Research on Anti-Slip and Wear Resistance of Concrete Pavement After Optimization of Stone-Planting Process

Abstract

1. Introduction

2. Materials and Tests

2.1. Materials

2.1.1. Cement

2.1.2. Silica Fume

2.1.3. Coarse Aggregates

2.1.4. Fine Aggregates

2.1.5. External Admixtures

2.1.6. Stone Planting

2.2. Stone-Planting Process

2.3. Stone-Planting Parameters

2.3.1. Stone Spreading Area

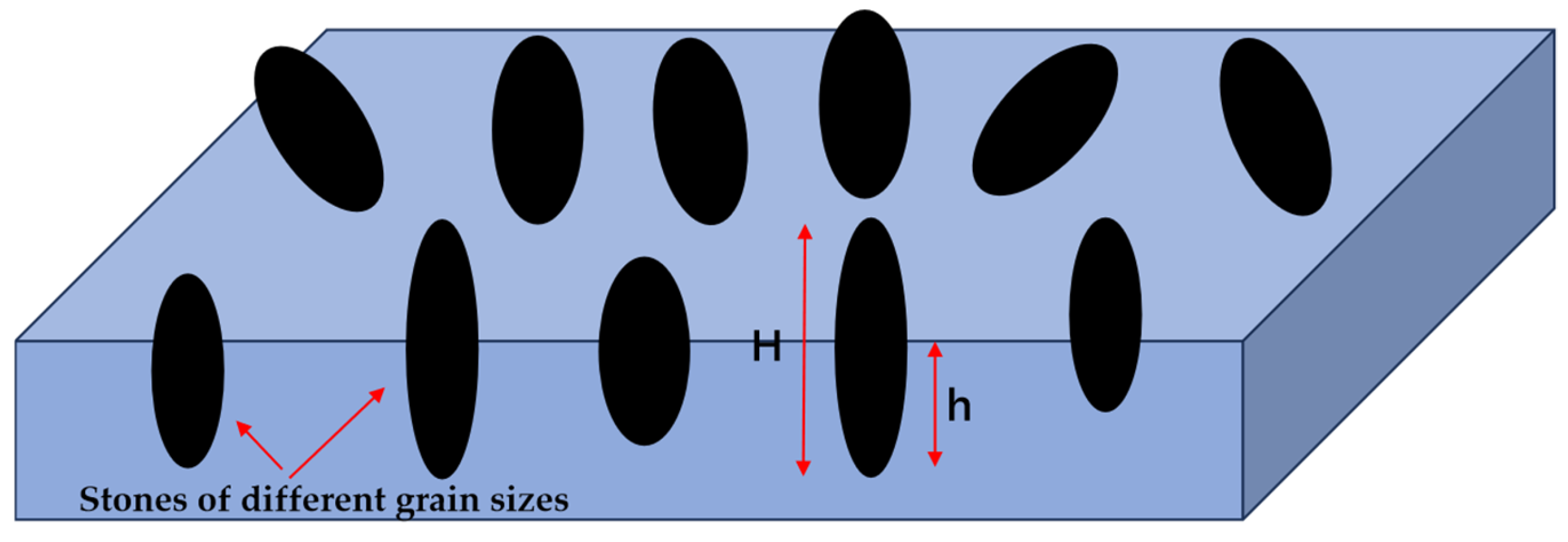

2.3.2. Indentation Depth

2.3.3. Types of Planting Stone

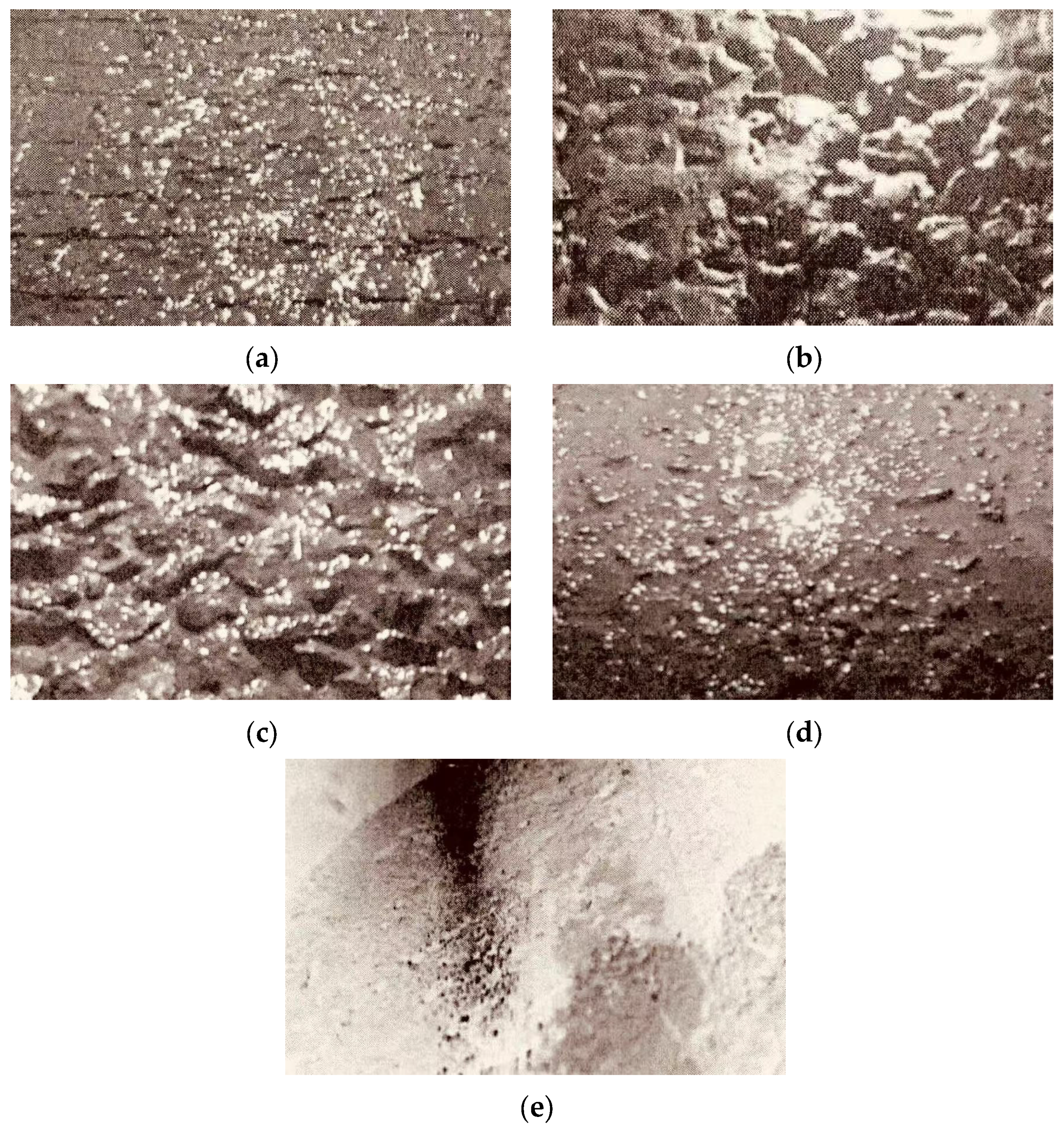

2.3.4. Surface Treatment of Planted Stones

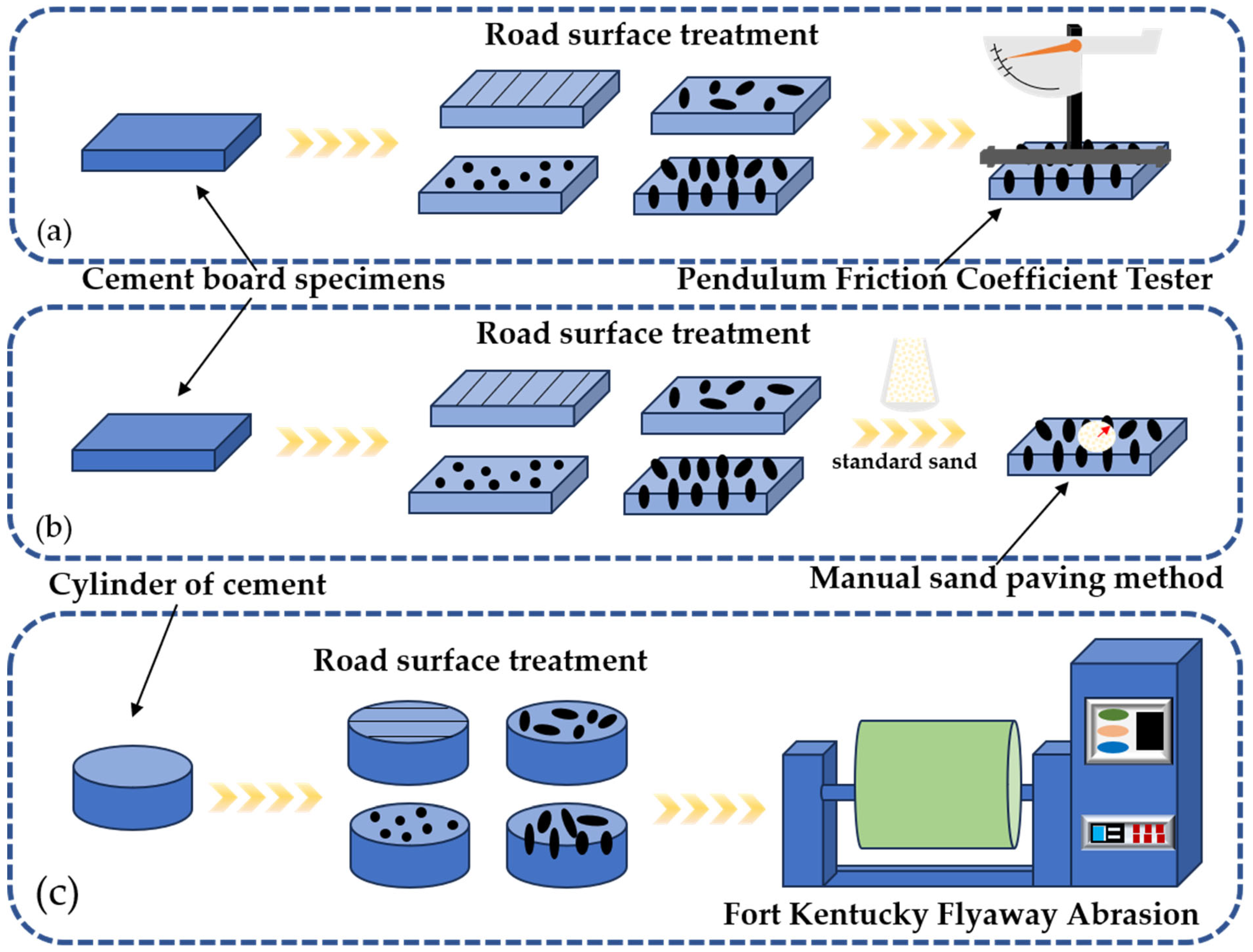

2.4. Planted Stone Anti-Slip and Abrasion Test

2.4.1. Pendulum Friction Coefficient

- F—value of the pendulum;

- W—mass of the pendulum in grams (g);

- H—distance from the center of gravity of the pendulum to the axis of oscillation in millimeters (mm);

- Z—the vertical distance below the zero position of the dial in millimeters (mm);

- P—the positive static pressure of the rubber sheet on the surface of the object to be measured, in Nm (N);

- D—sliding length of the rubber sheet on the road surface, in millimeters (mm);

- M—distance from the tip of the dial pointer to the center of rotation of the pointer, in millimeters (mm).

2.4.2. Manual Sand-Paving Method

- TD—texture depth of concrete surface in millimeters (mm);

- V—volume of sand and gravel, in millimeters (mm);

- D—sand surface diameter, in centimeters (cm).

2.4.3. Fort Kentucky Flyaway Abrasion Test

- —cement concrete flyaway losses (%);

- m0—quality of the specimen before the test (g);

- m1—mass of specimen remaining after test (g).

3. Results and Analysis

3.1. Analysis of Slip Resistance of Stone-Planted Cement Concrete

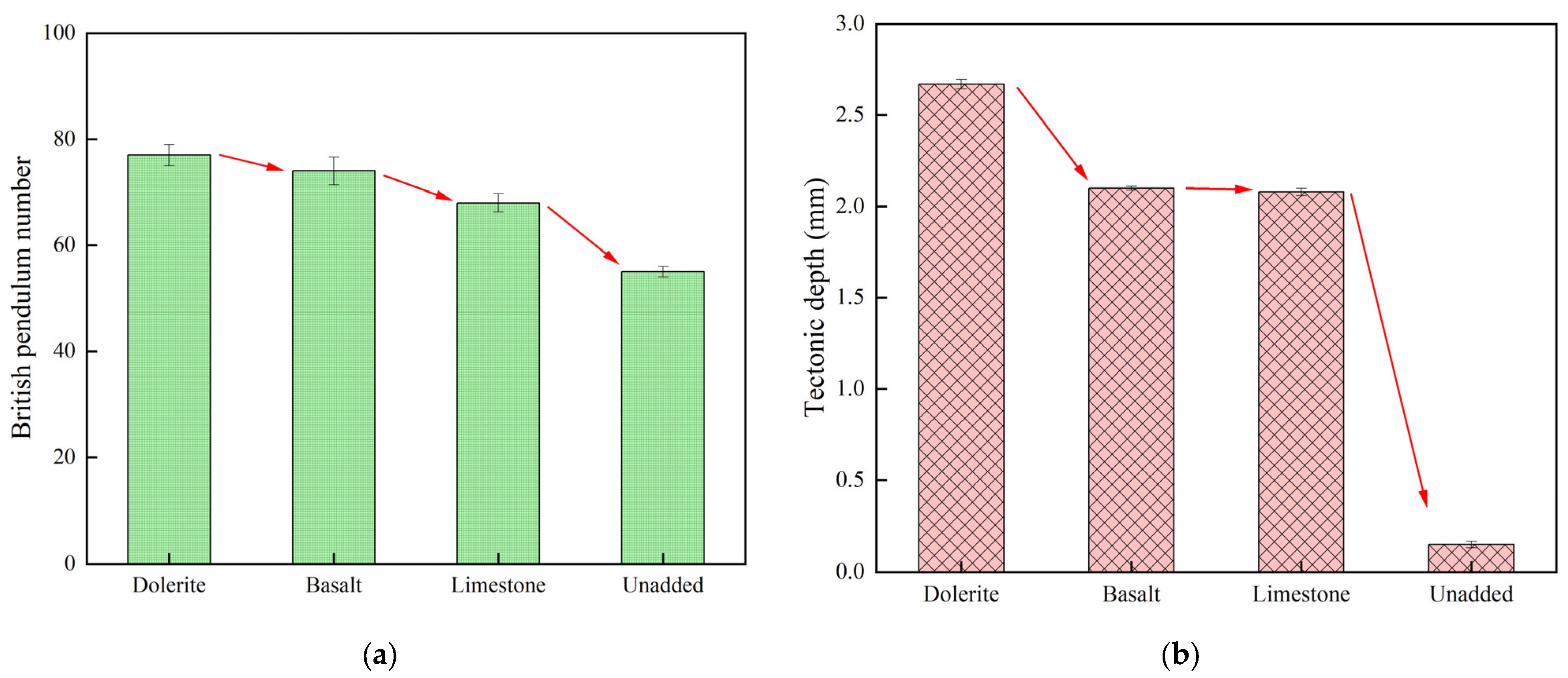

3.1.1. Effect of Stone Type on Anti-Slip Properties

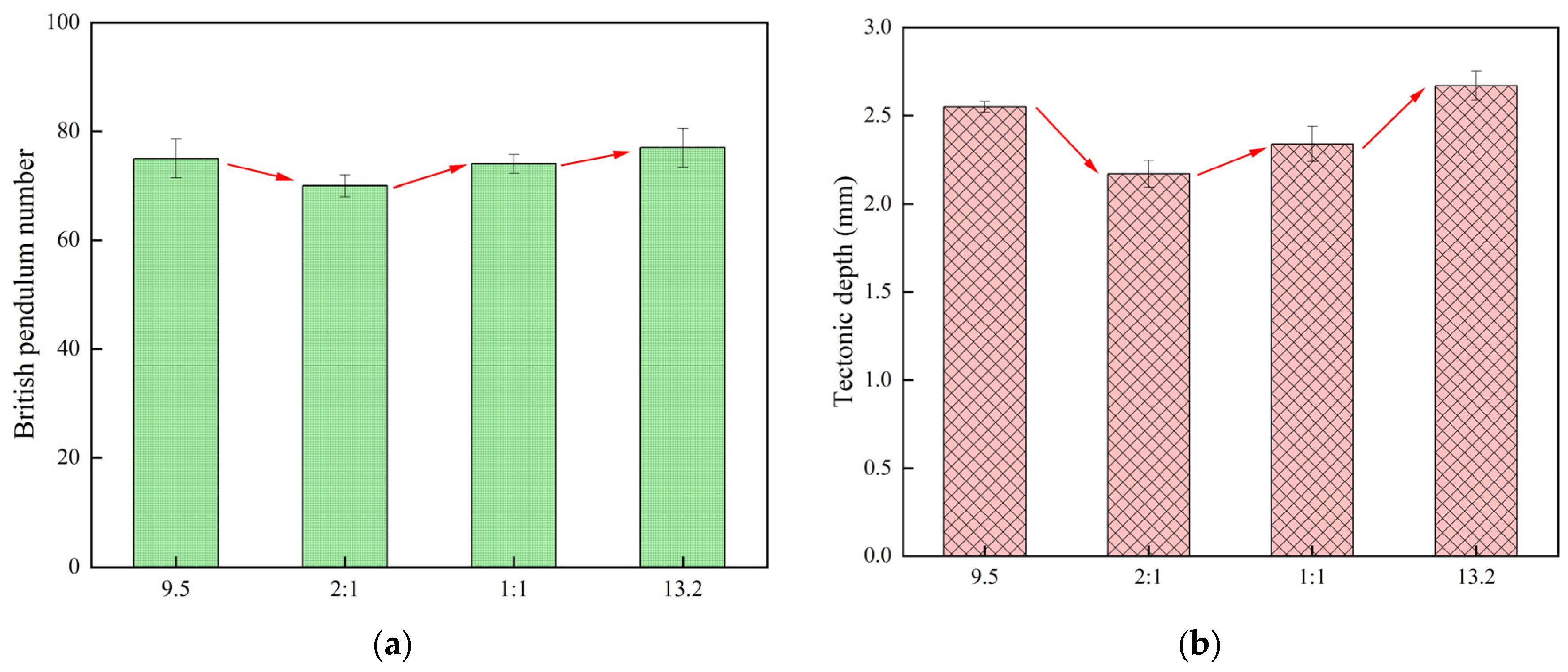

3.1.2. Effect of Stone Particle Size on Anti-Slip Properties

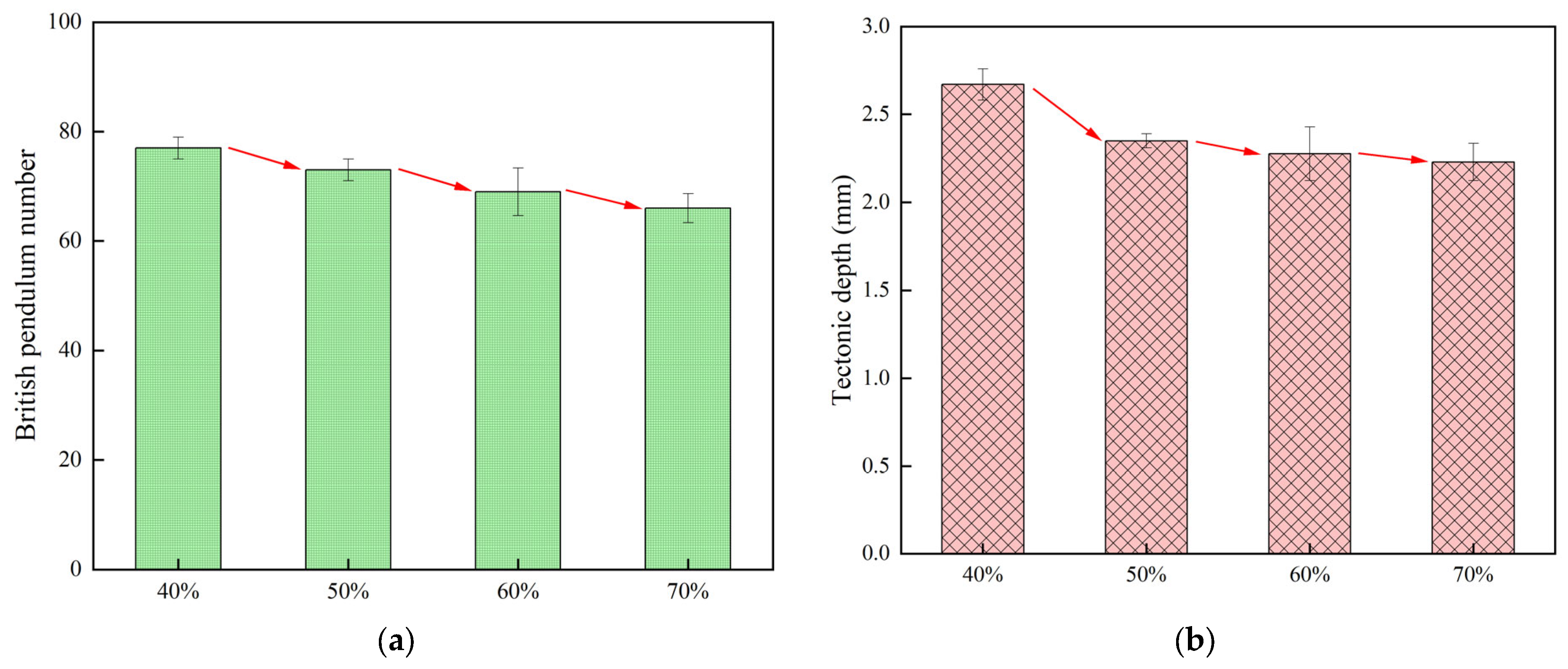

3.1.3. Effect of Stone Cover on Anti-Slip Performance

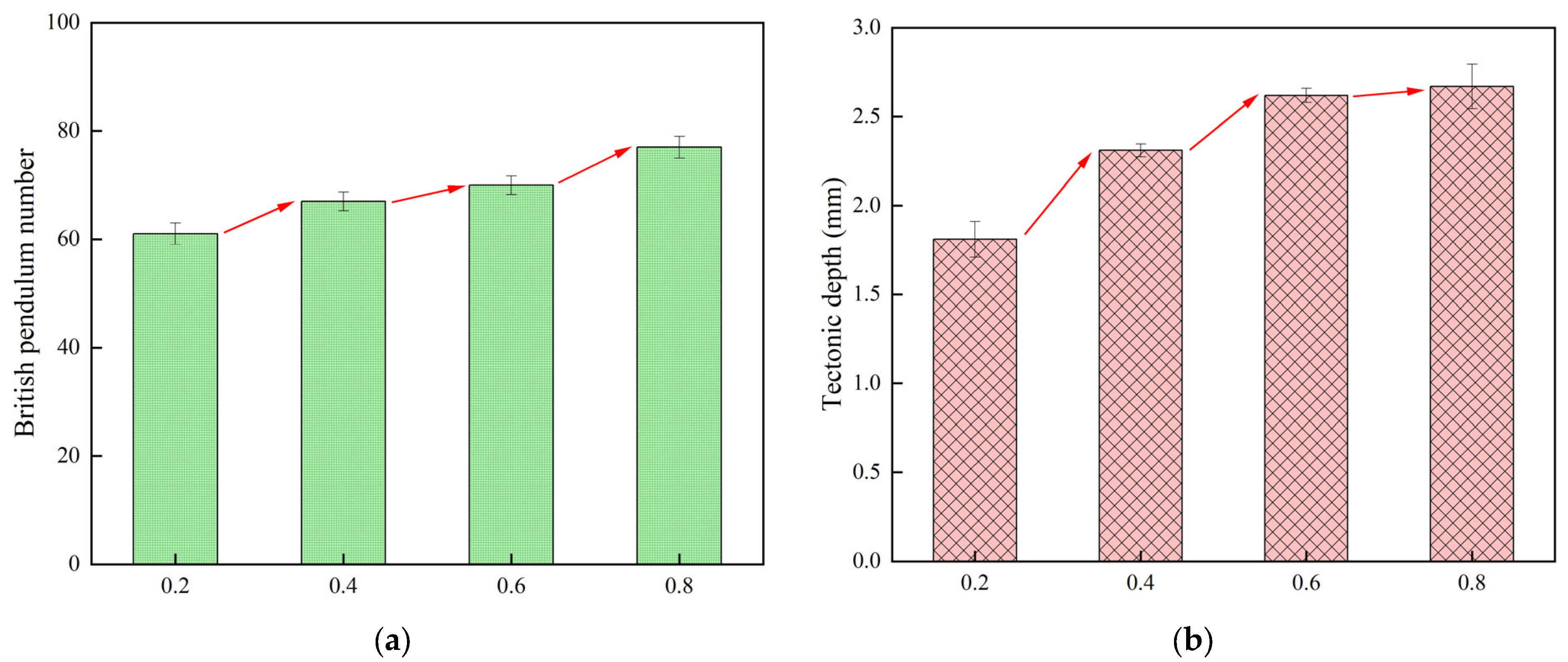

3.1.4. Effect of Stone Indentation Depth on Anti-Slip Performance

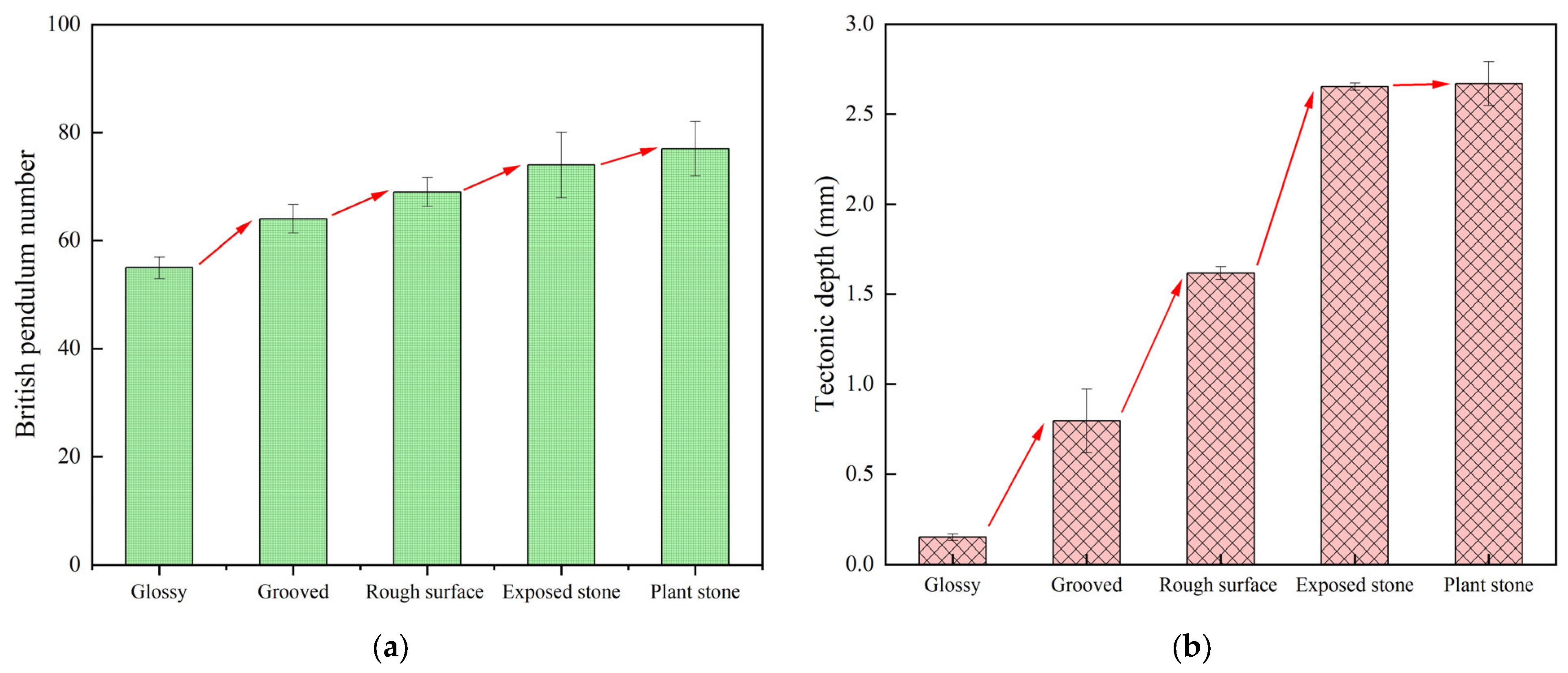

3.1.5. Effect of Surface Treatment on Anti-Slip Properties

3.2. Analysis of the Abrasion Resistance of Stone-Planted Cement Concrete

3.2.1. The Effect of Material Type on Abrasion Performance

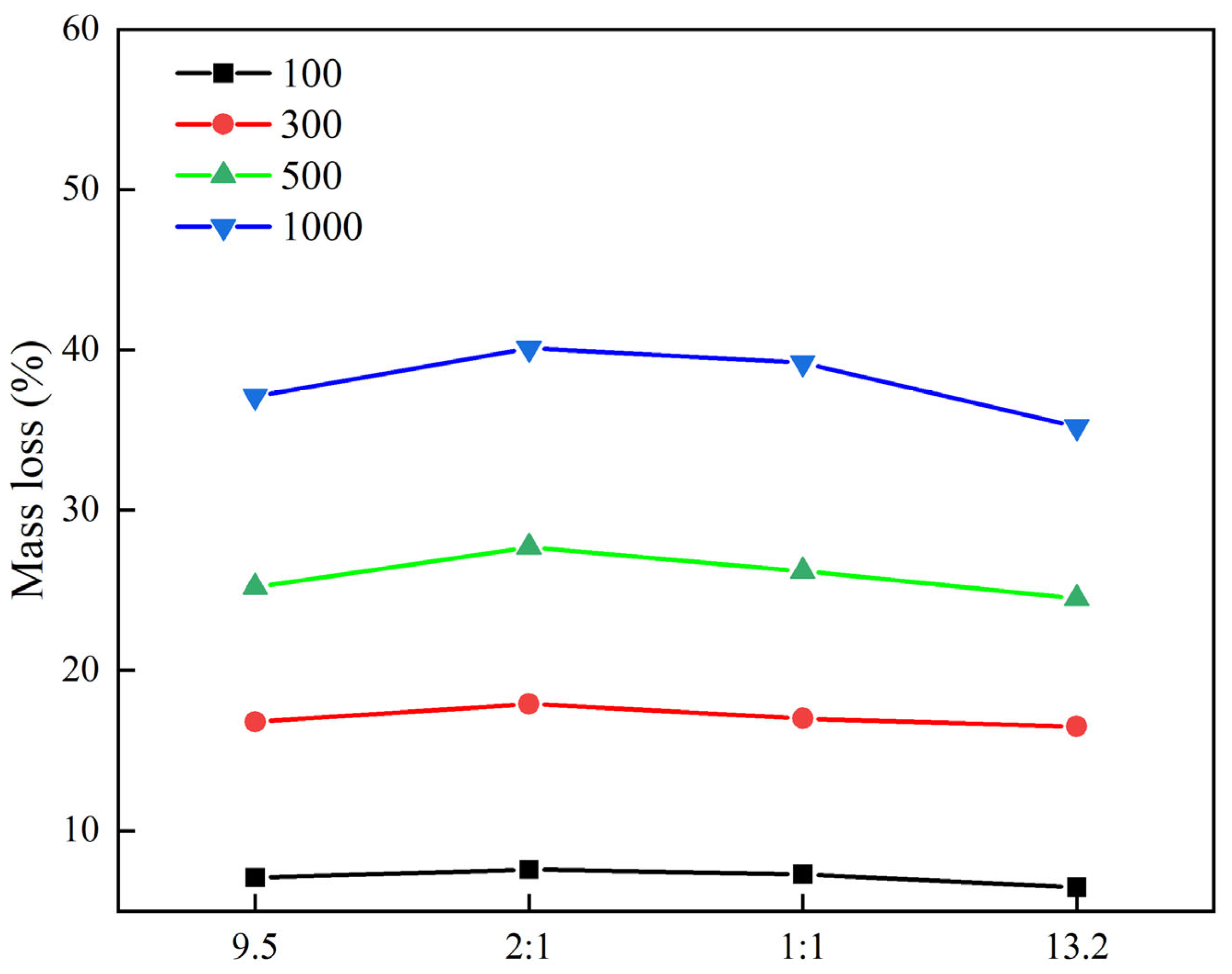

3.2.2. Effect of Stone Particle Size on Wear Resistance

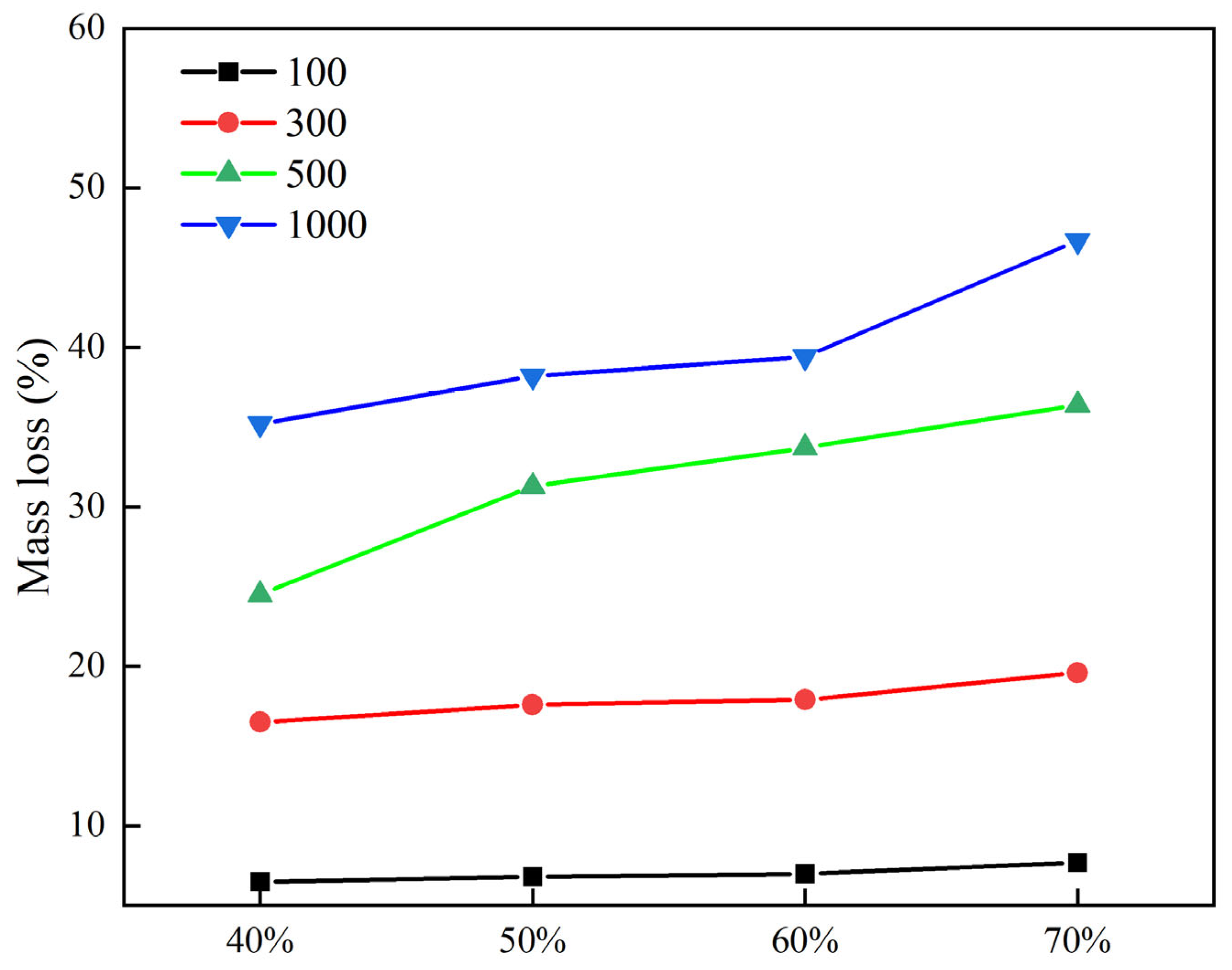

3.2.3. Effect of Stone Spreading Area on Wear Resistance

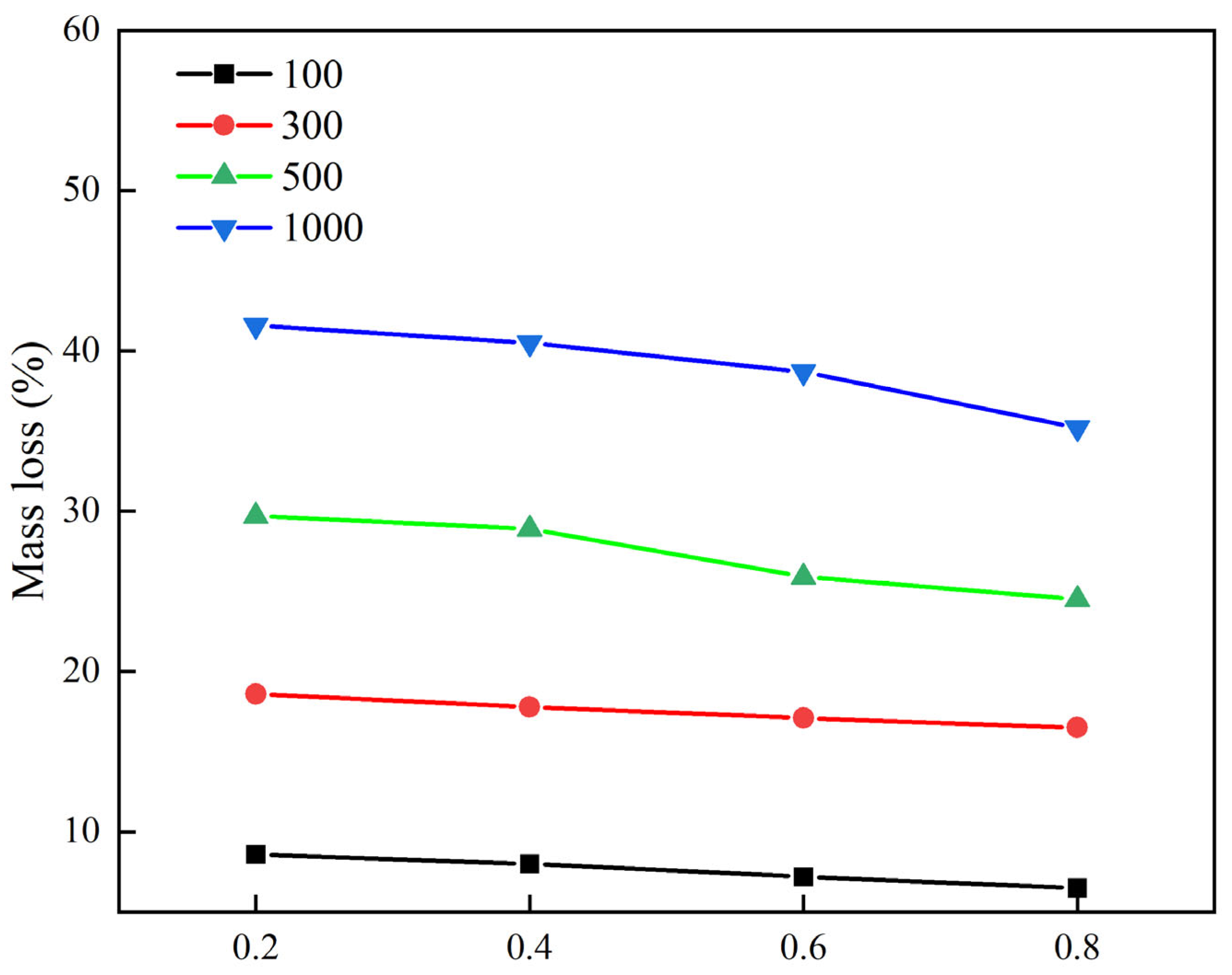

3.2.4. Effect of Stone Loading Depth on Wear Resistance

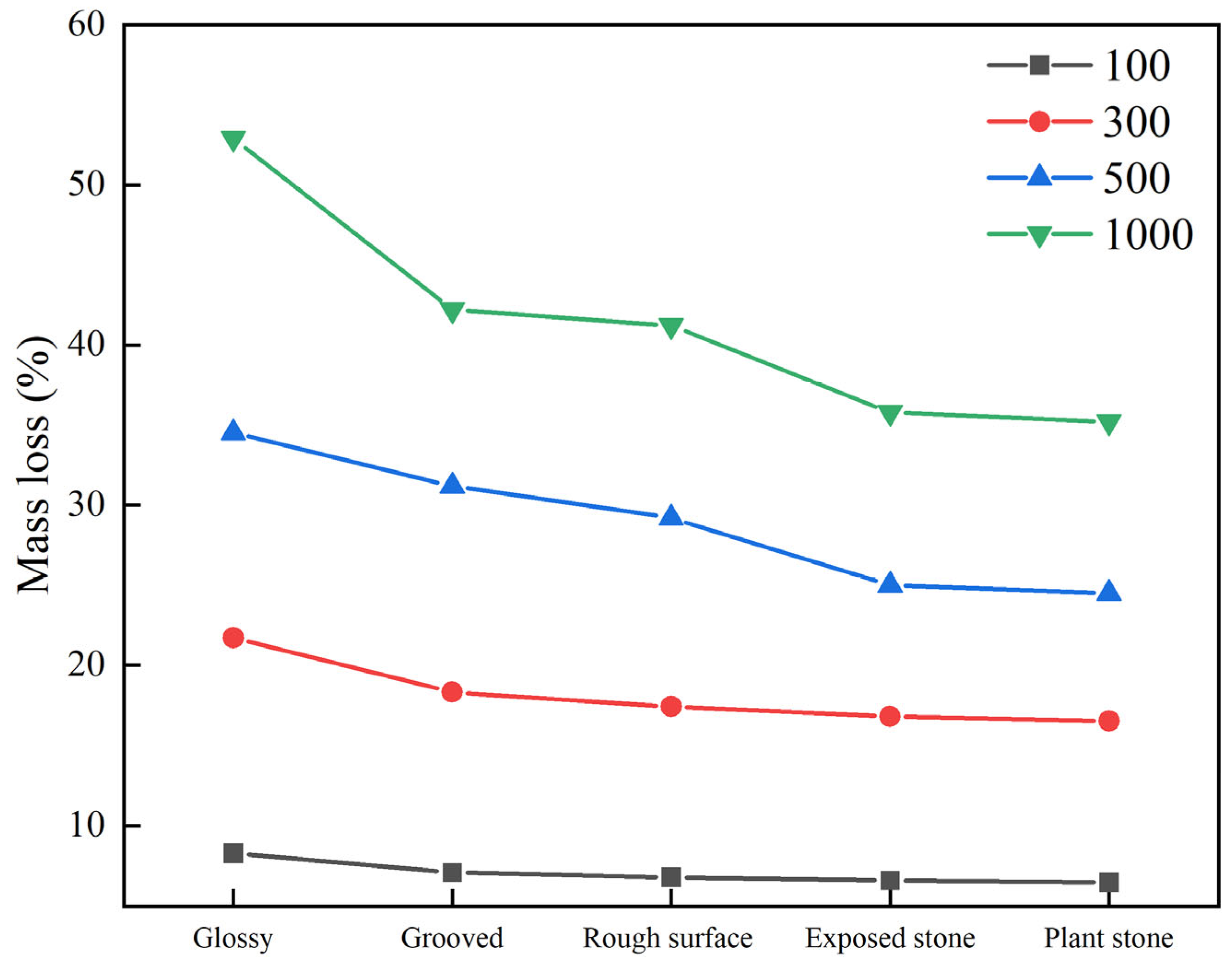

3.2.5. Effect of Different Surface Treatment Processes on Wear Resistance

4. Conclusions

- (1)

- It is concluded from the experimental analysis that dolerite, relative to basalt and limestone, blended into high-flow concrete will provide higher skid resistance and is an ideal type of stone-planting material.

- (2)

- When dolerite is selected as the stone-planting material, the best anti-slip effect can be obtained when the stone spreading rate is 40%, the stone particle size grading is 13.2 mm, and the value of the stone pressed into the pavement with the depth of indentation is 0.8.

- (3)

- The pendulum value of the pavement treated with stone planting increased by 40%, and the construction depth increased by 16.8 times relative to the bare pavement.

- (4)

- The fort Kentucky flyaway test discovered that, under the same process conditions, the planted stone material being gabbro had a stone spreading area of 40%, stone size gradation of 13.2 mm, indentation depth ratio of 0.8, and the best wear-resistant cement concrete panels.

- (5)

- Concrete stone-planting technology reduces the input of labor and machinery and improves the construction efficiency and construction process. At the same time, the application of stone-planting technology gives it excellent road performance such as anti-skid and wear resistance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bassan, S. Overview of traffic safety aspects and design in road tunnels. IATSS Res. 2016, 40, 35–46. [Google Scholar] [CrossRef]

- Wang, G.; Fang, Q.; Du, J.M.; Wang, J.; Li, Q.M. Deep learning-based prediction of steady surface settlement due to shield tunnelling. Autom. Constr. 2023, 154, 105006. [Google Scholar] [CrossRef]

- Qian, C.; Chen, J.; Luo, Y.; Zhao, Z. Monitoring and analysis of the operational environment in an extra-long highway tunnel with longitudinal ventilation. Tunn. Undergr. Space Technol. 2019, 83, 475–484. [Google Scholar] [CrossRef]

- Fang, Q.; Liu, X.; Zeng, K.H.; Zhang, X.D.; Zhou, M.Z.; Du, J.M. Centrifuge modelling of tunnelling below existing twin tunnels with different types of support. Undergr. Space 2022, 7, 1125–1138. [Google Scholar] [CrossRef]

- Zhang, D.; Zhang, K.; Zhang, Y. Evolution of aging depth gradient distribution in SBS-modified bitumen during the aging of field. Case Stud. Constr. Mater. 2024, 20, e03260. [Google Scholar] [CrossRef]

- Cong, L.; Wang, T.J. Effect of fine aggregate angularity on skid-resistance of asphalt pavement using accelerated pavement testing. Constr. Build. Mater. 2018, 168, 41–46. [Google Scholar]

- Wei, D.; Li, B.; Zhang, Z.; Han, F.; Zhang, X.; Zhang, M.; Li, L.; Wang, Q. Influence of surface texture characteristics on the noise in grooving concrete pavement. Appl. Sci. 2018, 8, 2141. [Google Scholar] [CrossRef]

- Moretti, L.; Cantisani, G.; Di Mascio, P.; Caro, S. Technical and economic evaluation of lighting and pavement in Italian road tunnels. Tunn. Undergr. Space Technol. 2017, 65, 42–52. [Google Scholar] [CrossRef]

- Sha, A.; Jiang, W.; Shan, J.; Wu, W.; Li, Y.; Zhang, S. Pavement structure and materials design for sea-crossing bridges and tunnel: Case study of the Hong Kong–Zhuhai–Macau Bridg. J. Road Eng. 2022, 2, 99–113. [Google Scholar] [CrossRef]

- Qin, Y.; Lai, J.; Li, C.; Fan, F.; Liu, T. Negative pressure testing standard for welded scar tightness of waterproofing sheet for tunnels: Experimental and Numerical Investigation. Tunn. Undergr. Space Technol. 2023, 133, 104930. [Google Scholar] [CrossRef]

- Tanlı, T.; Damdelen, Ö.; Pehlivan, S. Pehlivan. Influences of recycled plastic and treated wastewater containing with 50% GGBS content in sustainable concrete mixes. J. Mater. Res. Technol. 2022, 16, 110–128. [Google Scholar] [CrossRef]

- Roychand, R.; Li, J.; Kilmartin-Lynch, S.; Saberian, M.; Zhu, J.; Youssf, O.; Ngo, T. Carbon sequestration from waste and carbon dioxide mineralisation in concrete—A stronger, sustainable and eco-friendly solution to support circular economy. Constr. Build. Mater. 2023, 379, 131221. [Google Scholar] [CrossRef]

- Zhao, M.; Li, J.; Li, C. Experimental study and prediction of the long-term strength development of high-flowability concrete made of mixed sand and high-content fly ash. Constr. Build. Mater. 2024, 437, 137043. [Google Scholar] [CrossRef]

- Roychand, R.; Kilmartin-Lynch, S.; Saberian, M.; Li, J.; Zhang, G.; Li, C. Transforming spent coffee grounds into a valuable resource for the enhancement of concrete strength. J. Clean. Prod. 2023, 419, 138205. [Google Scholar] [CrossRef]

- Zhao, M.; Dai, M.; Li, J.; Li, C. Experimental study on pumpability and mechanical property of concrete with manufactured sand and super-fine river sand. Case Study Constr. Mater. 2023, 18, e01850. [Google Scholar]

- Zhang, H.; Cao, L.; Duan, Y. High-flowable and high-performance steel fiber reinforced concrete adapted by fly ash and silica fume. Case Stud. Constr. Mater. 2024, 20, e02796. [Google Scholar] [CrossRef]

- Choi, Y.-W.; Park, M.-S.; Choi, B.-K.; Oh, S.-R. Study on the evaluation of field application of high-fluidity concrete containing high volume fly ash. Adv. Mater. Sci. Eng. 2015, 2015, 507018. [Google Scholar] [CrossRef]

- Li, C.; Geng, H.; Zhou, S.; Dai, M.; Sun, B.; Li, F. Experimental study on preparation and performance of concrete with large content of fly-ash. Front. Mater. 2022, 8, 764820. [Google Scholar] [CrossRef]

- Ma, J.; Wang, D.; Zhao, S.; Duan, P.; Yang, S. Influence of particle morphology of ground fly ash on the fluidity and strength of cement paste. Materials 2021, 14, 283. [Google Scholar] [CrossRef]

- Feng, L.; Liu, W.; Jing, W. Mechanics and road performance of mudstone modified stabilized gravel subgrade in arid desert areas. Case Stud. Constr. Mater. 2024, 20, e02799. [Google Scholar] [CrossRef]

- Grosch, K.A. The relation between the friction and visco-elastic properties of rubber. Proc. R. Soc. Lond. Ser. Math. Phys. Sci. 1963, 274, 21–39. [Google Scholar]

- Chu, L.; Cui, X.; Zhang, K.; Fwa, T.F.; Han, S. Directional skid resistance characteristics of road pavement: Implications for friction measurements by british pendulum tester and dynamic friction tester. Transp. Res. Rec. J. Transp. Res. Board 2019, 2673, 793–803. [Google Scholar] [CrossRef]

- Eom, S.-H.; Jeon, H.-S.; Ryue, T.-G.; Lee, H.-J.; Kim, H.-G.; Abebe, T.N. Development of Anti-Icing and Skid-Resistant Road Surfaces Using Methyl Methacrylate (MMA) Resin-Based Composites. Materials 2025, 18, 501. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Lai, J.; Ren, Z.; Shi, Y.; Kong, X. Failure mechanical behaviors and prevention methods of shaft lining in China. Eng. Fail. Anal. 2023, 143, 106904. [Google Scholar] [CrossRef]

- ASTM E 303-93; Standard Test Method for Measuring Surface Frictional Properties Using the British Pendulum Tester. ASTM International: West Conshohocken, PA, USA, 2018.

- JTG F80/l-2017; Inspection and Evaluation Quality Standards for Highway Engineering Section 1 Civil Engineering. China Communications Press Co.: Beijing, China, 2017.

- Stępień, J.; Chomicz-Kowalska, A.; Tutaj-Dudała, M.; Dudała, M.; Maciejewski, K.; Ramiączek, P.; Iwański, M.M. Influence of Compaction Methods on Properties of Roller-Compacted Concrete Pavement Wearing Surfaces. Materials 2025, 18, 492. [Google Scholar] [CrossRef]

- Chen, H.; Sun, Z.; Zhang, X.; Fan, J. Tensile Fatigue Properties of Ordinary Plain Concrete and Reinforced Concrete under Flexural Loading. Materials 2023, 16, 6447. [Google Scholar] [CrossRef]

- JTG/T F30-2014; Technical Guidelines for Construction of Highway Cement Concrete Pavements. China Communications Press Co.: Beijing, China, 2014.

- JTG E30-2005; Test Methods of Cement and Concrete for Highway Engineering. China Communications Press Co.: Beijing, China, 2005.

- GB/T27690-2023; Silica Fume for Cement Mortar and Concrete. The Standards Press of China: Beijing, China, 2023.

- Wang, H.; Fan, W.; Chi, M.; Li, Y.; Zhang, X.; Xu, Z.; Jiang, S. Wear resistance and skid resistance of 100% reclaimed asphalt pavement. Constr. Build. Mater. 2025, 468, 140373. [Google Scholar] [CrossRef]

- Zhao, X.; Xue, L.; Xu, F. Asphalt pavement paving segregation detection method using more efficiency and quality texture features extract algorithm. Constr. Build. Mater. 2021, 277, 122302. [Google Scholar] [CrossRef]

| Projects | Test Results | Technical Requirement | ||

|---|---|---|---|---|

| Quasi-thickness water consumption (%) | 28.1 | - | ||

| Fineness (%) | 1.3 | ≤30% | ||

| Stability (Ray’s Clamp Method) | 0.49 | ≤5% | ||

| Condensation time (min) | Initial condensation time | 150 | ≥45 | |

| Final setting time | 245 | ≤600 | ||

| Strength (MPa) | Compressive strengths | 7 d | 34.1 | ≥17 |

| 28 d | 45.8 | ≥42.5 | ||

| Flexural strength | 7 d | 4.8 | ≥3.5 | |

| 28 d | 8.5 | ≥6.5 | ||

| Projects | Test Results | Technical Requirement | |

|---|---|---|---|

| Apparent density (kg/m3) | 2830 | ≥2500 | |

| Bulk density (kg/m3) | Loose | 1118 | - |

| Terse | 1580 | ≥1350 | |

| Clod content (%) | 0.5 | ≤0.5 | |

| Mud content (%) | 0.8 | ≤1 | |

| Needle flake content (%) | 5.3 | ≤15 | |

| Saturated water absorption (%) | 0.64 | - | |

| Projects | River Sand | Technical Requirement |

|---|---|---|

| Fineness Module | 2.9 | - |

| Apparent density (kg/m3) | 2700 | ≥2500 |

| Porosity (%) | 35 | - |

| Mud content (%) | 0.2 | - |

| Projects | Test Results | Technical Requirement |

|---|---|---|

| Exterior | Yellow | Yellow |

| Water reduction rate | 20 | ≥14% |

| PH value | 8 | 6–9 |

| Natrium sulfate | 8.3 | 8–10 |

| Net cement slurry flow rate | 230 mm | ≥140 mm |

| Mortar water reduction rate | 19.1% | ≥15% |

| Solid | 92% | ≥90% |

| Total alkali content | 3.22% | ≤5% |

| Projects | Dolerite | Basalt | Limestone | Technical Requirement |

|---|---|---|---|---|

| Apparent density (kg/m3) | 2986 | 2983 | 2730 | ≥2500 |

| Water absorption (%) | 0.6 | 1.10 | 0.68 | ≤2.0 |

| Crushing value (%) | 15.5 | 12.3 | 21.6 | ≤26 |

| Content of elongated flat particles (%) | 7.4 | 7.2 | 7.4 | ≤20 |

| Los Angeles abrasion loss (%) | 16.6 | 15.4 | 22.1 | ≤30 |

| Buffing value (BPN) | 45 | 45 | 42 | ≥42 |

| Fine aggregate angularity (S) | 38.6 | 39.7 | 32.8 | ≥30 |

| Firmness (%) | 2.8 | 3.1 | 2.2 | ≤5 |

| Comprehensive index of anti-slip and abrasion resistance (t) | 1.748 | 2.019 | 1.287 | - |

| Stone Size | Stone Types | ||

|---|---|---|---|

| Dolerite | Limestone | Basalt | |

| 9.5 | 13.15 | 12.18 | 13.32 |

| 13.2 | 17.99 | 15.97 | 16.17 |

| 9.5:13.2 = 1:1 | 15.57 | 14.08 | 14.75 |

| 9.5:13.2 = 2:1 | 14.76 | 13.44 | 14.27 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, J.; Feng, Z.; Cui, P. Research on Anti-Slip and Wear Resistance of Concrete Pavement After Optimization of Stone-Planting Process. Materials 2025, 18, 2210. https://doi.org/10.3390/ma18102210

Yuan J, Feng Z, Cui P. Research on Anti-Slip and Wear Resistance of Concrete Pavement After Optimization of Stone-Planting Process. Materials. 2025; 18(10):2210. https://doi.org/10.3390/ma18102210

Chicago/Turabian StyleYuan, Jianbo, Zezhong Feng, and Pei Cui. 2025. "Research on Anti-Slip and Wear Resistance of Concrete Pavement After Optimization of Stone-Planting Process" Materials 18, no. 10: 2210. https://doi.org/10.3390/ma18102210

APA StyleYuan, J., Feng, Z., & Cui, P. (2025). Research on Anti-Slip and Wear Resistance of Concrete Pavement After Optimization of Stone-Planting Process. Materials, 18(10), 2210. https://doi.org/10.3390/ma18102210