Preparation Process of In Situ MgB2 Material with Ex Situ MgB2 Barrier to Obtain Long Sections of Superconducting Multicore Wires

Abstract

1. Introduction

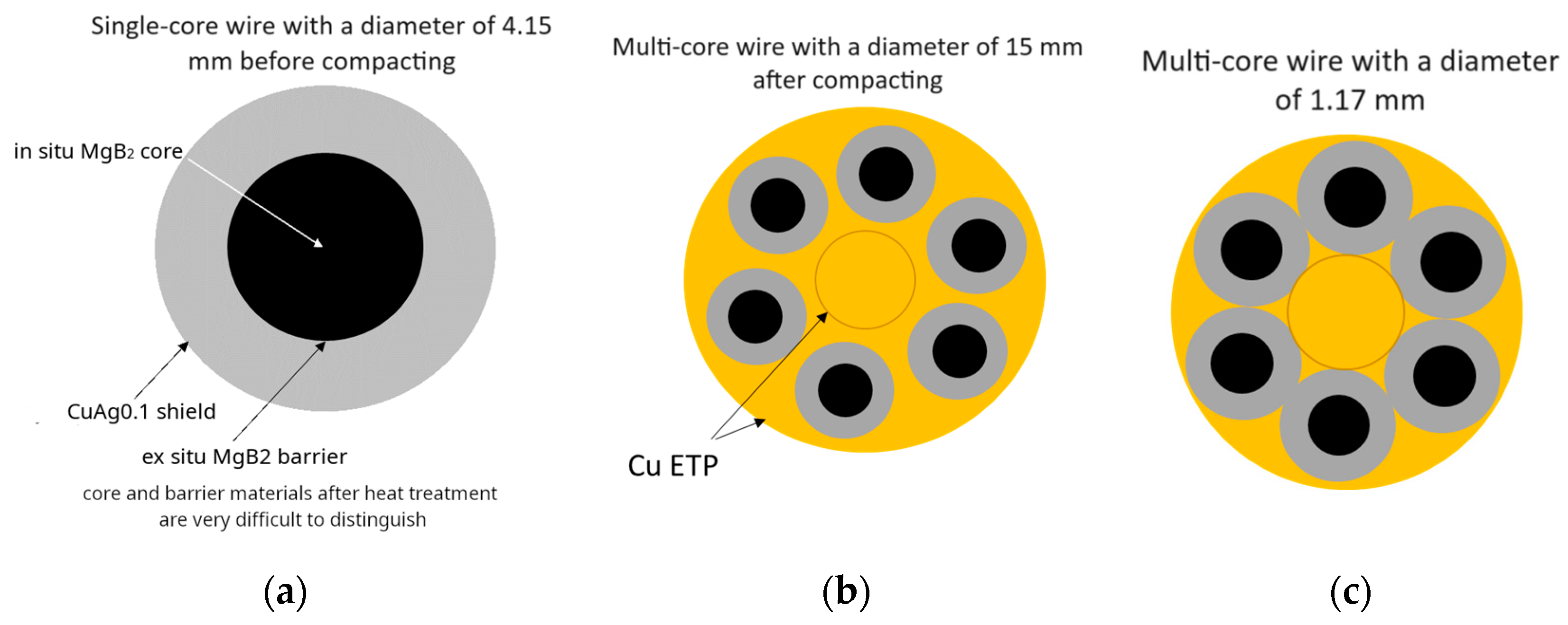

2. Materials and Methods

3. Results

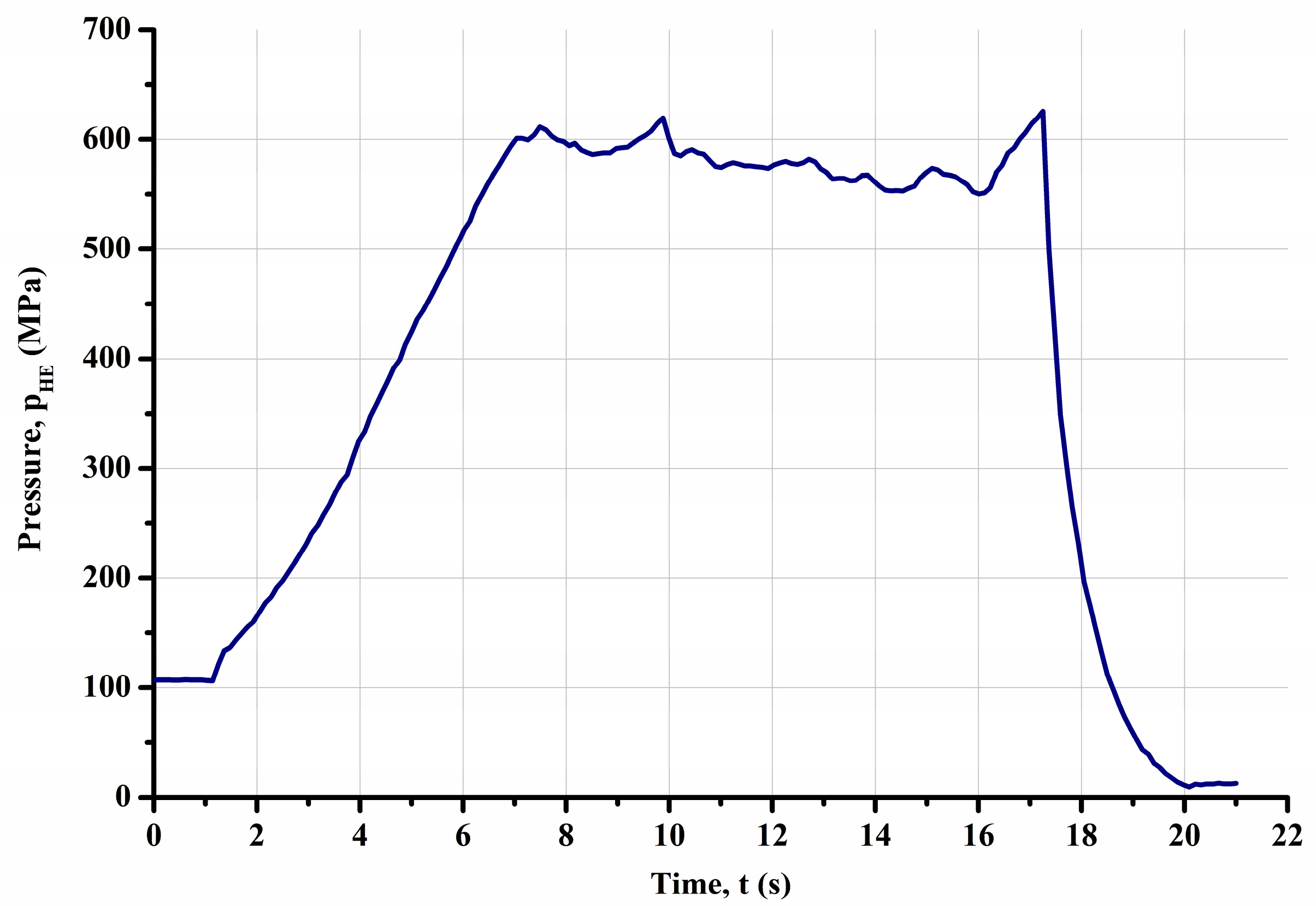

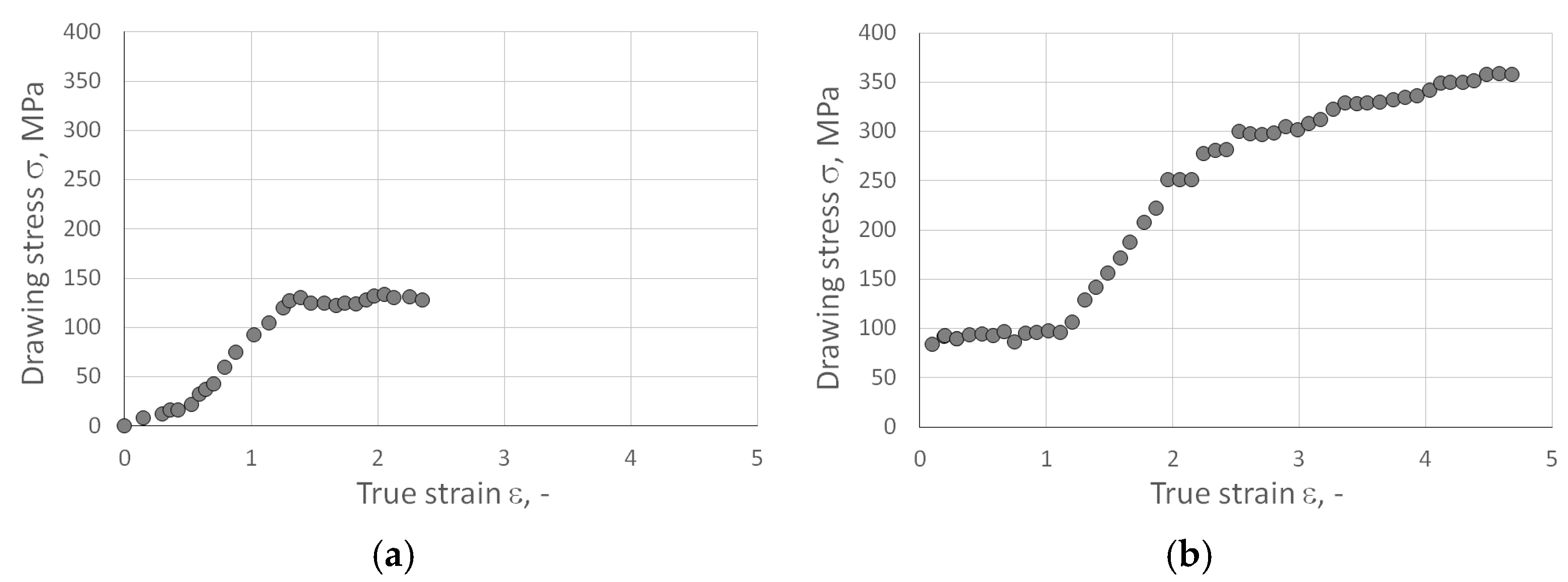

3.1. Results of Wire Drawing Process

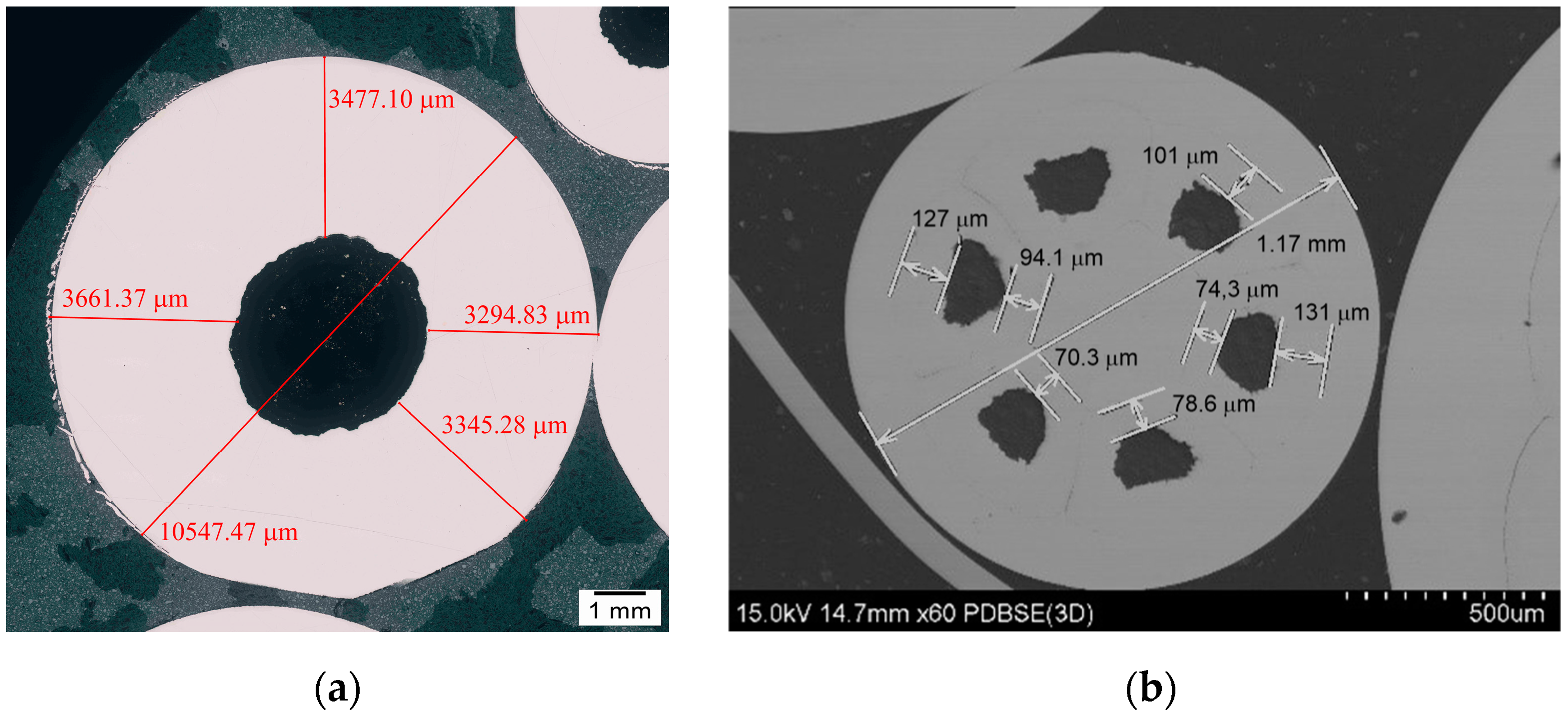

3.2. Microstructure Studies

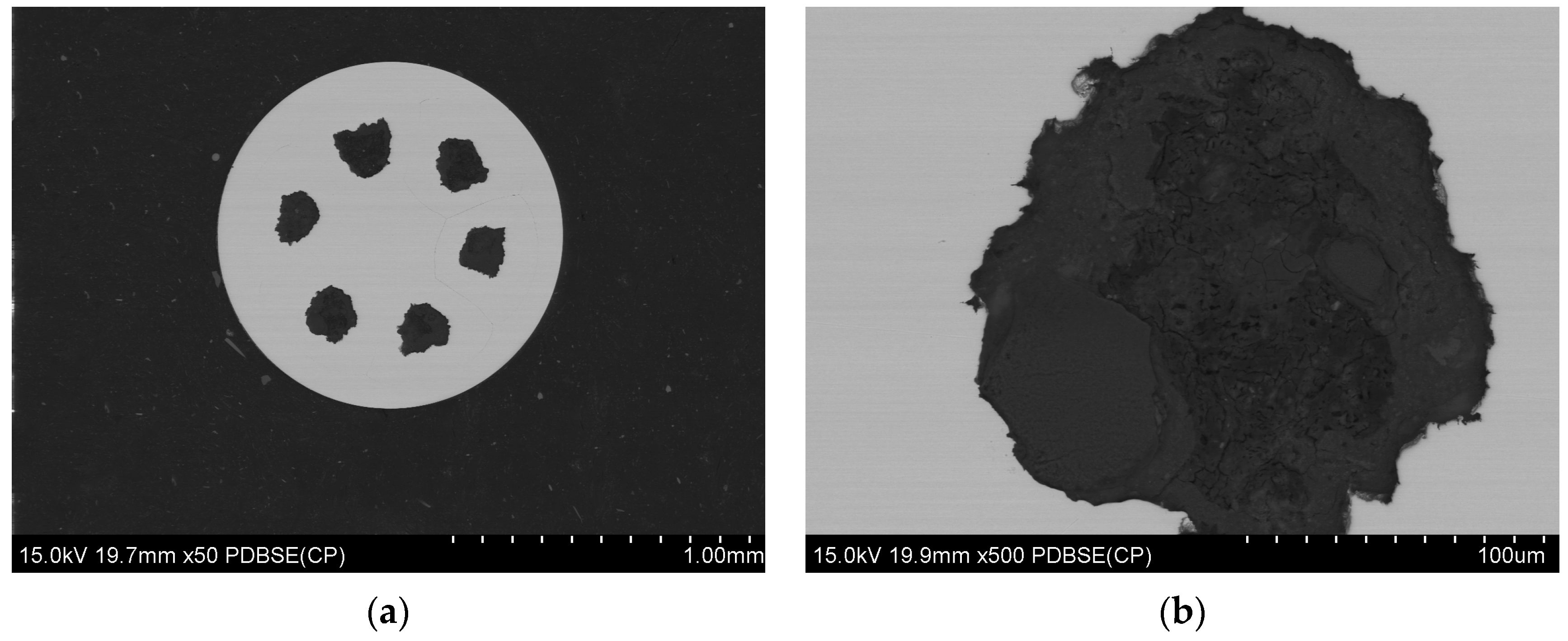

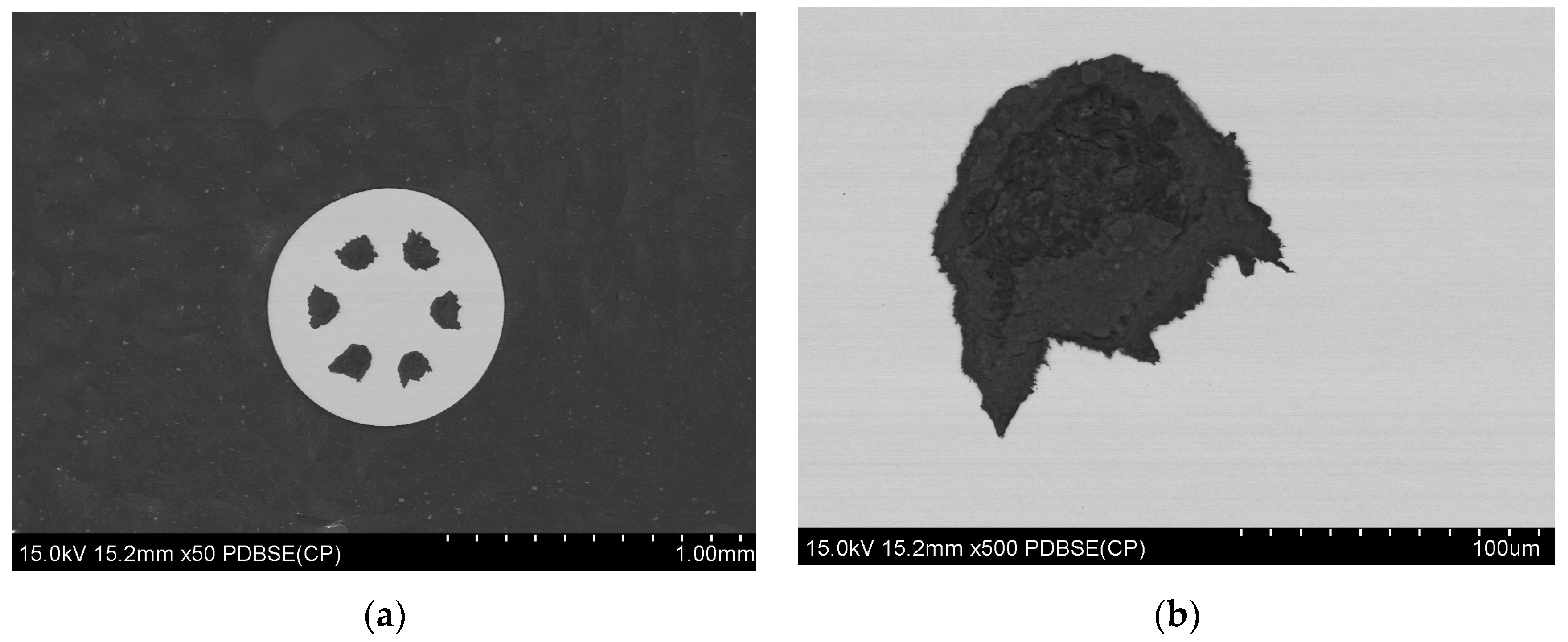

3.2.1. Microstructure After Wire Drawing Process and Before Final Heat Treatment

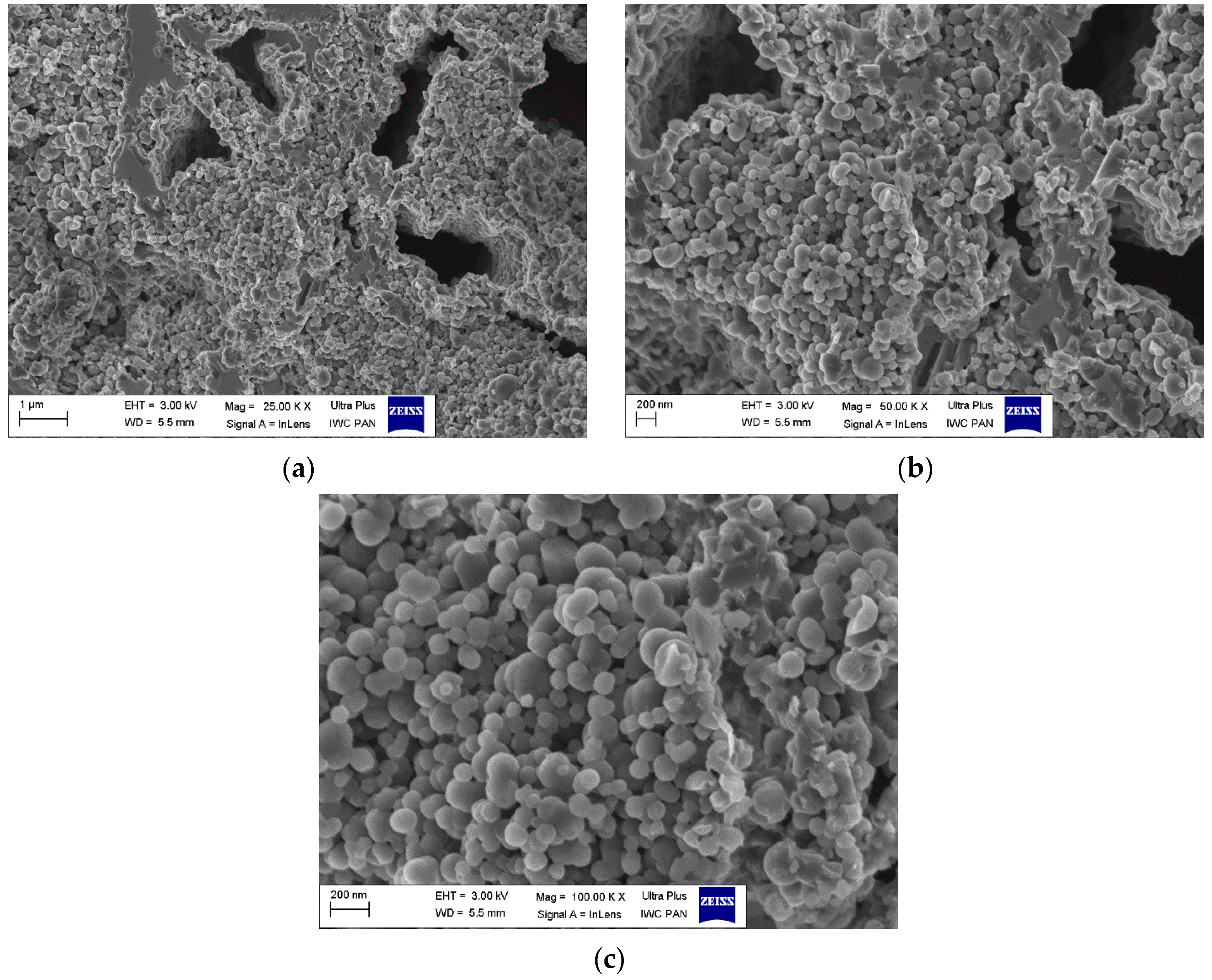

3.2.2. Microstructure After Final Heat Treatment Process

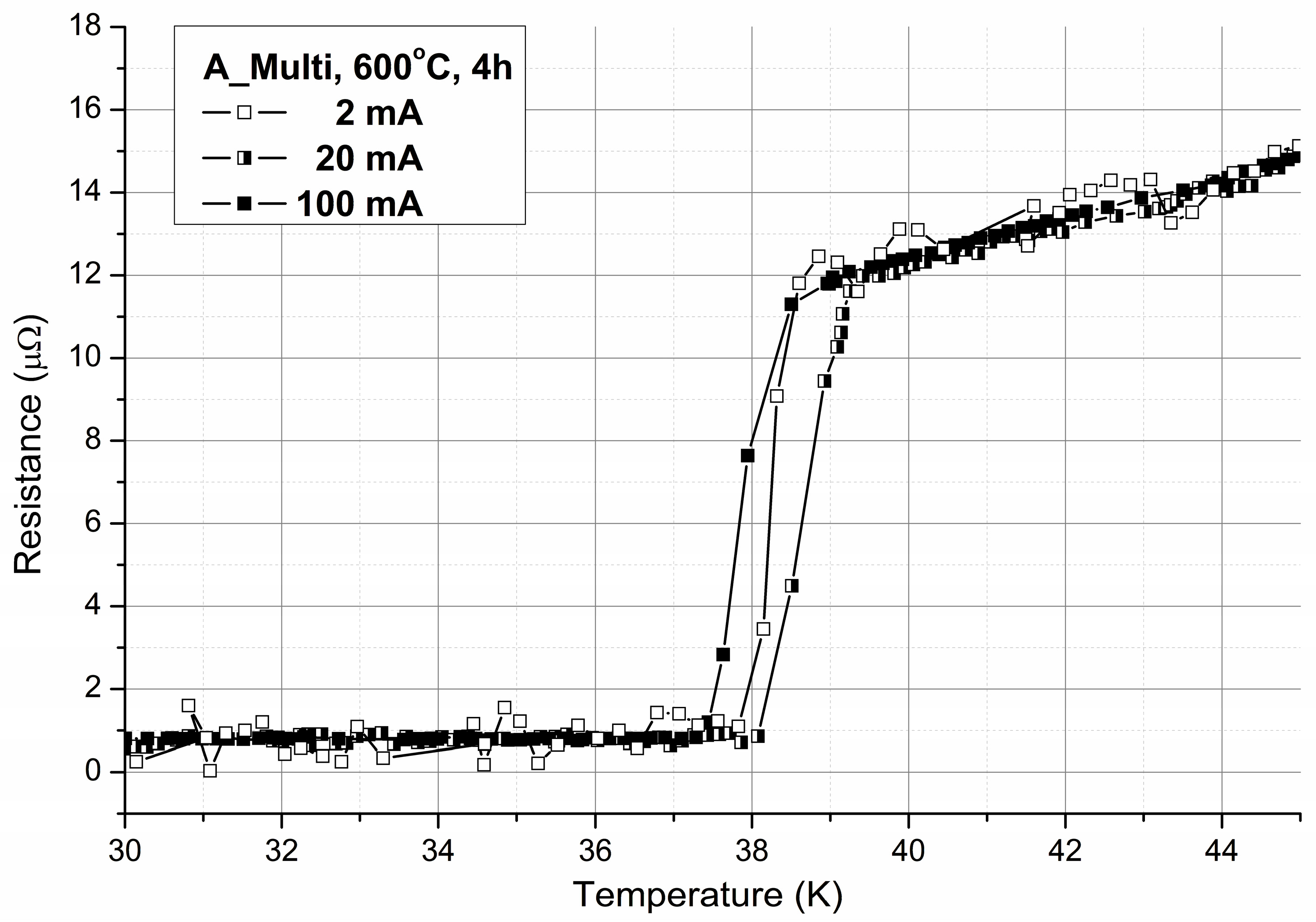

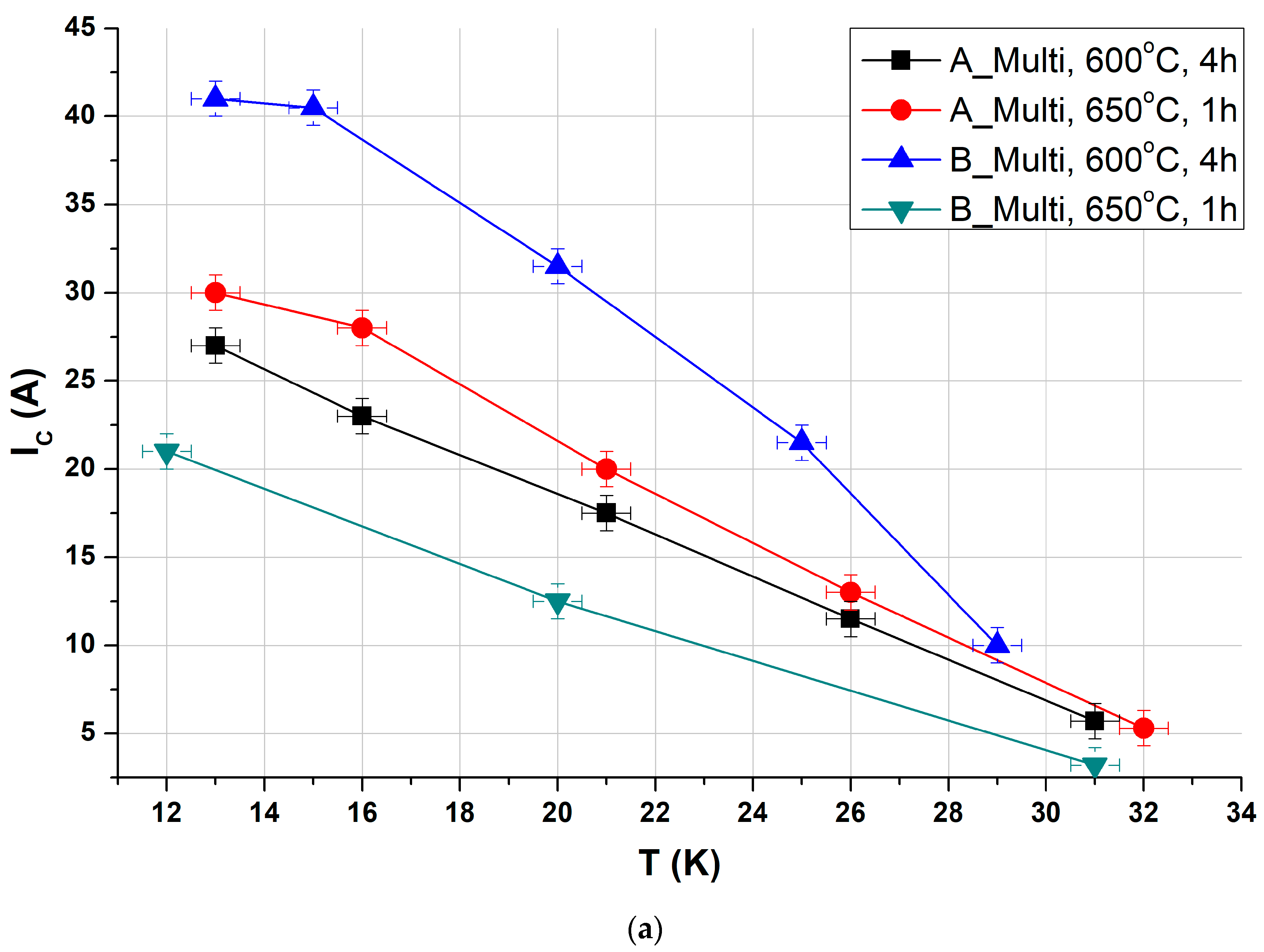

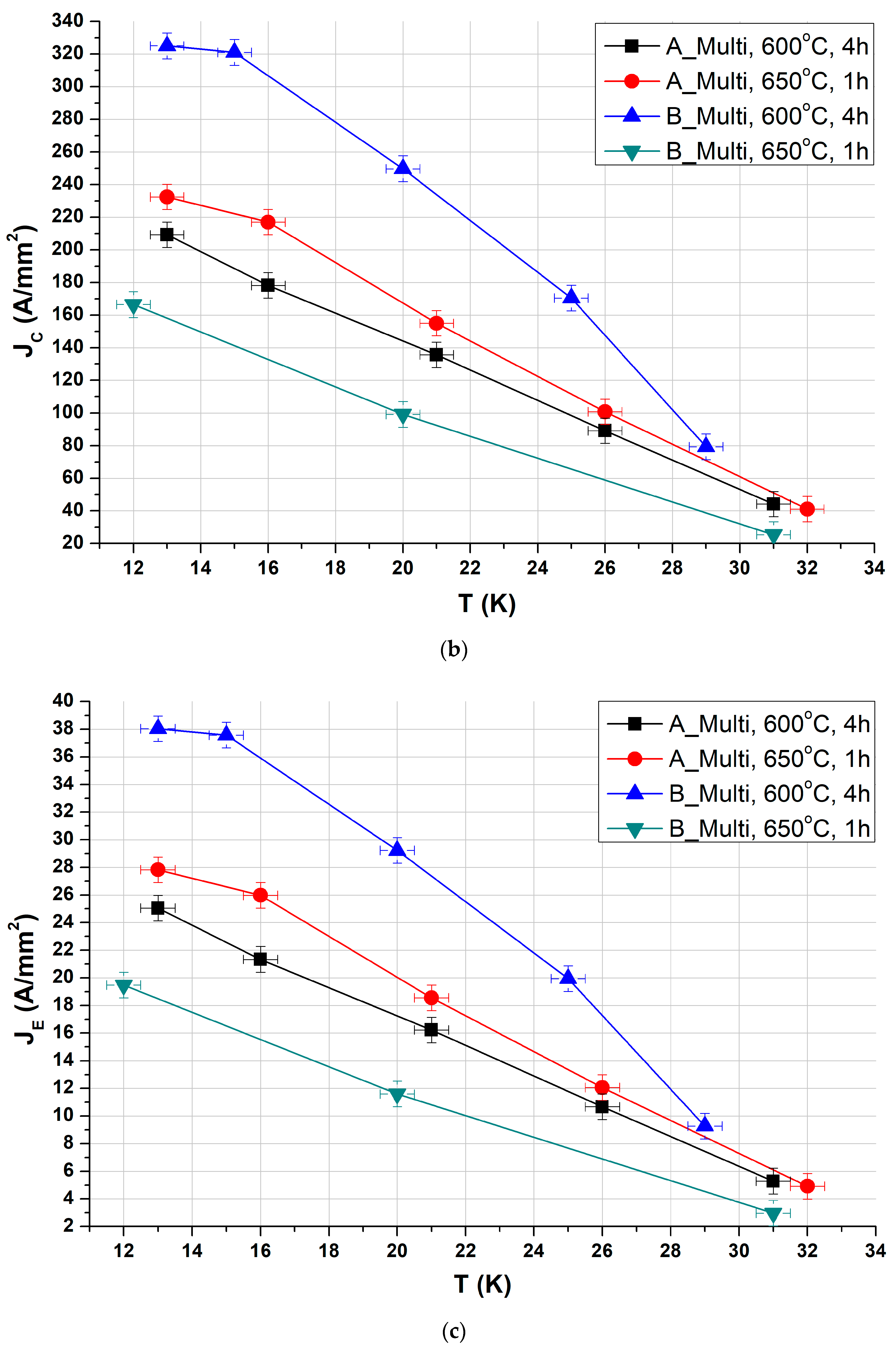

3.3. Critical Temperature and Criticl Current Density Measurements

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gajda, G.; Filar, K.; Morawski, A.; Gajda, D.; Przyslupski, P. The Effect of C and (Er, Sm, Eu)2O3 Doping and High Isostatic Pressing on Superconducting Properties of MgB2 Phase and Volume of Cylindrical MgB2 Ceramic Samples. J. Alloys Compd. 2023, 938, 168526. [Google Scholar] [CrossRef]

- Gajda, D.; Zaleski, A.; Morawski, A.; Cetner, T.; Thong, C.J.; Rindfleisch, M.A. Point Pinning Centers in SiC Doped MgB2 Wires after HIP. Supercond. Sci. Technol. 2016, 29, 085010. [Google Scholar] [CrossRef]

- Chen, S.K.; Wei, M.; MacManus-Driscoll, J.L. Strong Pinning Enhancement in MgB2 Using Very Small Dy2O3 Additions. Appl. Phys. Lett. 2006, 88, 192512. [Google Scholar] [CrossRef]

- Yang, Y.; Sumption, M.D.; Rindfleisch, M.; Tomsic, M.; Collings, E.W. Enhanced Higher Temperature Irreversibility Field and Critical Current Density in MgB2 Wires with Dy2O3 Additions. Supercond. Sci. Technol. 2021, 34, 25010. [Google Scholar] [CrossRef]

- Pan, X.F.; Cheng, C.H.; Zhao, Y. Effect of Rare-Earth Oxides Doping on the Superconductivity and Flux Pinning of MgB2 Superconductor. J. Supercond. Nov. Magn. 2011, 24, 1611–1616. [Google Scholar] [CrossRef]

- Erdem, Ö.; Yanmaz, E. Effect of Er Doping on the Superconducting Properties of Porous MgB2. Bull. Mater. Sci. 2015, 38, 89–93. [Google Scholar] [CrossRef]

- Sai Srikanth, A.; Muralidhar, M.; Sunsanee, P.; Jirsa, M.; Sakai, N.; Oka, T.; Murakami, M. Optimization of Carbon Encapsulated Boron Doping for High-Performance Bulk Sintered MgB2. Adv. Eng. Mater. 2020, 22, 2000478. [Google Scholar] [CrossRef]

- Ková, P.; Hušek, I.; Melišek, T.; Grivel, J.C.; Pachla, W.; Strbík, V.; Diduszko, R.; Homeyer, J.; Andersen, N.H. The Role of MgO Content in Ex Situ MgB2 Wires. Supercond. Sci. Technol. 2004, 17, L41–L46. [Google Scholar] [CrossRef]

- Grivel, J.C.; Andersen, N.H.; Pallewatta, P.G.A.P.; Zhao, Y.; Von Zimmermann, M. Influence of Bi, Se and Te Additions on the Formation Temperature of MgB2. Supercond. Sci. Technol. 2012, 25, 015010. [Google Scholar] [CrossRef]

- Kim, J.H.; Heo, Y.-U.; Matsumoto, A.; Kumakura, H.; Rindfleisch, M.; Tomsic, M.; Dou, S.X. Comparative Study of Mono- and Multi-Filament MgB2 Wires with Different Boron Powders and Malic Acid Addition. Supercond. Sci. Technol. 2010, 23, 075014. [Google Scholar] [CrossRef]

- Yetiş, H.; Avcl, D.; Karaboǧa, F.; Aksoy, C.; Gajda, D.; Martínez, E.; Tanylldlzl, F.M.; Zaleski, A.; Babij, M.; Tran, L.M.; et al. Transport and Structural Properties of MgB2/Fe Wires Produced by Redesigning Internal Mg Diffusion Process. Supercond. Sci. Technol. 2022, 35, 045012. [Google Scholar] [CrossRef]

- Liang, G.; Alessandrini, M.; Yen, F.; Hanna, M.; Fang, H.; Hoyt, C.; Lv, B.; Zeng, J.; Salama, K. Effects of MgO Impurities and Micro-Cracks on the Critical Current Density of Ti-Sheathed MgB2 Wires. Phys. C Supercond. 2007, 457, 47–54. [Google Scholar] [CrossRef]

- Li, W.X.; Zeng, R.; Wang, J.L.; Li, Y.; Dou, S.X. Dependence of Magnetoelectric Properties on Sintering Temperature for Nano-SiC-Doped MgB2/Fe Wires Made by Combined in Situ/Ex Situ Process. J. Appl. Phys. 2012, 111, 07E135. [Google Scholar] [CrossRef]

- Kario, A.; Morawski, A.; Glowacki, B.A.; Lada, T.; Smaga, M.; Diduszko, R.; Kolesnikov, D.; Zaleski, A.; Kondrat, A.; Gajda, D. Superconducting and Microstructural Properties of (Mg+2B)+MgB2/Cu Wires Obtained by High Gas Pressure Technology. Acta Phys. Pol. A 2007, 111, 693–703. [Google Scholar] [CrossRef]

- Woźniak, M.; Juda, K.L.; Hopkins, S.C.; Gajda, D.; Glowacki, B.A. Optimization of the Copper Addition to the Core of in Situ Cu-Sheathed MgB2 Wires. Supercond. Sci. Technol. 2013, 26, 105008. [Google Scholar] [CrossRef]

- Santra, S.; Grovenor, C.R.M.; Speller, S.C.; Kováč, P.; Kopera, L.; Hušek, I. Comparison of Interfacial and Critical Current Behaviour of Al+Al2O3 Sheathed MgB2 Wires with Ta and Ti Diffusion Barriers. J. Alloys Compd. 2019, 807, 151665. [Google Scholar] [CrossRef]

- Pachla, W.; Presz, A.; Diduszko, R.; Kovác, P.; Hušek, I. Structural Inhomogeneity of Superconducting Ex Situ MgB2/Cu Wires Made by the Powder-in-Tube Technique. Supercond. Sci. Technol. 2002, 15, 301. [Google Scholar] [CrossRef]

- Pachla, W.; Presz, A.; Ková, P.; Hušek, I.; Diduszko, R. Structural Characterization of Multifilament Heat Treated Ex Situ MgB2 Superconducting Wires with Cu and Fe Sheaths. Supercond. Sci. Technol. 2004, 17, 1289–1294. [Google Scholar] [CrossRef]

- Kováč, P.; Hušek, I.; Melišek, T. MgB2 Composite Superconductors Made by Ex Situ and In Situ Process. Adv. Sci. Technol. 2006, 47, 131–136. [Google Scholar]

- Li, G.Z.; Yang, Y.; Susner, M.A.; Sumption, M.D.; Collings, E.W. Critical Current Densities and N-Values of MgB2 Strands over a Wide Range of Temperatures and Fields. Supercond. Sci. Technol. 2012, 25, 025001. [Google Scholar] [CrossRef]

- Li, C.; Suo, H.; Ma, L.; Yang, L.; Maeda, M.; Patel, D.; Matsumoto, A.; Kumakura, H. Significant Improvement in Superconducting Properties of in Situ Powder-in-Tube MgB2 Wires through Anthracene Doping and Heat Treatment Optimization. Supercond. Sci. Technol. 2019, 32, 105004. [Google Scholar] [CrossRef]

- Filar, K.; Morawski, A.; Zaleski, A.; Tran, L.M.; Czujko, T.; Gajda, D. Superconducting Properties and Microstructure Changes after Heat Treatment of In Situ MgB2 Wires with Ex Situ MgB2 Barriers. J. Supercond. Nov. Magn. 2022, 35, 1491–1497. [Google Scholar] [CrossRef]

- Kováč, P.; Hušek, I.; Pachla, W.; Kulczyk, M.; Melišek, T.; Dvorák, T. As-Deformed Filament’s Density and Transport Currents of MgB2/Ti/Glidcop Wire. J. Alloys Compd. 2011, 509, 8783–8787. [Google Scholar] [CrossRef]

- Kováč, P.; Hušek, I.; Kulich, M.; Melišek, T.; Kováč, J.; Kopera, L. MgB2 Wires with Ti and NbTi Barrier Made by IMD Process. Cryogenics 2016, 79, 74–78. [Google Scholar] [CrossRef]

- Hušek, I.; Kováč, P.; Melišek, T.; Kopera, L. Thermally Stabilized MgB2 Composite Wires with Different Barriers. Cryogenics 2011, 51, 550–554. [Google Scholar] [CrossRef]

- Polák, M.; Demenčík, E.; Hušek, I.; Kopera, L.; Kováč, P.; Mozola, P.; Takács, S. AC Losses and Transverse Resistivity in Filamentary MgB2 Tape with Ti Barriers. Phys. C Supercond. Appl. 2011, 471, 389–394. [Google Scholar] [CrossRef]

- Glowacki, B.A.; Majoros, M.; Vickers, M.; Evetts, J.E.; Shi, Y.; McDougall, I. Superconductivity of Powder-in-Tube MgB2 Wires. Supercond. Sci. Technol. 2001, 14, 193–199. [Google Scholar] [CrossRef]

- Kováč, P.; Hušek, I.; Melišek, T.; Kulich, M.; Štrbík, V. MgB2 Composite Wires with Fe, Nb and Ta Sheaths. Supercond. Sci. Technol. 2006, 19, 600–605. [Google Scholar] [CrossRef]

- Glowacki, B.A.; Morawski, A. Composite Electrical Conductors and Method for Their Manufacture. U.S. Patent Application No. 12/098,475, 6 November 2008. [Google Scholar]

- Inoue, N.; Nishihara, M.; Kalpakjian, S. Hydrostatic Extrusion: Theory and Applications. J. Tribol. 1987, 109, 376. [Google Scholar] [CrossRef]

- Review Lecture: Hydrostatic Extrusion. Proc. R. Soc. London. A. Math. Phys. Sci. 1969, 311, 331–347. [CrossRef]

- Pachla, W.; Kováč, P.; Hušek, I.; Melišek, T.; Müler, M.; Štrbík, V.; Mazur, A.; Presz, A. The Effect of Hydrostatic Extrusion on the Jc (B) Characteristic of Ex Situ MgB2 Wires. Supercond. Sci. Technol. 2005, 18, 552–556. [Google Scholar] [CrossRef]

- Kováč, P.; Pachla, W.; Hušek, I.; Kulczyk, M.; Melišek, T.; Holúbek, T.; Diduszko, R.; Reissner, M. Multicore MgB2 Wires Made by Hydrostatic Extrusion. Phys. C Supercond. Appl. 2008, 468, 2356–2360. [Google Scholar] [CrossRef]

- Garbacz, H.; Topolski, K.; Motyka, M. Hydrostatic Extrusion. In Nanocrystalline Titanium; Elsevier: Amsterdam, The Netherlands, 2019; pp. 37–53. [Google Scholar] [CrossRef]

- Abcr GmbH. Available online: https://abcr.com/de_en/ (accessed on 12 December 2024).

- Pavezyum Kimya. Available online: https://pavtec.com.tr/ (accessed on 12 December 2024).

- ZwickRoell. Available online: https://www.zwickroell.com/products/pre-owned-market/used-tensile-testers-z010-z020-z050-z100/#c135325 (accessed on 12 December 2024).

- Nanostructuring of Metals by Hydrostatic Extrusion|Request PDF. Available online: https://www.researchgate.net/publication/285028103_Nanostructuring_of_metals_by_hydrostatic_extrusion (accessed on 10 January 2023).

- Zdunek, J.; Maj, P.; Kulczyk, M.; Mizera, J. Texture, Residual Stresses and Mechanical Properties Analysis in the Commercial 1.4462 Duplex Stainless Steel Subjected to Hydrostatic Extrusion. Arch. Civ. Mech. Eng. 2019, 19, 525–534. [Google Scholar] [CrossRef]

- Skiba, J.; Kulczyk, M.; Pachla, W.; Wiśniewski, T.S.; Smalc-Koziorowska, J. Effect of Severe Plastic Deformation Realized by Hydrostatic Extrusion on Heat Transfer in CP Ti Grade 2 and 316L Austenitic Stainless Steel. J. Nanomed. Nanotechnol. 2018, 9, 511. [Google Scholar] [CrossRef]

- Jarzębska, A.; Bieda, M.; Maj, Ł.; Chulist, R.; Wojtas, D.; Strąg, M.; Sułkowski, B.; Przybysz, S.; Pachla, W.; Sztwiertnia, K. Controlled Grain Refinement of Biodegradable Zn-Mg Alloy: The Effect of Magnesium Alloying and Multi-Pass Hydrostatic Extrusion Preceded by Hot Extrusion. Metall. Mater. Trans. A 2020, 51, 6784–6796. [Google Scholar] [CrossRef]

- Skiba, J.; Kulczyk, M.; Przybysz-Gloc, S.; Skorupska, M.; Niczyporuk, K. The Impact of Severe Plastic Deformations Obtained by Hydrostatic Extrusion on the Machinability of Ultrafine-Grained Ti Grade 2 Intended for Fasteners. Sci. Rep. 2022, 12, 16240. [Google Scholar] [CrossRef]

- Pachla, W.; Przybysz, S.; Jarzębska, A.; Bieda, M.; Sztwiertnia, K.; Kulczyk, M.; Skiba, J. Structural and Mechanical Aspects of Hypoeutectic Zn–Mg Binary Alloys for Biodegradable Vascular Stent Applications. Bioact. Mater. 2021, 6, 26–44. [Google Scholar] [CrossRef]

- Kaszuwara, W.; Pawlik, P.; Zygmuntowicz, J.; Michalski, B.; Kulczyk, M. Effect of Severe Deformation on the Microstructure and Properties of Nd-Fe-B Powders Caused by Hydrostatic Extrusion. J. Magn. Magn. Mater. 2021, 524, 167665. [Google Scholar] [CrossRef]

- Gizynski, T.; Kaszuwara, W.; Pawlik, P.; Kulczyk, M.; Leonowicz, M.; Michalski, B. Microstructure and Properties of Magnets Obtained by Hydrostatic Extrusion of Nd-Fe-B Powder. Acta Phys. Pol. A 2015, 127, 626–628. [Google Scholar] [CrossRef]

- Skiba, J.; Pachla, W.; Mazur, A.; Przybysz, S.; Kulczyk, M.; Przybysz, M.; Wróblewska, M. Press for Hydrostatic Extrusion with Back-Pressure and the Properties of Thus Extruded Materials. J. Mater. Process. Technol. 2014, 214, 67–74. [Google Scholar] [CrossRef]

- Pachla, W.; Skiba, J.; Kulczyk, M.; Przybysz, M. High-pressure equipment for cold severe plastic deformation working of materials. Met. Form./Obróbka Plast. Met. 2015, 26, 283. [Google Scholar]

| The Temperature of the Liquid Metal in the Crucible | The Temperature of the Bars After Leaving the Mold | Continuous Casting Speed | Mold Cooling Water Temperature | Mold Cooling Water Flow |

|---|---|---|---|---|

| 1180–1190 °C | 50–60 °C | 0.3 m/min. | 10–12 °C | 3–3.5 L/min. |

| Density | Brinell Hardness | Ultimate Tensile Strength | Yield Stress | Elongation to Break During Tensile Test | Electrical Conductivity | Relative Conductivity |

|---|---|---|---|---|---|---|

| ρ, g/cm3 | HB | UTS, MPa | YS, MPa | A200, % | σ, MS/m | %IACS |

| 8.94 | 85 | 195 | 120 | 38.5 | 58.0 | 100 |

| Notation/HE Pass | Billet Diameter d0 (mm) | Product Diameter df (mm) | True Strain ɛ = lnR 1 | Extrusion Pressure pHE (MPa) | Measurement Error (Standard Deviation) |

|---|---|---|---|---|---|

| A_Mono | 26.02 | 11.91 | 1.56 | 576 | ±16.68 |

| B_Mono |

| 12.15 | 11.55 | 11.02 | 10.50 | 10.00 | 9.50 | 9.10 | 8.70 | 8.35 | 8.00 | 7.65 | 7.30 | 6.97 |

| 6.65 | 6.32 | 6.05 | 5.77 | 5.50 | 5.30 | 5.00 | 4.77 | 4.55 | 4.35 | 4.15 | 3.96 | 3.78 |

| 3.61 | 3.44 | 3.29 | 3.14 | 3.00 | 2.86 | 2.73 | 2.61 | 2.49 | 2.37 | 2.26 | 2.16 | 2.07 |

| 1.97 | 1.87 | 1.78 | 1.70 | 1.62 | 1.55 | 1.49 | 1.42 | 1.36 | 1.29 | 1.23 | 1.17 |

| Sample | Cone Angle 2α | Single Operation Elongation | Wire Drawing Speed | Diameter Range | Total True Strain |

|---|---|---|---|---|---|

| ° | % | m/s | mm | - | |

| A_Mono B_Mono A_Multi B_Multi | 14 | 10 | 0.2 | 12.15–1.17 | 4.7 |

| Sample | Type of Material | Lubricant |

|---|---|---|

| A_Multi | Multicore, 6 + 1, without heat treatment | Multidraw Cu MF (Zeller + Gmalin) oil: density 950 kg/m3, viscosity 75 mm2/s, emulsion: pH 9.0, electrical conductivity 1100 µS/cm |

| B_Multi | Multicore, 6 + 1, with heat treatment: 350 °C/1 h |

| Sample | Type of Wire | Diameter [mm] | Heat Treatment Process |

|---|---|---|---|

| A_Multi_600 °C_4 h | 7-core with Cu outer coating, including: 6 cores—in situ with ex situ barrier and CuAg0.1 sheath; center core—Cu | 1.17/0.80 | T = 600 °C; p = 0.1 MPa; t = 4 h |

| B_Multi_600 °C_4 h | |||

| A_Multi_650 °C_1 h | 7-core with Cu outer coating, including: 6 cores—in situ with ex situ barrier and CuAg0.1 sheath; center core—Cu | 1.17/0.80 | T = 650 °C; p = 0.1 MPa; t = 1 h |

| B_Multi_650 °C_1 h |

| The Average HV5 Hardness Value of the Outer Coating and Sheath Material (kgf/mm2) | ||||||||

|---|---|---|---|---|---|---|---|---|

| Wire Diameter | 12.15 mm | 4.15 mm | 3 mm | 1.17 mm | ||||

| Outer Coating/Core Sheath Material | Cu ETP | CuAg0.1 | Cu ETP | CuAg0.1 | Cu ETP | CuAg0.1 | Cu ETP | CuAg0.1 |

| A_Multi | 108.1 | 111.2 | 120.4 | 125.1 | 122.3 | 127.5 | 129.4 | 136.3 |

| B_Multi | 113.3 | 115.6 | 123.0 | 129.5 | 128.7 | 134.1 | 134.8 | 141.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Filar, K.; Kawecki, A.; Morawski, A.J.; Sieja-Smaga, E.; Cetner, T.; Mamala, A.; Skiba, J.; Gajda, G. Preparation Process of In Situ MgB2 Material with Ex Situ MgB2 Barrier to Obtain Long Sections of Superconducting Multicore Wires. Materials 2025, 18, 126. https://doi.org/10.3390/ma18010126

Filar K, Kawecki A, Morawski AJ, Sieja-Smaga E, Cetner T, Mamala A, Skiba J, Gajda G. Preparation Process of In Situ MgB2 Material with Ex Situ MgB2 Barrier to Obtain Long Sections of Superconducting Multicore Wires. Materials. 2025; 18(1):126. https://doi.org/10.3390/ma18010126

Chicago/Turabian StyleFilar, Krzysztof, Artur Kawecki, Andrzej Jacek Morawski, Eliza Sieja-Smaga, Tomasz Cetner, Andrzej Mamala, Jacek Skiba, and Grzegorz Gajda. 2025. "Preparation Process of In Situ MgB2 Material with Ex Situ MgB2 Barrier to Obtain Long Sections of Superconducting Multicore Wires" Materials 18, no. 1: 126. https://doi.org/10.3390/ma18010126

APA StyleFilar, K., Kawecki, A., Morawski, A. J., Sieja-Smaga, E., Cetner, T., Mamala, A., Skiba, J., & Gajda, G. (2025). Preparation Process of In Situ MgB2 Material with Ex Situ MgB2 Barrier to Obtain Long Sections of Superconducting Multicore Wires. Materials, 18(1), 126. https://doi.org/10.3390/ma18010126