Conformation Effect on the Mechanical and Microbiological Behavior of Invisible Orthodontic Aligners

Abstract

:1. Introduction

2. Materials and Methods

2.1. Mechanical Assays

2.2. Scanning Electron Microscopy

2.3. Water Absorption

2.4. Microbiological Assays

2.4.1. Colony-Forming Units (CFU)

2.4.2. Metabolic Activity Assay

2.4.3. LIVE/DEAD Bacteria Viability

3. Results

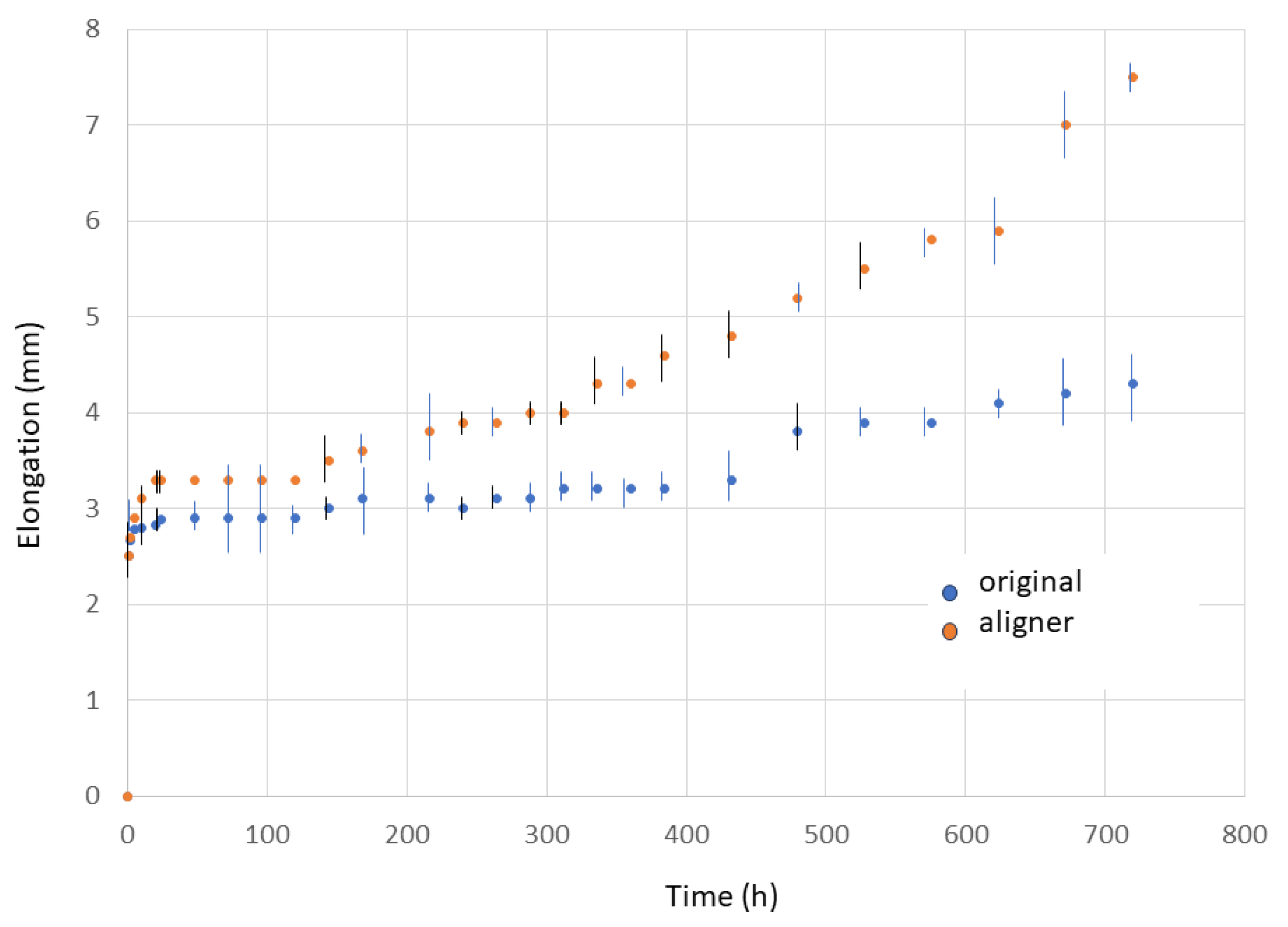

3.1. Mechanical Results

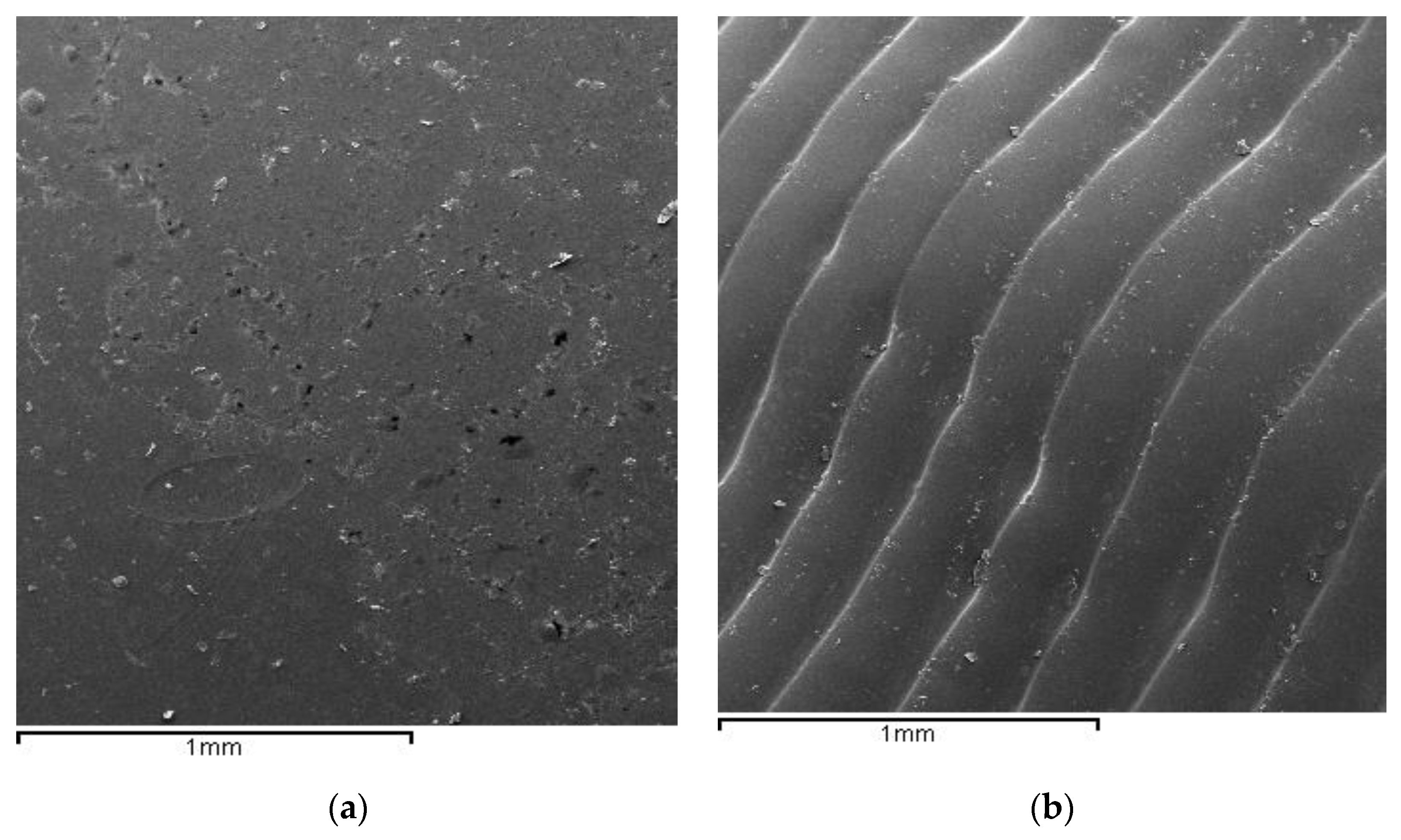

3.2. Scanning Electron Microscope

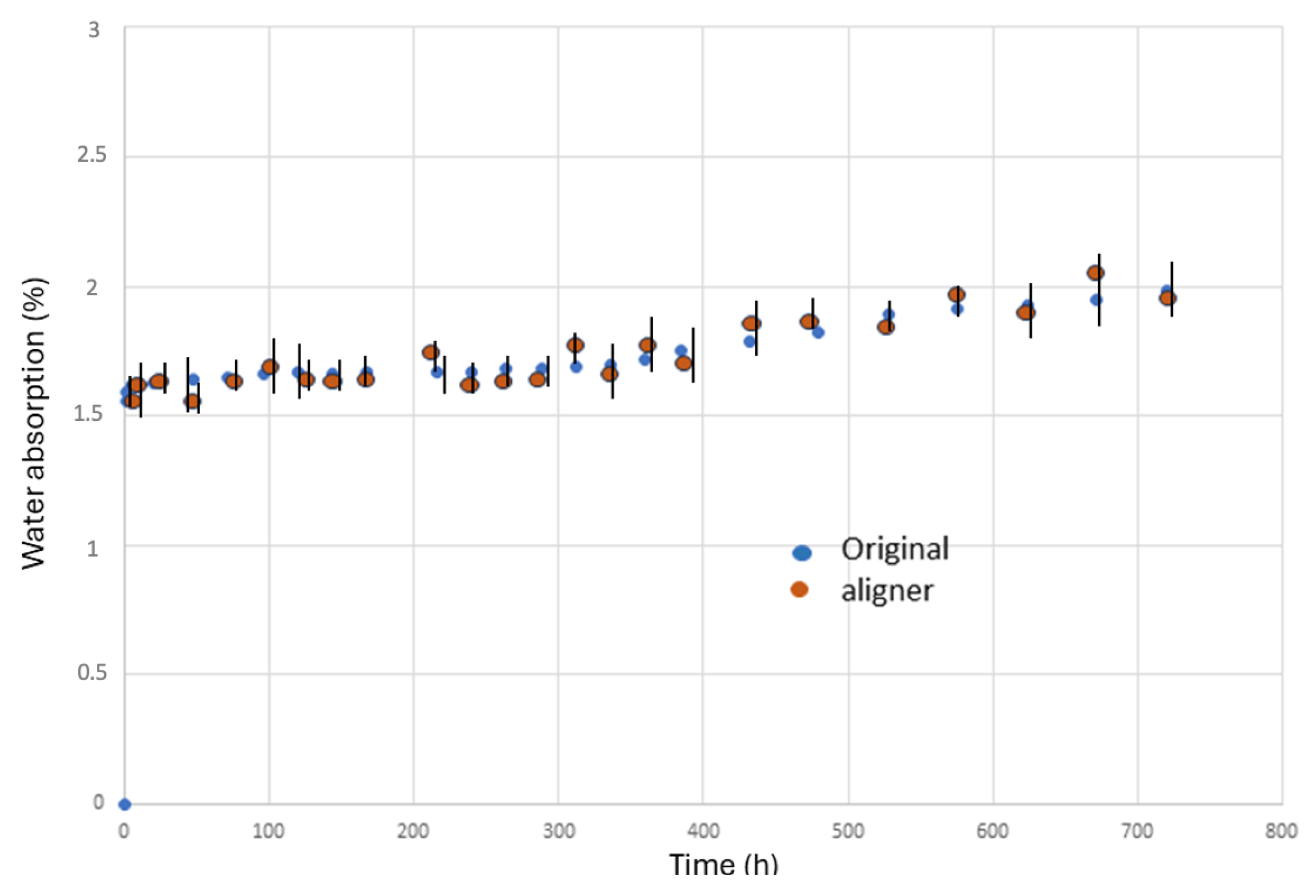

3.3. Water Absorption

3.4. Microbiological Results

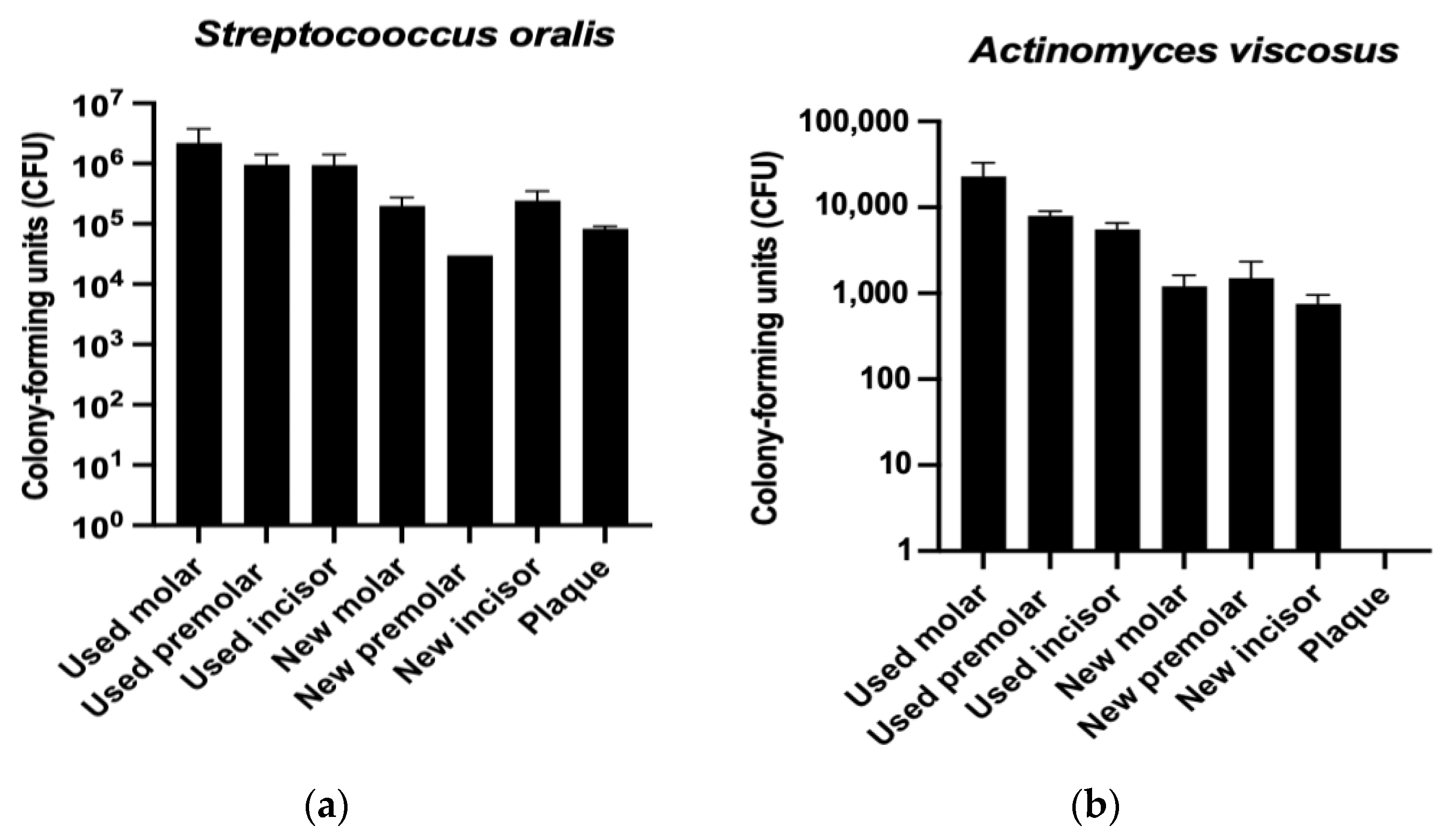

3.4.1. Colony-Forming Units (CFU)

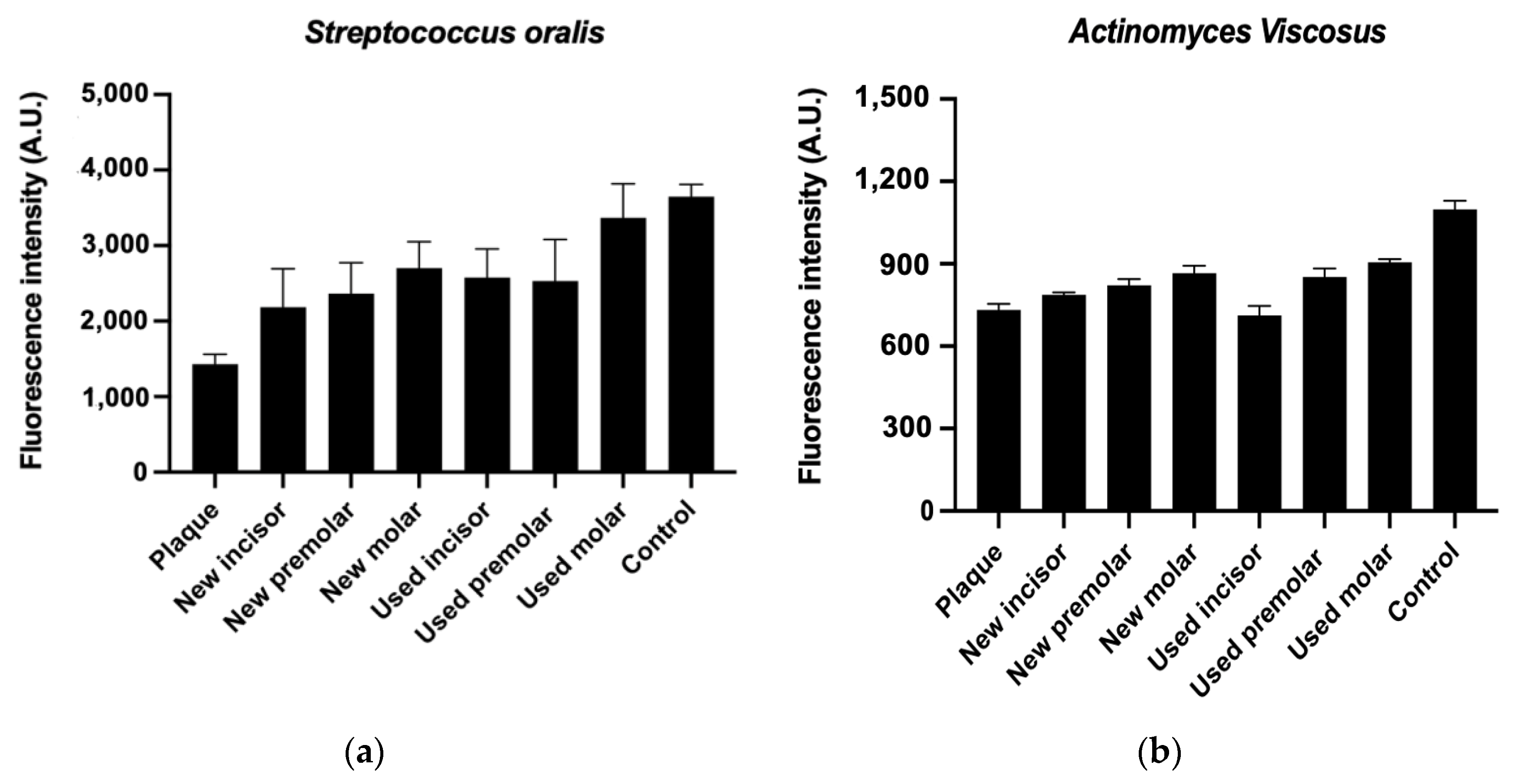

3.4.2. Metabolic Activity Assay

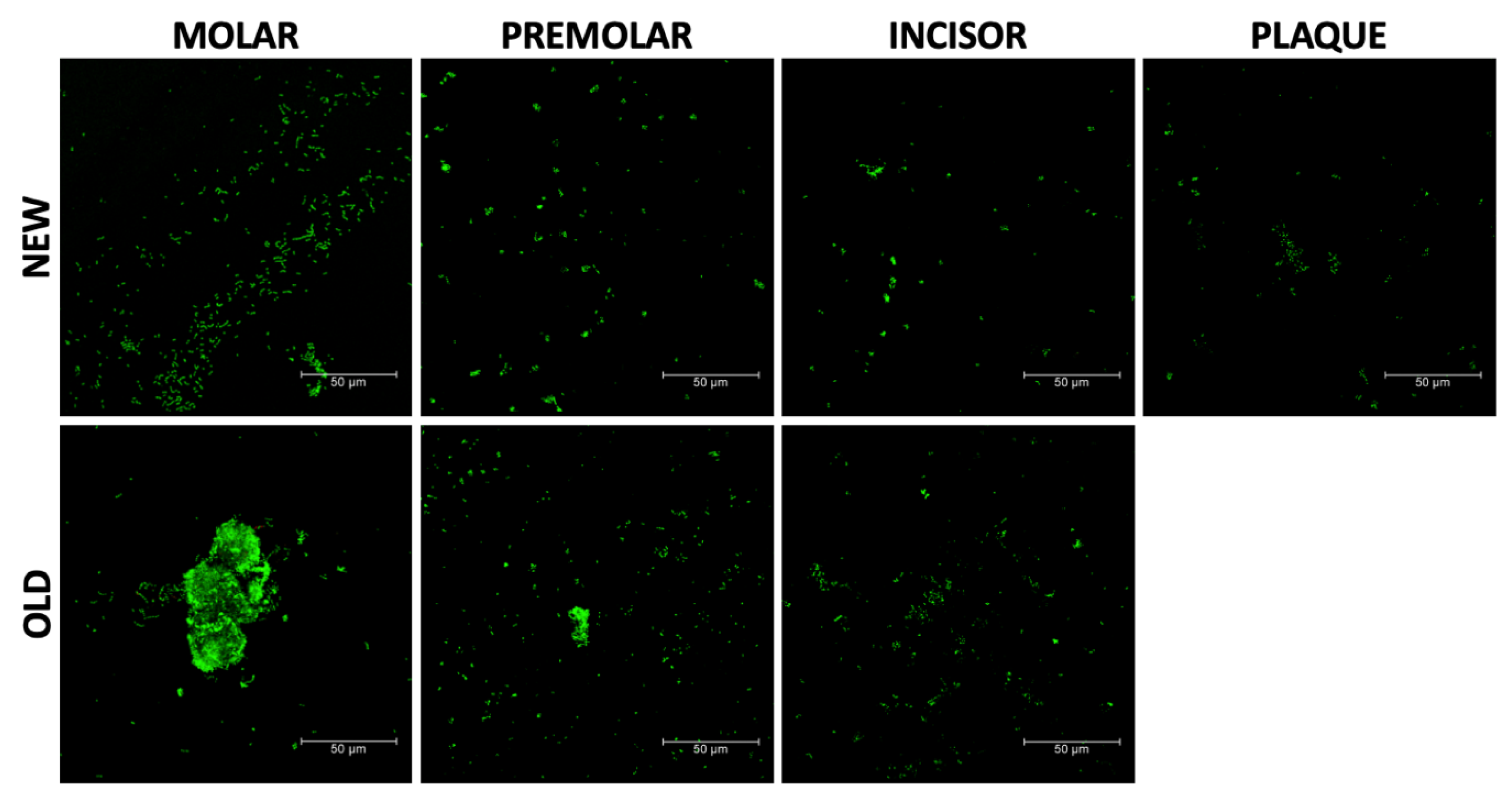

3.4.3. LIVE/DEAD Bacteria Viability

3.5. Statistical Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kesling, H.D. Coordinating the Predetermined Pattern and Tooth Positioner with Conventional Treatment. Am. J. Orthod. Oral. Surg. 1946, 32, 285–293. [Google Scholar] [CrossRef] [PubMed]

- Ponitz, R.J. Invisible Retainers. Am. J. Orthod. 1971, 59, 266–272. [Google Scholar] [CrossRef]

- Martorelli, M.; Gerbino, S.; Giudice, M.; Ausiello, P. A Comparison between Customized Clear and Removable Orthodontic Appliances Manufactured Using RP and CNC Techniques. Dent. Mater. 2013, 29, e1–e10. [Google Scholar] [CrossRef] [PubMed]

- Bichu, Y.M.; Alwafi, A.; Liu, X.; Andrews, J.; Ludwig, B.; Bichu, A.Y.; Zou, B. Advances in Orthodontic Clear Aligner Materials. Bioact. Mater. 2023, 22, 384–403. [Google Scholar] [CrossRef] [PubMed]

- Zheng, M.; Liu, R.; Ni, Z.; Yu, Z. Efficiency, Effectiveness and Treatment Stability of Clear Aligners: A Systematic Review and Meta-analysis. Orthod. Craniofac. Res. 2017, 20, 127–133. [Google Scholar] [CrossRef] [PubMed]

- Robertson, L.; Kaur, H.; Fagundes, N.C.F.; Romanyk, D.; Major, P.; Flores Mir, C. Effectiveness of Clear Aligner Therapy for Orthodontic Treatment: A Systematic Review. Orthod. Craniofac. Res. 2020, 23, 133–142. [Google Scholar] [CrossRef]

- Gomez, J.P.; Peña, F.M.; Martínez, V.; Giraldo, D.C.; Cardona, C.I. Initial Force Systems during Bodily Tooth Movement with Plastic Aligners and Composite Attachments: A Three-Dimensional Finite Element Analysis. Angle Orthod. 2015, 85, 454–460. [Google Scholar] [CrossRef] [PubMed]

- Kwon, J.-S.; Lee, Y.-K.; Lim, B.-S.; Lim, Y.-K. Force Delivery Properties of Thermoplastic Orthodontic Materials. Am. J. Orthod. Dentofac. Orthop. 2008, 133, 228–234. [Google Scholar] [CrossRef]

- Ke, Y.; Zhu, Y.; Zhu, M. A Comparison of Treatment Effectiveness between Clear Aligner and Fixed Appliance Therapies. BMC Oral. Health 2019, 19, 24. [Google Scholar] [CrossRef]

- Hartshorne, J.; Wertheimer, M.B. Emerging Insights and New Developments in Clear Aligner Therapy: A Review of the Literature. AJO-DO Clin. Companion 2022, 2, 311–324. [Google Scholar] [CrossRef]

- Tartaglia, G.M.; Mapelli, A.; Maspero, C.; Santaniello, T.; Serafin, M.; Farronato, M.; Caprioglio, A. Direct 3D Printing of Clear Orthodontic Aligners: Current State and Future Possibilities. Materials 2021, 14, 1799. [Google Scholar] [CrossRef] [PubMed]

- Panayi, N.C. Directly Printed Aligner: Aligning with the Future. Turk. J. Orthod. 2023, 36, 62–69. [Google Scholar] [CrossRef] [PubMed]

- Shirey, N.; Mendonca, G.; Groth, C.; Kim-Berman, H. Comparison of Mechanical Properties of 3-Dimensional Printed and Thermoformed Orthodontic Aligners. Am. J. Orthod. Dentofac. Orthop. 2023, 163, 720–728. [Google Scholar] [CrossRef]

- Kasgoz, A. Mechanical, Tensile Creep and Viscoelastic Properties of Thermoplastic Polyurethane/Polycarbonate Blends. Fibers Polym. 2021, 22, 295–305. [Google Scholar] [CrossRef]

- Jia, Y.; Peng, K.; Gong, X.; Zhang, Z. Creep and Recovery of Polypropylene/Carbon Nanotube Composites. Int. J. Plast. 2011, 27, 1239–1251. [Google Scholar] [CrossRef]

- Arab, S.; Nouhzadeh Malekshah, S.; Abouei Mehrizi, E.; Ebrahimi Khanghah, A.; Naseh, R.; Imani, M.M. Effect of Fixed Orthodontic Treatment on Salivary Flow, PH and Microbial Count. J. Dent. 2016, 13, 18–22. [Google Scholar]

- Taher, B.B.; Rasheed, T.A. The Impact of Adding Chitosan Nanoparticles on Biofilm Formation, Cytotoxicity, and Certain Physical and Mechanical Aspects of Directly Printed Orthodontic Clear Aligners. Nanomaterials 2023, 13, 2649. [Google Scholar] [CrossRef]

- Palmer, R.J.; Gordon, S.M.; Cisar, J.O.; Kolenbrander, P.E. Coaggregation-Mediated Interactions of Streptococci and Actinomyces Detected in Initial Human Dental Plaque. J. Bacteriol. 2003, 185, 3400–3409. [Google Scholar] [CrossRef]

- Yadav, R.K.; Krishnan, V. New Structural Insights into the PI-2 Pilus from Streptococcus Oralis, an Early Dental Plaque Colonizer. FEBS J. 2022, 289, 6342–6366. [Google Scholar] [CrossRef]

- Semiatin, S.L.; Fagin, P.N.; Levkulich, N.C.; Gockel, B.T.; Antolovich, B.F.; Crist, E.M.; Cormier, J.; Tiley, J.S. The Constant-Stress, Constant-Heating-Rate Test: A Novel Method for Characterizing Transient Mechanical Behavior of Metallic Materials. Metall. Mater. Trans. A 2022, 53, 394–406. [Google Scholar] [CrossRef]

- ISO62:2008; Plastics. ISO/TC61/SC6. International Standard Organization: Geneva, Switzerland, 2008.

- Leung, V.W.; Darvell, B.W. Artificial salivas for in vitro studies of dental materials. J Dent. 1997, 25, 475–484. [Google Scholar] [CrossRef]

- Sanjeevi, S.; Shanmugam, V.; Kumar, S.; Ganesan, V.; Sas, G.; Johnson, D.J.; Shanmugam, M.; Ayyanar, A.; Naresh, K.; Neisiany, R.E.; et al. Effects of Water Absorption on the Mechanical Properties of Hybrid Natural Fibre/Phenol Formaldehyde Composites. Sci. Rep. 2021, 11, 13385. [Google Scholar] [CrossRef]

- Manero, J.M.; Gil, F.J.; Padrós, E.; Planell, J.A. Applications of Environmental Scanning Electron Microscopy (ESEM) in Biomaterials Field. Microsc. Res. Tech. 2003, 61, 469–480. [Google Scholar] [CrossRef] [PubMed]

- Kohda, N.; Iijima, M.; Muguruma, T.; Brantley, W.A.; Ahluwalia, K.S.; Mizoguchi, I. Effects of Mechanical Properties of Thermoplastic Materials on the Initial Force of Thermoplastic Appliances. Angle Orthod. 2013, 83, 476–483. [Google Scholar] [CrossRef]

- Ryokawa, H.; Miyazaki, Y.; Fujishima, A.; Miyazaki, T.; Maki, K. The Mechanical Properties of Dental Thermoplastic Materials in a Simulated Intraoral Environment. Orthod. Waves 2006, 65, 64–72. [Google Scholar] [CrossRef]

- Schoenfeld, C.M.; Conard, G.J.; Lautenschlager, E.P. Monomer Release from Methacrylate Bone Cements during Simulated In Vivo Polymerization. J. Biomed. Mater. Res. 1979, 13, 135–147. [Google Scholar] [CrossRef]

- Rouzi, M.; Zhang, X.; Jiang, Q.; Long, H.; Lai, W.; Li, X. Impact of Clear Aligners on Oral Health and Oral Microbiome During Orthodontic Treatment. Int. Dent. J. 2023, 73, 603–611. [Google Scholar] [CrossRef] [PubMed]

- Pascual, B.; Gurruchaga, M.; Ginebra, M.P.; Gil, F.J.; Planell, J.A.; Goñi, I. Influence of the Modification of P/L Ratio on a New Formulation of Acrylic Bone Cement. Biomaterials 1999, 20, 465–474. [Google Scholar] [CrossRef]

- Tektas, S.; Thurnheer, T.; Eliades, T.; Attin, T.; Karygianni, L. Initial Bacterial Adhesion and Biofilm Formation on Aligner Materials. Antibiotics 2020, 9, 908. [Google Scholar] [CrossRef] [PubMed]

- Rodriguez-Fernandez, J.C.; Pastor, F.; Barrera Mora, J.M.; Brizuela, A.; Puigdollers, A.; Espinar, E.; Gil, F.J. Bacteriostatic Poly Ethylene Glycol Plasma Coatings for Orthodontic Titanium Mini-Implants. Materials 2022, 15, 7487. [Google Scholar] [CrossRef]

- Raghavan, S.; Abu Alhaija, E.S.; Duggal, M.S.; Narasimhan, S.; Al-Maweri, S.A. White Spot Lesions, Plaque Accumulation and Salivary Caries-Associated Bacteria in Clear Aligners Compared to Fixed Orthodontic Treatment. A Systematic Review and Meta- Analysis. BMC Oral. Health 2023, 23, 599. [Google Scholar] [CrossRef] [PubMed]

- Godoy-Gallardo, M.; Guillem-Marti, J.; Sevilla, P.; Manero, J.M.; Gil, F.J.; Rodriguez, D. Anhydride-Functional Silane Immobilized onto Titanium Surfaces Induces Osteoblast Cell Differentiation and Reduces Bacterial Adhesion and Biofilm Formation. Mater. Sci. Eng. C 2016, 59, 524–532. [Google Scholar] [CrossRef] [PubMed]

| Chemical Composition | g/dm3 |

|---|---|

| K2HPO4 | 0.20 |

| KCl | 1.20 |

| KSCN | 0.33 |

| Na2HPO4 | 0.26 |

| NaCl | 0.70 |

| NaHCO3 | 1.50 |

| Urea | 1.50 |

| Lactic acid | Until pH = 6.7 |

| Mechanical Properties | Original Plate | Aligner |

|---|---|---|

| Elastic limit (MPa) | 3.44 ± 0.15 | 3.95 ± 0.14 * |

| Deformation (%) | 237 ± 49 | 207 ± 29 * |

| Poisson’s ratio | 0.492 ± 0.101 | 0.489 ± 0.162 |

| Elastic modulus (GPa) | 0.015 ± 0.002 | 0.021 ± 0.004 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodríguez Fernández, J.C.; Pastor, F.; Mora, J.M.B.; Demiquels, E.; Espinar, E.; Gil, J. Conformation Effect on the Mechanical and Microbiological Behavior of Invisible Orthodontic Aligners. Materials 2024, 17, 1360. https://doi.org/10.3390/ma17061360

Rodríguez Fernández JC, Pastor F, Mora JMB, Demiquels E, Espinar E, Gil J. Conformation Effect on the Mechanical and Microbiological Behavior of Invisible Orthodontic Aligners. Materials. 2024; 17(6):1360. https://doi.org/10.3390/ma17061360

Chicago/Turabian StyleRodríguez Fernández, Juan Carlos, Francisco Pastor, José María Barrera Mora, Elena Demiquels, Eduardo Espinar, and Javier Gil. 2024. "Conformation Effect on the Mechanical and Microbiological Behavior of Invisible Orthodontic Aligners" Materials 17, no. 6: 1360. https://doi.org/10.3390/ma17061360