Lunar Regolith Improvement by Inducing Interparticle Adhesion with Capillary Forces

Abstract

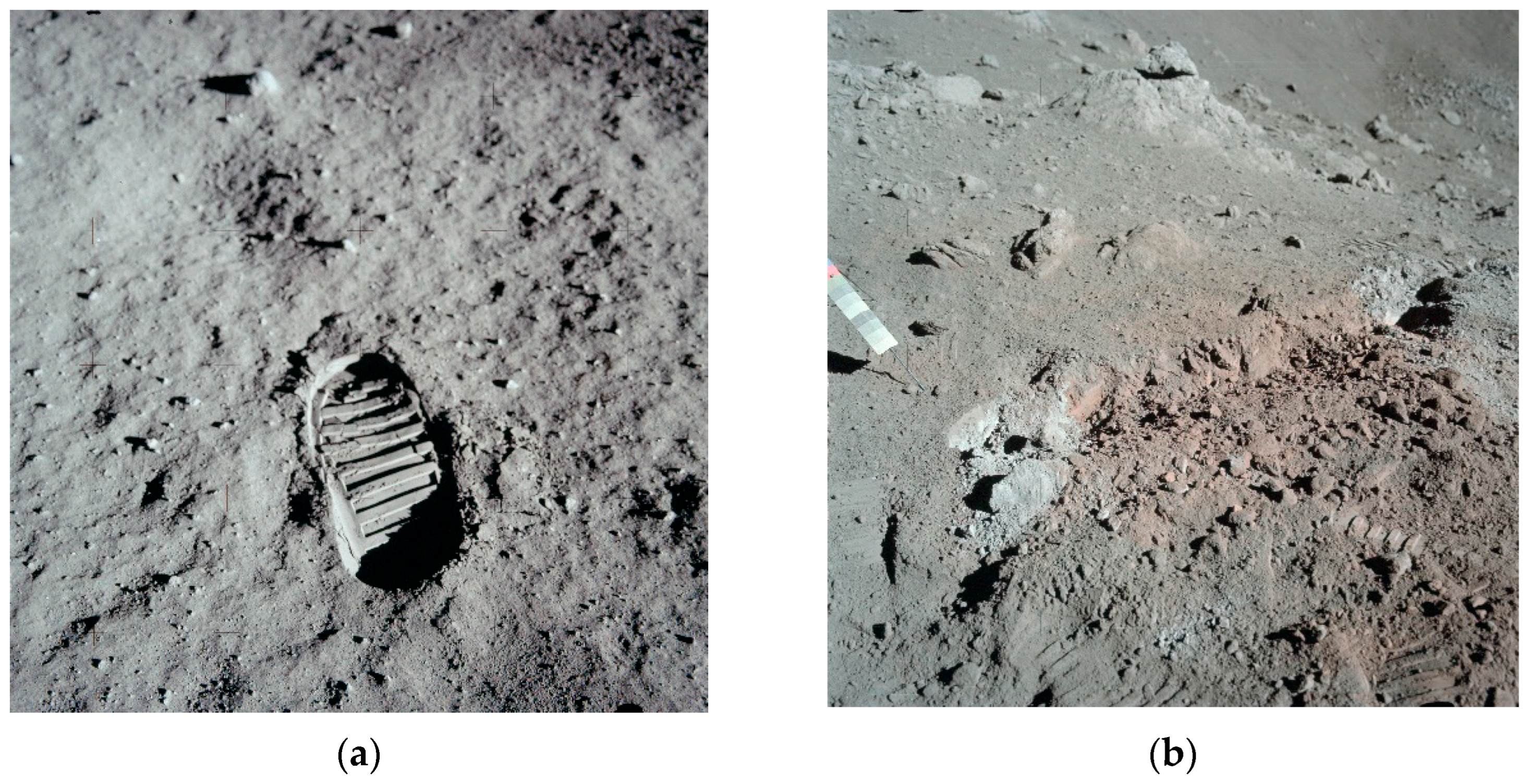

1. Introduction

2. Materials and Methods

2.1. Theoretical Foundations of Capillary Consolidation

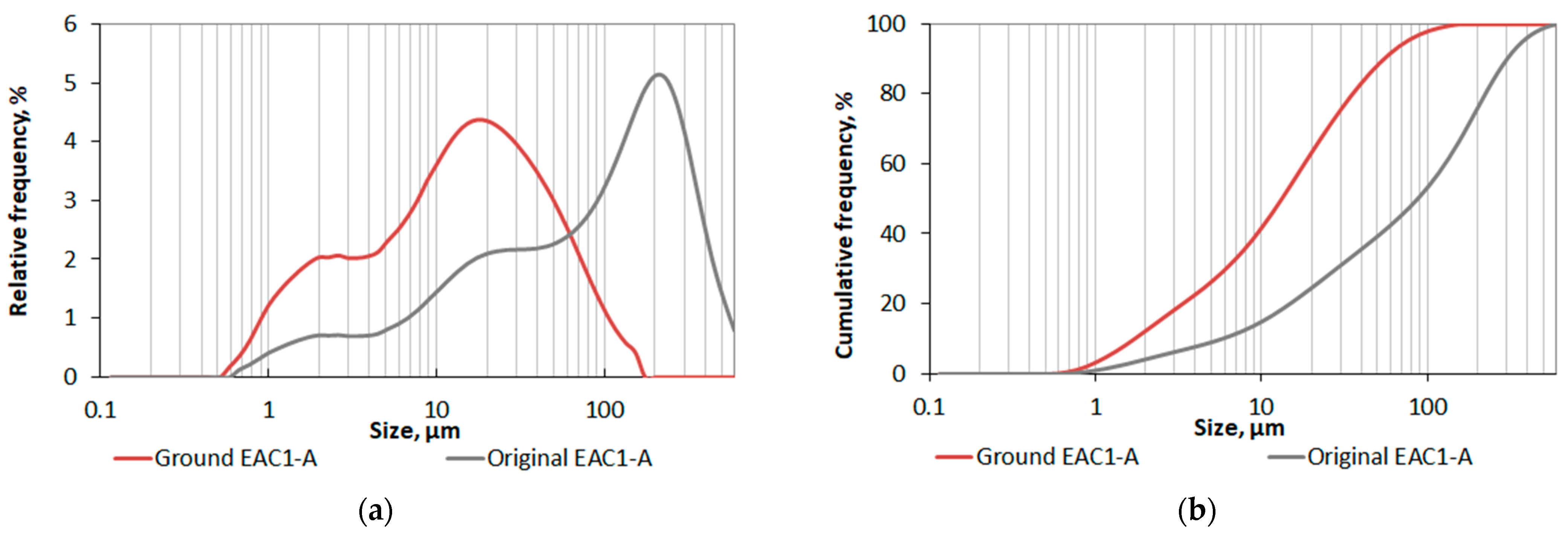

2.2. Material

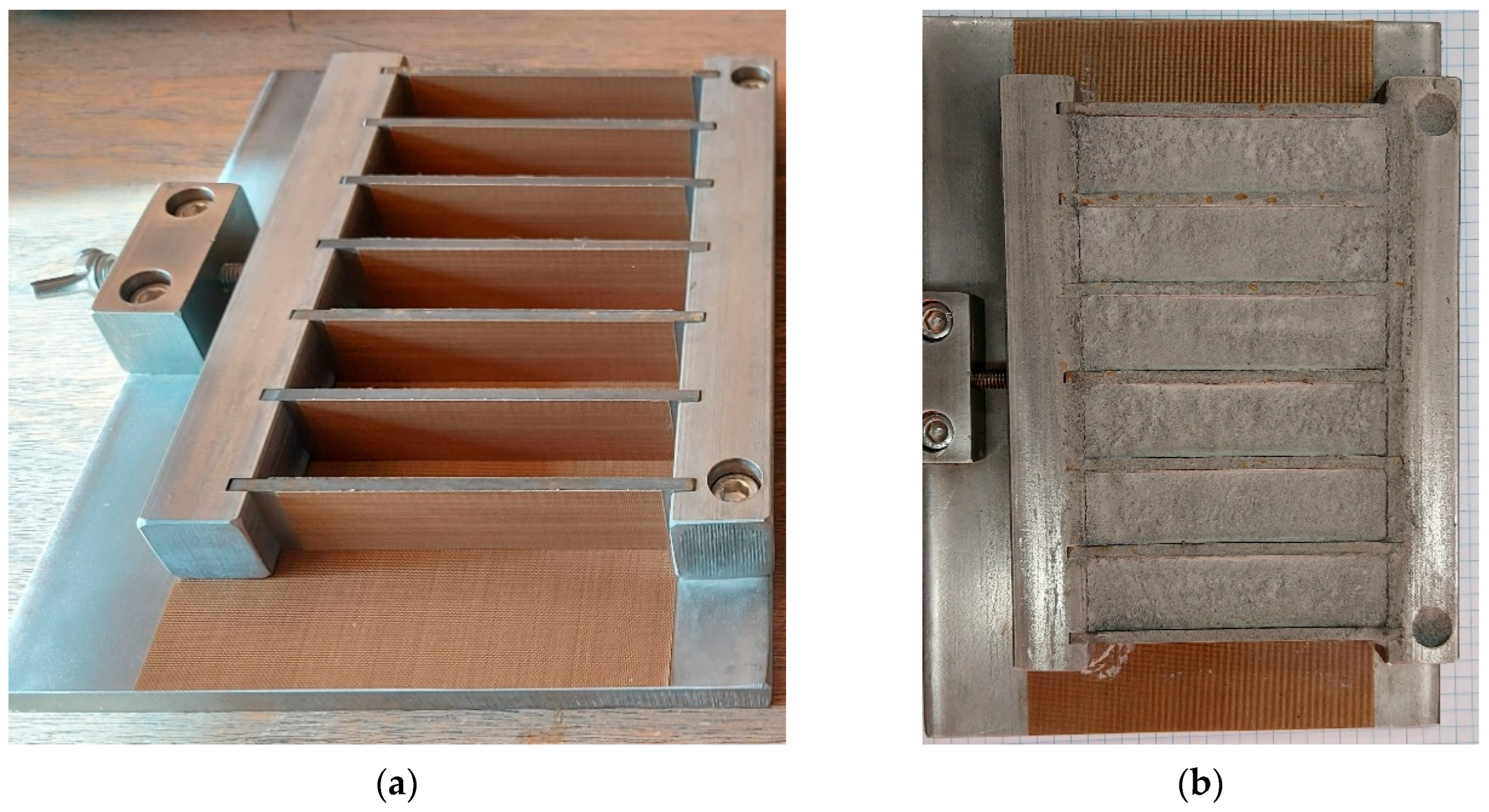

2.3. Specimens’ Prepration

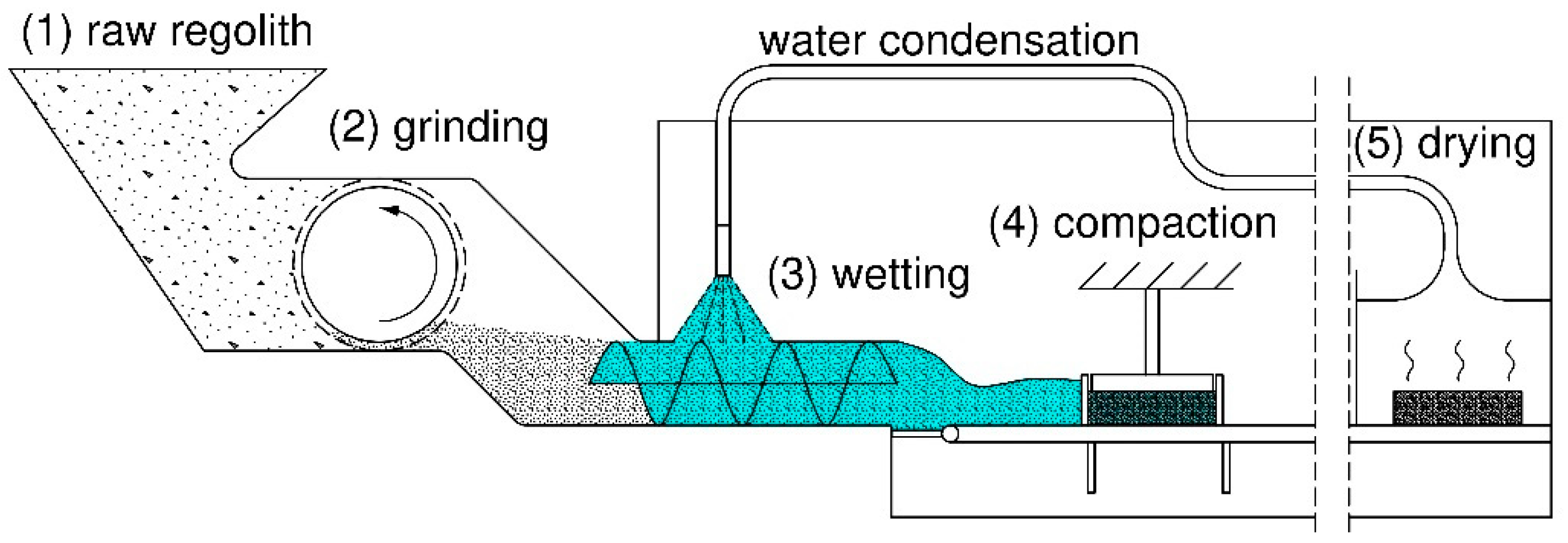

- Preparing fresh mix, by mixing 400 g of dry LRS material with 100 g of distilled water (water/LRS ratio of 0.25);

- Pouring the fresh mix into the molds;

- Air-drying in ambient conditions for 2 h to drain excess water and remove air bubbles from the mix;

- Oven-drying at a temperature of 127 °C for 22 h;

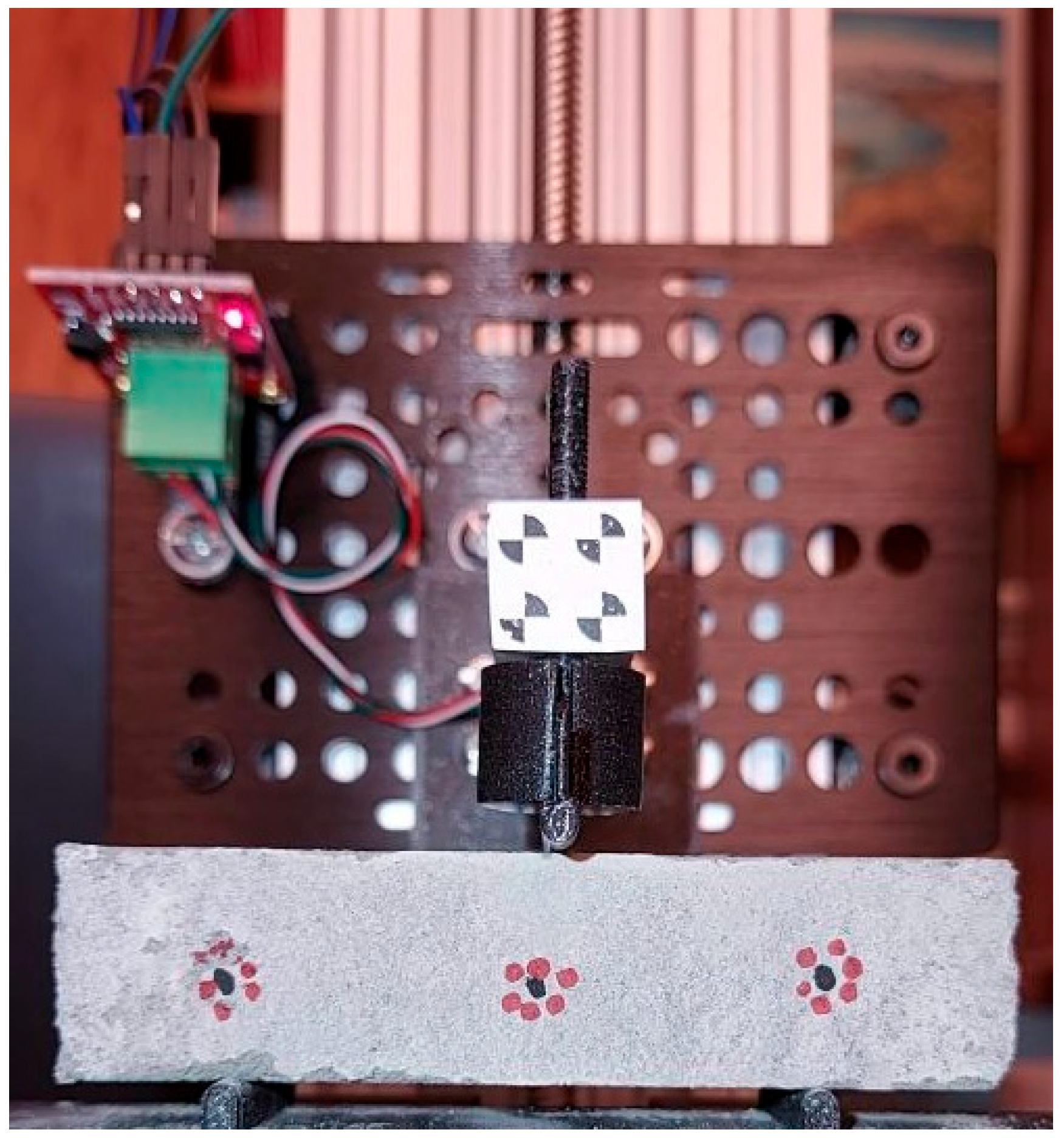

- Applying markers for digital image correlation (DIC) measurements.

2.4. Flexural Strength Test

2.5. Microscopic Observations

3. Results and Discussion

| Improvement Technique | Flexural Strength (MPa) | Reference |

|---|---|---|

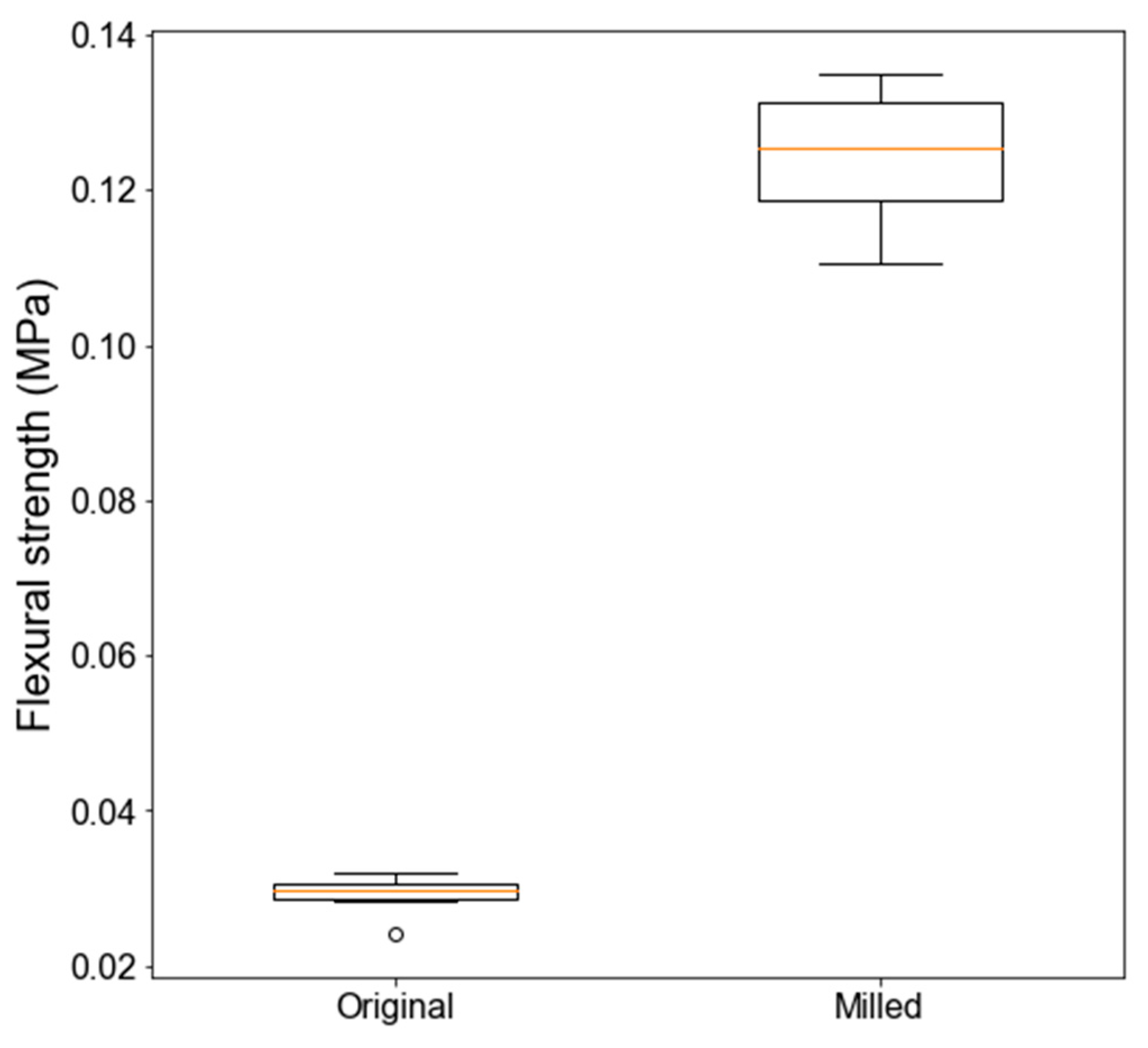

| Capillary Consolidation—original PSD | 0.029 | this study |

| Grinding + Capillary Consolidation | 0.123 | this study |

| Sintering | 0.23–0.55 | [34,35] |

| Portland cement binder | 6.8 | [12] |

| Polylactide binder | 0.43–19.01 | [36] |

| Alkali-activation | 7.16–8.80 | [14] |

4. Conclusions

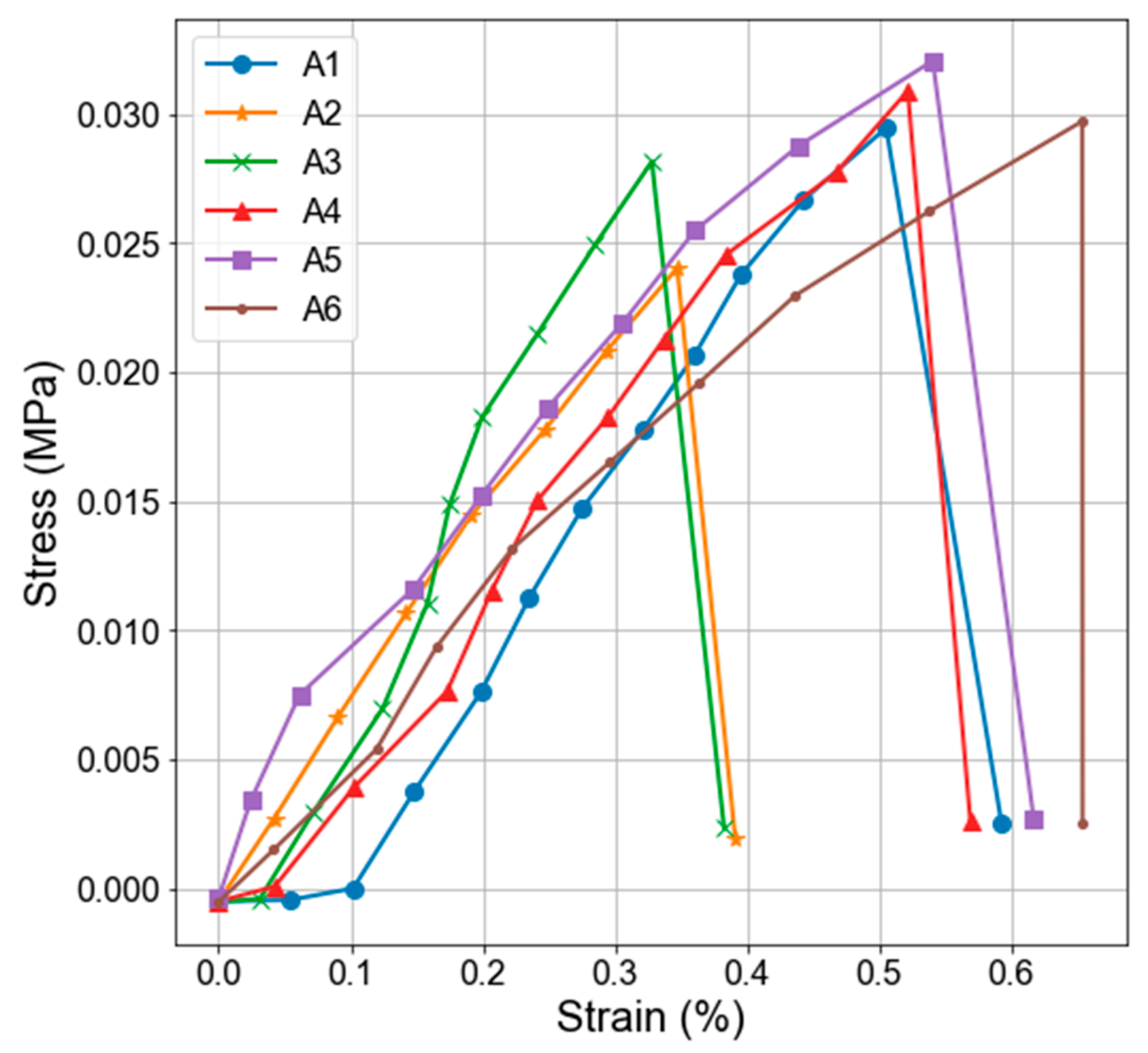

- The action of capillary forces can induce interparticle adhesion in loose regolith simulant; this way, a solid material showing a minimal flexural strength of 0.029 MPa can be created;

- CCR produced with the finer material shows greater strength; grinding of the regolith simulant allowed to obtain material four times stronger (flexural strength of 0.123 MPa);

- An additional advantage of binding fine particles of lunar regolith technology is creating a locally cleaner (dust-free) environment, which is beneficial for the durability of the equipment used on the Moon, especially the optical parts;

- The proposed workflow does not require additional materials, and water utilized in the process can be reused;

- This approach could be developed in the future, applying methods of improving intrinsic material properties without additives (e.g., as compaction).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| PSD | Particle size distribution |

| EAC-1A | European Astronaut Centre lunar regolith simulant 1 |

| CCR | Capillary-Consolidated Regolith |

| EN | European Norm |

| LRS | Lunar regolith simulant |

| NASA | National Aeronautics and Space Administration |

| OPC | Ordinary Portland Cement |

| LUNA | Proper noun of European Lunar Exploration Laboratory |

| CAS | Chemical Abstracts Service |

| ASR | Alkali–silica reaction |

| ACR | Alkali–carbonate reaction |

| PTFE | Polytetrafluoroethylene |

| DIC | Digital image correlation |

| TM-3000 | Table Microscope 3000—proper noun of the Hitachi microscope model |

| SEM | Scanning Electron Microscope |

| Dmin | Minimal diameter |

| D10 | Diameter/size below which 10% of all particles are found |

| D50 | Median diameter |

| Dm | Mean diameter |

| Dmax | Maximal diameter |

| SPA | Specific surface area |

References

- Artemis—NASA. Available online: https://www.nasa.gov/feature/artemis/ (accessed on 28 November 2024).

- Berger, E. The White House Puts a Price on the SLS Rocket—And It’s a Lot Again, Congress Is Urged to Allow a Commercial Launch of the Europa Clipper; Ars Technical: Cambridge, MA, USA, 2019. [Google Scholar]

- Isachenkov, M.; Chugunov, S.; Akhatov, I.; Shishkovsky, I. Regolith-Based Additive Manufacturing for Sustainable Development of Lunar Infrastructure–An Overview. Acta Astronaut. 2021, 180, 650–678. [Google Scholar] [CrossRef]

- Brown, H.M.; Boyd, A.K.; Denevi, B.W.; Henriksen, M.R.; Manheim, M.R.; Robinson, M.S.; Speyerer, E.J.; Wagner, R.V. Resource Potential of Lunar Permanently Shadowed Regions. Icarus 2022, 377, 114874. [Google Scholar] [CrossRef]

- Ice Confirmed at the Moon’s Poles. NASA Jet Propulsion Laboratory (JPL). Available online: https://www.jpl.nasa.gov/news/ice-confirmed-at-the-moons-poles/ (accessed on 28 November 2024).

- Moon Water and Ices—NASA Science. Available online: https://science.nasa.gov/moon/moon-water-and-ices/ (accessed on 28 November 2024).

- NASA Selects Intuitive Machines for South Pole Lunar Lander Mission—SpaceNews. Available online: https://spacenews.com/nasa-selects-intuitive-machines-for-south-pole-lunar-lander-mission/ (accessed on 28 November 2024).

- Lee, J.; Ann, K.Y.; Lee, T.S.; Mitikie, B.B. Bottom-up Heating Method for Producing Polyethylene Lunar Concrete in Lunar Environment. Adv. Space Res. 2018, 62, 164–173. [Google Scholar] [CrossRef]

- Grugel, R.N.; Toutanji, H. Sulfur “Concrete” for Lunar Applications–Sublimation Concerns. Adv. Space Res. 2008, 41, 103–112. [Google Scholar] [CrossRef]

- Sokołowska, J.J. Long-Term Compressive Strength of Polymer Concrete-like Composites with Various Fillers. Materials 2020, 13, 1207. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, L.; Tang, Y.; Chen, B. Pioneering Lunar Habitats through Comparative Analysis of In-Situ Concrete Technologies: A Critical Review. Constr. Build. Mater. 2024, 435, 136833. [Google Scholar] [CrossRef]

- Sokołowska, J.J.; Woyciechowski, P.; Kalinowski, M. Rheological Properties of Lunar Mortars. Appl. Sci. 2021, 11, 6961. [Google Scholar] [CrossRef]

- Pilehvar, S.; Arnhof, M.; Pamies, R.; Valentini, L.; Kjøniksen, A.-L. Utilization of Urea as an Accessible Superplasticizer on the Moon for Lunar Geopolymer Mixtures. J. Clean. Prod. 2020, 247, 119177. [Google Scholar] [CrossRef]

- Geng, Z.; Zhang, L.; Pan, H.; She, W.; Zhou, C.; Zhou, H.; Yu, Z.; Xu, Z. In-Situ Solidification of Alkali-Activated Lunar Regolith: Insights into the Chemical and Physical Origins. J. Clean. Prod. 2023, 391, 136147. [Google Scholar] [CrossRef]

- Juračka, D.; Katzer, J.; Kobaka, J.; Świca, I.; Seweryn, K. Concept of a 3D-Printed Voronoi Egg-Shaped Habitat for Permanent Lunar Outpost. Appl. Sci. 2023, 13, 1153. [Google Scholar] [CrossRef]

- Moon Exploration—NASA Science. Available online: https://science.nasa.gov/moon/exploration (accessed on 18 December 2024).

- Bednarz, S.; Rzyczniak, M.; Gonet, A.; Seweryn, K. Research of Formed Lunar Regholit Analog AGK-2010 / Badania Wytworzonego Analogu Gruntu Księżycowego AGK-2010. Arch. Min. Sci. 2013, 58, 551–556. [Google Scholar] [CrossRef]

- Sibille, L.; Carpenter, P.; Schlagheck, R.; French, R.A. Lunar Regolith Simulant Materials: Recommendations for Standardization, Production, and Usage; Marshall Space Flight Center MSFC: Huntsville, AL, USA, 2006. [Google Scholar]

- Engelschiøn, V.S.; Eriksson, S.R.; Cowley, A.; Fateri, M.; Meurisse, A.; Kueppers, U.; Sperl, M. EAC-1A: A Novel Large-Volume Lunar Regolith Simulant. Sci. Rep. 2020, 10, 5473. [Google Scholar] [CrossRef] [PubMed]

- Kendall, K. Molecular Adhesion and Its Applications: The Sticky Universe; Springer Science & Business Media: Berlin, Germany, 2007. [Google Scholar]

- Seiphoori, A.; Ma, X.-G.; Arratia, P.E.; Jerolmack, D.J. Formation of Stable Aggregates by Fluid-Assembled Solid Bridges. Proc. Natl. Acad. Sci. USA 2020, 117, 3375–3381. [Google Scholar] [CrossRef]

- Afolagboye, L.O.; Arije, Z.O.; Talabi, A.O.; Owoyemi, O.O. Effect of Pre-Test Drying Temperature on the Properties of Lateritic Soils. J. Nig. Soc. Phys. Sci. 2023, 5, 1109. [Google Scholar] [CrossRef]

- Sunil, B.M.; Deepa, A.V. Influence of Drying Temperature on Three Soils Physical Properties. Geotech. Geol. Eng. 2016, 34, 777–788. [Google Scholar] [CrossRef]

- Altalhe, E.; Imbark, K.; Alnaas, F. Effect of drying temperature on the physical properties of soil. Al-Mukhtar J. Eng. Res. 2022, 6, 63–70. [Google Scholar]

- Dekker, L.W.; Ritsema, C.J.; Oostindie, K.; Boersma, O.H. Effect of Drying Temperature on the Severity of Soil Water Repellency. Soil Sci. 1998, 163, 780–796. [Google Scholar] [CrossRef]

- Kemper, W.D.; Rosenau, R.C.; Dexter, A.R. Cohesion Development in Disrupted Soils as Affected by Clay and Organic Matter Content and Temperature. Soil Sci. Soc. Am. J. 1987, 51, 860–867. [Google Scholar] [CrossRef]

- Kemper, W.D.; Rosenau, R.C. Soil Cohesion as Affected by Time and Water Content. Soil Sci. Soc. Am. J. 1984, 48, 1001–1006. [Google Scholar] [CrossRef]

- Williamson, W. Strength of Dried Clay—A Review; American Ceramic Society Bulletin: Westerville, OH, USA, 1971. [Google Scholar]

- Basma, A.A.; Al-Homoud, A.S.; Al-Tabari, E.Y. Effects of Methods of Drying on the Engineering Behavior of Clays. Appl. Clay Sci. 1994, 9, 151–164. [Google Scholar] [CrossRef]

- Owsiak, Z.; Zapała-Sławeta, J.; Czapik, P. Diagnosis of Concrete Structures Distress Due to Alkali-Aggregate Reaction. Bull. Pol. Acad. Sci. Tech. Sci. 2015, 63, 23–29. [Google Scholar] [CrossRef]

- EN 196-1(2016); Methods of Testing Cement-Part 1. Comite Europeen de Normalisation: Brussels, Belgium, 2016.

- Lucas, B.D.; Kanade, T. An Iterative Image Registration Technique with an Application to Stereo Vision. In Proceedings of the IJCAI’81: 7th International Joint Conference on Artificial Intelligence, Vancouver, BC, Canada, 24–28 August 1981; Volume 2, pp. 674–679. [Google Scholar]

- Bradski, G. The openCV Library. Dr. Dobb’s J. Softw. Tools Prof. Program. 2000, 25, 120–123. [Google Scholar]

- Imhof, B.; Urbina, D.; Weiss, P.; Sperl, M.; Hoheneder, W.; Waclavicek, R.; Madakashira, H.; Salini, J.; Govindaraj, S.; Gancet, J.; et al. Advancing Solar Sintering for Building a Base on the Moon. In Proceedings of the 68th International Astronautical Congress (IAC), Adelaide, Australia, 25–29 September 2017; pp. 25–29. [Google Scholar]

- Johnson, D.K.M.; Dreyer, C.B.; Cannon, K.M.; Sowers, G. Pressure Sintered Icy Lunar Regolith Simulant (PSS): A Novel Icy Regolith Simulant Production Method. Icarus 2024, 410, 115885. [Google Scholar] [CrossRef]

- Torre, R.; Cowley, A.; Ferro, C.G. Low Binder Content Bricks: A Regolith-Based Solution for Sustainable Surface Construction on the Moon. Discov. Appl. Sci. 2024, 6, 88. [Google Scholar] [CrossRef]

- Naser, M.Z. Extraterrestrial Construction Materials. Prog. Mater. Sci. 2019, 105, 100577. [Google Scholar] [CrossRef]

- Akisheva, Y.; Gourinat, Y. Utilisation of Moon Regolith for Radiation Protection and Thermal Insulation in Permanent Lunar Habitats. Appl. Sci. 2021, 11, 3853. [Google Scholar] [CrossRef]

- Akisheva, Y.; Gourinat, Y.; Guatelli, S.; Dossat, C.; Robin-Chabanne, S.; Varotsou, A.; Cowley, A.; Makaya, A. Regolith-Based Lunar Habitats: An Engineering Approach to Radiation Shielding. CEAS Space J. 2024, 16, 667–676. [Google Scholar] [CrossRef]

- Gaier, J.R. The Effects of Lunar Dust on EVA Systems during the Apollo Missions; Glenn Research Center: Cleveland, OH, USA, 2007. [Google Scholar]

- Brzeziński, K. XFEM Simulation of the Influence of Cracking Introduced by Pre-Loading on the Strengthening of a Cement Treated Mixture. J. Theor. Appl. Mech. 2018, 56, 927. [Google Scholar] [CrossRef]

- Brzeziński, K.; Zbiciak, A.; Garbacz, A. Effect of Strengthening on the Fatigue Life of Construction Materials. Period. Polytech. Civ. Eng. 2019, 63, 288–295. [Google Scholar] [CrossRef]

| Parameter | EAC-1A Lunar Regolith Simulant | |

|---|---|---|

| Original | Ground | |

| Dmin [µm] | 0.67 | 0.58 |

| D10 [µm] | 5.87 | 1.73 |

| D50 (median) [µm] | 86.36 | 13.14 |

| Dm (mean) [µm] | 123.53 | 21.70 |

| Mode [µm] | 187.33 | 16.25 |

| Dmax [µm] | 592.39 | 152.45 |

| SPA 1 [cm2/cm3] | 4542.7 | 11,929.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brzeziński, K.; Sokołowska, J.J.; Przybyszewski, B. Lunar Regolith Improvement by Inducing Interparticle Adhesion with Capillary Forces. Materials 2025, 18, 2390. https://doi.org/10.3390/ma18102390

Brzeziński K, Sokołowska JJ, Przybyszewski B. Lunar Regolith Improvement by Inducing Interparticle Adhesion with Capillary Forces. Materials. 2025; 18(10):2390. https://doi.org/10.3390/ma18102390

Chicago/Turabian StyleBrzeziński, Karol, Joanna Julia Sokołowska, and Bartłomiej Przybyszewski. 2025. "Lunar Regolith Improvement by Inducing Interparticle Adhesion with Capillary Forces" Materials 18, no. 10: 2390. https://doi.org/10.3390/ma18102390

APA StyleBrzeziński, K., Sokołowska, J. J., & Przybyszewski, B. (2025). Lunar Regolith Improvement by Inducing Interparticle Adhesion with Capillary Forces. Materials, 18(10), 2390. https://doi.org/10.3390/ma18102390