Impacts of Morphology on the Fracture Resistance of the High-Strength Dual-Phase Steels

Abstract

1. Introduction

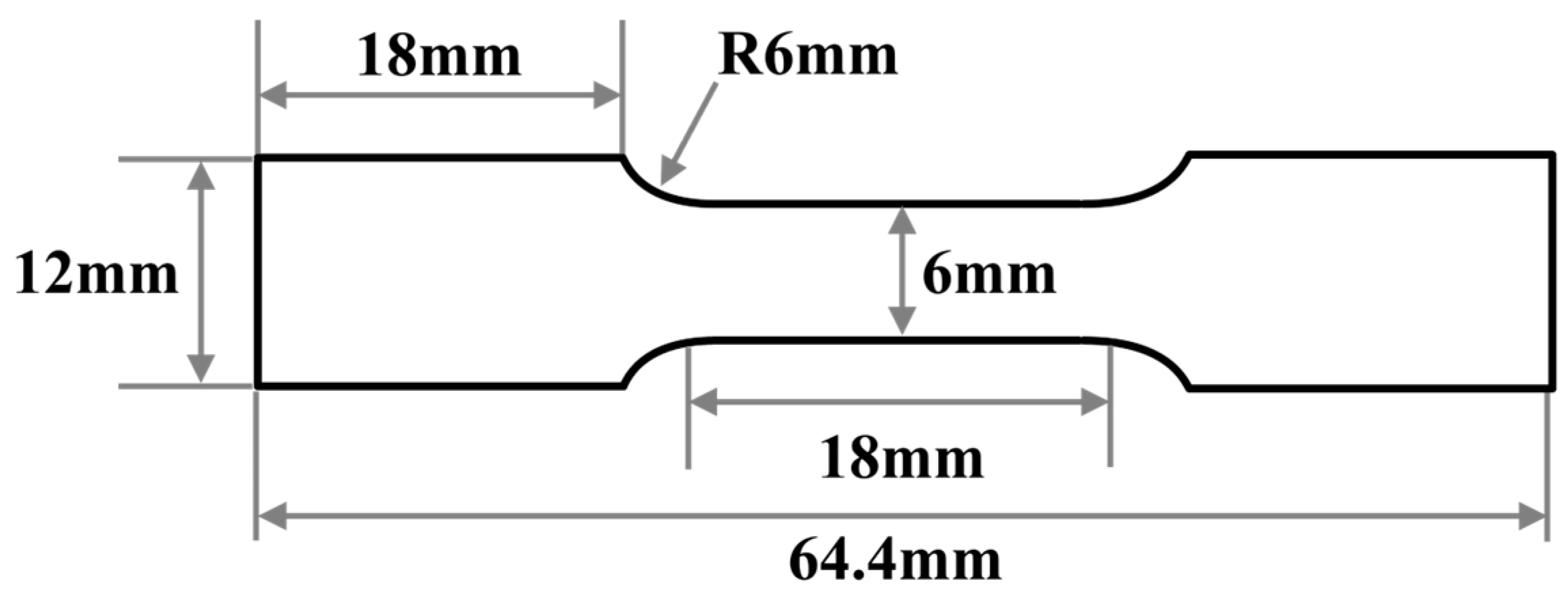

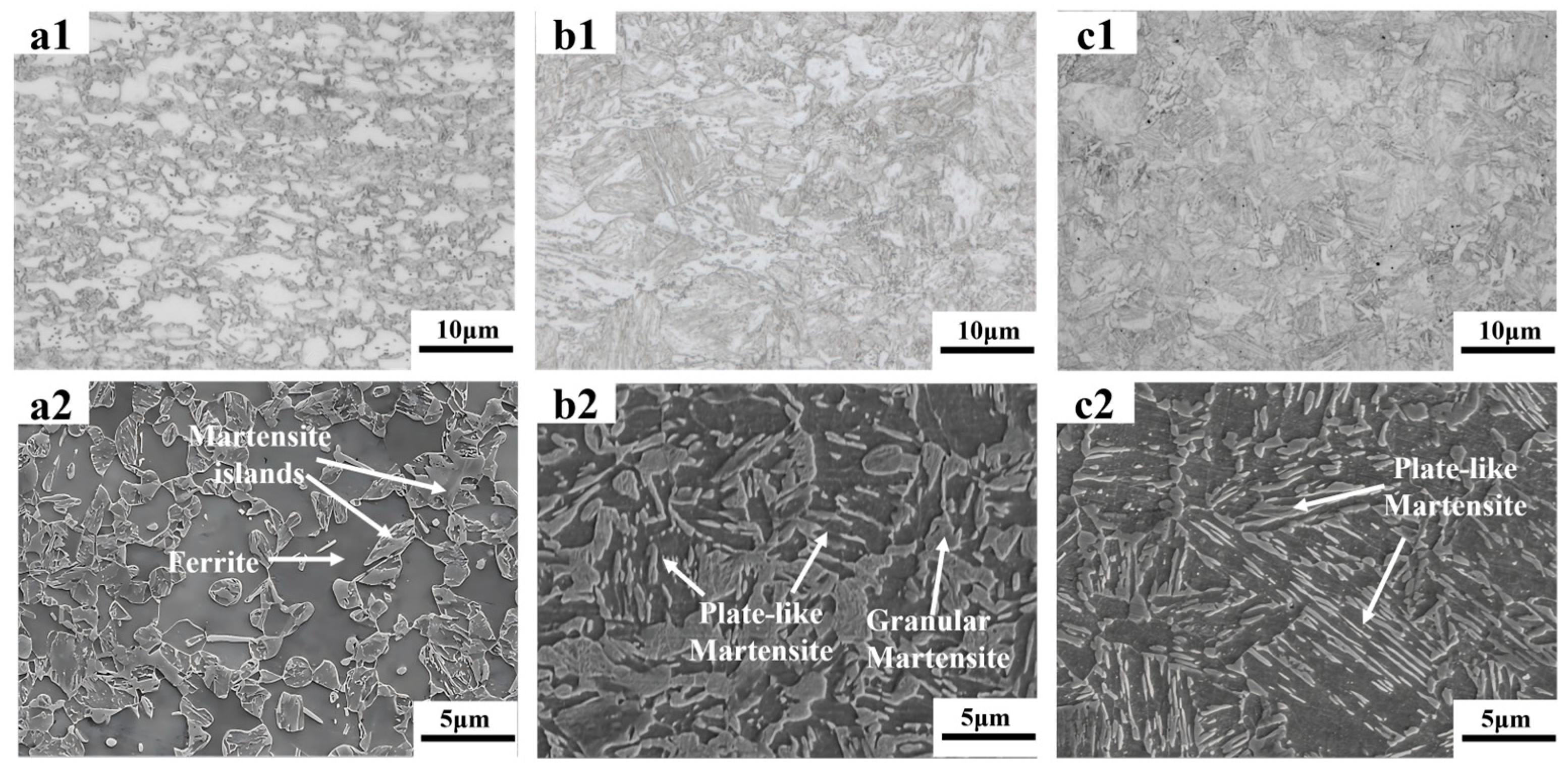

2. Materials and Methods

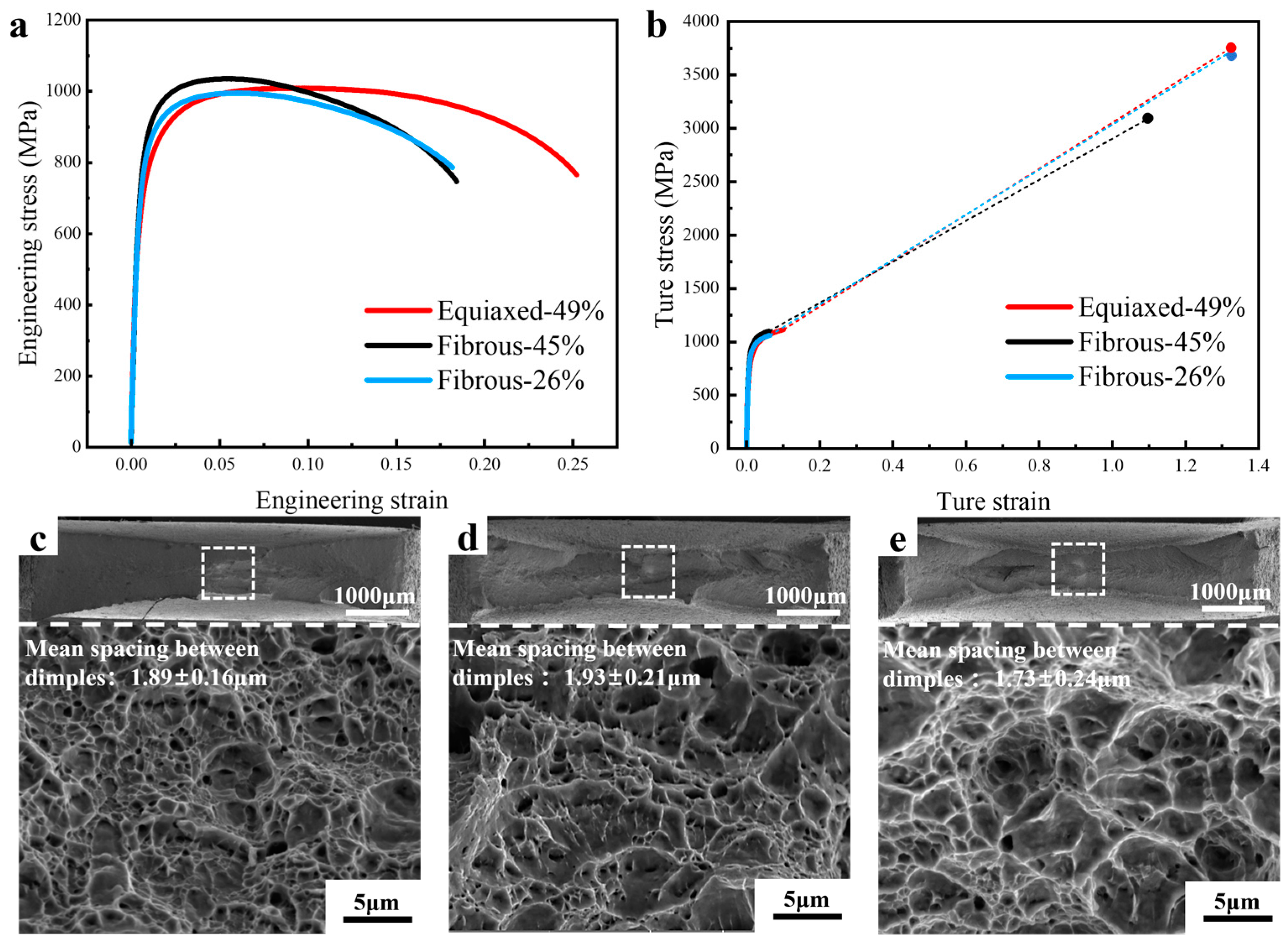

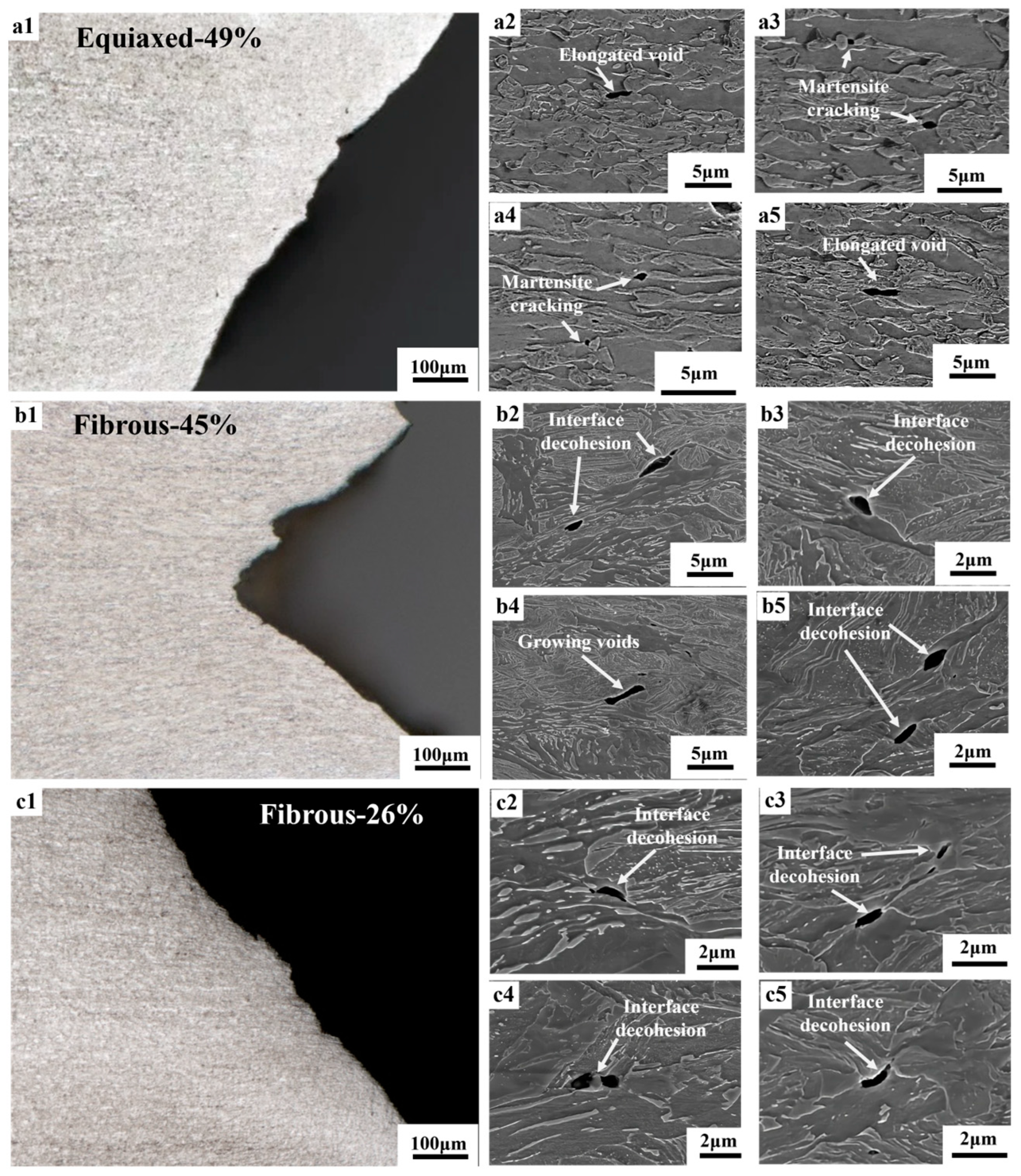

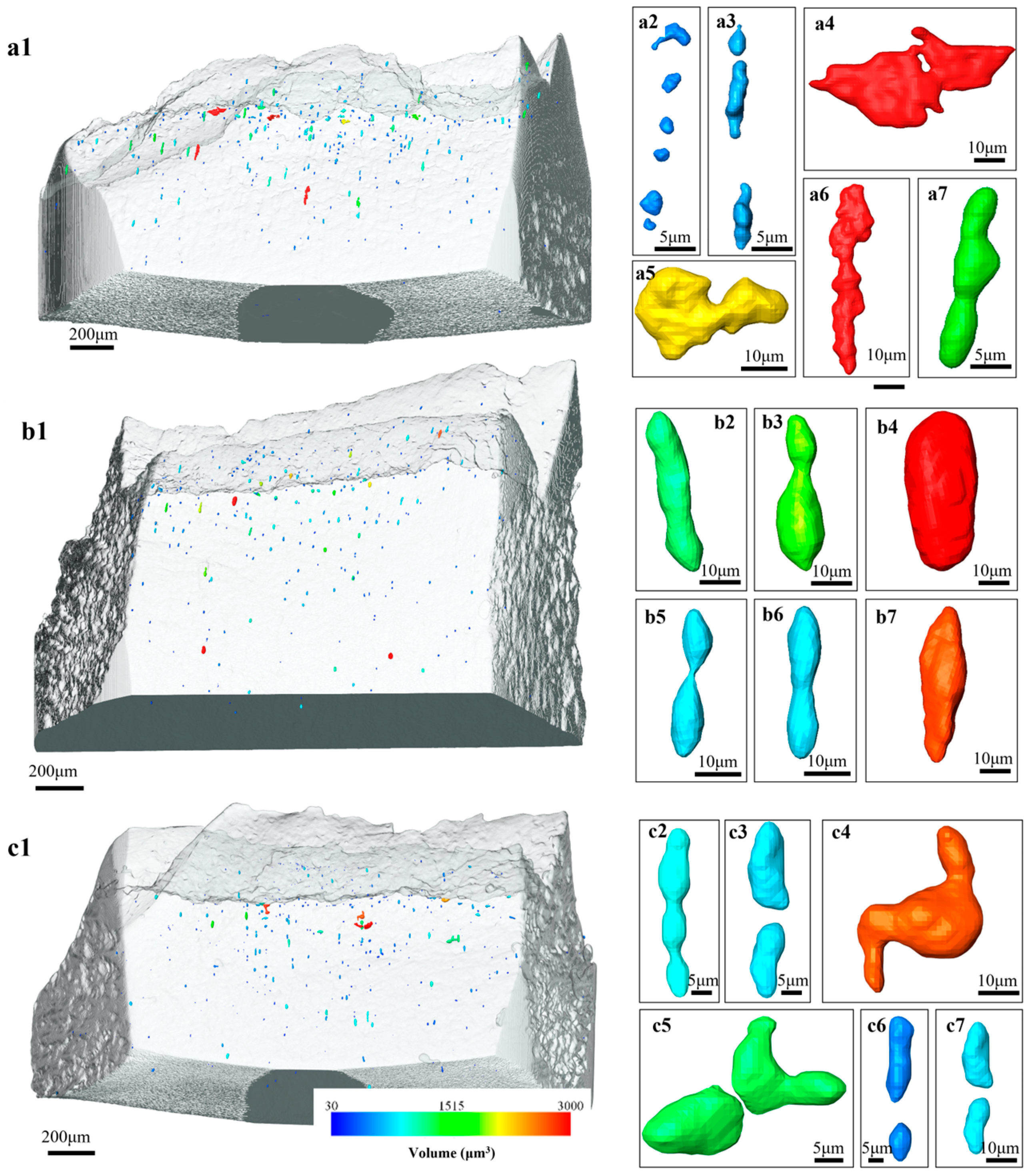

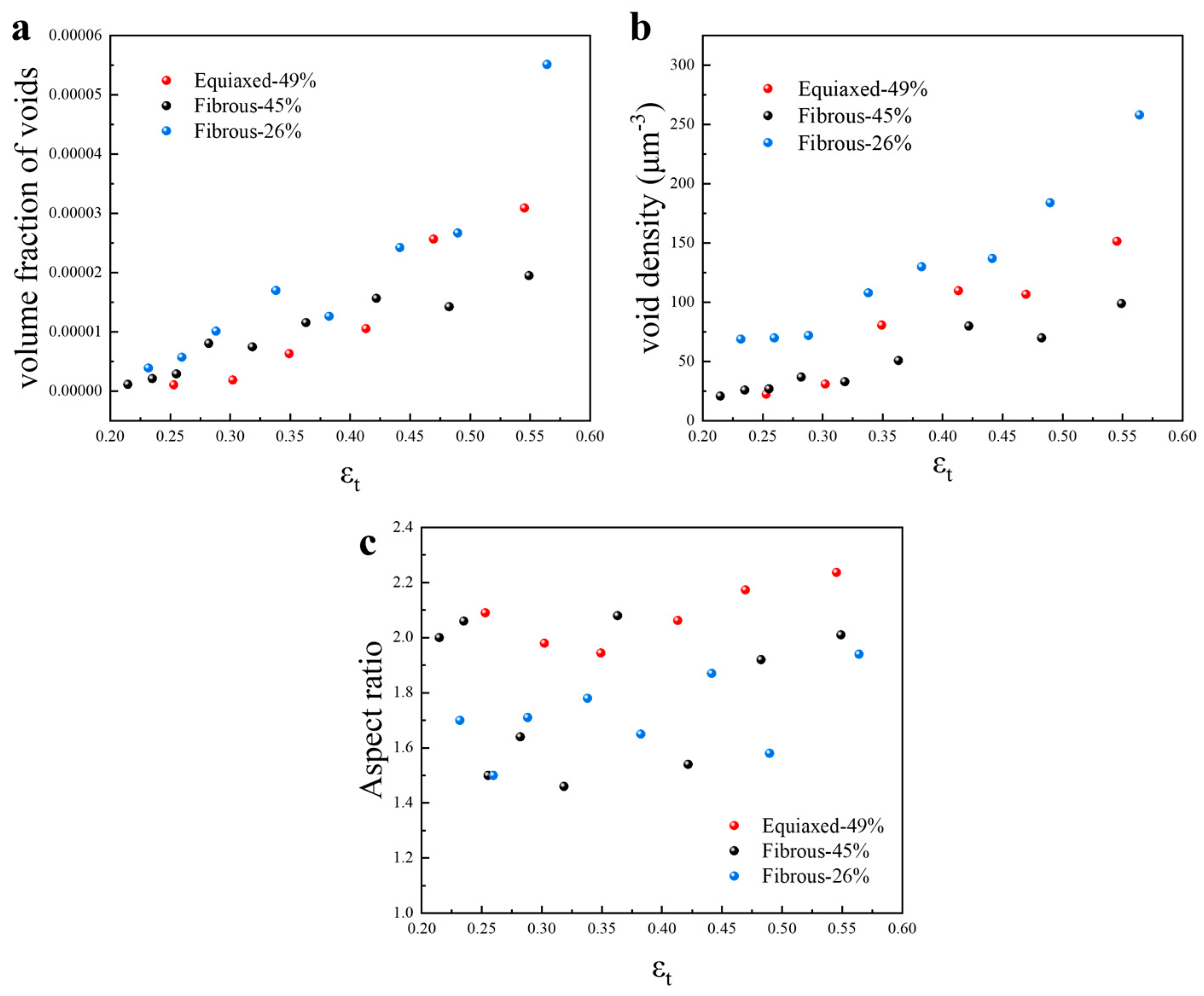

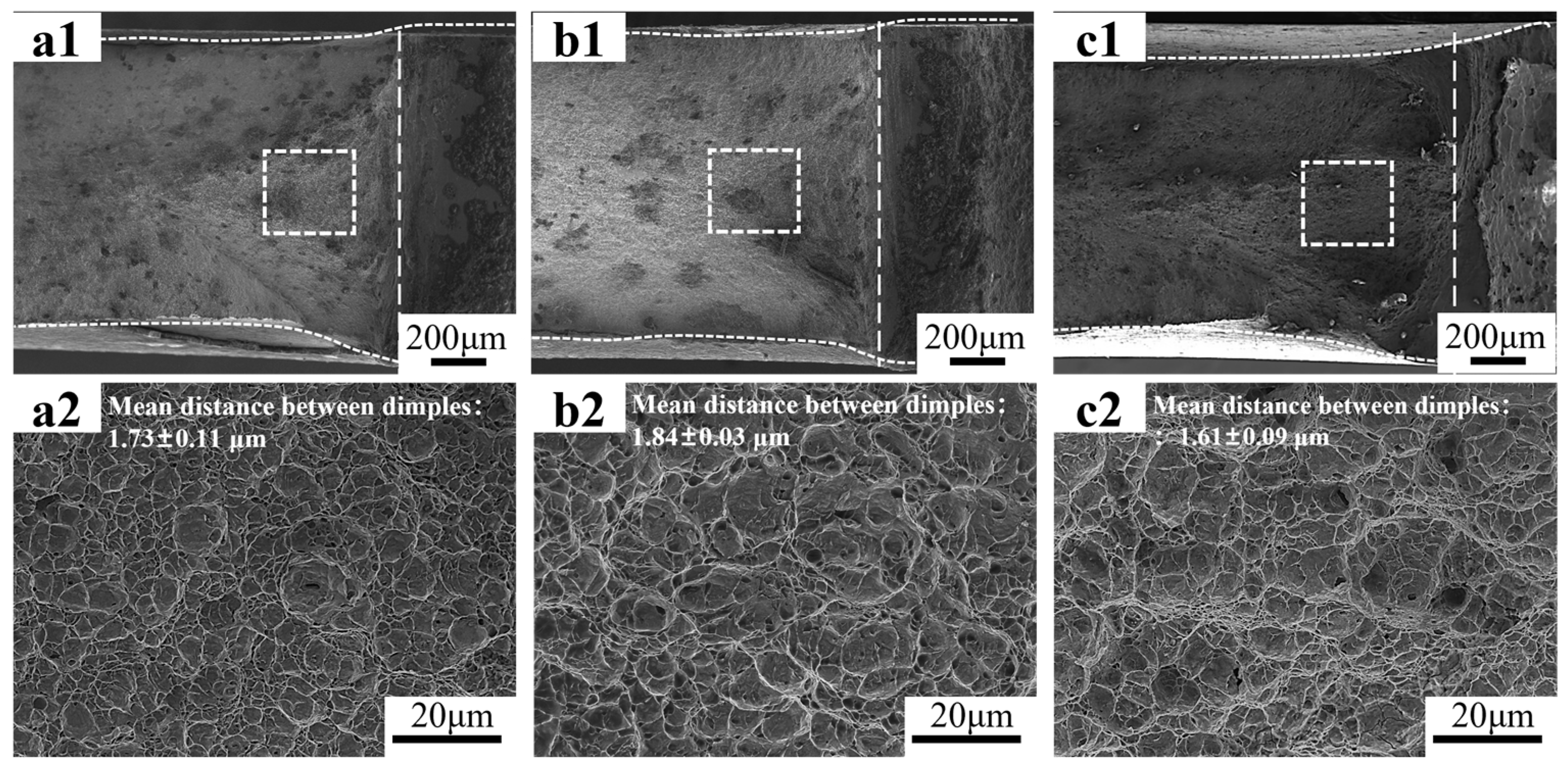

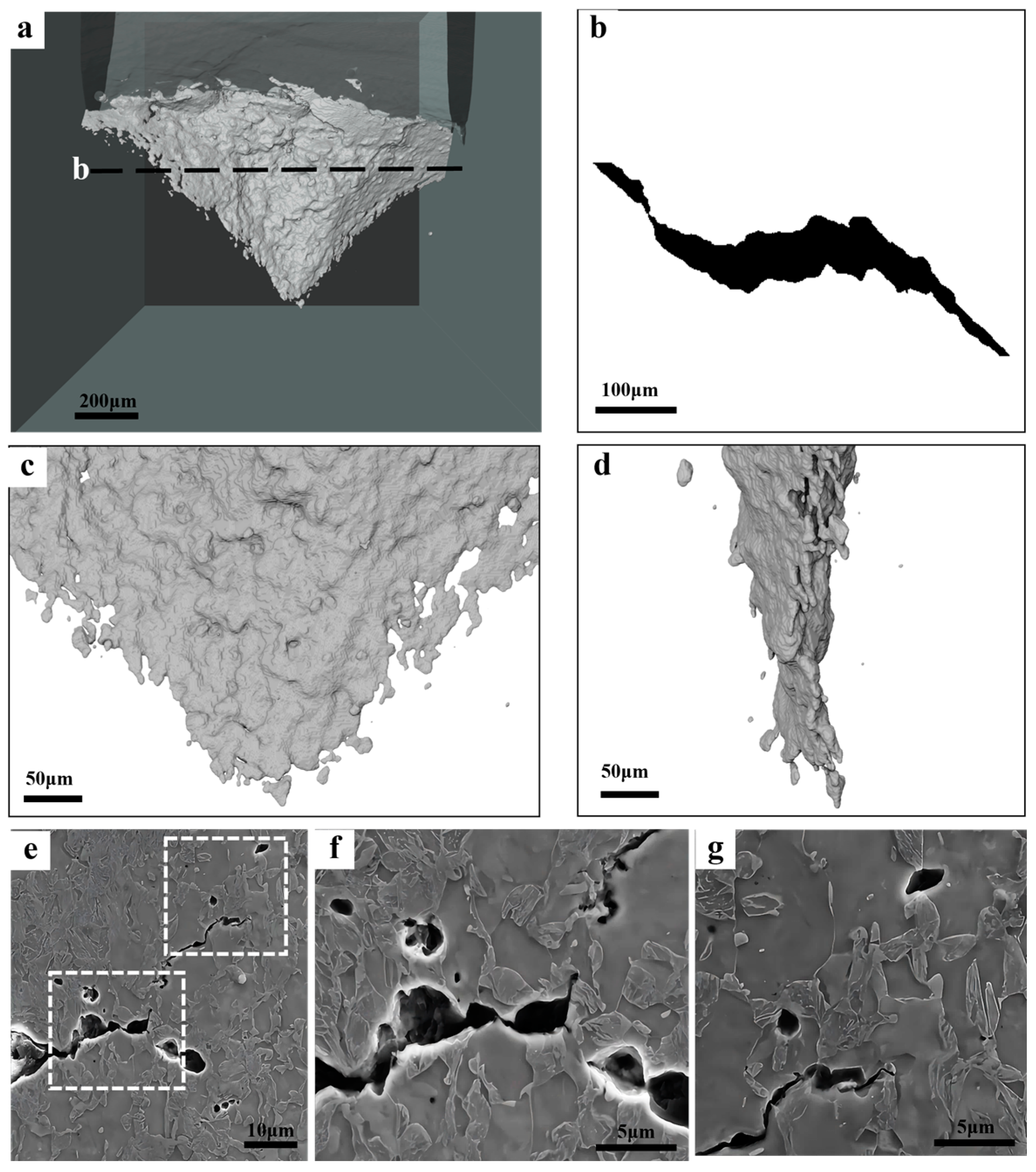

3. Results

4. Discussion

5. Conclusions

- (1)

- The fibrous morphology is efficient in increasing strength due to the ferrite grain refinement effect, but the uniform elongation is compromised by a lower strain hardening capability.

- (2)

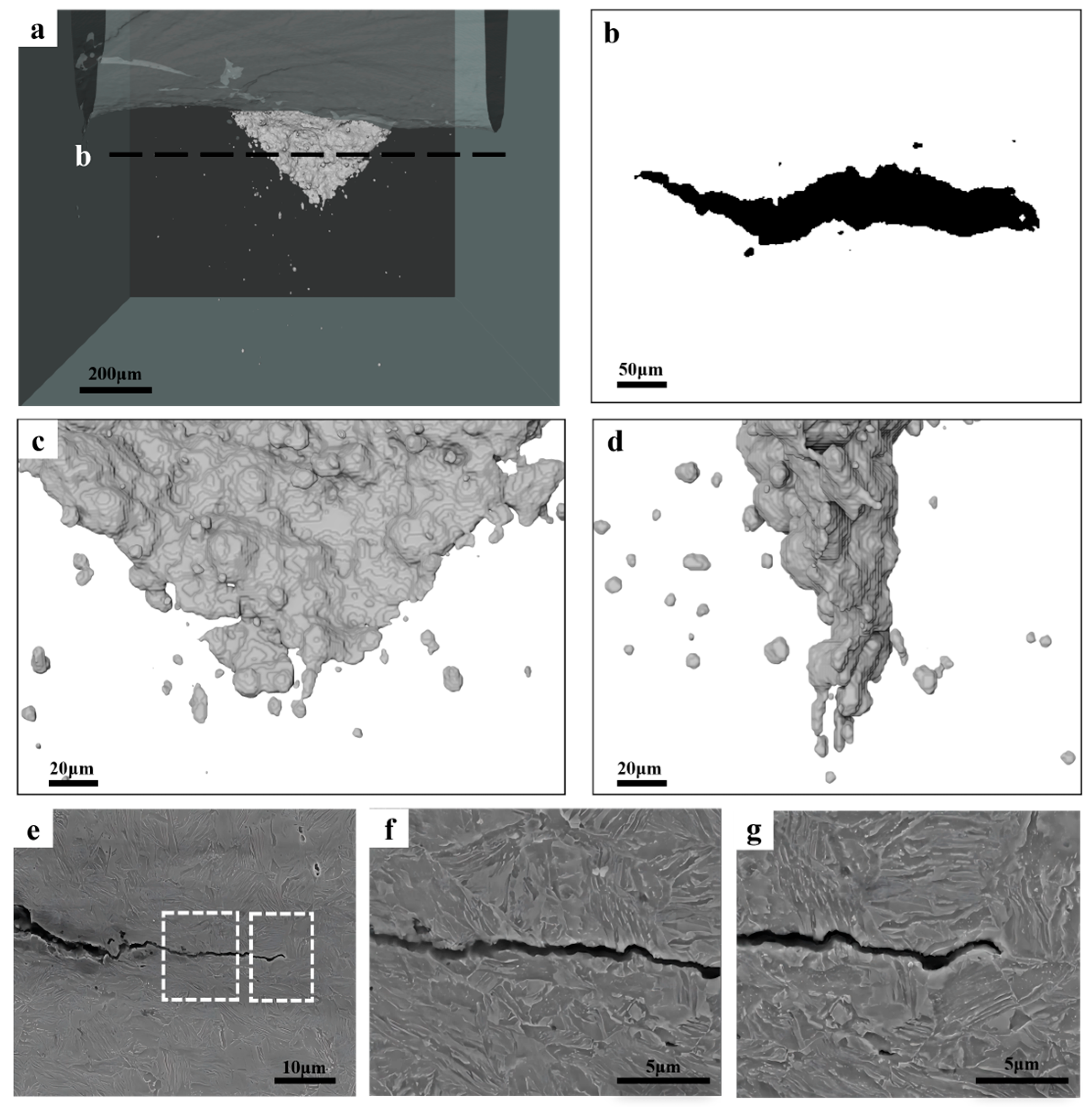

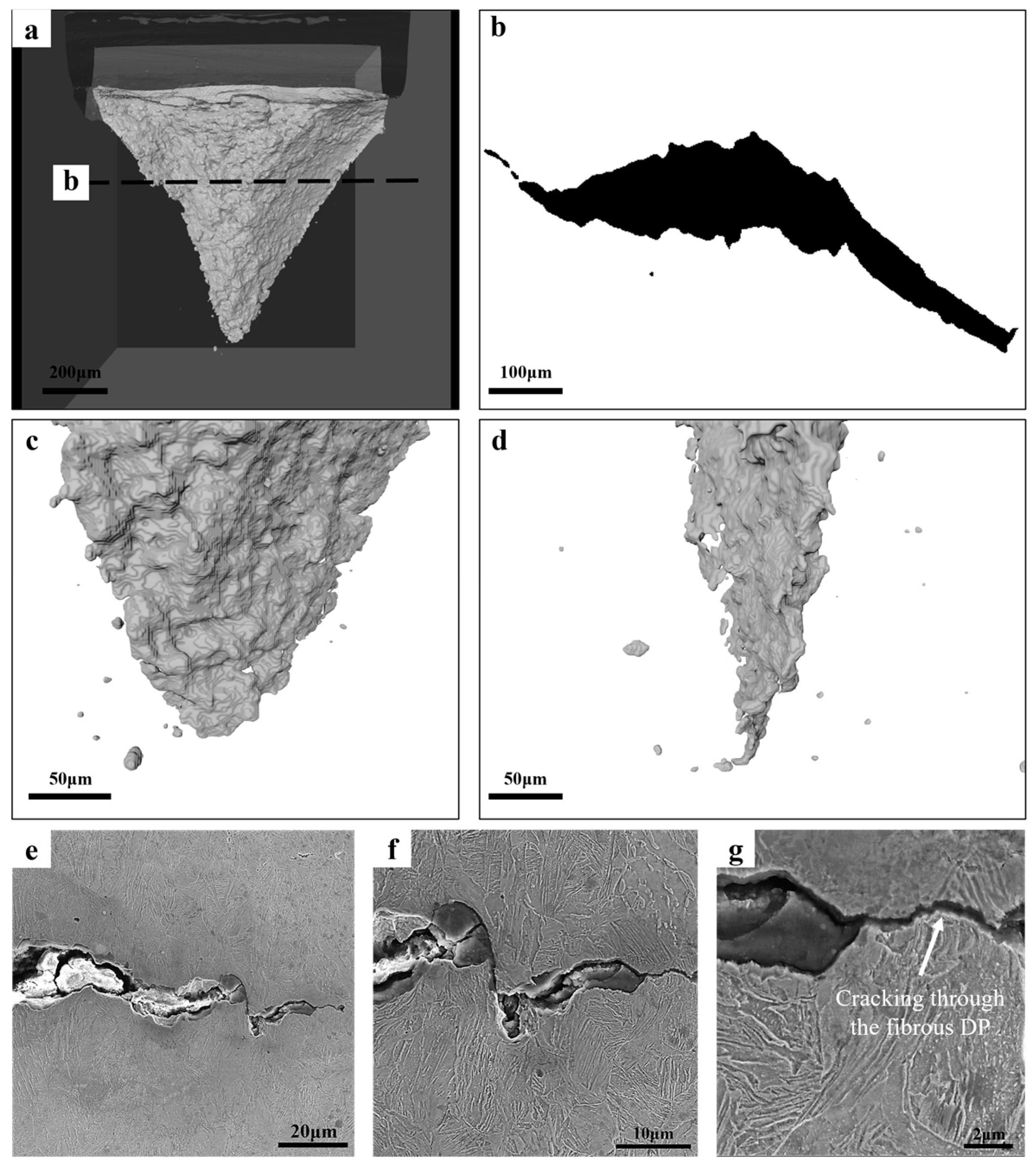

- The DP microstructures of Equiaxed-49%, Fibrous-45%, and Fibrous-26% involve a tensile strength above 1 GPa, but the damage mechanism is different. The major damage mechanism is martensite cracking in Equiaxed-49%, while that is interface decohesion in the fibrous microstructures.

- (3)

- Under uniaxial tension, the fibrous morphology does not improve the fracture strain. But under DENT tension, the measurements of EWF show that Fibrous-45% and Equiaxed-49% have similar fracture resistance, and the Fibrous-26% presents the highest value of we. The superior we of Fibrous-26% is presumably attributed to the larger energy dissipation by crack tip necking.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bouaziz, O.; Zurob, H.; Huang, M. Driving Force and Logic of Development of Advanced High Strength Steels for Automotive Applications. Steel Res. Int. 2013, 84, 937–947. [Google Scholar] [CrossRef]

- Lu, Q.; Lai, Q.; Chai, Z.; Wei, X.; Xiong, X.; Yi, H.; Huang, M.; Xu, W.; Wang, J. Revolutionizing car body manufacturing using a unified steel metallurgy concept. Sci. Adv. 2021, 7, abk0176. [Google Scholar] [CrossRef] [PubMed]

- Tasan, C.; Diehl, M.; Yan, D.; Bechtold, M.; Roters, F.; Schemmann, L.; Zheng, C.; Peranio, N.; Ponge, D.; Koyama, M.; et al. An Overview of Dual-Phase Steels: Advances in Microstructure-Oriented Processing and Micromechanically Guided Design. Annu. Rev. Mater. Res. 2015, 45, 391–431. [Google Scholar] [CrossRef]

- Allain, S.Y.; Pushkareva, I.; Teixeira, J.; Gouné, M.; Scott, C. Dual-Phase Steels: The First Family of Advanced High Strength Steels. In Encyclopedia of Materials: Metals and Alloys; Elsevier: Oxford, UK, 2022; pp. 37–62. [Google Scholar]

- Frómeta, D.; Parareda, S.; Lara, A.; Molas, S.; Casellas, D.; Jonsén, P.; Calvo, J. Identification of fracture toughness parameters to understand the fracture resistance of advanced high strength sheet steels. Eng. Fract. Mech. 2020, 229, 106949. [Google Scholar] [CrossRef]

- Frómeta, D.; Lara, A.; Casas, B.; Casellas, D. Fracture toughness measurements to understand local ductility of advanced high strength steels. IOP Conf. Ser. Mater. Sci. Eng. 2019, 651, 012071. [Google Scholar] [CrossRef]

- Lai, Q.; Brassart, L.; Bouaziz, O.; Gouné, M.; Verdier, M.; Parry, G.; Perlade, A.; Bréchet, Y.; Pardoen, T. Influence of martensite volume fraction and hardness on the plastic behavior of dual-phase steels: Experiments and micromechanical modeling. Int. J. Plast. 2016, 80, 187–203. [Google Scholar] [CrossRef]

- Tang, A.; Liu, H.; Chen, R.; Liu, G.; Lai, Q.; Zhong, Y.; Wang, L.; Wang, J.; Lu, Q.; Shen, Y. Mesoscopic origin of damage nu-cleation in dual-phase steels. Int. J. Plast. 2021, 137, 102920. [Google Scholar] [CrossRef]

- Maire, E.; Bouaziz, O.; Di Michiel, M.; Verdu, C. Initiation and growth of damage in a dual-phase steel observed by X-ray microtomography. Acta Mater. 2008, 56, 4954–4964. [Google Scholar] [CrossRef]

- Azuma, M.; Goutianos, S.; Hansen, N.; Winther, G.; Huang, X. Effect of hardness of martensite and ferrite on void formation in dual phase steel. Mater. Sci. Technol. 2012, 28, 1092–1100. [Google Scholar] [CrossRef]

- Park, M.-H.; Fujimura, Y.; Shibata, A.; Tsuji, N. Effect of martensite hardness on mechanical properties and stress/strain-partitioning behavior in ferrite + martensite dual-phase steels. Mater. Sci. Eng. A 2024, 916, 147301. [Google Scholar] [CrossRef]

- Mazinani, M.; Poole, W. Effect of Martensite Plasticity on the Deformation Behavior of a Low-Carbon Dual-Phase Steel. Met. Mater. Trans. A 2007, 38, 328–339. [Google Scholar] [CrossRef]

- Samei, J.; Zhou, L.; Kang, J.; Wilkinson, D.S. Microstructural analysis of ductility and fracture in fine-grained and ultrafine-grained vanadium-added DP1300 steels. Int. J. Plast. 2019, 117, 58–70. [Google Scholar] [CrossRef]

- Pelligra, C.; Samei, J.; Kang, J.; Wilkinson, D.S. The effect of vanadium on microstrain partitioning and localized damage during deformation of unnotched and notched DP1300 steels. Int. J. Plast. 2022, 158, 103435. [Google Scholar] [CrossRef]

- Calcagnotto, M.; Ponge, D.; Raabe, D. Effect of grain refinement to 1μm on strength and toughness of dual-phase steels. Mater. Sci. Eng. A 2010, 527, 7832–7840. [Google Scholar] [CrossRef]

- Park, M.-H.; Shibata, A.; Harjo, S.; Tsuji, N. Grain refinement of dual phase steel maximizes deformation ability of martensite, leading to simultaneous enhancement of strength and ductility. Acta Mater. 2025, 292, 121061. [Google Scholar] [CrossRef]

- Ogatsu, K.; Ogawa, T.; Chen, T.-T.; Sun, F.; Adachi, Y. Dramatic improvement in strength–ductility balance of dual-phase steels by optimizing features of ferrite phase. J. Mater. Res. Technol. 2025, 35, 289–297. [Google Scholar] [CrossRef]

- Kim, N.J.; Thomas, G. Effects of morphology on the mechanical behavior of a dual phase Fe/2Si/0.1C steel. Met. Trans. A 1981, 12, 483–489. [Google Scholar] [CrossRef]

- Ismail, K.; Perlade, A.; Jacques, P.J.; Pardoen, T. Outstanding cracking resistance of fibrous dual phase steels. Acta Mater. 2021, 207, 116700. [Google Scholar] [CrossRef]

- Ismail, K.; Perlade, A.; Jacques, P.J.; Pardoen, T.; Brassart, L. Impact of second phase morphology and orientation on the plastic behavior of dual-phase steels. Int. J. Plast. 2019, 118, 130–146. [Google Scholar] [CrossRef]

- Shi, P.; Ren, Y.; Zhang, X.; Wang, H.; Chen, J.; Pei, Y.; Yan, J.; Zheng, H.; Zhang, J. Role of martensite morphology on mechanical response of dual-phase steel produced by partial reversion from martensite. Mater. Sci. Eng. A 2024, 893, 146116. [Google Scholar] [CrossRef]

- Liu, L.; Li, L.; He, J.; Liang, Z.; Peng, Z.; Gao, J.; Luo, Z.; Huang, M. The unexpected low fracture toughness of dual-phase steels caused by ferrite/martensite interface decohesion. Scr. Mater. 2024, 244, 116030. [Google Scholar] [CrossRef]

- Liu, L.; He, J.; Li, L.; Liang, Z.; Peng, Z.; Gao, J.; Huang, M.; Luo, Z. Making ultrahigh-strength dual-phase steels tough: Ex-periment; simulation. J. Mater. Sci. Technol. 2025, 226, 302–316. [Google Scholar] [CrossRef]

- Lai, Q.; Chang, S.; Wei, Y.; Wu, S.; Jacques, P.; Pardoen, T.; Fan, G. Impact of ε-martensite on the fracture resistance of high-Mn steels. Mater. Res. Lett. 2024, 12, 700–708. [Google Scholar] [CrossRef]

- Lai, Q.; Chen, Z.; Wei, Y.; Lu, Q.; Ma, Y.; Wang, J.; Fan, G. Towards the understanding of fracture resistance of an ultrahigh-strength martensitic press-hardened steel. J. Mater. Res. Technol. 2023, 27, 1996–2006. [Google Scholar] [CrossRef]

- Xiong, Z.; Jacques, P.J.; Perlade, A.; Pardoen, T. Ductile and intergranular brittle fracture in a two-step quenching and parti-tioning steel. Scr. Mater. 2018, 157, 6–9. [Google Scholar] [CrossRef]

- Frómeta, D.; Lara, A.; Grifé, L.; Dieudonné, T.; Dietsch, P.; Rehrl, J.; Suppan, C.; Casellas, D.; Calvo, J. Fracture Resistance of Advanced High-Strength Steel Sheets for Automotive Applications. Met. Mater. Trans. A 2021, 52, 840–856. [Google Scholar] [CrossRef]

- Frómeta, D.; Cuadrado, N.; Rehrl, J.; Suppan, C.; Dieudonné, T.; Dietsch, P.; Calvo, J.; Casellas, D. Microstructural effects on fracture toughness of ultra-high strength dual phase sheet steels. Mater. Sci. Eng. A 2021, 802, 140631. [Google Scholar] [CrossRef]

- Xiong, Z.; Jacques, P.J.; Perlade, A.; Pardoen, T. Characterization and Control of the Compromise Between Tensile Properties and Fracture Toughness in a Quenched and Partitioned Steel. Met. Mater. Trans. A 2019, 50, 3502–3513. [Google Scholar] [CrossRef]

- Cotterell, B.; Reddel, J.K. The essential work of plane stress ductile fracture. Int. J. Fract. 1977, 13, 267–277. [Google Scholar] [CrossRef]

- Hilhorst, A.; Pardoen, T.; Jacques, P. Optimization of the essential work of fracture method for characterization of the fracture resistance of metallic sheets. Eng. Fract. Mech. 2022, 268, 108442. [Google Scholar] [CrossRef]

- Lacroix, G.; Pardoen, T.; Jacques, P. The fracture toughness of TRIP-assisted multiphase steels. Acta Mater. 2008, 56, 3900–3913. [Google Scholar] [CrossRef]

- Avramovic-Cingara, G.; Saleh, C.; Jain, M.; Wilkinson, D. Void Nucleation and Growth in Dual-Phase Steel 600 during Uniaxial Tensile Testing. Met. Mater. Trans. A 2009, 40, 3117–3127. [Google Scholar] [CrossRef]

- Requena, G.; Maire, E.; Leguen, C.; Thuillier, S. Separation of nucleation and growth of voids during tensile deformation of a dual phase steel using synchrotron microtomography. Mater. Sci. Eng. A 2014, 589, 242–251. [Google Scholar] [CrossRef]

- Anderson, T.L. Fracture Mechanics: Fundamentals and Applications, 4th ed.; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Teixeira, J.; Moreno, M.; Allain, S.; Oberbillig, C.; Geandier, G.; Bonnet, F. Intercritical annealing of cold-rolled ferrite-pearlite steel: Microstructure evolutions and phase transformation kinetics. Acta Mater. 2021, 212, 116920. [Google Scholar] [CrossRef]

- Azizi-Alizamini, H.; Militzer, M.; Poole, W.J. Formation of Ultrafine Grained Dual Phase Steels through Rapid Heating. ISIJ Int. 2011, 51, 958–964. [Google Scholar] [CrossRef]

- Hutchinson, B.; Hagström, J.; Karlsson, O.; Lindell, D.; Tornberg, M.; Lindberg, F.; Thuvander, M. Microstructures and hardness of as-quenched martensites (0.1–0.5%C). Acta Mater. 2011, 59, 5845–5858. [Google Scholar] [CrossRef]

- Badinier, G.; Sinclair, C.; Sauvage, X.; Wang, X.; Bylik, V.; Gouné, M.; Danoix, F. Microstructural heterogeneity and its relationship to the strength of martensite. Mater. Sci. Eng. A 2015, 638, 329–339. [Google Scholar] [CrossRef]

- Mehrabi, A.; McDermid, J.R.; Wang, X.; Zurob, H. Austenite Nucleation and Growth as a Function of Starting Microstructure for a Fe–0.15C–5.56Mn–1.1Si–1.89Al Medium-Mn Steel. Steel Res. Int. 2023, 94, 2200952. [Google Scholar] [CrossRef]

- Wei, R.; Enomoto, M.; Hadian, R.; Zurob, H.S.; Purdy, G.R. Growth of austenite from as-quenched martensite during inter-critical annealing in an Fe–0.1C–3Mn–1.5Si alloy. Acta Mater. 2013, 61, 697–707. [Google Scholar] [CrossRef]

- Morito, S.; Huang, X.; Furuhara, T.; Maki, T.; Hansen, N. The morphology and crystallography of lath martensite in alloy steels. Acta Mater. 2006, 54, 5323–5331. [Google Scholar] [CrossRef]

- Morito, S.; Yoshida, H.; Maki, T.; Huang, X. Effect of block size on the strength of lath martensite in low carbon steels. Mater. Sci. Eng. A 2006, 438–440, 237–240. [Google Scholar] [CrossRef]

- Sinclair, C.; Poole, W.; Bréchet, Y. A model for the grain size dependent work hardening of copper. Scr. Mater. 2006, 55, 739–742. [Google Scholar] [CrossRef]

- Landron, C.; Bouaziz, O.; Maire, E.; Adrien, J. Characterization and modeling of void nucleation by interface decohesion in dual phase steels. Scr. Mater. 2010, 63, 973–976. [Google Scholar] [CrossRef]

- Pardoen, T.; Marchal, Y.; Delannay, F. Thickness dependence of cracking resistance in thin aluminium plates. J. Mech. Phys. Solids 1999, 47, 2093–2123. [Google Scholar] [CrossRef]

- Hilhorst, A.; Jacques, P.J.; Pardoen, T. Towards the best strength, ductility, and toughness combination: High entropy alloys are excellent, stainless steels are exceptional. Acta Mater. 2023, 260, 119280. [Google Scholar] [CrossRef]

- Pardoen, T.; Hutchinson, J. Micromechanics-based model for trends in toughness of ductile metals. Acta Mater. 2003, 51, 133–148. [Google Scholar] [CrossRef]

| YS (MPa) | UTS (MPa) | UE | Area Reduction | Fracture Strain | Fracture Stress (MPa) | |

|---|---|---|---|---|---|---|

| Equiaxed-49% | 707 ± 7 | 1005 ± 11 | 0.104 ± 0.004 | 0.72 ± 0.05 | 1.31 ± 0.08 | 3711 ± 32 |

| Fibrous-45% | 837 ± 12 | 1052 ± 8 | 0.058 ± 0.013 | 0.66 ± 0.03 | 1.08 ± 0.02 | 3064 ± 59 |

| Fibrous-26% | 779 ± 9 | 1004 ± 14 | 0.061 ± 0.018 | 0.73 ± 0.07 | 1.30 ± 0.05 | 3692 ± 44 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, H.; Jia, Z.; Lai, Q. Impacts of Morphology on the Fracture Resistance of the High-Strength Dual-Phase Steels. Materials 2025, 18, 2253. https://doi.org/10.3390/ma18102253

Xu H, Jia Z, Lai Q. Impacts of Morphology on the Fracture Resistance of the High-Strength Dual-Phase Steels. Materials. 2025; 18(10):2253. https://doi.org/10.3390/ma18102253

Chicago/Turabian StyleXu, Hao, Zhihong Jia, and Qingquan Lai. 2025. "Impacts of Morphology on the Fracture Resistance of the High-Strength Dual-Phase Steels" Materials 18, no. 10: 2253. https://doi.org/10.3390/ma18102253

APA StyleXu, H., Jia, Z., & Lai, Q. (2025). Impacts of Morphology on the Fracture Resistance of the High-Strength Dual-Phase Steels. Materials, 18(10), 2253. https://doi.org/10.3390/ma18102253