Enhancement of a Magnetically Controlled Cathodic Arc Source for the Deposition of Multi-Component Hard Nitride Coatings

Abstract

1. Introduction

2. Experimental Details

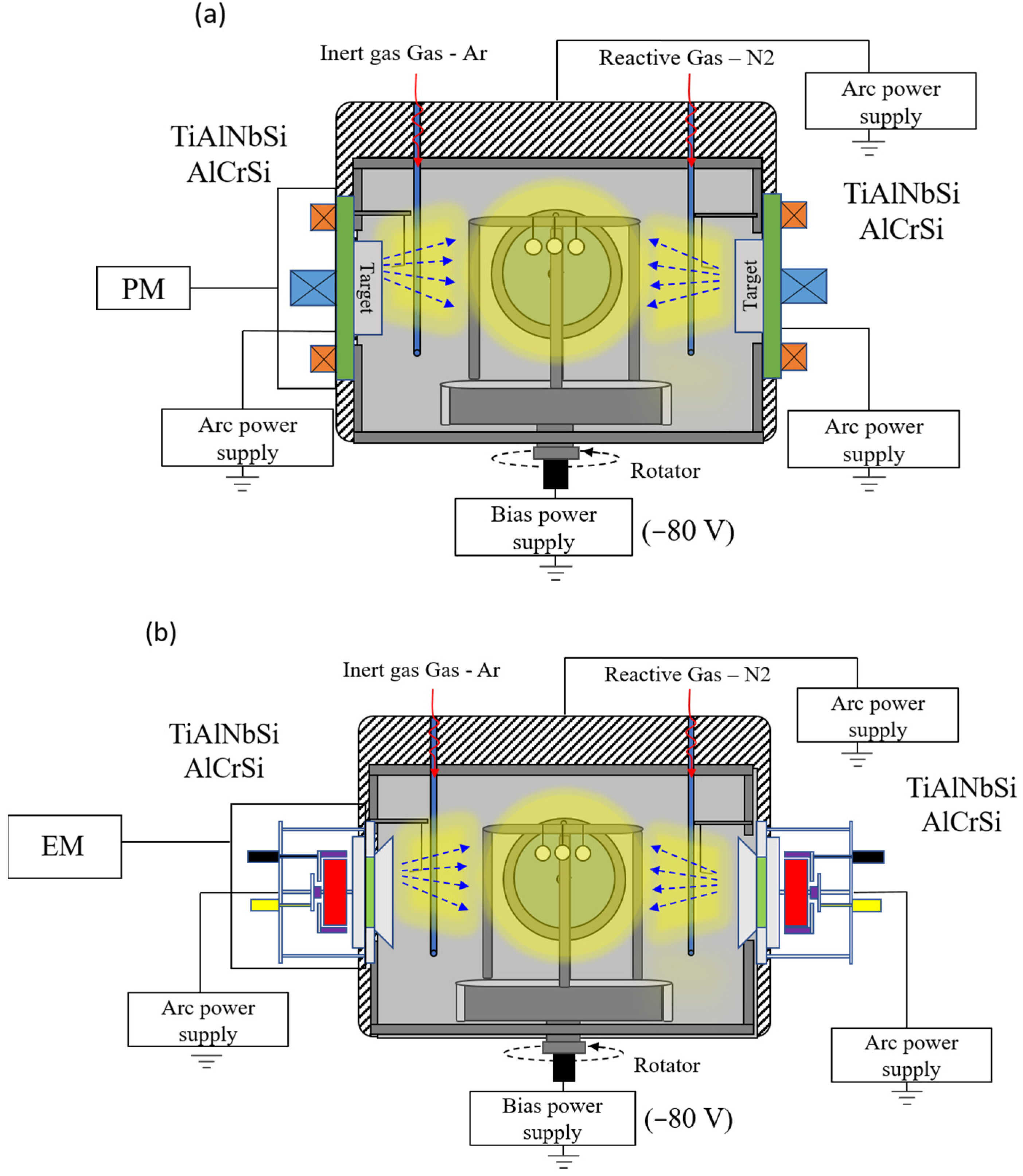

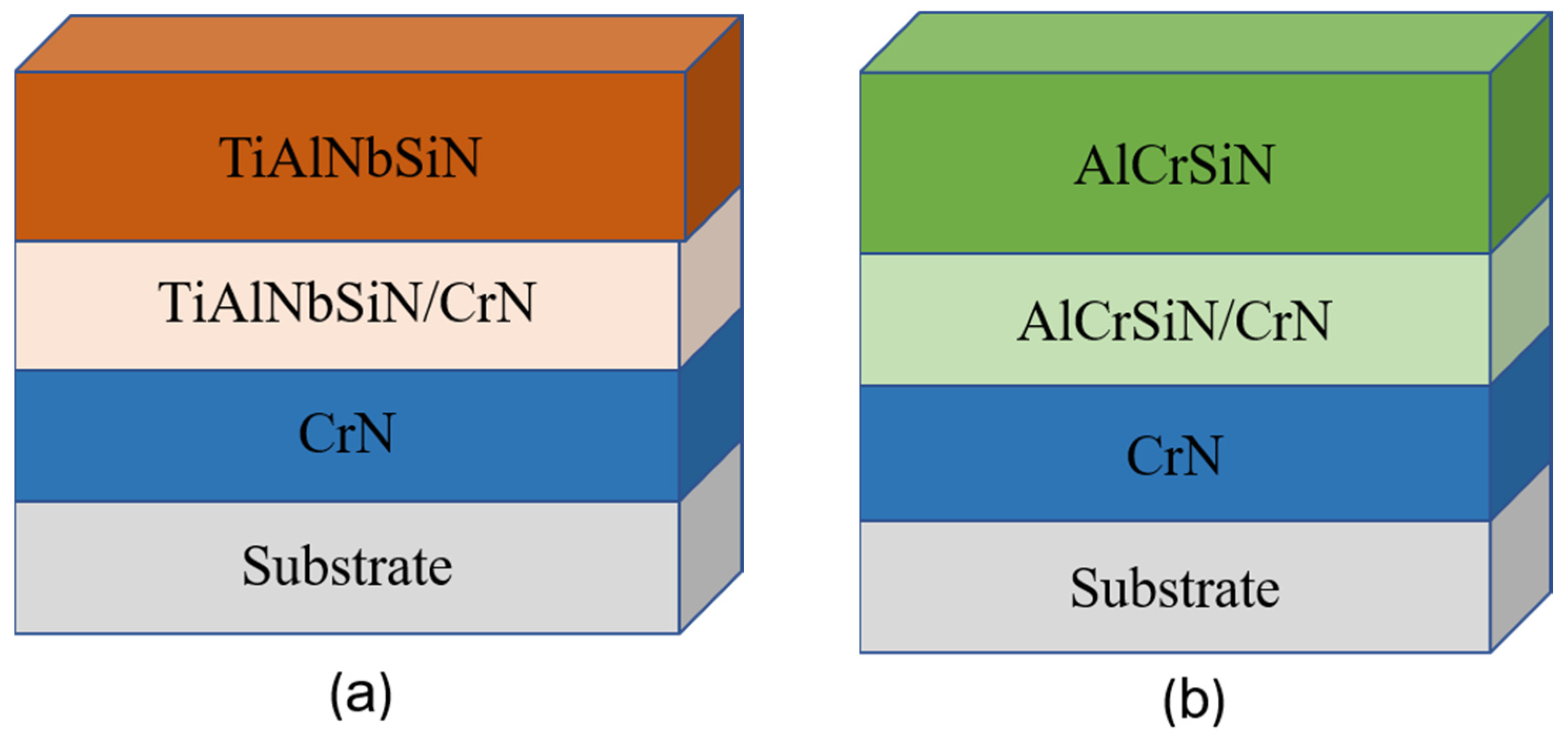

2.1. Coating Deposition

2.2. Coating Characterization

3. Results and Discussion

3.1. Chemical Composition

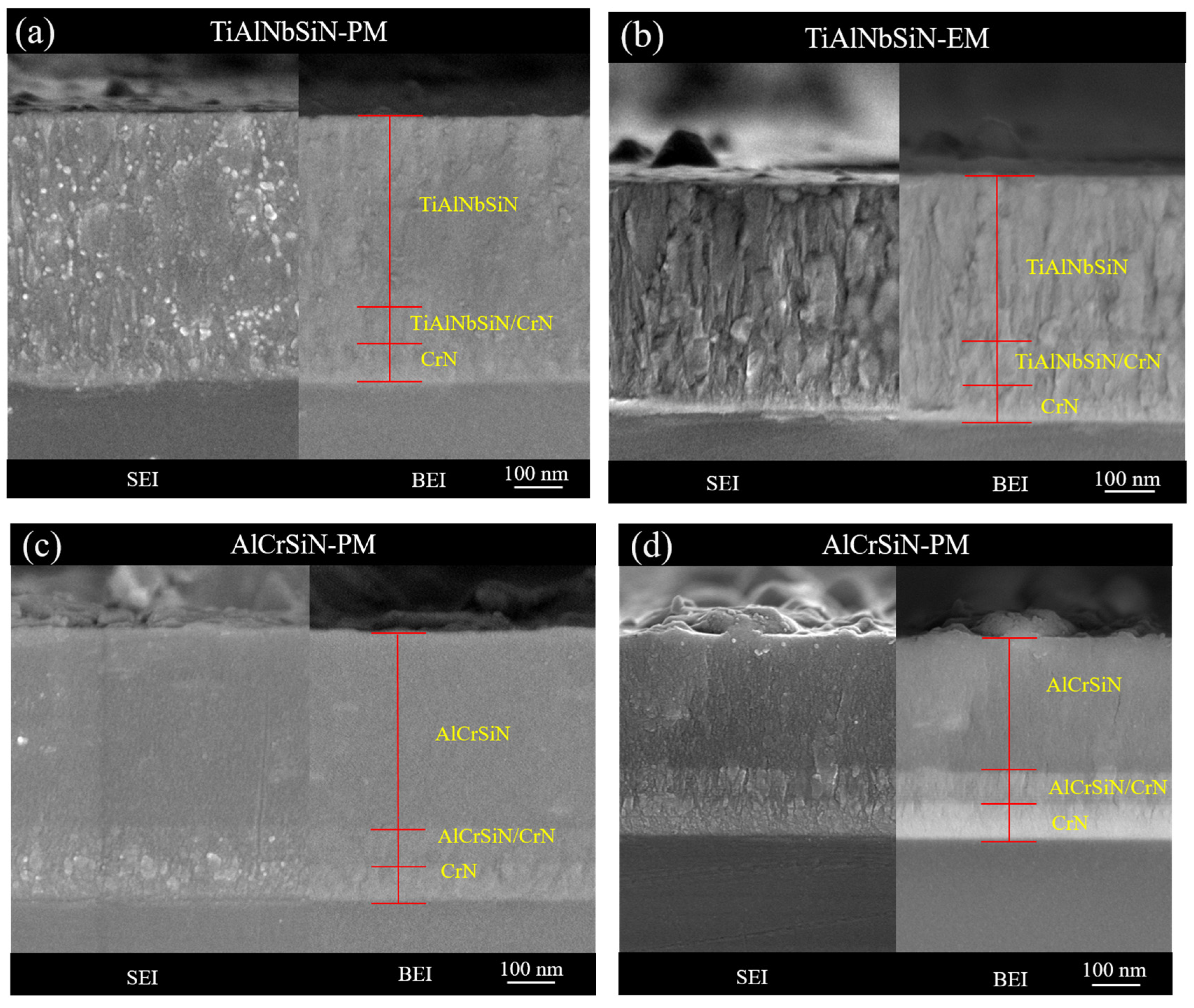

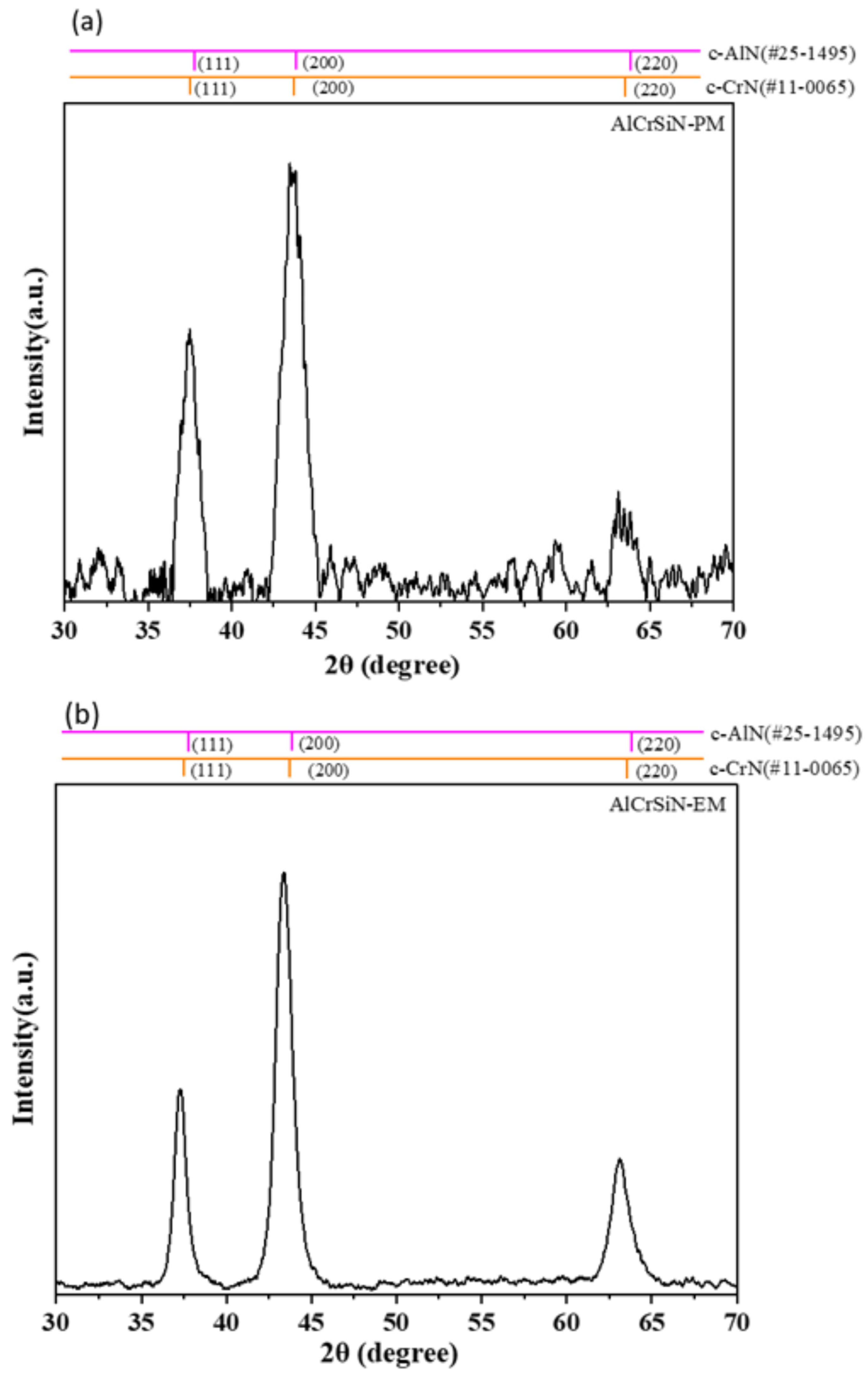

3.2. Microstructure Characterization

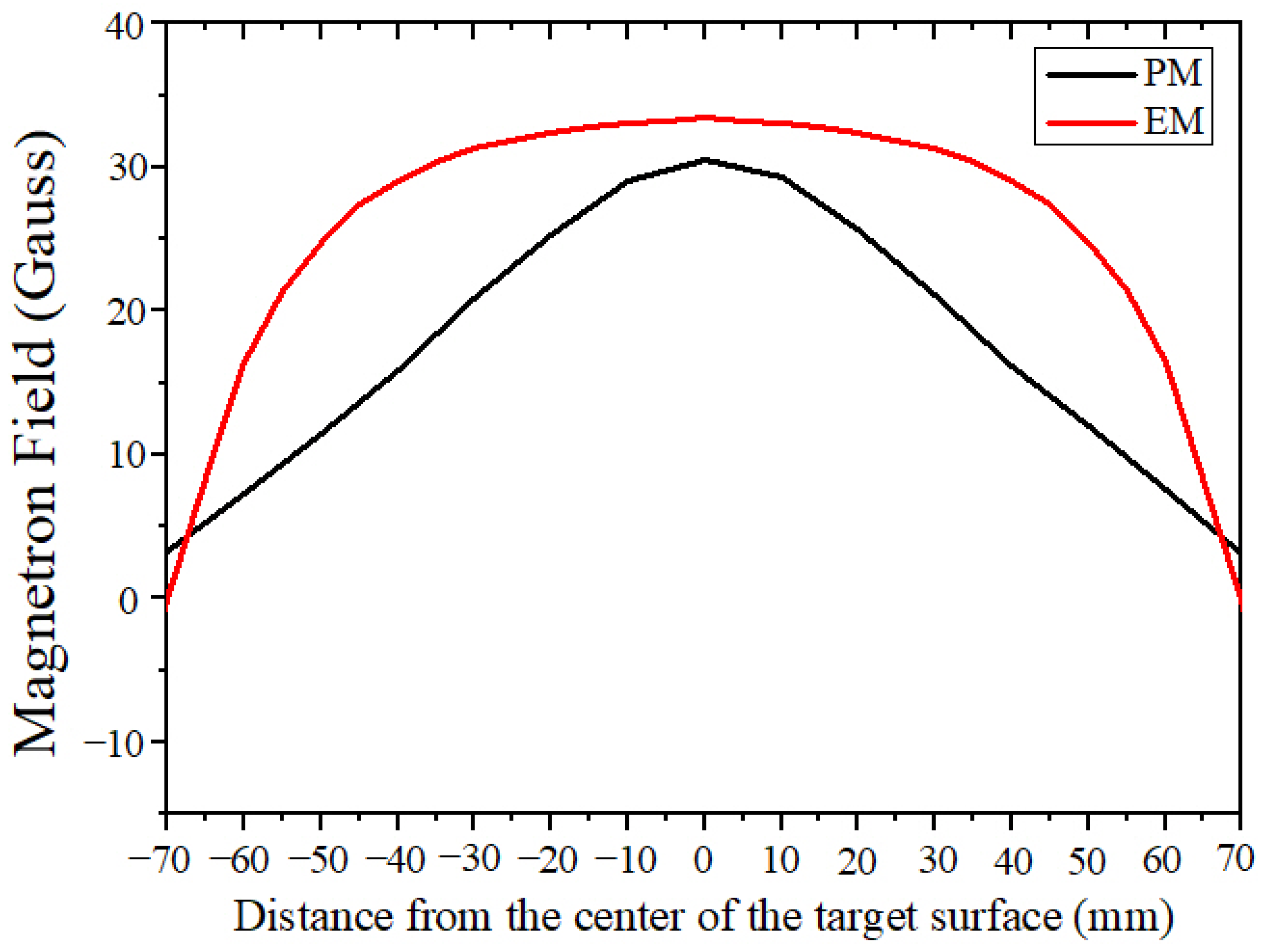

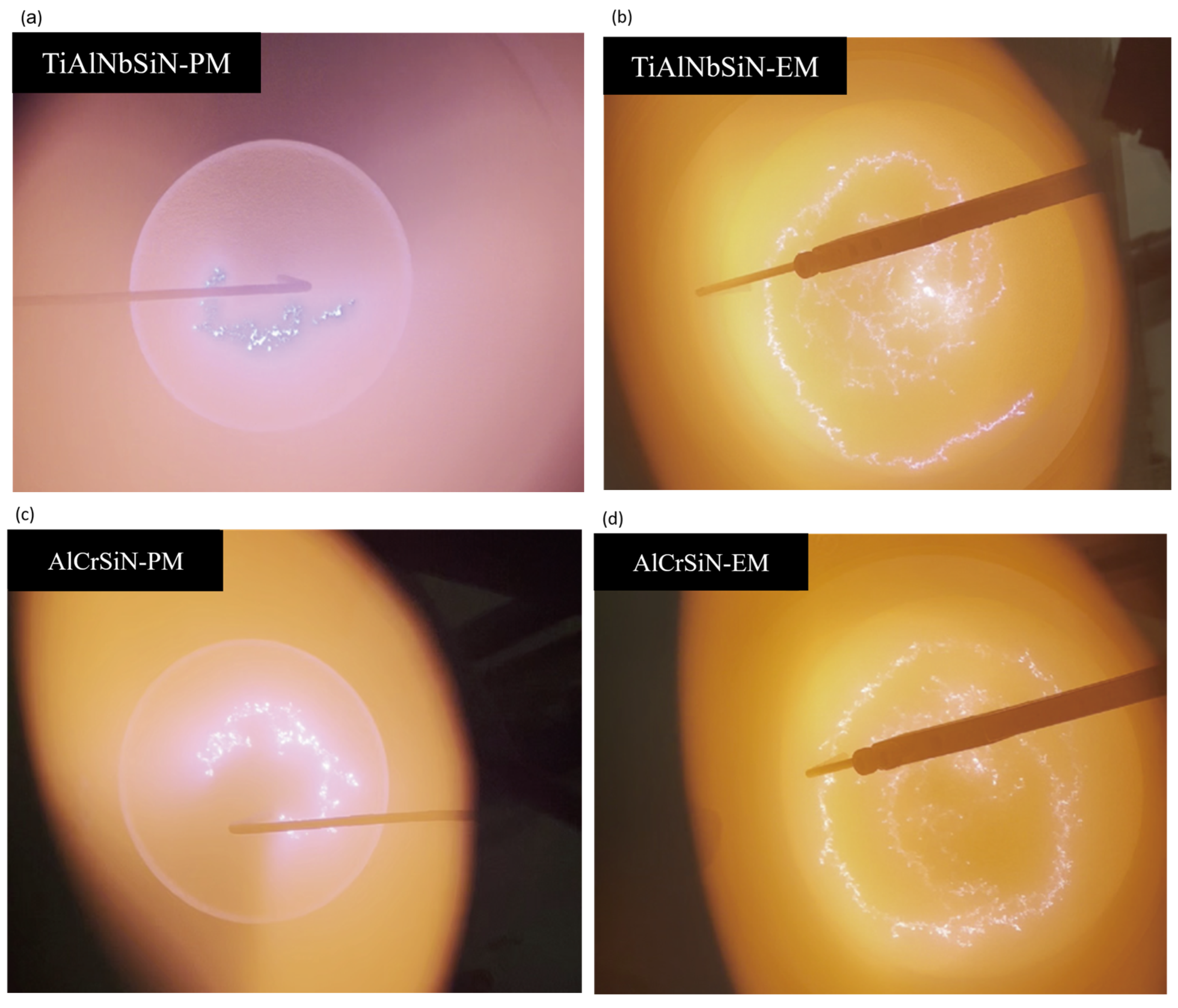

3.3. Magnetic Field Distribution and Arc Type

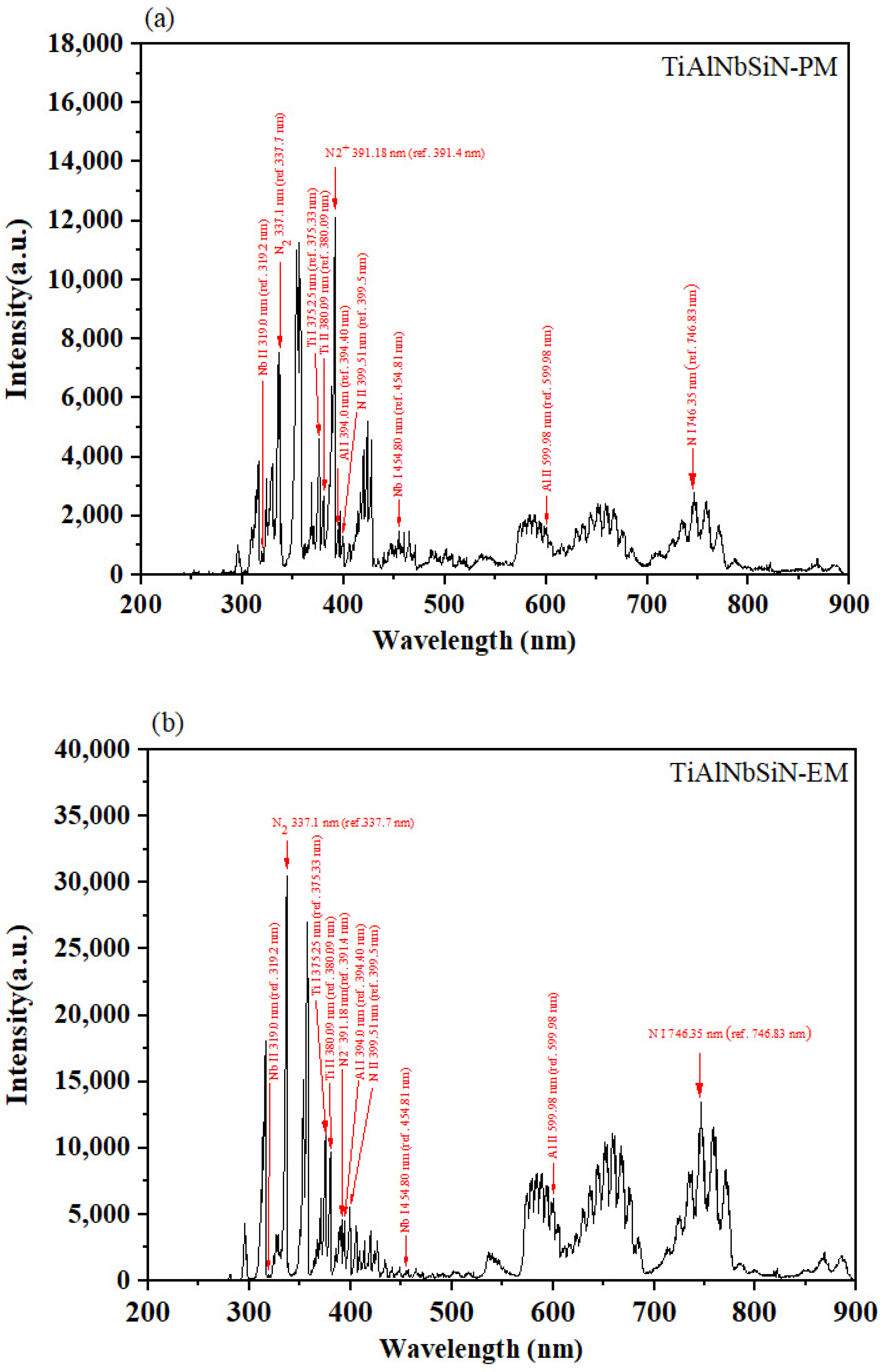

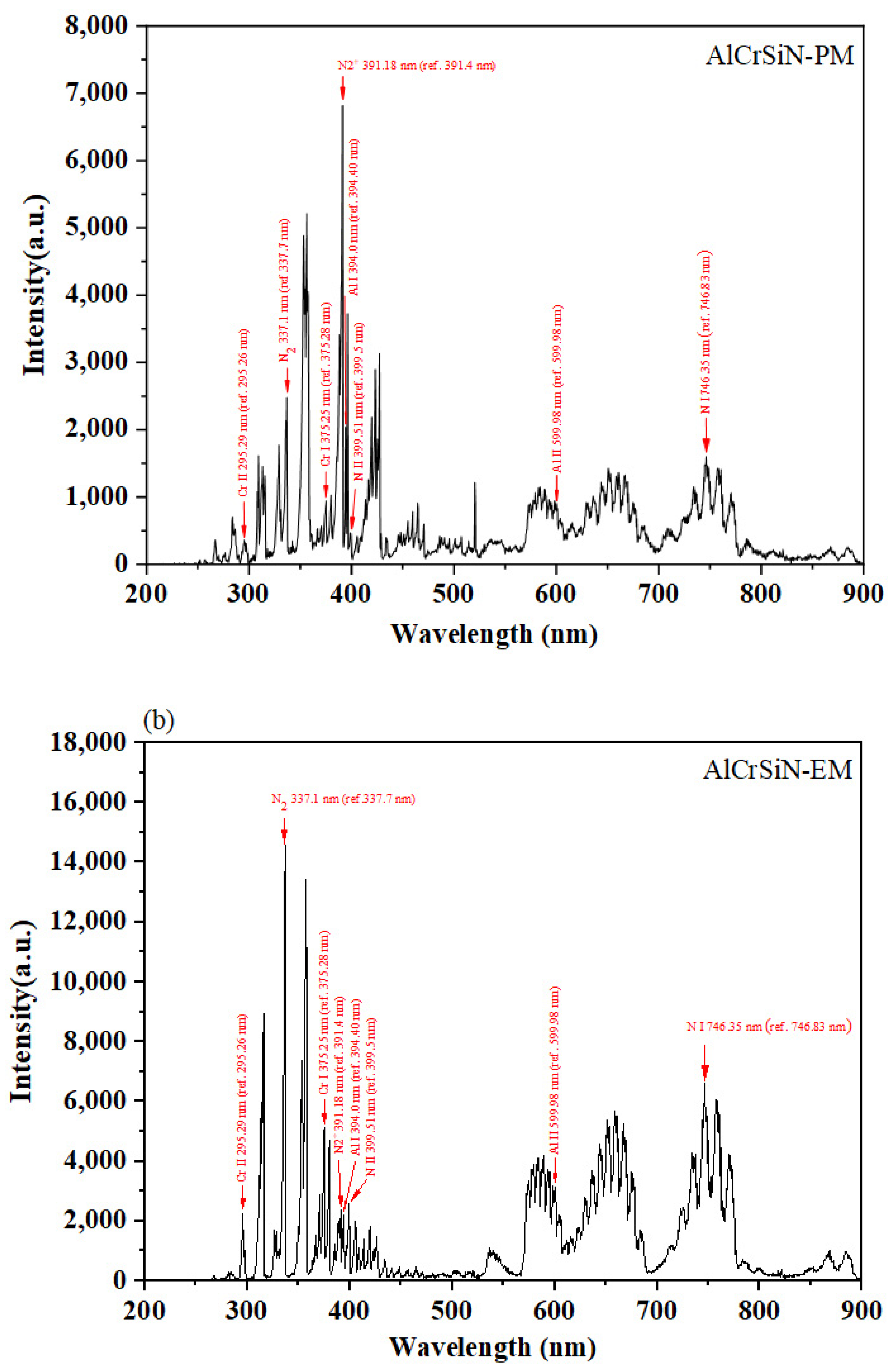

3.4. Optical Emission Spectroscopy (OES)

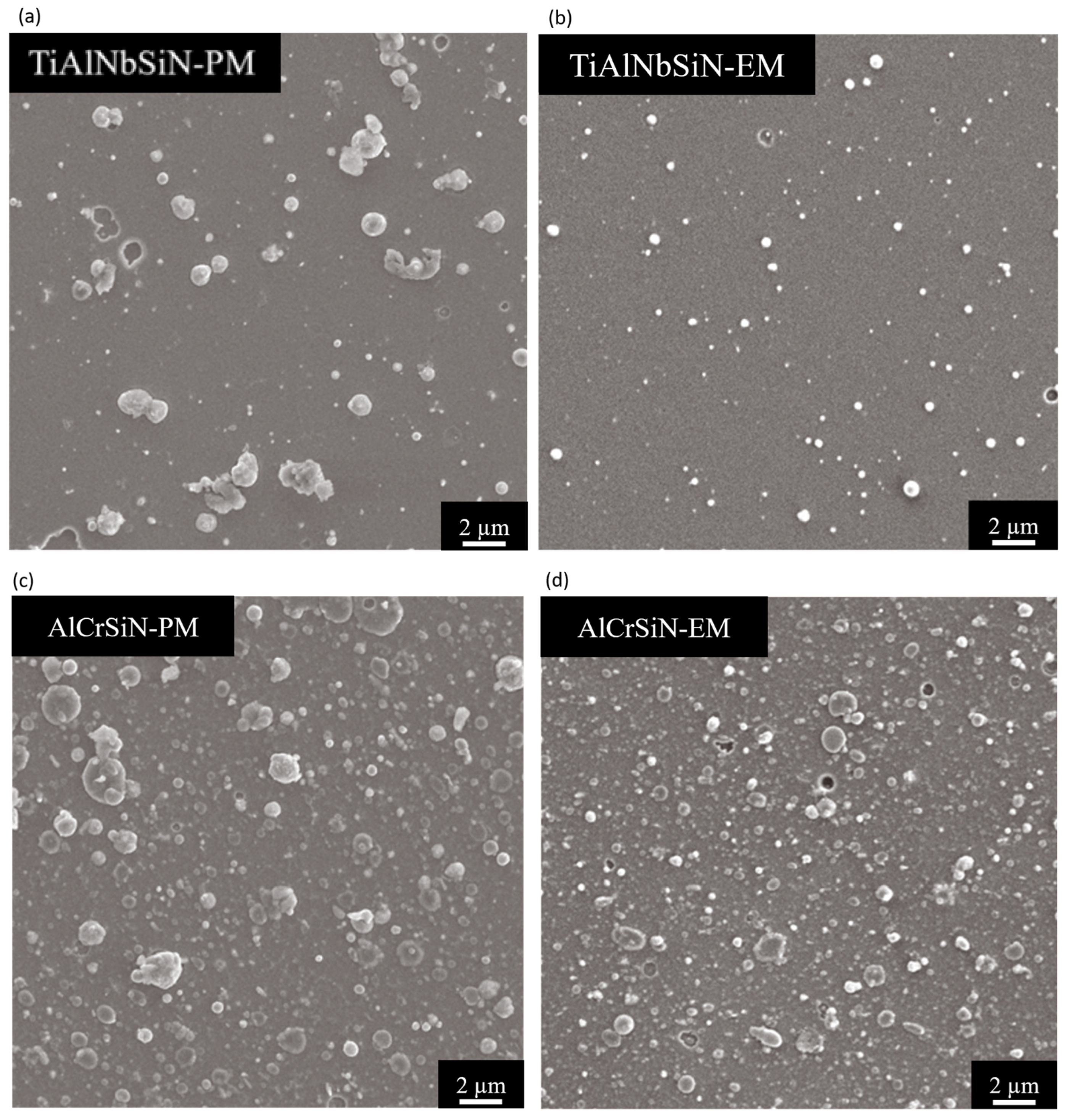

3.5. Surface Characteristics

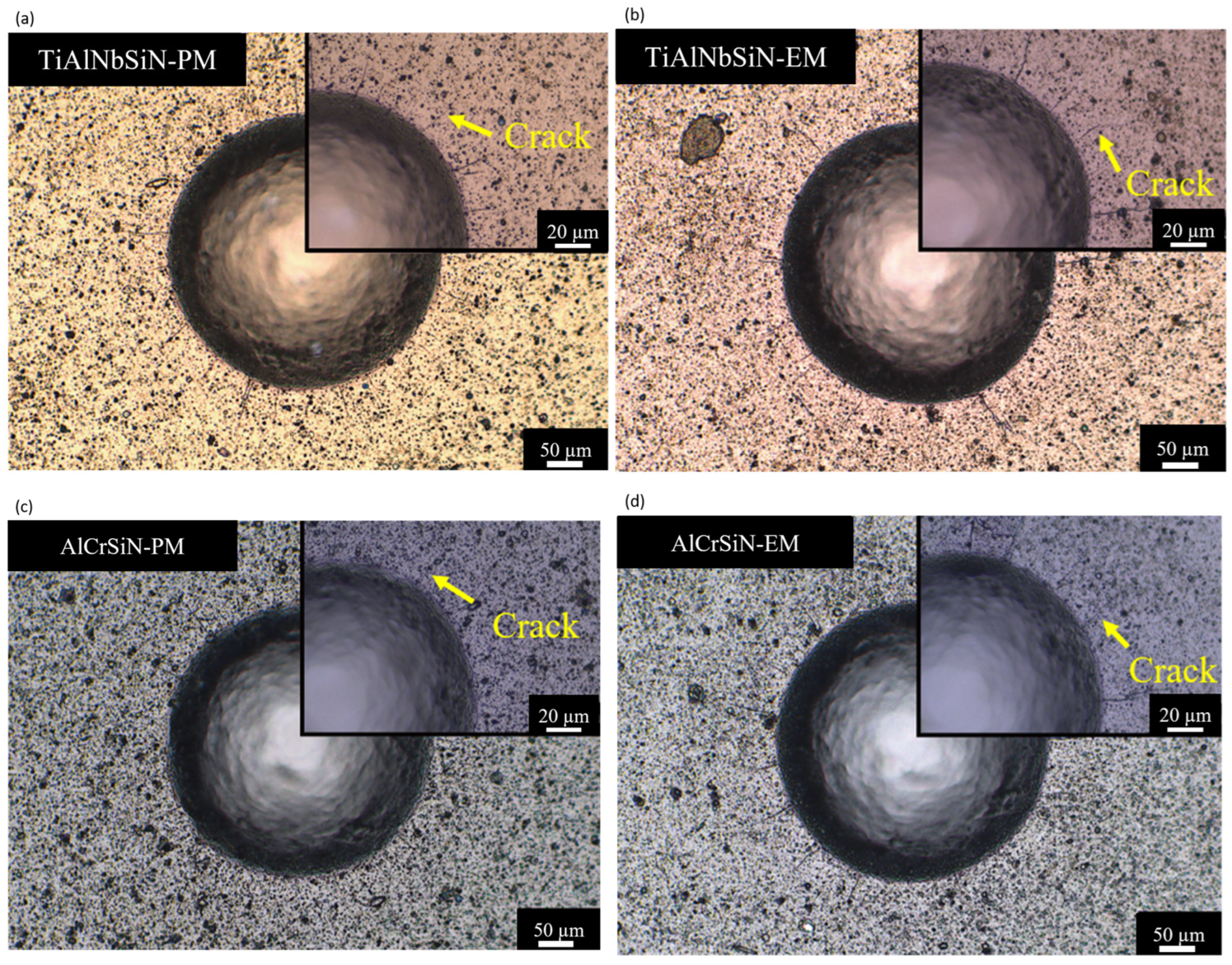

3.6. Adhesion Strength and Mechanical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Groover, M.P. Fundamentals of Modern Manufacturing: Materials, Processes, and Systems; John Wiley & Sons: Hoboken, NJ, USA, 2010. [Google Scholar]

- Chen, Y.; Wang, J.; Chen, M. Enhancing the machining performance by cutting tool surface modifications: A focused review. Mach. Sci. Technol. 2019, 23, 477–509. [Google Scholar] [CrossRef]

- Toboła, D. Influence of sequential surface treatment processes on tribological performance of Vanadis 6 cold work tool steel. Wear 2022, 488–489, 204106. [Google Scholar] [CrossRef]

- Ariharan, N.; Sriram, C.; Radhika, N.; Aswin, S.; Haridas, S. A comprehensive review of vapour deposited coatings for cutting tools: Properties and recent advances. Trans. IMF 2022, 100, 262–275. [Google Scholar] [CrossRef]

- Badaluddin, N.A.; Zamri, W.; Din, M.F.M.; Mohamed, I.F.; Ghani, J.A. Coatings of cutting tools and their contribution to improve mechanical properties: A brief review. Int. J. Appl. Eng. Res 2018, 13, 11653–11664. [Google Scholar]

- Sahoo, P.; Patra, K.; Pimenov, D.Y. Enhancement of micro milling performance by abrasion-resistant coated tools with optimized thin-film thickness: Analytical and experimental characterization. Int. J. Adv. Manuf. Technol. 2022, 120, 2993–3015. [Google Scholar] [CrossRef]

- Zafar, M.Q.; Uddin, G.M.; Asim, M.; Khan, A.A.; Tahir, Z.-U.-R.; Hayat, N.; Ghufran, M.; Jawad, M. Comparative analysis of low-temperature PVD-based TiN nano-thin-film-coated and -uncoated TNMG inserts in dry machining. J. Chin. Inst. Eng. 2020, 43, 143–152. [Google Scholar] [CrossRef]

- Marchin, N.; Ashrafizadeh, F. Effect of carbon addition on tribological performance of TiSiN coatings produced by cathodic arc physical vapour deposition. Surf. Coat. Technol. 2021, 407, 126781. [Google Scholar] [CrossRef]

- Li, C.; Wang, L.; Shang, L.; Cao, X.; Zhang, G.; Yu, Y.; Li, W.; Zhang, S.; Hu, H. Mechanical and high-temperature tribological properties of CrAlN/TiSiN multilayer coating deposited by PVD. Ceram. Int. 2021, 47, 29285–29294. [Google Scholar] [CrossRef]

- Durmaz, Y.M.; Yildiz, F. The wear performance of carbide tools coated with TiAlSiN, AlCrN and TiAlN ceramic films in intelligent machining process. Ceram. Int. 2019, 45, 3839–3848. [Google Scholar] [CrossRef]

- Tillmann, W.; Dildrop, M. Influence of Si content on mechanical and tribological properties of TiAlSiN PVD coatings at elevated temperatures. Surf. Coat. Technol. 2017, 321, 448–454. [Google Scholar] [CrossRef]

- Lin, N.; Huang, X.; Zhang, X.; Fan, A.; Qin, L.; Tang, B. In vitro assessments on bacterial adhesion and corrosion performance of TiN coating on Ti6Al4V titanium alloy synthesized by multi-arc ion plating. Appl. Surf. Sci. 2012, 258, 7047–7051. [Google Scholar] [CrossRef]

- Lee, D.B.; Lee, Y.C.; Kwon, S.C. High temperature oxidation of a CrN coating deposited on a steel substrate by ion plating. Surf. Coat. Technol. 2001, 141, 227–231. [Google Scholar] [CrossRef]

- Castanho, J.M.; Vieira, M.T. Effect of ductile layers in mechanical behaviour of TiAlN thin coatings. J. Mater. Process. Technol. 2003, 143–144, 352–357. [Google Scholar] [CrossRef]

- Drozd, K.; Walczak, M.; Szala, M.; Gancarczyk, K. Tribological Behavior of AlCrSiN-Coated Tool Steel K340 Versus Popular Tool Steel Grades. Materials 2020, 13, 4895. [Google Scholar] [CrossRef]

- Cai, F.; Gao, Y.; Zhang, S.; Zhang, L.; Wang, Q. Gradient architecture of Si containing layer and improved cutting performance of AlCrSiN coated tools. Wear 2019, 424–425, 193–202. [Google Scholar] [CrossRef]

- Wu, W.; Chen, W.; Yang, S.; Lin, Y.; Zhang, S.; Cho, T.-Y.; Lee, G.H.; Kwon, S.-C. Design of AlCrSiN multilayers and nanocomposite coating for HSS cutting tools. Appl. Surf. Sci. 2015, 351, 803–810. [Google Scholar] [CrossRef]

- Vennemann, A.; Stock, H.R.; Kohlscheen, J.; Rambadt, S.; Erkens, G. Oxidation resistance of titanium–aluminium–silicon nitride coatings. Surf. Coat. Technol. 2003, 174–175, 408–415. [Google Scholar] [CrossRef]

- Zhang, K.; Xin, L.; Ma, T.; Chang, H.; Lu, Y.; Feng, C.; Zhu, S.; Wang, F. Investigation of the role of silicon in TiAlSiN coating deposited on TiAl alloys during long-term oxidation. Corros. Sci. 2022, 204, 110394. [Google Scholar] [CrossRef]

- Sanchette, F.; Ducros, C.; Schmitt, T.; Steyer, P.; Billard, A. Nanostructured hard coatings deposited by cathodic arc deposition: From concepts to applications. Surf. Coat. Technol. 2011, 205, 5444–5453. [Google Scholar] [CrossRef]

- Boxman, R.L.; Goldsmith, S. Macroparticle Contamination in Cathodic Arc Coatings—Generation, Transport and Control. Surf Coat. Tech. 1992, 52, 39–50. [Google Scholar] [CrossRef]

- Falabella, S.; Karpov, D. Arc source designs. In Handbook of Vacuum Arc Science and Technology; Elsevier: Amsterdam, The Netherlands, 1995; pp. 396–423. [Google Scholar] [CrossRef]

- Chaar, A.B.B.; Syed, B.; Hsu, T.-W.; Johansson-Jöesaar, M.; Andersson, J.M.; Henrion, G.; Johnson, L.J.S.; Mücklich, F.; Odén, M. The Effect of Cathodic Arc Guiding Magnetic Field on the Growth of (Ti0.36Al0.64)N Coatings. Coatings 2019, 9, 660. [Google Scholar] [CrossRef]

- Feng, K.-J.; Guo, C.-Q.; Lin, S.-S.; Fu, Z.-Q.; Shi, Q.; Su, Y.-F.; Wang, W.; Dai, M.-J. Structure and properties of ta-C films prepared by vacuum cathodic arc with an unbalanced external electromagnetic field. Ceram. Int. 2022, 48, 111–119. [Google Scholar] [CrossRef]

- ISO 26443:2008; Fine Ceramics (Advanced Ceramics, Advanced Technical Ceramics)—Rockwell Indentation Test for Evaluation of Adhesion of Ceramic Coatings. ISO: Geneva, Switzerland, 2008.

- Saha, R.; Nix, W.D. Effects of the substrate on the determination of thin film mechanical properties by nanoindentation. Acta Mater. 2002, 50, 23–38. [Google Scholar] [CrossRef]

- Wu, H.; Li, Y.; Tang, X.; Hussain, G.; Zhao, H.; Li, Q.; Adedotun, A. Nano-mechanical characterization of plasma surface tungstenized layer by depth-sensing nano-indentation measurement. Appl. Surf. Sci. 2015, 324, 160–167. [Google Scholar] [CrossRef]

- Wang, Q.M.; Kim, K.H. Microstructural control of Cr–Si–N films by a hybrid arc ion plating and magnetron sputtering process. Acta Mater. 2009, 57, 4974–4987. [Google Scholar] [CrossRef]

- Anders, A. A structure zone diagram including plasma-based deposition and ion etching. Thin Solid Films 2010, 518, 4087–4090. [Google Scholar] [CrossRef]

- Tritremmel, C.; Daniel, R.; Lechthaler, M.; Polcik, P.; Mitterer, C. Influence of Al and Si content on structure and mechanical properties of arc evaporated Al–Cr–Si–N thin films. Thin Solid Films 2013, 534, 403–409. [Google Scholar] [CrossRef]

- Zhang, J.; Yin, L. Microstructure and mechanical properties of (Ti,Al,Nb)N hard films with N-gradient distributions. Thin Solid Films 2015, 584, 141–145. [Google Scholar] [CrossRef]

- PalDey, S.; Deevi, S.C. Single layer and multilayer wear resistant coatings of (Ti,Al)N: A review. Mater. Sci. Eng. A—Struct. Mater. Prop. Microstruct. Process. 2003, 342, 58–79. [Google Scholar] [CrossRef]

- Veprek, S.; Veprek-Heijman, M.J.G. Industrial applications of superhard nanocomposite coatings. Surf. Coat. Technol. 2008, 202, 5063–5073. [Google Scholar] [CrossRef]

- Swift, P.D. Macroparticles in films deposited by steered cathodic arc. J. Phys. D Appl. Phys. 1996, 29, 2025. [Google Scholar] [CrossRef]

- Lang, W.C.; Xiao, J.Q.; Gong, J.; Sun, C.; Huang, R.F.; Wen, L.S. Study on cathode spot motion and macroparticles reduction in axisymmetric magnetic field-enhanced vacuum arc deposition. Vacuum 2010, 84, 1111–1117. [Google Scholar] [CrossRef]

- Siriprom, W.; Chananonnawathorn, C.; Kongsriprapan, S.; Teanchai, K.; Herman; Horprathum, M. Preparation and characterization of CrN thin film by DC reactive magnetron sputtering. Mater. Today Proc. 2018, 5, 15224–15227. [Google Scholar] [CrossRef]

- Qayyum, A.; Zeb, S.; Naveed, M.A.; Rehman, N.U.; Ghauri, S.A.; Zakaullah, M. Optical emission spectroscopy of Ar–N2 mixture plasma. J. Quant. Spectrosc. Radiat. Transf. 2007, 107, 361–371. [Google Scholar] [CrossRef]

- Wiatrowski, A.; Patela, S.; Kunicki, P.; Posadowski, W. Effective reactive pulsed magnetron sputtering of aluminium oxide—Properties of films deposited utilizing automated process stabilizer. Vacuum 2016, 134, 54–62. [Google Scholar] [CrossRef]

- Mayrhofer, P.H.; Mitterer, C.; Hultman, L.; Clemens, H. Microstructural design of hard coatings. Prog. Mater. Sci. 2006, 51, 1032–1114. [Google Scholar] [CrossRef]

- Warcholinski, B.; Gilewicz, A.; Myslinski, P.; Dobruchowska, E.; Murzynski, D.; Kuznetsova, T.A. Effect of Silicon Concentration on the Properties of Al-Cr-Si-N Coatings Deposited Using Cathodic Arc Evaporation. Materials 2020, 13, 4717. [Google Scholar] [CrossRef]

- Soldán, J.; Neidhardt, J.; Sartory, B.; Kaindl, R.; Čerstvý, R.; Mayrhofer, P.H.; Tessadri, R.; Polcik, P.; Lechthaler, M.; Mitterer, C. Structure–property relations of arc-evaporated Al–Cr–Si–N coatings. Surf. Coat. Technol. 2008, 202, 3555–3562. [Google Scholar] [CrossRef]

- Ding, X.-z.; Zeng, X.T.; Liu, Y.C. Structure and properties of CrAlSiN Nanocomposite coatings deposited by lateral rotating cathod arc. Thin Solid Films 2011, 519, 1894–1900. [Google Scholar] [CrossRef]

| Parameter | |

|---|---|

| Arc Source | Permanent magnet arc source Electromagnet arc source |

| Target (at.%) | Ti44Al40Nb12Si4 Al60Cr30Si10 |

| Reactive Gas | N2 |

| Work Pressure | 3.33 Pa |

| Target Current (A) | 80 |

| Bias Voltage (V) | −80 |

| Temperature (°C) | 300~400 |

| Rotation Speed (rpm) | 2 |

| Coatings | Chemical Composition (at.%) | |||||

|---|---|---|---|---|---|---|

| N | Al | Ti | Nb | Si | Cr | |

| TiAlNbSiN-PM | 49.8 ± 0.7 | 16.8 ± 0.5 | 24.8 ± 0.3 | 7.8 ± 0.3 | 0.8 ± 0.1 | - |

| TiAlNbSiN-EM | 50.1 ± 0.5 | 17.1 ± 0.3 | 24.0 ± 0.2 | 7.9 ± 0.2 | 0.9 ± 0.1 | - |

| AlCrSiN-PM | 49.6 ± 0.2 | 28.3 ± 0.4 | - | - | 3.8 ± 0.4 | 18.3 ± 0.1 |

| AlCrSiN-EM | 50.6 ± 0.3 | 28.8 ± 0.5 | - | - | 3.4 ± 0.3 | 17.2 ± 0.1 |

| Coatings | TiAlNbSiN-PM | TiAlNbSiN-EM |

|---|---|---|

| Sa (nm) | 34.63 ± 2.17 | 13.92 ± 2.09 |

| Coatings | AlCrSiN-PM | AlCrSiN-EM |

| Sa (nm) | 72.81 ± 5.5 | 46.33 ± 5.32 |

| Coatings | Hardness (GPa) | Young’s Modulus (GPa) | H/E | H3/E2 |

|---|---|---|---|---|

| TiAlNbSiN | ||||

| PM | 28.3 ± 1.4 | 372.4 ± 10.4 | 0.071 | 0.144 |

| EM | 31.2 ± 1.9 | 371.0 ± 9.9 | 0.079 | 0.194 |

| AlCrSiN | ||||

| PM | 25.5 ± 0.6 | 274.2 ± 4.4 | 0.087 | 0.195 |

| EM | 32.6 ± 0.5 | 343.6 ± 8.6 | 0.089 | 0.257 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, V.-T.; Chang, Y.-Y.; Chen, Y.-R. Enhancement of a Magnetically Controlled Cathodic Arc Source for the Deposition of Multi-Component Hard Nitride Coatings. Materials 2025, 18, 2276. https://doi.org/10.3390/ma18102276

Tang V-T, Chang Y-Y, Chen Y-R. Enhancement of a Magnetically Controlled Cathodic Arc Source for the Deposition of Multi-Component Hard Nitride Coatings. Materials. 2025; 18(10):2276. https://doi.org/10.3390/ma18102276

Chicago/Turabian StyleTang, Van-Tien, Yin-Yu Chang, and Yi-Ru Chen. 2025. "Enhancement of a Magnetically Controlled Cathodic Arc Source for the Deposition of Multi-Component Hard Nitride Coatings" Materials 18, no. 10: 2276. https://doi.org/10.3390/ma18102276

APA StyleTang, V.-T., Chang, Y.-Y., & Chen, Y.-R. (2025). Enhancement of a Magnetically Controlled Cathodic Arc Source for the Deposition of Multi-Component Hard Nitride Coatings. Materials, 18(10), 2276. https://doi.org/10.3390/ma18102276