Recycling of Industrial Waste as Soil Binding Additives—Effects on Soil Mechanical and Hydraulic Properties during Its Stabilisation before Road Construction

Abstract

1. Introduction

- The best strengthening and sealing soil-stabilizing additives;

- The utilization of waste materials in a safe manner without posing a pollution risk to the environment.

2. Materials and Methods

2.1. Materials—Commercial Soil Stabilizing Additives

- Geosta K-1 constitutes ion exchange agents that have a beneficial effect on cement hydration. Basically, it is a mixture of salts, i.e., chlorides of magnesium, sodium, potassium, calcium, and iron; potassium carbonate and iron; aluminum; and sodium sulfates. The pioneer of this type of additive is the Dutch company Geo-Products B.V. (Maastricht, The Netherlands), which has been offering a loose ion exchange agent under the trade name GEOSTA K-1 for many years, including on the Polish market [36].

- ROADBOND EN 1™ (Saint Andrews, MB, Canada) stabilizer causes clay to release weakly ionized water molecules from the clay matrix and replaces the water with strongly ionized sulfate radicals. The exchange is permanent and takes place at normal pH levels. As in lime stabilization, metal hydrates are formed, which help increase the strength of the clay, and by leaving the clay matrix intact, the permeability is significantly reduced. When mixed with base material and compatible in-place material, ROADBOND EN 1™ stabilizer dissolves the mineral salts and natural cementitious properties of the soil. Mixing the soil disperses the dissolved material into the void spaces between the soil grains, where it cures and crystallizes. The re-crystallized mineral salts and natural cements form an effective bond that results in improved strength, load-bearing capacity, and durability. The replacement of weakly ionized water molecules with strongly ionized sulfate radicals, along with the increased dry density, make the treated soil more resistant to water penetration. This reduces shrink-swell potential along with freeze–thaw damage [37].

- ETONIS® 1400 S is a polymer dispersion for soil stabilization. When ETONIS® 1400 S is applied to the soil, the product forms polymer bridges between the soil or aggregate particles and hydrated cement particles. ETONIS® 1400 S is responsible for the formation of a flexible and robust network that is durable and water-resistant [38]. ROKAmin SRK8P4 is a specialized cationic surfactant. The product is a quaternized, ethoxylated, and oxypropylated fatty amine of animal origin. The product is available in the form of a clear, viscous liquid with a maximum color of 130 on the iodine scale. ROKAmin SRK8P4 dissolves well in hot water as well as in organic solvents such as chloroform. Supplied by Wacker Chemie AG Headquarters, Hanns-Seidel Platz 4, 81737 Munich, Germany.

- PROROAD™, supplied by Phoenix Distribution (Mornington, VIC, Australia), is a sealing and stabilizing fluid (2 separate components) supplied in concentrated form in 1000 L IBC containers or 200- and 120-L barrels. The final product is non-toxic, environmentally safe, and easy to use. There is no requirement to use special construction teams due to the application of the product. The specific gravity for Proroad is 1.06 and 1.4 for Proroad Waterproof.

- TEQUAT LC90i is a cationic surfactant. It is obtained by the condensation of fatty acids of animal origin and triethanolamine, followed by quaternization. The product is offered in isopropanol, in the form of a soft paste with a color ranging from white to yellow. Tequat LC90i contains 90% of the active substance with the INCI name: Dihydrogenated Tallowethyl Hydroxyethylmonium Methosulfate and Ditallowethyl Hydroxyethylmonium Methosulfate. The product forms dispersions in water. Supplied by PCC Group, Sienkiewicza 4, 56-120 Brzeg Dolny, Poland [39].

2.2. Materials—Waste-Derived Additives

- Based on CBPD (cement bypass dust), waste ash from the ceramic industry, the so-called ash from the brickworks bypass, is an alternative to the popularly used commercial binder GEOSTA (constituting a mixture of salts, i.e., chlorides of magnesium, sodium, potassium, calcium, and iron, potassium carbonate and iron; aluminum; and sodium sulfates) described in the text below as ash.

- Sulfuric acid of waste origin, which is an alternative to the popularly used Roadbond EN-1 soil stabilizer. It fundamentally alters the ability of clay to hold adsorbed water, which is water held by electrical attraction.

- Pyrolytic oils and waxes from waste plastics, described in the text below as polyolefin emulsions, based on products formed during the thermal destruction of polyolefins, made of:

- ⚬

- pure HDPE (High Density PolyEthylene);

- ⚬

- waste mixed plastics;

- ⚬

- waste tires;

- ⚬

- waste PE foil.

- Emulsion from chewing gum waste.

2.3. Mixture Preparation

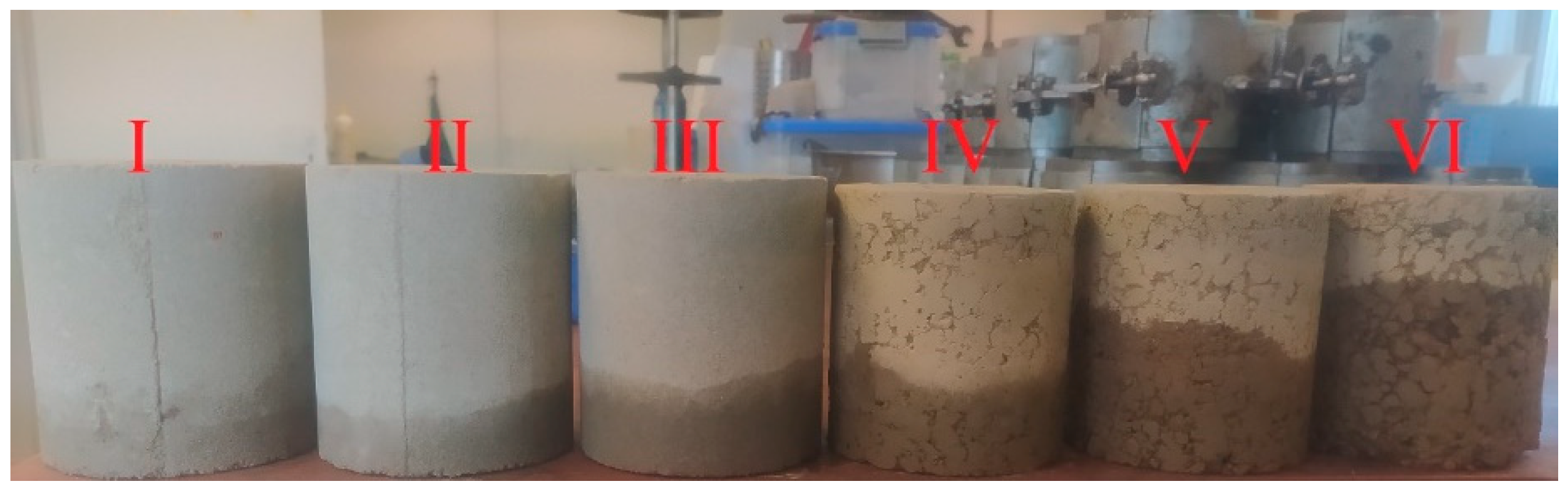

2.4. Sample Preparation for Mechanical Tests

2.5. Compressive Strength Test

2.6. Capillary Rise Test

- WN—Capillary rise/absorption coefficient (%);

- mw—mass of the soaked sample (via capillary rise or immersion) (g);

- ms—mass of dried sample (g).

2.7. Water Absorption Test

2.8. Frost Resistance Test

2.9. Soil Stabilization Standards

- -

- Load capacity;

- -

- Bursting.

- -

- By analyzing the type of soil, the content of fine particles, the sand index, and water conditions (groundwater depth, embankment height, excavation depth);

- -

- By testing the load-bearing capacity of the substrate in the most humid or saturated conditions—the CBR index should be determined.

3. Results

3.1. Single Additions—Compressive Strength

3.1.1. Commercial Additives

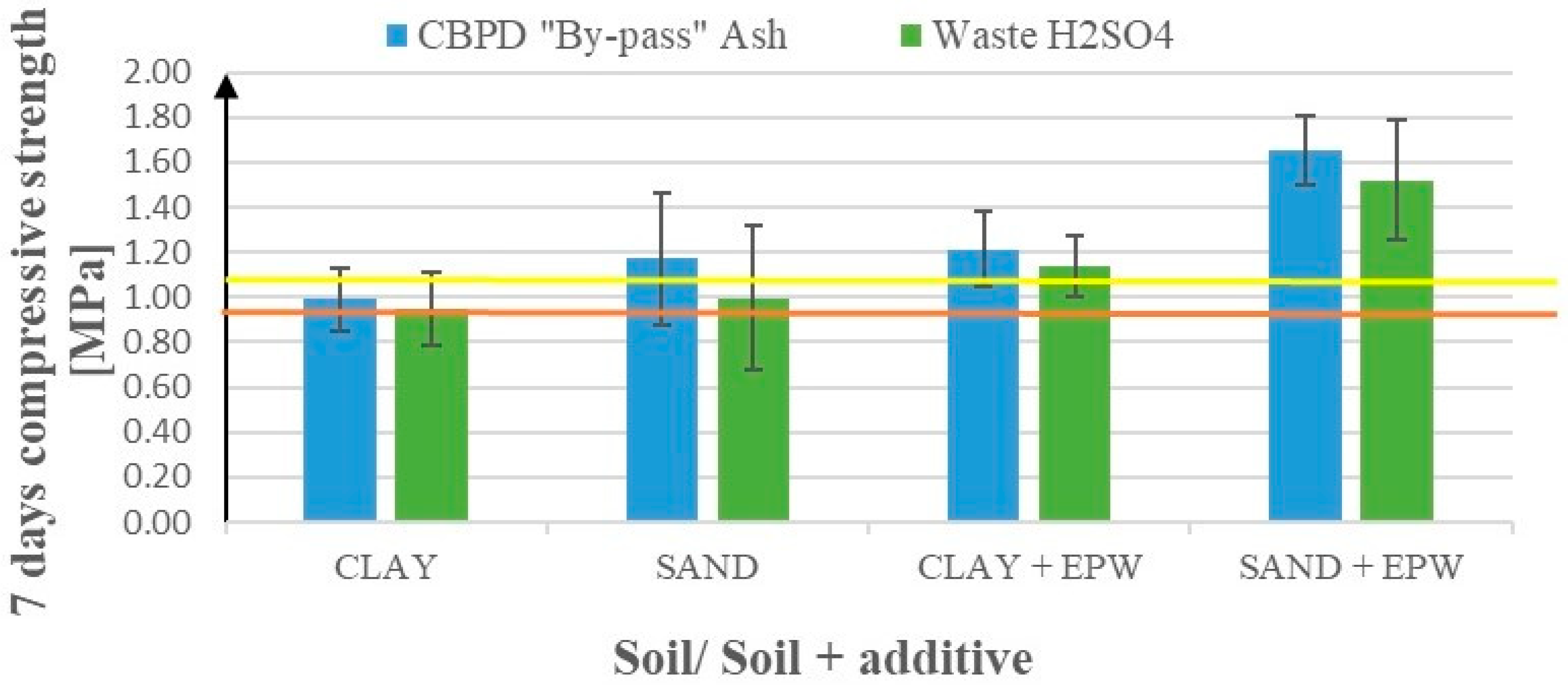

3.1.2. CBPD “By-Pass” Ash and Sulphuric Acid

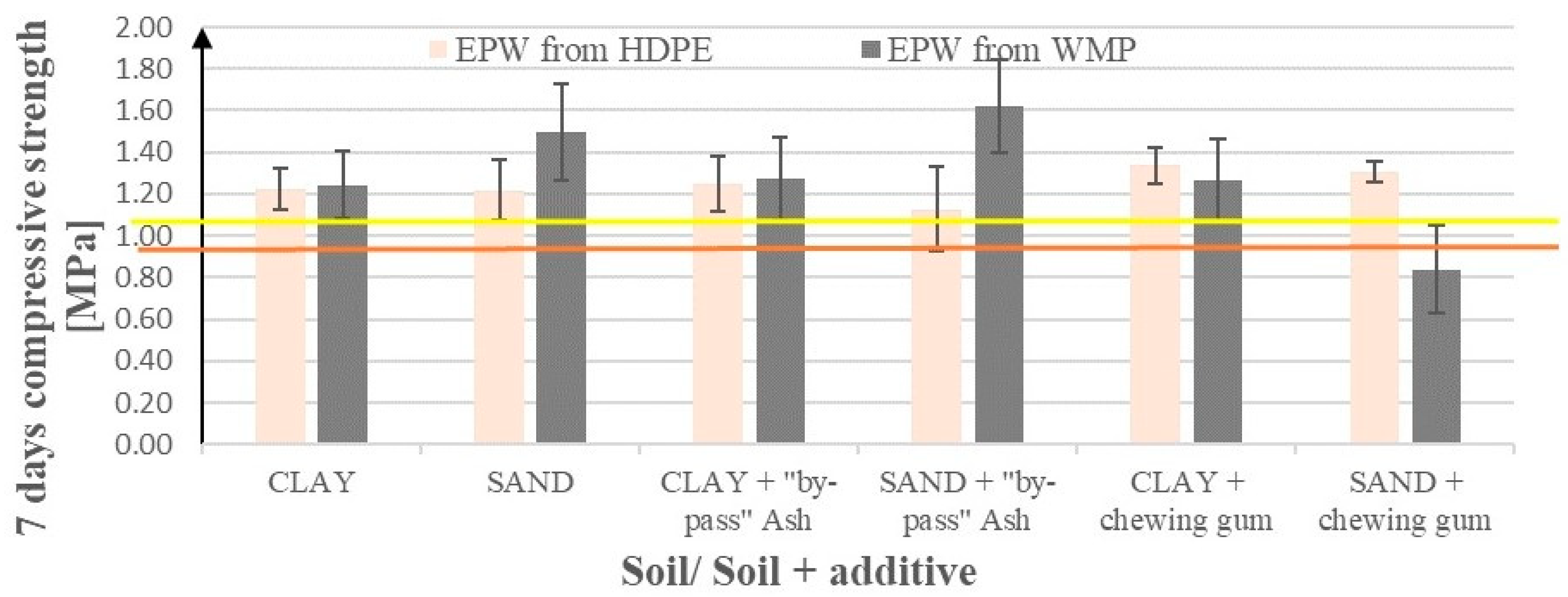

3.1.3. Pyrolytic Waxes

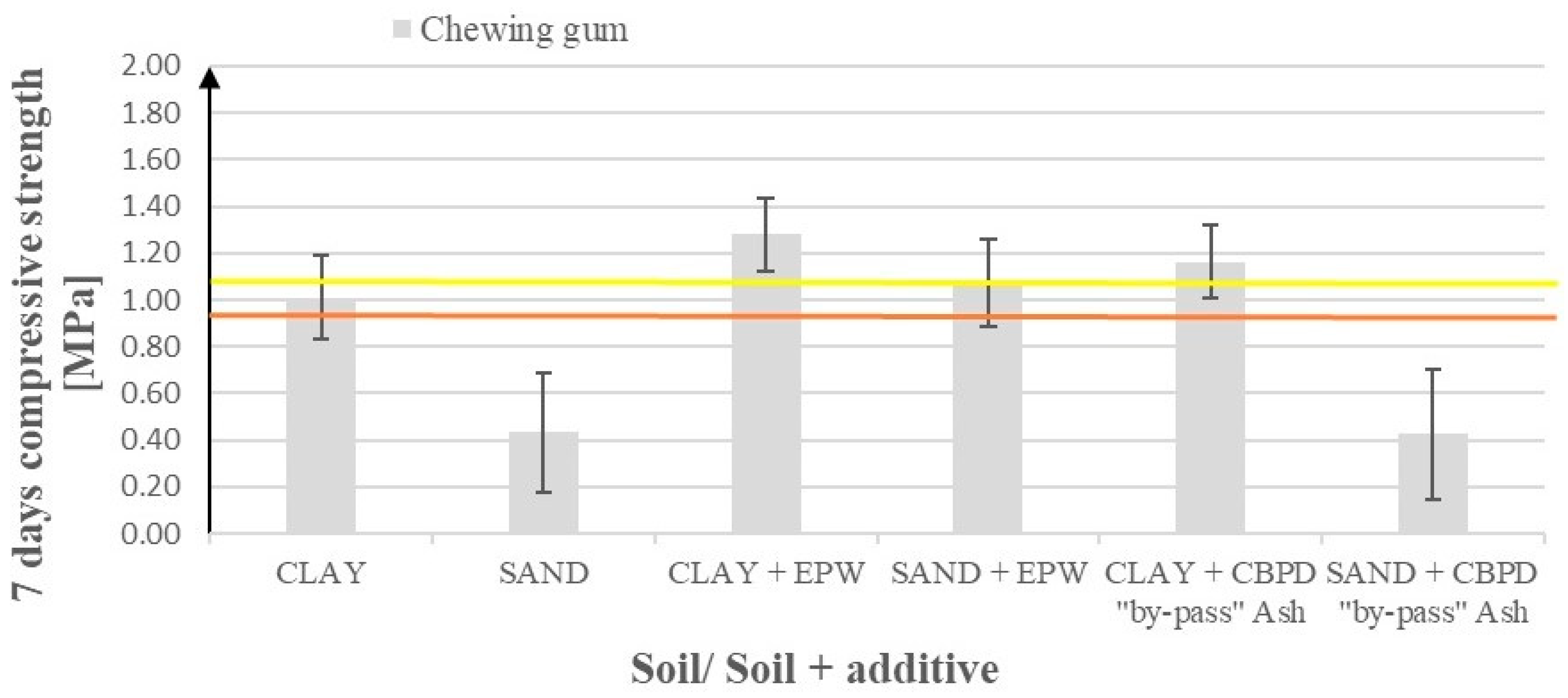

3.1.4. Emulsions from Chewing Gum Waste

3.2. Hybrid Additions—Compressive Strength

3.2.1. CBPD “By-Pass” Waste Ash and Sulphuric Acid with the Addition of EPW

3.2.2. EPW from Polyolefins with the Addition of Substitutes of the Commercial Stabilizer (“By-Pass” Waste Ash and Waste Sulfuric Acid)

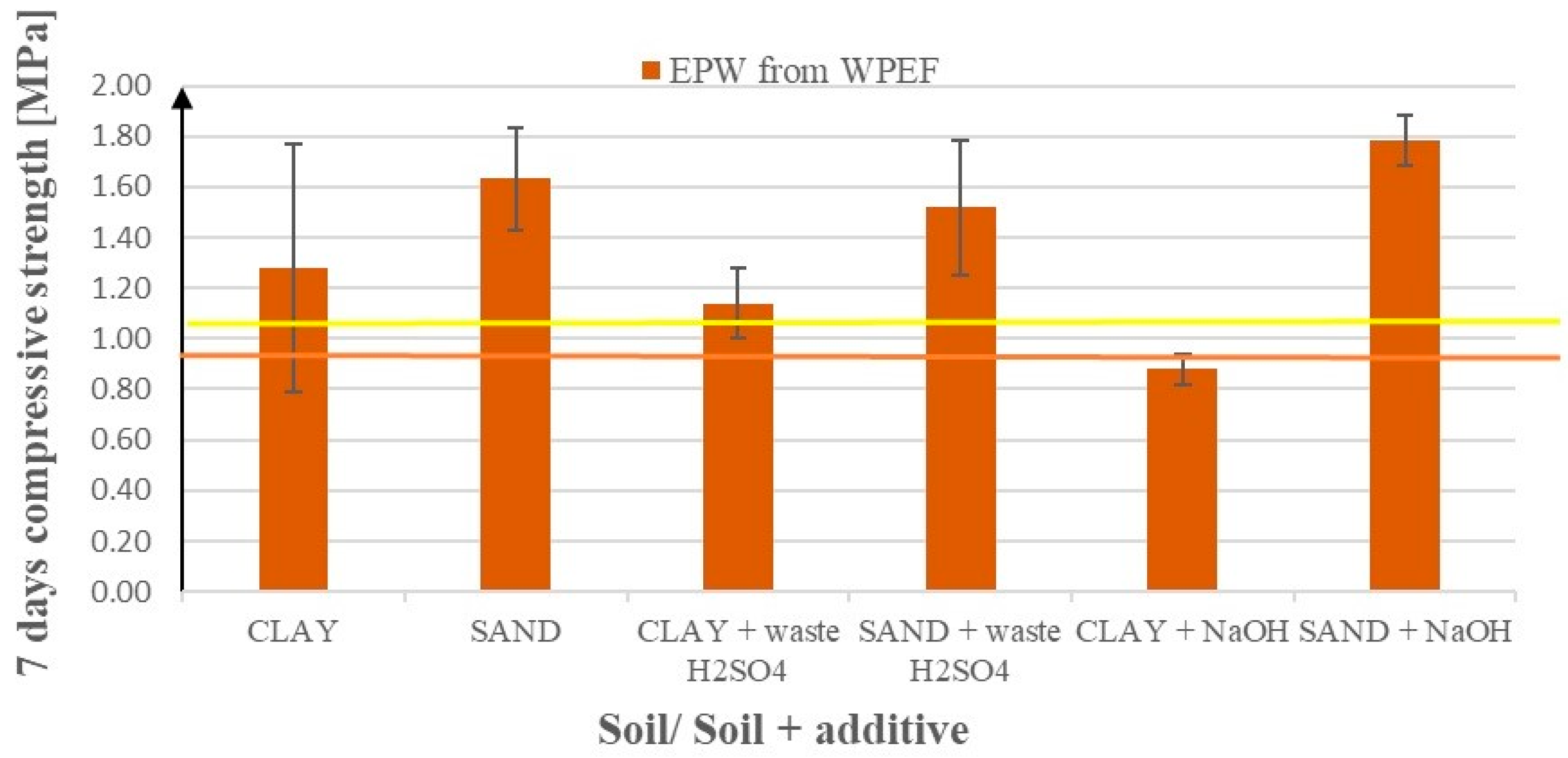

3.2.3. EPW from Polyolefins with the Addition of Emulsion from Chewing Gum Waste or NaOH

3.2.4. Emulsions from Chewing Gum Waste with the Addition of EPW from WMP or CBPD “By-Pass” Waste Ash from the Ceramic Industry

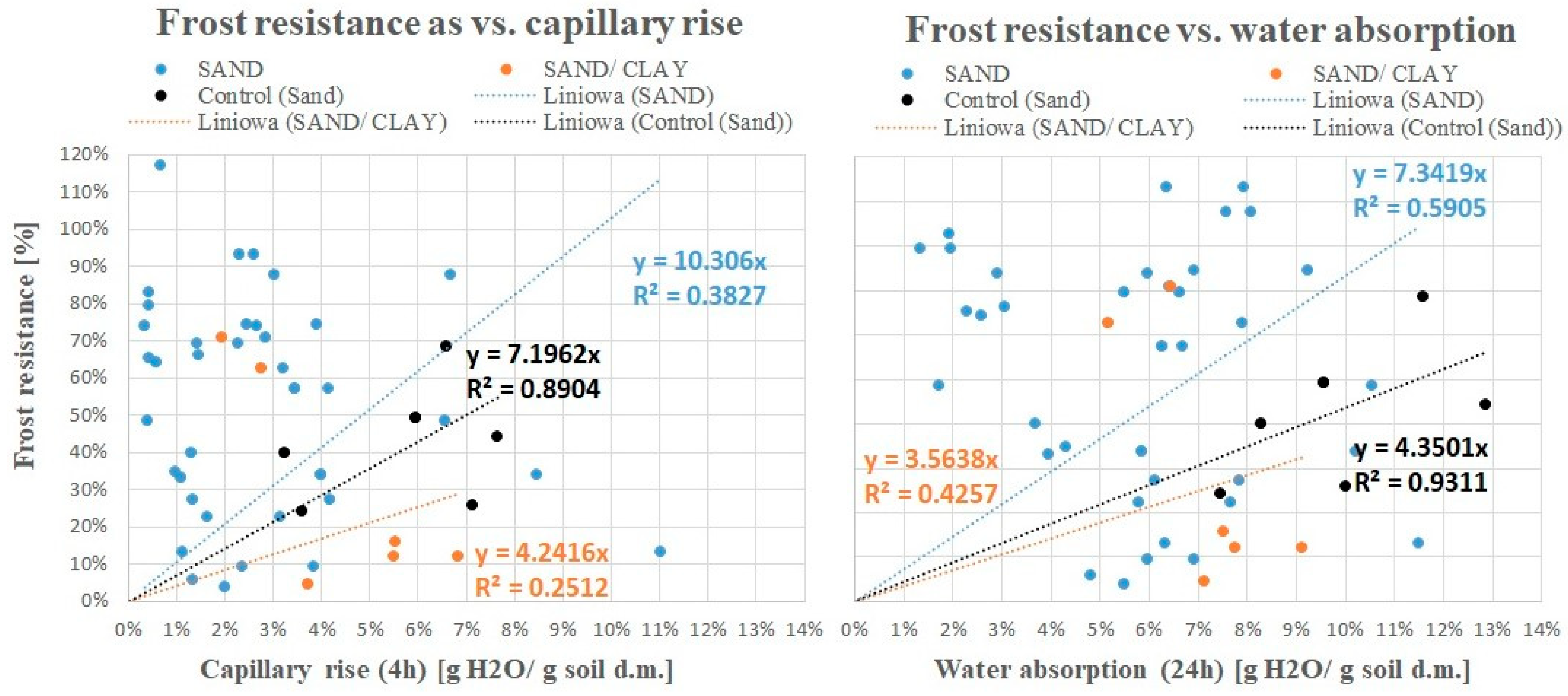

3.3. Soil Water Absorption and Frost Resistance—Introductory Investigations of Response to Hybrid Additions

3.4. Soil Compressive Strength, Water Absorption, and Frost Resistance after Hybrid Additions

3.4.1. The Best Sealing Materials—Sorted by Frost Resistance

3.4.2. The Best Sealing Materials—Sorted by the Capillary Rise

3.4.3. The Best Strengthening Materials—Chosen Taking into Account Compressive Strength after 7 Days

3.4.4. Best Strengthening Materials—Chosen Taking into Account Compressive Strength after 28 Days

4. Discussion

4.1. Effects of Waste-Based Additives on Compressive Strength

4.2. Effects of Waste-Based Additives on Hydraulic Properties (Water Transport and Frost Resistance)

4.3. Optimized Strengthening and Sealing Materials—Sorted by Optimization Parameter

5. Conclusions

- For SAND: EPW from WPEF + waste H2SO4 (69.5% FR, 45.6% 7-day UCS increase, 8.8% 28-day UCS increase) waste tire pyrolytic oil emulsion (74.3% FR, 17.5% 7-day UCS increase, 18.9% 28-day UCS increase), EPW from WMP + “by-pass” waste ash + NaOH (57.3% FR, 79.6% 7-day UCS increase, 27.6% 28-day UCS increase), EPW from WPEF + NaOH (87.6% FR, 40.9% 7-day UCS increase, 26.6% 28-day UCS increase), and EPW from WPEF (93% FR, 15.1% 7-day UCS increase);

- For CLAY: EPW from WPEF + NaOH (7.5% FR, 40.8% 7-day UCS increase, 119.1% 28-day UCS increase), EPW from WPEF + waste H2SO4 (2.8% FR, 80.7% 7-day UCS increase, 64.4% 28-day UCS increase), and solely EPW from WPEF (6.9% FR, 6.9% 28-day UCS increase).

6. Patents

- “Hydraulic sealing binder for cohesive soils and the method of its production and connection with the native cohesive soil”, No. P.438697, on behalf of Construction Company WACIŃSKI Witold Waciński

- “Sealing additive for hydraulic binder for non-cohesive soils and grained native soils, method of its production, and connection with native soil”, No. P.444266, on behalf of Construction Company WACIŃSKI Witold Waciński

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Patel, A. Geotechnical Investigations and Improvement of Ground Conditions; Cambridge Press: Cambridge, UK, 2019; pp. 1–201. [Google Scholar] [CrossRef]

- Alzhanova, G.Z.; Aibuldinov, Y.K.; Iskakova, Z.B.; Khabidolda, S.M.; Abdiyussupov, G.G.; Omirzak, M.T.; Murali, G.; Vatin, N.I. Development of Environmentally Clean Construction Materials Using Industrial Waste. Materials 2022, 15, 5726. [Google Scholar] [CrossRef] [PubMed]

- Abukhettala, M.; Fall, M. Geotechnical Characterization of Plastic Waste Materials in Pavement Subgrade Applications. Transp. Geotech. 2021, 27, 100472. [Google Scholar] [CrossRef]

- Salik, T.; Gandomi, A.H. Improvement of Shear Strength of Cohesive Soils by Additives: A Review. In Basics of Computational Geophysics; Elsevier: Amsterdam, The Netherlands, 2021; pp. 189–211. [Google Scholar] [CrossRef]

- Indiramma, P.; Sudharani, C.; Needhidasan, S. Utilization of Fly Ash and Lime to Stabilize the Expansive Soil and to Sustain Pollution Free Environment—An Experimental Study. Mater. Today Proc. 2020, 22, 694–700. [Google Scholar] [CrossRef]

- Bahmani, S.H.; Farzadnia, N.; Asadi, A.; Huat, B.B.K. The Effect of Size and Replacement Content of Nanosilica on Strength Development of Cement Treated Residual Soil. Constr. Build. Mater. 2016, 118, 294–306. [Google Scholar] [CrossRef]

- Choobbasti, A.J.; Kutanaei, S.S. Microstructure Characteristics of Cement-Stabilized Sandy Soil Using Nanosilica. J. Rock Mech. Geotech. Eng. 2017, 9, 981–988. [Google Scholar] [CrossRef]

- Ghasabkolaei, N.; Janalizadeh Choobbasti, A.; Roshan, N.; Ghasemi, S.E. Geotechnical Properties of the Soils Modified with Nanomaterials: A Comprehensive Review. Arch. Civ. Mech. Eng. 2017, 17, 639–650. [Google Scholar] [CrossRef]

- Cabrera, M.; Rosales, J.; Ayuso, J.; Estaire, J.; Agrela, F. Feasibility of Using Olive Biomass Bottom Ash in the Sub-Bases of Roads and Rural Paths. Constr. Build. Mater. 2018, 181, 266–275. [Google Scholar] [CrossRef]

- Gu, K.; Jin, F.; Al-Tabbaa, A.; Shi, B.; Liu, C.; Gao, L. Incorporation of Reactive Magnesia and Quicklime in Sustainable Binders for Soil Stabilisation. Eng. Geol. 2015, 195, 53–62. [Google Scholar] [CrossRef]

- Manso, J.M.; Ortega-López, V.; Polanco, J.A.; Setién, J. The Use of Ladle Furnace Slag in Soil Stabilization. Constr. Build. Mater. 2013, 40, 126–134. [Google Scholar] [CrossRef]

- Khemissa, M.; Mahamedi, A. Cement and Lime Mixture Stabilization of an Expansive Overconsolidated Clay. Appl. Clay Sci. 2014, 95, 104–110. [Google Scholar] [CrossRef]

- Douadi, A.; Hebbache, K.; Boutlikht, M.; Tabchouche, S.; Belebchouche, C.; Hammouche, R.; Del Serrone, G.; Moretti, L. Physical and Mechanical Effects of Silica Sand in Cement Mortars: Experimental and Statistical Modeling. Materials 2023, 16, 6861. [Google Scholar] [CrossRef] [PubMed]

- Umar, I.H.; Lin, H. Marble Powder as a Soil Stabilizer: An Experimental Investigation of the Geotechnical Properties and Unconfined Compressive Strength Analysis. Materials 2024, 17, 1208. [Google Scholar] [CrossRef] [PubMed]

- Gallego-Quintana, P.; Ojeda-Farias, O.F.; Alvarez-Rosario, A.; Alvarez-Sánchez, E.J.; Landa-Ruiz, L.; Terán-Torres, B.T.; Mendoza-Rangel, J.M.; Baltazar-Zamora, M.Á. Analysis of the Mechanical Properties of a Stabilized Subgrade Type Soil under a Sustainable Approach for Construction. Materials 2023, 16, 6395. [Google Scholar] [CrossRef] [PubMed]

- Roy, T.K. Influence of Sand on Strength Characteristics of Cohesive Soil for Using as Subgrade of Road. Procedia Soc. Behav. Sci. 2013, 104, 218–224. [Google Scholar] [CrossRef]

- Ali Said Al Alawi, A.; Gopalakrishnan, K.; Parameswari, K.; Majid Salim Al Aamri, A.; Said Al Kaabi, K.; Nirmala, R. Enhancement of the Existing Soil Strength Using the Waste Materials as a Stabilization Resource for Sustainable Development. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Ojuri, O.O.; Osagie, P.O.; Oluyemi-Ayibiowu, B.D.; Fadugba, O.G.; Tanimola, M.O.; Chauhan, V.B.; Jayejeje, O.O. Eco-Friendly Stabilization of Highway Lateritic Soil with Cow Bone Powder Admixed Lime and Plastic Granules Reinforcement. Clean. Waste Syst. 2022, 2, 100012. [Google Scholar] [CrossRef]

- Malik, P.; Mishra, S.K. A Comprehensive Review of Soil Strength Improvement Using Geosynthetics. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Boobalan, S.C.; Anandakumar, P.K.; Sathasivam, M. Utilization of Waste Plastic Sheets as Soil Stabilization Materials. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Díaz-López, J.L.; Cabrera, M.; Agrela, F.; Rosales, J. Geotechnical and Engineering Properties of Expansive Clayey Soil Stabilized with Biomass Ash and Nanomaterials for Its Application in Structural Road Layers. Geomech. Energy Environ. 2023, 36, 100496. [Google Scholar] [CrossRef]

- Stevulova, N.; Strigáč, J.; Junak, J.; Terpakova, E.; Holub, M. Incorporation of Cement Bypass Dust in Hydraulic Road Binder. Materials 2020, 14, 41. [Google Scholar] [CrossRef]

- Sulaiman, H.; Taha, M.R.; Abd Rahman, N.; Mohd Taib, A. Performance of Soil Stabilized with Biopolymer Materials—Xanthan Gum and Guar Gum. Phys. Chem. Earth Parts A/B/C 2022, 128, 103276. [Google Scholar] [CrossRef]

- Liu, J.; Che, W.; Lan, X.; Hu, M.; Qi, M.; Song, Z.; Sun, M.; Jing, M.; Qian, W.; Qi, C. Performance and Mechanism of a Novel Biopolymer Binder for Clayey Soil Stabilization: Mechanical Properties and Microstructure Characteristics. Transp. Geotech. 2023, 42, 101044. [Google Scholar] [CrossRef]

- Song, Z.; Liu, J.; Yu, Y.; Hao, S.; Jiang, B.; Song, J.; Kanungo, D.P.; Sun, S.; Bai, Y. Characterization of Artificially Reconstructed Clayey Soil Treated by Polyol Prepolymer for Rock-Slope Topsoil Erosion Control. Eng. Geol. 2021, 287, 106114. [Google Scholar] [CrossRef]

- Waciński, W.; Kuligowski, K.; Zając, M.; Urbaniak, W.; Olejarczyk, M. Hydraulic Sealing Binder for Cohesive Soils and Method of Its Production and Joining with the Native Cohesive Soil. 2021, Patent Application Nr 438697. Available online: https://ewyszukiwarka.pue.uprp.gov.pl/search/pwp-details/P.438697 (accessed on 15 April 2024).

- Dudekula, J.R.; Anil Kumar, S.; Chigurupati, S. Experimental Investigation on Geopolymer-Stabilized Expansive Soil. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Ayub, F.; Khan, S.A. An Overview of Geopolymer Composites for Stabilization of Soft Soils. Constr. Build. Mater. 2023, 404, 133195. [Google Scholar] [CrossRef]

- Leite, R.d.C.; Lucheta, A.R.; Holanda, R.B.; Silva, P.M.P.; Carmo, A.L.V.d.; Gomes, F.G.; Leite, R.d.C.; de Melo, C.C.A.; Costa, R.V.d.; Montini, M.; et al. Environmental and Agronomic Assessment of Soil Conditioners Produced from Bauxite Residue and Oil Palm Wastes. Environ. Res. 2023, 233, 116474. [Google Scholar] [CrossRef] [PubMed]

- James, J.; Devi, V.V. Bauxite Residue as a Binary Additive in Lime Treated Soil Composites. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Olejarczyk, M.; Rykowska, I.; Urbaniak, W. Management of Solid Waste Containing Fluoride—A Review. Materials 2022, 15, 3461. [Google Scholar] [CrossRef]

- Zhu, H.; Chang, C.S.; Rish, J.W. Normal and Tangential Compliance for Conforming Binder Contact I: Elastic Binder. Int. J. Solids Struct. 1996, 33, 4337–4349. [Google Scholar] [CrossRef]

- Saulick, Y.; Lourenço, S.D.N.; Baudet, B.A. Optimising the Hydrophobicity of Sands by Silanisation and Powder Coating. Géotechnique 2020, 71, 250–259. [Google Scholar] [CrossRef]

- Barnat-Hunek, D.; Smarzewski, P.; Łagód, G.; Suchorab, Z. Evaluation of the Contact Angle of Hydrophobised Lightweight-Aggregate Concrete with Sewage Sludge. Ecol. Chem. Eng. S 2015, 22, 625–635. [Google Scholar] [CrossRef]

- Bardet, J.P.; Jesmani, M.; Jabbari, N.; Lourenco, S.D.N. Permeability and Compressibility of Wax-Coated Sands. Géotechnique 2015, 64, 341–350. [Google Scholar] [CrossRef]

- Nowoczesne Rozwiązania Drogowe. Środek Jonowymienny do Stabilizacji—NASCON. Available online: https://www.nascon.pl/stabilizacja/srodek-jonowymienny-do-stabilizacji/ (accessed on 21 January 2024).

- Roadbond Soil Stabilizer. About Roadbond EN 1TM. Available online: https://roadbondsoil.com/about-roadbond/ (accessed on 22 January 2024).

- Wacker Chemie, A.G. ETONIS® 1400 S Polymer Dispersions. Available online: https://www.wacker.com/h/en-us/polymer-dispersions/etonis-1400-s/p/000095032 (accessed on 22 January 2024).

- Product Portal of the PCC Group. TEQUAT LC 90i. Available online: https://www.products.pcc.eu/en/id/16620/tequat-lc-90i-tallow-esterquat-3/ (accessed on 5 April 2024).

- EN 13286-50; Unbound and Hydraulically Bound Mixtures—Part 50: Method for the Manufacture of Test Specimens of Hydraulically Bound Mixtures Using Proctor Equipment or Vibrating Table Compaction. BSI Standard Limited: London, UK, 2004.

- EN 13286 41; Unbound and Hydraulically Bound Mixtures—Part 41: Test Method for Compressive Strength of Hydraulically Bound Mixtures. European Standard. BSI Standard Limited: London, UK, 2021.

- WT-5 2010; Technical Requirements. General Directorate for National Roads and Motorways. Generalna Dyrekcja Dróg Krajowych i Autostrad: Warsaw, Poland, 2010.

- Naik, R.; Kumar, S.; Saha, G. Novel Framework for Assessing Economic Viability and Environmental Impacts: Use of Waste Products in Soil Stabilization. Constr. Build. Mater. 2024, 411, 134329. [Google Scholar] [CrossRef]

- Párraga Morales, D.; Saldanha, R.B.; Aguada, J.M.; Consoli, N.C. Alkali-Activation of Agro-Industrial Waste for Stabilization of Lateritic Soils. Transp. Geotech. 2024, 45, 101187. [Google Scholar] [CrossRef]

- Kasehchi, E.; Arjomand, M.A.; Alizadeh Elizei, M.H. Experimental Investigation of the Feasibility of Stabilizing Inshore Silty Sand Soil Using Geopolymer Based on Ceramic Waste Powder: An Approach to Upcycling Waste Material for Sustainable Construction. Case Stud. Constr. Mater. 2024, 20, e02979. [Google Scholar] [CrossRef]

- Tonini de Araújo, M.; Tonatto Ferrazzo, S.; Mansur Chaves, H.; Gravina da Rocha, C.; Cesar Consoli, N. Mechanical Behavior, Mineralogy, and Microstructure of Alkali-Activated Wastes-Based Binder for a Clayey Soil Stabilization. Constr. Build. Mater. 2023, 362, 129757. [Google Scholar] [CrossRef]

- Al-Subari, B.L.; Hilal, A.; Ekinci, A. Life Cycle Assessment of Soil Stabilization Using Cement and Waste Additives. Constr. Build. Mater. 2023, 403, 133045. [Google Scholar] [CrossRef]

- Gupta, G.; Sood, H.; Gupta, P.K. Economic and Environmental Assessment of Industrial Wastes Stabilized Clay and Sand Soil Subgrades Using Experimental and Theoretical Approaches. Constr. Build. Mater. 2024, 422, 135787. [Google Scholar] [CrossRef]

- Kassa, A.; Sekine, R.; Dorji, T.; Pathak, G.K.; Hayano, K.; Yamauchi, H.; Mochizuki, Y. Insights into Water Absorption Characteristics of Various Waste-Based Inorganic Additives and Their Application for Soil Stabilization. J. Clean. Prod. 2024, 446, 141470. [Google Scholar] [CrossRef]

| Waste-Based Material Tested | Dosages Used/8 kg of Soil and 5% Cement | National Potential [t/year] | Commercial Equivalent |

|---|---|---|---|

| 1. Pyrolytic wax from mixed plastic waste, emulsion (EPW from WMP) | <700 g | 4–5 M | ROKAmin 1/ Tequat LC90i 2 |

| 2. CBPD “by-pass” waste ash from the ceramic industry | 10–200 g | 30,000 | Geosta 3 |

| 3. Emulsion from chewing gum waste | 10–40 g | 12,000 | ROKAmin/ Tequat LC90i |

| 4. Waste tire pyrolytic oil (WTPO), emulsion | 20–140 g | Not in production | ROKAmin SRK8P4/Tequat LC90i |

| 5. Pyrolytic wax from HDPE, emulsion (EPW from HDPE) | 20–100 g | Not in production | ROKAmin SRK8P4/Tequat LC90i |

| 6. Pyrolytic wax from waste PE foil, emulsion (EPW from WPEF) | 20–700 g | Not in production | ROKAmin SRK8P4/Tequat LC90i |

| 7. Waste sulfuric acid with limonene | <420 g | No data | Roadbond EN-1 4 |

| 8. Waste cream emulsion from the cosmetics industry | 10–60 g | 120 | ROKAmin/ Tequat LC90i |

| 9. Waste powder, including soda (sodium bicarbonate), from the cosmetics industry | 40–140 g | 60 | ROKAmin/ Tequat LC90i |

| Additive | Geosta K-1 | ROADBOND EN-1 | ETONIS 1400S | |||

|---|---|---|---|---|---|---|

| Soil | Clay | Sand | Clay | Sand | Clay | Sand |

| Samples | 11 | 7 | 2 | 1 | 3 | 5 |

| MPa (7 d) | 0.47 | 0.45 | 1.10 | 1.17 | 0.96 | 0.85 |

| SD/2 | 0.13 | 0.18 | 0.21 | 0 | 0.18 | 0.21 |

| Change (%) 1 | −49.56% | −56.85% | 17.27% | 11.34% | −25%:+52% | −19.72% |

| Additive | “By-Pass” Waste Ash | Waste H2SO4 | ||

|---|---|---|---|---|

| Soil | Clay | Sand | Clay | Sand |

| Samples | 63 | 63 | 24 | 23 |

| MPa (7 d) | 0.99 | 1.17 | 0.95 | 0.99 |

| SD/2 | 0.14 | 0.29 | 0.16 | 0.32 |

| Change (%) 1 | 5.67% | 11.08% | 1.36% | −5.63% |

| Additive | EPW from HDPE | EPW from WMP | EPW from WPEF | |||

|---|---|---|---|---|---|---|

| Soil | Clay | Sand | Clay | Sand | Clay | Sand |

| Samples | 7 | 8 | 13 | 14 | 17 | 20 |

| MPa (7 d) | 1.23 | 1.22 | 1.24 | 1.49 | 1.28 | 1.63 |

| SD/2 | 0.10 | 0.15 | 0.16 | 0.23 | 0.49 | 0.20 |

| Change (%) 1 | 30.77% | 15.67% | 32.75% | 41.75% | 36.77% | 54.84% |

| Additive | Chewing Gum Waste | |

|---|---|---|

| Soil | Clay | Sand |

| Samples | 48 | 32 |

| MPa (7 d) | 1.01 | 0.43 |

| SD/2 | 0.18 | 0.26 |

| Change (%) | 7.92% | −58.99% |

| Additive | CBPD “By-Pass” Ash + EPW | Waste H2SO4 + EPW | ||

|---|---|---|---|---|

| Soil | Clay | Sand | Clay | Sand |

| Samples | 14 | 14 | 8 | 9 |

| MPa (7 d) | 1.21 | 1.66 | 1.14 | 1.52 |

| SD/2 | 0.16 | 0.15 | 0.13 | 0.27 |

| Change (%) 1 | 29.67% | 57.12% | 21.87% | 44.14% |

| Additive | HDPE EPW + “By-Pass” Waste Ash | EPW from WMP + “By-Pass” Waste Ash | EPW from WPEF + Waste H2SO4 | |||

|---|---|---|---|---|---|---|

| Soil | Clay | Sand | Clay | Sand | Clay | Sand |

| Samples | 3 | 4 | 8 | 10 | 9 | 9 |

| MPa (7 d) | 1.25 | 1.13 | 1.27 | 1.62 | 1.14 | 1.52 |

| SD/2 | 0.13 | 0.20 | 0.20 | 0.22 | 0.14 | 0.27 |

| Change (%) 1 | 33.25% | 6.96% | 35.74% | 53.76% | 21.69% | 44.14% |

| Additive | EPW from HDPE + Chewing Gum Waste | EPW from WMP + Chewing Gum Waste | EPW from WPEF + NaOH | |||

|---|---|---|---|---|---|---|

| Soil | Clay | Sand | Clay | Sand | Clay | Sand |

| Samples | 4 | 4 | 8 | 4 | 3 | 7 |

| MPa (7 d) | 1.34 | 1.31 | 1.26 | 0.84 | 0.88 | 1.79 |

| SD/2 | 0.09 | 0.05 | 0.20 | 0.21 | 0.06 | 0.10 |

| Change (%) 1 | 42.70% | 24.20% | 34.91% | −20.65% | −6.15% | 69.35% |

| Additive | Chewing Gum | Chewing Gum + EPW WMP | Chewing Gum + “By-Pass” Ash | |||

|---|---|---|---|---|---|---|

| Soil | Clay | Sand | Clay | Sand | Clay | Sand |

| Samples | 48 | 32 | 13 | 8 | 22 | 12 |

| MPa (7 d) | 1.01 | 0.43 | 1.28 | 1.07 | 1.16 | 0.43 |

| SD/2 | 0.18 | 0.26 | 0.16 | 0.19 | 0.16 | 0.28 |

| Change (%) 1 | 7.92% | −58.99% | 36.67% | 1.77% | 23.97% | −59.60% |

| Additive | +5% Cement (Control Scenario) | |

| Soil | Sand | |

| 1. Frost resistance | % | 35.6 |

| 2. Capillary rise (4 h) | g H2O/g soil dm (%) | 6.0 |

| 3. Water absorption (24 h) | g H2O/g soil dm (%) | 9.9 |

| 4. Compressive strength 7 d | MPa | 1.150 |

| 5. Compressive strength 28 d | MPa | 1.983 |

| Additive | +5% Cement (Control Scenario) | |

| Soil | Clay | |

| 1. Frost resistance | % | NA * |

| 2. Capillary rise (4 h) | g H2O/g soil dm (%) | 4.24 |

| 3. Water absorption (24 h) | g H2O/g soil dm (%) | 11.5 |

| 4. Compressive strength 7 d | MPa | 0.705 |

| 5. Compressive strength 28 d | MPa | 0.844 |

| Additive | A EPW from WPEF | A + NaOH | Waste Tires Pyrolytic Oil WTPO (em.) | A + Waste H2SO4 | A + “By-Pass” Ash + NaOH | “By-Pass” Ash + MgO |

|---|---|---|---|---|---|---|

| Soil | Sand | |||||

| 1. Frost resistance | 93.03% | 87.58% | 74.31% | 69.45% | 57.25% | 48.47% |

| 2. Capillary rise (4 h) | 2.31% | 6.69% | 2.45% | 1.43% | 3.46% | 6.55% |

| 3. Water absorption (24 h) | 7.93% | 8.07% | 9.25% | 6.63% | 6.26% | 10.55% |

| 4. Compressive strength 1 | 15.10% | 33.03% | 17.47% | 37.46% | 69.51% | 47.14% |

| 5. Compressive strength 2 | −3.16% | 23.70% | 18.88% | 6.29% | 24.71% | 4.11% |

| Additive | A EPW from WPEF | EPW from WMP + SS 3 | B Sulfonated EPW from WMP | B + Nivea soap Waste | B + Cream Waste | A + Waste H2SO4 |

|---|---|---|---|---|---|---|

| Soil | Sand | |||||

| 1. Frost resistance | 93.03% | NA | NA | NA | NA | 69.45% |

| 2. Capillary rise (4 h) | 2.31% | 0.45% | 0.55% | 0.96% | 1.11% | 1.43% |

| 3. Water absorption (24 h) | 7.93% | 1.98% | 5.63% | 5.14% | 5.05% | 6.63% |

| 4. Compressive strength 1 | 15.10% | 41.02% | 31.64% | 26.62% | 37.03% | 37.46% |

| 5. Compressive strength 2 | −3.16% | NA | NA | NA | NA | 6.29% |

| Additive | A EPW from WPEF | A + NaOH + TequatLC90i | A + “By-Pass” Waste Ash + NaOH | A + “By-Pass” Waste Ash + TequatLC90i | A + Waste H2SO4 | A + NaOH |

|---|---|---|---|---|---|---|

| Soil | Clay | |||||

| 1. Frost resistance | NA | NA | NA | NA | NA | 7.53% |

| 2. Capillary rise (4 h) | 6.92% | 4.18% | 4.06% | 3.61% | 2.82% | 2.36% |

| 3. Water absorption (24 h) | 13.71% | 11.38% | 11.56% | 11.51% | 9.36% | 8.38% |

| 4. Compressive strength 1 | −31.84% | −5.92% | −2.43% | −24.73% | 80.68% | 40.84% |

| 5. Compressive strength 2 | −40.71% | NA | NA | NA | 64.42% | 119.07% |

| Additive | A EPW from WPEF | A + Waste H2SO4 | EPW from WMP + “By-Pass” Waste Ash + NaOH | Sulfonated EPW from WMP | EPW from WMP + Cream | EPW from WMP + Cream + Powder |

|---|---|---|---|---|---|---|

| Soil | Sand | |||||

| 1. Frost resistance | 93.03% | 69.45% | 57,25% | NA | NA | NA |

| 2. Capillary rise (4 h) | 2.31% | 1.43% | 3.46% | 0.99% | 0.98% | 0.95% |

| 3. Water absorption (24 h) | 7.93% | 6.63% | 6.26% | 3.91% | 4.31% | 2.81% |

| 4. Compressive strength 1 | 15.10% | 37.46% | 79.60% | 88.31% | 101.42% | 142.42% |

| 5. Compressive strength 2 | −3.16% | 6.29% | 27.59% | NA | NA | NA |

| Additive | A EPW from WPEF | A + NaOH | A + NaOH + Chewing Gum (em.) | Chewing Gum (em.) + NaOH + “By-Pass” Waste Ash | A + NaOH + TequatLC90i | A + ProRoad Waterproof |

|---|---|---|---|---|---|---|

| Soil | Clay | |||||

| 1. Frost resistance | NA | 7.53% | NA | NA | NA | NA |

| 2. Capillary rise (4 h) | 6.92% | 2.36% | 10.21% | 9.98% | 0.98% | 16.42% |

| 3. Water absorption (24 h) | 13.71% | 8.38% | NA | NA | 4.31% | NA |

| 4. Compressive strength 1 | −31.84% | 40.84% | 50.30% | 23.25% | 101.42% | 11.67% |

| 5. Compressive strength 2 | −40.71% | 119.07% | NA | NA | NA | −11.37% |

| Additive | A EPW from WPEF | A + Waste H2SO4 | “By-Pass” Waste Ash + MgO | WTPO (em.) | A + NaOH | EPW from WMP +“By-Pass” Ash + NaOH |

|---|---|---|---|---|---|---|

| Soil | Sand | |||||

| 1. Frost resistance | 93.03% | 69.45% | 48.47% | 74.31% | 87.58% | 57.25% |

| 2. Capillary rise (4 h) | 2.31% | 1.43% | 6.55% | 2.45% | 6.69% | 3.46% |

| 3. Water absorption (24 h) | 7.93% | 6.63% | 10.55% | 9.25% | 8.07% | 6.26% |

| 4. Compressive strength 1 | 15.10% | 37.46% | 55.90% | 17.47% | 40.95% | 79.60% |

| 5. Compressive strength 2 | −3.16% | 6.29% | 6.52% | 18.88% | 26.57% | 27.59% |

| Additive | A EPW from WPEF | A + ProRoad Waterproof | A + Waste H2SO4 | A + NaOH |

|---|---|---|---|---|

| Soil | Clay | |||

| 1. Frost resistance | NA | NA | NA | 7.53% |

| 2. Capillary rise (4 h) | 6.92% | 16.42% | 2.82% | 2.36% |

| 3. Water absorption (24 h) | 13.71% | NA | 9.36% | 8.38% |

| 4. Compressive strength 1 | −31.84% | 11.67% | 80.68% | 40.84% |

| 5. Compressive strength 2 | −40.71% | −11.37% | 64.42% | 119.07% |

| Additive | A EPW from WPEF | A + Waste H2SO4 | WTPO (em.) | WMP + “By-Pass” Waste Ash + NaOH | A + NaOH |

|---|---|---|---|---|---|

| Soil | Sand | ||||

| 1. Frost resistance | 93.03% | 69.45% | 74.31% | 57.25% | 87.58% |

| 2. Capillary rise (4 h) | 2.31% | 1.43% | 2.45% | 3.46% | 6.69% |

| 3. Water absorption (24 h) | 7.93% | 6.63% | 9.25% | 6.26% | 8.07% |

| 4. Compressive strength 1 | 15.10% | 45.63% | 17.47% | 79.60% | 40.95% |

| 5. Compressive strength 2 | −3.16% | 8.75% | 18.88% | 27.59% | 26.57% |

| 6. Optimization parameter 3 | 67.5 | 12.90 | 19.49 | 26.31 | 49.68 |

| Additive | A EPW from WPEF | A + Waste H2SO4 | A + NaOH |

|---|---|---|---|

| Soil | Clay | ||

| 1. Frost resistance | 6.92% | NA | 7.53% |

| 2. Capillary rise (4 h) | 13.71% | 2.82% | 2.36% |

| 3. Water absorption (24 h) | −31.84% | 9.36% | 8.38% |

| 4. Compressive strength 1 | −40.71% | 80.68% | 40.84% |

| 5. Compressive strength 2 | 6.92% | 64.42% | 119.07% |

| 6. Optimization parameter 3 | 231.49 | 37.68 | 24.32 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Waciński, W.; Kuligowski, K.; Olejarczyk, M.; Zając, M.; Urbaniak, W.; Cyske, W.; Kazimierski, P.; Tylingo, R.; Mania, S.; Cenian, A. Recycling of Industrial Waste as Soil Binding Additives—Effects on Soil Mechanical and Hydraulic Properties during Its Stabilisation before Road Construction. Materials 2024, 17, 2000. https://doi.org/10.3390/ma17092000

Waciński W, Kuligowski K, Olejarczyk M, Zając M, Urbaniak W, Cyske W, Kazimierski P, Tylingo R, Mania S, Cenian A. Recycling of Industrial Waste as Soil Binding Additives—Effects on Soil Mechanical and Hydraulic Properties during Its Stabilisation before Road Construction. Materials. 2024; 17(9):2000. https://doi.org/10.3390/ma17092000

Chicago/Turabian StyleWaciński, Witold, Ksawery Kuligowski, Małgorzata Olejarczyk, Marek Zając, Włodzimierz Urbaniak, Waldemar Cyske, Paweł Kazimierski, Robert Tylingo, Szymon Mania, and Adam Cenian. 2024. "Recycling of Industrial Waste as Soil Binding Additives—Effects on Soil Mechanical and Hydraulic Properties during Its Stabilisation before Road Construction" Materials 17, no. 9: 2000. https://doi.org/10.3390/ma17092000

APA StyleWaciński, W., Kuligowski, K., Olejarczyk, M., Zając, M., Urbaniak, W., Cyske, W., Kazimierski, P., Tylingo, R., Mania, S., & Cenian, A. (2024). Recycling of Industrial Waste as Soil Binding Additives—Effects on Soil Mechanical and Hydraulic Properties during Its Stabilisation before Road Construction. Materials, 17(9), 2000. https://doi.org/10.3390/ma17092000