Finite Element Simulation and Microstructural Evolution Investigation in Hot Stamping Process of Ti6Al4V Alloy Sheets

Abstract

1. Introduction

2. Materials and Experimental Details

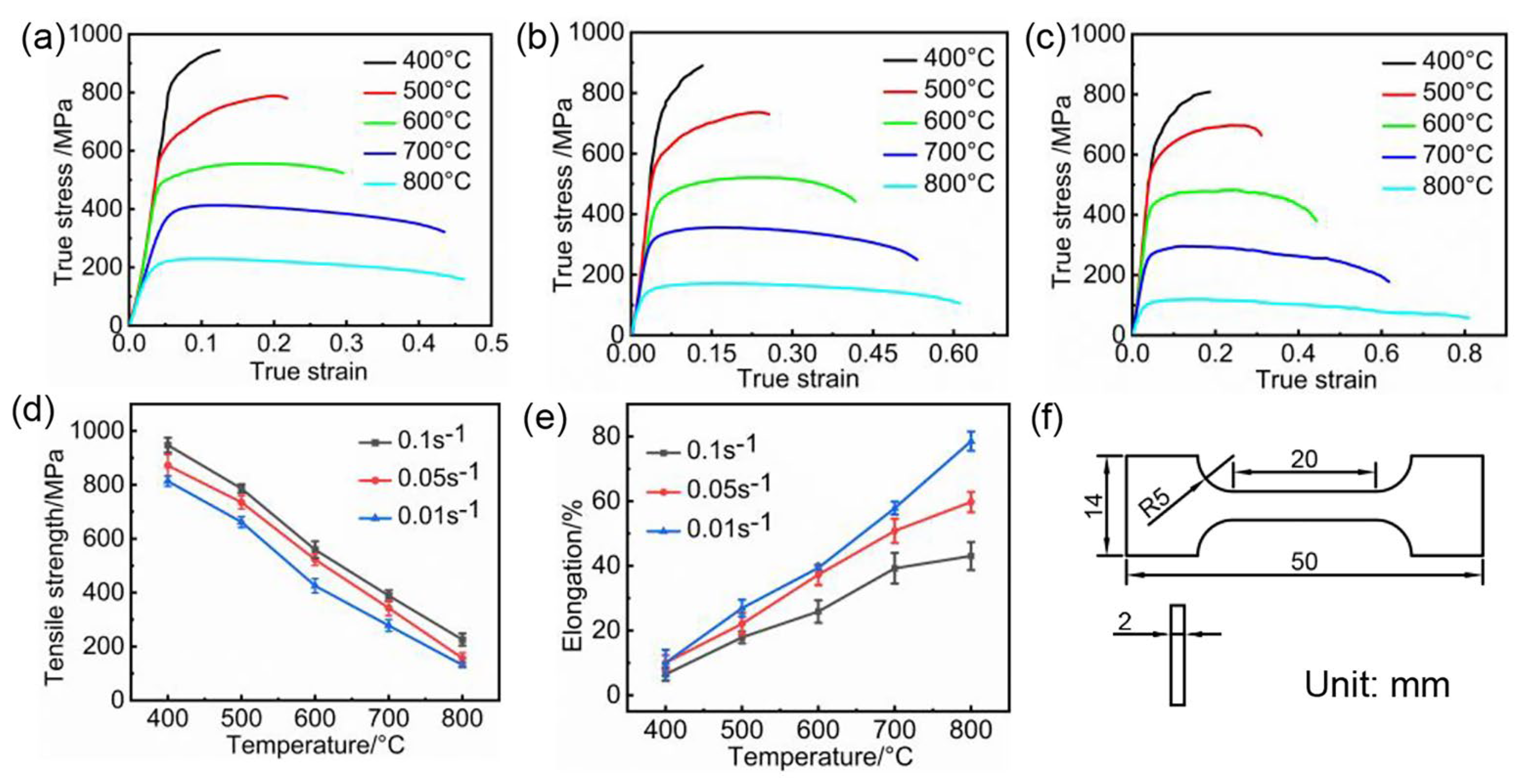

2.1. Materials Model

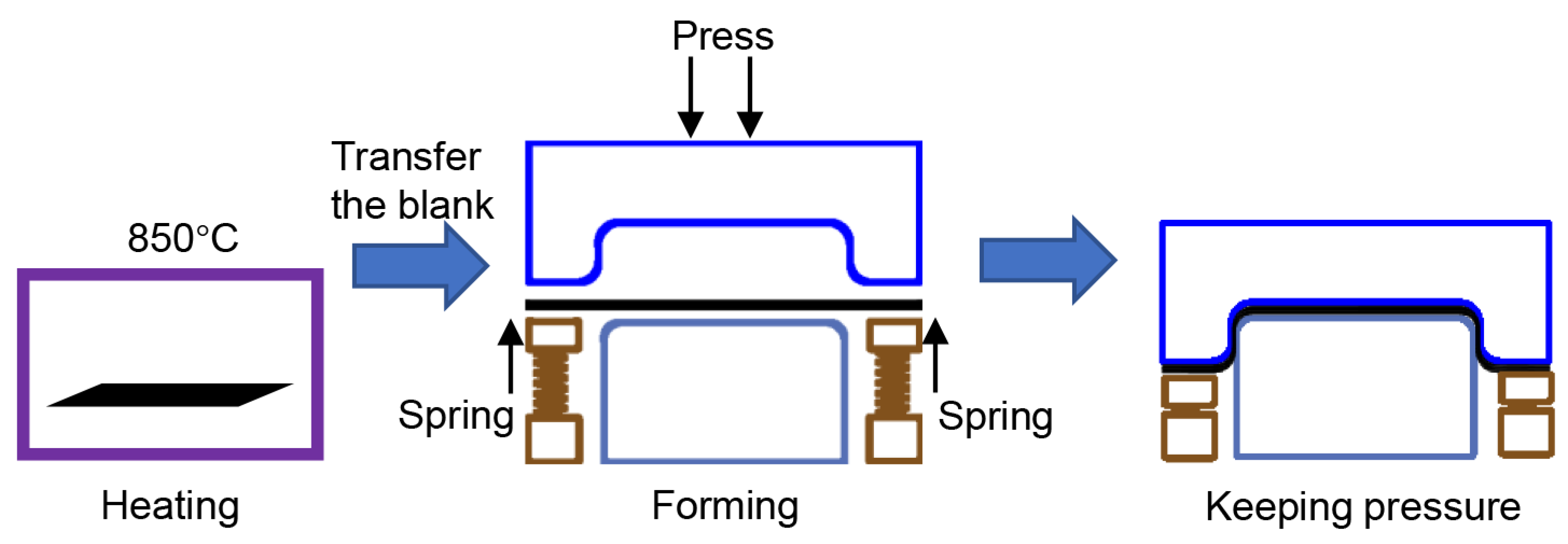

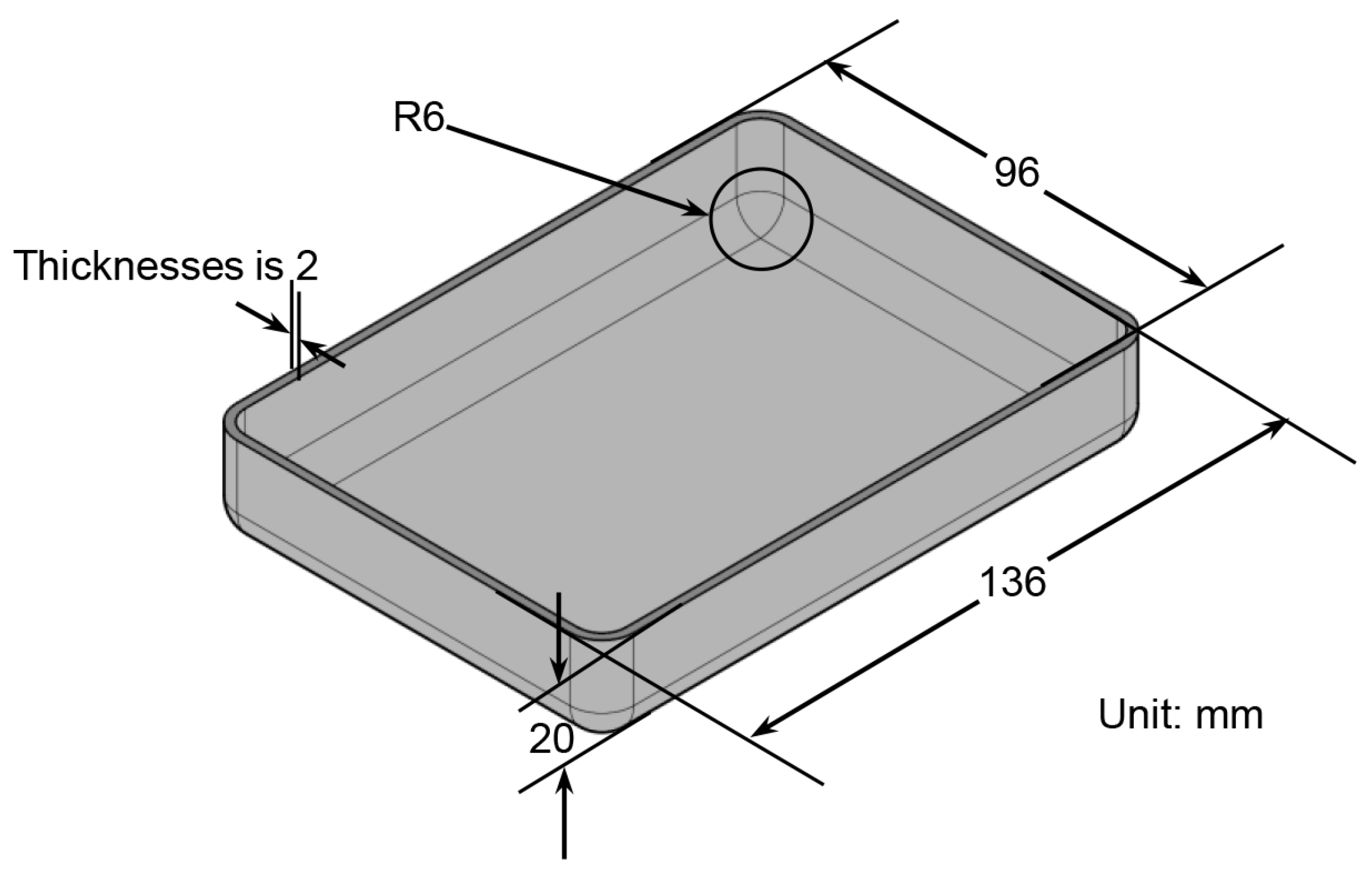

2.2. Forming Processes and Parts

3. Research Results for Hot Stamping and Forming of Case Parts

3.1. Numerical Simulation of Hot Stamping of Titanium Alloys

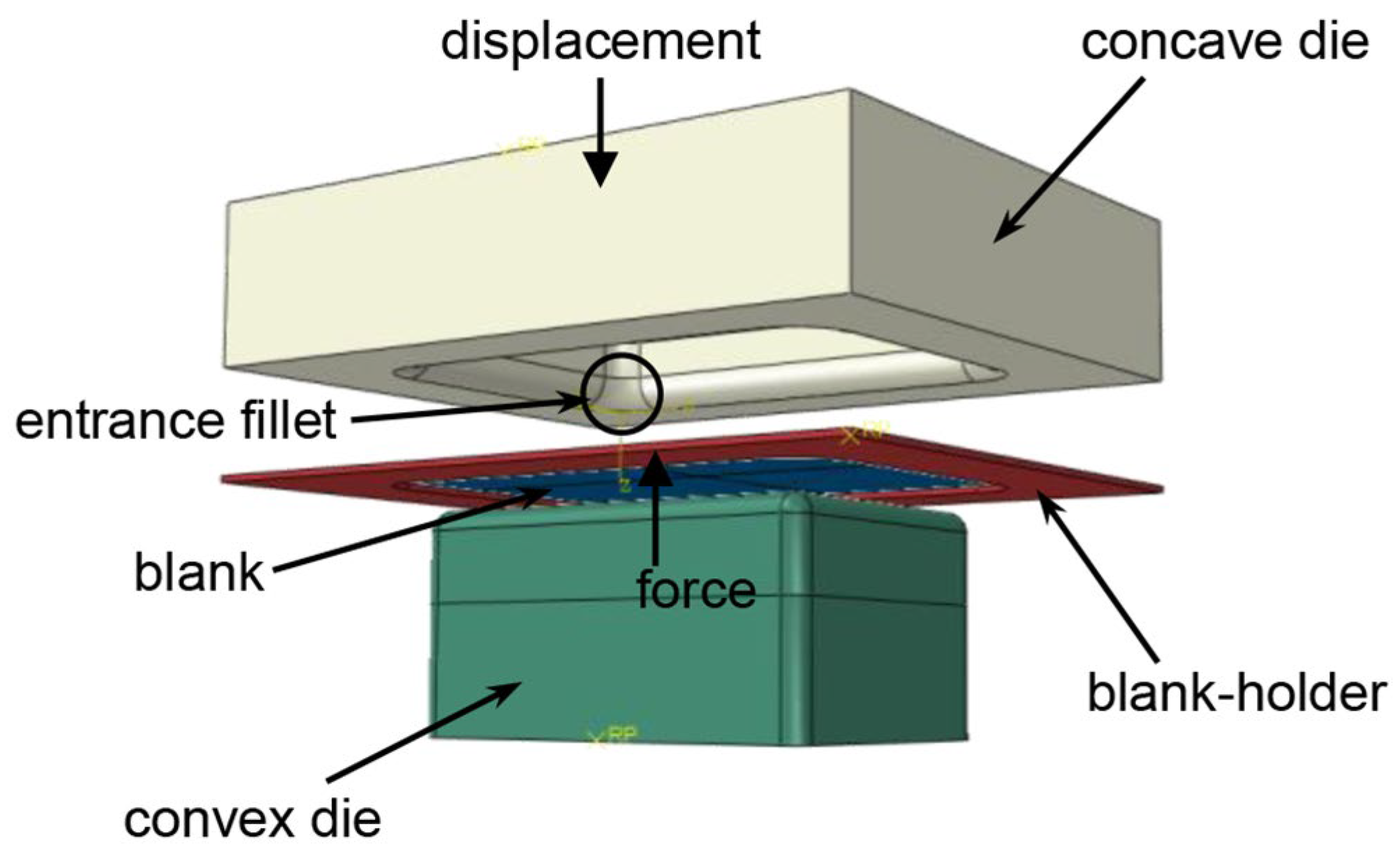

3.1.1. Construction of the Finite Element Model

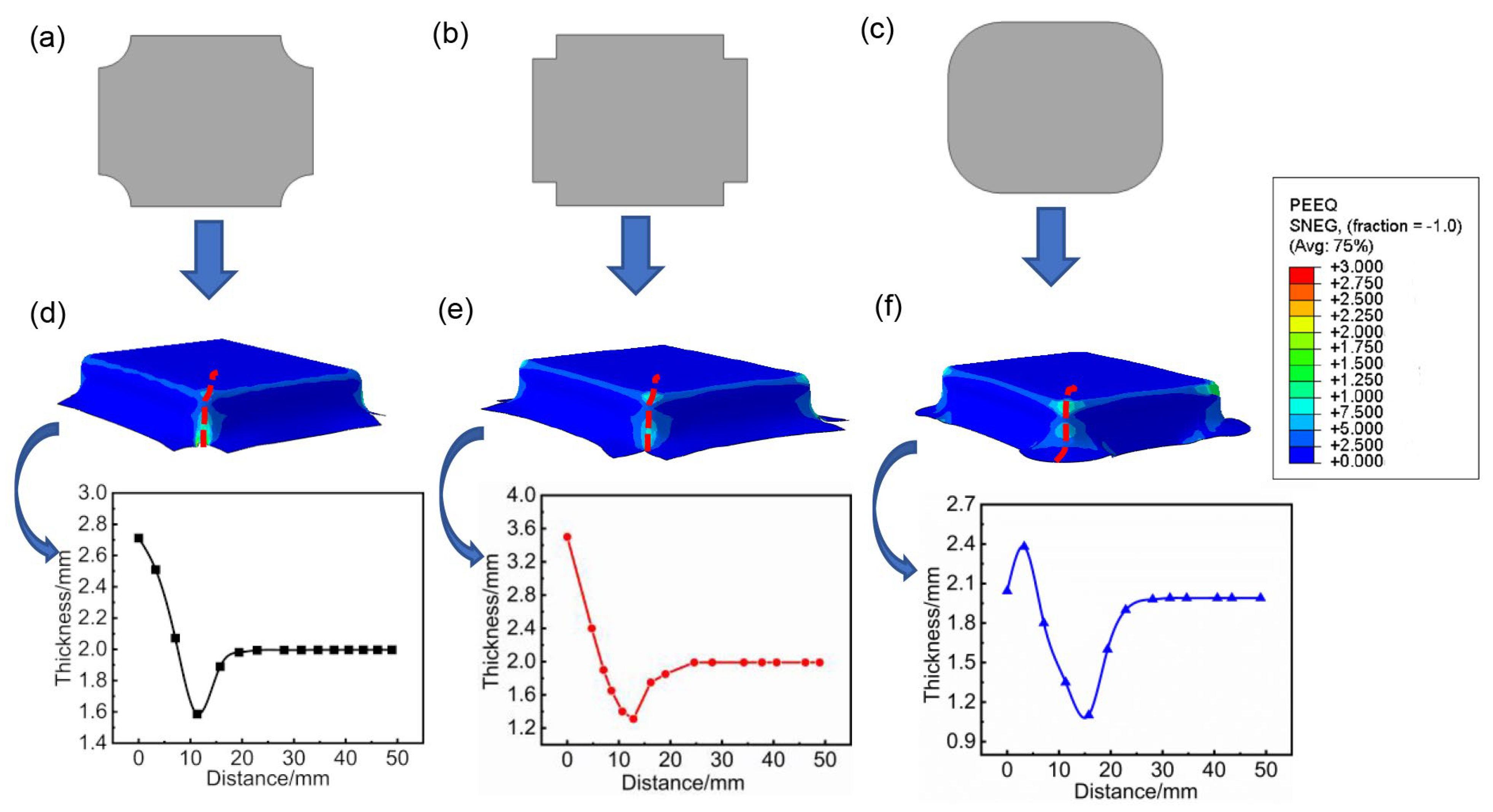

3.1.2. Optimization of Blank Shape

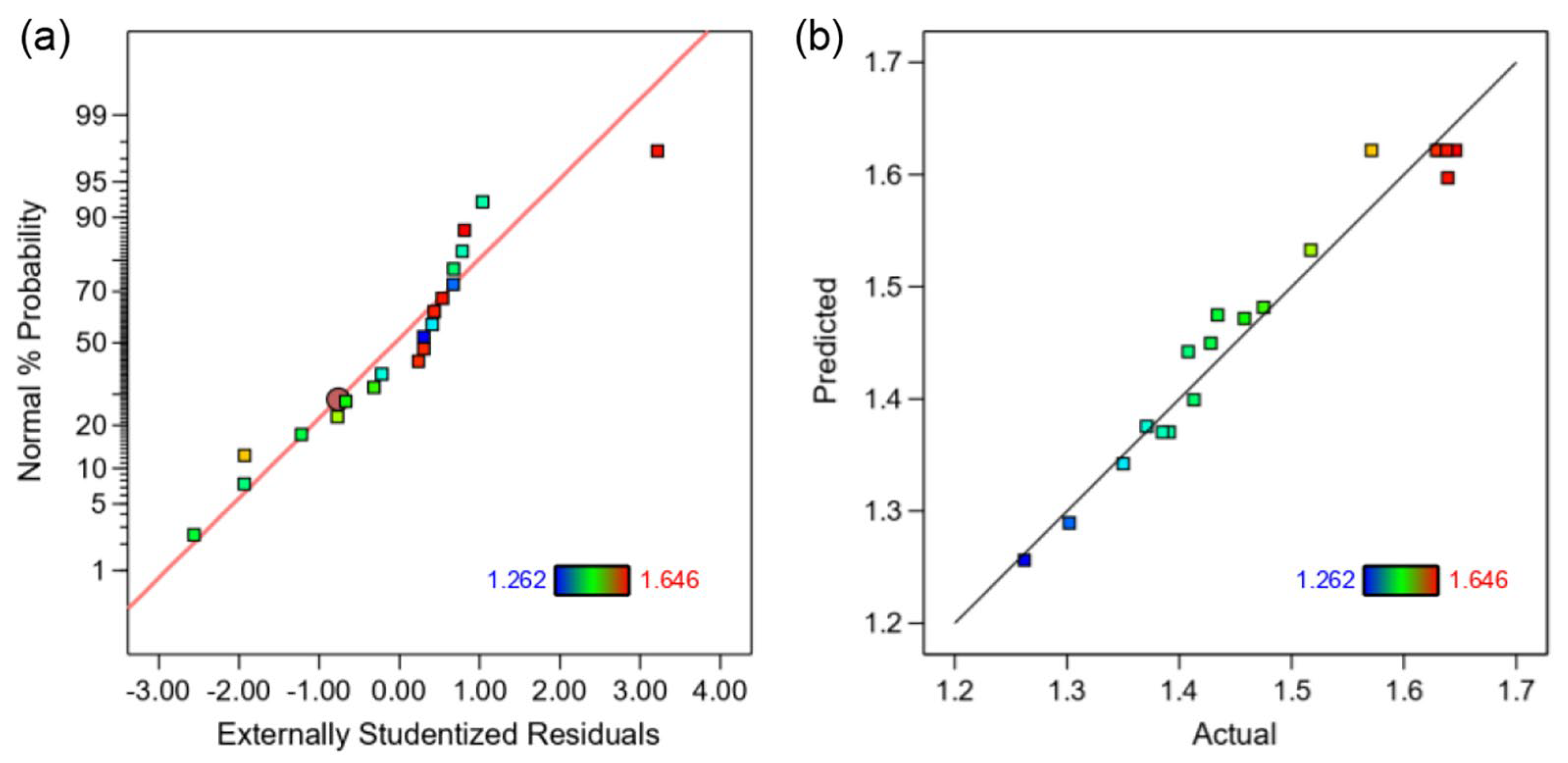

3.1.3. Determination of Forming Process Parameters

3.2. Hot Stamping Experimental Verification

4. Conclusions

- The thermomechanical properties of Ti6Al4V alloy at different temperatures (400 °C, 500 °C, 600 °C, 700 °C, 800 °C) and different strain rates (0.1 s−1, 0.05 s−1, 0.01 s−1) were investigated, which showed that with the rise in deformation temperature and the decrease in strain rate, the tensile strength of the material decreased, while the elongation increased, indicating the plasticity of material was enhanced. The tensile strength of the material at 400 °C was higher than 808 MPa, which was close to its mechanical properties at room temperature, indicating that the hot stamping process of the blank should be above this temperature.

- The performance analysis revealed that under the conditions of a blank-holder force of 10.591 kN, a friction coefficient of 0.314, and an entrance fillet radius of 10.347 mm, optimal performance for titanium alloy box-shaped components in hot stamping was achieved. The simulation results were validated through hot stamping experiments, and the results showed good agreement.

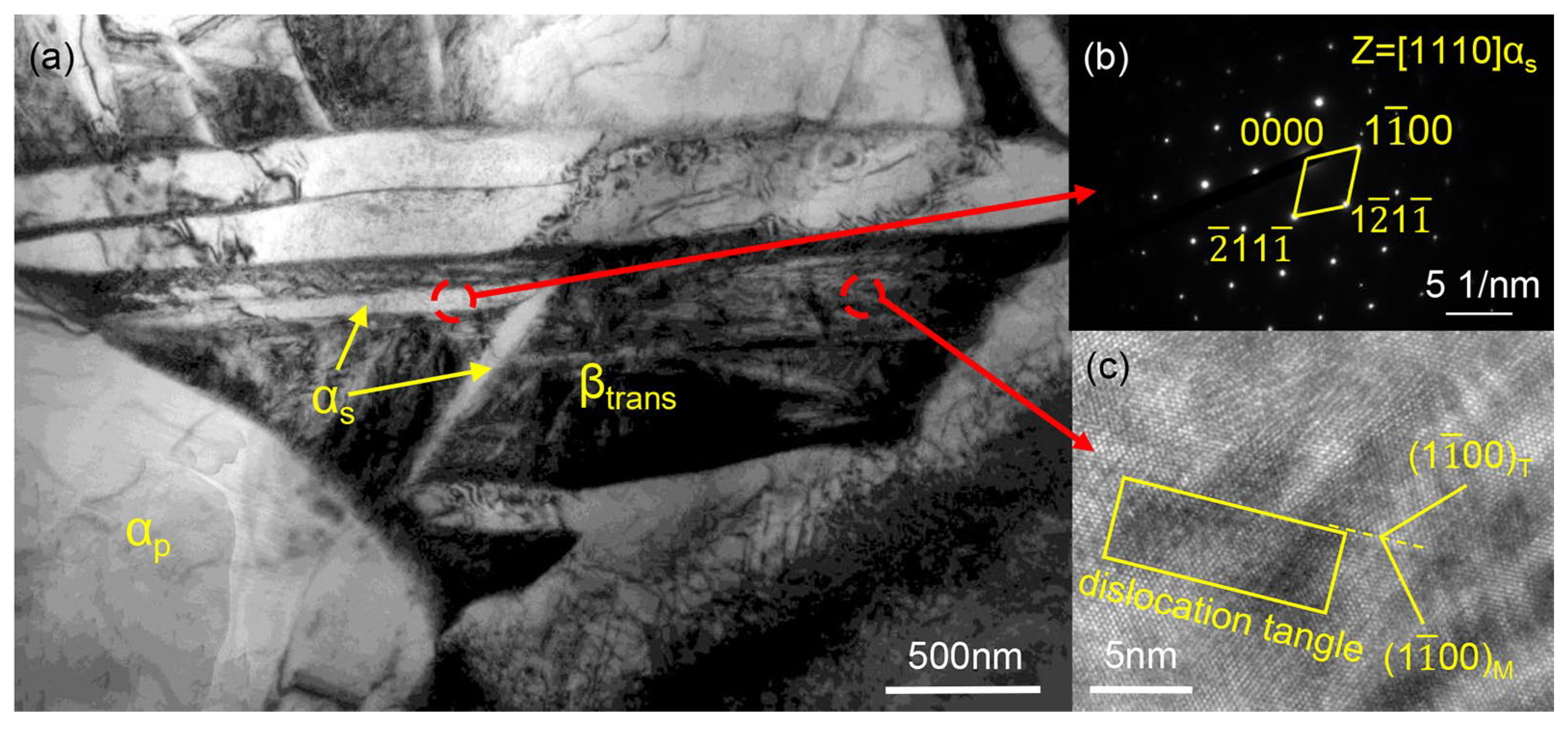

- The research on the microstructural evolution of the formed parts indicated that in hot stamping formation at a heating temperature of 850 °C, a higher cooling rate induces the precipitation of a secondary α phase, resulting in higher local hardness in formed parts. The sidewalls of the box-shaped parts with higher deformation undergo grain refinement strengthening and were therefore of slightly higher hardness than the bottom of the box-shaped parts. The formed box-shaped parts exhibited a uniform and fine microstructure overall, demonstrating high forming quality.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Marin, E.; Lanzutti, A. Biomedical Applications of Titanium Alloys: A Comprehensive Review. Materials 2024, 17, 114. [Google Scholar] [CrossRef] [PubMed]

- Nafi, M.A.; Karim, M.A.; Lalvani, S.; James, P.F.; Sommers, A.; Jahan, M.P. Investigating wettability and corrosion resistance of the titanium alloy surface engineered by the WEDM process. Manuf. Lett. 2023, 35, 450–459. [Google Scholar] [CrossRef]

- Singh, N.; Hameed, P.; Ummethala, R.; Manivasagam, G.; Prashanth, K.G.; Eckert, J. Selective laser manufacturing of Ti-based alloys and composites: Impact of process parameters, application trends, and future prospects. Mater. Today Adv. 2020, 8, 100097. [Google Scholar] [CrossRef]

- Trzepiecinski, T.; Najm, S.M. Current Trends in Metallic Materials for Body Panels and Structural Members Used in the Automotive Industry. Materials 2024, 17, 590. [Google Scholar] [CrossRef]

- Ismaeel, A.; Xu, D.; Li, X.; Zhang, J.; Yang, R. Effect of texture on the mechanical and micromechanical properties of a dual-phase titanium alloy. J. Mater. Res. Technol. 2023, 27, 6833–6846. [Google Scholar] [CrossRef]

- Maksim, O.S.; Alexandr, M.Z.; Tatiana, A.C.; Evgeniy, Y.R. In Design of the stamping process of large-sized turbine blades taking into account the technological characteristics of titanium alloys. Mater. Today Proc. 2020, 30, 700–706. [Google Scholar]

- Akula, S.P.; Ojha, M.; Rao, K.L.; Gupta, A.K. A review on superplastic forming of Ti-6Al-4V and other titanium alloys. Mater. Today Commun. 2023, 34, 105343. [Google Scholar] [CrossRef]

- Astarita, A.; Armentani, E.; Ceretti, E.; Giorleo, L.; Mastrilli, P.; Paradiso, V.; Scherillo, F.; Squillace, A.; Velotti, C. Hot stretch forming of a titanium alloy component for aeronautic: Mechanical and modeling. Key Eng. Mater. 2013, 554–557, 647–656. [Google Scholar] [CrossRef]

- Kopec, M.; Wang, K.H.; Politis, D.J.; Wang, Y.Q.; Wang, L.L.; Lin, J.G. Formability and microstructure evolution mechanisms of Ti6Al4V alloy during a novel hot stamping process. Mater. Sci. Eng. A 2018, 719, 72–81. [Google Scholar] [CrossRef]

- Liu, X.C.; Kopec, M.; El Fakir, O.; Qu, H.T.; Wang, Y.Q.; Wang, L.L.; Li, Z.Q. Characterisation of the interfacial heat transfer coefficient in hot stamping of titanium alloys. Int. Commun. Heat. Mass. Transfer 2020, 113, 104535. [Google Scholar] [CrossRef]

- Gao, S.; Sang, Y.; Li, Q.H.; Sun, Y.L.; Wu, Y.H.; Wang, H.R. Constitutive modeling and microstructure research on the deformation mechanism of Ti-6Al-4V alloy under hot forming condition. J. Alloys Compd. 2022, 892, 162128. [Google Scholar] [CrossRef]

- Liu, C.; Zhou, G.; Wang, X.; Liu, J.J.; Li, J.L.; Zhang, H.Y.; Chen, L.J. Rheological Law and Mechanism for Superplastic Deformation of Ti-6Al-4V. Materials 2019, 12, 3520. [Google Scholar] [CrossRef]

- Wang, K.H.; Wang, L.L.; Zheng, K.L.; He, Z.B.; Politis, D.J.; Liu, G.; Yuan, S.J. High-efficiency forming processes for complex thin-walled titanium alloys components: State-of-the-art and perspectives. Int. J. Extreme Manuf. 2020, 2, 032001. [Google Scholar] [CrossRef]

- Chen, Y.; Han, G.F.; Li, S.H.; Li, Y.F.; Li, Z.Q.; Lin, Z.Q. Time-dependent springback prediction with stress relaxation effect for non-isothermal hot stamping of titanium alloy sheets. Int. J. Adv. Manuf. Tech. 2021, 115, 637–653. [Google Scholar] [CrossRef]

- Yang, X.M.; Wang, B.Y.; Zhou, J. Numerical and experimental study on formability of TC4 alloy in a novel multi-layer sheet hot stamping process. Int. J. Adv. Manuf. Technol. 2020, 110, 1233–1247. [Google Scholar] [CrossRef]

- Yi, L.L.; Yu, G.; Tang, Z.M.; Li, X.; Gu, Z.W. Investigation of the Hot Stamping-in-Die Quenching Composite Forming Process of 5083 Aluminum Alloy Skin. Materials 2023, 16, 2742. [Google Scholar] [CrossRef]

- Tang, Z.M.; Gu, Z.W.; Li, Y.; Li, X.; Yu, G.; Yi, L.L. Study on the Effect of the Pre-Forming of 22MnB5 Steel in Indirect Hot Stamping. Materials 2023, 16, 3739. [Google Scholar] [CrossRef]

- Neumann, R.; Schuster, S.; Gibmeier, J.; Böhlke, T. Two-scale simulation of the hot stamping process based on a Hashin-Shtrikman type mean field model. J. Mater. Process. Technol. 2019, 267, 124–140. [Google Scholar] [CrossRef]

- Zhou, J.; Yang, X.M.; Wang, B.Y.; Mu, Y.H. Investigation of interfacial heat transfer characterization for TC4 alloy in triple-layer sheet hot stamping process. Int. J. Adv. Manuf. Technol. 2022, 121, 5779–5792. [Google Scholar] [CrossRef]

- Mehta, K.K. Temperature dependent constitutive plastic flow behaviour of titanium alloy Ti6Al4V. Int. J. Mater. Res. 2023, 114, 359–367. [Google Scholar] [CrossRef]

- Çakir, F.H.; Çelik, O.N. Influence of Cryogenic Treatment on Microstructure and Mechanical Properties of Ti6Al4V Alloy. J. Mater. Eng. Perform. 2020, 29, 6974–6984. [Google Scholar] [CrossRef]

- Kattire, P.; Paul, S.; Singh, R.; Yan, W.Y. Experimental characterization of laser cladding of CPM 9V on H13 tool steel for die repair applications. J. Manuf. Process 2015, 20, 492–499. [Google Scholar] [CrossRef]

- Saidi, B.; Moreau, L.G.; Cherouat, A.; Nasri, R. Experimental and numerical study on warm single-point incremental sheet forming (WSPIF) of titanium alloy Ti-6Al-4V, using cartridge heaters. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 534. [Google Scholar] [CrossRef]

- Fiorentino, A.; Ceretti, E.; Giardini, C. Experimental and Numerical Method for the Analysis of Warm Titanium Sheet Stamping of an Automotive Component. Adv. Mater. Sci. Eng. 2015, 2015, 137964. [Google Scholar] [CrossRef][Green Version]

- Branco, A.C.; Moreira, V.; Reis, J.A.; Colaço, R.; Figueiredo-Pina, C.G.; Serro, A.P. Influence of contact configuration and lubricating conditions on the microtriboactivity of the zirconia-Ti6Al4V pair used in dental applications. J. Mech. Behav. Biomed. Mater. 2019, 91, 164–173. [Google Scholar] [CrossRef] [PubMed]

- Box, G.; Wilson, K. On the experimental attainment of optimum conditions. J. R. Stat. Soc. 1951, 13, 1–45. [Google Scholar] [CrossRef]

- Sangsefidi, Y.; Mehraein, M.; Ghodsian, M.; Motalebizadeh, M.R. Evaluation and Analysis of Flow over Arced Weirs Using Traditional and Response Surface Methodologies. J. Hydraul. Eng. 2017, 143, 04017048. [Google Scholar] [CrossRef]

- Amirmotalebi, E.; Samadi, N. Optimization of Removal of Ibuprofen Antibiotic from Water in the Presence of ZnO/Fe2O3 and ZnO/activated Carbon Nanoparticles Using Response Surface Methodology. Anal. Bioanal. Chem. Res. 2024, 11, 123–137. [Google Scholar]

- Ibrahim, M.I.; Bakhori, N.M.; Nor, A.F.M.; Mohammad, R.; Abd Aziz, S.; Daud, M.Y.M.; Kuan, H.T.N.; Mahardika, M.; Hassan, M.Z. Central Composite Design for Optimization of Kenaf-Reinforced Epoxy Composite Bonding Performance. Bioresources 2024, 19, 605–619. [Google Scholar] [CrossRef]

- Pandey, N.; Thakur, C. Statistical Comparison of Response Surface Methodology-Based Central Composite Design and Hybrid Central Composite Design for Paper Mill Wastewater Treatment by Electrocoagulation. Proc. Integr. Optim. 2020, 4, 343–359. [Google Scholar] [CrossRef]

- Pravina, R.; Uthayakumar, H.; Sivasamy, A. Hybrid approach based on response surface methodology and artificial neural networks coupled with genetic algorithm (RSM-GA-ANN) for the Prediction and optimization for the Photodegradation of dye using nano ZnO anchored glass fiber under solar light irradiation. J. Taiwan Inst. Chem. Eng. 2023, 153, 105248. [Google Scholar]

- Haque, M.; Ray, S.; Mita, A.F.; Mozumder, A.; Karmaker, T.; Akter, S. Prediction and optimization of hardened properties of concrete prepared with granite dust and scrapped copper wire using response surface methodology. Heliyon 2024, 10, e24705. [Google Scholar] [CrossRef]

- Sun, Y.G.; Zhang, C.J.; Feng, H.; Zhang, S.Z.; Han, J.C.; Zhang, W.G.; Zhao, E.T.; Wang, H.W. Dynamic recrystallization mechanism and improved mechanical properties of a near α high temperature titanium alloy processed by severe plastic deformation. Mater. Charact. 2020, 163, 110281. [Google Scholar] [CrossRef]

- Ma, X.Z.; Chen, Z.Y.; Xiang, Z.L.; Zhang, S.W.; Ding, X.X.; Li, T. Microstructure and Mechanical Properties Evolution of High-Temperature Titanium Alloys with In Situ Synthesized TiB Whiskers. J. Mater. Eng. Perform. 2024. [Google Scholar]

- Singh, P.P.; Mula, S.; Ghosh, S. Grain refinement, strain hardening and fracture in thermomechanically processed ultra-strong microalloyed steel. Mater. Today Commun. 2024, 38, 107582. [Google Scholar] [CrossRef]

- Wang, K.H.; Kopec, M.; Chang, S.P.; Qu, B.; Liu, J.; Politis, D.J.; Wang, L.L.; Liu, G. Enhanced formability and forming efficiency for two-phase titanium alloys by Fast light Alloys Stamping Technology (FAST). Mater. Des. 2020, 194, 108948. [Google Scholar] [CrossRef]

- Saier, A.; Esen, I.; Ahlatci, H.; Keskin, E. Effect of Oxidation Process on Mechanical and Tribological Behaviour of Titanium Grade 5 Alloy. Materials 2024, 17, 776. [Google Scholar] [CrossRef] [PubMed]

- Singh, A.R.; Bhattacharya, A.S.; Butcher, C.; Daun, K.J. Experimental artefacts affecting characterization of the evolving interfacial heat transfer coefficient in hot stamping of Al-Si coated 22MnB5 steel. Appl. Therm. Eng. 2024, 236, 121604. [Google Scholar] [CrossRef]

- Zhu, S.; Yang, H.; Guo, L.G.; Fan, X.G. Effect of cooling rate on microstructure evolution during α/β heat treatment of TA15 titanium alloy. Mater. Charact. 2012, 70, 101–110. [Google Scholar] [CrossRef]

| Element | Ti | Al | V | Fe |

|---|---|---|---|---|

| Content/wt% | Bal. | 6.0 | 3.92 | 0.19 |

| Run | A | B | C | R |

|---|---|---|---|---|

| Blank-Holder Force/kN | Friction Coefficient | Entrance Fillet radius/mm | Min Thickness (mm) | |

| 1 | 11 | 0.35 | 10 | 1.571 |

| 2 | 15 | 0.4 | 12 | 1.413 |

| 3 | 11 | 0.35 | 6 | 1.262 |

| 4 | 16 | 0.3 | 8 | 1.458 |

| 5 | 11 | 0.45 | 10 | 1.428 |

| 6 | 6 | 0.4 | 8 | 1.391 |

| 7 | 11 | 0.35 | 10 | 1.638 |

| 8 | 11 | 0.35 | 10 | 1.635 |

| 9 | 11 | 0.35 | 14 | 1.385 |

| 10 | 11 | 0.25 | 10 | 1.639 |

| 11 | 16 | 0.4 | 8 | 1.371 |

| 12 | 6 | 0.3 | 12 | 1.517 |

| 13 | 16 | 0.3 | 12 | 1.434 |

| 14 | 6 | 0.3 | 8 | 1.408 |

| 15 | 11 | 0.35 | 10 | 1.646 |

| 16 | 6 | 0.4 | 12 | 1.475 |

| 17 | 11 | 0.35 | 10 | 1.629 |

| 18 | 1 | 0.35 | 10 | 1.350 |

| 19 | 11 | 0.35 | 10 | 1.631 |

| 20 | 21 | 0.35 | 10 | 1.302 |

| Source | Sum of Squares | df | Mean Square | f-Value | p-Value |

|---|---|---|---|---|---|

| Model | 0.2860 | 9 | 0.0318 | 30.59 | <0.0001 |

| A | 0.0028 | 1 | 0.0028 | 2.68 | 0.1328 |

| B | 0.0217 | 1 | 0.0217 | 20.87 | 0.0010 |

| C | 0.0131 | 1 | 0.0131 | 12.56 | 0.0053 |

| AB | 0.0003 | 1 | 0.0003 | 0.2889 | 0.6027 |

| AC | 0.0038 | 1 | 0.0038 | 3.68 | 0.0839 |

| BC | 0.0002 | 1 | 0.0002 | 0.2022 | 0.6625 |

| A2 | 0.1469 | 1 | 0.1469 | 141.41 | <0.0001 |

| B2 | 0.0152 | 1 | 0.0153 | 14.61 | 0.0034 |

| C2 | 0.1493 | 1 | 0.1493 | 143.73 | <0.0001 |

| Residual | 0.0104 | 10 | 0.0010 | ||

| Lake of fit | 0.0067 | 5 | 0.0013 | 1.82 | 0.2626 |

| Pure error | 0.0037 | 5 | 0.0007 | ||

| Cor total | 0.2964 | 19 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qu, M.; Gu, Z.; Li, X.; Wang, J.; Yu, G.; Yi, L. Finite Element Simulation and Microstructural Evolution Investigation in Hot Stamping Process of Ti6Al4V Alloy Sheets. Materials 2024, 17, 1388. https://doi.org/10.3390/ma17061388

Qu M, Gu Z, Li X, Wang J, Yu G, Yi L. Finite Element Simulation and Microstructural Evolution Investigation in Hot Stamping Process of Ti6Al4V Alloy Sheets. Materials. 2024; 17(6):1388. https://doi.org/10.3390/ma17061388

Chicago/Turabian StyleQu, Mingjia, Zhengwei Gu, Xin Li, Jianbo Wang, Ge Yu, and Lingling Yi. 2024. "Finite Element Simulation and Microstructural Evolution Investigation in Hot Stamping Process of Ti6Al4V Alloy Sheets" Materials 17, no. 6: 1388. https://doi.org/10.3390/ma17061388

APA StyleQu, M., Gu, Z., Li, X., Wang, J., Yu, G., & Yi, L. (2024). Finite Element Simulation and Microstructural Evolution Investigation in Hot Stamping Process of Ti6Al4V Alloy Sheets. Materials, 17(6), 1388. https://doi.org/10.3390/ma17061388