Investigation of Rutting and Aging Performance of Gap-Graded Rubberized Asphalt Mixtures

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

| Property: | Type of Bitumen | |||

|---|---|---|---|---|

| 45/80-55 PmB | 45/80-55 CR | 45/80-65 PmB | 45/80-65 CR | |

| Penetration in 25 °C, 0.1 mm, acc. EN 1426 [23] | 43 | 53 | 52 | 45 |

| R&B Temperature, °C, acc. EN 1427 [24] | 60 | 55 | 72 | 76 |

| Dynamic viscosity, Pa·s, acc. EN 12596 [25] | ||||

| 90 °C | 35.321 | 19.058 | 43.728 | 81.833 |

| 135 °C | 1.225 | 0.859 | 1.813 | 1.947 |

| 160 °C | 0.373 | 0.303 | 0.596 | 0.563 |

2.2. Methods

2.2.1. Resistance to Rutting Test Methods

2.2.2. Dynamic Modulus Test Method in AMPT/SPT

2.2.3. Resistance to Aging Test Methods

- Short-term aging—Performed on a loose mixture, this simulates the aging of the mineral–asphalt mix during production and transport;

- Long-term aging—Performed on a compacted mixture, this simulates the operational aging of the mineral–asphalt mix in the layer after compaction.

- Unaged specimens (reference), i.e., specimens not subjected to short-term and long-term aging—After the asphalt mixture was mixed and the mixture reached a temperature of 145 ± 5 °C, the specimens were compacted;

- Specimens after short-term aging—The asphalt mixture was mixed in a mechanical mixer at a temperature of about 145 ± 5 °C, and then the loose mixture was subjected to a short-term aging process. The mixture was spread in sheet metal forms so that the layer thickness was from 2.5 to 5.0 cm. The molds with the mixture were stored in an oven with forced air flow at a temperature of 135 ± 3 °C for 4 h ± 5 min. The mixture was cyclically mixed every hour. Then, the mixture was heated to a temperature of 145 ± 5 °C and the specimens were compacted;

- Specimens after long-term aging—Long-term aging involved storing the formed and compacted specimens after short-term aging in an oven with air flow for 5 days (120 ± 0.5 h) at a temperature of 85 ± 3 °C. The specimens were wrapped in a fine copper mesh to protect against possible deformations. An image of the samples prepared for long-term aging is shown in Figure 3.

- Change in the stiffness modulus;

- Change in the indirect tensile strength.

- For the first time, they were tested by performing a non-destructive test of the stiffness modulus following an indirect tensile scheme (IT-CY);

- for the second time, they were tested by performing a destructive test of the indirect tensile strength.

3. Results and Discussion

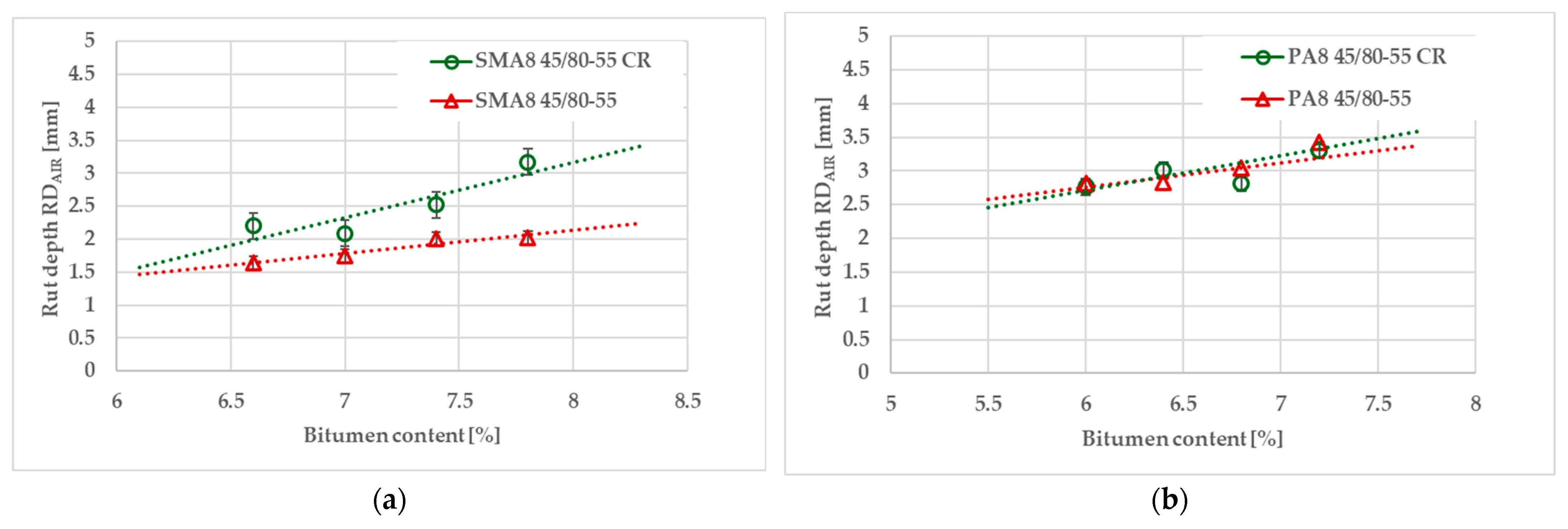

3.1. Test Results for Resistance to Permanent Deformation

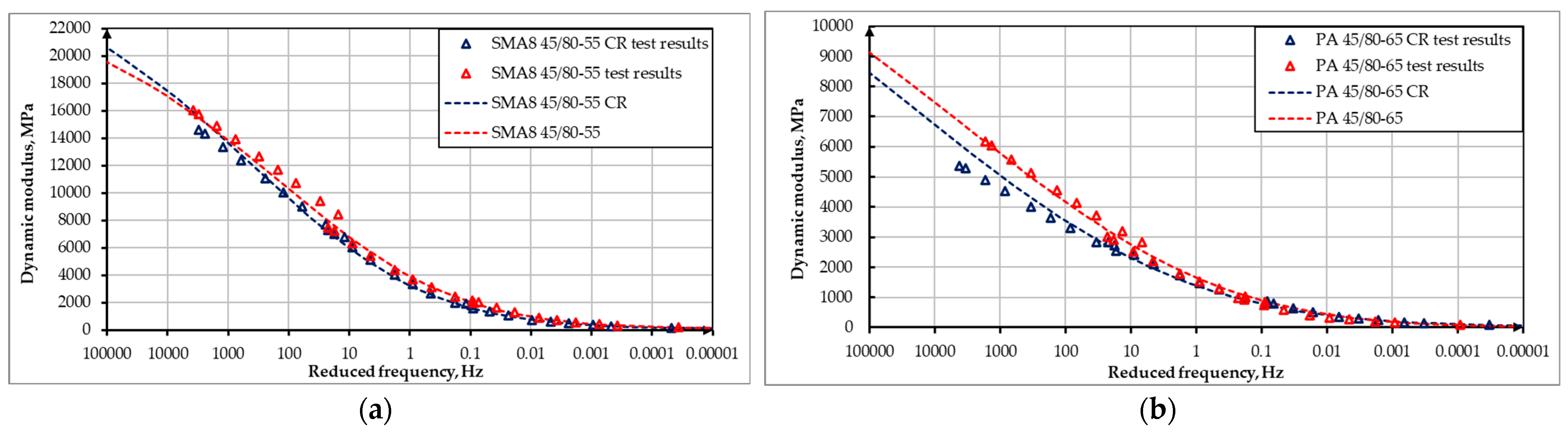

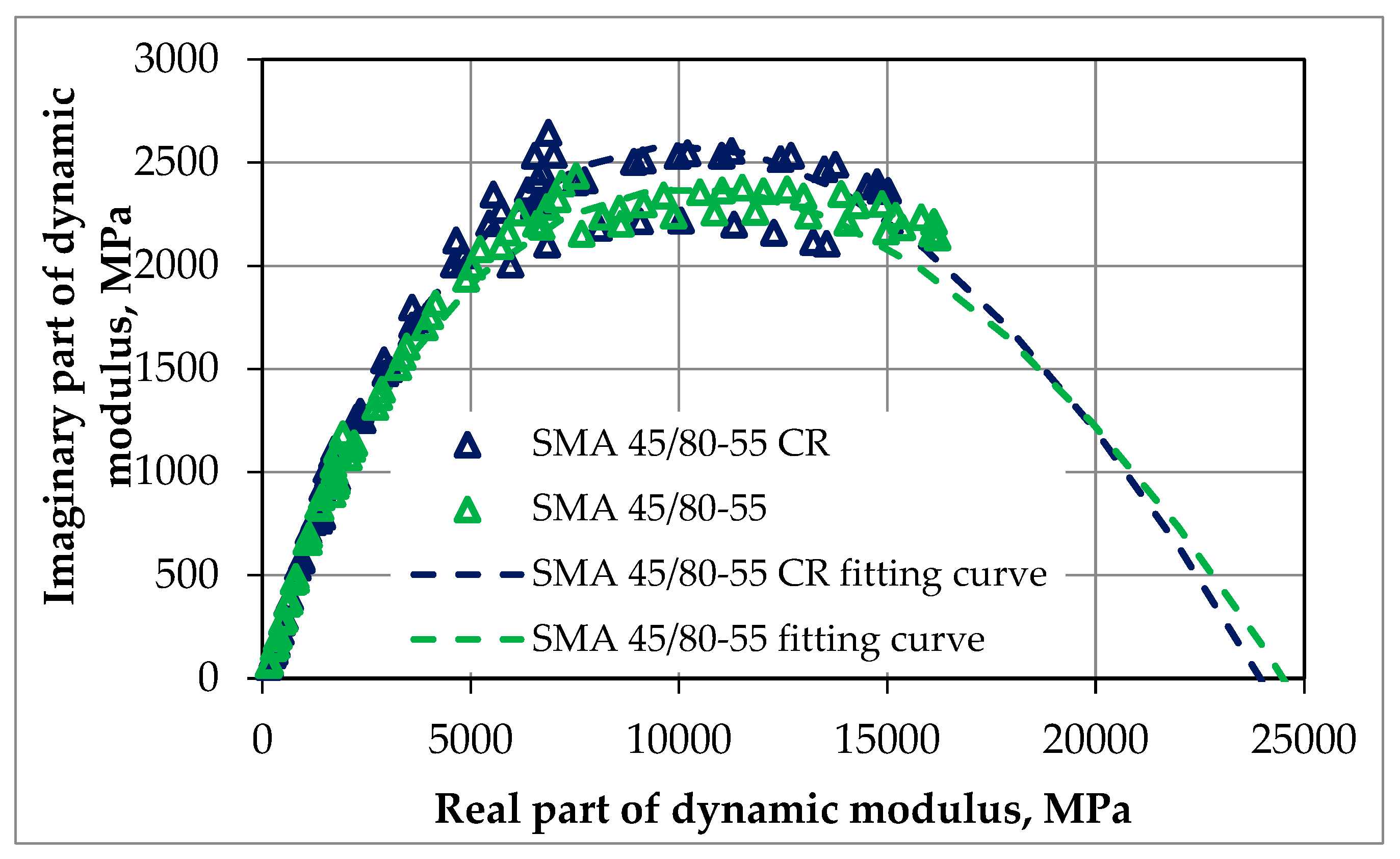

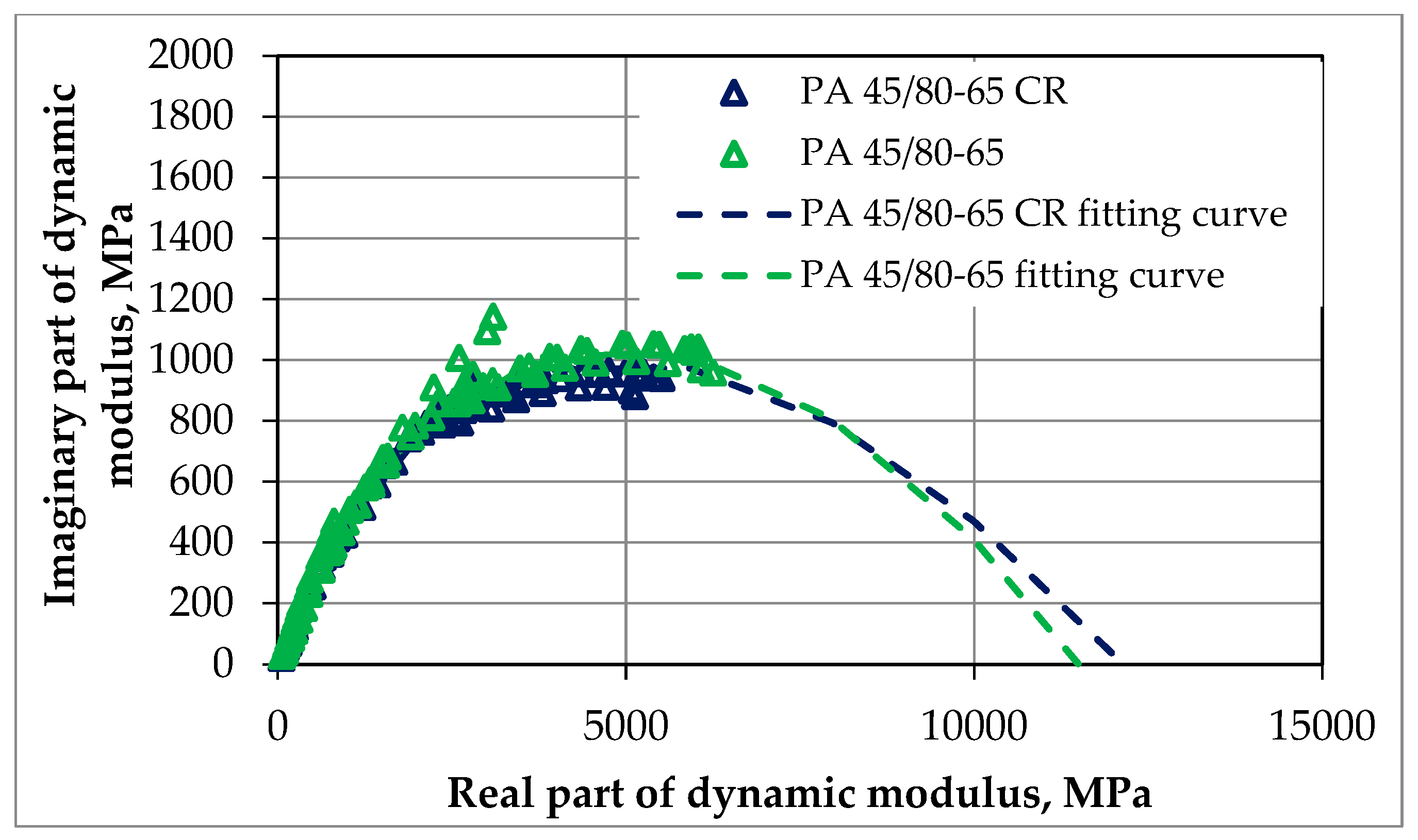

3.2. Test Results for Dynamic Modulus in AMPT/SPT Equipment

3.3. Test Results and Analysis of the Resistance to Aging

- Index of stiffness modulus (ISM);

- Indirect tensile strength index (ITSI).

- In the case of the SMA mixture, the comparison of stiffness modulus indices shows that the use of rubber to modify bitumen did not affect either short-term or long-term aging;

- In the case of the porous asphalt (PA) mixture, the use of rubber to modify the bitumen significantly reduces the value of the index of stiffness modulus (ISM). The high values of the stiffness modulus obtained for the porous asphalt mixture in comparison with the SMA mixture are noteworthy. This may indicate that the PA mixture has greater susceptibility to aging, especially long-term aging;

- In the case of the SMA mixture, the comparison of indirect tensile strength indices shows that the use of rubber to modify bitumen has a beneficial effect on both short-term and long-term aging;

- In the case of the porous asphalt (PA) mixture, the addition of rubber to modified bitumen did not significantly affect the value of the indirect tensile strength index (ITSI). The values obtained regarding the indirect tensile strength indices for the porous asphalt (PA) mixture are not as high as those for the stiffness modulus indices;

- The tests validated our expectation that, with aging, the stiffness of the materials will increase, regardless of the bitumen used, especially in mixtures with higher void content values (PA 8). On the other hand, changes in the indirect tensile strength showed that, during aging, the material does not become more brittle and therefore more susceptible to cracking, regardless of the type of the mixture tested and the type of bitumen used.

4. Conclusions

- Based on the rutting test, it can be concluded that polymer-modified bitumen supplemented with rubber allows for the design of asphalt mixtures that are resistant to permanent deformations and do not differ substantially from the same mixtures containing bitumen without the addition of rubber.

- Dynamic moduli and phase angles show a less elastic character of mixtures made using rubber–polymer-modified bitumens (lower dynamic moduli and higher phase angles at temperatures from 4 °C to 40 °C), but the differences were not significant.

- The aging tests showed that, with aging, the stiffness of the materials increases irrespective of the type of bitumen used, especially in the more open asphalt mixture (PA 8). The increase in stiffness after aging can be more significant depending on the gap-graded asphalt mixtures’ resistance to low-temperature cracking.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| GGAM | Gap-graded asphalt mixture |

| SMA | Stone mastic asphalt |

| PA | Porous asphalt |

| BBTM | Béton Bitumineuse Très Mince |

| SBS | Styrene-butadiene-styrene |

| PMB | Polymer-modified bitumen |

| RMB | Rubber-modified bitumen |

| AMPT/SPT | Asphalt Mixture Performance Tester/Simple Performance Tester |

| ITS | Indirect tensile strength |

| CR | Crumb rubber |

| ISM | Index of stiffness modulus |

| ITSI | Indirect tensile strength index |

References

- Huang, B.; Shu, X.; Chen, X. Advanced asphalt materials for sustainable pavement construction. J. Mater. Civ. Eng. 2020, 32, 04020276. [Google Scholar] [CrossRef]

- Wang, H.; Li, Z.; You, Z. Performance comparison of porous asphalt mixtures using SBS and rubber-modified bitumen. Road Mater. Pavement Des. 2018, 19, 111–126. [Google Scholar]

- Watson, D.; Qureshi, N.A.; Xie, Z.; Tran, N. Investigations of Open-Graded Friction Course in Alabama; National Center for Asphalt Technology (NCAT): Auburn, AL, USA; Alabama Department of Transportation (ALDOT): Montgomery, AL, USA, 2020; NCAT Report 20-07, ALDOT 930-790. [Google Scholar]

- Yue, Y.; Abdelsalam, M.; Eisa, M.S. Aggregate Gradation Variation on the Properties of Asphalt Mixtures. Coatings 2022, 12, 1608. [Google Scholar] [CrossRef]

- Xu, G.X.; Kunru, L.; Chunxi, L.; Wang, H.; Leng, Z.; Chen, X. Noise reduction performance and maintenance time of porous asphalt pavement. Constr. Build. Mater. 2024, 452, 138913. [Google Scholar] [CrossRef]

- Lu, X.; Isacsson, U. Modification of road bitumens with thermoplastic polymers. Polym. Test. 1998, 17, 409–416. [Google Scholar] [CrossRef]

- Airey, G.D. Rheological properties of styrene-butadiene-styrene polymer-modified road bitumens. Fuel 2003, 82, 1709–1719. [Google Scholar] [CrossRef]

- González, A.; Poulikakos, L.; Porot, L.; Stempihar, J. Cost-benefit analysis of polymer-modified asphalt in road construction. Transp. Res. Rec. 2021, 2675, 117–129. [Google Scholar]

- Fang, J.; Yu, R.; Liu, X.; Wu, S. Recycling waste tires in asphalt mixtures: A review. Resour. Conserv. Recycl. 2019, 146, 152–165. [Google Scholar] [CrossRef]

- Shen, D.H.; Amirkhanian, S.N.; Tang, B. Influence of surface area and size of crumb rubber on high-temperature properties of rubberized binders. Constr. Build. Mater. 2009, 23, 304–310. [Google Scholar] [CrossRef]

- Ding, H.; Zhao, H.; Huang, B. Performance evaluation of rubber-modified asphalt binders and mixtures: A comprehensive review. Constr. Build. Mater. 2020, 257, 119507. [Google Scholar] [CrossRef]

- Navarro, F.J.; Partal, P.; Martínez-Boza, F.; Gallegos, C. Rheological characteristics of ground tire rubber-modified bitumens. Chem. Eng. J. 2004, 112, 89–97. [Google Scholar] [CrossRef]

- Li, J.; Wang, L.; Liu, P. Industrial production of rubber-modified bitumen and its performance in asphalt mixtures. J. Clean. Prod. 2022, 334, 130230. [Google Scholar] [CrossRef]

- Zhou, X.; Zhang, Z.; Wu, P. Industrial-scale production of rubber-modified asphalt and its application in pavement engineering. Int. J. Pavement Res. Technol. 2017, 10, 278–287. [Google Scholar] [CrossRef]

- Krol, J.; Czajkowski, P.; Radziszewski, P.; Kowalski, K.J.; Sarnowski, M. Viscoelastic properties of polymer and crumb rubber modified bitumen, laboratory and field investigation. In Proceedings of the International Scientific Conference, Road Research and Administration, Car 2013, Bucharest, Romania, 4–5 July 2013. [Google Scholar]

- Swieczko-Zurek, B.; Jaskula, P.; Ejsmont, A.J.; Kedzierska, A.; Czajkowski, P. Rolling resistance and tyre/road noise on rubberized asphalt pavement in Poland. Road Mater. Pavement Des. 2017, 18, 151–167. [Google Scholar] [CrossRef]

- EN 14023; Bitumen and Bituminous Binders—Specification Framework for Polymer Modified Bitumens. European Committee for Standardization (CEN): Brussels, Belgium, 2010.

- Pszczola, M.; Jaczewski, M.; Szydlowski, C.; Judycki, J.; Dolzycki, B. Evaluation of low temperature properties of rubberized asphalt mixtures. Procedia Eng. 2017, 172, 897–904. [Google Scholar] [CrossRef]

- WT-2, 2010; Technical Guidelines, Asphalt Pavements on State Roads, Asphalt Mixes. General Directorate for National Roads and Motorways: Warsaw, Poland, 2010. (In Polish)

- EN 13108-5; Bituminous Mixtures—Material Specifications—Part 5: Stone Mastic Asphalt. European Committee for Standardization (CEN): Brussels, Belgium, 2016.

- EN 13108-7; Bituminous Mixtures—Material Specifications—Part 7: Porous Asphalt. European Committee for Standardization (CEN): Brussels, Belgium, 2016.

- AASHTO R 30-02; Standard Practice for Mixture Conditioning of Hot-Mix Asphalt (HMA), Standard Specifications for Transportation Materials and Methods of Sampling and Testing, Part 1B: Specifications, 26th Edition. American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2006.

- EN 1426; Bitumen and Bituminous Binders—Determination of Needle Penetration. European Committee for Standardization (CEN): Brussels, Belgium, 2015.

- EN 1427; Bitumen and Bituminous Binders—Determination of the Softening Point—Ring and Ball Method. European Committee for Standardization (CEN): Brussels, Belgium, 2016.

- EN 12596; Bitumen and Bituminous Binders—Determination of Dynamic Viscosity by Vacuum Capillary. European Committee for Standardization (CEN): Brussels, Belgium, 2023.

- EN 12697-22; Bituminous Mixtures—Test Methods—Part 22: Wheel Tracking. European Committee for Standardization (CEN): Brussels, Belgium, 2023.

- NCHRP 9-29; NCHRP Report 513: Simple Performance Tester for Superpave Mix Design, First-Article Development and Evaluation. Transportation Research Board, Project 9-29; National Cooperative Highway Research Program: Washington, DC, USA, 2001.

- AASHTO TP 62; Standard Method of Test for Determining Dynamic Modulus of Hot Mix Asphalt (HMA), Standard Specifications for Transportation Materials and Methods of Sampling and Testing. American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2007.

- EN 12697-26; Bituminous Mixtures—Test Methods—Part 26: Stiffness. European Committee for Standardization (CEN): Brussels, Belgium, 2023.

| Type of Asphalt Mixture | ||||

|---|---|---|---|---|

| Property | SMA8 | SMA8 CR | PA8 | PA8 CR |

| Passes, mm | ||||

| 11.2 | 100.0 | 100.0 | ||

| 8 | 94.2 | 91.2 | ||

| 5.6 | 41.2 | 13.4 | ||

| 2 | 25.6 | 6.7 | ||

| 0.125 | 11.9 | 4.8 | ||

| 0.625 | 9.7 | 4.1 | ||

| Type of aggregate | gneiss, granodiorite, and limestone | gneiss, granodiorite, and limestone | ||

| Bitumen content, % w/w | 7.0 | 6.5 | ||

| Type of bitumen | 45/80-55 PmB | 45/80-55 CR | 45/80-65 PmB | 45/80-65 CR |

| Parameter Tested: | Open-Graded Asphalt Mixture | |||

|---|---|---|---|---|

| SMA8 45/80-55 | SMA8 45/80-55 CR | PA8 45/80-65 | PA8 45/80-65 CR | |

| Stiffness Modulus at 25 °C, MPa | ||||

| Reference specimens | 2270 | 1607 | 641 | 1103 |

| After short-term aging, MPa | 2937 | 2075 | 1023 | 1573 |

| After long-term aging, MPa | 3150 | 2465 | 1335 | 2088 |

| Index of stiffness modulus, ISM | ||||

| ISM—after short-term aging, % | 129 | 129 | 159 | 143 |

| ISM—after long-term aging, % | 138 | 153 | 208 | 189 |

| Indirect tensile strength at 25 °C, MPa | ||||

| Reference specimens | 1.08 | 1.01 | 0.43 | 0.53 |

| After short-term aging, MPa | 1.33 | 1.04 | 0.57 | 0.69 |

| After long-term aging, MPa | 1.24 | 1.09 | 0.57 | 0.74 |

| Indirect tensile strength index, ITSI | ||||

| ITSI—after short term aging, % | 123 | 103 | 132 | 130 |

| ITSI—after long-term aging, % | 115 | 108 | 132 | 139 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pszczola, M.; Dolzycki, B. Investigation of Rutting and Aging Performance of Gap-Graded Rubberized Asphalt Mixtures. Materials 2025, 18, 2263. https://doi.org/10.3390/ma18102263

Pszczola M, Dolzycki B. Investigation of Rutting and Aging Performance of Gap-Graded Rubberized Asphalt Mixtures. Materials. 2025; 18(10):2263. https://doi.org/10.3390/ma18102263

Chicago/Turabian StylePszczola, Marek, and Bohdan Dolzycki. 2025. "Investigation of Rutting and Aging Performance of Gap-Graded Rubberized Asphalt Mixtures" Materials 18, no. 10: 2263. https://doi.org/10.3390/ma18102263

APA StylePszczola, M., & Dolzycki, B. (2025). Investigation of Rutting and Aging Performance of Gap-Graded Rubberized Asphalt Mixtures. Materials, 18(10), 2263. https://doi.org/10.3390/ma18102263