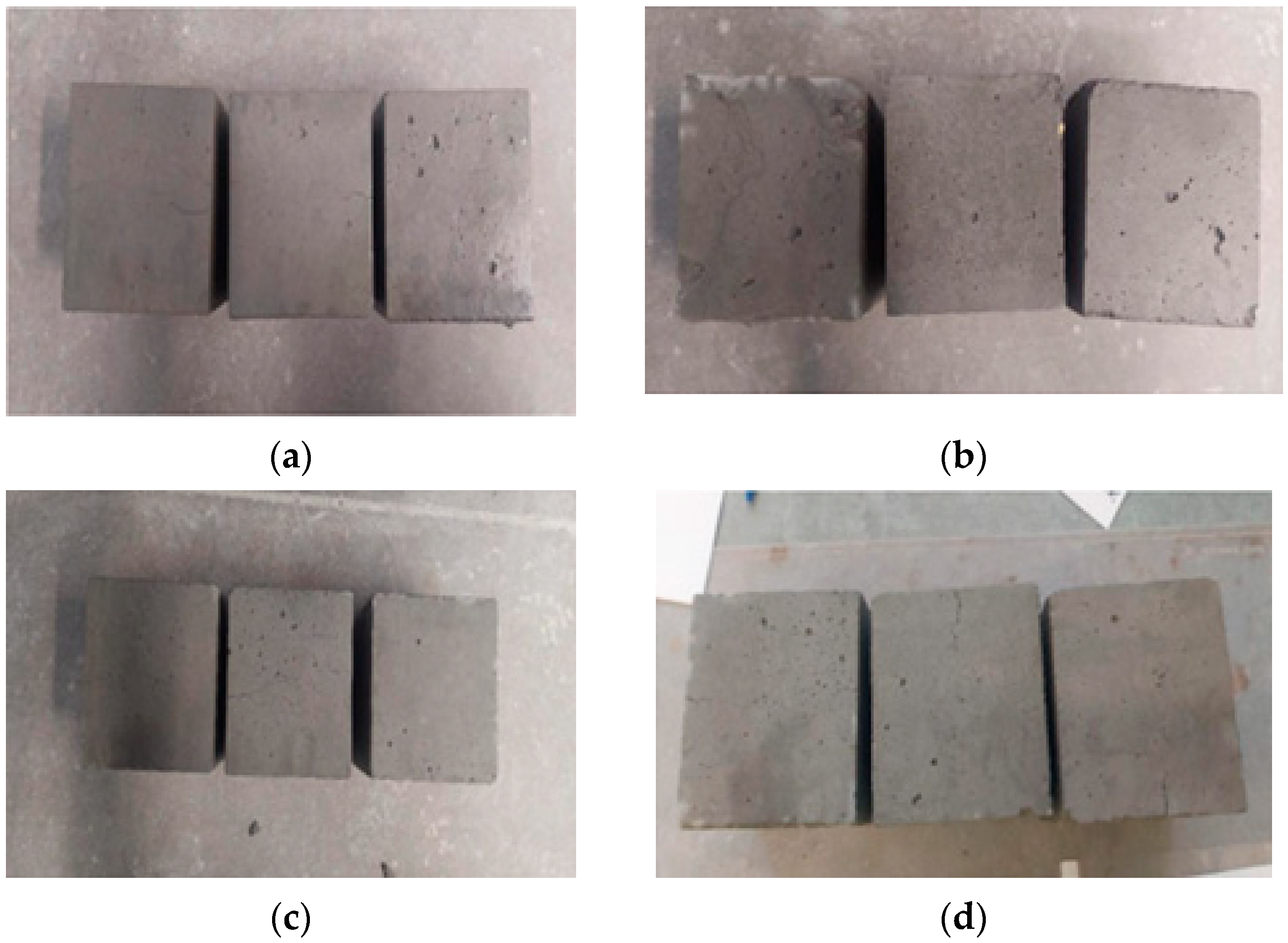

3.2.3. Frost Resistance

- No cracks in the samples after all freezing and thawing cycles;

- A difference of no more than 5% in the mass of samples soaked in water before and after the frost resistance test;

- A decrease in compressive strength between reference samples and frozen samples of no more than 20%.

3.2.4. Water Absorption

3.2.5. Concrete Density

3.3. Assessment of the Research in the Context of CO2 Emissions and the Possibility of Their Reduction by Using Alternative Materials

- Increased durability—concretes with added fibres exhibit better resistance to bending, abrasion, and frost, which extends their service life and reduces the need for repairs, thereby lowering emissions associated with maintenance and reconstruction.

- Improved frost resistance (WSZ and WST)—enhanced performance during freeze–thaw cycles minimises structural damage, reducing the need for repairs and renovations, and the consumption of cement, which in turn helps lower emissions.

- Mix optimisation—the potential to reduce the amount of cement used while maintaining high mechanical performance (especially in SCC reinforced with WSZ) can significantly contribute to lowering CO2 emissions.

- Steel fibres (WSTs)—have the largest carbon footprint due to the energy consumption involved in their manufacture.

- Glass fibres (WSZs)—require high temperatures for production, which also generates emissions, though lower than those associated with steel fibres.

- Polypropylene fibres (PPFs)—are derived from petroleum, resulting in emissions related to the processing of petrochemical resources.

- Reducing the amount of cement through the use of mineral additives.

- Use of cements with lower CO2 emissions.

- Use of natural fibres instead of synthetic ones.

4. Conclusions

- Compressive Strength—Glass fibres (GFs) improved compressive strength (+1.6%) and proved to be the most effective where concrete is required to exhibit high durability. The presence of steel (SF) and polypropylene fibres (PPFs) decreased compressive strength, which may be due to increased porosity or the suboptimal internal structure of the mix.

- Flexural Strength—The greatest increase in flexural strength was observed with glass fibres (+29.2%), suggesting their usefulness in structures exposed to dynamic loads and cracking risk. Steel fibres also significantly improved flexural strength (+18.8%), while polypropylene fibres, although to a lesser extent (+12.5%), still offered improvements over the reference mix.

- Water Absorption—The lowest water absorption was recorded in SCC with glass fibres (−10.9%), which translates into better durability in environments exposed to moisture and freeze–thaw cycles. Polypropylene fibres also reduced water absorption (−7.3%), which is important for elements prone to shrinkage and degradation. Steel fibres increased absorption (+26.6%), limiting their use in humid environments without additional protection.

- Density—The greatest increase in density was recorded in SCC with steel fibres (+1.81%) and polypropylene fibres (+1.77%), potentially increasing the self-weight of structural elements. The most optimal combination of density and strength was achieved with glass fibres (+0.99%), confirming their high performance.

- Glass fibres (GFs) show the best overall impact on mechanical properties and durability of SCC. They can contribute to reducing the need for repairs and extending the service life of structures, indirectly supporting CO2 reduction goals. They are recommended for use in precast elements, load-bearing structures, and constructions exposed to dynamic loads.

- Polypropylene fibres (PPFs) improve water absorption resistance and are particularly suitable for structures exposed to high humidity and shrinkage risks (e.g., tunnels, insulation, and fire-resistant components). Their low weight and thermal properties may support the design of lighter, more sustainable structures.

- Steel fibres (SFs) enhance flexural strength, making them suitable for industrial floors and other elements subjected to heavy dynamic loads. However, their increased water absorption limits their use in aggressive environments without additional protective measures.

- The use of fibres as additives to SCC can form part of a broader CO2 reduction strategy in construction—by increasing durability, reducing repair frequency, and partially replacing cement. While fibres themselves do not directly reduce emissions from cement production, their application aligns with broader sustainable development objectives.

- This research results indicate that the optimal selection of fibre type and quantity can not only improve SCC properties but also increase its durability, thereby reducing the overall carbon footprint over the structure’s life cycle.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ogrodnik, P.; Szulej, J.; Franus, W. The wastes of sanitary ceramics as recycling aggregate to special concretes. Materials 2018, 11, 1275. [Google Scholar] [CrossRef] [PubMed]

- Ogrodnik, P.; Szulej, J. The assessment of possibility of using sanitary ceramic waste as concrete aggregate—Determination of the basic material characteristics. Appl. Sci. 2018, 8, 1205. [Google Scholar] [CrossRef]

- Klimek, B.; Szulej, J.; Ogrodnik, P. The effect of replacing sand with aggregate from sanitary ceramic waste on the durability of stucco mortars. Clean Technol. Environ. Policy 2020, 22, 1929–1941. [Google Scholar] [CrossRef]

- Szulej, J.; Ogrodnik, P.; Klimek, B. Zeolite tuff and recycled ceramic sanitary ware aggregate in production of concrete. Sustainability 2019, 11, 1782. [Google Scholar] [CrossRef]

- Powęzka, A.; Szulej, J.; Ogrodnik, P. Reuse of heat resistant glass cullet in cement composites subjected to thermal load. Materials 2020, 13, 4434. [Google Scholar] [CrossRef]

- Rutkowska, G.; Ogrodnik, P.; Żółtowski, M.; Powęzka, A.; Kucharski, M.; Krejsa, M. Fly Ash from the Thermal Transformation of Sewage Sludge as an Additive to Concrete Resistant to Environmental Influences in Communication Tunnels. Appl. Sci. 2022, 12, 1802. [Google Scholar] [CrossRef]

- Ogrodnik, P.; Rutkowska, G.; Szulej, J.; Żółtowski, M.; Powęzka, A.; Badyda, A. Cement Mortars with Addition of Fly Ash from Thermal Transformation of Sewage Sludge and Zeolite. Energies 2022, 15, 1399. [Google Scholar] [CrossRef]

- Szulej, J.; Ogrodnik, P.; Chyliński, F.; Klimek, B.; Powęzka, A.; Żółtowski, M.; Baryłka, A. The Use of Recycled Ceramics and Ash from Municipal Sewage Sludge as Concrete Fillers. Sustainability 2024, 16, 11251. [Google Scholar] [CrossRef]

- International Statistics Yearbook. Available online: https://stat.gov.pl/en/topics/statistical-yearbooks/statistical-yearbooks/concise-statistical-yearbook-of-poland-2020,1,21.html (accessed on 12 February 2025).

- IEA—Shaping a Secure and Sustainable Energy Future for All. Available online: www.iea.org (accessed on 12 February 2025).

- Aïtcin, P.C. Cements of yesterday and today: Concrete of tomorrow. Cem. Concr. Res. 2000, 30, 1349–1359. [Google Scholar] [CrossRef]

- AR6 Synthesis Report: Climate Change 2023. Available online: https://www.ipcc.ch/report/sixth-assessment-report-cycle (accessed on 12 March 2023).

- Amran, M.; Makul, N.; Fediuk, R.; Lee, Y.H.; Vatin, N.I.; Lee, Y.Y.; Mohammed, K. Global carbon recoverability experiences from the cement industry. Case Stud. Constr. Mater. 2022, 17, e01439. [Google Scholar] [CrossRef]

- Andrew, R.M. Global CO2 emissions from cement production, 1928–2018. Earth Syst. Sci. Data. 2019, 11, 1675–1710. [Google Scholar] [CrossRef]

- Tollefson, J. Can the world’s most polluting heavy industries decarbonize. Available online: https://e360.yale.edu/features/can-the-worlds-most-polluting-heavy-industries-decarbonize (accessed on 23 September 2021).

- European Commission. Fit for 55: Delivering the EU’s 2030 Climate Target on the Way to Climate Neutrality. Available online: https://ec.europa.eu/commission/presscorner/detail/en/IP_21_3541 (accessed on 14 July 2021).

- CEMBUREAU. Activity Report 2021. Available online: https://cembureau.eu/media/03cgodyp/2021-activity-report.pdf (accessed on 27 June 2022).

- Chatham House. Making Concrete Change: Innovation in Low-Carbon Cement and Concrete. 2018. Available online: https://www.chathamhouse.org/2018/06/making-concrete-change-innovation-low-carbon-cement-and-concrete (accessed on 14 December 2020).

- Van Damme, H. Concrete material science: Past, present, and future innovations. Cem. Concr. Res. 2018, 112, 5–24. [Google Scholar] [CrossRef]

- Smith, J.; Peters, R. The Role of Alternative Materials in Reducing CO2 Emissions in the Concrete Industry. J. Clean. Prod. 2018, 200, 150–160. [Google Scholar]

- Deja, J.; Gawlicki, M.; Kohutek, Z.B.; Kotwica, Ł.; Łagosz, A.; Mróz, R.; Pichór, W. Beton: Technologie i Metody Badań; Stowarzyszenie Producentów Cementu, Silesian University of Technology: Kraków, Polska, 2020; p. 940. [Google Scholar]

- Gołaszewski, J. Projektowanie Betonu Samozagęszczalnego; Wydawnictwo Naukowe PWN SA: Warszawa, Polska, 2021; p. 188. [Google Scholar]

- Ogrodnik, P.; Rutkowska, G.; Powęzka, A.; Żółtowski, M.; Szulej, J.; Wiśniewski, K.; Howorus, P. Research on the Effect of Fire Thermal Energy on the Microstructure and Properties Mechanical of Fiber-Reinforced Cement Mortars. Energies 2023, 16, 6450. [Google Scholar] [CrossRef]

- EN 206+A2:2021-08; Concrete—Requirements, Performance, Production and Compliance. European Commission: Brussels, Belgium, 2021.

- De La Rosa, A.; Ruiz, G.; Poveda, E.; Cifuentes, H. Optimizing constituent ranges in self-compacting steel-fiber reinforced concrete: A methodological approach. Constr. Build. Mater. 2025, 482, 141434. [Google Scholar] [CrossRef]

- Persson, B. On the internal frostresistance of self-compacting concrete, with and without polypropylene fibres. Mater. Struct. 2006, 39, 707–716. [Google Scholar] [CrossRef]

- Szwabowski, J.; Miera, P. Frost resistance of self-compacting concrete reinforced with polypropylene fiber. In Proceedings of the Concrete Days: Tradition and Modernity. Conference, Wisła, Poland, 11–13 October 2010; pp. 807–815. [Google Scholar]

- De La Rosa, A.; Ruiz, G.; Moreno, R. Experimental study on quasi-static mixed mode fracture in self-compacting concrete with longitudinal reinforcement and steel fibers. Theor. Appl. Fract. Mech. 2025, 135, 104776. [Google Scholar] [CrossRef]

- Al Rifai, M.; Sikora, K.; Hadi, M. Effect of micro steel fibers volume fraction on behavior of high-strength self-compacting concrete. Constr. Build. Mater. 2024, 450, 138709. [Google Scholar] [CrossRef]

- Eltantawi, I.; Sheikh; Hadi, M. Influence of stainless steel fibres on the mechanical properties of self-compacting ultra-high-performance geopolymer concrete. Constr. Build. Mater. 2025, 463, 140092. [Google Scholar] [CrossRef]

- Al Rifai, M.; Sikora, K.; Hadi, M. Magnetic alignment of micro steel fibers embedded in self-compacting concrete. Constr. Build. Mater. 2024, 412, 134796. [Google Scholar] [CrossRef]

- Ponikiewski, T. Relationships between self-compaction and strength of fiber concrete in the aspect of variable technological factors. Motorw. Mag. 2012, 7, 38–42. [Google Scholar]

- Prasad, M.L.V.; Kumar, P.R. Determination of the bending moment—Curvature relationship of self-compacting fiber concrete with longitudinal and transverse reinforcement. Cement. Wapno. Beton. 2015, 5, 269–283. [Google Scholar]

- Ponikiewski, T. Technological Aspects of the Use of Self-Compacting Concrete Modified with Dispersed Reinforcement; Scientific Works of the Institute of Civil Engineering of the Wrocław University of Science and Technology, Series: Studies and Materials—Technology and Management in Construction; Publishing House of the Wrocław University of Science and Technology: Wrocław, Poland, 2006; Volume 87, pp. 75–82. [Google Scholar]

- Ponikiewski, T.; Szwabowski, J. Workability and strength of self-compacting concretes modified with steel fibers. In Proceedings of the 20th Scientific and Technical Conference “Concrete and Prefabrication—Jadwisin 2006”, Serock, Poland, 17–19 May 2006; pp. 22–29. [Google Scholar]

- Moghaddam, H.; Lotfollahi-Yaghin, M.; Maleki, A. Comprehensive analysis of mechanical characteristics in self-compacting concrete (SCC) with aluminum oxide (Al2O3) nanoparticles and glass fibers: An experimental and analytical investigation. Case Stud. Constr. Mater. 2025, 22, e04095. [Google Scholar] [CrossRef]

- Zhang, F.; Lu, Z.; Wang, D. Working and mechanical properties of waste glass fiber reinforced self-compacting recycled concrete. Constr. Build. Mater. 2024, 439, 137172. [Google Scholar] [CrossRef]

- Nwaokete, D.; Ince, C.; Derogar, S.; Nicolaides, D.; Ball, R. Environmental impact and sustainable development of pozzolanic concrete incorporating polypropylene fibers: A database study. Resour. Conserv. Recycl. 2025, 215, 108142. [Google Scholar] [CrossRef]

- Altalabani, D.; Bzeni, D.; Linsel, S. Mechanical properties and load deflection relationship of polypropylene fiber reinforced self-compacting lightweight concrete. Constr. Build. Mater. 2020, 252, 119084. [Google Scholar] [CrossRef]

- EN 197-1:2012; Cement—Part 1: Composition, Requirements and Conformity Criteria for Common Cements. Association Francaise de Normalisation: Saint-Denis, France, 2012.

- Cement Manufacturer’s Details. 2024. Available online: https://www.cemex.pl/cementownia-chelm.aspx (accessed on 19 May 2025).

- EN 1097-6:2022-07; Tests for Mechanical and Physical Properties of Aggregates—Part 6: Determination of Particle Density and Water Absorption. European Commission: Brussels, Belgium, 2022.

- EN 1008:2004; Mixing Water for Concrete. European Commission: Brussels, Belgium, 2004.

- Admixture Manufacturer Data. 2024. Available online: www.cemex.pl/isoplast-1528 (accessed on 19 May 2025).

- Admixture Manufacturer Data. 2024. Available online: www.cemex.pl/isoflow-7495 (accessed on 19 May 2025).

- EN 12350-2:2019-07; Testing Concrete Mix—Part 2: Consistency Testing by the Slump Cone Method. European Commission: Brussels, Belgium, 2019.

- EN 12350-6:2019-08; Testing of Concrete Mix—Part 6: Density. European Commission: Brussels, Belgium, 2019.

- EN 12350-7:2019-08; Testing of Concrete Mix—Part 7: Air Content—Pressure Methods. European Commission: Brussels, Belgium, 2019.

- EN 12350-9:2012; Testing of Concrete Mix (Designation of Concrete Properties SCC)—Part 9: Viscosity Test Using a V-Funnel. European Commission: Brussels, Belgium, 2012.

- EN 12350-10:2012; Testing of Concrete Mix (SCC Concrete Properties Marking)—Flowability Test Using L-Box. European Commission: Brussels, Belgium, 2012.

- EN 12390-3:2019-07; Testing of Concrete—Part 3: Compressive Strength of Test Specimens. European Commission: Brussels, Belgium, 2019.

- EN 12390-5:2019-08; Testing of Concrete—Part 5: Flexural Strength of Test Specimens. European Commission: Brussels, Belgium, 2019.

- EN 12390-7:2019-08; Concrete Testing—Part 7: Density of Concrete. European Commission: Brussels, Belgium, 2019.

- PN-88/B-06250:2004; Ordinary Concrete. European Commission: Brussels, Belgium, 2004.

| Properties | Assumptions | Test Results |

|---|---|---|

| sulphate content (as SO3) | 4.0 | 2.89 |

| chloride content [%] | ≤0.10 | 0.058 |

| start of setting time [min] | ≥60 | 214 |

| end of setting time [min] | - | 251 |

| volume stability [mm] | ≤10 | 1.5 |

| water demand [%] | - | 29.2 |

| compressive strength [MPa] after 2 days/after 28 days | ≥20.0 | 24.1 |

| ≥42.5 and ≤62.5 | 52.4 | |

| specific surface area [cm3/g] | - | 4620 |

| alkali content Na2Oeq [%] | - | 0.79 |

| Properties | Isoplast 1528 | Isoflow 7495 |

|---|---|---|

| density [g/cm3] | 1.14 ± 0.03 | 1.07 ± 0.02 |

| form | liquid | liquid |

| color | brown | light yellow |

| pH | 5.0 ± 1.0 | 4.0 ± 1.0 |

| content Cl− [%] | ≤0.10% | ≤0.10 |

| content Na2O [%] | ≤1.50% | ≤1.50 |

| Type of Concrete | Concrete-Mix Components [kg/m3] | ||||||

|---|---|---|---|---|---|---|---|

| Water | Sand | Gravel | Cement | Fibres | Isoplast | Isoflow | |

| BZ | 160 | 640 | 960 | 380 | - | 2.67 | 5.70 |

| WPO | 160 | 634 | 951 | 380 | 3.00 | 2.67 | 7.22 |

| WSZ | 160 | 634 | 951 | 380 | 5.00 | 2.67 | 6.84 |

| WST | 180 | 613 | 920 | 380 | 25.00 | 2.67 | 6.27 |

| Type of Concrete | Properties of Concrete Mix | ||||

|---|---|---|---|---|---|

| Consistency/Flow Diameter [mm] | Density [kg/m3] | Air Content [%] | Viscosity [s] | PL2 Throughput Rate | |

| BZ | SF1/625 | 2.298 | 3.0 | 6.5/VF1 | 0.90 |

| WPO | SF1/595 | 2.292 | 3.0 | 9.5/VF2 | 0.80 |

| WSZ | SF1/600 | 2.296 | 3.0 | 6.5/VF1 | 1.00 |

| WST | SF1/620 | 2.314 | 3.0 | 7.0/VF1 | 0.95 |

| Type of Concrete | Average Compressive Strength [MPa] | Average Strength Loss of Samples Subjected to Freezing [%] | Average Weight [g] | Average Weight Loss [%] | ||

|---|---|---|---|---|---|---|

| Base Samples | After 150 Freezing Cycles | Before Freezing | After 150 Freezing Cycles | |||

| BZ | 63.89 | 36.08 | 43.53 | 2337.2 | 2342.8 | 0.242 |

| WPO | 60.95 | 39.62 | 35.00 | 2372.2 | 2401.3 | 1.226 |

| WSZ | 64.12 | 37.74 | 41.14 | 2333.7 | 2367.3 | 1.443 |

| WST | 60.96 | 37.46 | 38.55 | 2380.1 | 2410.5 | 1.278 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rutkowska, G.; Szulej, J.; Ogrodnik, P. The Influence of Fibre and Fly Ash Additions on the Properties of Self-Compacting Concrete. Materials 2025, 18, 2565. https://doi.org/10.3390/ma18112565

Rutkowska G, Szulej J, Ogrodnik P. The Influence of Fibre and Fly Ash Additions on the Properties of Self-Compacting Concrete. Materials. 2025; 18(11):2565. https://doi.org/10.3390/ma18112565

Chicago/Turabian StyleRutkowska, Gabriela, Jacek Szulej, and Paweł Ogrodnik. 2025. "The Influence of Fibre and Fly Ash Additions on the Properties of Self-Compacting Concrete" Materials 18, no. 11: 2565. https://doi.org/10.3390/ma18112565

APA StyleRutkowska, G., Szulej, J., & Ogrodnik, P. (2025). The Influence of Fibre and Fly Ash Additions on the Properties of Self-Compacting Concrete. Materials, 18(11), 2565. https://doi.org/10.3390/ma18112565