Effects of Heat Treatment Cooling Methods on Precipitated Phase and Tensile Properties of Fe-18Mn-10Al-1C-5Ni Lightweight Steel

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Processing

2.2. Microstructural Characterization and Mechanical Testing

3. Results

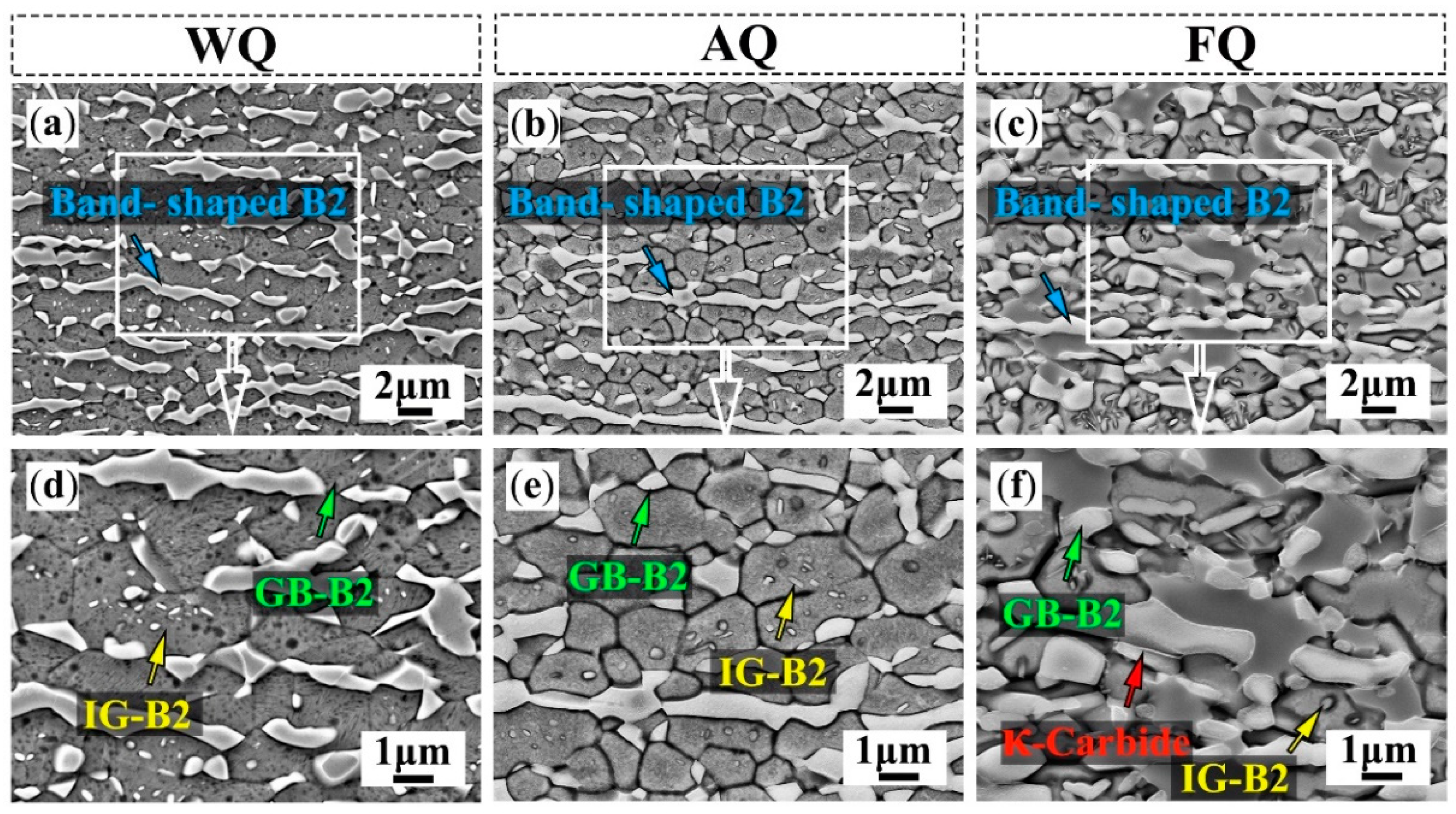

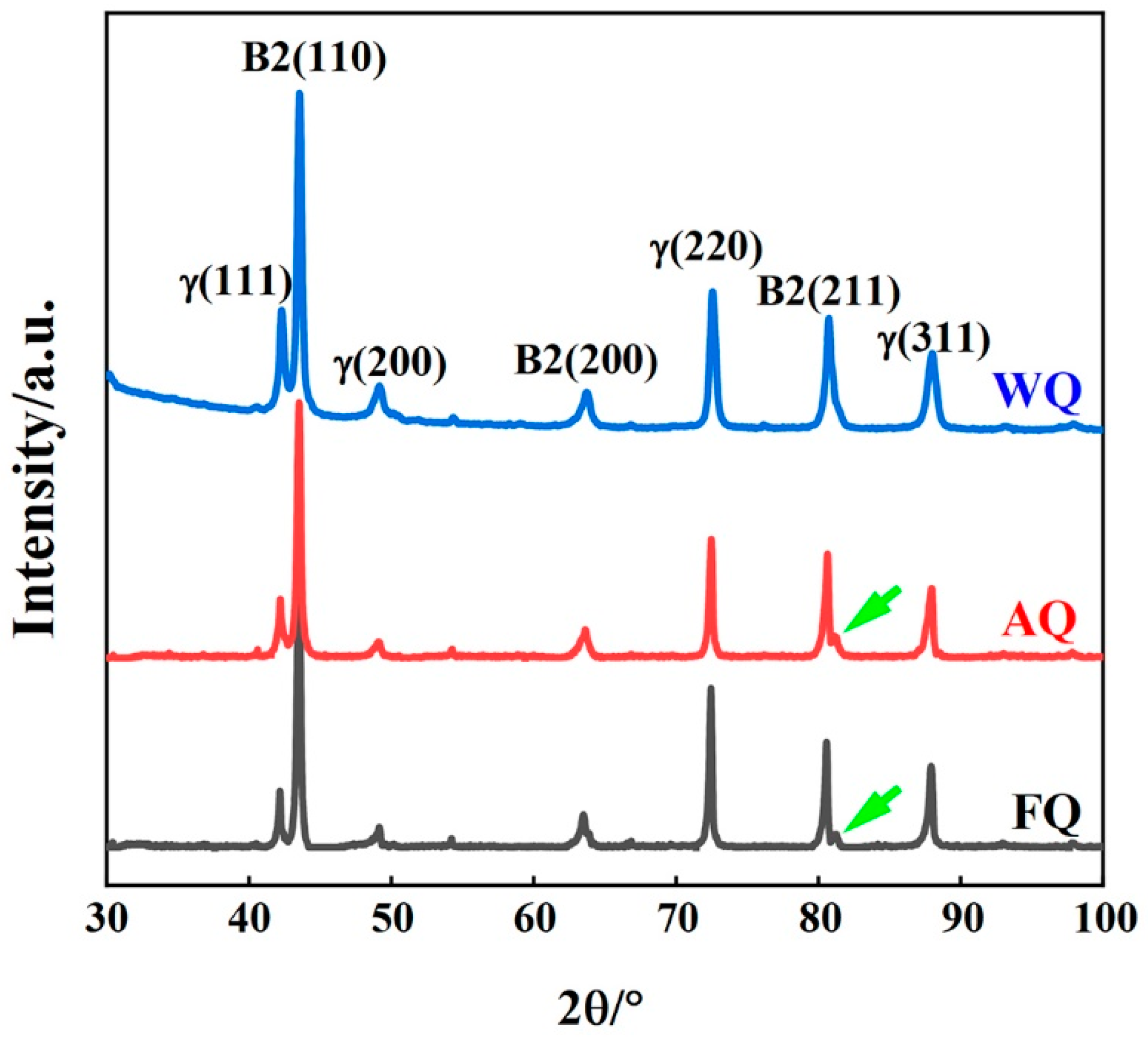

3.1. Microstructure Characterization

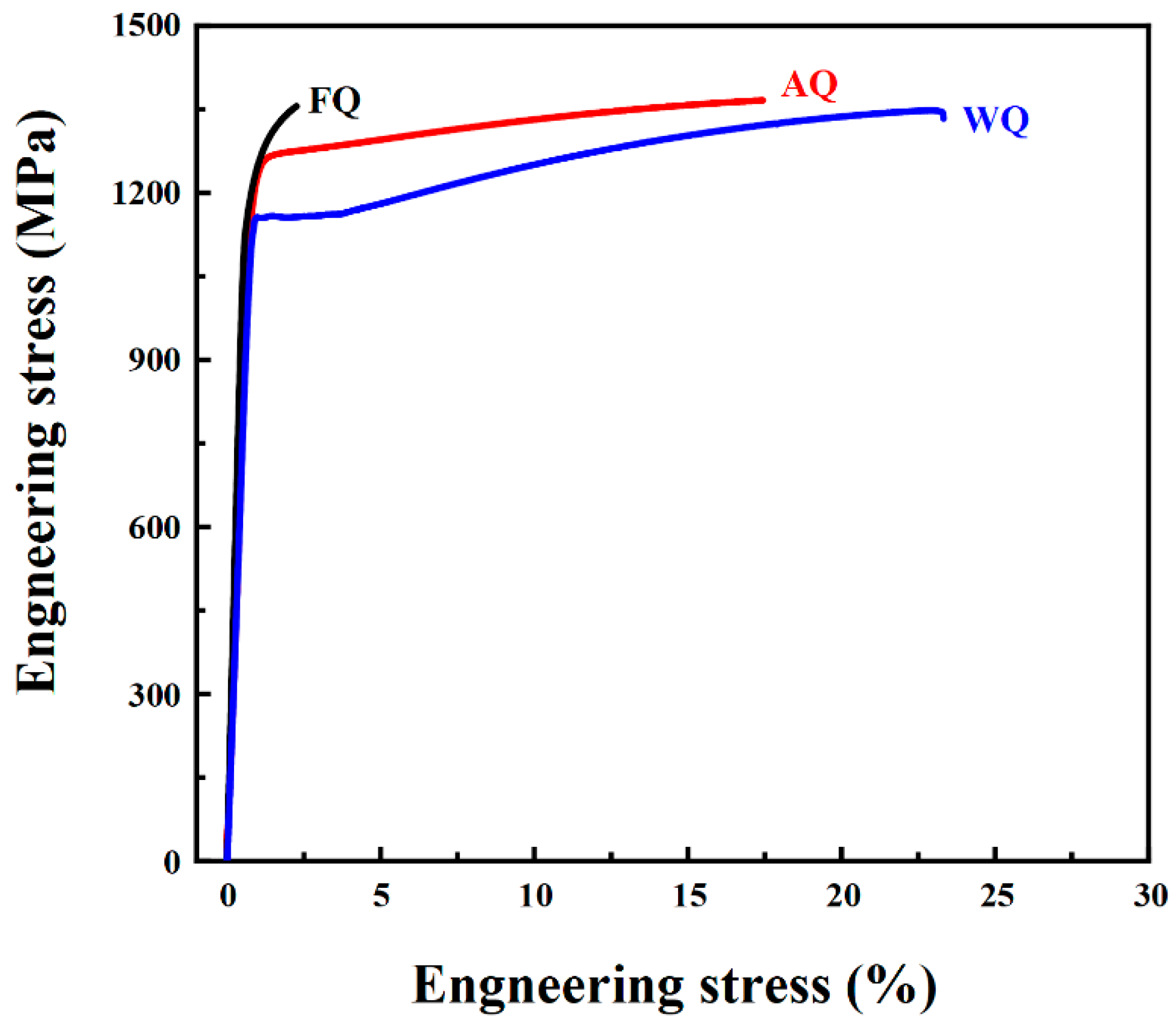

3.2. Mechanical Properties

4. Discussion

4.1. Microstructural Factors Influencing the Tensile Properties

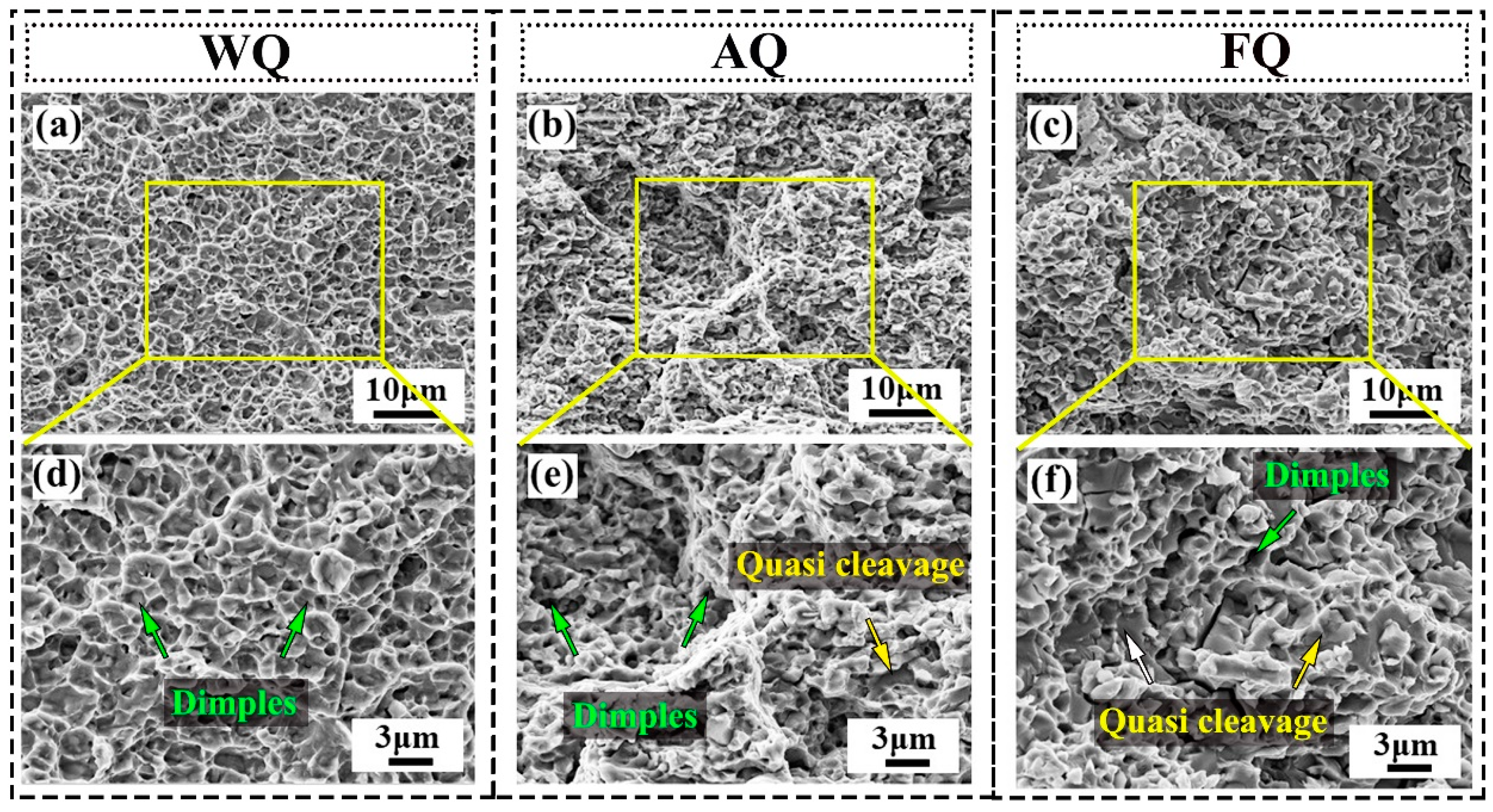

4.2. Fracture Behavior Investigation and Analysis of the Samples

5. Conclusions

- (1)

- The microstructure of the WQ sample comprised austenite, grain boundary B2 (GB-B2), and intragranular B2 (IG-B2). The B2 phase had a volume fraction of 25.8%, with the average grain sizes of the GB-B2 and IG-B2 being 1700 nm and 230 nm, respectively. The yield strength and tensile strength of the WQ sample were 1094 MPa and 1315 MPa, respectively, accompanied by an elongation of 23.3%;

- (2)

- Compared with the WQ sample, the IG-B2 particles in the AQ sample did not change significantly (239 nm), while nano-sized κ-carbides appeared at the grain boundaries and within the grains. After the air cooling treatment, the yield strength and ultimate tensile strength of the AQ sample were significantly improved to 1232 MPa and 1347 MPa, respectively, while ensuring that the ductility was not seriously deteriorated (17.4%). This excellent strength–plasticity balance can be mainly attributed to the synergistic effect of GB-B2, IG-B2 particles, and nano-sized κ-carbides in austenite;

- (3)

- Compared with the WQ and AQ samples, the IG-B2 particles in the FQ sample became coarser (332 nm). Meanwhile, the intragranular κ-carbides also coarsened, especially at the B2–austenite interfaces, where new κ-carbides grew to 170 nm. Furnace quenching led to a severe deterioration in the elongation during the tensile deformation process, and the κ-carbides at the phase boundaries promoted the nucleation of voids and microcracks.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| WQ | Water quenching |

| AQ | Air cooling |

| FQ | Furnace cooling |

References

- Wang, Z.; Lu, W.; Zhao, H.; He, J.; Wang, K.; Zhou, B.; Ponge, D.; Raabe, D.; Li, Z. Formation mechanism of κ-carbides and deformation behavior in Si-alloyed FeMnAlC lightweight steels. Acta Mater. 2020, 198, 258–270. [Google Scholar] [CrossRef]

- Tang, Y.; Li, B.; Shi, H.; Guo, Y.; Zhang, S.; Zhang, J.; Zhang, X.; Liu, R. Simultaneous improvement of corrosion and wear resistance of Fe–Mn–Al–C lightweight steels: The role of Cr/Mo. Mater. Charact. 2023, 205, 113274. [Google Scholar] [CrossRef]

- Ha, H.-Y.; Kim, K.-W.; Park, S.-J.; Lee, T.-H.; Park, H.; Moon, J.; Hong, H.-U.; Lee, C.-H. Effects of Cr on pitting corrosion resistance and passive film properties of austenitic Fe–19Mn–12Al–1.5 C lightweight steel. Corros. Sci. 2022, 206, 110529. [Google Scholar] [CrossRef]

- Ha, H.-Y.; Kim, K.-W.; Park, S.-J.; Lee, C.-H.; Lee, T.-H.; Hong, H.-U.; Moon, J. A comparative study on passive films of Fe–11Cr stainless steel and Fe–20Mn–11.5Al–1.4C–5Cr lightweight steel. J. Mater. Res. Technol. 2023, 26, 6135–6145. [Google Scholar] [CrossRef]

- Zhang, J.; Raabe, D.; Tasan, C.C. Designing duplex, ultrafine-grained Fe-Mn-Al-C steels by tuning phase transformation and recrystallization kinetics. Acta Mater. 2017, 141, 374–387. [Google Scholar] [CrossRef]

- Ley, N.A.; Young, M.L.; Hornbuckle, B.C.; Field, D.M.; Limmer, K.R. Toughness enhancing mechanisms in age hardened Fe–Mn–Al–C steels. Mater. Sci. Eng. A 2021, 820, 141518. [Google Scholar] [CrossRef]

- Gutierrez-Urrutia, I.; Raabe, D. Influence of Al content and precipitation state on the mechanical behavior of austenitic high-Mn low-density steels. Scr. Mater. 2013, 68, 343–347. [Google Scholar] [CrossRef]

- Bentley, A.P.; Altstetter, C.J.; Fourie, J.W.; Kirkbride, A.N. Processing and properties of Fe-Mn-Al alloys. Mater. Sci. Eng. 1986, 82, 13–25. [Google Scholar]

- Sohn, S.S.; Hong, S.; Lee, J.; Suh, B.-C.; Kim, S.-K.; Lee, B.-J.; Kim, N.J.; Lee, S. Effects of Mn and Al contents on cryogenic-temperature tensile and Charpy impact properties in four austenitic high-Mn steels. Acta Mater. 2015, 100, 39–52. [Google Scholar] [CrossRef]

- Bouaziz, O.; Allain, S.; Scott, C.P.; Cugy, P.; Barbier, D. High manganese austenitic twinning induced plasticity steels: A review of the microstructure properties relationships. Curr. Opin. Solid State Mater. Sci. 2011, 15, 141–168. [Google Scholar] [CrossRef]

- Lu, W.J.; Zhang, X.F.; Qin, R.S. κ-carbide hardening in a low-density high-Al high-Mn multiphase steel. Mater. Lett. 2015, 138, 96–99. [Google Scholar] [CrossRef]

- Liu, D.; Cai, M.; Ding, H.; Han, D. Control of inter/intra-granular κ -carbides and its influence on overall mechanical properties of a Fe-11Mn-10Al-1.25C low density steel. Mater. Sci. Eng. A 2018, 715, 25–32. [Google Scholar] [CrossRef]

- Zhang, G.; Ma, W.; Tang, Y.; Wang, F.; Zhang, X.; Wang, Q.; Liu, R. Investigation on the microstructural evolution and mechanical properties of partially recrystallized Fe-27Mn-10Al-1.4C steel. Mater. Sci. Eng. A 2022, 833, 142545. [Google Scholar] [CrossRef]

- Choi, K.; Seo, C.-H.; Lee, H.; Kim, S.K.; Kwak, J.H.; Chin, K.G.; Park, K.-T.; Kim, N.J. Effect of aging on the microstructure and deformation behavior of austenite base lightweight Fe–28Mn–9Al–0.8C steel. Scr. Mater. 2010, 63, 1028–1031. [Google Scholar] [CrossRef]

- Chen, X.P.; Xu, Y.P.; Ren, P.; Li, W.J.; Cao, W.Q.; Liu, Q. Aging hardening response and β-Mn transformation behavior of high carbon high manganese austenitic low-density Fe-30Mn-10Al-2C steel. Mater. Sci. Eng. A 2017, 703, 167–172. [Google Scholar] [CrossRef]

- Chen, P.; Zhang, F.; Zhang, Q.C.; Du, J.H.; Shi, F.; Li, X.W. Precipitation behavior of κ-carbides and its relationship with mechanical properties of Fe–Mn–Al–C lightweight austenitic steel. J. Mater. Res. Technol. 2023, 25, 3780–3788. [Google Scholar] [CrossRef]

- Kim, S.H.; Kim, H.; Kim, N.J. Brittle intermetallic compound makes ultrastrong low-density steel with large ductility. Nature 2015, 518, 77–79. [Google Scholar] [CrossRef] [PubMed]

- Yang, M.X.; Yuan, F.P.; Xie, Q.G.; Wang, Y.D.; Ma, E.; Wu, X.L. Strain hardening in Fe–16Mn–10Al–0.86C–5Ni high specific strength steel. Acta Mater. 2016, 109, 213–222. [Google Scholar] [CrossRef]

- Jiang, S.; Wang, H.; Wu, Y.; Liu, X.; Chen, H.; Yao, M.; Gault, B.; Ponge, D.; Raabe, D.; Hirata, A.; et al. Ultrastrong steel via minimal lattice misfit and high-density nanoprecipitation. Nature 2017, 544, 460–464. [Google Scholar] [CrossRef]

- Zargaran, A.; Trang, T.T.T.; Park, G.; Kim, N.J. κ-Carbide assisted nucleation of B2: A novel pathway to develop high specific strength steels. Acta Mater. 2021, 220, 117349. [Google Scholar] [CrossRef]

- Wang, J.; Yang, M.; Wu, X.; Yuan, F. Achieving better synergy of strength and ductility by adjusting size and volume fraction of coherent κ′–carbides in a lightweight steel. Mater. Sci. Eng. A 2022, 857, 144085. [Google Scholar] [CrossRef]

- Zhang, B.-G.; Zhang, X.-M.; Liu, H.-T. Precipitation behavior of B2 and κ-carbide during aging and its effect on mechanical properties in Al-containing high strength steel. Mater. Charact. 2021, 178, 111291. [Google Scholar] [CrossRef]

- Hwang, J.H.; Trang, T.T.T.; Lee, O.; Park, G.; Zargaran, A.; Kim, N.J. mprovement of strength–Ductility balance of B2-strengthened lightweight steel. Acta Mater. 2020, 191, 1–12. [Google Scholar] [CrossRef]

- Liu, D.; Ding, H.; Cai, M.; Han, D. Mechanical behaviors of a lower-Mn-added Fe–11Mn–10Al–1.25C lightweight steel with distinguished microstructural features. Mater. Lett. 2019, 242, 131–134. [Google Scholar] [CrossRef]

- Banis, A.; Gomez, A.; Dutta, A.; Sabirov, I.; Petrov, R.H. The effect of nano-sized κ-carbides on the mechanical properties of an Fe-Mn-Al-C alloy. Mater. Charact. 2023, 205, 113364. [Google Scholar] [CrossRef]

- Lu, W.J.; Qin, R.S. nfluence of κ-carbide interface structure on the formability of lightweight steels. Mater. Des. 2016, 104, 211–216. [Google Scholar] [CrossRef]

- Cheng, J.; Ju, D.; Liu, J.; Liu, N.; Wu, Z.; Zhang, J. Achieving synergy of strength and ductility of eutectic high-entropy alloys via continuous precipitation of nano-precipitates. Vacuum 2025, 238, 114309. [Google Scholar] [CrossRef]

- Chen, Z.; Ren, C.; Le, W.; An, B. Precipitation behavior and precipitates characterization of Al-Zn-Mg-Cu alloy during the non-isothermal aging process. Vacuum 2024, 233, 113946. [Google Scholar] [CrossRef]

- Zhou, Y.; Xiao, L.; Li, Y.; Deng, X.; Wang, Z. Tailoring yield strength in Fe-20Mn-9Al-1.5C-3Cr-2Ni austenitic lightweight steels achieved by larger volume and size κ′-Carbide under extended aging. Mater. Lett. 2025, 381, 137804. [Google Scholar] [CrossRef]

- Li, P.; Sun, H.L.; Xiao, N.; Ding, H.; Guo, X.F. Optimizing the synergy of strength and ductility in a Fe–18Mn–8Al–1C–5Ni lightweight steel by adjusting the distribution, volume fraction and size of B2 phases and κ-carbides. J. Mater. Res. Technol. 2025, 34, 501–510. [Google Scholar] [CrossRef]

- Ko, U.-S.; Kim, C.; Park, S.-J.; Hong, H.-U. Influence of dynamic strain aging on low-cycle fatigue behavior in nano-sized κ-carbide strengthened FeMnAlC lightweight steel. Int. J. Fatigue 2024, 181, 108149. [Google Scholar] [CrossRef]

- Chen, H.; Qin, S.; Kong, X.; Men, S.; Wang, D.; Chen, Z.; Guo, C.; Geng, Y.; Wang, Y.; Chen, X.; et al. Brittle precipitates regulation in Ni/Ti composition gradient materials under pulsed current. J. Mater. Res. Technol. 2025, 35, 4189–4203. [Google Scholar] [CrossRef]

- Lee, G.H.; Kim, B.; Jeon, J.B.; Park, M.; Noh, S.; Kim, B.J. Precipitate phase behavior and mechanical properties of Inconel 718 according to aging heat treatment time. Mater. Sci. Eng. A 2025, 924, 147776. [Google Scholar] [CrossRef]

- Zhang, L.; Song, R.; Zhao, C.; Yang, F. Work hardening behavior involving the substructural evolution of an austenite–ferrite Fe–Mn–Al–C steel. Mater. Sci. Eng. A 2015, 640, 225–234. [Google Scholar] [CrossRef]

- Raabe, D.; Herbig, M.; Sandlöbes, S.; Li, Y.; Tytko, D.; Kuzmina, M.; Ponge, D.; Choi, P.P. Grain boundary segregation engineering in metallic alloys: A pathway to the design of interfaces. Curr. Opin. Solid State Mater. Sci. 2014, 18, 253–261. [Google Scholar] [CrossRef]

- Lu, W.J.; Qin, R.S. Structure-property relationships in dual-phase steels. Metal Sci. 1982, 16, 371–382. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Cao, H.; Lou, Y.; Cao, L.; Gao, Y.; Zhao, L. Effects of Heat Treatment Cooling Methods on Precipitated Phase and Tensile Properties of Fe-18Mn-10Al-1C-5Ni Lightweight Steel. Materials 2025, 18, 2364. https://doi.org/10.3390/ma18102364

Wang Y, Cao H, Lou Y, Cao L, Gao Y, Zhao L. Effects of Heat Treatment Cooling Methods on Precipitated Phase and Tensile Properties of Fe-18Mn-10Al-1C-5Ni Lightweight Steel. Materials. 2025; 18(10):2364. https://doi.org/10.3390/ma18102364

Chicago/Turabian StyleWang, Yu, Heng Cao, Yanchun Lou, Lei Cao, Yunbao Gao, and Ling Zhao. 2025. "Effects of Heat Treatment Cooling Methods on Precipitated Phase and Tensile Properties of Fe-18Mn-10Al-1C-5Ni Lightweight Steel" Materials 18, no. 10: 2364. https://doi.org/10.3390/ma18102364

APA StyleWang, Y., Cao, H., Lou, Y., Cao, L., Gao, Y., & Zhao, L. (2025). Effects of Heat Treatment Cooling Methods on Precipitated Phase and Tensile Properties of Fe-18Mn-10Al-1C-5Ni Lightweight Steel. Materials, 18(10), 2364. https://doi.org/10.3390/ma18102364