Research on Bending Creep Test and Long-Term Creep Behavior Prediction of Asphalt Concrete

Abstract

:1. Introduction

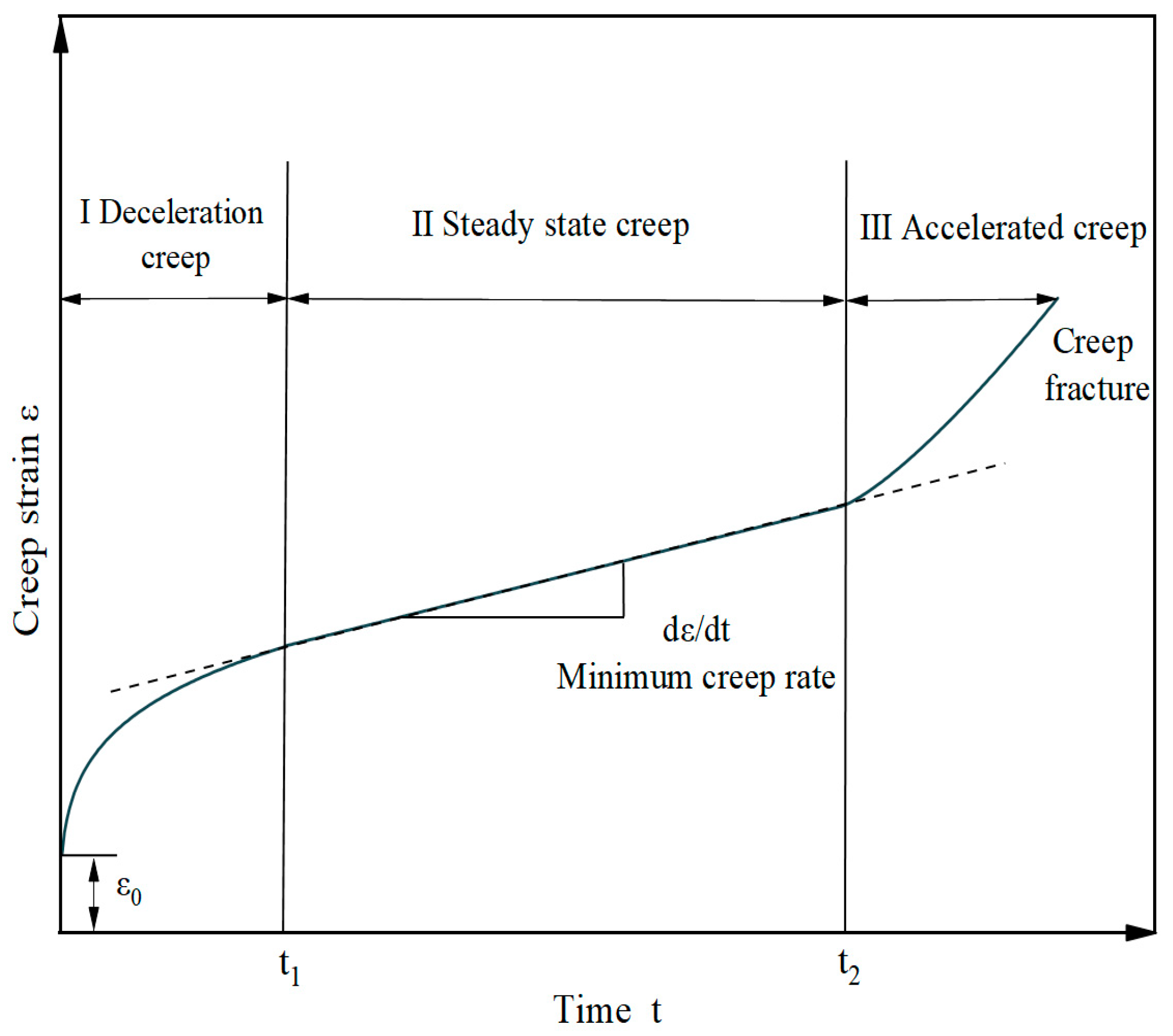

2. Theoretical Background

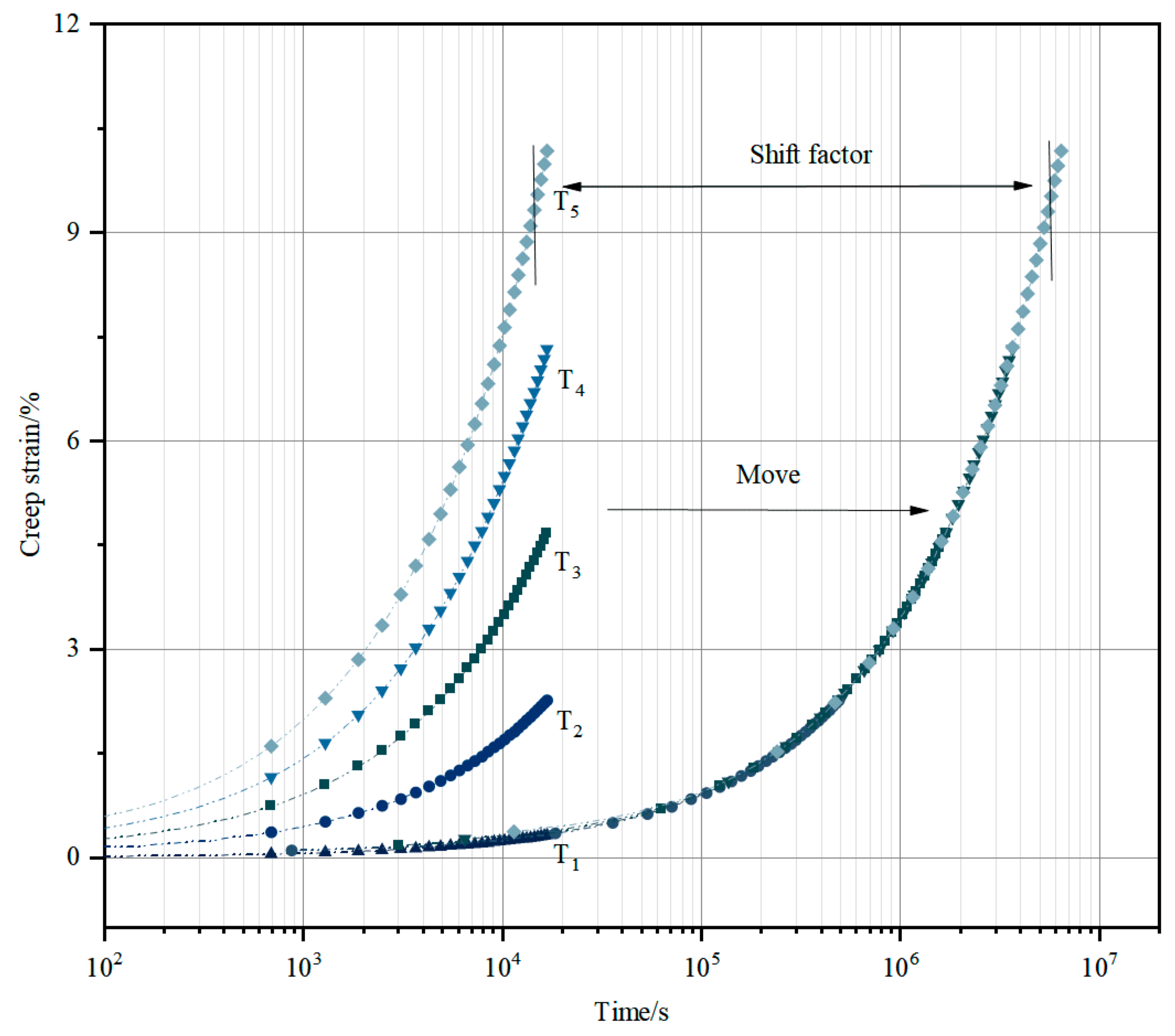

2.1. The Time–Temperature–Stress Superposition Principle

2.2. Creep Constitutive Model

3. Material and Methods

3.1. Test Materials and Equipment

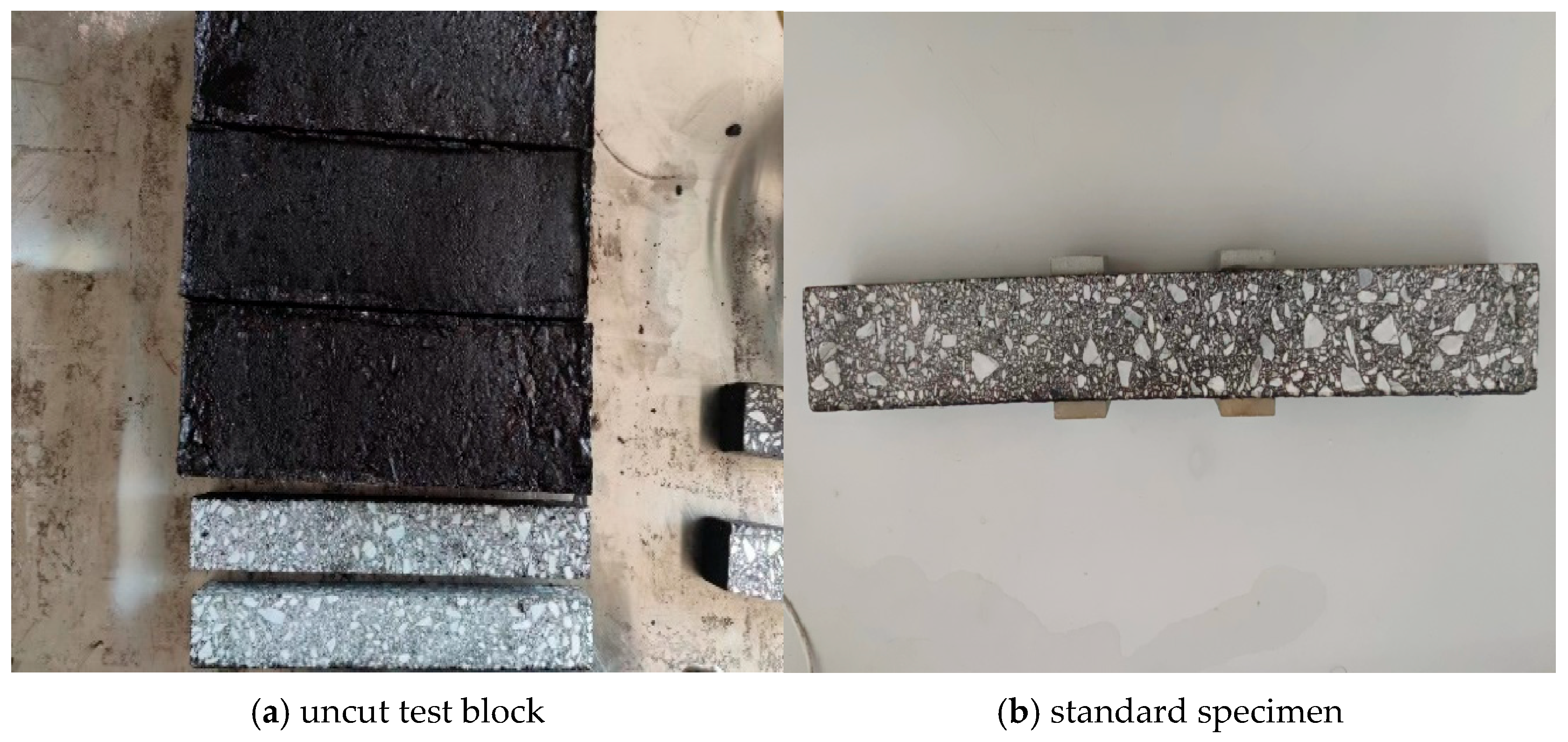

3.1.1. Test Materials

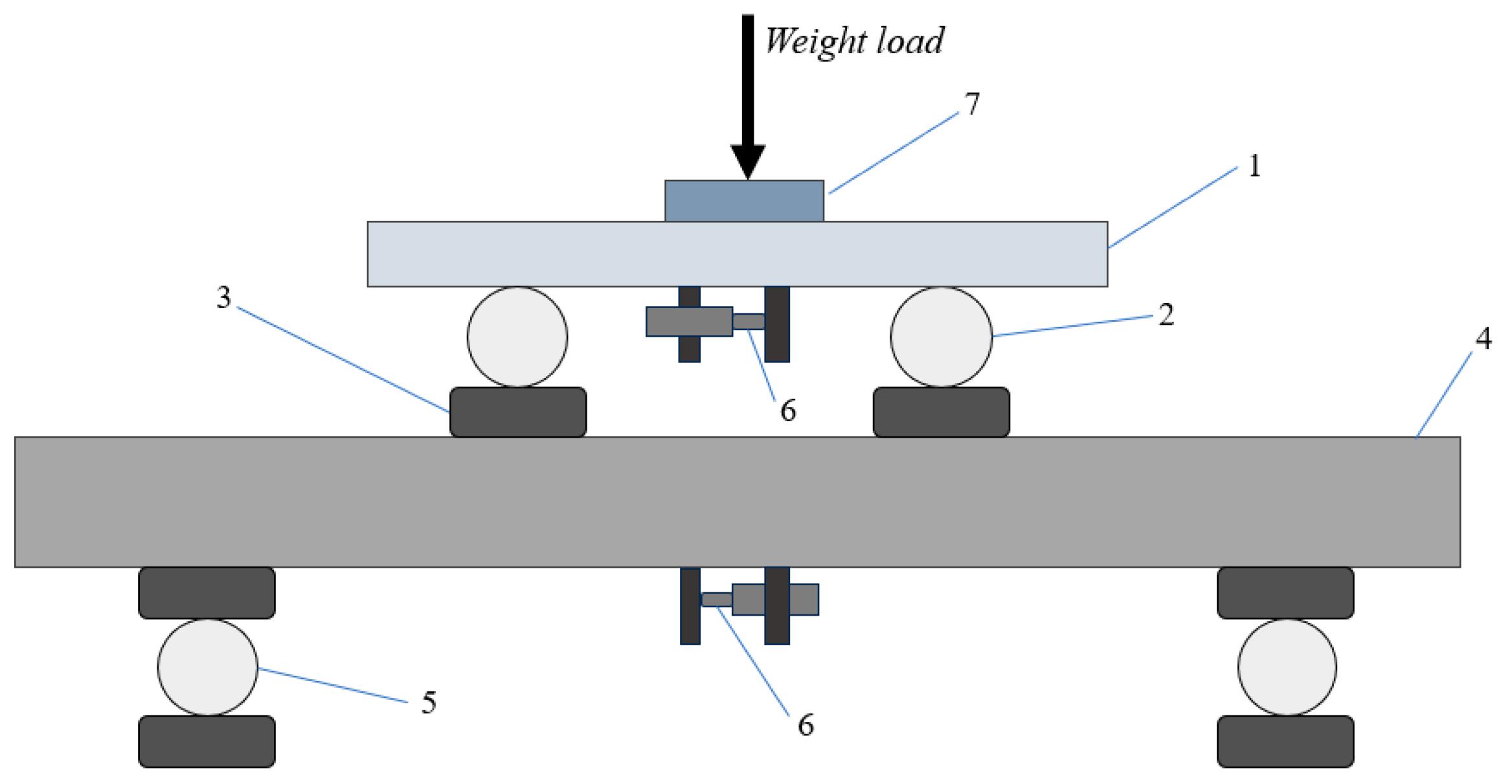

3.1.2. Test Equipment

3.2. Design of Bending Creep Test

4. Results and Discussion

4.1. Analysis of Bending Creep Test of Asphalt Concrete

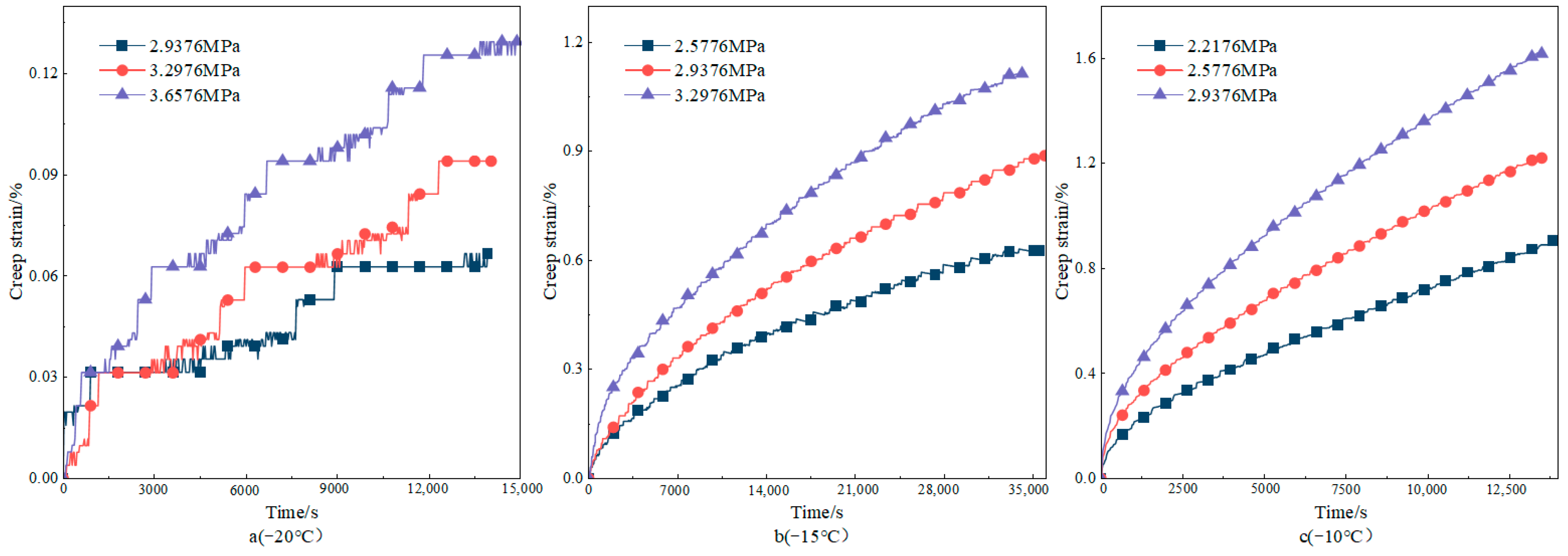

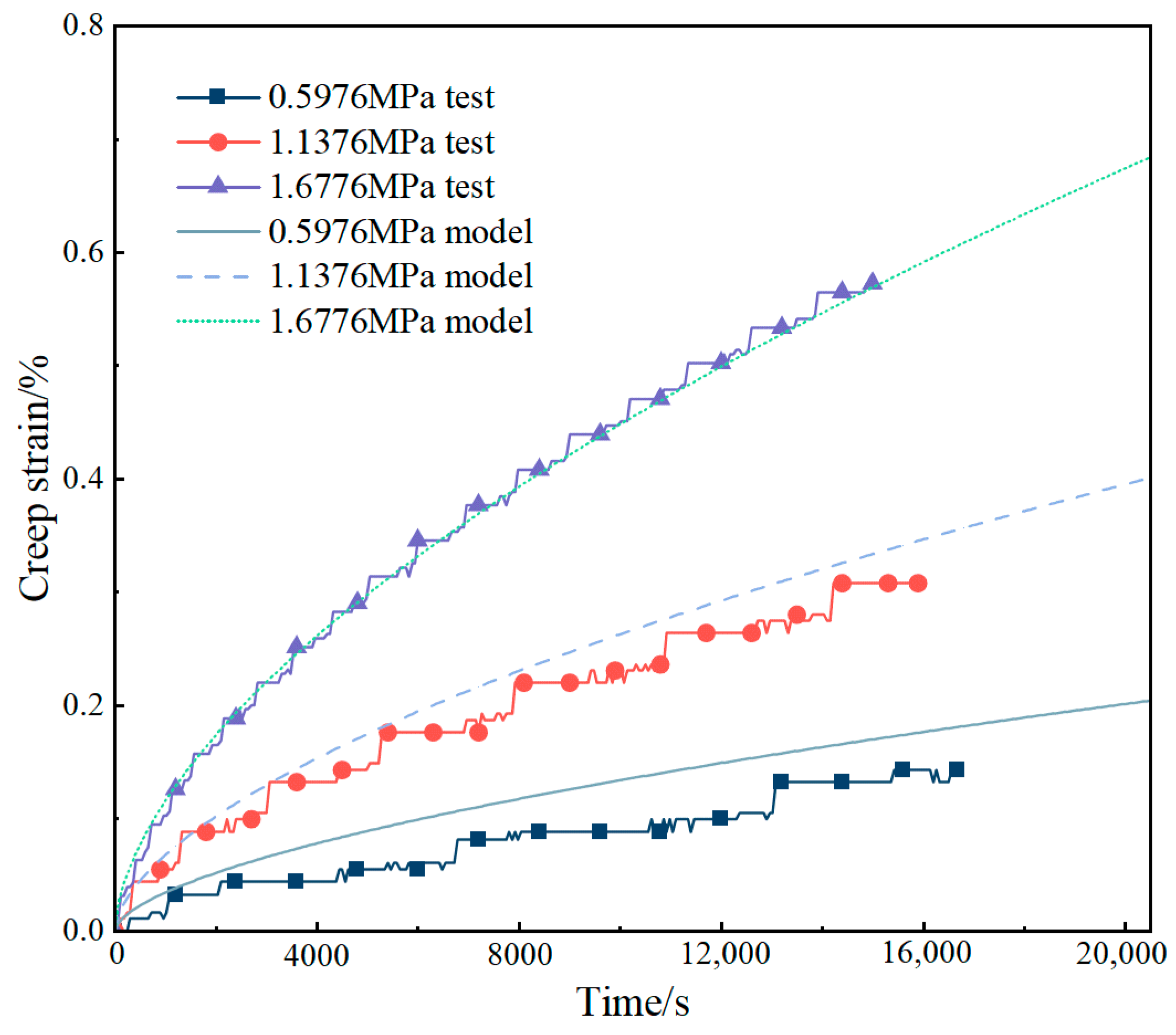

4.1.1. Creep Response Analysis

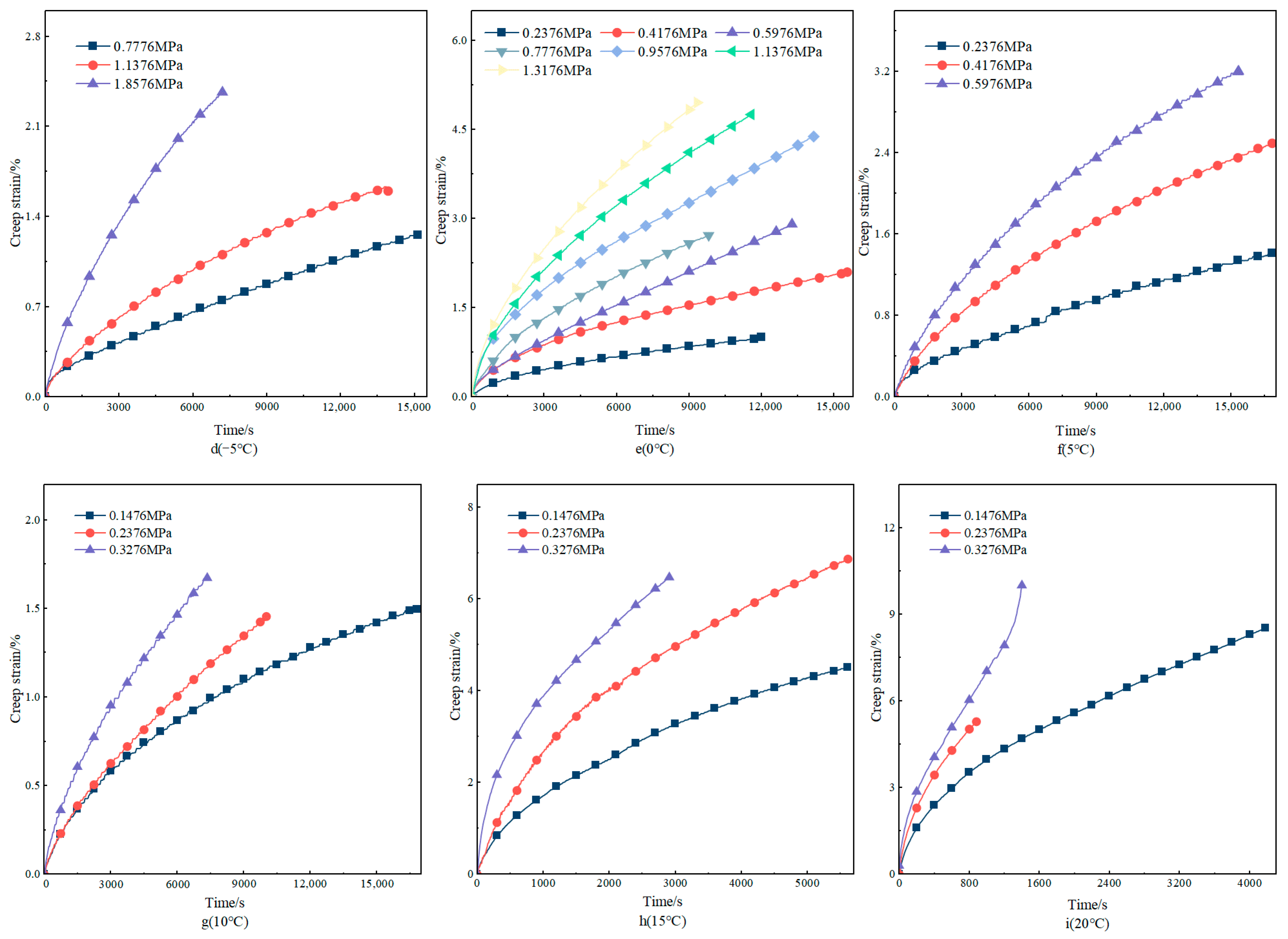

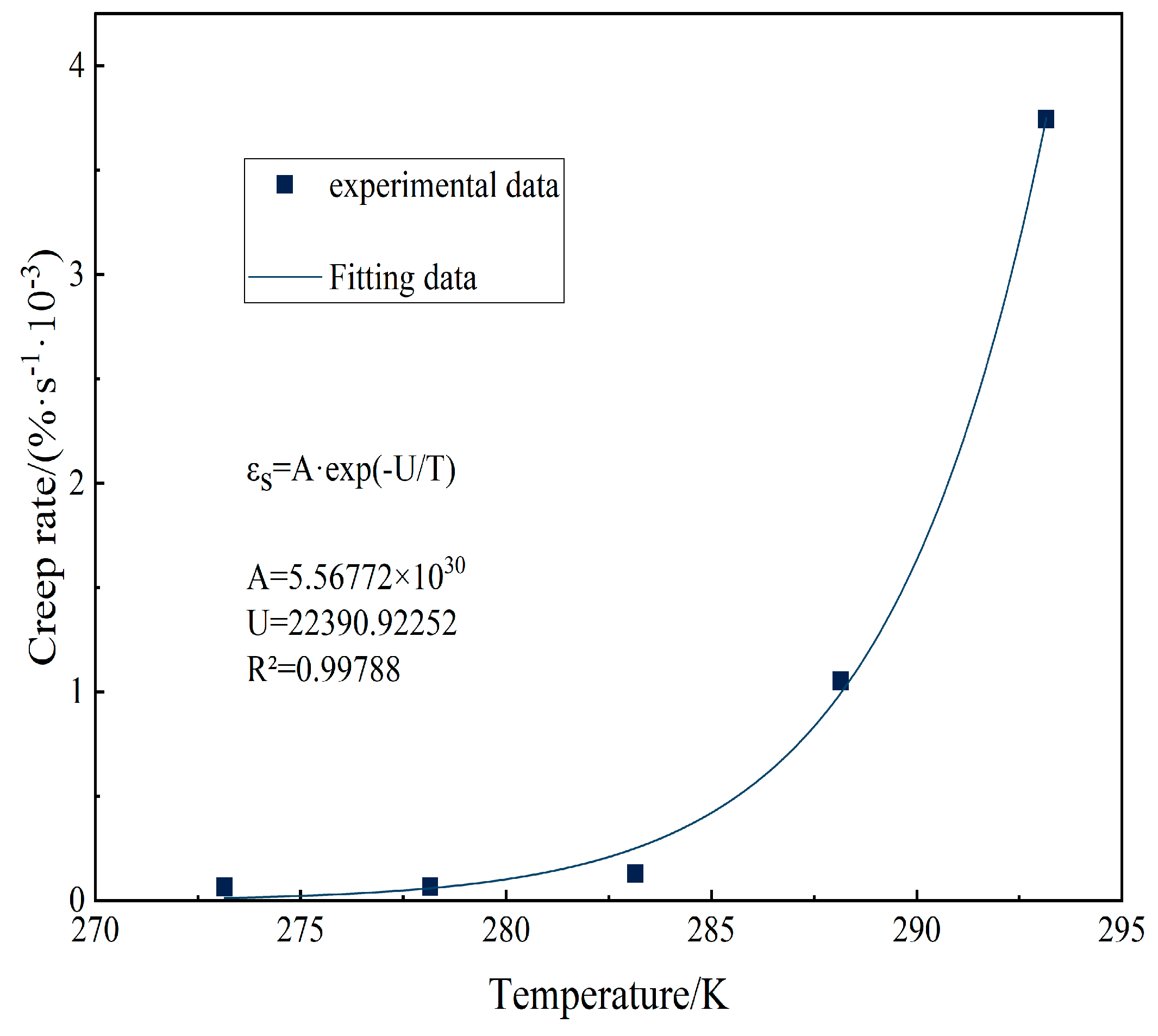

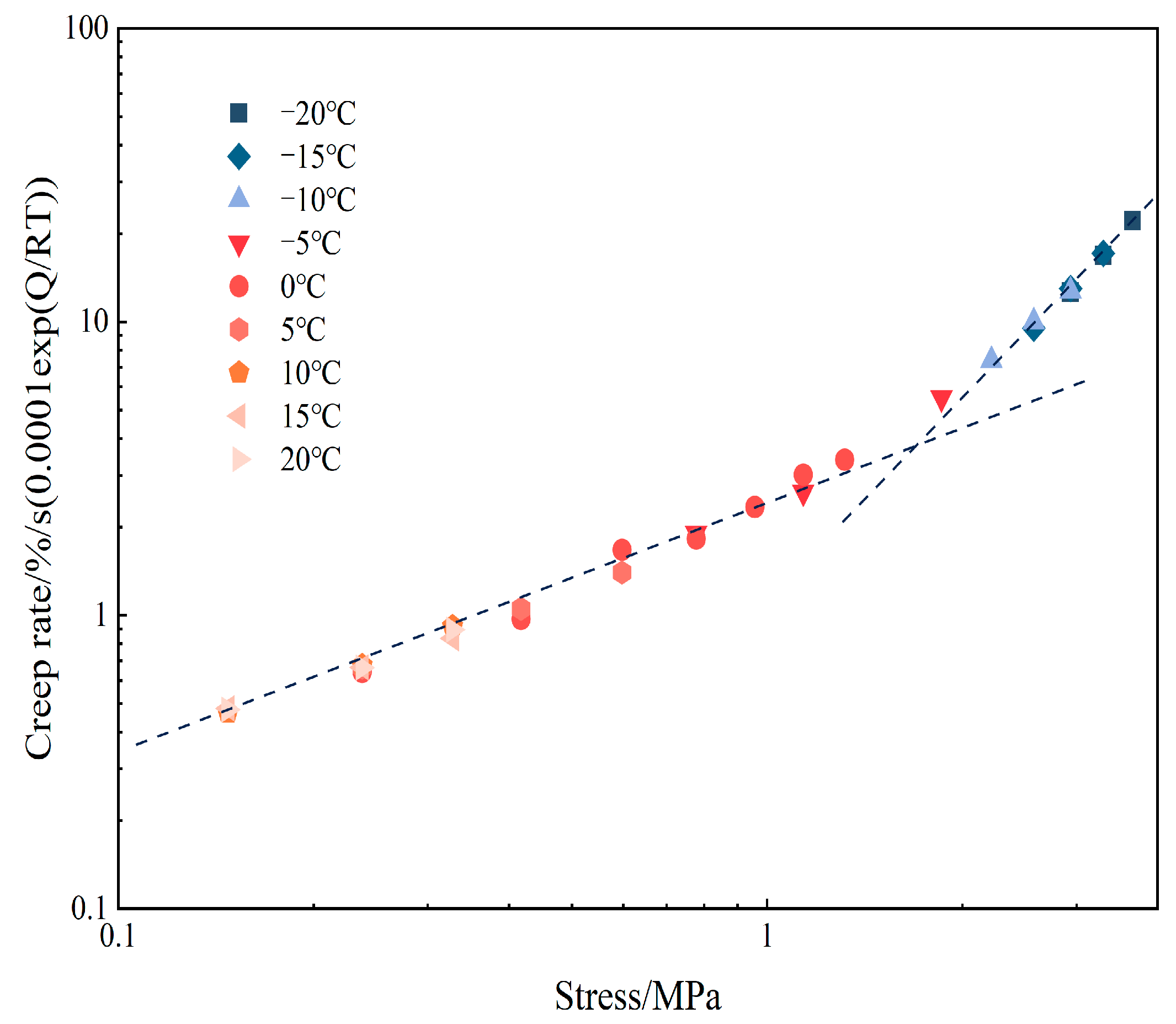

4.1.2. Creep Rate Analysis

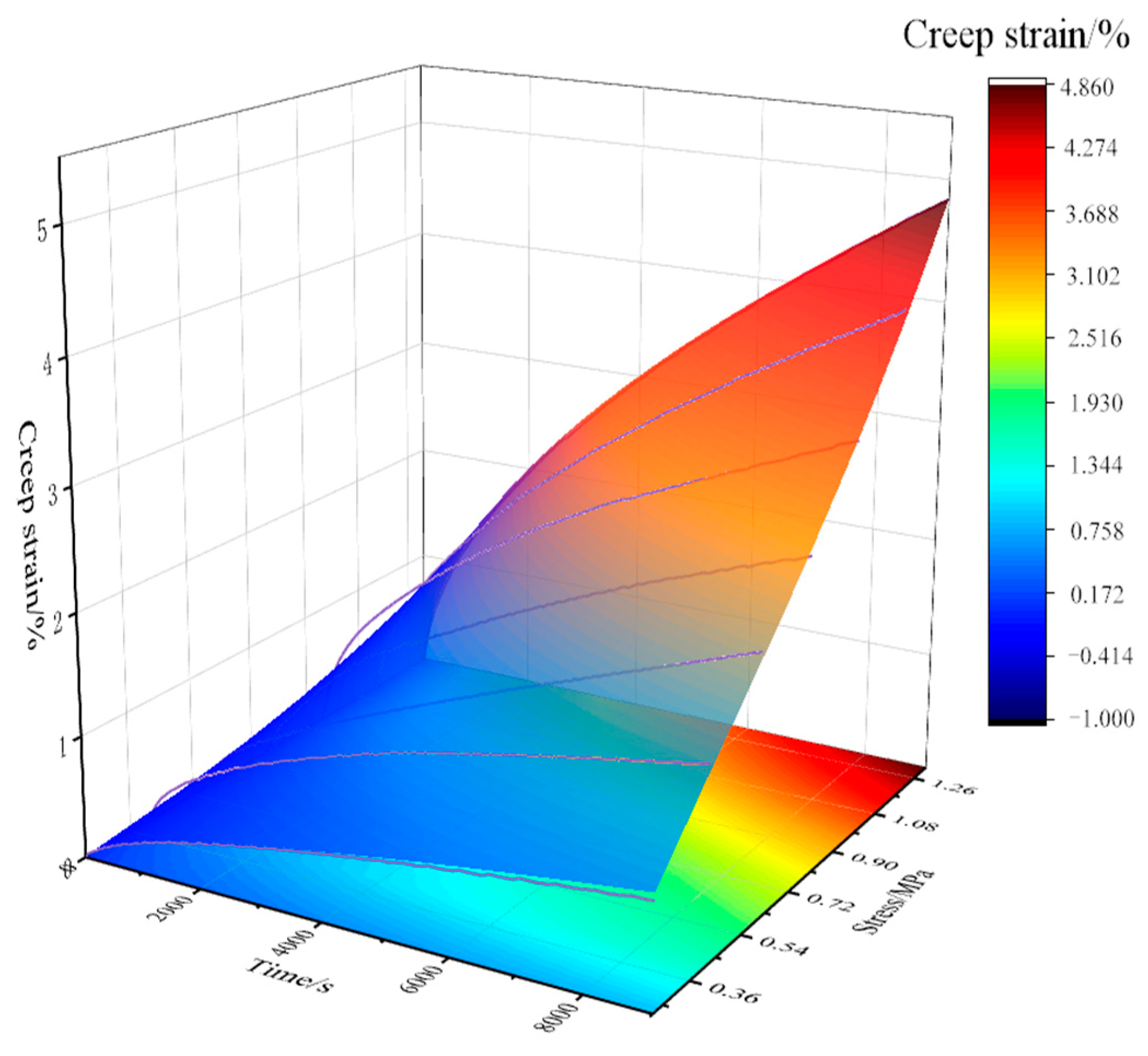

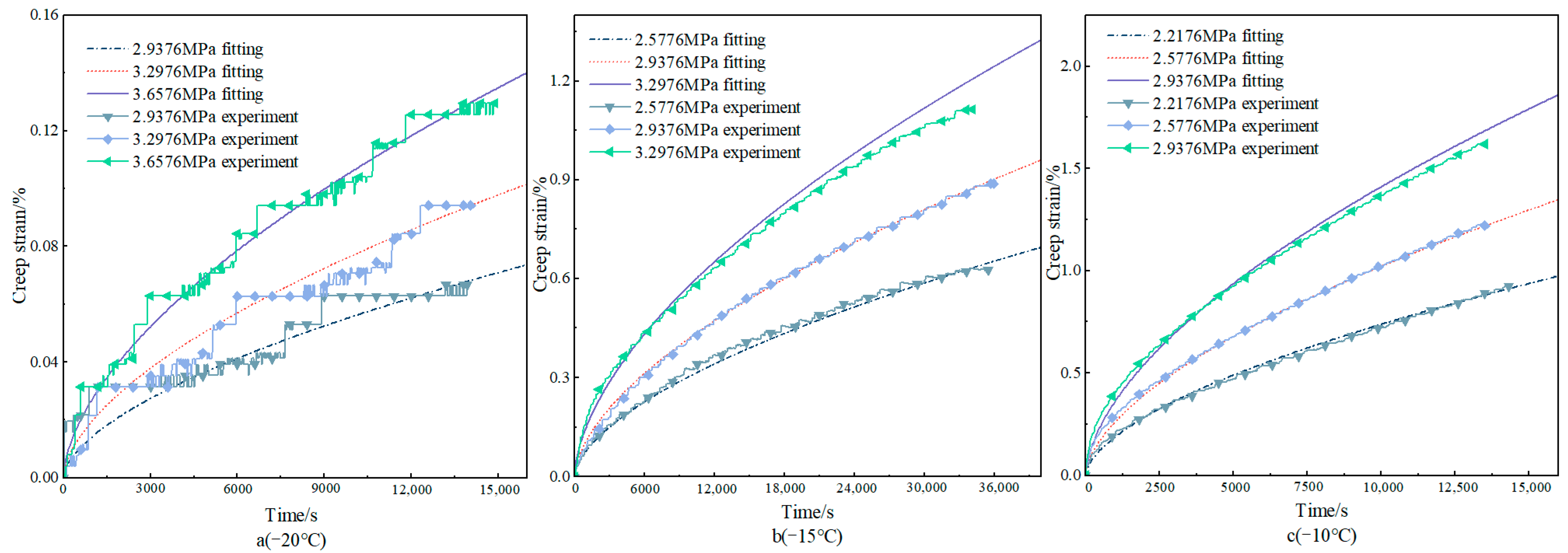

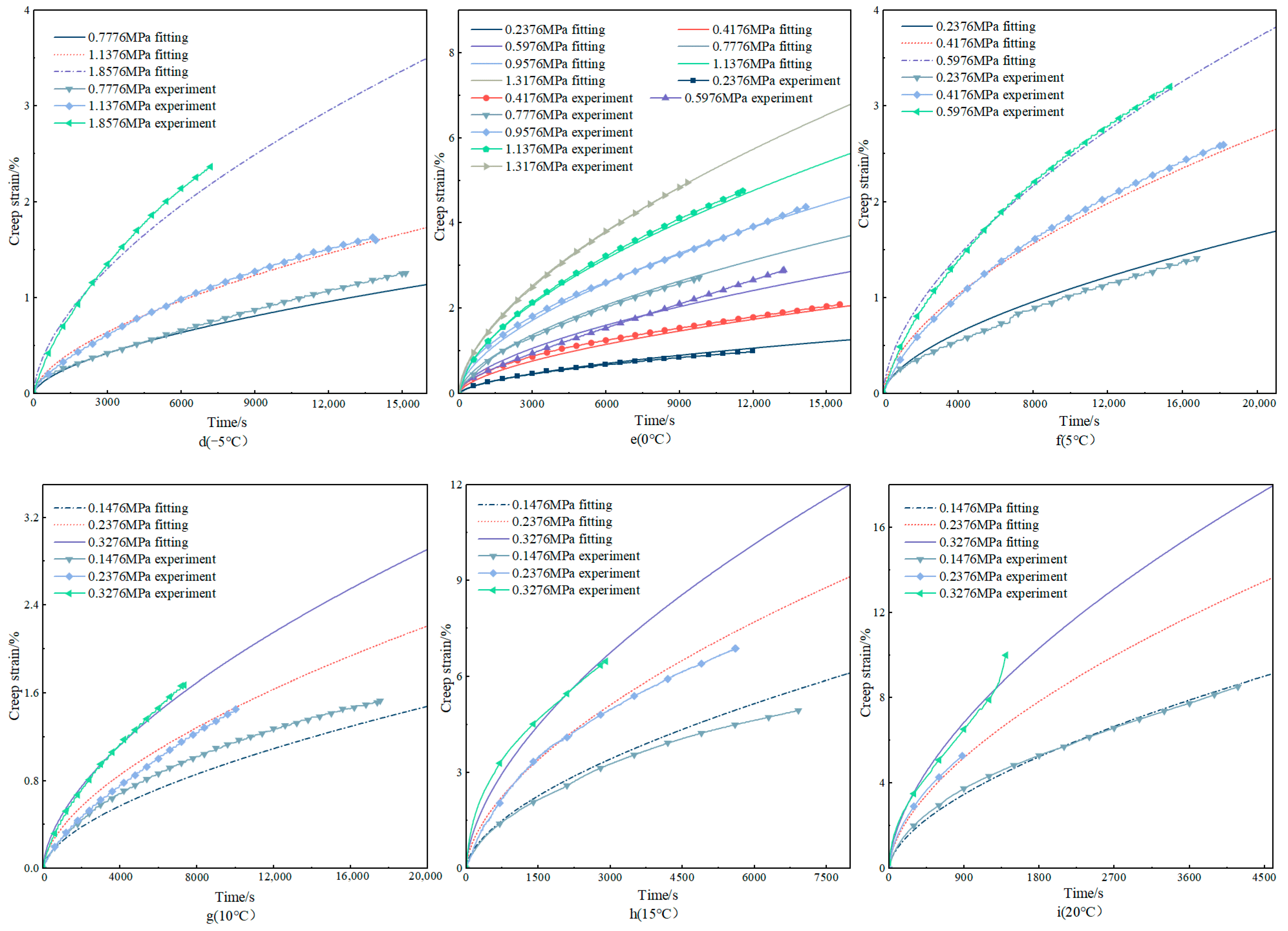

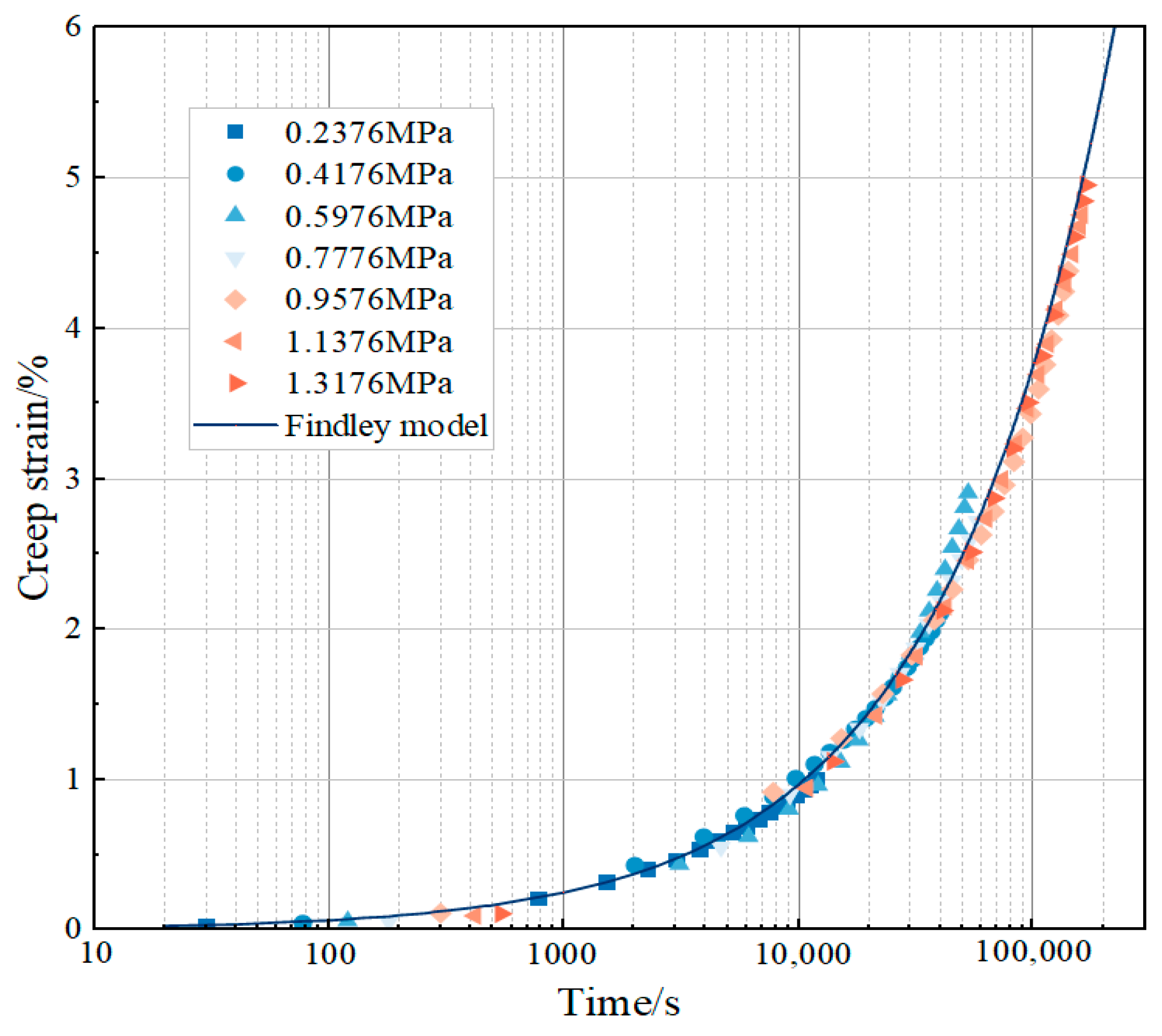

4.2. Prediction of Long-Term Creep Behavior Based on Temperature-Dependent Constitutive Model

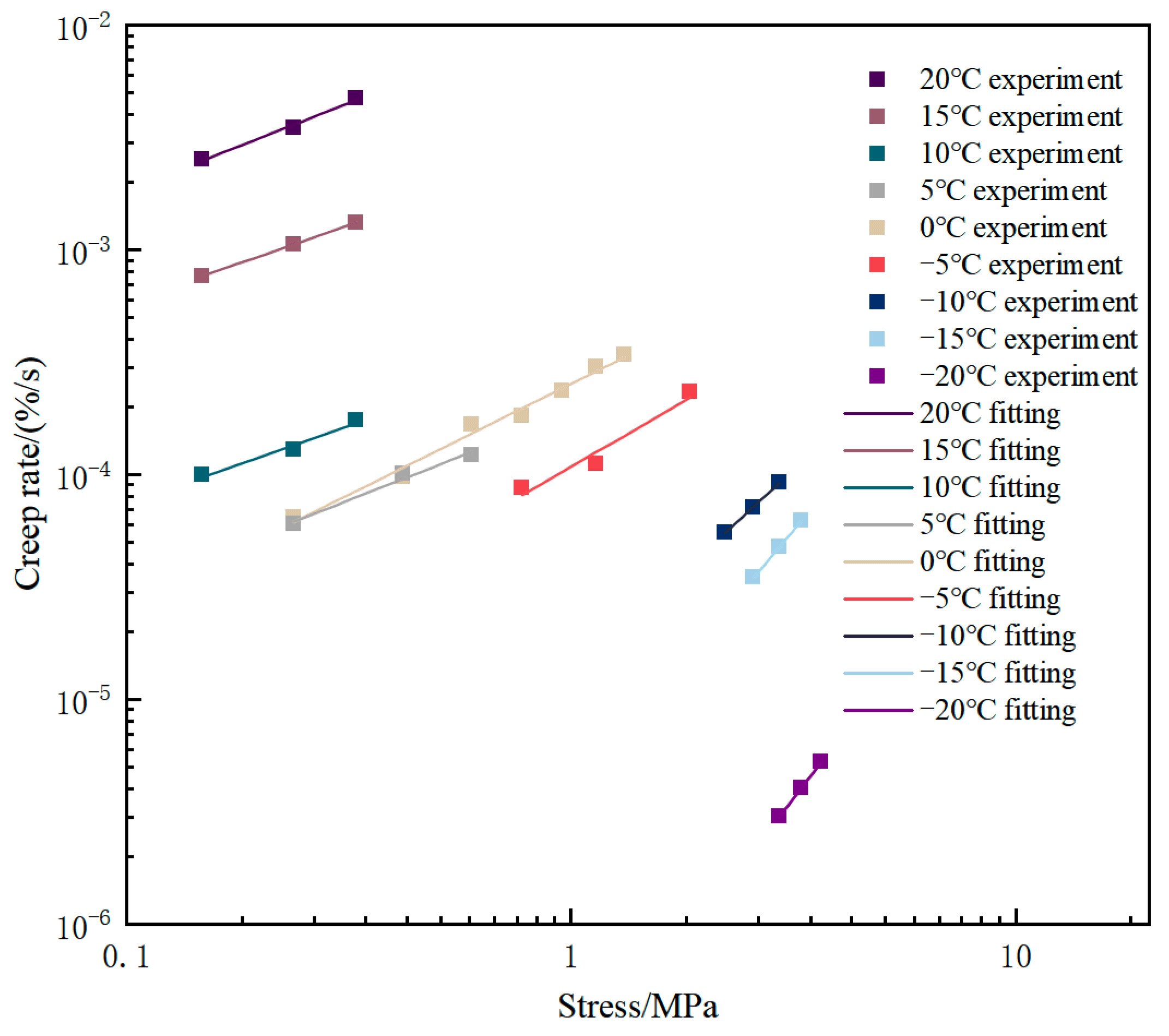

4.2.1. Temperature-Dependent Constitutive Model

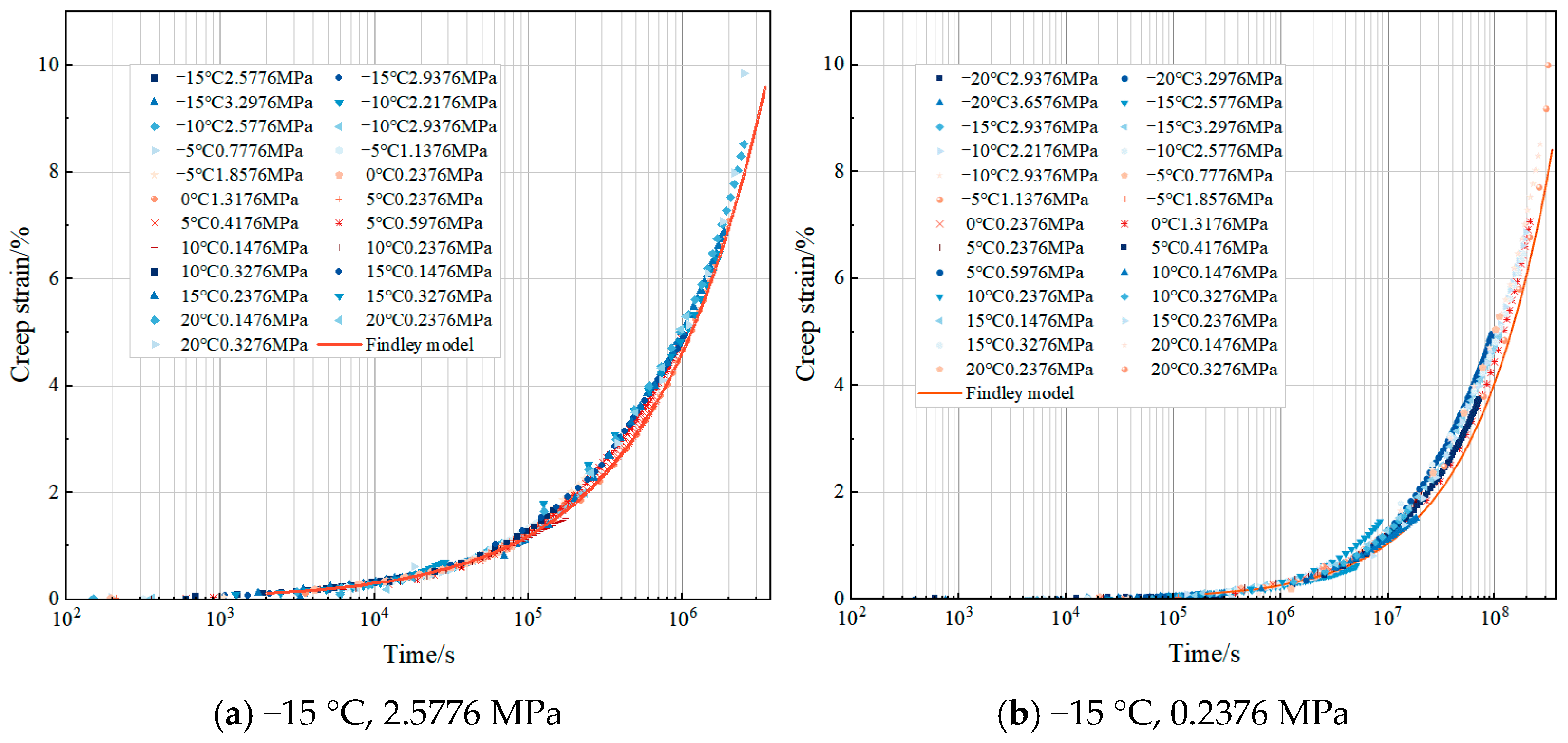

4.2.2. Prediction of Long-Term Creep Behavior

5. Conclusions

- The creep behavior of asphalt concrete exhibits significant temperature and stress dependence. With the increase in loading stress or the increase in temperature, the creep strain of asphalt concrete at the same time increases, while the creep rate also shows an accelerating trend, especially in high-stress conditions, showing obvious nonlinear creep behavior.

- Elevated stress levels or temperature increases accelerate the creep process of asphalt concrete. The experimental results demonstrate that under the condition of 0.2376 MPa, the temperature increased from 0 °C to 20 °C, and the strain at the creep time of 9330 s nearly increased by 24 times. The loading stress increased from 0.2376 MPa to 1.3176 MPa at 0 °C, and the strain nearly increased by six times at the creep time of 880 s.

- This study verified the applicability of the Findley constitutive model in investigating the mechanical properties of asphalt concrete facings. Based on this model, creep curve extrapolation was performed to simulate the creep deformation behavior of asphalt concrete under variable temperature–stress regimes. The findings provide scientific and systematic theoretical support for the long-term performance evaluation and durability design of asphalt concrete structures in complex environments, and is able to effectively simulate and predict the creep deformation of asphalt concrete in actual projects.

- The long-term creep behavior of asphalt concrete under low-temperature conditions was predicted by combining the Findley constitutive model and TTSSP. Under the stress conditions of −15 °C and 0.2376 MPa, it takes nearly 8 years for asphalt concrete to reach 8% of the creep strain. This phenomenon clarifies the creep deformation law of asphalt concrete under long-term low-temperature loads: the low-temperature environment significantly delays the creep deformation rate of asphalt concrete, but the long-term strain accumulation still poses a potential risk to the structural stability. This prediction result can provide a theoretical basis for the structural design optimization of asphalt concrete facings in actual engineering, ensuring that they maintain sufficient bearing capacity and stability within the expected service life.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, L.J.; Xue, C.Y.; Tashi, D.Z. Experimental study on characteristics of creep deformation of asphalt concrete used in core dam under low temperature. J. Hohai University. Nat. Sci. 2021, 49, 419–424. (In Chinese) [Google Scholar]

- Jahangiri, B.; Karimi, M.M.; Giraldo-Londono, O.; Buttlar, W.G. Characterization of viscoelastic properties of asphalt mixture at low temperatures using DC(T) creep test. Constr. Build. Mater. 2021, 298, 123731. [Google Scholar] [CrossRef]

- Pszczola, M.; Jaczewski, M.; Rys, D.; Jaskula, P.; Szydlowski, C. Evaluation of Asphalt Mixture Low-Temperature Performance in Bending Beam Creep Test. Materials 2018, 11, 100. [Google Scholar] [CrossRef] [PubMed]

- Boussabnia, M.M.; Perraton, D.; Benedetto, H.D.; Lamothe, S.; Proteau, M. Validation of time temperature superposition principle for high modulus asphalt concrete in the linear viscoelastic and fatigue domains. Fatigue Fract. Eng. Mater. Struct. 2022, 46, 80–95. [Google Scholar] [CrossRef]

- Zhang, Y.B.; Zhu, Y.; Wang, W.B.; Ning, Z.Y.; Feng, S.; Höeg, K. Compressive and tensile stress–strain-strength behavior of asphalt concrete at different temperatures and strain rates. Constr. Build. Mater. 2021, 311, 125362. [Google Scholar] [CrossRef]

- Wang, W.B.; Hu, K.; Feng, S.; Li, G.; Höeg, K. Shear behavior of hydraulic asphalt concrete at different temperatures and strain rates. Constr. Build. Mater. 2020, 230, 117022. [Google Scholar] [CrossRef]

- Teltayev, B.B.; Iskakbayev, A.I.; Abu, B.D. Steady-state deformation of asphalt concrete. Constr. Build. Mater. 2022, 349, 128754. [Google Scholar] [CrossRef]

- Iskakbayev, A.; Teltayev, B.; Rossi, C.O. Steady-State Creep of Asphalt Concrete. Appl. Sci. 2017, 7, 142. [Google Scholar] [CrossRef]

- Yu, L.S.; Li, J.M.; Pang, Y.; Han, X.N. Experimental Study on Viscoelastic Properties of Hydraulic Asphalt Concrete. Water Resour. Power 2023, 41, 139–142. (In Chinese) [Google Scholar]

- Nguyen, Q.T.; Herve, D.B.; Sauzeat, C. Linear and nonlinear viscoelastic behaviour of bituminous mixtures. Mater. Struct. 2015, 48, 2339–2351. [Google Scholar] [CrossRef]

- Costanzi, M.; Cebon, D. Generalized phenomenological model for the viscoelasticity of idealized asphalts. J. Mater. Civil Eng. 2014, 26, 399–410. [Google Scholar] [CrossRef]

- Bai, F.; Yang, X.H.; Yin, A.Y.; Zeng, G.W. Modified cross model for predicting long-term creep behavior of sand asphalt. Constr. Build. Mater. 2014, 65, 43–50. [Google Scholar] [CrossRef]

- Arabani, M.; Kamboozia, N. The linear visco-elastic behaviour of glasphalt mixture under dynamic loading conditions. Constr. Build. Mater. 2014, 41, 594–601. [Google Scholar] [CrossRef]

- Al-Qadi, I.L.; Yoo, P.J.; Elseifi, M.A.; Nelson, S. Creep behavior of hot-mix asphalt due to heavy vehicular tire loading. J. Eng. Mech. 2009, 135, 1265–1273. [Google Scholar] [CrossRef]

- Tanks, J.; Rader, K.; Sharp, S.; Sakai, T. Accelerated creep and creep-rupture testing of transverse unidirectional carbon/epoxy lamina based on the stepped isostress method. Compos. Struct. 2017, 159, 455–462. [Google Scholar] [CrossRef]

- Homkhiew, C.; Ratanawilai, T.; Thongruang, W. Time-temperature and stress dependent behaviors of composites made from recycled polypropylene and rubberwood flour. Constr. Build. Mater. 2014, 6, 98–104. [Google Scholar] [CrossRef]

- Yang, Z.Q.; Wang, H.; Ma, X.F.; Shang, F.L.; Ma, Y.; Shao, Z.W.; Hou, D.M. Flexural creep tests and long-term mechanical behavior of fiber-reinforced polymeric composite tubes. Compos. Struct. 2018, 193, 154–164. [Google Scholar] [CrossRef]

- Schildmeyer, A.J.; Wolcott, M.P.; Bender, D.A. Investigation of the temperature-dependent mechanical behavior of a polypropylene-pine composite. J. Mater. Civil Eng. 2009, 21, 460–466. [Google Scholar] [CrossRef]

- Cuciniello, G.; Leandri, P.; Polacco, G.; Airey, G.; Losa, M. Applicability of time-temperature superposition for laboratory-aged neat and SBS-modified bitumens. Constr. Build. Mater. 2020, 263, 120964. [Google Scholar] [CrossRef]

- Chang, F.C.; Lam, F.; Kadla, J.F. Application of time-temperature-stress superposition on creep of wood-plastic composites. Mech. Time-Depend. Mat. 2013, 17, 427–437. [Google Scholar] [CrossRef]

- Zheng, M.L.; Han, L.L.; Qiu, Z.P.; Li, H.Y.; Ma, Q.L.; Che, F. Simulation of Permanent Deformation in High-Modulus Asphalt Pavement Using the Bailey-Norton Creep Law. J. Mater. Civil Eng. 2016, 28, 04016020. [Google Scholar] [CrossRef]

- Tak, T.N.; Prakash, A.; Keralavarma, S.M.; Samajdar, I.; Guruprasad, P.J. A Discrete Dislocation Dynamics model of creep in polycrystals. J. Mech. Phys. Solids 2023, 179, 105385. [Google Scholar] [CrossRef]

- DL/T 5362-2018; Test Code for Hydraulic Asphalt Concrete. China Electric Power Press: Beijing, China, 2018.

- Yang, Z.H.; Yang, W.; Yang, H.H.; Liu, L.; He, J.X. Study of stress-strain relationship of hydraulic asphalt concrete at low to intermediate temperatures based on experimental data regression. Constr. Build. Mater. 2023, 409, 134059. [Google Scholar] [CrossRef]

- Onifade, I.; Huang, K.; Birgisson, B. The scalar modulus: A novel parameter for predicting creep properties of asphalt mixtures. Constr. Build. Mater. 2024, 424, 135880. [Google Scholar] [CrossRef]

- Chen, S.Q.; Xu, L.; Jia, S.Q.; Wang, J.C. Characterization of the nonlinear viscoelastic constitutive model of asphalt mixture. Case Stud. Constr. Mat. 2023, 18, e0192. [Google Scholar] [CrossRef]

- Taherkhani, H.; Afroozi, S. Investigating the creep properties of asphaltic concrete containing nano-silica. Sādhanā 2018, 43, 24. [Google Scholar] [CrossRef]

- Iskakbayev, A.I.; Teltayev, B.B.; Yestayev, K.Z.; Abu, B.D. Long-term strength of asphalt concrete and its applications. Constr. Build. Mater. 2020, 244, 118325. [Google Scholar] [CrossRef]

- Pulngern, T.; Chitsamran, T.; Chucheepsakul, S.; Rosarpitak, V.; Patcharaphun, S.; Sombatsompop, N. Effect of temperature on mechanical properties and creep responses for wood/PVC composites. Constr. Build. Mater. 2016, 111, 191–198. [Google Scholar] [CrossRef]

- Karimi, M.M.; Tabatabaee, N.; Jahangiri, B.; Darabi, M.K. Constitutive modeling of hardening-relaxation response of asphalt concrete in cyclic compressive loading. Constr. Build. Mater. 2017, 137, 169–184. [Google Scholar] [CrossRef]

- Huang, T.; Wang, Z.Y.; Dong, H.W.; Qin, H.Y.; Liu, H.F.; Cao, Z.L. Time-Temperature-Stress Equivalent Characteristics and Nonlinear Viscoelastic Model of Asphalt Mixture under Triaxial Compressive Stress State. J. Mater. Civil Eng. 2024, 36, 04023543. [Google Scholar] [CrossRef]

- Zhao, J.; Zhao, W.G.; Xie, K.Z.; Yang, Y. A Fractional Creep Constitutive Model Considering the Viscoelastic–Viscoplastic Coexistence Mechanism. Materials 2023, 16, 6131. [Google Scholar] [CrossRef] [PubMed]

- Du, J.H.; Li, F. Propagation Characteristics of Dispersion Cracks in Asphalt Concrete at Low Temperatures. J. Mater. Civil Eng. 2024, 36, 04024179. [Google Scholar] [CrossRef]

| Index | Unit | Technical Requirements | Experimental Results |

|---|---|---|---|

| Apparent Density | g/cm3 | ≥2.6 | 2.710 |

| Grade of Adhesion to Asphalt | Grade | ≥4 | 5 |

| Water Absorption | % | ≤2 | 0.48 |

| Durability | % | ≤12 | 1.3 |

| Heat Resistance | -- | No cracking, decomposition | Qualified |

| Index | Unit | Technical Requirements | Limestone | Description |

|---|---|---|---|---|

| Apparent Density | g/cm3 | ≥2.55 | 2.734 | -- |

| Grade of Adhesion to Asphalt | % | ≤2 | 0.4 | -- |

| Water Stability Grade | grade | ≥6 | 9 | Sodium carbonate solution boiled for 1 min |

| Organic Matter and Soil Content | % | ≤2 | 0.0 | -- |

| Index | Unit | Technical Requirements | Experimental Results |

|---|---|---|---|

| Apparent Density | g/cm3 | ≥2.5 | 2.717 |

| Hydrophilicity Coefficient | -- | ≤1.0 | 0.6 |

| Water Absorption | % | ≤0.5 | 0.2 |

| Fineness < 0.6 mm | % | 100 | 100 |

| Fineness < 0.15 mm | % | >90 | 100 |

| Fineness < 0.075 mm | % | >85 | 100 |

| Index | Unit | Quality Indicator | Detection Result |

|---|---|---|---|

| Penetration (25 °C, 100 g, 5 s) | 1/10 mm | 60~80 | 68.1 |

| Ductility (5 cm/min, 15 °C) | cm | ≥150 | >150 |

| Ductility (1 cm/min, 4 °C) | cm | ≥15 | 41.3 |

| Softening Point | °C | 48~55 | 48.1 |

| Density (25 °C) | g/cm3 | Measured | 0.986 |

| The Mass Change of Film After Oven Experiment | % | ±0.8 | −0.10 |

| Penetration Ratio (25 °C) After Film Oven Experiment | % | ≥61 | 80.6 |

| Film Oven Experiment Ductility (5 cm/min, 15 °C) | cm | ≥80 | >100 |

| Film Oven Experiment Ductility (1 cm/min, 4 °C) | cm | ≥4 | 16.7 |

| Experimental Conditions | Experimental Temperature, °C | Absolute Temperature, K | Loading Stress, MPa |

|---|---|---|---|

| 1 | −20 | 253.15 | 2.9376, 3.2976, 3.6576 |

| 2 | −15 | 258.15 | 2.5776, 2.9376, 3.2976 |

| 3 | −10 | 263.15 | 2.2176, 2.5776, 2.9376 |

| 4 | −5 | 268.15 | 0.7776, 1.1376, 1.8576 |

| 5 | 0 | 273.15 | 0.2376, 0.4176, 0.5976, 0.7776, 0.9576, 1.1376, 1.3176 |

| 6 | 5 | 278.15 | 0.2376, 0.4176, 0.5976 |

| 7 | 10 | 283.15 | 0.1476, 0.2376, 0.3276 |

| 8 | 15 | 288.15 | 0.1476, 0.2376, 0.3276 |

| 9 | 20 | 293.15 | 0.1476, 0.2376, 0.3276 |

| Temperature/°C | logA | A | n | R2 |

|---|---|---|---|---|

| 20 | −1.95612 | 0.011063 | 0.77958 | 0.99309 |

| 15 | −2.54703 | 0.002838 | 0.68655 | 0.99982 |

| 10 | −3.43575 | 0.000367 | 0.69494 | 0.97522 |

| 5 | −3.59647 | 0.000253 | 0.98729 | 0.9863 |

| 0 | −3.72618 | 0.000188 | 0.77512 | 0.98323 |

| −5 | −3.96487 | 0.000108 | 1.14454 | 0.95634 |

| −10 | −5.05639 | 8.78 × 10−6 | 1.96361 | 0.99814 |

| −15 | −4.95713 | 1.1 × 10−5 | 0.84855 | 0.99995 |

| −20 | −6.7184 | 1.91 × 10−7 | 2.55179 | 0.99983 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Y.; Yang, C.; Zhong, Z.; Huang, C.; Zhang, Y.; Feng, S.; Li, S.; Jiang, R. Research on Bending Creep Test and Long-Term Creep Behavior Prediction of Asphalt Concrete. Materials 2025, 18, 2381. https://doi.org/10.3390/ma18102381

Zhu Y, Yang C, Zhong Z, Huang C, Zhang Y, Feng S, Li S, Jiang R. Research on Bending Creep Test and Long-Term Creep Behavior Prediction of Asphalt Concrete. Materials. 2025; 18(10):2381. https://doi.org/10.3390/ma18102381

Chicago/Turabian StyleZhu, Yue, Changhong Yang, Zimo Zhong, Changsheng Huang, Yingbo Zhang, Shan Feng, Shutian Li, and Rengui Jiang. 2025. "Research on Bending Creep Test and Long-Term Creep Behavior Prediction of Asphalt Concrete" Materials 18, no. 10: 2381. https://doi.org/10.3390/ma18102381

APA StyleZhu, Y., Yang, C., Zhong, Z., Huang, C., Zhang, Y., Feng, S., Li, S., & Jiang, R. (2025). Research on Bending Creep Test and Long-Term Creep Behavior Prediction of Asphalt Concrete. Materials, 18(10), 2381. https://doi.org/10.3390/ma18102381