Additive Manufactured FeCrNi Medium Entropy Alloy Lattice Structure with Excellent Dynamic Mechanical Properties

Abstract

1. Introduction

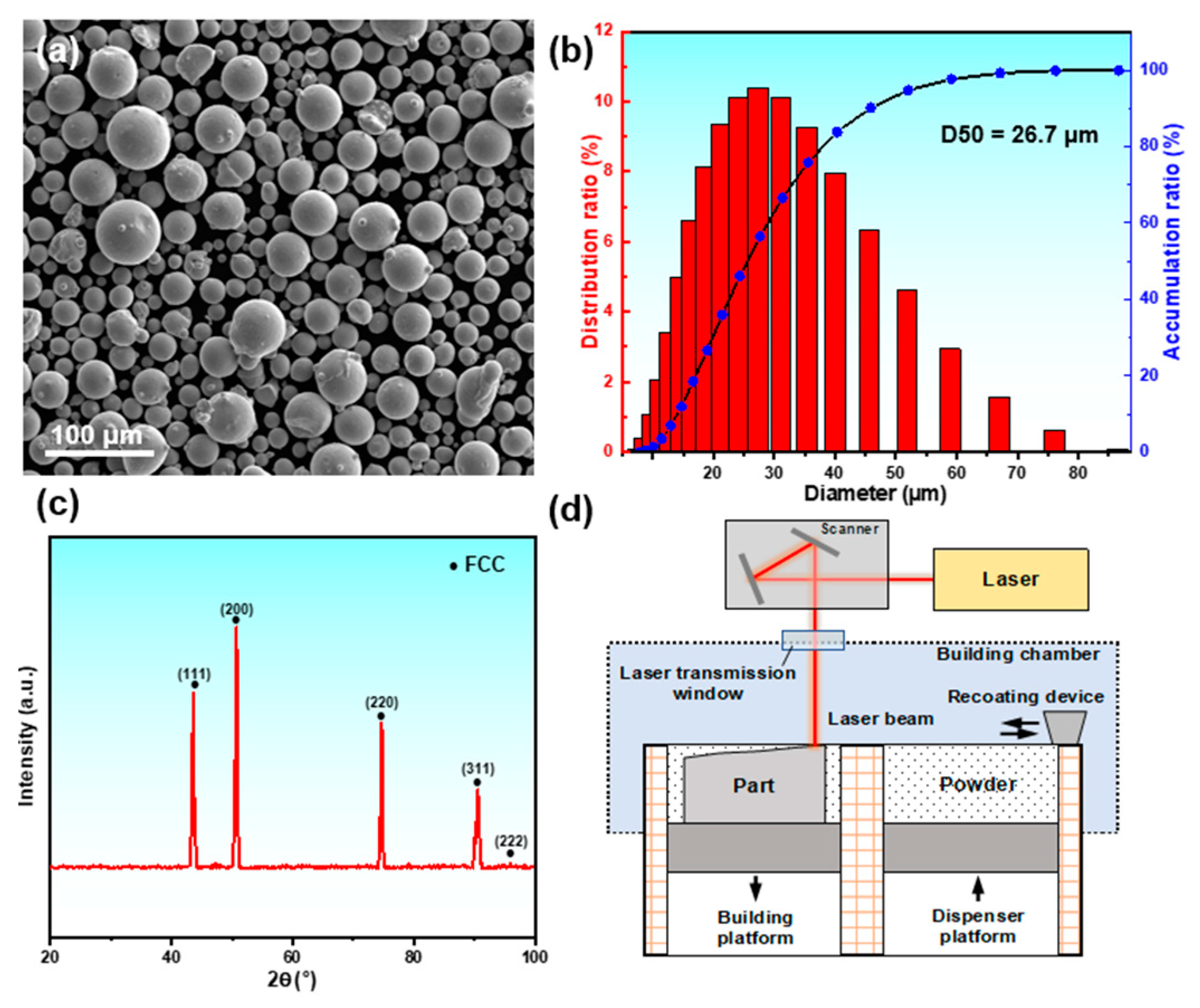

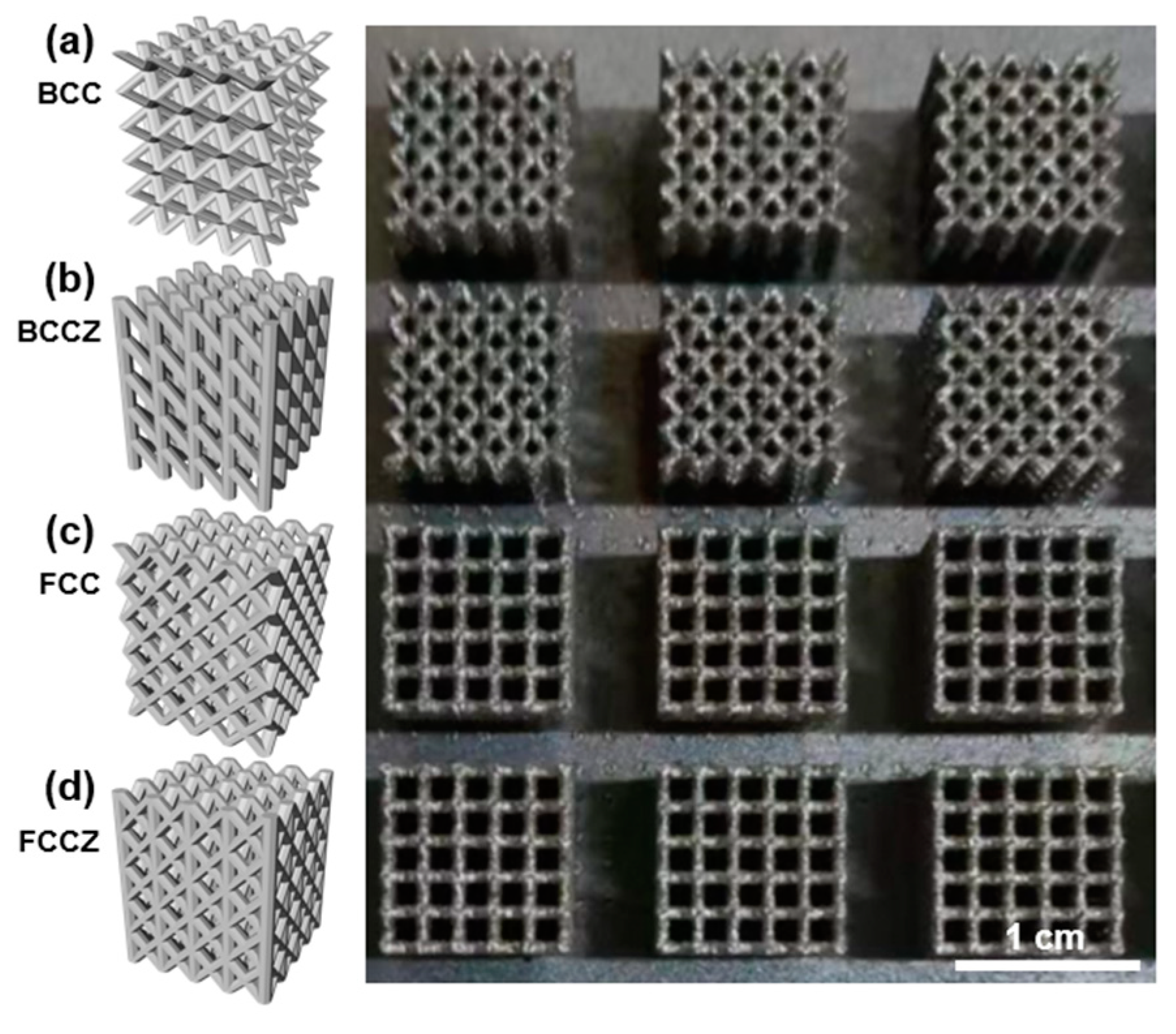

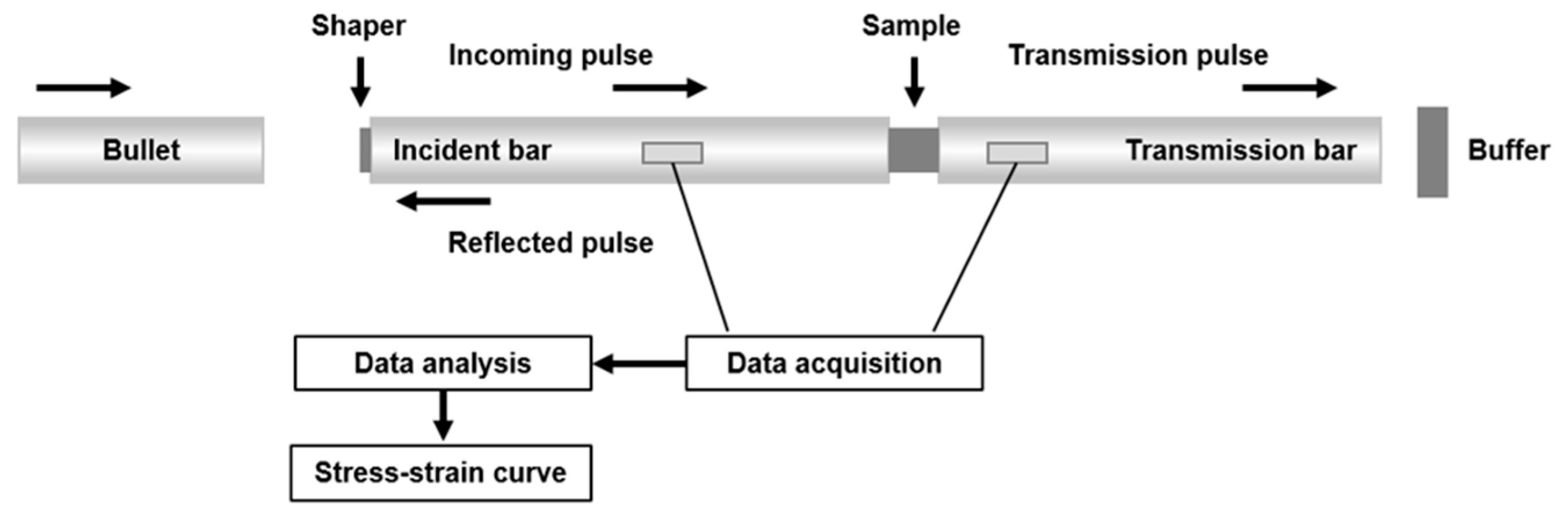

2. Experimental Procedure

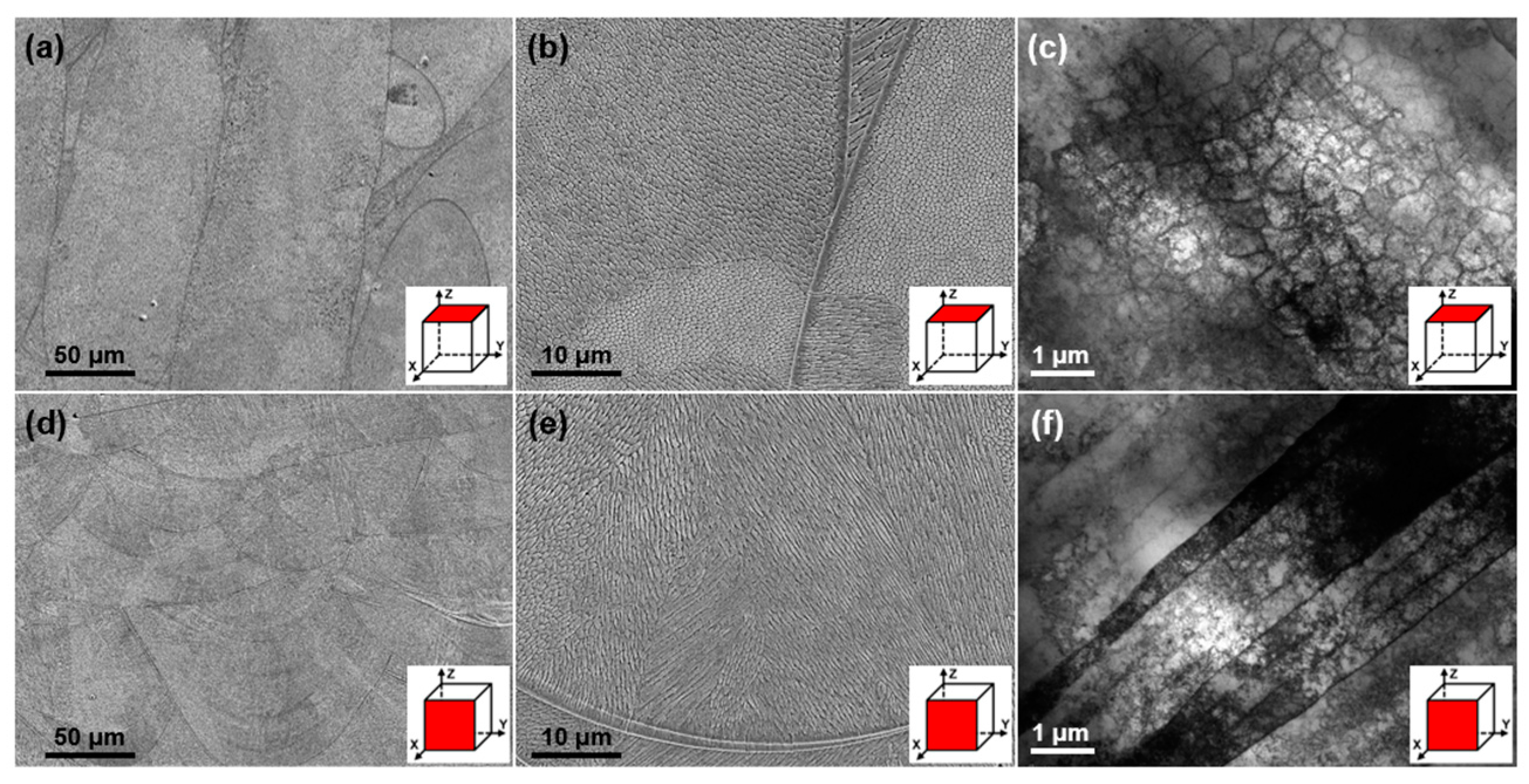

3. Results and Discussion

4. Conclusions

- (1)

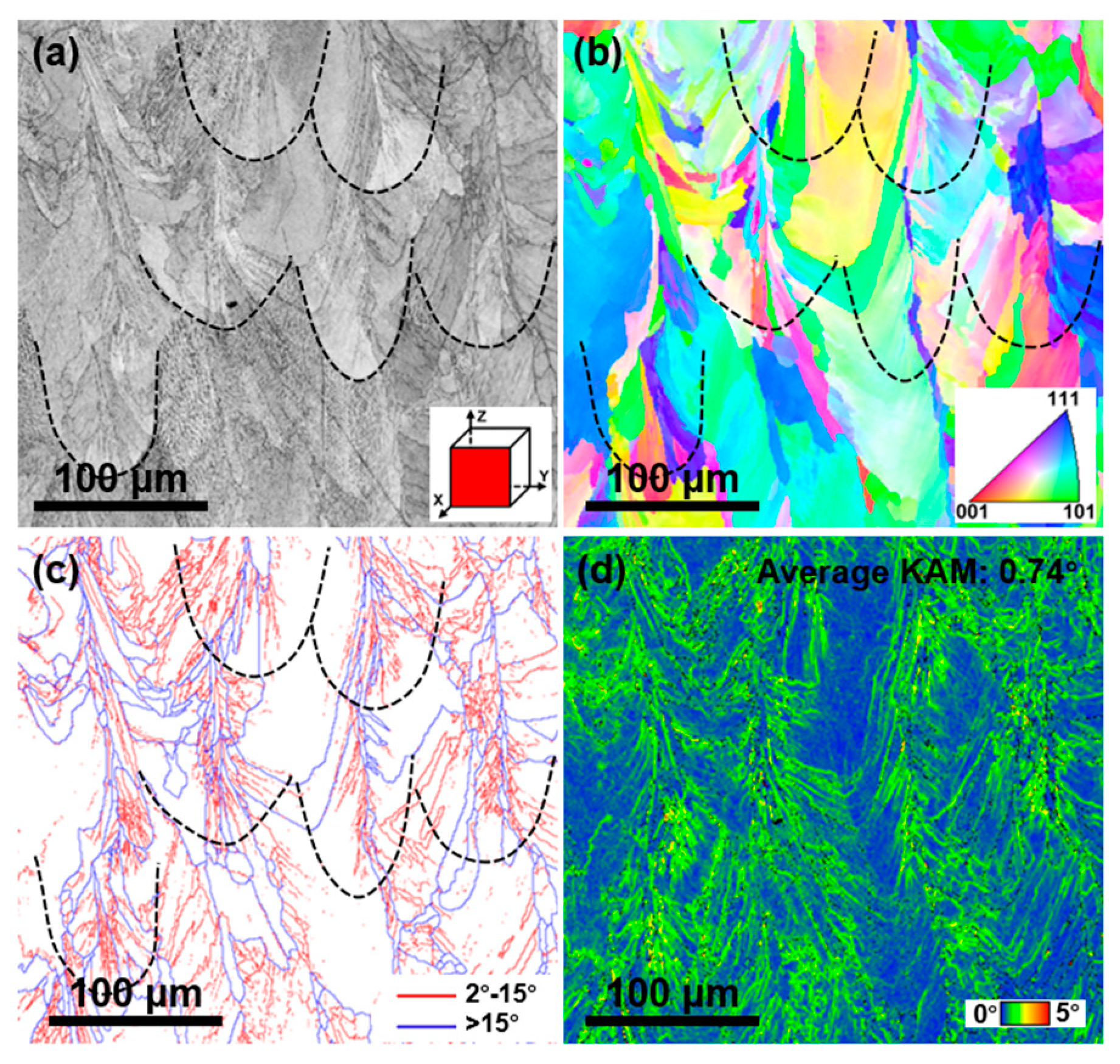

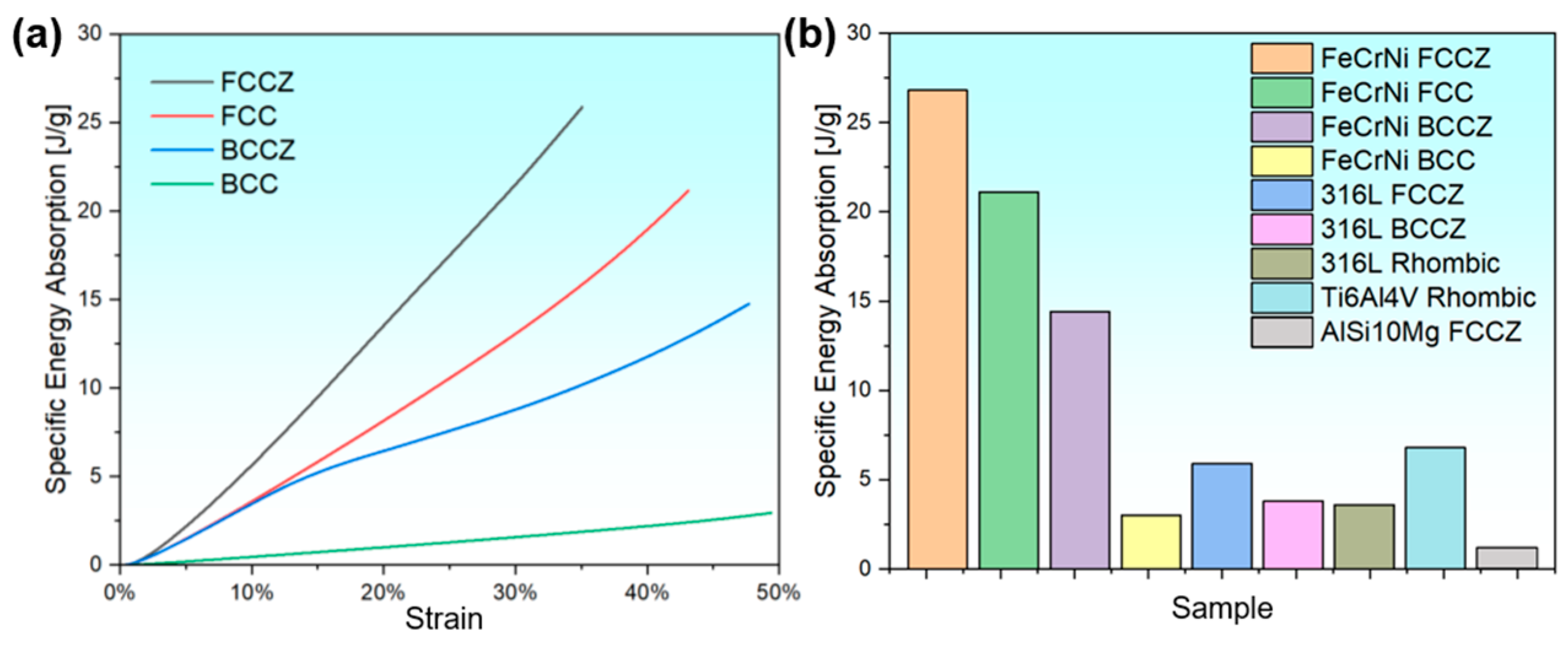

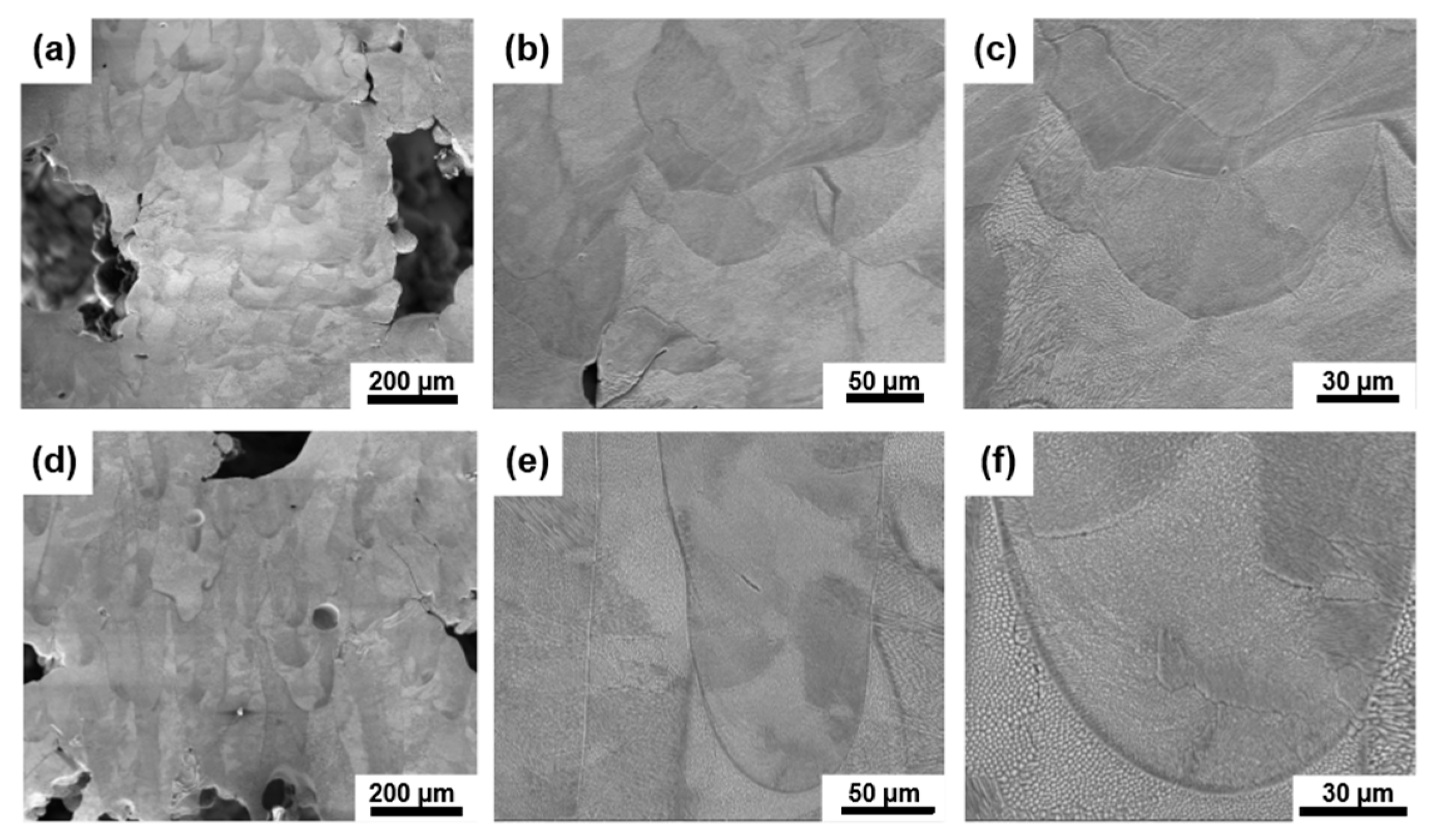

- The FeCrNi lattice structure demonstrates superior specific strength and specific energy absorption compared to other materials like common 316L and AlSi10Mg lattice structures. Its deformation mechanism is primarily governed by macrostructural deformation, with no significant microstructural deformation observed, such as twins and microbands typically seen in MEAs/HEAs.

- (2)

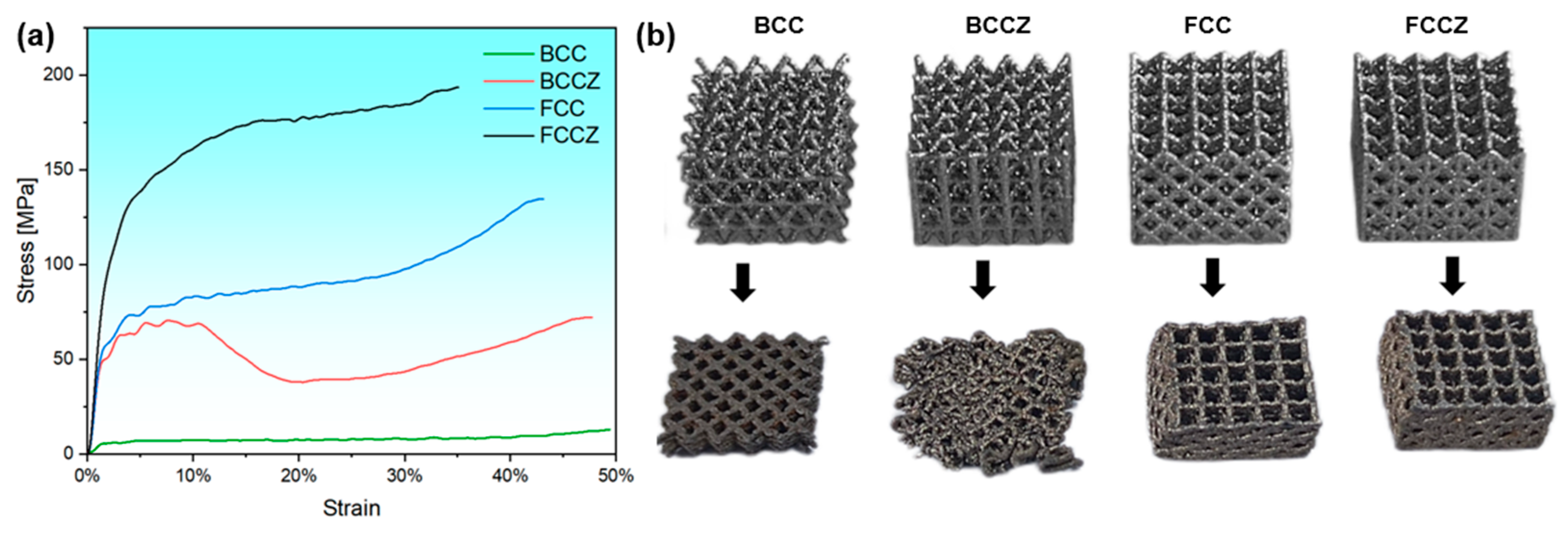

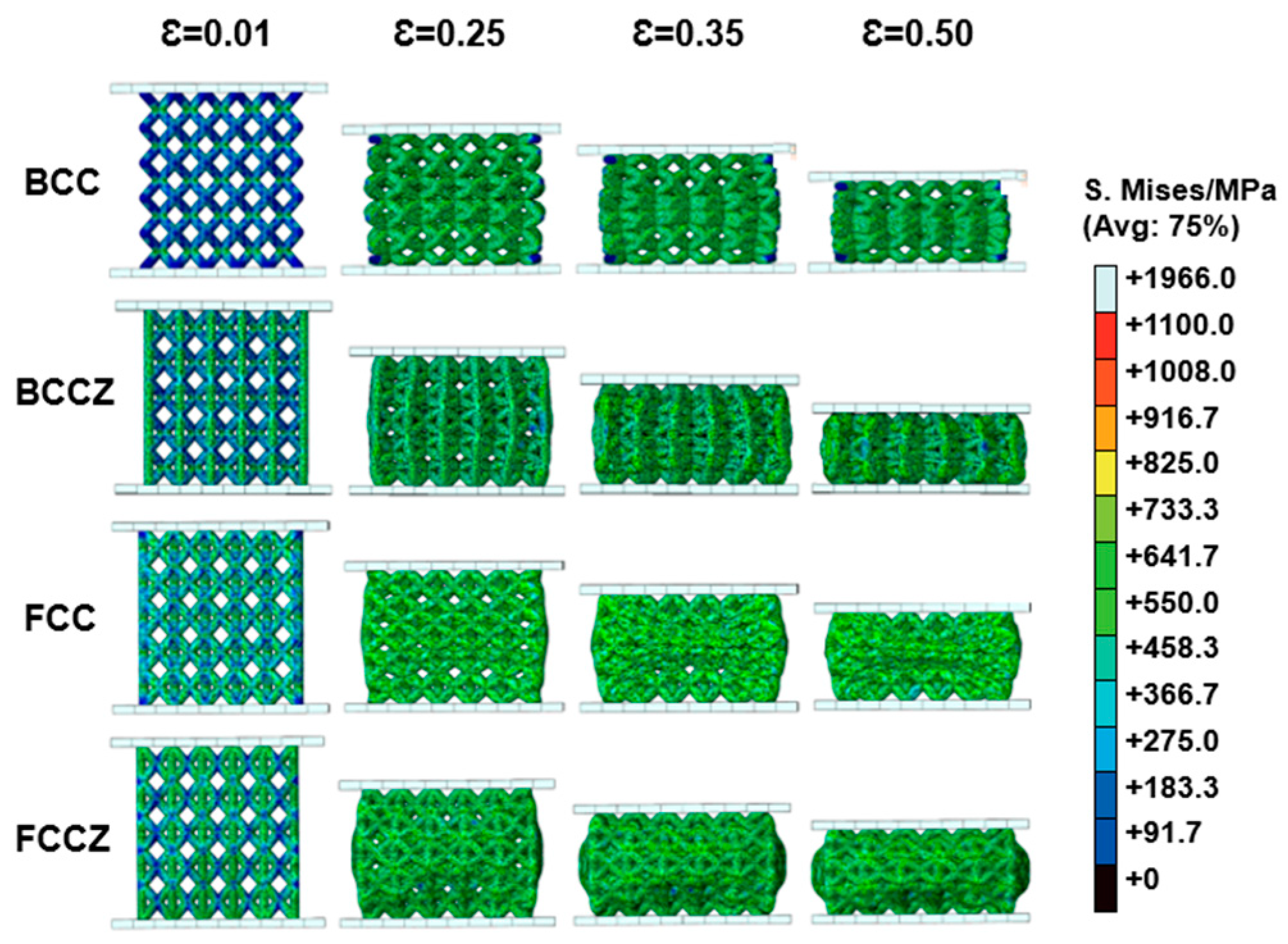

- Among the four lattice structures, the FCCZ structure exhibits the optimal dynamic mechanical performance. Finite element simulations of the compression process reveal that in BCC and BCCZ lattice structures, stress concentrates at the nodes, while in FCC and FCCZ lattice structures, stress concentrates on the struts. The FCC and FCCZ lattice structures, which are dominated by axial compressive deformation, exhibit higher strength. The FCCZ structure, in particular, stands out due to its specific characteristics that enhance its strength and energy absorption capabilities.

- (3)

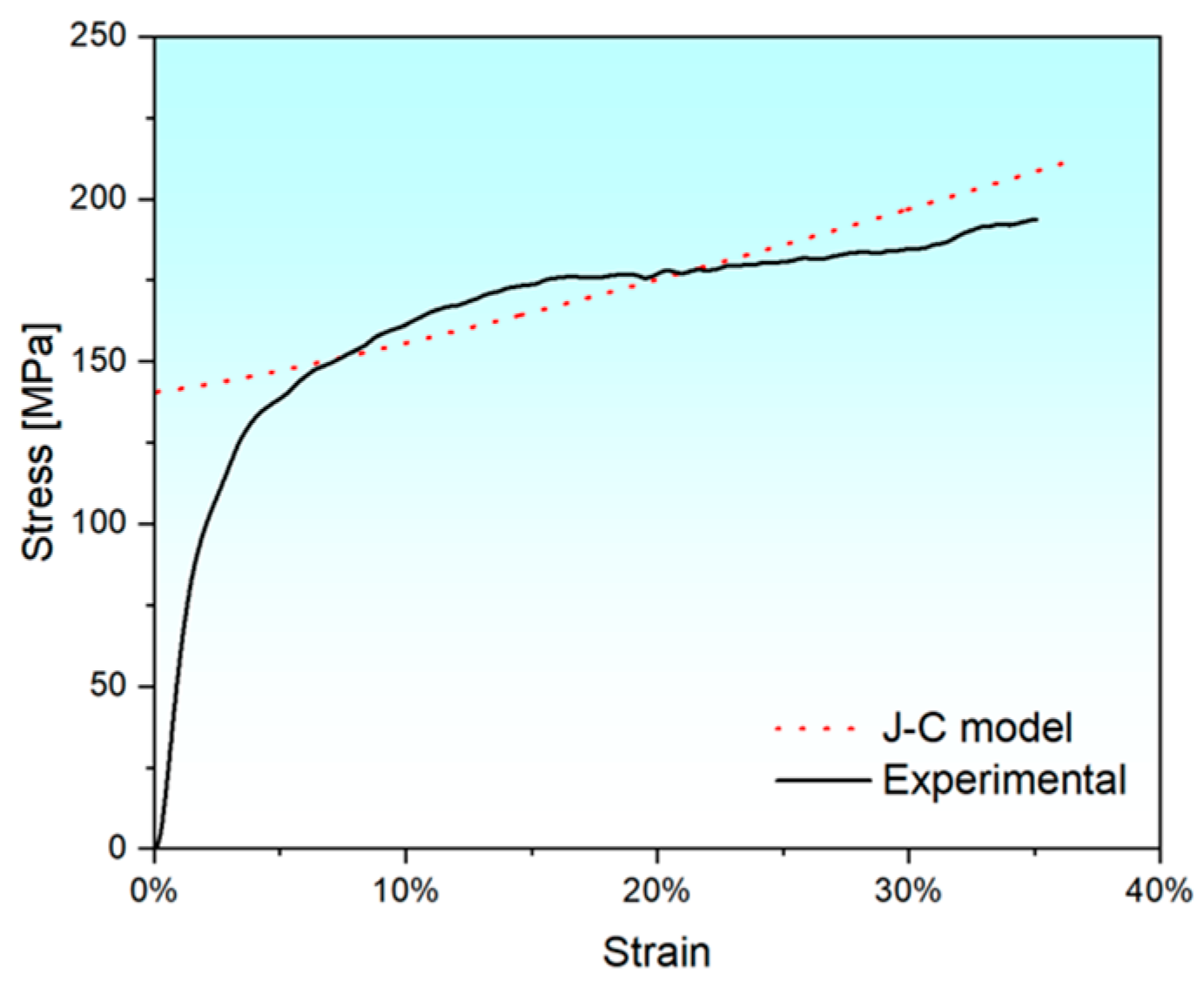

- The J-C constitutive model for the FeCrNi FCCZ lattice structure at room temperature is expressed as: . The J-C constitutive model shows good agreement in predicting the strength and stress response of the FeCrNi FCCZ lattice structure under dynamic impact.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Khan, N.; Riccio, A. A systematic review of design for additive manufacturing of aerospace lattice structures: Current trends and future directions. Prog. Aerosp. Sci. 2024, 149, 101021. [Google Scholar] [CrossRef]

- Peng, S.; Mooraj, S.; Feng, R.; Liu, L.; Ren, J.; Liu, Y.; Kong, F.; Xiao, Z.; Zhu, C.; Liaw, P.K.; et al. Additive manufacturing of three-dimensional (3D)-architected CoCrFeNiMn high-entropy alloy with great energy absorption. Scr. Mater. 2021, 190, 46–51. [Google Scholar] [CrossRef]

- Chen, M.; Jia, Z.; Wang, Z.; Xiang, C.; Pu, J.; Sun, G.; Han, E.H. Insights into the passivity and electrochemistry of CoCrFeMnNi high entropy alloy fabricated by underwater laser direct metal deposition. Corros. Sci. 2024, 237, 112289. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, S.; Yan, S.; Zhao, Y.; Zhang, Y. Enhancing the mechanical performance of additively manufactured lattice structure via locally reinforcing struts: Coupled influence of structure and microstructure. Mater. Sci. Eng. A 2025, 927, 147989. [Google Scholar] [CrossRef]

- Fu, A.; Xie, Z.; Wang, J.; Cao, Y.; Wang, B.; Li, J.; Fang, Q.; Li, X.; Liu, B.; Liu, Y. Controlling of cellular substructure and its effect on mechanical properties of FeCoCrNiMo0.2 high entropy alloy fabricated by selective laser melting. Mater. Sci. Eng. A 2024, 901, 146547. [Google Scholar] [CrossRef]

- Kang, D.; Park, S.; Son, Y.; Yeon, S.; Kim, S.H.; Kim, I. Multi-lattice inner structures for high-strength and light-weight in metal selective laser melting process. Mater. Des. 2019, 175, 107786. [Google Scholar] [CrossRef]

- Mora, S.; Pugno, N.M.; Misseroni, D. 3D printed architected lattice structures by material jetting. Mater. Today 2022, 59, 107–132. [Google Scholar] [CrossRef]

- Yang, X.; Ma, W.; Gu, W.; Zhang, Z.; Wang, B.; Wang, Y.; Liu, S. Multi-scale microstructure high-strength titanium alloy lattice structure manufactured via selective laser melting. RSC Adv. 2021, 11, 22734–22743. [Google Scholar] [CrossRef]

- Li, Z.H.; Nie, Y.F.; Liu, B.; Kuai, Z.Z.; Zhao, M.; Liu, F. Mechanical properties of AlSi10Mg lattice structures fabricated by selective laser melting. Mater. Des. 2020, 192, 108709. [Google Scholar] [CrossRef]

- Lee, J.M.; Lee, J.E.; Kim, J.H.; Kim, S.W. Compressive Behavior of 316L Stainless Steel Lattice Structures Fabricated by Selective Laser Melting. Korean, J. Met. Mater. 2020, 58, 227–233. [Google Scholar] [CrossRef]

- Xiao, Z.; Yang, Y.; Xiao, R.; Bai, Y.; Song, C.; Wang, D. Evaluation of topology-optimized lattice structures manufactured via selective laser melting. Mater. Des. 2018, 143, 27–37. [Google Scholar] [CrossRef]

- Fu, A.; Liu, B.; Li, Z.; Yang, T.; Cao, Y.; He, J.; Wang, B.; Li, J.; Fang, Q.; Cheng, X. Superb impact resistance of nano-precipitation-strengthened high-entropy alloys. Adv. Powder Mater. 2025, 100277. [Google Scholar] [CrossRef]

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Fu, A.; Liu, B.; Lu, W.; Liu, B.; Li, J.; Fang, Q.; Li, Z.; Liu, Y. A novel supersaturated medium entropy alloy with superior tensile properties and corrosion resistance. Scr. Mater. 2020, 186, 381–386. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, J.; Pei, Z. Machine learning for high-entropy alloys: Progress, challenges and opportunities. Prog. Mater. Sci. 2023, 131, 101018. [Google Scholar] [CrossRef]

- Gludovatz, B.; Hohenwarter, A.; Catoor, D.; Chang, E.H.; George, E.P.; Ritchie, R.O. A fracture-resistant high-entropy alloy for cryogenic applications. Science 2014, 345, 1153–1158. [Google Scholar] [CrossRef] [PubMed]

- Liu, D.; Yu, Q.; Kabra, S.; Jiang, M.; Forna-Kreutzer, P.; Zhang, R.; Payne, M.; Walsh, F.; Gludovatz, B.; Asta, M. Exceptional fracture toughness of CrCoNi-based medium-and high-entropy alloys at 20 kelvin. Science 2022, 378, 978–983. [Google Scholar] [CrossRef]

- Fu, A.; Liu, B.; Liu, B.; Cao, Y.; Wang, J.; Liao, T.; Li, J.; Fang, Q.; Liaw, P.K.; Liu, Y. A novel cobalt-free oxide dispersion strengthened medium-entropy alloy with outstanding mechanical properties and irradiation resistance. J. Mater. Sci. Technol. 2023, 152, 190–200. [Google Scholar] [CrossRef]

- Gao, Q.; Kou, Z.; Zhou, C.; Liu, X.; Zhang, J.; Gong, J.; Song, K.; Hu, L.; Liu, Z.; Zhang, Z. Exceptional strength-ductility synergy in a casting multi-principal element alloy with a hierarchically heterogeneous structure. Mater. Today 2024, 81, 70–83. [Google Scholar] [CrossRef]

- Andreoli, A.F.; Shuleshova, O.; Witusiewicz, V.T.; Wu, Y.; Yang, Y.; Ivashko, O.; Dippel, A.C.; Zimmermann, M.V.; Nielsch, K.; Kaban, I. In situ study of non-equilibrium solidification of CoCrFeNi high-entropy alloy and CrFeNi and CoCrNi ternary suballoys. Acta Mater. 2021, 212, 116880. [Google Scholar] [CrossRef]

- Wang, J.; Fu, A.; Liu, B.; Chen, Y.; Cao, Y.; Zhou, H.; Wang, B.; Li, X.; Li, J.; Fang, Q. Weakening the mechanical property anisotropy of additively manufactured medium entropy alloy by controlling the cellular structure. Addit. Manuf. 2024, 89, 104303. [Google Scholar] [CrossRef]

- Fu, A.; Liu, B.; Li, Z.; Wang, B.; Cao, Y.; Liu, Y. Dynamic deformation behavior of a FeCrNi medium entropy alloy. J. Mater. Sci. Technol. 2022, 100, 120–128. [Google Scholar] [CrossRef]

- Maconachie, T.; Leary, M.; Tran, P.; Harris, J.; Liu, Q.; Lu, G.; Ruan, D.; Faruque, O.; Brandt, M. The effect of topology on the quasi-static and dynamic behaviour of SLM AlSi10Mg lattice structures. Int. J. Adv. Manuf. Technol. 2022, 118, 4085–4104. [Google Scholar] [CrossRef]

- Cao, X.; Xiao, D.; Li, Y.; Wen, W.; Zhao, T.; Chen, Z.; Jiang, Y.; Fang, D. Dynamic compressive behavior of a modified additively manufactured rhombic dodecahedron 316L stainless steel lattice structure. Thin-Walled Struct. 2020, 148, 106586. [Google Scholar] [CrossRef]

- Xiao, L.; Song, W.; Wang, C.; Liu, H.; Tang, H.; Wang, J. Mechanical behavior of open-cell rhombic dodecahedron Ti–6Al–4V lattice structure. Mater. Sci. Eng. A 2015, 640, 375–384. [Google Scholar] [CrossRef]

- Brenne, F.; Niendorf, T. Load distribution and damage evolution in bending and stretch dominated Ti-6Al-4V cellular structures processed by selective laser melting. Int. J. Fatigue 2019, 121, 219–228. [Google Scholar] [CrossRef]

- Park, K.M.; Min, K.S.; Roh, Y.S. Design optimization of lattice structures under compression: Study of unit cell types and cell arrangements. Materials 2021, 15, 97. [Google Scholar] [CrossRef]

- Sirigiri, V.K.R.; Gudiga, V.Y.; Gattu, U.S.; Suneesh, G.; Buddaraju, K.M. A review on Johnson Cook material model. Mater. Today Proc. 2022, 62, 3450–3456. [Google Scholar] [CrossRef]

- Cao, C.; Tong, W.; Bukhari, S.; Xu, J.; Hao, Y.; Gu, P.; Hao, H.; Peng, L. Dynamic tensile deformation and microstructural evolution of AlxCrMnFeCoNi high-entropy alloys. Mater. Sci. Eng. A 2019, 759, 648–654. [Google Scholar] [CrossRef]

- Wang, X.; Huang, C.; Zou, B.; Liu, H.; Zhu, H.; Wang, J. Dynamic behavior and a modified Johnson–Cook constitutive model of Inconel 718 at high strain rate·and elevated temperature. Mater. Sci. Eng. A 2013, 580, 385–390. [Google Scholar] [CrossRef]

| ε | σ | C |

|---|---|---|

| 0.104 | 162.8 | 0.023 |

| 0.127 | 169.1 | 0.024 |

| 0.159 | 175.6 | 0.024 |

| 0.232 | 179.4 | 0.018 |

| 0.283 | 183.6 | 0.015 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, L.; Li, Z.; Liu, W.; Fu, A.; Wang, J.; Cao, Y.; Liu, B. Additive Manufactured FeCrNi Medium Entropy Alloy Lattice Structure with Excellent Dynamic Mechanical Properties. Materials 2025, 18, 2173. https://doi.org/10.3390/ma18102173

Yuan L, Li Z, Liu W, Fu A, Wang J, Cao Y, Liu B. Additive Manufactured FeCrNi Medium Entropy Alloy Lattice Structure with Excellent Dynamic Mechanical Properties. Materials. 2025; 18(10):2173. https://doi.org/10.3390/ma18102173

Chicago/Turabian StyleYuan, Lei, Zongshu Li, Wentao Liu, Ao Fu, Jian Wang, Yuankui Cao, and Bin Liu. 2025. "Additive Manufactured FeCrNi Medium Entropy Alloy Lattice Structure with Excellent Dynamic Mechanical Properties" Materials 18, no. 10: 2173. https://doi.org/10.3390/ma18102173

APA StyleYuan, L., Li, Z., Liu, W., Fu, A., Wang, J., Cao, Y., & Liu, B. (2025). Additive Manufactured FeCrNi Medium Entropy Alloy Lattice Structure with Excellent Dynamic Mechanical Properties. Materials, 18(10), 2173. https://doi.org/10.3390/ma18102173