Interface Optimization, Microstructural Characterization, and Mechanical Performance of CuCrZr/GH4169 Multi-Material Structures Manufactured via LPBF-LDED Integrated Additive Manufacturing

Abstract

1. Introduction

2. Materials and Methods

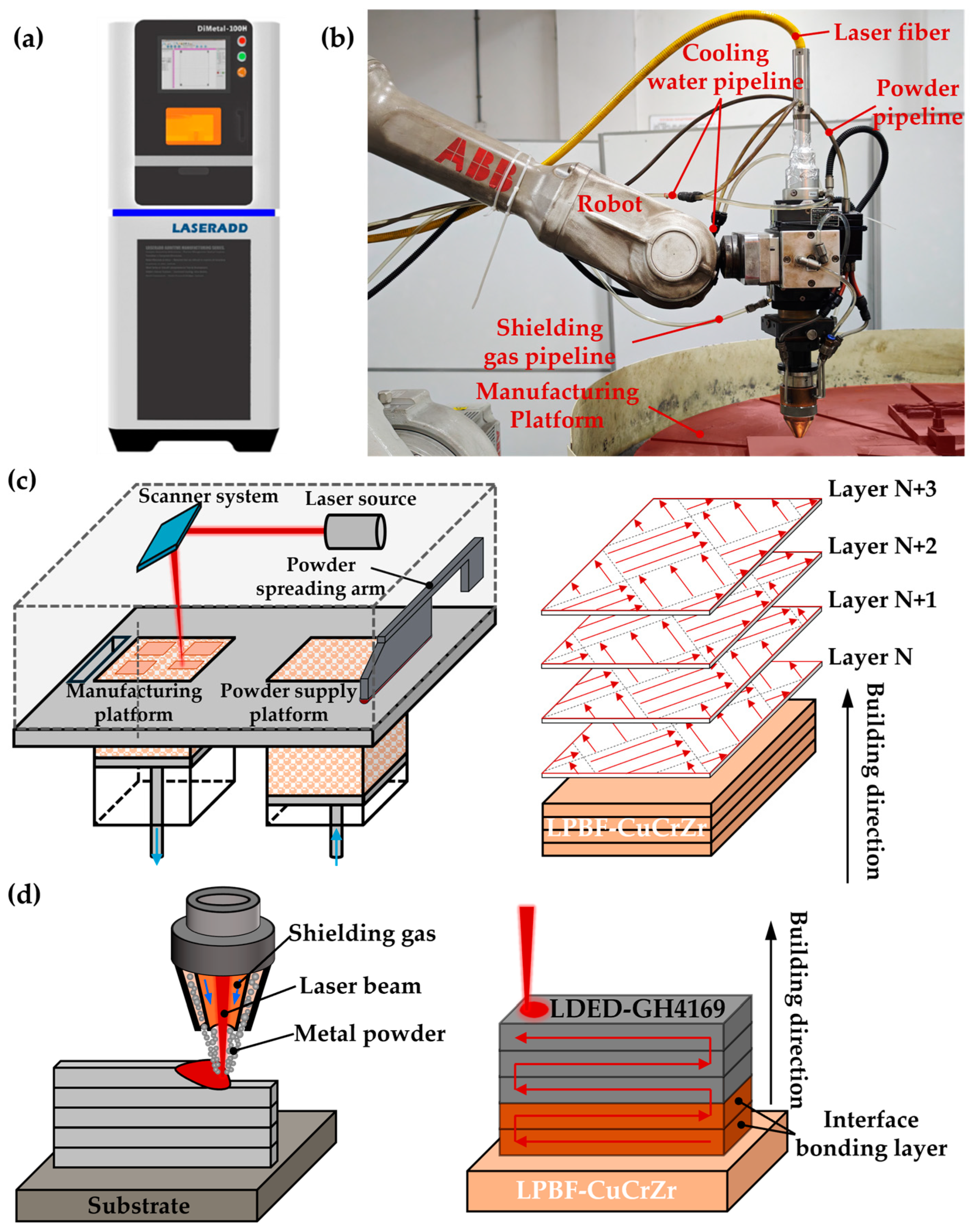

2.1. Materials and Equipment

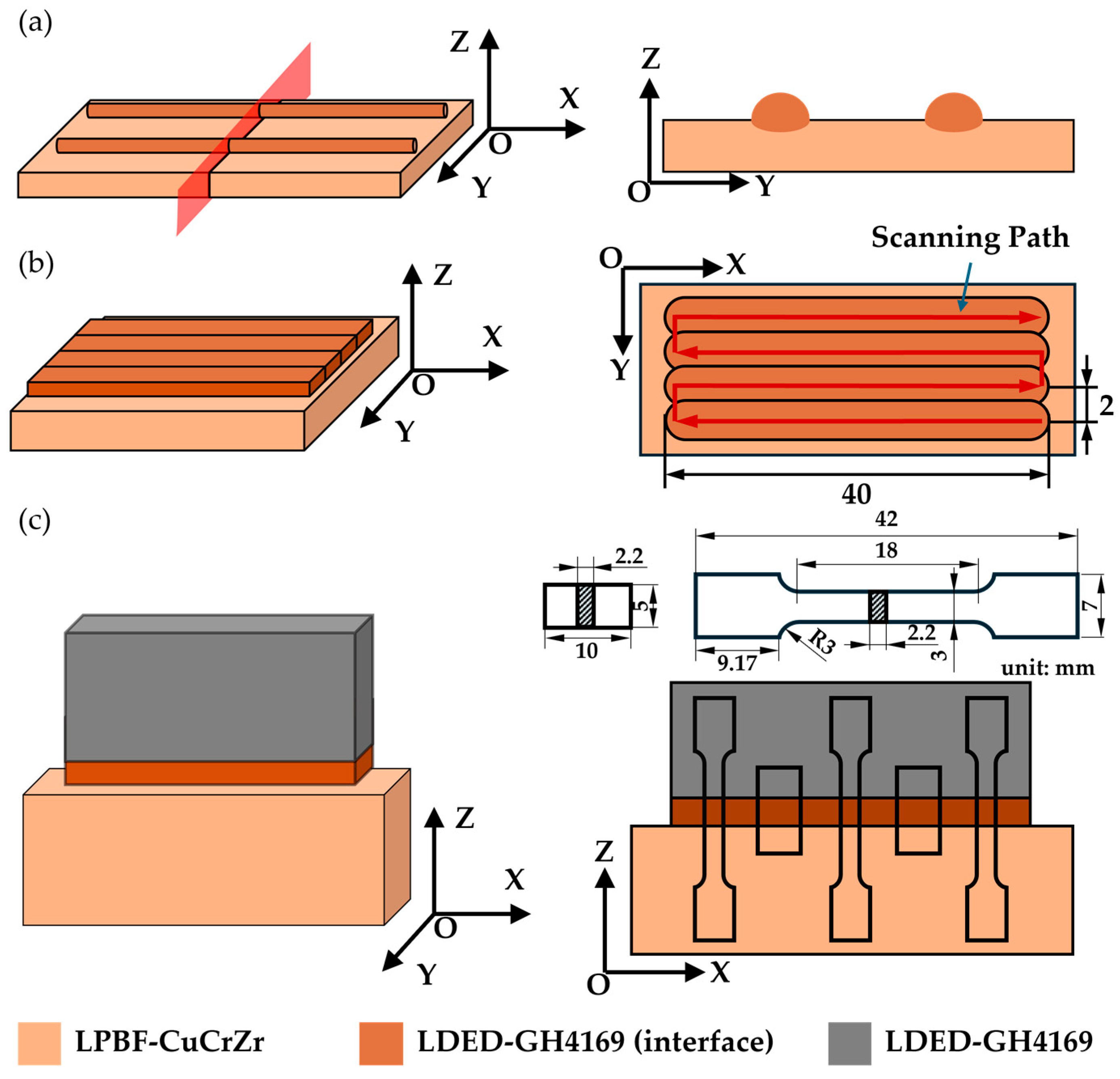

2.2. Experimental Methods

2.3. Analysis and Testing Methods

3. Results

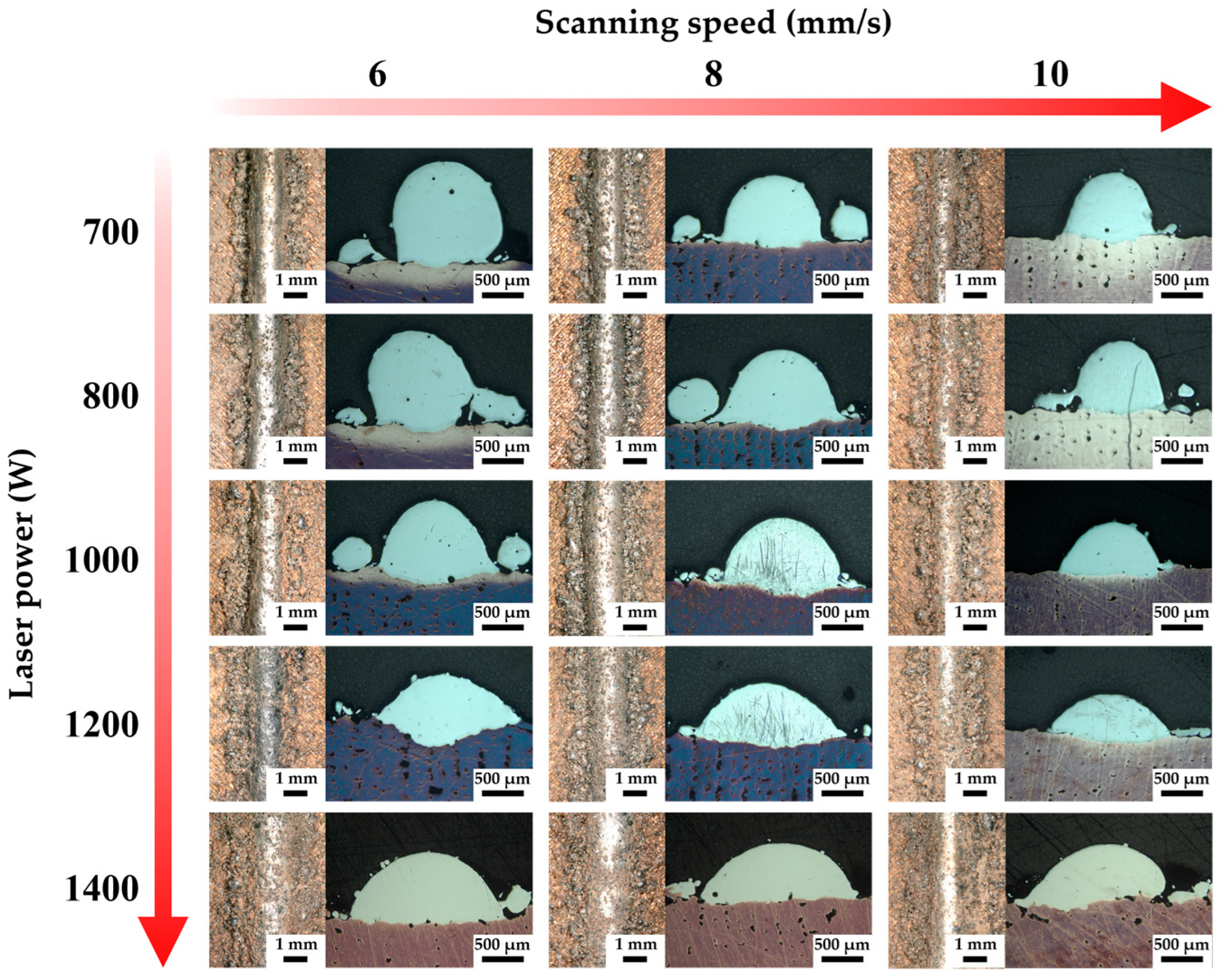

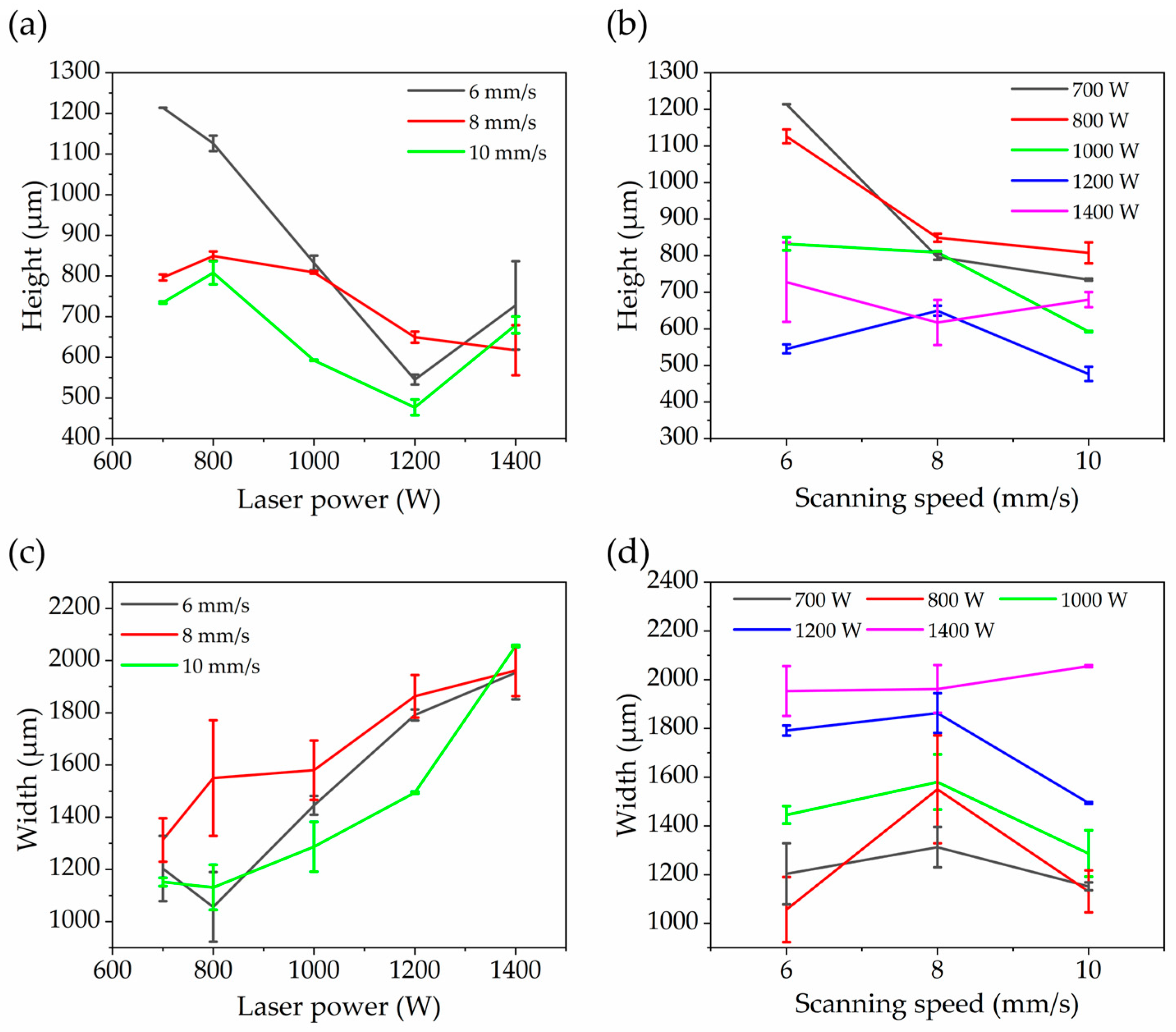

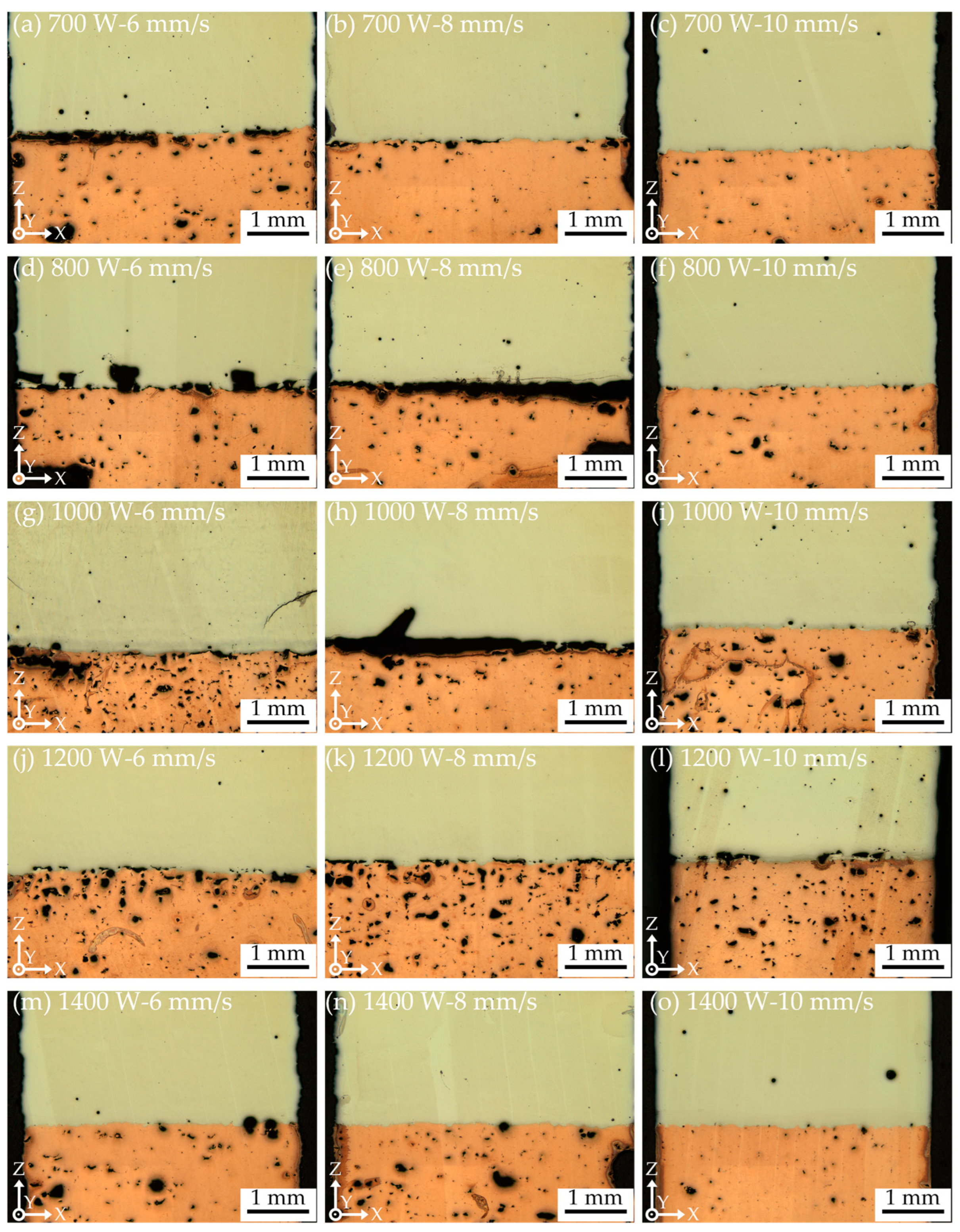

3.1. Single Melt Track of GH4169 Deposited on the CuCrZr Matrix

3.2. Single-Layer Specimen of GH4169 Deposited on the CuCrZr Matrix

3.3. LLIAM of CuCrZr/GH4169 Thin-Walled Specimens

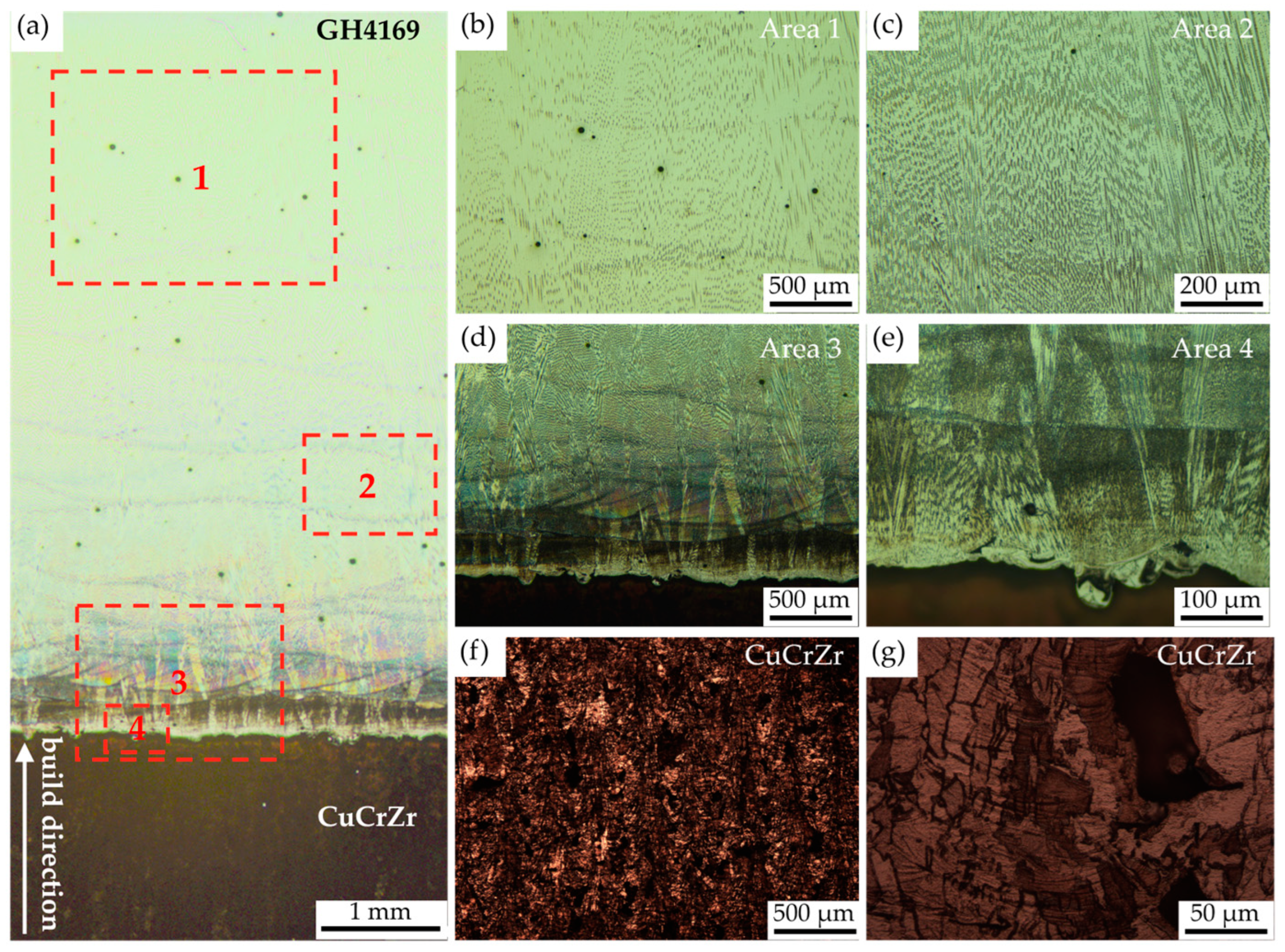

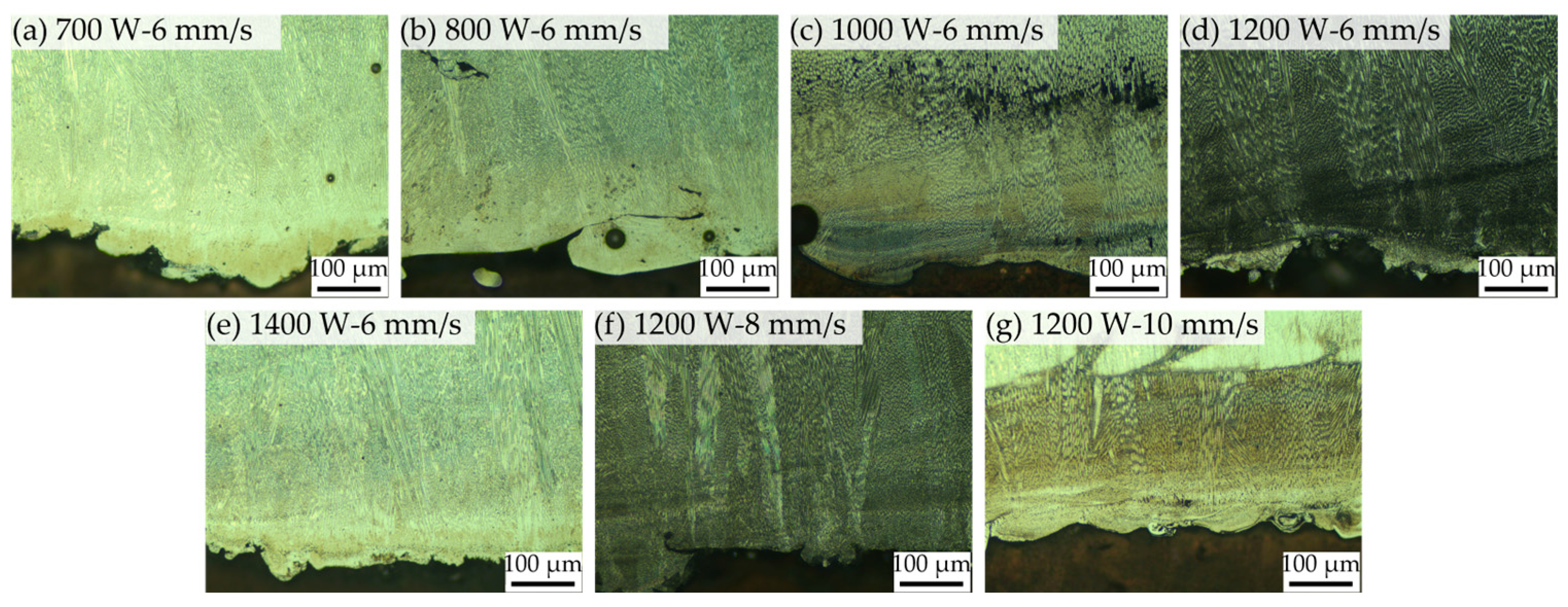

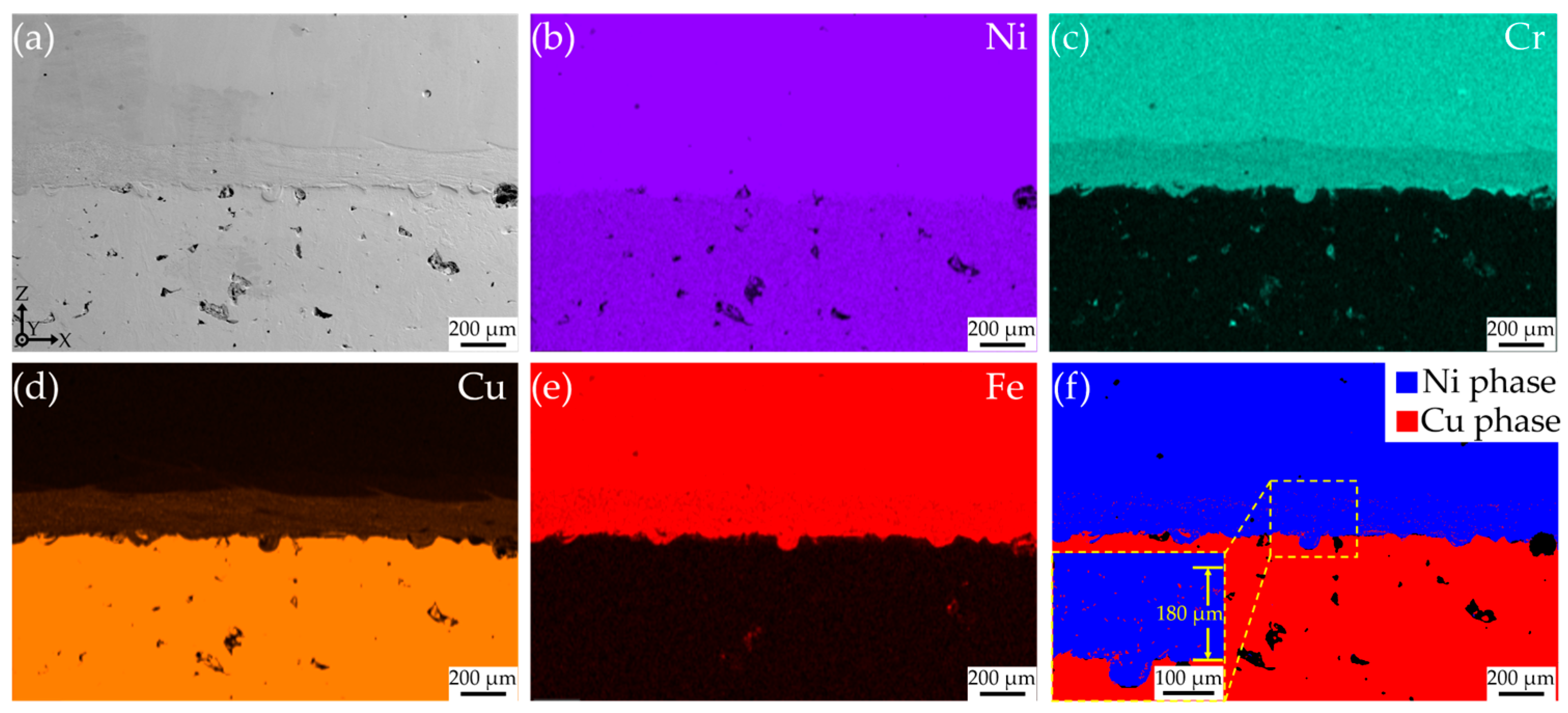

3.3.1. Metallography

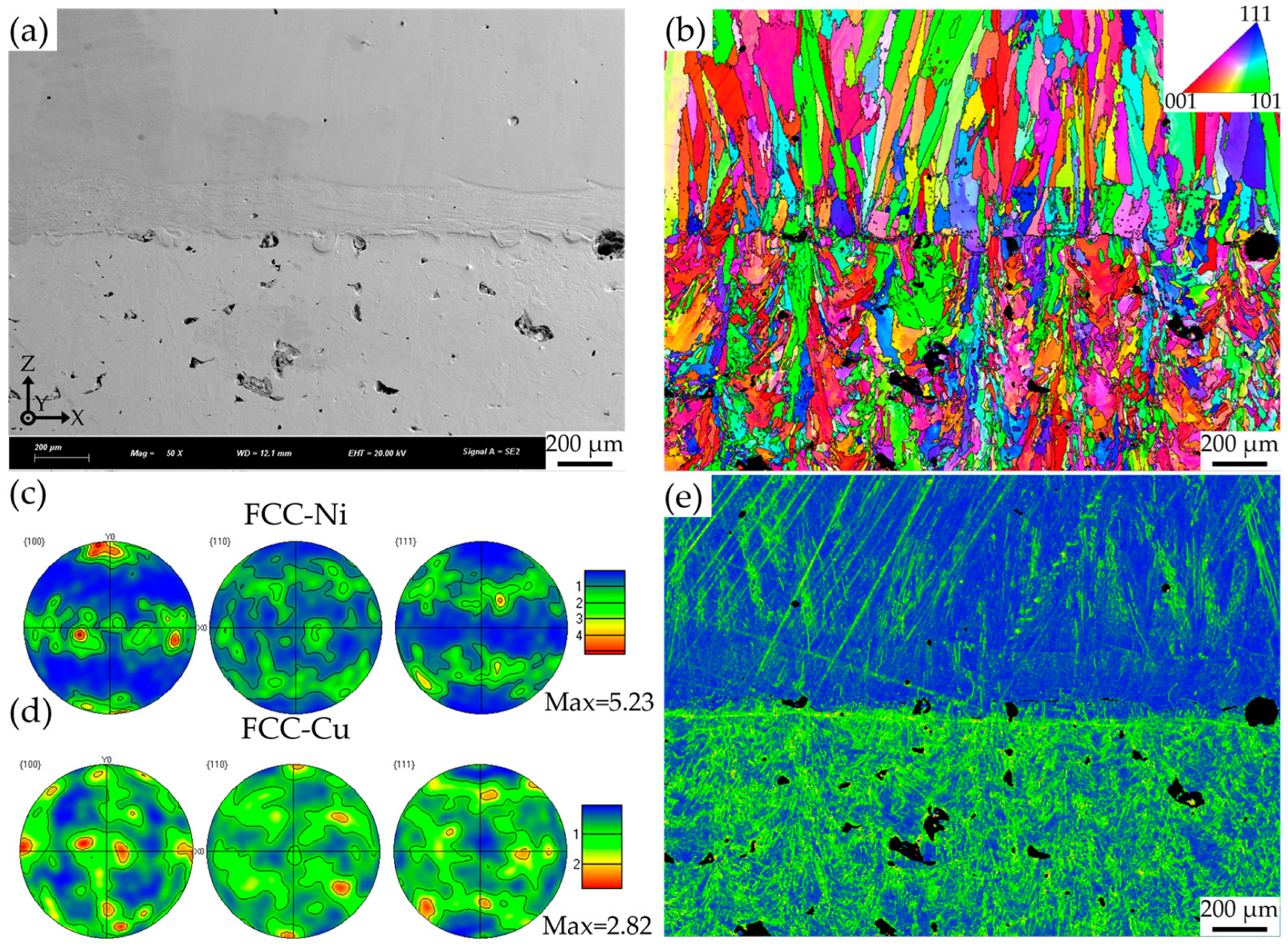

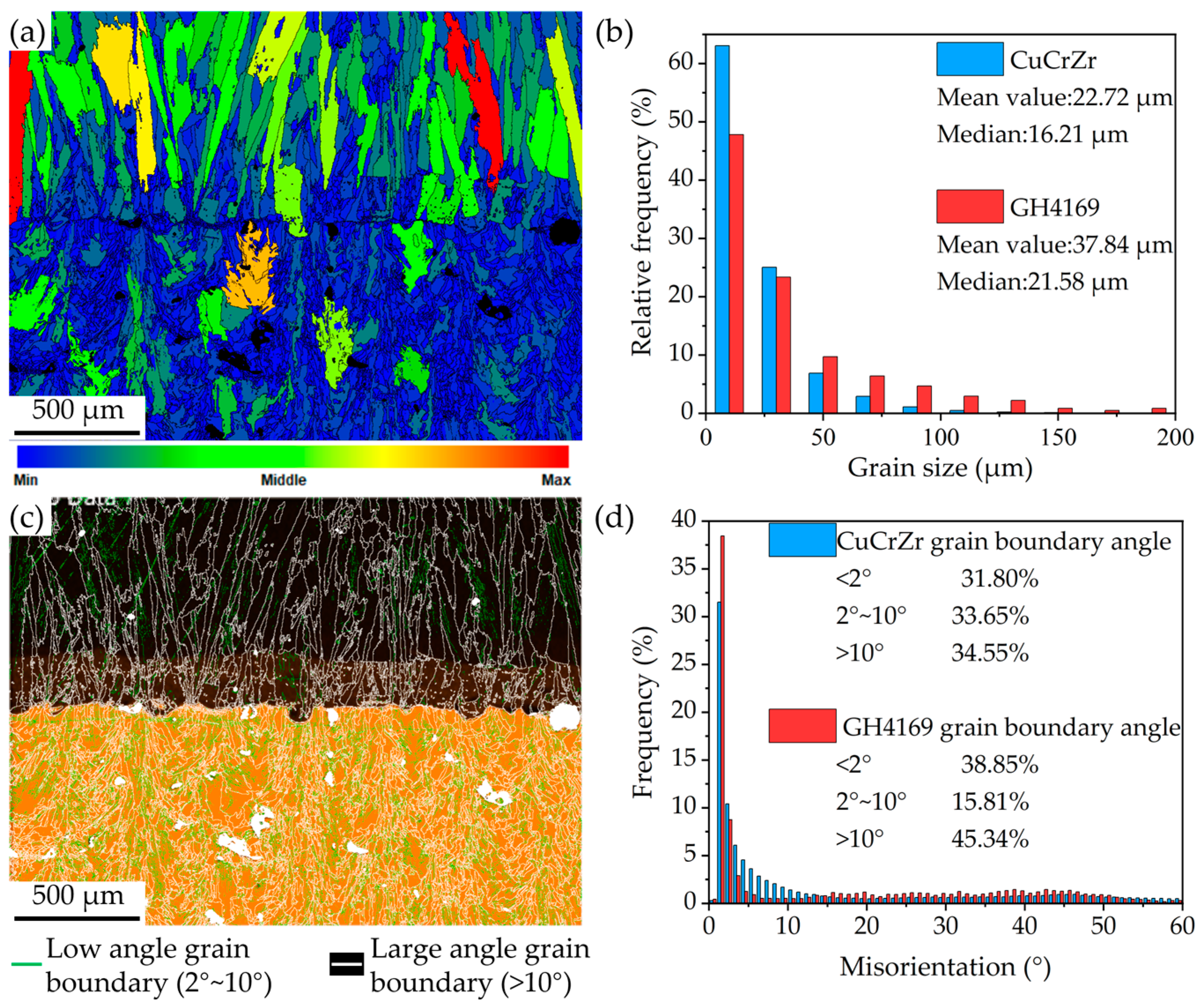

3.3.2. Microstructure

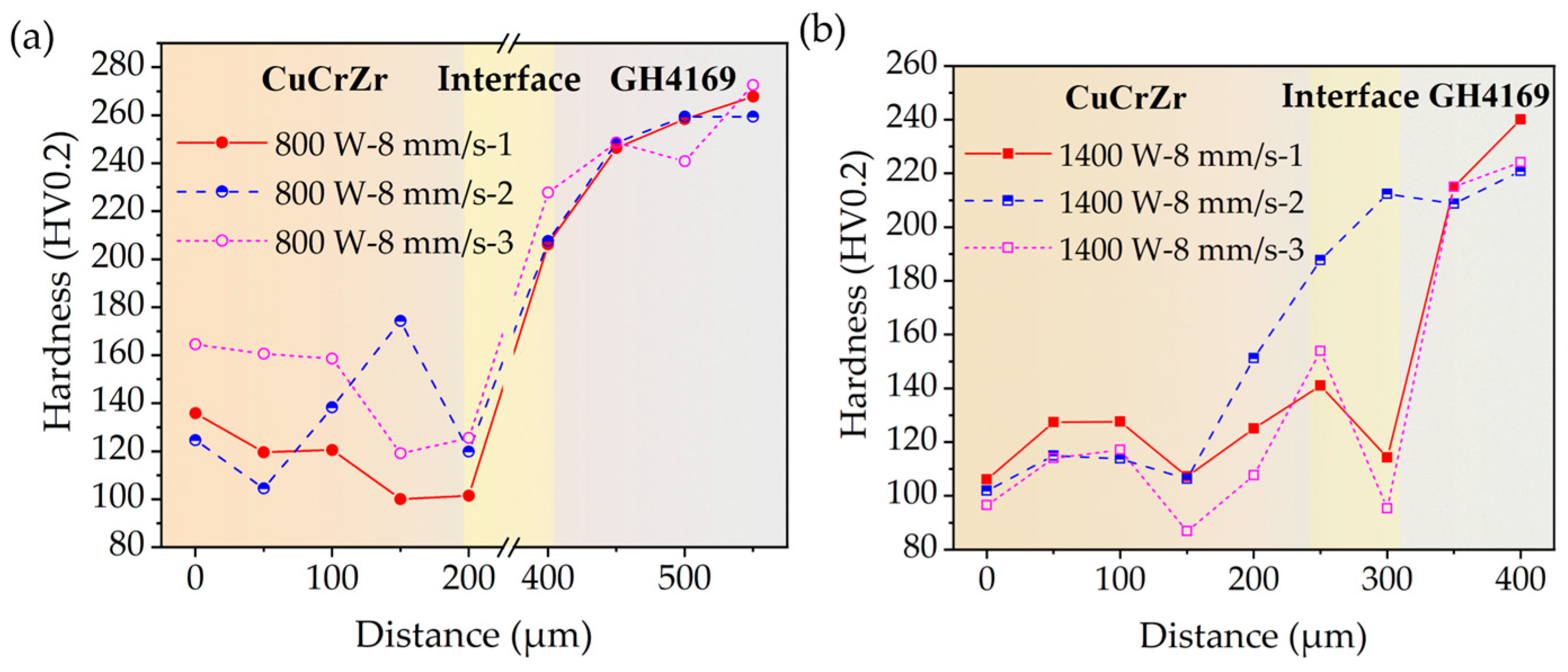

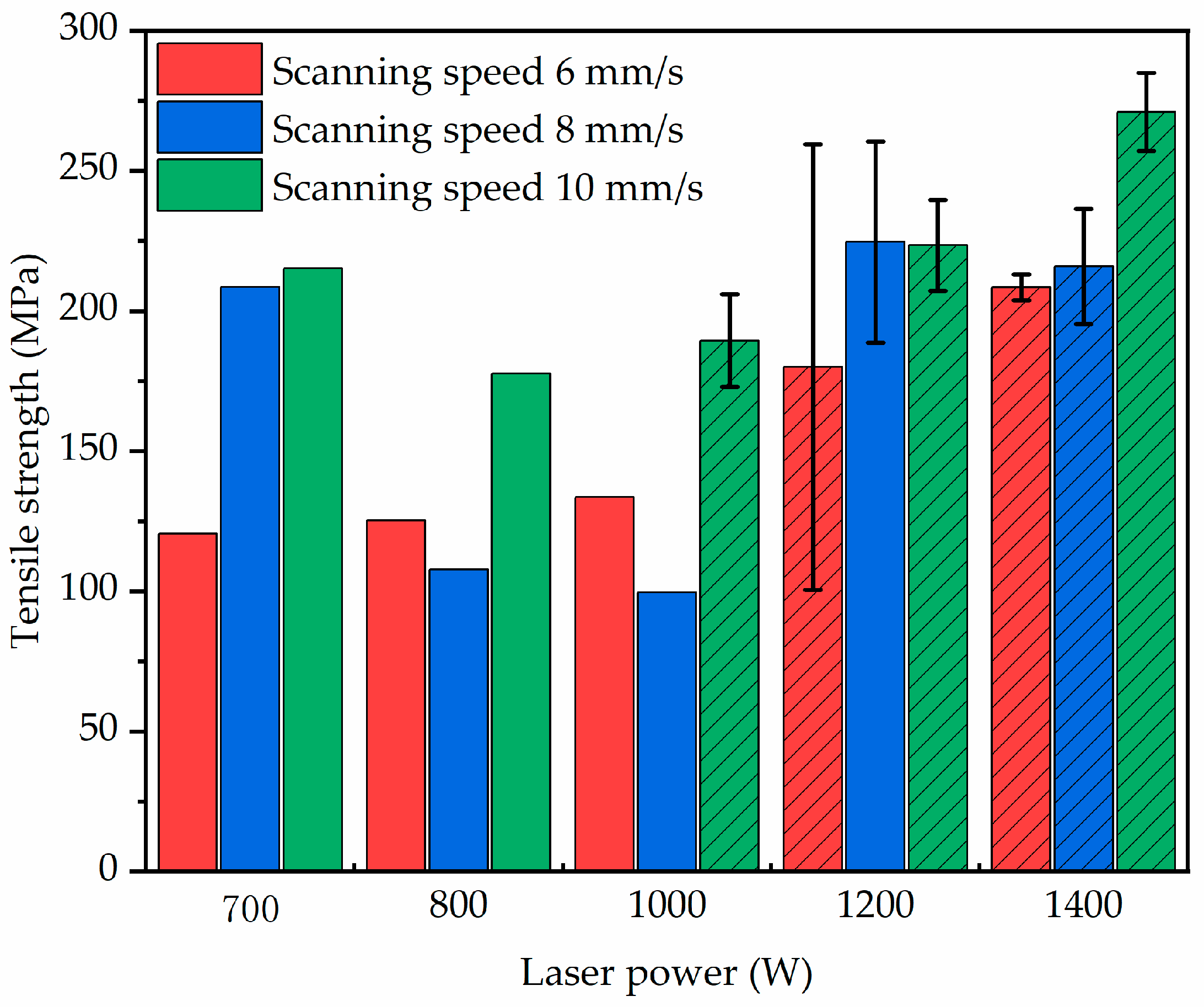

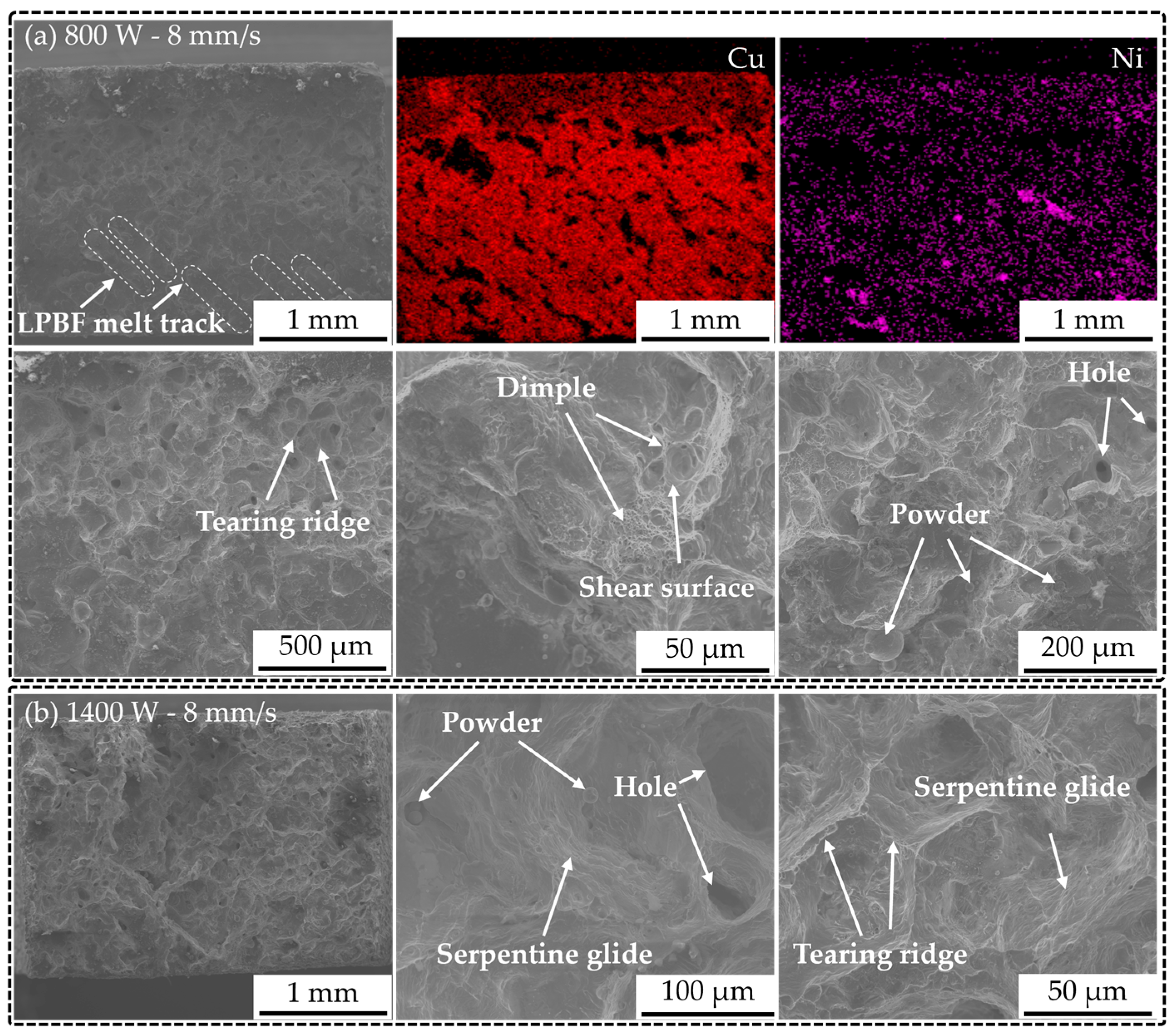

3.3.3. Mechanical Properties

4. Discussion

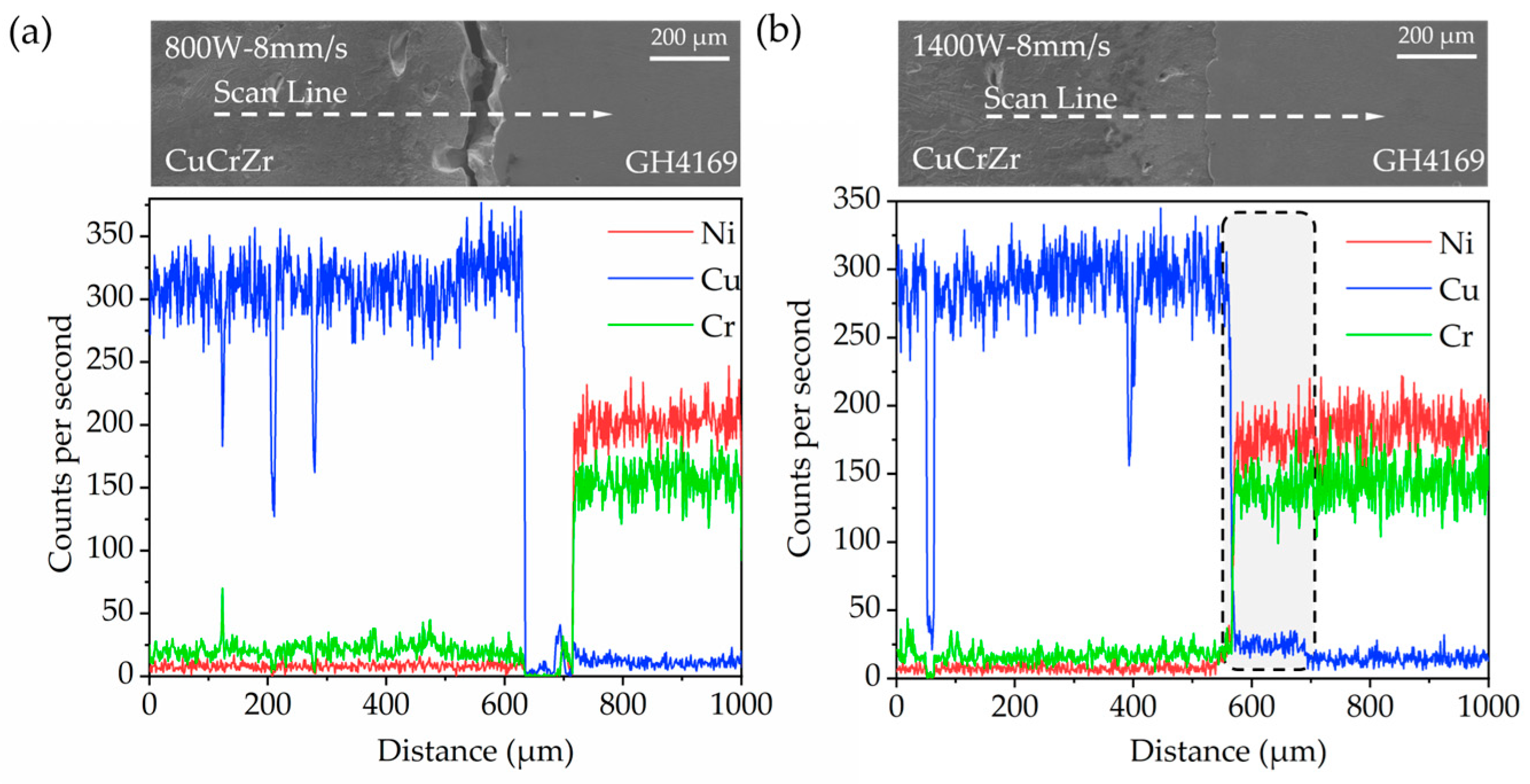

4.1. Compatibility of CuCrZr/GH4169 Multi-Material Structures

4.2. Behavior of the Melt Pool and Defect Formation in a Matrix with High Thermal Conductivity and High Reflectivity

4.3. Stress at the CuCrZr/GH4169 Multi-Material Interface

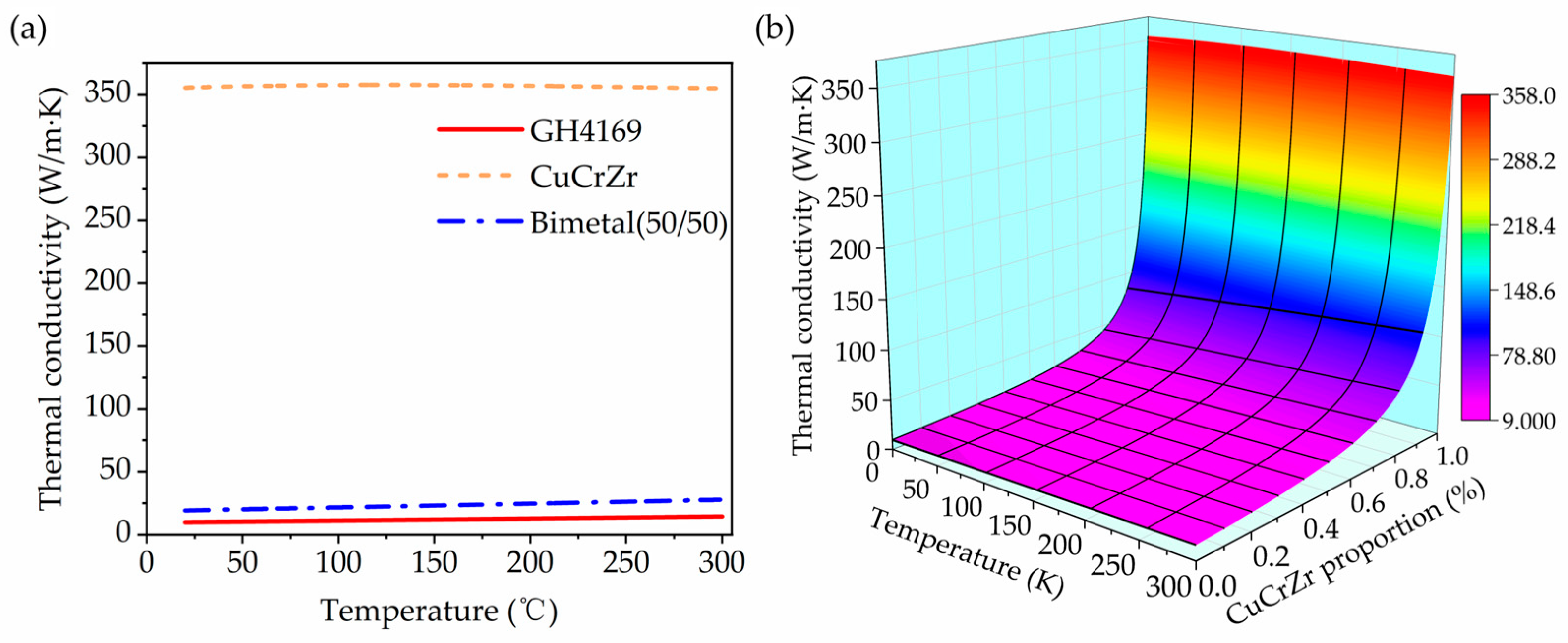

4.4. Thermal Conductivity of CuCrZr/GH4169 Multi-Materials

5. Conclusions

- Due to the good compatibility between Cu and Ni at high temperatures, GH4169 and CuCrZr can bond effectively over a wide range of process parameters. At laser line energy densities above 140 J/mm, a strong bond is achieved with minimal defects in the overlap regions between adjacent melt tracks. However, at low laser powers, issues such as porosity, poor bonding, and even cracking occur. In these cases, the interface lacks a distinct transition zone, and the hardness variation across the interface is abrupt. Conversely, high laser power results in a better interface, with Cu segregation phases present in the transition zone, measuring 100–200 μm in width. The microhardness profile near the interface shows a gradual increase, and tensile tests typically fracture on the CuCrZr side, with an average tensile strength of 234 MPa.

- Mechanism of Defect Formation at the Interface Clarified for High-Conductivity Substrate. Systematic analysis revealed that CuCrZr’s high thermal conductivity (354 W/m·K) and low infrared absorptivity limited melt pool energy accumulation, leading to incomplete fusion and crack formation under low laser power. Elevated laser power (≥1200 W) suppressed such defects by shifting the melt pool behavior toward sufficient mixing and Marangoni-driven convection, enabling stable LDED on reflective substrates.

- Thermal Conductivity and Mechanical Performance Balance: Adjusting the thickness ratio of GH4169 and CuCrZr in the bimaterial structure effectively tunes the thermal conductivity. A 50/50 thickness ratio achieves a thermal conductivity approximately twice that of GH4169. However, enhancements in thermal conductivity are often accompanied by reductions in mechanical strength. Therefore, balancing thermal and mechanical properties is crucial to meet the practical requirements of bimaterial components.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gu, D.; Shi, X.; Poprawe, R.; Bourell, D.L.; Setchi, R.; Zhu, J. Material-structure-performance integrated laser-metal additive manufacturing. Science 2021, 372, eabg1487. [Google Scholar] [CrossRef]

- Onuike, B.; Heer, B.; Bandyopadhyay, A. Additive manufacturing of Inconel 718—Copper alloy bimetallic structure using laser engineered net shaping (LENS™). Addit. Manuf. 2018, 21, 133–140. [Google Scholar] [CrossRef]

- Zhang, B.; Xiao, H.; Zhang, W.; Yang, H.; Wang, Y.; Peng, D.; Zhu, H.; Chen, B. Influence of the thermal conductivity of different CuCr0. 8 substrate state on the formability of laser directed energy deposition Inconel718 single track. Mater. Charact. 2023, 202, 113015. [Google Scholar] [CrossRef]

- Tan, C.; Weng, F.; Sui, S.; Chew, Y.; Bi, G. Progress and perspectives in laser additive manufacturing of key aeroengine materials. Int. J. Mach. Tools Manuf. 2021, 170, 103804. [Google Scholar] [CrossRef]

- Verma, A.; Kapil, A.; Klobčar, D.; Sharma, A. A review on multiplicity in multi-material additive manufacturing: Process, capability, scale, and structure. Materials 2023, 16, 5246. [Google Scholar] [CrossRef] [PubMed]

- Repnin, A.; Borisov, E.; Popovich, A. Formation of the Cu+ Nb Interlayer in the Inconel 718/Ti6Al4V Multi-Material Obtained by Selective Laser Melting. Materials 2024, 17, 5801. [Google Scholar] [CrossRef]

- Melzer, D.; Džugan, J.; Koukolíková, M.; Rzepa, S.; Vavřík, J. Structural integrity and mechanical properties of the functionally graded material based on 316L/IN718 processed by DED technology. Mater. Sci. Eng. A 2021, 811, 141038. [Google Scholar] [CrossRef]

- Nabavi, S.F.; Farshidianfar, A.; Dalir, H. Comprehensive review: Advancements in modeling geometrical and mechanical characteristics of laser powder bed fusion process. Opt. Laser Technol. 2025, 180, 111480. [Google Scholar] [CrossRef]

- Imran, M.M.; Che Idris, A.; De Silva, L.C.; Kim, Y.-B.; Abas, P.E. Advancements in 3D printing: Directed energy deposition techniques, defect analysis, and quality monitoring. Technologies 2024, 12, 86. [Google Scholar] [CrossRef]

- Yadav, P.; Rigo, O.; Arvieu, C.; Lacoste, E. Feasibility Study of Advanced Manufacturing Processes: Integrating LPBF and LMD for Inconel 718. J. Adv. Join. Process. 2025, 11, 100296. [Google Scholar] [CrossRef]

- Gong, J.; Wei, K.; Liu, M.; Song, W.; Li, X.; Zeng, X. Microstructure and mechanical properties of AlSi10Mg alloy built by laser powder bed fusion/direct energy deposition hybrid laser additive manufacturing. Addit. Manuf. 2022, 59, 103160. [Google Scholar] [CrossRef]

- Zhang, B.; Zhang, W.; Xiao, H.; Zhu, H.; Yang, H.; Wang, Y.; Chen, B. QCr0. 8 Cu alloy/S06 stainless steel bimetal structure via In718 multi-interlayer fabricated by laser powder hybrid additive manufacturing. J. Mater. Res. Technol. 2023, 24, 1034–1042. [Google Scholar] [CrossRef]

- Bettencourt, C.J. Mechanical Properties and Microstructure of Multi-Materials Fabricated Through a Combination of LPBF and DED Additive Manufacturing Techniques. Master’s Thesis, Utah State University, Logan, UT, USA, 2024. [Google Scholar] [CrossRef]

- Montero-Sistiaga, M.; Osinga, T.; Haagsma, R.; Bottazzi, O.; Esveldt, V.; Bautmans, L.; Hamer, W.; de Smit, M. Hybrid and Multi-Material Production of a Check Valve Combining Laser Powder Bed Fusion and Directed Energy Deposition Technologies. In Proceedings of the Euro PM2024, Malmo, Sweden, 29 September–2 October 2024. [Google Scholar] [CrossRef]

- Gradl, P.R.; Protz, C.; Fikes, J.; Ellis, D.; Evans, L.; Clark, A.; Miller, S.; Hudson, T. Lightweight thrust chamber assemblies using multi-alloy additive manufacturing and composite overwrap. In Proceedings of the AIAA Propulsion and Energy 2020 Forum, Virtual Event, 24–28 August 2020; p. 3787. [Google Scholar]

- Zhang, L.; Dong, P.; Zeng, Y.; Yao, H.; Chen, J. Additive manufacturing of Inconel 718/CuCrZr multi-metallic materials fabricated by laser powder bed fusion. Addit. Manuf. 2024, 92, 104377. [Google Scholar] [CrossRef]

- Hasanov, S.; Alkunte, S.; Rajeshirke, M.; Gupta, A.; Huseynov, O.; Fidan, I.; Alifui-Segbaya, F.; Rennie, A. Review on additive manufacturing of multi-material parts: Progress and challenges. J. Manuf. Mater. Process. 2021, 6, 4. [Google Scholar] [CrossRef]

- ZainElabdeen, I.H.; Ismail, L.; Mohamed, O.F.; Khan, K.A.; Schiffer, A. Recent advancements in hybrid additive manufacturing of similar and dissimilar metals via laser powder bed fusion. Mater. Sci. Eng. A 2024, 909, 146833. [Google Scholar] [CrossRef]

- Li, Z.; Kuai, Z.; Liu, B.; Chen, Y.; Li, H.; Wang, Y.; Huo, W.; Wei, M.; Yang, H.; Bai, P. Selective laser melting of 316L–CuCrZr bimetallic structure via IN718 transition layer. J. Mater. Res. Technol. 2023, 25, 3819–3834. [Google Scholar] [CrossRef]

- Yi, J.; Kang, J.; Wang, T.; Wang, X.; Hu, Y.; Feng, T.; Feng, Y.; Wu, P. Effect of laser energy density on the microstructure, mechanical properties, and deformation of Inconel 718 samples fabricated by selective laser melting. J. Alloys Compd. 2019, 786, 481–488. [Google Scholar] [CrossRef]

- Zhang, D.; Liu, A.; Yin, B.; Wen, P. Additive manufacturing of duplex stainless steels-a critical review. J. Manuf. Process. 2022, 73, 496–517. [Google Scholar] [CrossRef]

- Tang, X.; Chen, X.; Sun, F.; Li, L.; Liu, P.; Zhou, H.; Fu, S.; Li, A. A study on the mechanical and electrical properties of high-strength CuCrZr alloy fabricated using laser powder bed fusion. J. Alloys Compd. 2022, 924, 166627. [Google Scholar] [CrossRef]

- Bai, Y.; Zhao, C.; Zhang, Y.; Chen, J.; Wang, H. Additively manufactured CuCrZr alloy: Microstructure, mechanical properties and machinability. Mater. Sci. Eng. A 2021, 819, 141528. [Google Scholar] [CrossRef]

- Zhou, H.; Yang, Y.; Han, C.; Wei, Y.; Liu, Z.; Tai, Z.; Zhang, S.; Wang, D. Laser directed energy deposition/milling hybrid additive manufacturing of thin-walled GH4169 alloy: Effect of processing strategy on its microstructure and mechanical properties. Mater. Sci. Eng. A 2023, 882, 145480. [Google Scholar] [CrossRef]

- Li, J.; Kuai, Z.; Li, Z.; Liu, B.; Chen, Y.; Lu, S.; Nie, Y.; Yang, Z. Effects of process parameters on the relative density and properties of CuCrZr alloy produced by selective laser melting. Metals 2022, 12, 701. [Google Scholar] [CrossRef]

- Xu, L.; Zhang, Y.; Zhao, L.; Ren, W.; Han, Y. Performance improvement for the CuCrZr alloy produced by laser powder bed fusion using the remelting process. Materials 2024, 17, 624. [Google Scholar] [CrossRef] [PubMed]

- Biffi, C.A.; Fiocchi, J.; Boldrini, S.; Tuissi, A. CuCrZr alloy manufactured by LPBF process: Correlation between microstructure, mechanical and thermal properties. Lasers Manuf. Mater. Process. 2024, 11, 143–153. [Google Scholar] [CrossRef]

- Fang, X.; Xia, W.; Wei, Q.; Wu, Y.; Lv, W.; Guo, W. Preparation of Cu-Cr-Zr alloy by laser powder bed fusion: Parameter optimization, microstructure, mechanical and thermal properties for microelectronic applications. Metals 2021, 11, 1410. [Google Scholar] [CrossRef]

- Zhang, X.; Sun, C.; Pan, T.; Flood, A.; Zhang, Y.; Li, L.; Liou, F. Additive manufacturing of copper–H13 tool steel bi-metallic structures via Ni-based multi-interlayer. Addit. Manuf. 2020, 36, 101474. [Google Scholar] [CrossRef]

- Baker, H.; Okamoto, H. ASM Handbook. Vol. 3. Alloy Phase Diagrams; ASM International: Novelty, OH, USA, 1992. [Google Scholar]

- King, J.; Sullivan, M.; Slaughter, G. Development of an improved stainless steel to ferritic steel transition joint. Weld. J. 1977, 56, 354–358. [Google Scholar]

- Svetlizky, D.; Das, M.; Zheng, B.; Vyatskikh, A.L.; Bose, S.; Bandyopadhyay, A.; Schoenung, J.M.; Lavernia, E.J.; Eliaz, N. Directed energy deposition (DED) additive manufacturing: Physical characteristics, defects, challenges and applications. Mater. Today 2021, 49, 271–295. [Google Scholar] [CrossRef]

- Brueckner, F.; Riede, M.; Müller, M.; Marquardt, F.; Willner, R.; Seidel, A.; Lopéz, E.; Leyens, C.; Beyer, E. Enhanced manufacturing possibilities using multi-materials in laser metal deposition. J. Laser Appl. 2018, 30, 032308. [Google Scholar] [CrossRef]

- Bertoli, U.S.; Wolfer, A.J.; Matthews, M.J.; Delplanque, J.-P.R.; Schoenung, J.M. On the limitations of volumetric energy density as a design parameter for selective laser melting. Mater. Des. 2017, 113, 331–340. [Google Scholar] [CrossRef]

- King, W.E.; Barth, H.D.; Castillo, V.M.; Gallegos, G.F.; Gibbs, J.W.; Hahn, D.E.; Kamath, C.; Rubenchik, A.M. Observation of keyhole-mode laser melting in laser powder-bed fusion additive manufacturing. J. Mater. Process. Technol. 2014, 214, 2915–2925. [Google Scholar] [CrossRef]

- Reichardt, A.; Shapiro, A.A.; Otis, R.; Dillon, R.P.; Borgonia, J.P.; McEnerney, B.W.; Hosemann, P.; Beese, A.M. Advances in additive manufacturing of metal-based functionally graded materials. Int. Mater. Rev. 2021, 66, 1–29. [Google Scholar] [CrossRef]

- Kruth, J.-P.; Froyen, L.; Van Vaerenbergh, J.; Mercelis, P.; Rombouts, M.; Lauwers, B. Selective laser melting of iron-based powder. J. Mater. Process. Technol. 2004, 149, 616–622. [Google Scholar] [CrossRef]

- Pintsuk, G.; Blumm, J.; Hohenauer, W.; Hula, R.C.; Koppitz, T.; Lindig, S.; Pitzer, D.; Rohde, M.; Schoderböck, P.; Schubert, T. Interlaboratory test on thermophysical properties of the ITER grade heat sink material copper–chromium–zirconium. Int. J. Thermophys. 2010, 31, 2147–2158. [Google Scholar] [CrossRef]

- Agazhanov, A.S.; Samoshkin, D.; Kozlovskii, Y.M. Thermophysical properties of Inconel 718 alloy. J. Phys. Conf. Ser. 2019, 1382, 012175. [Google Scholar] [CrossRef]

| CuCrZr (LPBF) | Cr | Zr | Fe | Si | P | Cu |

| 0.5–1.5 | 0.05–0.25 | <0.05 | <0.05 | <0.01 | Bal | |

| GH4169 (LDED) | C | Cr | Ni | Nb | Mo | Ti |

| 0.02–0.06 | 17.0–20.0 | 50.0–55.0 | 5.0–5.5 | 2.8–3.3 | 0.65–1.15 | |

| Al | Co | Si | Mg | Cu | Fe | |

| 0.2–0.8 | ≤1.00 | ≤0.35 | ≤0.01 | ≤0.3 | Bal |

| Process Parameters | CuCrZr (LPBF) | GH4169 (LDED) | |

|---|---|---|---|

| Interface Integration Process | Thin-Walled Solid Process | ||

| Laser power (W) | 400 | 700, 800, 1000, 1200, 1400 | 1000 |

| Scanning speed (mm/s) | 900 | 6, 8, 10 | 10 |

| Scanning spacing (mm) | 0.11 | 2 | — |

| Layer height (mm) | 0.03 | — | 0.36 |

| Powder feed rate (g/min) | — | 11.76 | |

| Scanning strategy | Partition and interlayer orthogonal scanning | Interlayer bidirectional scanning | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, D.; Lv, J.; Liu, Z.; Liu, L.; Wei, Y.; Chang, C.; Zhou, W.; Zhang, Y.; Han, C. Interface Optimization, Microstructural Characterization, and Mechanical Performance of CuCrZr/GH4169 Multi-Material Structures Manufactured via LPBF-LDED Integrated Additive Manufacturing. Materials 2025, 18, 2206. https://doi.org/10.3390/ma18102206

Wang D, Lv J, Liu Z, Liu L, Wei Y, Chang C, Zhou W, Zhang Y, Han C. Interface Optimization, Microstructural Characterization, and Mechanical Performance of CuCrZr/GH4169 Multi-Material Structures Manufactured via LPBF-LDED Integrated Additive Manufacturing. Materials. 2025; 18(10):2206. https://doi.org/10.3390/ma18102206

Chicago/Turabian StyleWang, Di, Jiale Lv, Zhenyu Liu, Linqing Liu, Yang Wei, Cheng Chang, Wei Zhou, Yingjie Zhang, and Changjun Han. 2025. "Interface Optimization, Microstructural Characterization, and Mechanical Performance of CuCrZr/GH4169 Multi-Material Structures Manufactured via LPBF-LDED Integrated Additive Manufacturing" Materials 18, no. 10: 2206. https://doi.org/10.3390/ma18102206

APA StyleWang, D., Lv, J., Liu, Z., Liu, L., Wei, Y., Chang, C., Zhou, W., Zhang, Y., & Han, C. (2025). Interface Optimization, Microstructural Characterization, and Mechanical Performance of CuCrZr/GH4169 Multi-Material Structures Manufactured via LPBF-LDED Integrated Additive Manufacturing. Materials, 18(10), 2206. https://doi.org/10.3390/ma18102206