Highly Stable, Flexible, Transparent Hybrid Strontium Titanate Conductive Thin Films with Embedded Cu Nanowires

Abstract

1. Introduction

2. Materials and Methods

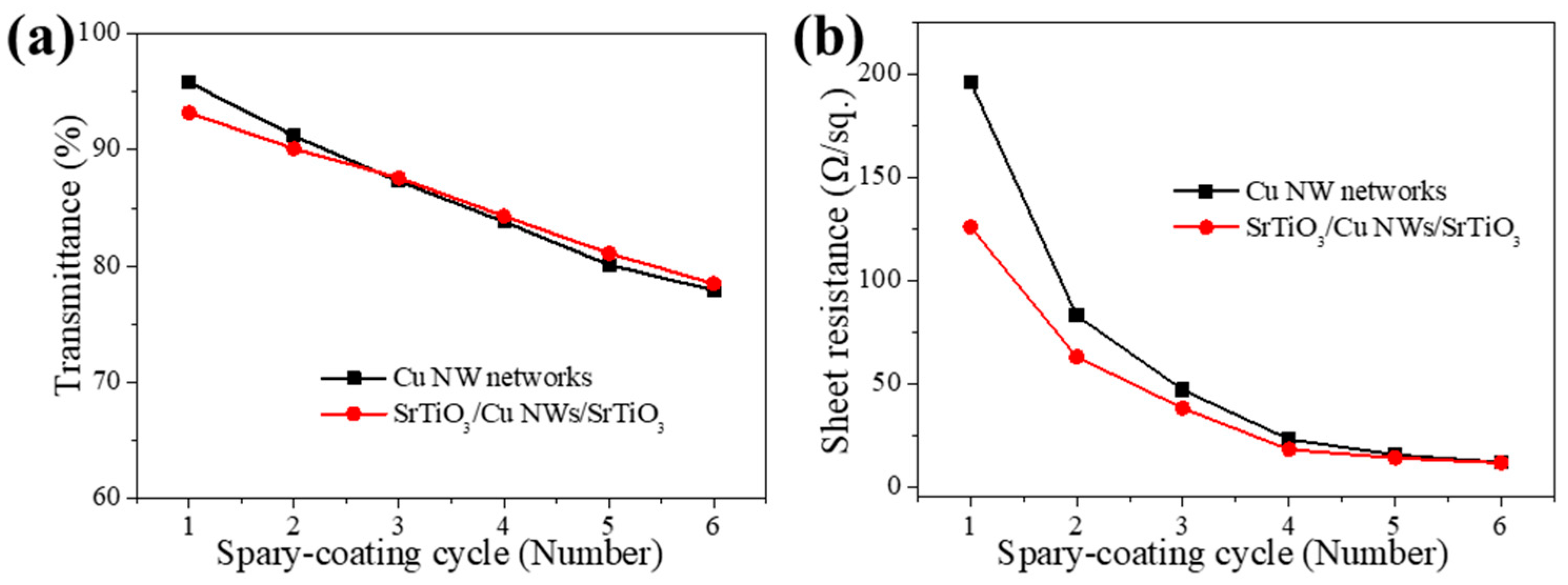

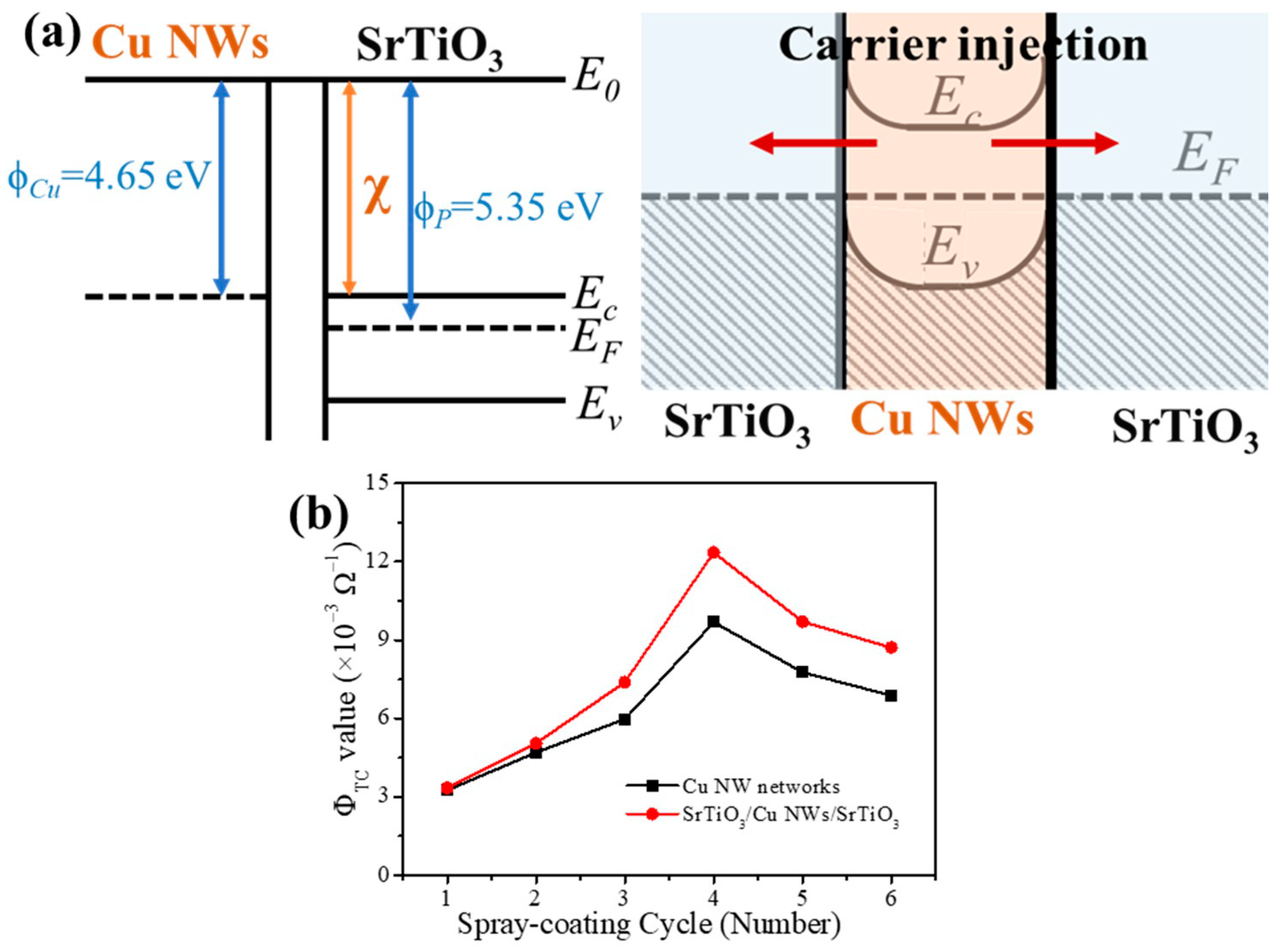

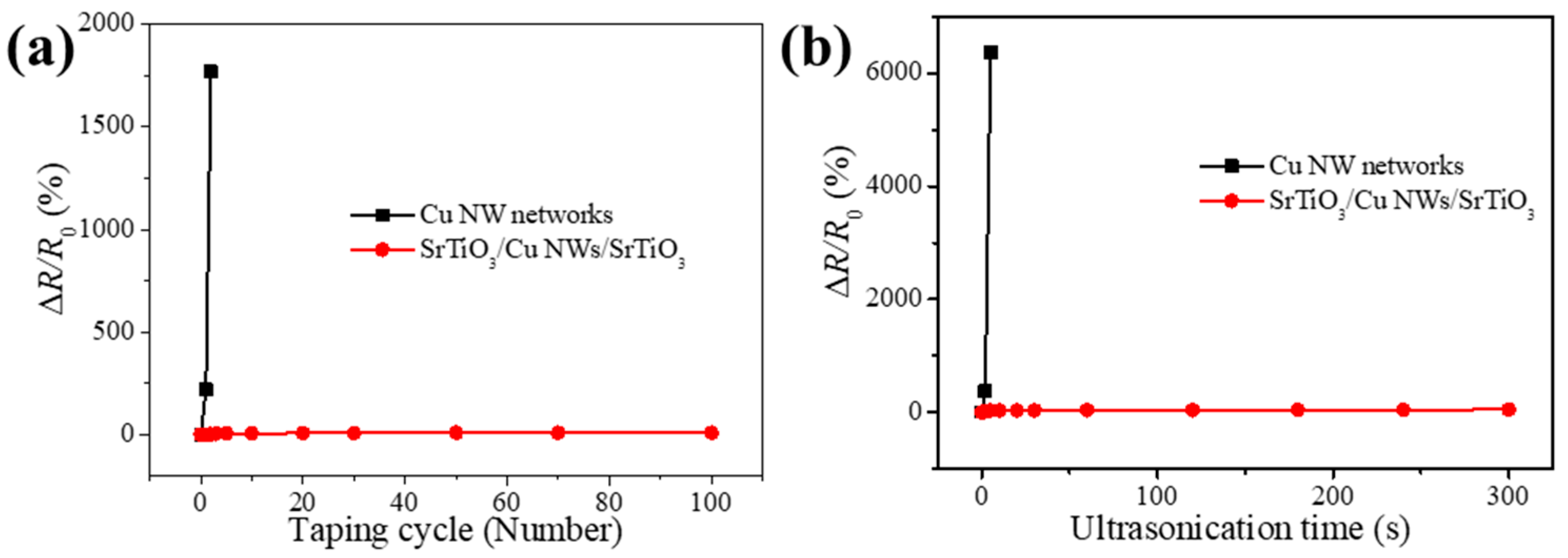

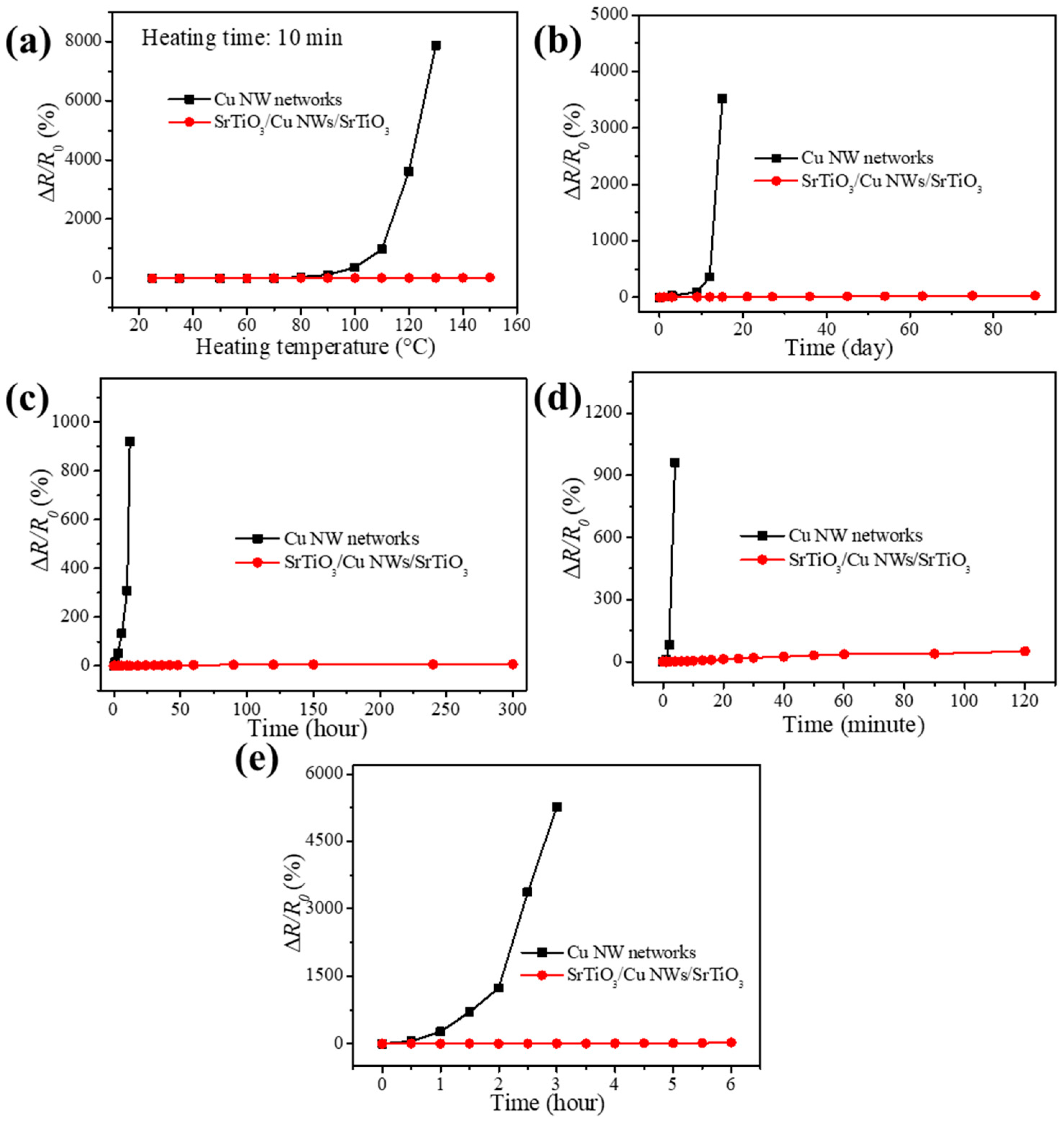

3. Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yao, F.; Li, W.; Sks, S.K.; Fukuhara, C.; Badhulika, S.; Kong, C.Y. Scalable one-step synthesis of reduced graphene oxide: Towards flexible transparent conductive films and active supercapacitor electrodes. Chem. Eng. J. 2024, 488, 150828. [Google Scholar] [CrossRef]

- Yu, S.; Song, L.; Wu, C.; Li, L. Enhanced conductivity and stability of Cu-embedded zinc tin oxide flexible transparent conductive thin films. Ceram. Inter. 2022, 48, 15925–15931. [Google Scholar] [CrossRef]

- Huang, H.; Wang, J.; Liu, Y.; Zhao, M.; Zhang, N.; Hu, Y.; Fan, F.; Feng, J.; Li, Z.; Zou, Z. Stacking textured films on lattice-mismatched transparent conducting oxides via matched Voronoi cell of oxygen sublattice. Nat. Mater. 2024, 23, 383–390. [Google Scholar] [CrossRef]

- Jin, W.Y.; Ovhal, M.M.; Lee, H.B.; Tyagi, B.; Kang, J.W. Scalable, all-printed photocapacitor fibers and modules based on metal-embedded flexible transparent conductive electrodes for self-charging wearable applications. Adv. Energy Mater. 2021, 11, 2003509. [Google Scholar] [CrossRef]

- Qiu, T.; Akinoglu, E.M.; Luo, B.; Konarova, M.; Yun, J.H.; Gentle, I.R.; Wang, L. Nanosphere lithography: A versatile approach to develop transparent conductive films for optoelectronic applications. Adv. Mater. 2022, 34, 2103842. [Google Scholar] [CrossRef]

- Nguyen, V.H.; Papanastasiou, D.T.; Resende, J.; Bardet, L.; Sannicolo, T.; Jiménez, C.; Muñoz-Rojas, D.; Nguyen, N.D.; Bellet, D. Advances in flexible metallic transparent electrodes. Small 2022, 18, 2106006. [Google Scholar] [CrossRef]

- Anand, A.; Islam, M.M.; Meitzner, R.; Schubert, U.S.; Hoppe, H. Introduction of a novel figure of merit for the assessment of transparent conductive electrodes in photovoltaics: Exact and approximate form. Adv. Energy Mater. 2021, 11, 2100875. [Google Scholar] [CrossRef]

- Wang, T.; Lu, K.; Xu, Z.; Lin, Z.; Ning, H.; Qiu, T.; Yang, Z.; Zheng, H.; Yao, R.; Peng, J. Recent developments in flexible transparent electrode. Crystals 2021, 11, 511. [Google Scholar] [CrossRef]

- Zhao, W.; Jiang, M.; Wang, W.; Liu, S.; Huang, W.; Zhao, Q. Flexible transparent supercapacitors: Materials and devices. Adv. Funct. Mater. 2021, 31, 2009136. [Google Scholar] [CrossRef]

- Fan, Q.; Miao, J.; Liu, X.; Zuo, X.; Zhang, W.; Tian, M.; Zhu, S.; Qu, L.; Zhang, X. Biomimetic hierarchically silver nanowire interwoven MXene mesh for flexible transparent electrodes and invisible camouflage electronics. Nano Lett. 2022, 22, 740–750. [Google Scholar] [CrossRef]

- Yu, S.; Liu, Z.; Zhao, L.; Gong, B. High-performance flexible transparent conductive tape based on copper nanowires. Opt. Mater. 2021, 119, 111301. [Google Scholar] [CrossRef]

- Sánchez-Iglesias, A.; Rivas-Murias, B.; Grzelczak, M.; Pérez-Juste, J.; Liz-Marzán, L.M.; Rivadulla, F.; Correa-Duarte, M.A. Highly transparent and conductive films of densely aligned ultrathin Au nanowire monolayers. Nano Lett. 2012, 12, 6066–6070. [Google Scholar] [CrossRef]

- Kumar, A.; Shaikh, M.O.; Chuang, C.H. Silver nanowire synthesis and strategies for fabricating transparent conducting electrodes. Nanomaterials 2021, 11, 693. [Google Scholar] [CrossRef] [PubMed]

- Scardaci, V. Copper nanowires for transparent electrodes: Properties, challenges and applications. Appl. Sci. 2021, 11, 8035. [Google Scholar] [CrossRef]

- Huang, S.; Liu, Y.; Yang, F.; Wang, Y.; Yu, T.; Ma, D. Metal nanowires for transparent conductive electrodes in flexible chromatic devices: A review. Environ. Chem. Lett. 2022, 20, 3005–3037. [Google Scholar] [CrossRef]

- Yu, S.; Li, J.; Zhao, L.; Gong, B.; Li, L. Folding-insensitive, flexible transparent conductive electrodes based on copper nanowires. Sol. Energy Mater. Sol. Cells 2021, 231, 111323. [Google Scholar] [CrossRef]

- Cetin, O.; Cakir, O.; Koylan, S.; Doganay, D.; Khan, Y.; Unalan, H.E. All-solution processed, highly stable MXene/Cu nanowire networks for flexible transparent thin-film heaters. ACS Appl. Nano Mater. 2023, 6, 22446–22458. [Google Scholar] [CrossRef]

- Dimngaihvungi, E.; Singh, M.; Pani, B.; Singh, A.K. Silver and copper nanowire-based nanocomposite for transparent electrodes: Deposition methods and applications in solar cells. Compos. Interfaces 2023, 30, 1449–1481. [Google Scholar] [CrossRef]

- Chiu, J.M.; Wahdini, I.; Shen, Y.N.; Tseng, C.Y.; Sharma, J.; Tai, Y. Highly stable copper nanowire-based transparent conducting electrode utilizing polyimide as a protective layer. ACS Appl. Energy Mater. 2023, 6, 5058–5066. [Google Scholar] [CrossRef]

- Zhao, L.; Li, J.; Song, Z.; Wang, X.; Yu, S. Self-assembled growth of SnO2 nanoshells on copper nanowires for stable and transparent conductors. ACS Appl. Nano Mater. 2023, 6, 10658–10667. [Google Scholar] [CrossRef]

- Kim, S.; Lee, G.; Lee, C.; Yang, G.; Park, S.; Min, Y. Synthesis of Bimetallic Cu-Au Nanotubes and Cu@Au Core-Shell Nanowires for Anti-Oxidative Electrodes. Korean J. Mater. Res. 2025, 35, 9–17. [Google Scholar] [CrossRef]

- Stewart, I.E.; Ye, S.; Chen, Z.; Flowers, P.F.; Wiley, B.J. Synthesis of Cu–Ag, Cu–Au, and Cu–Pt core–shell nanowires and their use in transparent conducting films. Chem. Mater. 2015, 27, 7788–7794. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, S.; Tian, Y.; Liu, Y.; Wen, J.; Huang, Y.; Hang, C.; Zheng, Z.; Wang, C. Electrodeposition fabrication of Cu@Ni core shell nanowire network for highly stable transparent conductive films. Chem. Eng. J. 2020, 390, 124495. [Google Scholar] [CrossRef]

- Kuo, Y.-C.; Fan, J.; Zong, L.; Chen, F.; Feng, Z.; Liu, C.; Wan, T.; Gu, Z.; Hu, L.; Guan, P.; et al. Rational design of robust Cu@Ag core-shell nanowires for wearable electronics applications. Chem. Eng. J. 2024, 496, 154001. [Google Scholar] [CrossRef]

- Li, X.; Wang, Y.; Hou, Y.; Yin, C.; Yin, Z. Graphene nanosheet/Cu nanowire composite aerogel with a thin PDMS coating for electrically conductive pressure sensing rubber. Compos. Part A Appl. Sci. Manuf. 2021, 140, 106192. [Google Scholar] [CrossRef]

- Kumar, D.R.; Woo, K.; Moon, J. Promising wet chemical strategies to synthesize Cu nanowires for emerging electronic applications. Nanoscale 2015, 7, 17195–17210. [Google Scholar] [CrossRef]

- Yu, S.; Li, J.; Zhao, L.; Wu, M.; Dong, H.; Li, L. Simultaneously enhanced performances of flexible CuNW networks by covering ATO layer for polymer solar cells. Sol. Energy Mater. Sol. Cells 2021, 221, 110885. [Google Scholar] [CrossRef]

- Li, X.; Wang, Y.; Yin, C.; Yin, Z. Copper nanowires in recent electronic applications: Progress and perspectives. J. Mater. Chem. C 2020, 8, 849–872. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, M.; Li, F.; Zhao, H.; Wen, Z. Decoration of Cu nanowires with chemically modified TiO2 nanoparticles for their improved photocatalytic performance. J. Mater. Sci. 2013, 48, 6728–6736. [Google Scholar] [CrossRef]

- Asif, M.; Afaq, A.; Amin, M.; Raouf, K.; Majeed, A.; Asif, M. Optical properties of strontium titanate (STO) thin films using transfer matrix method. Mater. Today Commun. 2023, 37, 106966. [Google Scholar] [CrossRef]

- Tumarkin, A.; Sapego, E.; Gagarin, A.; Bogdan, A.; Karamov, A.; Serenkov, I.; Sakharov, V. SrTiO3 Thin Films on Dielectric Substrates for Microwave Applications. Coatings 2023, 14, 3. [Google Scholar] [CrossRef]

- Khalid, M.A.U.; Kim, S.W.; Lee, J.; Soomro, A.M.; Rehman, M.M.; Lee, B.G.; Choi, K.H. Resistive switching device based on SrTiO3/PVA hybrid composite thin film as active layer. Polymer 2020, 189, 122183. [Google Scholar] [CrossRef]

- Yin, Z.; Song, S.K.; Cho, S.; You, D.J.; Yoo, J.; Chang, S.T.; Kim, Y.S. Curved copper nanowires-based robust flexible transparent electrodes via all-solution approach. Nano Res. 2017, 10, 3077–3091. [Google Scholar] [CrossRef]

- Kınacı, B.; Akın, N.; Durukan, İ.; Memmedli, T.; Özçelik, S. The study on characterizations of SrTiO3 thin films with different growth temperatures. Superlattices Microstruct. 2014, 76, 234–243. [Google Scholar] [CrossRef]

- Yu, S.; Dong, H.; Zhao, L.; Wang, Z.; Wu, C. Highly transparent and low resistance BaSnO3/Ag nanowire composite thin films. Curr. Appl. Phys. 2024, 57, 86–92. [Google Scholar] [CrossRef]

- Cong, L.; Zhao, H.; Han, Y.; Zhang, S.; Gao, C.; Cheng, Z.; Yang, J.; Wang, H. Transparent, low dark current, fast response ultraviolet and short-wavelength blue photons photodetector based on Graphene/SrTiO3 single crystal. Curr. Appl. Phys. 2024, 63, 136–142. [Google Scholar] [CrossRef]

- Ma, J.; Zhong, W.; You, L.; Pei, Y.; Lu, C.; Xiao, Z.; Shen, Z.; Jiang, X.; Qian, N.; Liu, X.; et al. Band bending caused by forming heterojunctions in Cu-Cu2O/rGO-NH2 semiconductor materials and surface coordination of N-methylimidazole, and the intrinsic nature of synergistic effect on the catalysis of selective aerobic oxidation of alcohols. Appl. Surf. Sci. 2022, 605, 154563. [Google Scholar] [CrossRef]

- Zheng, K.O.; Rosli, N.; Rashid, M.M.M.; Halim, M.M. Influence of copper contact thickness on Cu/ZnO nanorods-enhanced Schottky diode. Physica B 2023, 648, 414425. [Google Scholar] [CrossRef]

- He, W.; Ye, C. Flexible transparent conductive films on the basis of Ag nanowires: Design and applications: A review. J. Mater. Sci. Technol. 2015, 31, 581–588. [Google Scholar] [CrossRef]

- Park, H.J.; Park, J.H.; Choi, J.I.; Lee, J.Y.; Chae, J.H.; Kim, D. Fabrication of transparent conductive films with a sandwich structure composed of ITO/Cu/ITO. Vacuum 2008, 83, 448–450. [Google Scholar] [CrossRef]

- Haacke, G. New figure of merit for transparent conductors. J. Appl. Phys. 1976, 47, 4086–4089. [Google Scholar] [CrossRef]

- Wilke, J.; Macchi, V.; De Caro, R.; Stecco, C. Fascia thickness, aging and flexibility: Is there an association? J. Anat. 2019, 234, 43–49. [Google Scholar] [CrossRef]

- Xu, W.H.; Wang, L.; Guo, Z.; Chen, X.; Liu, J.; Huang, X.J. Copper nanowires as nanoscale interconnects: Their stability, electrical transport, and mechanical properties. ACS Nano 2015, 9, 241–250. [Google Scholar] [CrossRef]

- Nam, V.B.; Lee, D. Copper nanowires and their applications for flexible, transparent conducting films: A review. Nanomaterials 2016, 6, 47. [Google Scholar] [CrossRef]

- Yang, Y.; Li, W.; Sreenivasan Narayanan, S.; Wang, X.; Zhao, H. Advanced printing transfer of assembled silver nanowire network into elastomer for constructing stretchable conductors. Adv. Eng. Mater. 2023, 25, 2300675. [Google Scholar] [CrossRef]

- Afre, R.A.; Sharma, N.; Sharon, M.; Sharon, M. Transparent conducting oxide films for various applications: A review. Rev. Adv. Mater. Sci. 2018, 53, 79–89. [Google Scholar] [CrossRef]

- You, W.; Liao, B.; Wan, S.; Guo, X. Research progress on the stability of transparent conductive films for silver nanowires. Microelectron. Reliab. 2024, 156, 115394. [Google Scholar] [CrossRef]

- Chen, K.X.; Gao, L.Y.; Meng, Z.C.; Liu, Z.Q. Modulation on the twinning microstructure of Cu nanowires and its effect on oxidation behaviour. Chem. Eng. J. 2024, 496, 154308. [Google Scholar] [CrossRef]

- Boehme, M.; Charton, C. Properties of ITO on PET film in dependence on the coating conditions and thermal processing. Surf. Coat. Tech. 2005, 200, 932–935. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, M.; Yu, S.; Song, L.; Li, J.; Feng, J. Highly Stable, Flexible, Transparent Hybrid Strontium Titanate Conductive Thin Films with Embedded Cu Nanowires. Materials 2025, 18, 2398. https://doi.org/10.3390/ma18102398

Liu M, Yu S, Song L, Li J, Feng J. Highly Stable, Flexible, Transparent Hybrid Strontium Titanate Conductive Thin Films with Embedded Cu Nanowires. Materials. 2025; 18(10):2398. https://doi.org/10.3390/ma18102398

Chicago/Turabian StyleLiu, Ming, Shihui Yu, Lijun Song, Jiesong Li, and Jian Feng. 2025. "Highly Stable, Flexible, Transparent Hybrid Strontium Titanate Conductive Thin Films with Embedded Cu Nanowires" Materials 18, no. 10: 2398. https://doi.org/10.3390/ma18102398

APA StyleLiu, M., Yu, S., Song, L., Li, J., & Feng, J. (2025). Highly Stable, Flexible, Transparent Hybrid Strontium Titanate Conductive Thin Films with Embedded Cu Nanowires. Materials, 18(10), 2398. https://doi.org/10.3390/ma18102398