Advanced Non-Destructive Testing Simulation and Modeling Approaches for Fiber-Reinforced Polymer Pipes: A Review

Abstract

1. Introduction

2. Overview of Non-Destructive Testing (NDT)

2.1. Conventional NDT Techniques and Their Applications

- Ultrasonic testing (UT): High-frequency sound waves are transmitted to a material to detect internal flaws, characterize thickness, or evaluate bonding quality [18,19,20,21]. UT is effective for metallic and some composite materials, but may face limitations in highly attenuative or anisotropic materials such as FRP [22].

- Magnetic particle testing (MT): Detects surface and near-surface discontinuities in ferromagnetic materials by applying magnetic fields and ferrous particles. MT is inapplicable to nonmagnetic materials, such as FRP.

- Visual inspection (VI): The simplest form of NDT that relies on direct observation to detect visible defects. However, it is inherently limited to surface-level defects and is highly subjective.

2.2. Challenges of Conventional NDT on Composite Structures

- Anisotropic and heterogeneous nature: FRP materials consist of fiber and resin matrices with directional properties, making wave propagation unpredictable in UT and other wave-based methods.

- Complex defect modes: FRP structures exhibit unique failure mechanisms, such as delamination, fiber breakage, matrix cracking, and void formation, many of which are difficult to detect using surface-focused methods such as PT or VI.

- Low density and low contrast: RT struggles to differentiate between the matrix and fiber in FRP materials owing to the low X-ray absorption contrast compared to metallic materials.

- Human interpretation dependency: Many NDT results, especially from AET and UT, rely heavily on the expertise of the inspector, leading to inconsistencies and subjectivity in defect characterization [44].

- Limited depth resolution: Techniques such as IRT and PT are constrained to detect surface or near-surface anomalies, which may not capture the critical subsurface damage in thick-walled FRP structures.

- Inspection time and cost: Traditional methods may require multiple setups, manual scanning, and subjective interpretation, leading to increased inspection times and costs, particularly for large or complex FRP installations.

2.3. The Need for Advanced NDT Approaches

- Advanced imaging and sensing technologies: such as X-ray computed tomography (XCT) [61,62,63,64], phased array ultrasonic testing (PAUT) [65,66,67,68,69], eddy current testing (ECT) [70,71,72], high-frequency eddy current testing (HF-ECT) [73,74,75], and thermographic methods optimized through simulation [76,77,78].

3. Fiber-Reinforced Polymer/Plastic

3.1. Types of Fiber-Reinforced Polymer

- Carbon fiber-reinforced polymer (CFRP): CFRP composites employ carbon fibers as reinforcements with a noteworthy strength-to-weight ratio and stiffness. Apart from typical carbon material attributes such as high-temperature resistance, friction resistance, and corrosion resistance, CFRP possesses exceptional specific strength, specific modulus, and fatigue resistance [83,84]. CFRPs can be used as CFRP materials in aerospace, automotive, sporting goods, and structural engineering applications [85].

- Aramid fiber-reinforced polymer (AFRP): AFRP composites incorporate aramid fibers, such as Kevlar, for reinforcement. These fibers impart high tensile strength, impact resistance, and flame resistance to the composite materials [86]. AFRP is commonly used in body armor, protective gears, and structural applications where high strength and durability are critical [87,88].

- Natural fiber-reinforced polymer (NFRP): NFRP composites incorporate natural fibers, such as jute, hemp, or flax, as reinforcements and are valued for their environmental friendliness, nonhomogeneous composition, and diverse applications in automotive interiors, furniture, and construction [93,94,95]. Natural fibers have gained significant attention in recent years owing to their numerous advantages including cost-effectiveness, low density, exceptional flexibility, recyclability, and sustainability. However, their widespread use is limited by their relatively low impact strength and hydrophilicity [96].

- Hybrid fiber-reinforced polymer (HFRP): HFRP composites are formulated by combining various fiber types, including natural/synthetic hybrid fibers, to achieve a comprehensive balance of properties such as strength, stiffness, and cost-effectiveness [97,98,99]. These composites were designed to satisfy the specific requirements of applications that require a combination of attributes [100,101,102,103].

Thermoplastic Resins in FRP Manufacturing

3.2. Manufacturing Method

- Pultrusion process: Pultruded FRP composites are fabricated by pulling continuous fibers through a resin bath and then through a shaping die. This process created continuous profiles with consistent cross-sectional shapes. Pultruded FRP is used in structural applications, such as beams, tubes, and rods [137].

- Filament-wound process: Filament-wound FRP composites are created by winding continuous fibers, typically glass or carbon, around a rotating mandrel and impregnating them with resin. This method produces cylindrical or tubular shapes and is commonly used in pressure vessels and pipes [138].

- Hand lay-up process: Hand lay-up FRP involves manually applying layers of fiber and resin to a mold. This is a versatile method for creating custom FRP products or for small-area repair of FRP products. However, they may exhibit variations in their quality and consistency [139].

- Spray-up process: Spray-up FRP involves spraying a mixture of chopped fibers and resin onto a mold. This is a fast and cost-effective method to obtain large and simple shapes [140].

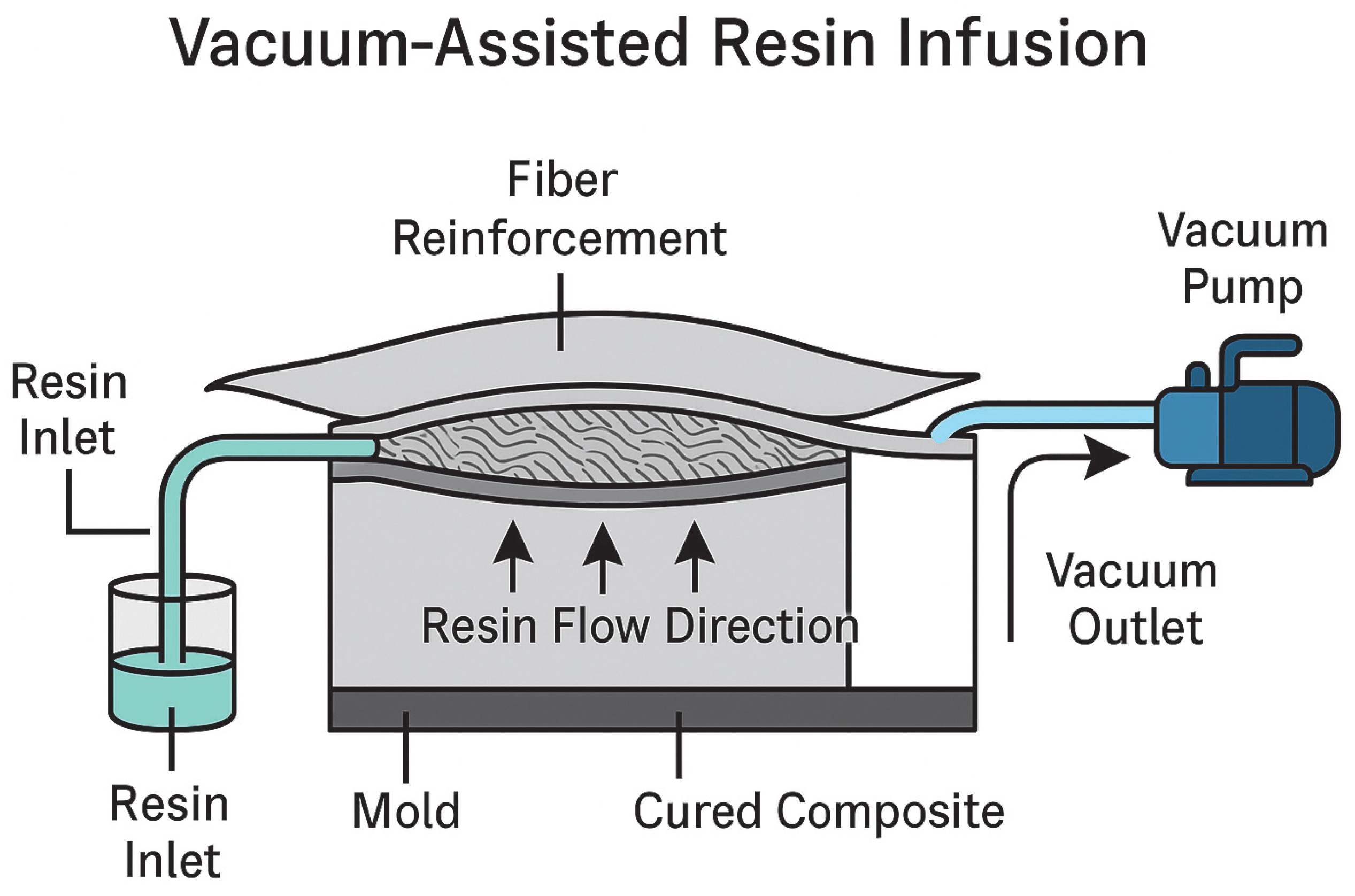

3.2.1. Vacuum- and Pressure-Assisted Resin Infusion Methods

3.2.2. Materials and Manufacturing Technologies for FRP Pipe Production

3.3. Common Defects in FRP Materials During Manufacturing

- Voids: Voids are areas within composite materials that contain air pockets that weaken their structure and reduce their strength [158]. The formation of voids can be attributed to several factors including incomplete resin wetting, entrapped air bubbles during lay-up or infusion, and resin shrinkage. To prevent the formation of voids, it is crucial to ensure thorough mixing of the resin and proper wetting of the fibers [159]. Additionally, vacuum- or pressure-assisted resin infusion should be implemented to reduce air entrapment, and the curing conditions should be controlled to minimize resin shrinkage [160].

- Delamination: Delamination is a phenomenon that occurs when the layers of reinforcement fibers separate, leading to a reduction in the material’s integrity and expansion during service while increasing the stress and impact [161]. The formation of delamination can be attributed to several factors, including poor bonding, inadequate pressure during curing, and repeated thermal stress. To prevent delamination, it is crucial to ensure that adequate pressure is applied during curing and good surface preparation. Additionally, the design components should be minimized to reduce the thermal cycling stress and prevent delamination [162,163,164].

- Fiber misalignment: Improper fiber alignment can result in the creation of weak points or anisotropy in the composite material. This may be caused by inadequate equipment maintenance, incorrect positioning during the lay-up process, or inadequate training of personnel. Regular equipment maintenance and personnel training are essential for preventing fiber misalignment [165,166].

- Resin-rich or resin-poor areas: An inconsistent distribution of resin or uneven fiber distribution can result in areas with either excessive or inadequate resin content, which can negatively impact the structural integrity [158]. This is caused by improper resin application during the lay-up process, and the resin flow within the mold may not be consistent. To prevent the need for careful control of resin application, it is vital to ensure even coverage and consistent resin flow.

- Surface imperfections: The presence of cracks, bubbles, or other irregularities on the surfaces of FRP components can negatively affect their aesthetic appearance and functionality. The appearance of these imperfections can be attributed to several factors, including defects or damage to the mold, contaminants, or foreign particles present during the lay-up process, and variations in the curing process. To prevent the formation of surface imperfections, it is recommended to regularly inspect and maintain the molds, ensure a clean and controlled environment during the lay-up process, and monitor and control curing conditions to ensure consistency.

Geometric Deformation Defects

- Spring-in: Spring-in manifests as an angular deviation in the curved or angled parts when they relax after demolding. This defect is commonly observed in elbows, flanges, and pipe fittings, where the final angle exceeds the intended dimensions, leading to assembly and alignment complications. The root causes of spring-in include residual stresses within the composite, differential thermal contraction between the fiber and resin matrix, and uneven curing shrinkage. To mitigate spring-in, manufacturers can optimize tooling design and cure schedules, implement symmetric fiber layups to balance stresses, and utilize process simulations to predict and compensate for the expected deformations. Additionally, post-curing treatments or mechanical trimming can be employed to restore dimensional tolerances [167].

- Warpage: Warpage occurs when a component is distorted out of the plane, resulting in dimensional instability or surface waviness. In FRP pipes, warpage can affect the roundness, straightness, and flange flatness of the product, thereby complicating sealing and joint integrity. The factors contributing to warpage include asymmetric layups, uneven curing, thermal gradients, and tooling design limitations [168]. To prevent warpage, it is essential to design symmetric fiber layups, control curing conditions to ensure uniformity, and optimize tooling to minimize the thermal gradients. Advanced process simulations can also be used to predict and compensate for warpage tendencies, while post-processing steps, such as controlled cooling and mechanical straightening, can help restore dimensional accuracy [169,170].

- Shrinkage: Shrinkage is another critical geometric deformation defect that occurs during the curing or cooling of FRP components. As the resin cures and cools, it contracts, potentially leading to dimensional reductions in pipe diameter or thickness [171]. Excessive shrinkage can cause fitment issues and compromise the pressure containment capability of the pipes. The primary causes of shrinkage include the inherent volumetric contraction of the resin during curing and the differential cooling rates between the composite and mold [172,173]. To mitigate shrinkage, manufacturers can select low-shrinkage resin formulations, optimize curing cycles to control cooling rates, and employ shrinkage-compensating tooling designs. Additionally, incorporating reinforcing fibers with appropriate coefficients of thermal expansion can help reduce shrinkage-related deformation [174,175].

4. Using Digital Technologies to Enhance NDT Performance

4.1. Numerical Modeling and Simulation: Purpose and Classification of Methods

- To categorize the leading numerical methods applied in NDT, including FEM, BEM, finite integration technique (FIT), Monte Carlo simulation, and semi-analytical models.

- To demonstrate their practical applications across various NDT techniques, they were supported by findings from recent literature.

- To summarize their comparative advantages, limitations, and reported performance metrics to assist practitioners and researchers in selecting appropriate methods for specific NDT scenarios.

4.1.1. Finite Element Method Applications in NDT

- Acharjee and Bandyopadhyay [179] applied FEM to assess the structural integrity of fire-damaged reinforced concrete members, demonstrating how temperature load impacts structural responses and validating their computational predictions with experimental results.

- Munalli et al. [180] combined FIT and FEM to simulate microwave-based NDT to detect damage in CFRP materials. Their study analyzed scattering parameters (S-parameters) to differentiate between healthy and damaged regions, showing a good correlation with experimental data.

- Evans et al. [181] integrated the FEM with experimental validation to predict the type, location, and extent of impact damage in CFRP laminates subjected to low-velocity impacts. Their hybrid modeling-experimental approach provided a comprehensive understanding of the damage mechanisms.

- Feito et al. [182] used FEM to simulate the mechanical behavior of open-hole CFRP laminates under tensile and fatigue loading and achieved close agreement with the experimental strain distribution and crack progression results.

- Fang and Maldague [40] utilized the FEM to model the thermal response of CFRP specimens with controlled defects. Their simulation data were subsequently used to train a gated recurrent unit (GRU) deep learning model, which successfully quantified the defect depth from thermal signals.

- Ratsakou et al. [183] validated a semi-analytical truncated region eigenfunction expansion (TREE) model by comparing it with FEM-based COMSOL simulations for the IRT of delaminated planar structures, confirming FEM’s role as a validation benchmark.

- Notebaert et al. [184] demonstrated the use of COMSOL Multiphysics FEM simulations to model the active thermographic inspections of additively manufactured composite parts, achieving a high degree of agreement between the simulated and experimental results.

- Kim et al. [185] focused on modeling and simulating IRT to detect subsurface defects in hydroelectric penstocks. The study used ANSYS version 19.2.0 to build a 3D penstock model and simulate lock-in infrared thermography.

4.1.2. Boundary Element Method (BEM) and Semi-Analytical Models

- Baskaran et al. [189] developed a BEM-based framework to model the eddy current responses for flaw detection in conductive materials. Their study integrated BEM results with Gaussian statistical models to improve POD estimation, demonstrating that BEM could accurately compute impedance changes with less than 5% error compared to the experimental data.

- Apostol et al. [72] proposed analytical and numerical models based on Maxwell’s equations to enhance ECT signal interpretation. Their approach validated the numerical results using semi-analytical solutions, reinforcing the reliability of the BEM in electromagnetic NDT.

- Hachi et al. [190] employed a hybrid 3D FEM and magnetic vector potential formulation to simulate the eddy current density distribution in CFRP composites. Their work highlighted the anisotropic electrical behavior of CFRP, demonstrating BEM’s applicability in complex material characterizations.

- Ratsakou et al. [183] developed a TREE semi-analytical model to simulate heat propagation in delaminated structures. Their results showed strong agreement with the FEM-based COMSOL simulations, validating the efficiency and accuracy of their approach for infrared thermography applications.

- Apostol et al. [72] further demonstrated the usefulness of analytical modeling in eddy current analysis, providing closed-form solutions for magnetic vector potentials in layered media.

- Hachi et al. [190] validated their numerical results using analytical solutions for unidirectional CFRP plates, ensuring the consistency and reliability of their computational models.

4.1.3. Finite Integration Technique (FIT), Monte Carlo Methods, and Other Numerical Approaches

Finite Integration Technique

- Munalli et al. [180] combined FIT and FEM to simulate the use of microwave NDT techniques for damage detection in CFRP. Their study demonstrated that variations in S-parameters could effectively distinguish between healthy and defective areas. FIT simulations correlated well with experimental measurements, confirming their value for electromagnetic wave-based NDT applications.

Monte Carlo Simulation Methods

- Mousa et al. [195] used the GEANT4 GATE toolkit to simulate computed radiography testing (CRT) of carbon steel plates and pipes, demonstrating improved image quality and system optimization without the need for extensive physical trials.

- Sari et al. [196] applied Monte Carlo simulations to model gamma-ray backscatter for detecting voids in concrete, validating the method using experimental data to ensure accurate calibration.

- Kumar et al. [197] optimized the radiographic parameters for inspecting nuclear fuel reprocessing tanks using aRTist, a radiography simulation software, and achieved good alignment with experimental observations.

Other Numerical Techniques and Hybrid Approaches

- Osipov et al. [198] introduced a high-performance algorithm for simulating digital radiography testing (DRT) of large, complex industrial components, enabling realistic image generation without extensive experimental testing.

- Rodat et al. [199] presented a metamodeling simulator that integrates human factors into MAPOD studies, allowing a realistic simulation of human-influenced inspection outcomes.

- Lei et al. [200] used SimSUNDT software for a fully simulation-based POD study of PAUT, demonstrating the feasibility of generating reliable POD curves without extensive physical experiments.

4.1.4. Analytical Insights and Selection Considerations

- Type of NDT technique being modeled (ultrasonic, radiographic, electromagnetic, thermal, etc.).

- Complexity of component geometry (simple plate versus complex 3D structure).

- Nature of materials (isotropic metals vs. anisotropic composites).

- Computational resources and time constraints.

- Required output accuracy and validation requirements.

- FEM is the most versatile and widely validated method, particularly for multiphysics problems in complex composite structures.

- The BEM and semi-analytical models offer faster computations for specific electromagnetic and thermal applications, making them ideal for iterative design studies or POD evaluations.

- Monte Carlo methods are used in radiography optimization to reduce experimental exposure requirements and radiation safety risks.

- Hybrid and meta-modeling approaches provide a realistic simulation of human and environmental variability, making them valuable for risk-based decision-making frameworks, such as MAPOD.

4.2. Machine Learning and Deep Learning in NDT

4.2.1. Overview of Machine Learning Models for NDT

- Support vector machines (SVM): Owing to their high classification accuracy, SVMs have been effectively applied in defect classification tasks such as identifying crack-like and pore-like defects in ultrasonic phased array images. The Poly-SVM variant demonstrated classification accuracies of up to 93%, outperforming several competing models [201,202,203].

- Decision trees (CART): The CART models offer high interpretability, allowing inspectors to trace the decision-making process. However, their performance may be lower than that of other models on complex datasets, owing to overfitting risks.

4.2.2. Overview of Deep Learning in NDT

4.2.3. Practical Integration of ML and DL into NDT Workflows

- 1.

- Virtual inspection planning using simulationNumerical methods such as FEM, BEM, or FIT are used to simulate defect responses and optimize inspection parameters before physical testing.

- 2.

- Physical Data AcquisitionStandard NDT techniques, such as PAUT, IRT, XCT, and ECT, are employed to collect raw inspection data, including ultrasonic waveforms, thermal images, and radiographic projections.

- 3.

- Data Preprocessing and Feature ExtractionRaw signals or images are pre-processed to extract relevant features such as amplitude, frequency content, temperature gradients, or geometric descriptors.

- 4.

- Machine Learning-Based Defect ClassificationThe pre-processed features are fed into ML models such as SVM, KNN, CART, or Naïve Bayes to automatically classify the type, location, and severity of detected defects. This step significantly reduces human interpretation efforts and standardizes defect assessments.

- 5.

- Model Validation and Performance TuningML models are trained and validated using historical datasets or synthetic data generated from simulations to ensure robustness and generalizability to real-world inspections.

- 6.

- Integration with digital twin and predictive maintenance platformsAdvanced workflows may further integrate ML outputs with digital twin models or IoT sensor networks, thereby enabling real-time monitoring, predictive maintenance, and lifecycle management.

4.2.4. Deployment Considerations, Data Management, and Industrial Integration

4.2.5. Advantages and Challenges of ML and DL Integration in NDT

5. Summary and Discussion

5.1. Comparative Performance Analysis

5.2. Key Observations and Industrial Implications

- Simulation-based techniques (e.g., FEM, BEM, and Monte Carlo) offer reliable pre-inspection planning tools, enabling the optimization of sensor configuration, parameter tuning, and MAPOD evaluation.

- ML methods provide effective solutions for feature-based defect classification, particularly when well-labeled data are available.

- DL approaches are effective in handling large and complex datasets, achieving state-of-the-art performance in classification and segmentation, particularly in imaging-based NDT (e.g., radiography, infrared, and ultrasonic C-scan).

- The combination of simulation and AI methods allows for synergistic workflows such as training ML models on synthetic defect data generated from simulations.

- These approaches are increasingly compatible with Industry 4.0, offering opportunities for real-time monitoring, predictive maintenance, and digital twin integration.

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tai, J.L.; Sultan, M.T.H.; Shahar, F.S. Experimental Study on the Efficacy of Ultrasound in In-Situ Detection of Corrosion in Palm Oil Refining Equipment. J. Teknol. 2024, 86, 151–159. [Google Scholar] [CrossRef]

- Vanaei, H.R.; Eslami, A.; Egbewande, A. A Review on Pipeline Corrosion, in-Line Inspection (ILI), and Corrosion Growth Rate Models. Int. J. Press. Vessel. Pip. 2017, 149, 43–54. [Google Scholar] [CrossRef]

- Amoah, P.; Owusu-Poku, S.; Ajubala, G.A. Investigation of Wall Thickness, Corrosion, and Deposits in Industrial Pipelines Using Radiographic Technique. Int. J. Corros. 2023, 2023, 4924399. [Google Scholar] [CrossRef]

- Mu, W.; Gao, Y.; Wang, Y.; Liu, G.; Hu, H. Modeling and Analysis of Acoustic Emission Generated by Fatigue Cracking. Sensors 2022, 22, 1208. [Google Scholar] [CrossRef]

- Tanvir, F.; Sattar, T.; Mba, D.; Edwards, G. Identification of Fatigue Damage Evaluation Using Entropy of Acoustic Emission Waveform. SN Appl. Sci. 2020, 2, 138. [Google Scholar] [CrossRef]

- Guan, R.; Lu, Y.; Wang, K.; Su, Z. Quantitative Fatigue Crack Evaluation in Pipeline Structures Using Nonlinear Cylindrical Waves. Smart Mater. Struct. 2019, 28, 025015. [Google Scholar] [CrossRef]

- Tai, J.L.; Sultan, M.T.H.; Shahar, F.S. Processing Plants Damage Mechanisms and On-Stream Inspection Using Phased Array Corrosion Mapping—A Systematic Review. Pertanika J. Sci. Technol. 2024, 32, 1665–1685. [Google Scholar] [CrossRef]

- Przemysław Sobkiewicz; Bienkowski, P.; Błazejewski, W. Microwave Non-Destructive Testing for Delamination Detection in Layered Composite Pipelines. Sensors 2021, 21, 4168. [Google Scholar] [CrossRef]

- Li, X.K.; Liu, P.F. Delamination Analysis of Carbon Fiber Composites Under Dynamic Loads Using Acoustic Emission. J. Fail. Anal. Prev. 2016, 16, 142–153. [Google Scholar] [CrossRef]

- Lecheb, S.; Daoui, A.; Brihmat, C.; Mechakra, H.; Chellil, A.; Safi, B.; Kebir, H. Study of Composite Pipelines Damaged by Corrosion: Control by Non-Destructive Testing. Hung. J. Ind. Chem. 2023, 51, 1–6. [Google Scholar] [CrossRef]

- Xin, M.L.; Chen, Y.; Li, M.D.; Wang, Z.G.; Gu, G.H. The Research of Penetration Testing in the FRP Pipe Applications. IOP Conf. Ser. Mater. Sci. Eng. 2018, 292, 012080. [Google Scholar] [CrossRef]

- Matsukawa, S.; Yoshida, K.; Okuda, T.; Hazama, M.; Kurokawa, S.; Murata, H. Non-Destructive Inspection Method for FRPM Pipelines Utilising Time-Domain Responses of Microwave Guided-Modes. Electron. Lett. 2020, 56, 982–985. [Google Scholar] [CrossRef]

- Malla, P.; Khedmatgozar Dolati, S.S.; Ortiz, J.D.; Mehrabi, A.B.; Nanni, A.; Dinh, K. Feasibility of Conventional Non-Destructive Testing Methods in Detecting Embedded FRP Reinforcements. Appl. Sci. 2023, 13, 4399. [Google Scholar] [CrossRef]

- Zhang, T.; Mahdi, M.; Issa, M.; Xu, C.; Ozevin, D. Experimental Study on Monitoring Damage Progression of Basalt-FRP Reinforced Concrete Slabs Using Acoustic Emission and Machine Learning. Sensors 2023, 23, 8356. [Google Scholar] [CrossRef]

- Brizuela, J.; Camacho, J.; Cosarinsky, G.; Iriarte, J.M.; Cruza, J.F. Improving Elevation Resolution in Phased-Array Inspections for NDT. NDT E Int. 2019, 101, 1–16. [Google Scholar] [CrossRef]

- Martín-Díaz, C.; Rubio-Cintas, M.D.; Benaissa, K. Ndt Techniques Applied for the Inspection of Flare Stacks. Int. J. Ind. Eng. Res. Dev. 2018, 9, 1–12. [Google Scholar] [CrossRef]

- Montinaro, N.; Cerniglia, D.; Pitarresi, G. Evaluation of Interlaminar Delaminations in Titanium-Graphite Fibre Metal Laminates by Infrared NDT Techniques. NDT E Int. 2018, 98, 134–146. [Google Scholar] [CrossRef]

- Matalgah, K.; Ravindranath, P.K.; Pulipati, D.; Fleck, T.J. Automated Quantification of Interlaminar Delaminations in Carbon-Fiber-Reinforced Polymers via High-Resolution Ultrasonic Testing. Polymers 2023, 15, 4691. [Google Scholar] [CrossRef]

- Jasiūnienė, E.; Mažeika, L.; Samaitis, V.; Cicėnas, V.; Mattsson, D. Ultrasonic Non-Destructive Testing of Complex Titanium/Carbon Fibre Composite Joints. Ultrasonics 2019, 95, 13–21. [Google Scholar] [CrossRef]

- Ibrahim, M.E. Ultrasonic Inspection of Hybrid Polymer Matrix Composites. Compos. Sci. Technol. 2021, 208, 5–13. [Google Scholar] [CrossRef]

- Rizwan, M.K.; Laureti, S.; Mooshofer, H.; Goldammer, M.; Ricci, M. Ultrasonic Imaging of Thick Carbon Fiber Reinforced Polymers through Pulse-Compression-Based Phased Array. Appl. Sci. 2021, 11, 1508. [Google Scholar] [CrossRef]

- Tai, J.L.; Sultan, M.T.H.; Shahar, F.S. Comparative Analysis of Ultrasonic Inspection Techniques for Corrosion Monitoring in Petrochemical Plants Using Analytic Hierarchy Process (AHP). Pertanika J. Sci. Technol. 2025, 33, 1439–1457. [Google Scholar] [CrossRef]

- Anoshkin, A.N.; Osokin, V.M.; Tretyakov, A.A.; Potrakhov, N.N.; Bessonov, V.B. Application of Operational Radiographic Inspection Method for Flaw Detection of Blade Straightener from Polymeric Composite Materials. J. Phys. Conf. Ser. 2017, 808, 012003. [Google Scholar] [CrossRef]

- Kusk, M.W.; Jensen, J.M.; Gram, E.H.; Nielsen, J.; Precht, H. Anode Heel Effect: Does It Impact Image Quality in Digital Radiography? A Systematic Literature Review. Radiography 2021, 27, 976–981. [Google Scholar] [CrossRef]

- Xu Feng, L.; Jie, S.; Lu, S.; Wang, L. Application of On-Line Digital Radiographic Inspection for Pipeline with Insulation. J. Phys. Conf. Ser. 2022, 2366, 012006. [Google Scholar] [CrossRef]

- Gholizadeh, S. A Review of Non-Destructive Testing Methods of Composite Materials. Procedia Struct. Integr. 2016, 1, 50–57. [Google Scholar] [CrossRef]

- Pacana, A.; Siwiec, D.; Bednárová, L. Method of Choice: A Fluorescent Penetrant Taking into Account Sustainability Criteria. Sustainability 2020, 12, 5854. [Google Scholar] [CrossRef]

- Endramawan, T.; Sifa, A. Non Destructive Test Dye Penetrant and Ultrasonic on Welding SMAW Butt Joint with Acceptance Criteria ASME Standard. IOP Conf. Ser. Mater. Sci. Eng. 2018, 306, 012122. [Google Scholar] [CrossRef]

- Vera, J.; Caballero, L.; Taboada, M. Reliability of Dye Penetrant Inspection Method to Detect Weld Discontinuities. Russ. J. Nondestruct. Test. 2024, 60, 85–95. [Google Scholar] [CrossRef]

- Šofer, M.; Cienciala, J.; Fusek, M.; Pavlicek, P.; Moravec, R. Damage Analysis of Composite CFRP Tubes Using Acoustic Emission Monitoring. Materials 2021, 14, 786. [Google Scholar] [CrossRef]

- Oliveira, T.L.L.; Bortoluzzi, D.B.; Barbosa, L.C.M.; Ancelotti, A.C. Acoustic Emission Analysis of Mode II Interlaminar Fracture Toughness of 3D Reinforced CFRP. NDT 2024, 2, 32–52. [Google Scholar] [CrossRef]

- Samborski, S.; Korzec, I. Application of the Acoustic Emission Technique for Damage Identification in the Fiber Reinforced Polymer Composites. Adv. Sci. Technol. Res. J. 2023, 17, 210–221. [Google Scholar] [CrossRef]

- Ghadarah, N.; Ayre, D. A Review on Acoustic Emission Testing for Structural Health Monitoring of Polymer-Based Composites. Sensors 2023, 23, 6945. [Google Scholar] [CrossRef]

- Barile, C.; Casavola, C.; Pappalettera, G.; Kannan, V.P. Application of Different Acoustic Emission Descriptors in Damage Assessment of Fiber Reinforced Plastics: A Comprehensive Review. Eng. Fract. Mech. 2020, 235, 107083. [Google Scholar] [CrossRef]

- Hamam, Z.; Godin, N.; Fusco, C.; Doitrand, A.; Monnier, T. Acoustic Emission Signal Due to Fiber Break and Fiber Matrix Debonding in Model Composite: A Computational Study. Appl. Sci. 2021, 11, 8406. [Google Scholar] [CrossRef]

- Bashkov, O.V.; Romashko, R.V.; Zaikov, V.I.; Panin, S.V.; Bezruk, M.N.; Khun, K.; Bashkov, I.O. Detecting Acoustic-Emission Signals with Fiber-Optic Interference Transducers. Russ. J. Nondestruct. Test. 2017, 53, 415–421. [Google Scholar] [CrossRef]

- Ghahremani, P.; Najafabadi, M.A.; Alimirzaei, S.; Fotouhi, M. Acoustic Emission-Based Analysis of Damage Mechanisms in Filament Wound Fiber Reinforced Composite Tubes. Sensors 2023, 23, 6994. [Google Scholar] [CrossRef]

- Saeedifar, M.; Zarouchas, D. Damage Characterization of Laminated Composites Using Acoustic Emission: A Review. Compos. B Eng. 2020, 195, 108039. [Google Scholar] [CrossRef]

- Tai, J.L.; Sultan, M.T.H.; Łukaszewicz, A.; Siemiątkowski, Z.; Skorulski, G.; Shahar, F.S. Preventing Catastrophic Failures: A Review of Applying Acoustic Emission Testing in Multi-Bolted Flanges. Metals 2025, 15, 438. [Google Scholar] [CrossRef]

- Fang, Q.; Maldague, X. A Method of Defect Depth Estimation for Simulated Infrared Thermography Data with Deep Learning. Appl. Sci. 2020, 10, 6819. [Google Scholar] [CrossRef]

- Qu, Z.; Jiang, P.; Zhang, W. Development and Application of Infrared Thermography Non-Destructive Testing Techniques. Sensors 2020, 20, 3851. [Google Scholar] [CrossRef]

- Liu, K.; Ma, Z.; Liu, Y.; Yang, J.; Yao, Y. Enhanced Defect Detection in Carbon Fiber Reinforced Polymer Composites via Generative Kernel Principal Component Thermography. Polymers 2021, 13, 825. [Google Scholar] [CrossRef]

- Pitarresi, G.; Scalici, T.; Catalanotti, G. Infrared Thermography Assisted Evaluation of Static and Fatigue Mode II Fracture Toughness in FRP Composites. Compos. Struct. 2019, 226, 111220. [Google Scholar] [CrossRef]

- Tai, J.L.; Sultan, M.T.H.; Shahar, F.S.; Łukaszewicz, A.; Oksiuta, Z.; Grzejda, R. Ultrasound Corrosion Mapping on Hot Stainless Steel Surfaces. Metals 2024, 14, 1425. [Google Scholar] [CrossRef]

- Yosifov, M.; Reiter, M.; Heupl, S.; Gusenbauer, C.; Fröhler, B.; Fernández- Gutiérrez, R.; De Beenhouwer, J.; Sijbers, J.; Kastner, J.; Heinzl, C. Probability of Detection Applied to X-Ray Inspection Using Numerical Simulations. Nondestruct. Test. Eval. 2022, 37, 536–551. [Google Scholar] [CrossRef]

- Chen, H.X.; Fan, D.L.; Fang, L.; Zhang, G.Y.; Cao, C.H.; Huang, W.J.; Huang, J.M.; Yang, L. Finite Element Numerical Simulation Analysis Based on Ultrasonic Phased Array. IOP Conf. Ser. Mater. Sci. Eng. 2019, 657, 012011. [Google Scholar] [CrossRef]

- Le Noir de Carlan, M.; Jason, L.; Davenne, L. Numerical Simulation of Anchor Pullout and Shear Tests Using a Regularized Damage Model. Appl. Sci. 2024, 14, 11262. [Google Scholar] [CrossRef]

- Efimov, A.G.; Kanter, B.M.; Kuzelev, N.R.; Martyanov, E.V.; Shubochkin, A.E. Numerical Simulation of Non-Destructive Remote Field Eddy Current Testing of Rolled Metal Tubes. J. Phys. Conf. Ser. 2019, 1327, 012012. [Google Scholar] [CrossRef]

- Ciaburro, G.; Iannace, G. Machine-Learning-Based Methods for Acoustic Emission Testing: A Review. Appl. Sci. 2022, 12, 10476. [Google Scholar] [CrossRef]

- Yang, Q.; Liu, Y.; Chen, T.; Tong, Y. Federated Machine Learning: Concept and Applications. ACM Trans. Intell. Syst. Technol. 2019, 10, 12. [Google Scholar] [CrossRef]

- Lei, Y.; Yang, B.; Jiang, X.; Jia, F.; Li, N.; Nandi, A.K. Applications of Machine Learning to Machine Fault Diagnosis: A Review and Roadmap. Mech. Syst. Signal Process 2020, 138, 106587. [Google Scholar] [CrossRef]

- Zhang, Z.; Tang, F.; Cao, Q.; Pan, H.; Wang, X.; Lin, Z. Deep Learning-Enriched Stress Level Identification of Pretensioned Rods via Guided Wave Approaches. Buildings 2022, 12, 1772. [Google Scholar] [CrossRef]

- Inderyas, O.; Alver, N.; Tayfur, S.; Shimamoto, Y.; Suzuki, T. Deep Learning-Based Acoustic Emission Signal Filtration Model in Reinforced Concrete. Arab. J. Sci. Eng. 2024, 50, 1885–1903. [Google Scholar] [CrossRef]

- Fu, Y.; Zhu, G.; Zhu, M.; Xuan, F. Digital Twin for Integration of Design-Manufacturing-Maintenance: An Overview. Chin. J. Mech. Eng. (Engl. Ed.) 2022, 35, 80. [Google Scholar] [CrossRef]

- Attaran, M.; Celik, B.G. Digital Twin: Benefits, Use Cases, Challenges, and Opportunities. Decis. Anal. J. 2023, 6, 100165. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, H.; Liu, A.; Nee, A.Y.C. Digital Twin in Industry: State-of-the-Art. IEEE Trans. Ind. Inform. 2019, 15, 2405–2415. [Google Scholar] [CrossRef]

- Sharma, A.; Kosasih, E.; Zhang, J.; Brintrup, A.; Calinescu, A. Digital Twins: State of the Art Theory and Practice, Challenges, and Open Research Questions. J. Ind. Inf. Integr. 2022, 30, 100383. [Google Scholar] [CrossRef]

- Kim, F.H.; Pintar, A.; Obaton, A.F.; Fox, J.; Tarr, J.; Donmez, A. Merging Experiments and Computer Simulations in X-Ray Computed Tomography Probability of Detection Analysis of Additive Manufacturing Flaws. NDT E Int. 2021, 119, 102416. [Google Scholar] [CrossRef]

- Falcetelli, F.; Yue, N.; Rossi, L.; Bolognini, G.; Bastianini, F.; Zarouchas, D.; Di Sante, R. A Model-Assisted Probability of Detection Framework for Optical Fiber Sensors. Sensors 2023, 23, 4813. [Google Scholar] [CrossRef]

- Lee, D.; Yoon, S.; Park, J.; Eum, S.; Cho, H. Demonstration of Model-Assisted Probability of Detection Framework for Ultrasonic Inspection of Cracks in Compressor Blades. NDT E Int. 2022, 128, 102618. [Google Scholar] [CrossRef]

- Chipanga, T.; Nemraoui, O.; Ismail, F. Damage Assessment of Low-Velocity Impacted Sandwich Composite Structures Using X-Ray Micro-Computed Tomography. J. Eng. 2024, 2024, 6147948. [Google Scholar] [CrossRef]

- Zhao, X.; Li, J.; Su, S.; Jiang, N. Prediction Models of Mechanical Properties of Jute/PLA Composite Based on X-Ray Computed Tomography. Polymers 2024, 16, 160. [Google Scholar] [CrossRef]

- Tsamos, A.; Evsevleev, S.; Fioresi, R.; Faglioni, F.; Bruno, G. Synthetic Data Generation for Automatic Segmentation of X-Ray Computed Tomography Reconstructions of Complex Microstructures. J. Imaging 2023, 9, 22. [Google Scholar] [CrossRef]

- Ziółkowski, G.; Pach, J.; Pyka, D.; Kurzynowski, T.; Jamroziak, K. X-Ray Computed Tomography for the Development of Ballistic Composite. Materials 2020, 13, 5566. [Google Scholar] [CrossRef] [PubMed]

- Antin, K.N.; Machado, M.A.; Santos, T.G.; Vilaça, P. Evaluation of Different Non-Destructive Testing Methods to Detect Imperfections in Unidirectional Carbon Fiber Composite Ropes. J. Nondestruct. Eval. 2019, 38, 23. [Google Scholar] [CrossRef]

- Taheri, H.; Hassen, A.A. Nondestructive Ultrasonic Inspection of Composite Materials: A Comparative Advantage of Phased Array Ultrasonic. Appl. Sci. 2019, 9, 1628. [Google Scholar] [CrossRef]

- Mohd Tahir, M.F.; Echtermeyer, A.T. Phased Array Ultrasonic Testing on Thick Glass Fiber Reinforced Thermoplastic Composite Pipe Implementing the Classical Time-Corrected Gain Method. J. Nondestruct. Eval. 2024, 43, 74. [Google Scholar] [CrossRef]

- Camineroa, M.A.; García-Morenoa, I.; Rodrígueza, G.P.; Chacónb, J.M. Internal Damage Evaluation of Composite Structures Using Phased Array Ultrasonic Technique: Impact Damage Assessment in CFRP and 3D Printed Reinforced Composites. Compos. B Eng. 2018, 165, 131–142. [Google Scholar] [CrossRef]

- Tai, J.L.; Grzejda, R.; Sultan, M.T.H.; Łukaszewicz, A.; Shahar, F.S.; Tarasiuk, W.; Rychlik, A. Experimental Investigation on the Corrosion Detectability of A36 Low Carbon Steel by the Method of Phased Array Corrosion Mapping. Materials 2023, 16, 5297. [Google Scholar] [CrossRef]

- Pelkner, M.; Casperson, R.; Pohl, R.; Munzke, D.; Becker, B. Eddy Current Testing of Composite Pressure Vessels. Int. J. Appl. Electromagn. Mech. 2019, 59, 1221–1226. [Google Scholar] [CrossRef]

- Abdelli, D.E.; Nguyen, T.T.; Clenet, S.; Cheriet, A. Stochastic Metamodel for Probability of Detection Estimation of Eddy-Current Testing Problem in Random Geometric. IEEE Trans. Magn. 2019, 55, 6200604. [Google Scholar] [CrossRef]

- Apostol, E.S.; Nedelcu, A.; Daniel, D.V.; Chiriţǎ, I.; Tǎnase, N. Mathematical Modeling of Eddy Current Non-Destructive Testing. In Proceedings of the 2017 10th International Symposium on Advanced Topics in Electrical Engineering (ATEE 2017), Bucharest, Romania, 23–25 March 2017; pp. 469–474. [Google Scholar] [CrossRef]

- To, A.; Li, Z.; Dixon, S. Improved Detection of Surface Defects at Sample Edges Using High-Frequency Eddy Current Amplitude and Phase Measurements. Nondestruct. Test. Eval. 2022, 37, 795–819. [Google Scholar] [CrossRef]

- Cao, B.; Li, X.; Wang, M.; Fan, M. Analytical Modelling and Simulations for High-Frequency Eddy Current Testing with Planar Spiral Coils. Nondestruct. Test. Eval. 2021, 36, 195–208. [Google Scholar] [CrossRef]

- Tytko, G.; Adamczyk-Habrajska, M.; Li, Y.; Liu, Z.; Kopec, M. High Frequency Eddy Current Method in Inspection of Aluminide Coatings Integrity after Simulating Service Loads. Measurement 2025, 252, 117356. [Google Scholar] [CrossRef]

- Švantner, M.; Muzika, L.; Moskovchenko, A.; Pereira, C.M.C.; Das, S. Repeatability Study of Flash-Pulse Thermographic Inspection of CFRP Samples. Eng. Proc. 2021, 8, 1. [Google Scholar] [CrossRef]

- Pirinu, A.; Saponaro, A.; Nobile, R.; Panella, F.W. Low-Velocity Impact Damage Quantification on Sandwich Panels by Thermographic and Ultrasonic Procedures. Exp. Tech. 2024, 48, 299–322. [Google Scholar] [CrossRef]

- Peeters, J.; Ibarra-Castanedo, C.; Khodayar, F.; Mokhtari, Y.; Sfarra, S.; Zhang, H.; Maldague, X.; Dirckx, J.J.J.; Steenackers, G. Optimised Dynamic Line Scan Thermographic Detection of CFRP Inserts Using FE Updating and POD Analysis. NDT E Int. 2018, 93, 141–149. [Google Scholar] [CrossRef]

- Tai, J.L.; Sultan, M.T.H.; Łukaszewicz, A.; Shahar, F.S.; Oksiuta, Z.; Krishnamoorthy, R.R. Enhancing Turnaround Maintenance in Process Plants through On-Stream Phased Array Corrosion Mapping: A Review. Appl. Sci. 2024, 14, 6707. [Google Scholar] [CrossRef]

- De Almeida, P.D.; Pereira, G.R. Phased Array Inspection of Glass Fiber Reinforced Polymers Pipeline Joints. J. Mater. Res. Technol. 2019, 8, 4736–4740. [Google Scholar] [CrossRef]

- Hao, Z.; Liu, H.; Yan, N.; Wang, Z.; Bai, X.; Han, J.; Mi, C.; Jia, S.; Sun, G.; Zhu, L.; et al. In-Situ Test and Numerical Simulation of Anchoring Performance of Embedded Rock GFRP Anchor. Buildings 2023, 13, 2799. [Google Scholar] [CrossRef]

- Shu, W.; Liao, L.; Zhou, P.; Huang, B.; Chen, W. Three-Point Bending Damage Detection of GFRP Composites Doped with Graphene Oxide by Acoustic Emission Technology. iScience 2023, 26, 108511. [Google Scholar] [CrossRef] [PubMed]

- Nair, A.; Cai, C.S.; Kong, X. Using Acoustic Emission to Monitor Failure Modes in CFRP-Strengthened Concrete Structures. J. Aerosp. Eng. 2020, 33, 04019110. [Google Scholar] [CrossRef]

- Mills-Dadson, B.; Tran, D.; Asamene, K.; Whitlow, T.; Sundaresan, M. Acoustic Emission Monitoring of Unstable Damage Growth in CFRP Composites under Tension. AIP Conf. Proc. 2017, 1806, 070009. [Google Scholar]

- Luo, Z.; Li, F.; Su, H.; Cao, H.; Lin, L. Surface Adaptive Ultrasonic Testing on Defects in CFRP Radii. Jixie Gongcheng Xuebao/J. Mech. Eng. 2022, 58, 312–318. [Google Scholar] [CrossRef]

- Xiao, H.; Sultan, M.T.H.; Shahar, F.S.; Gaff, M.; Hui, D. Recent Developments in the Mechanical Properties of Hybrid Fiber Metal Laminates in the Automotive Industry: A Review. Rev. Adv. Mater. Sci. 2023, 62, 20220328. [Google Scholar] [CrossRef]

- Liu, Y.; Natsuki, T.; Suzuki, D.; Huang, C.; Cui, L.; Ni, Q.Q. Low-Velocity Impact-Resistance of Aramid Fiber Three-Dimensional Woven Textile-Reinforced Thermoplastic-Epoxy Composites. J. Thermoplast. Compos. Mater. 2023, 37, 2827–2857. [Google Scholar] [CrossRef]

- Zhang, B.; Jia, L.; Tian, M.; Ning, N.; Zhang, L.; Wang, W. Surface and Interface Modification of Aramid Fiber and Its Reinforcement for Polymer Composites: A Review. Eur. Polym. J. 2021, 147, 110352. [Google Scholar] [CrossRef]

- Liu, H.; Yu, Y.; Liu, Y.; Zhang, M.; Li, L.; Ma, L.; Sun, Y.; Wang, W. A Review on Basalt Fiber Composites and Their Applications in Clean Energy Sector and Power Grids. Polymers 2022, 14, 2376. [Google Scholar] [CrossRef]

- Selcuk, S.; Ahmetoglu, U.; Gokce, E.C. Basalt Fiber Reinforced Polymer Composites (BFRP) Other than Rebars: A Review. Mater. Today Commun. 2023, 37, 107359. [Google Scholar] [CrossRef]

- Song, K.; Yu, Y.; Liu, Y.; Zhao, J. Flexural Performance Study of Basalt-Fiber-Reinforced Polymer Bar Basalt-Fiber-Reinforced Concrete Beams. Buildings 2023, 13, 2583. [Google Scholar] [CrossRef]

- Vinay, S.S.; Sanjay, M.R.; Siengchin, S.; Venkatesh, C.V. Basalt Fiber Reinforced Polymer Composites Filled with Nano Fillers: A Short Review. Mater. Today Proc. 2022, 52, 2460–2466. [Google Scholar] [CrossRef]

- Loganathan, T.M.; Sultan, M.T.H.; Muhammad Amir, S.M.; Jamil, J.; Yusof, M.R.; Md Shah, A.U. Infrared Thermographic and Ultrasonic Inspection of Randomly-Oriented Short-Natural Fiber-Reinforced Polymeric Composites. Front. Mater. 2021, 7, 604459. [Google Scholar] [CrossRef]

- Zhang, H.; Sfarra, S.; Sarasini, F.; Santulli, C.; Fernandes, H.; Avdelidis, N.P.; Ibarra-Castanedo, C.; Maldague, X.P.V. Thermographic Non-Destructive Evaluation for Natural Fiber-Reinforced Composite Laminates. Appl. Sci. 2018, 8, 240. [Google Scholar] [CrossRef]

- Wang, Z.; Chegdani, F.; Yalamarti, N.; Takabi, B.; Tai, B.; El Mansori, M.; Bukkapatnam, S. Acoustic Emission Characterization of Natural Fiber Reinforced Plastic Composite Machining Using a Random Forest Machine Learning Model. J. Manuf. Sci. Eng. Trans. ASME 2020, 142, 031003. [Google Scholar] [CrossRef]

- Chen, J.; Yu, Z.; Jin, H. Nondestructive Testing and Evaluation Techniques of Defects in Fiber-Reinforced Polymer Composites: A Review. Front. Mater. 2022, 9, 986645. [Google Scholar] [CrossRef]

- Joseph, L.; Madhavan, M.K.; Jayanarayanan, K.; Pegoretti, A. Evaluation of Hybrid Fiber Multiscale Polymer Composites for Structural Confinement under Cyclic Axial Compressive Loading. J. Compos. Sci. 2023, 7, 152. [Google Scholar] [CrossRef]

- Singh, P.; Singari, R.M.; Mishra, R.S.; Bajwa, G.S. A Review on Recent Development on Polymeric Hybrid Composite and Analysis of Their Enhanced Mechanical Performance. Mater. Today Proc. 2022, 56, 3692–3701. [Google Scholar] [CrossRef]

- Bafakeeh, O.T.; Shewakh, W.M.; Abu-Oqail, A.; Abd-Elaziem, W.; Abdel Ghafaar, M.; Abu-Okail, M. Synthesis and Characterization of Hybrid Fiber-Reinforced Polymer by Adding Ceramic Nanoparticles for Aeronautical Structural Applications. Polymers 2021, 13, 4116. [Google Scholar] [CrossRef]

- Bruno, M.; Esposito, L.; Papa, I.; Viscusi, A. Design, Manufacturing, and Numerical Characterization of Hybrid Fiber Reinforced Polymer under Dynamic Loads. J. Mater. Eng. Perform. 2023, 32, 3905–3913. [Google Scholar] [CrossRef]

- Bhaskar, R.; Reddivari, S.; Vadapalli, B.; Sanduru, T.; Buddi, K.; Maksudovna, V.; Joshi, A.; Reddy Reddivari, B.; Vadapalli, S.; Sanduru, B.; et al. Fabrication and Mechanical Properties of Hybrid Fibre-Reinforced Polymer Hybrid Composite with Graphene Nanoplatelets and Multiwalled Carbon Nanotubes. Cogent Eng. 2024, 11, 2343586. [Google Scholar] [CrossRef]

- Islam, T.; Chaion, M.H.; Jalil, M.A.; Rafi, A.S.; Mushtari, F.; Dhar, A.K.; Hossain, S. Advancements and Challenges in Natural Fiber-Reinforced Hybrid Composites: A Comprehensive Review. SPE Polym. 2024, 5, 481–506. [Google Scholar] [CrossRef]

- Mohanraj, C.M.; Rameshkumar, R.; Mariappan, M.; Mohankumar, A.; Rajendran, B.; Senthamaraikannan, P.; Suyambulingam, I.; Kumar, R. Recent Progress in Fiber Reinforced Polymer Hybrid Composites and Its Challenges—A Comprehensive Review. J. Nat. Fibers 2025, 22, 2495911. [Google Scholar] [CrossRef]

- Bannister, A.; Nemcova, A.; Johnson, D.; Blackburn, M. Selection and Deployment of Non-Destructive Testing for through-Life Integrity Assurance of Composite-Repaired Pipes. Inst. Chem. Eng. Symp. Ser. 2020, 2020, 1–14. [Google Scholar]

- Mousa, S.; Alomari, A.S.; Vantadori, S.; Alhazmi, W.H.; Abd-Elhady, A.A.; Sallam, H.E.D.M. Mechanical Behavior of Epoxy Reinforced by Hybrid Short Palm/Glass Fibers. Sustainability 2022, 14, 9425. [Google Scholar] [CrossRef]

- Pranathi, K.; Md, S.; Ayub, A.; Paul, C.H.; Singh, S.; Hanumantharaju, H.G.; Ravi, S.; Yadla, T.; Nagaraj Goud, B.; Vyshnavi, V.; et al. An Experimental Study on E-Glass Fiber Reinforced Epoxy with Nano-Silica for an Aircraft Structural Applications. J. Phys. Conf. Ser. 2024, 2837, 012004. [Google Scholar] [CrossRef]

- Bhanuprakash, L.; Varghese, S.; Singh, S.K. Glass Fibre Reinforced Epoxy Composites Modified with Graphene Nanofillers: Electrical Characterization. J. Nanomater. 2022, 2022, 4611251. [Google Scholar] [CrossRef]

- Subbarayalu, V.; Chinnaraman, S.; Ayyanar, A.; Chinnapalanisamy, J.; Subbarayalu, V.; Chinnaraman, S.; Ayyanar, A.; Chinnapalanisamy, J. Mechanical Properties of Vinyl Ester Hybrid Composite Laminates Reinforced with Screw Pine and Glass Fiber. AIMS Mater. Sci. 2024, 11, 114–128. [Google Scholar] [CrossRef]

- Thomason, J.; Xypolias, G. A Study of the Moisture Absorption Characteristics of Vinyl Ester Polymer and Unidirectional Glass Fibre Vinyl Ester Laminates. J. Compos. Sci. 2024, 8, 214. [Google Scholar] [CrossRef]

- Gupta, B.N.V.S.K.G.; Yadav, A.; Hiremath, M.M.; Prusty, R.K.; Ray, B.C. Enhancement of Mechanical Properties of Glass Fiber Reinforced Vinyl Ester Composites by Embedding Multi-Walled Carbon Nanotubes through Solution Processing Technique. Mater. Today Proc. 2020, 27, 1045–1050. [Google Scholar] [CrossRef]

- Thomason, J.; Xypolias, G. Hydrothermal Ageing of Glass Fibre Reinforced Vinyl Ester Composites: A Review. Polymers 2023, 15, 835. [Google Scholar] [CrossRef]

- Nazaruddin, N.; Akram, A.; Hasanuddin, I.; Iqbal, M.; Kurniawan, R.; Putra, R. Mechanical Properties of Glass Fiber Reinforced Polyester Resin for Use as the Wall of the Acehnese Boat ‘Thep-Thep’. IOP Conf. Ser. Mater. Sci. Eng. 2019, 523, 012080. [Google Scholar] [CrossRef]

- Singh, M.M.; Kumar, H.; Kumar, G.H.; Sivaiah, P.; Nagesha, K.V.; Ajay, K.M.; Vijaya, G. Determination of Strength Parameters of Glass Fibers Reinforced Composites for Engineering Applications. Silicon 2020, 12, 1–11. [Google Scholar] [CrossRef]

- Abbood, I.S.; Odaa, S.A.; Hasan, K.F.; Jasim, M.A. Properties Evaluation of Fiber Reinforced Polymers and Their Constituent Materials Used in Structures—A Review. Mater. Today Proc. 2021, 43, 1003–1008. [Google Scholar] [CrossRef]

- Setyanto, D.; Jayatun, Y.A.; Basoeki, P.D.; De Fretes, A. Physical Properties of Glass-Fibre-Reinforced Polymer Filled with Alumina Trihydrate and Calcium Carbonate. Polymers 2022, 14, 2464. [Google Scholar] [CrossRef]

- Hu, B.; Shen, S.; Zhai, M.; Zhao, N.; Huang, H.; Duan, Y.; Ma, J.; Wan, T.; Shao, W.; Zhang, Q. Development of Thermoplastic Epoxy Resin-Based Multifunctional Flexible Composite Film and Its Shape Memory Performance Research. Mater. Today Commun. 2024, 40, 109842. [Google Scholar] [CrossRef]

- Wu, J.; Li, C.; Hailatihan, B.; Mi, L.; Baheti, Y.; Yan, Y. Effect of the Addition of Thermoplastic Resin and Composite on Mechanical and Thermal Properties of Epoxy Resin. Polymers 2022, 14, 1087. [Google Scholar] [CrossRef]

- Miranda, R.; Luciano, M.; Fiore, V.; Valenza, A. Development of Bio-Based and Recyclable Epoxy Adhesives by Modification with Thermoplastic Polymers. Polymers 2025, 17, 131. [Google Scholar] [CrossRef]

- Bhagwat, Y.; Nayak, G.; Pandit, P.; Lakshmi, A. Effect of Polypropylene Fibres on Strength and Durability Performance of M-Sand Self Compacting Concrete. Cogent Eng. 2023, 10, 2233783. [Google Scholar] [CrossRef]

- Wu, J.; Hu, L.; Hu, C.; Wang, Y.; Zhou, J.; Li, X. Impact of Polypropylene Fiber on the Mechanical and Physical Properties of Pervious Concrete: An Experimental Investigation. Buildings 2023, 13, 1966. [Google Scholar] [CrossRef]

- Hedjazi, S.; Castillo, D. Utilizing Polypropylene Fiber in Sustainable Structural Concrete Mixtures. CivilEng 2022, 3, 562–572. [Google Scholar] [CrossRef]

- Saberian, M.; Tajaddini, A.; Li, J.; Zhang, G.; Wang, L.; Sun, D.; Maqsood, T.; Roychand, R. Mechanical Properties of Polypropylene Fibre Reinforced Recycled Concrete Aggregate for Sustainable Road Base and Subbase Applications. Constr. Build. Mater. 2023, 405, 133352. [Google Scholar] [CrossRef]

- Yao, X.; Han, Y.; Shen, L.; Zhu, D. Experimental Study on the Effect of Polypropylene Fiber on Compressive Strength and Fracture Properties of High-Strength Concrete after Elevated Temperatures. J. Build. Eng. 2024, 86, 108860. [Google Scholar] [CrossRef]

- Suraweera, S.M.D.V.; De Silva, S. Effect of Recycled Polyethylene Terephthalate (PET) Fibres on Fresh and Hardened Properties of Concrete: A Review. Int. J. Sustain. Eng. 2023, 16, 269–284. [Google Scholar] [CrossRef]

- Özaşik, N.; Eren, Ö. Influence of Recycled Polyethylene Terephthalate Fibres on Plastic Shrinkage and Mechanical Properties of Concrete. Front. Struct. Civ. Eng. 2022, 16, 792–802. [Google Scholar] [CrossRef]

- Ma, J.; Hesp, S.A.M. Effect of Recycled Polyethylene Terephthalate (PET) Fiber on the Fracture Resistance of Asphalt Mixtures. Constr. Build. Mater. 2022, 342, 127944. [Google Scholar] [CrossRef]

- Gnoffo, C.; Arrigo, R.; Frache, A. An Upcycling Strategy for Polyethylene Terephthalate Fibers: All-Polymer Composites with Enhanced Mechanical Properties. J. Compos. Sci. 2024, 8, 527. [Google Scholar] [CrossRef]

- Zhou, Z.; Li, S.; Hu, G.; Wu, J.; Yao, C.; Niu, F. On the Use of Recycled Polyethylene Terephthalate Fiber in One-Part Geopolymer Stabilized Soft Soil: Tensile Performance and Sustainability Analysis. Dev. Built Environ. 2025, 21, 100641. [Google Scholar] [CrossRef]

- Molinar-Díaz, J.; Parsons, A.J.; Ahmed, I.; Warrior, N.A.; Harper, L.T. Poly-Ether-Ether-Ketone (PEEK) Biomaterials and Composites: Challenges, Progress, and Opportunities. Polym. Rev. 2024, 65, 527–565. [Google Scholar] [CrossRef]

- Lee, S.; Jeon, I.S.; Jho, J.Y. Mechanical Properties of Polyetheretherketone Composites with Surface-Modified Hydroxyapatite Nanofibers and Carbon Fibers. Macromol. Res. 2022, 30, 261–270. [Google Scholar] [CrossRef]

- Lu, S.; Zhang, B.; Niu, J.; Yang, C.; Sun, C.; Wang, L.; Li, D. High-Strength Carbon Fiber-Reinforced Polyether-Ether-Ketone Composites with Longer Fiber Retention Length Manufactured via Screw Extrusion-Based 3D Printing. Addit. Manuf. 2024, 86, 104200. [Google Scholar] [CrossRef]

- Dai, J.N.; Kou, S.Q.; Yang, H.Y.; Xu, Z.B.; Shu, S.L.; Qiu, F.; Jiang, Q.C.; Zhang, L.C. High-Content Continuous Carbon Fibers Reinforced PEEK Matrix Composite with Ultra-High Mechanical and Wear Performance at Elevated Temperature. Compos. Struct. 2022, 295, 115837. [Google Scholar] [CrossRef]

- Eun, J.H.; Choi, B.K.; Sung, S.M.; Kim, M.S.; Lee, J.S. Effect of Toughened Polyamide-Coated Carbon Fiber Fabric on the Mechanical Performance and Fracture Toughness of CFRP. J. Compos. Mater. 2021, 55, 2721–2738. [Google Scholar] [CrossRef]

- Kohutiar, M.; Kakošová, L.; Krbata, M.; Janík, R.; Fekiač, J.J.; Breznická, A.; Eckert, M.; Mikuš, P.; Timárová, Ľ. Comprehensive Review: Technological Approaches, Properties, and Applications of Pure and Reinforced Polyamide 6 (PA6) and Polyamide 12 (PA12) Composite Materials. Polymers 2025, 17, 442. [Google Scholar] [CrossRef]

- Jafari, M.M.; Jahandari, S.; Ozbakkaloglu, T.; Rasekh, H.; Jahed Armaghani, D.; Rahmani, A. Mechanical Properties of Polyamide Fiber-Reinforced Lime–Cement Concrete. Sustainability 2023, 15, 11484. [Google Scholar] [CrossRef]

- Ai, L.; Flowers, S.; Mesaric, T.; Henderson, B.; Houck, S.; Ziehl, P. Acoustic Emission-Based Detection of Impacts on Thermoplastic Aircraft Control Surfaces: A Preliminary Study. Appl. Sci. 2023, 13, 6573. [Google Scholar] [CrossRef]

- Balakrishnan, T.S.; Sultan, M.T.H.; Naveen, J.; Shahar, F.S.; Najeeb, M.I.; Shah, A.U.M.; Khan, T.; Sebaey, T.A. Selection of Natural Fibre for Pultruded Hybrid Synthetic/Natural Fibre Reinforced Polymer Composites Using Analytical Hierarchy Process for Structural Applications. Polymers 2022, 14, 3178. [Google Scholar] [CrossRef] [PubMed]

- Saghir, F.; Gohari, S.; Mozafari, F.; Moslemi, N.; Burvill, C.; Smith, A.; Lucas, S. Mechanical Characterization of Particulated FRP Composite Pipes: A Comprehensive Experimental Study. Polym. Test. 2021, 93, 107001. [Google Scholar] [CrossRef]

- Ashrith, H.S.; Jeevan, T.P.; Xu, J. A Review on the Fabrication and Mechanical Characterization of Fibrous Composites for Engineering Applications. J. Compos. Sci. 2023, 7, 252. [Google Scholar] [CrossRef]

- Rajak, D.K.; Wagh, P.H.; Linul, E. Manufacturing Technologies of Carbon/Glass Fiber-Reinforced Polymer Composites and Their Properties: A Review. Polymers 2021, 13, 3721. [Google Scholar] [CrossRef]

- Agwa, M.A.; Youssef, S.M.; Ali-Eldin, S.S.; Megahed, M. Integrated Vacuum Assisted Resin Infusion and Resin Transfer Molding Technique for Manufacturing of Nano-Filled Glass Fiber Reinforced Epoxy Composite. J. Ind. Text. 2022, 51, 5113S–5144S. [Google Scholar] [CrossRef]

- Shen, R.; Liu, T.; Liu, H.; Zou, X.; Gong, Y.; Guo, H. An Enhanced Vacuum-Assisted Resin Transfer Molding Process and Its Pressure Effect on Resin Infusion Behavior and Composite Material Performance. Polymers 2024, 16, 1386. [Google Scholar] [CrossRef]

- Wang, T.; Huang, K.; Guo, L.; Zheng, T.; Zeng, F. An Automated Vacuum Infusion Process for Manufacturing High-Quality Fiber-Reinforced Composites. Compos. Struct. 2023, 309, 116717. [Google Scholar] [CrossRef]

- Shah, M.; Chaudhary, V. Flow Modeling and Simulation Study of Vacuum Assisted Resin Transfer Molding (VARTM) Process: A Review. IOP Conf. Ser. Mater. Sci. Eng. 2020, 872, 012087. [Google Scholar] [CrossRef]

- Liu, Y.N.; Yuan, C.; Liu, C.; Pan, J.; Dong, Q. Study on the Resin Infusion Process Based on Automated Fiber Placement Fabricated Dry Fiber Preform. Sci. Rep. 2019, 9, 7440. [Google Scholar] [CrossRef] [PubMed]

- Phyo Maung, P.; Lin Htet, T.; Malysheva, G.V. Simulation and Optimization of Vacuum Assisted Resin Infusion Process for Large-Sized Structures Made of Carbon Fiber-Reinforced Plastics. IOP Conf. Ser. Mater. Sci. Eng. 2020, 709, 022041. [Google Scholar] [CrossRef]

- Shi, J.; Zhang, W.; Zhang, J.; Yuan, S.; Chen, H. Mechanical, Thermal Properties and Void Characteristics of Bamboo Fiber-Reinforced Epoxy Resin Composites Prepared by Vacuum-Assisted Resin Transfer Molding Process. J. Nat. Fibers 2023, 20, 2187919. [Google Scholar] [CrossRef]

- Lionetto, F.; Moscatello, A.; Totaro, G.; Raffone, M.; Maffezzoli, A. Experimental and Numerical Study of Vacuum Resin Infusion of Stiffened Carbon Fiber Reinforced Panels. Materials 2020, 13, 4800. [Google Scholar] [CrossRef] [PubMed]

- Aryaswara, L.G.; Santos, G.N.C.; Muflikhun, M.A. Defect Characteristics of Unidirectional Glass Fiber Reinforced Epoxy Manufactured via Vacuum Assisted Resin Infusion. Mater. Today Proc. 2022, 66, 2796–2800. [Google Scholar] [CrossRef]

- Silva, D.; Rocha, R.; Ribeiro, F.; Monteiro, H. Environmental Impact of an Innovative Aeronautic Carbon Composite Manufactured via Heated Vacuum-Assisted Resin Transfer Molding. Sustainability 2024, 16, 3253. [Google Scholar] [CrossRef]

- Kim, J.I.; Hwang, Y.T.; Choi, K.H.; Kim, H.J.; Kim, H.S. Prediction of the Vacuum Assisted Resin Transfer Molding (VARTM) Process Considering the Directional Permeability of Sheared Woven Fabric. Compos. Struct. 2019, 211, 236–243. [Google Scholar] [CrossRef]

- Liu, X.; Cao, Y.; Zhang, C.; Zhou, L.; Gao, Y.; Wang, W.; Guan, H.; Mu, S.; Zhang, J. Study on Mechanical Properties of Vacuum-Infused Glass Fiber Reinforced Thermoplastic Methacrylic Resin Composites. Polym. Compos. 2024, 45, 7024–7038. [Google Scholar] [CrossRef]

- Bobba, S.; Leman, Z.; Zainuddin, E.S.; Sapuan, S.M. Failures Analysis of E-Glass Fibre Reinforced Pipes in Oil and Gas Industry: A Review. IOP Conf. Ser. Mater. Sci. Eng. 2017, 217, 012004. [Google Scholar] [CrossRef]

- Kong, L.; Shi, Q.; Zhang, B. Experimental Analysis of a Novel GFRP Stiffened Pipe. Appl. Sci. 2022, 12, 10306. [Google Scholar] [CrossRef]

- Diniță, A.; Ripeanu, R.G.; Ilincă, C.N.; Cursaru, D.; Matei, D.; Naim, R.I.; Tănase, M.; Portoacă, A.I. Advancements in Fiber-Reinforced Polymer Composites: A Comprehensive Analysis. Polymers 2024, 16, 2. [Google Scholar] [CrossRef]

- Kennedy, S.M.; Jeen Robert, R.B.; Malkiya Rasalin Prince, R.; Hikku, G.S.; Kaliraj, M. A Comprehensive Overview of the Fabrication and Testing Methods of FRP Composite Pipes. MethodsX 2024, 13, 102990. [Google Scholar] [CrossRef]

- Alabtah, F.G.; Mahdi, E.; Eliyan, F.F. The Use of Fiber Reinforced Polymeric Composites in Pipelines: A Review. Compos. Struct. 2021, 276, 114595. [Google Scholar] [CrossRef]

- Wang, B.; Zhong, S.; Lee, T.L.; Fancey, K.S.; Mi, J. Non-Destructive Testing and Evaluation of Composite Materials/Structures: A State-of-the-Art Review. Adv. Mech. Eng. 2020, 12, 1–28. [Google Scholar] [CrossRef]

- Lewis, C.; Yavuz, B.O.; Longana, M.L.; Belnoue, J.P.H.; Ramakrishnan, K.R.; Ward, C.; Hamerton, I. A Review on the Modelling of Aligned Discontinuous Fibre Composites. J. Compos. Sci. 2024, 8, 318. [Google Scholar] [CrossRef]

- Mehdikhani, M.; Gorbatikh, L.; Verpoest, I.; Lomov, S.V. Voids in Fiber-Reinforced Polymer Composites: A Review on Their Formation, Characteristics, and Effects on Mechanical Performance. J. Compos. Mater. 2019, 53, 1579–1669. [Google Scholar] [CrossRef]

- Ma, M.; Cao, H.; Jiang, M.; Sun, L.; Zhang, L.; Zhang, F.; Sui, Q.; Tian, A.; Liang, J.; Jia, L. High Precision Detection Method for Delamination Defects in Carbon Fiber Composite Laminates Based on Ultrasonic Technique and Signal Correlation Algorithm. Materials 2020, 13, 3840. [Google Scholar] [CrossRef]

- Ellison, A.; Kim, H. Shadowed Delamination Area Estimation in Ultrasonic C-Scans of Impacted Composites Validated by X-Ray CT. J. Compos. Mater. 2020, 54, 549–561. [Google Scholar] [CrossRef]

- Yi, Q.; Tian, G.Y.; Malekmohammadi, H.; Zhu, J.; Laureti, S.; Ricci, M. New Features for Delamination Depth Evaluation in Carbon Fiber Reinforced Plastic Materials Using Eddy Current Pulse-Compression Thermography. NDT E Int. 2019, 102, 264–273. [Google Scholar] [CrossRef]

- Laureti, S.; Khalid Rizwan, M.; Malekmohammadi, H.; Burrascano, P.; Natali, M.; Torre, L.; Rallini, M.; Puri, I.; Hutchins, D.; Ricci, M. Delamination Detection in Polymeric Ablative Materials Using Pulse-Compression Thermography and Air-Coupled Ultrasound. Sensors 2019, 19, 2198. [Google Scholar] [CrossRef]

- Drummer, J.; Tafesh, F.; Fiedler, B. Effect of Fiber Misalignment and Environmental Temperature on the Compressive Behavior of Fiber Composites. Polymers 2023, 15, 2833. [Google Scholar] [CrossRef] [PubMed]

- Jafarypouria, M.; Lomov, S.V.; Mahato, B.; Abaimov, S.G. The Effect of Fibre Misalignment in an Impregnated Fibre Bundle on Stress Concentrations. Compos. Part. A Appl. Sci. Manuf. 2024, 178, 108001. [Google Scholar] [CrossRef]

- Aggarwal, S.; Kumar, K.; Aggarwal, M.L. Analysis of Glass Fiber-Reinforced Composite Leaf Springs in a Light Commercial Vehicle. Sci. Rep. 2024, 14, 20126. [Google Scholar] [CrossRef] [PubMed]

- Coca-Gonzalez, M.; Jimenez-Martinez, M. Warpage: Causes, Manufacturing Processes and Future Challenges: A Review. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2024, 1–17. [Google Scholar] [CrossRef]

- Collins, C.; Batista, N.L.; Hubert, P. Warpage Investigation of Carbon/PEEK Discontinuous Long Fibre Thin Panels. J. Compos. Mater. 2021, 55, 3529–3537. [Google Scholar] [CrossRef]

- Diaz, M.; Baur, J.W. Warpage of Thin Additively Manufactured Continuous Fiber Thermoset Composites. Addit. Manuf. 2025, 102, 104749. [Google Scholar] [CrossRef]

- Amaguaña, M.; Guamán, L.; Gómez, N.B.Y.; Khorami, M.; Calvo, M.; Albuja-Sánchez, J. Test Method for Studying the Shrinkage Effect under Controlled Environmental Conditions for Concrete Reinforced with Coconut Fibres. Materials 2023, 16, 3247. [Google Scholar] [CrossRef]

- Aghaee, K.; Khayat, K.H. Effect of Shrinkage-Mitigating Materials on Performance of Fiber-Reinforced Concrete—An Overview. Constr. Build. Mater. 2021, 305, 124586. [Google Scholar] [CrossRef]

- Aghaee, K.; Khayat, K.H. Design and Performance of Fiber-Reinforced Shrinkage Compensating Eco-Friendly Concrete. Constr. Build. Mater. 2023, 408, 133803. [Google Scholar] [CrossRef]

- Saradar, A.; Tahmouresi, B.; Mohseni, E.; Shadmani, A. Restrained Shrinkage Cracking of Fiber-Reinforced High-Strength Concrete. Fibers 2018, 6, 12. [Google Scholar] [CrossRef]

- Sui, J.; Li, X.; Zhang, H.; Xu, F.; Deng, J.; Hu, R.; Chen, M. Effect of Different Fibers on Shrinkage Properties and Bonding Properties of Geopolymer Mortar Repair Materials and Analysis of the Mechanism. Coatings 2023, 13, 1542. [Google Scholar] [CrossRef]

- Łukaszewicz, A. Nonlinear Numerical Model of Friction Heating during Rotary Friction Welding. J. Frict. Wear 2018, 39, 476–482. [Google Scholar] [CrossRef]

- Sidun, P.; Łukaszewicz, A. Verification of Ram-Press Pipe Bending Process Using Elasto-Plastic FEM Model. Acta Mech. Autom. 2017, 11, 47–52. [Google Scholar] [CrossRef]

- Łukaszewicz, A. Temperature Field in the Contact Zone in the Course of Rotary Friction Welding of Metals. Mater. Sci. 2019, 55, 39–45. [Google Scholar] [CrossRef]

- Acharjee, D.; Bandyopadhyay, D. A Numerical Study on the Fire Induced Collapse of a Real Life Warehouse Structure Based on Post-Fire NDT Results. J. Mines Met. Fuels 2023, 71, 1235–1249. [Google Scholar] [CrossRef]

- Munalli, D.; Dimitrakis, G.; Chronopoulos, D.; Greedy, S.; Long, A. The Use of Free-Space Microwave Non-Destructive Techniques_ Simulation of Damage Detection in Carbon Fibre Reinforced Composites. In Proceedings of the 11th Symposium on NDT in Aerospace, Paris, France, 13–15 November 2019; pp. 1–10. [Google Scholar]

- Evans, E.E.; Brooks, R.A.; Liu, J.; Hall, Z.E.C.; Liu, H.; Lowe, T.J.E.; Withers, P.J.; Kinloch, A.J.; Dear, J.P. Comparison of X-Ray Computed Tomography and Ultrasonic C-Scan Techniques and Numerical Modelling of Impact Damage in a CFRP Composite Laminate. Appl. Compos. Mater. 2024, 31, 249–264. [Google Scholar] [CrossRef]

- Feito, N.; Calvo, J.V.; Belda, R.; Giner, E. An Experimental and Numerical Investigation to Characterize an Aerospace Composite Material with Open-Hole Using Non-Destructive Techniques. Sensors 2020, 20, 4148. [Google Scholar] [CrossRef]

- Ratsakou, A.; Reboud, C.; Skarlatos, A.; Lesselier, D. Fast Simulation Approach Dedicated to Infrared Thermographic Inspection of Delaminated Planar Pieces. AIP Conf. Proc. 2019, 2102, 120004. [Google Scholar] [CrossRef]

- Notebaert, A.; Quinten, J.; Moonens, M.; Olmez, V.; Barros, C.; Cunha, S.S.; Demarbaix, A. Numerical Modelling of the Heat Source and the Thermal Response of an Additively Manufactured Composite during an Active Thermographic Inspection. Materials 2024, 17, 13. [Google Scholar] [CrossRef]

- Kim, H.J.; Shrestha, R.; Pradhan, S.S.; Gurung, P.; Bhattarai, P.; Lamichhane, N.; Kim, C.S.; Shrestha, R. Modelling and Simulation for Defect Detection in Hydroelectric Penstock Using Infrared Thermography. Therm. Sci. Eng. 2023, 6, 2494. [Google Scholar] [CrossRef]

- Marrazzo, M.; Sharif Khodaei, Z.; Aliabadi, M.H.F. Laplace Domain Boundary Element Method for Structural Health Monitoring of Poly-Crystalline Materials at Micro-Scale. Appl. Sci. 2023, 13, 13138. [Google Scholar] [CrossRef]

- Bao, Y.; Liu, Z.; Bowler, J.R.; Song, J. Nested Kernel Degeneration-Based Boundary Element Method Solver for Rapid Computation of Eddy Current Signals. NDT E Int. 2022, 128, 102633. [Google Scholar] [CrossRef]

- Tai, J.L.; Sultan, M.T.H.; Shahar, F.S.; Yidris, N.; Basri, A.A.; Md Shah, A.U. Exploring Probability of Detection (POD) Analysis in Nondestructive Testing: A Comprehensive Review and Potential Applications in Phased Array Ultrasonic Corrosion Mapping. Pertanika J. Sci. Technol. 2024, 32, 2165–2191. [Google Scholar] [CrossRef]

- Baskaran, P.; Pasadas, D.J.; Ramos, H.G.; Ribeiro, A.L. Integration of Multiple Response Signals into the Probability of Detection Modelling in Eddy Current NDE of Flaws. NDT E Int. 2021, 118, 102401. [Google Scholar] [CrossRef]

- Hachi, D.; Benhadda, N.; Helifa, B.; Lefkaier, I.K.; Abdelhadi, B. Composite Material Characterization Using Eddy Current by 3D FEM Associated with Iterative Technique. Adv. Electromagn. 2019, 8, 8–15. [Google Scholar] [CrossRef]

- Xi, Z.; Li, S.; Feng, C.; Wang, X.; Luo, X. Analytical Modeling and Non-Dimensionalization Study for Endoscopic Ultrasound Acoustic Field in Tubular Structure. NDT E Int. 2025, 150, 103275. [Google Scholar] [CrossRef]

- Cheikh, K.; Boudi, E.L.M.; Rabi, R.; Mokhliss, H. Balancing the Maintenance Strategies to Making Decisions Using Monte Carlo Method. MethodsX 2024, 13, 102819. [Google Scholar] [CrossRef]

- Wicaksono, F.D.; Arshad, Y.B.; Sihombing, H. Norm-Dist Monte-Carlo Integrative Method for the Improvement of Fuzzy Analytic Hierarchy Process. Heliyon 2020, 6, e03607. [Google Scholar] [CrossRef] [PubMed]

- Yao, M.; Kaftandjian, V.; Peterzol-Parmentier, A.; Schumm, A.; Duvauchelle, P. Hybrid Monte Carlo and Deterministic Simulation Approach for Modeling a Computed Radiography Imaging Chain from X-Ray Exposure to Optical Readout. Nucl. Instrum. Methods Phys. Res. A 2019, 941, 162328. [Google Scholar] [CrossRef]

- Mousa, T.; Taha, E.; Alnadwi, F.; Siddig, M.; Banoqitah, E. Simulation Study on X-Ray Radiographic Testing of Welds. In Challenges and Recent Advancements in Nuclear Energy Systems—Proceedings of Saudi International Conference on Nuclear Power Engineering SCOPE; Springer: Cham, Switzerland, 2024. [Google Scholar]

- Sari, M.B.; Wirawan, R.; Waris, A.; Kim, H.J.; Djamal, M. Simulation of Void Detection System Using Gamma-Ray Compton Scattering Technique. J. Eng. Technol. Sci. 2019, 51, 369–379. [Google Scholar] [CrossRef]

- Kumar, S.; Menaka, M.; Venkatraman, B. Radiographic Simulation and Validation Studies on Weld Joints of Annular Tanks and Cylindrical Tanks. IOP Conf. Ser. Mater. Sci. Eng. 2019, 554, 012008. [Google Scholar] [CrossRef]

- Osipov, S.P.; Chakhlov, S.V.; Kairalapov, D.U.; Sirot’yan, E.V. Numerical Modeling of Radiographic Images as the Basis for Correctly Designing Digital Radiography Systems of Large-Sized Objects. Russ. J. Nondestruct. Test. 2019, 55, 136–149. [Google Scholar] [CrossRef]

- Rodat, D.; Guibert, F.; Dominguez, N.; Calmon, P. Operational NDT Simulator, towards Human Factors Integration in Simulated Probability of Detection. AIP Conf. Proc. 2017, 1806, 140004. [Google Scholar] [CrossRef]

- Lei, X.; Wirdelius, H.; Rosell, A. Simulation-Based Investigation of a Probability of Detection (POD) Model Using Phased Array Ultrasonic Testing (PAUT) Technique. J. Nondestruct. Eval. 2022, 41, 40. [Google Scholar] [CrossRef]

- Vives, J.; Palací, J.; Heart, J.; Vives, J.; Palací, J.; Heart, J. SVM-Algorithm for Supervision, Monitoring and Detection Vibration in Wind Turbines. J. Comput. Commun. 2022, 10, 44–55. [Google Scholar] [CrossRef]

- Da Silva Souza, J.; Luz Dos Santos, M.V.; Suzuki Bayma, R.; Amarante Mesquita, A.L. Analysis of Window Size and Statistical Features for SVM-Based Fault Diagnosis in Bearings. IEEE Lat. Am. Trans. 2021, 19, 243–249. [Google Scholar] [CrossRef]

- Dobrzycki, A.; Mikulski, S.; Opydo, W. Using ANN and SVM for the Detection of Acoustic Emission Signals Accompanying Epoxy Resin Electrical Treeing. Appl. Sci. 2019, 9, 1523. [Google Scholar] [CrossRef]

- Kiyak, E.O.; Ghasemkhani, B. High-Level K-Nearest Neighbors (HLKNN): A Supervised Machine Learning Model for Classification Analysis. Electronics 2023, 12, 3828. [Google Scholar] [CrossRef]

- Grochowalski, J.M.; Chady, T. Rapid Identification of Material Defects Based on Pulsed Multifrequency Eddy Current Testing and the K-Nearest Neighbor Method. Materials 2023, 16, 6650. [Google Scholar] [CrossRef] [PubMed]

- Shu, L.; Zhang, H.; You, Y.; Cui, Y.; Chen, W. Towards Fire Prediction Accuracy Enhancements by Leveraging an Improved Naïve Bayes Algorithm. Symmetry 2021, 13, 530. [Google Scholar] [CrossRef]

- Kaushik, K.; Bhardwaj, A.; Dahiya, S.; Maashi, M.S.; Al Moteri, M.; Aljebreen, M.; Bharany, S. Multinomial Naive Bayesian Classifier Framework for Systematic Analysis of Smart IoT Devices. Sensors 2022, 22, 7318. [Google Scholar] [CrossRef]

- Malarvel, M.; Singh, H. An Autonomous Technique for Weld Defects Detection and Classification Using Multi-Class Support Vector Machine in X-Radiography Image. Optik 2021, 231, 166342. [Google Scholar] [CrossRef]

- Cormerais, R.; Duclos, A.; Wasselynck, G.; Berthiau, G.; Longo, R. A Data Fusion Method for Non-Destructive Testing by Means of Artificial Neural Networks. Sensors 2021, 21, 2598. [Google Scholar] [CrossRef]

- Alhammad, M.; Avdelidis, N.P.; Ibarra-Castanedo, C.; Torbali, M.E.; Genest, M.; Zhang, H.; Zolotas, A.; Maldgue, X.P.V. Automated Impact Damage Detection Technique for Composites Based on Thermographic Image Processing and Machine Learning Classification. Sensors 2022, 22, 9031. [Google Scholar] [CrossRef]

- Palma-Ramírez, D.; Ross-Veitía, B.D.; Font-Ariosa, P.; Espinel-Hernández, A.; Sanchez-Roca, A.; Carvajal-Fals, H.; Nuñez-Alvarez, J.R.; Hernández-Herrera, H. Deep Convolutional Neural Network for Weld Defect Classification in Radiographic Images. Heliyon 2024, 10, e30590. [Google Scholar] [CrossRef]

- Posilović, L.; Medak, D.; Milković, F.; Subašić, M.; Budimir, M.; Lončarić, S. Deep Learning-Based Anomaly Detection from Ultrasonic Images. Ultrasonics 2022, 124, 106737. [Google Scholar] [CrossRef]

- Park, S.K.; Kim, J.; Park, D.G.; Jo, M.; Lee, J.; Lee, J. Experimental Investigation to Improve Inspection Accuracy of Magnetic Field Imaging-Based NDT Using Deep Neural Network. Russ. J. Nondestruct. Test. 2022, 58, 732–744. [Google Scholar] [CrossRef]

- Nele, L.; Mattera, G.; Vozza, M. Deep Neural Networks for Defects Detection in Gas Metal Arc Welding. Appl. Sci. 2022, 12, 3615. [Google Scholar] [CrossRef]

- Hena, B.; Wei, Z.; Castanedo, C.I.; Maldague, X. Deep Learning Neural Network Performance on NDT Digital X-Ray Radiography Images: Analyzing the Impact of Image Quality Parameters—An Experimental Study. Sensors 2023, 23, 4324. [Google Scholar] [CrossRef]

- Fotouhi, S.; Pashmforoush, F.; Bodaghi, M.; Fotouhi, M. Autonomous Damage Recognition in Visual Inspection of Laminated Composite Structures Using Deep Learning. Compos. Struct. 2021, 268, 113960. [Google Scholar] [CrossRef]

- Cha, Y.J.; Choi, W.; Büyüköztürk, O. Deep Learning-Based Crack Damage Detection Using Convolutional Neural Networks. Comput.-Aided Civ. Infrastruct. Eng. 2017, 32, 361–378. [Google Scholar] [CrossRef]

- Wei, Z.; Osman, A.; Valeske, B.; Maldague, X. Pulsed Thermography Dataset for Training Deep Learning Models. Appl. Sci. 2023, 13, 2901. [Google Scholar] [CrossRef]

- Virkkunen, I.; Koskinen, T.; Jessen-Juhler, O.; Rinta-aho, J. Augmented Ultrasonic Data for Machine Learning. J. Nondestruct. Eval. 2021, 40, 4. [Google Scholar] [CrossRef]

- Trouvé-Peloux, P.; Abeloos, B.; Ben Fekih, A.; Trottier, C.; Roche, J.M. Benefit of Neural Network for the Optimization of Defect Detection on Composite Material Using Ultrasonic Non Destructive Testing. In Proceedings of the 48th Annual Review of Progress in Quantitative Nondestructive Evaluation (QNDE 2021), Virtual, 28–30 July 2021. [Google Scholar] [CrossRef]

- Yosifov, M.; Weinberger, P.; Reiter, M.; Fröhler, B.; De Beenhouwer, J.; Sijbers, J.; Kastner, J.; Heinzl, C. Defect Detectability Analysis via Probability of Defect Detection between Traditional and Deep Learning Methods in Numerical Simulations. e-J. Nondestruct. Test. 2023, 28, 2–11. [Google Scholar] [CrossRef] [PubMed]

- Wei, Z.; Fernandes, H.; Herrmann, H.G.; Tarpani, J.R.; Osman, A. A Deep Learning Method for the Impact Damage Segmentation of Curve-Shaped Cfrp Specimens Inspected by Infrared Thermography. Sensors 2021, 21, 395. [Google Scholar] [CrossRef]

- Guo, F.; Li, W.; Jiang, P.; Chen, F.; Yang, C. Deep Learning Approach for Damage Classification Based on Acoustic Emission Data in Composite Materials. Materials 2022, 15, 4270. [Google Scholar] [CrossRef]

- Du, W.; Shen, H.; Fu, J.; Zhang, G.; He, Q. Approaches for Improvement of the X-Ray Image Defect Detection of Automobile Casting Aluminum Parts Based on Deep Learning. NDT E Int. 2019, 107, 102144. [Google Scholar] [CrossRef]

- Pointon, J.L.; Wen, T.; Tugwell-Allsup, J.; Sújar, A.; Létang, J.M.; Vidal, F.P. Simulation of X-Ray Projections on GPU: Benchmarking GVirtualXray with Clinically Realistic Phantoms. Comput. Methods Programs Biomed. 2023, 234, 107500. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Fan, Z.; Chen, X.; Cheng, J.; Chen, W.; Wang, Z.; Bu, Y. Automated Classification of Pipeline Defects from Ultrasonic Phased Array Total Focusing Method Imaging. Energies 2022, 15, 8272. [Google Scholar] [CrossRef]

| FRP Composite Type | Reinforcement | Key Properties | Typical Applications | Typical Mechanical Properties |

|---|---|---|---|---|

| GFRP (Glass Fiber-Reinforced Polymer) | Glass fibers | High strength, corrosion resistance, electrical insulation | Construction, automotive, marine | Tensile Strength: 500–900 MPa, Modulus: 35–55 GPa, Density: 1.8–2.0 g/cm3 |

| CFRP (Carbon Fiber-Reinforced Polymer) | Carbon fibers | High strength-to-weight ratio, high stiffness, corrosion resistance | Aerospace, automotive, sporting goods, structural engineering | Tensile Strength: 600–3500 MPa, Modulus: 70–250 GPa, Density: 1.5–1.6 g/cm3 |

| AFRP (Aramid Fiber-Reinforced Polymer) | Aramid fibers (e.g., Kevlar) | High tensile strength, impact resistance, flame resistance | Body armor, protective gear, structural applications | Tensile Strength: 3000–3600 MPa, Modulus: 60–125 GPa, Density: 1.44 g/cm3 |

| BFRP (Basalt Fiber-Reinforced Polymer) | Basalt fibers | High-temperature resistance | Construction, infrastructure repair and reinforcement | Tensile Strength: 2000–4840 MPa, Modulus: 89–93 GPa, Density: 2.7 g/cm3 |

| NFRP (Natural Fiber-Reinforced Polymer) | Natural fibers (e.g., jute, hemp, flax) | Environmental friendliness, low density, flexibility, cost-effectiveness | Automotive interiors, furniture, construction | Tensile Strength: 200–900 MPa, Modulus: 10–30 GPa, Density: 1.2–1.5 g/cm3 |

| HFRP (Hybrid Fiber-Reinforced Polymer) | Combination of various fiber types | Balanced properties (strength, stiffness, cost-effectiveness) | Wide range of applications | Varies based on fiber combination |

| Resin Type | Advantages | Disadvantages | Typical Properties |

|---|---|---|---|

| Polyester | Low cost, good chemical resistance, easy to process | Lower mechanical strength, poor elongation | Tensile Strength: 40–100 MPa, Tg: 70–80 °C, Low viscosity |

| Epoxy | High strength, excellent adhesion, good mechanical properties | Higher cost, sensitive to curing conditions | Tensile Strength: 70–150 MPa, Tg: 120–180 °C, Moderate viscosity |

| Vinyl Ester | High chemical resistance, good mechanical properties, good toughness | More expensive than polyester, handling precautions required | Tensile Strength: 80–130 MPa, Tg: 90–140 °C, Moderate viscosity |

| Thermoplastic Resin | Key Properties | Advantages | Limitations | Example Applications |

|---|---|---|---|---|

| Polypropylene (PP) | Low density, good chemical resistance | Lightweight, cost-effective, corrosion-resistant | Low thermal stability, limited mechanical strength | Chemical pipelines, water systems |

| Polyethylene Terephthalate (PET) | Good mechanical strength, chemical resistance, recyclable | High impact resistance, good environmental profile | Moisture sensitivity, thermal limitations | Water treatment, automotive parts |

| Polyetheretherketone (PEEK) | High mechanical and thermal performance | Excellent chemical and thermal resistance, high strength-to-weight | High cost, requires high processing temperature | Aerospace, oil and gas piping |

| Polyamide (Nylon) | High toughness, moderate moisture absorption | Good impact resistance, flexible processing | Moisture sensitivity, lower chemical resistance than PEEK | Automotive, industrial piping |

| Modeling Method | Strengths | Limitations | Typical Applications | Reported Performance |

|---|---|---|---|---|