1. Introduction

Water is one of the main factors causing various types of distresses in the early service stage of asphalt pavement [

1]. It is well accepted that there are two main forms of damage caused by water to asphalt pavement [

2]; one is to weaken the adhesion between asphalt and aggregates, and the other is to deteriorate the internal cohesion of asphalt [

3,

4,

5]. Water not only causes loss of cohesion, but also decreases the adhesion between asphalt and aggregate, and this decrease in adhesion affects many properties of asphalt pavements [

6,

7,

8].

For asphalt pavement in service, the damage caused by water is actually a very complex process. Studies have shown that free water infiltrating into the interior of asphalt pavement structure will form super-porous water flow under the action of vehicle load, and the asphalt pavement undergoing the dual action of load and pore water scouring finally generates structural damage [

9,

10,

11]. Therefore, the effect of dynamic water pressure cannot be ignored for asphalt pavement in service. With the continuous construction of asphalt pavement, especially the application of porous asphalt pavement, the water damage caused by dynamic water pressure to asphalt pavement is becoming more and more prominent [

12]. The dynamic water pressure accelerates the adhesion loss and cohesion loss. This is because the liquid water in the pavement structure can flow freely in the channel connecting the voids, and the asphalt pavement will gradually dense under the repeated load of the vehicle, so that the connected voids lose permeability, which will produce excessive pore water pressure, and such void water pressure will accelerate the stripping of asphalt and aggregate, resulting in moisture damage [

13].

Currently, the water stability of asphalt mixture is mainly evaluated under the static water damage conditions. In the static water evaluation methods, two types of test specimens are used; one is uncompacted asphalt mixture (asphalt or asphalt mastic coated aggregate, loose asphalt mixture, etc.), and the other is compacted asphalt mixture (Marshall specimen, cored specimen, etc.) [

14,

15]. The water stability of asphalt mixture is determined based on the loss of asphalt of uncompacted asphalt mixture and the loss of Marshall stability, indirect tensile strength, etc. Although these methods are simple to operate, the water-soaked or freeze-thaw conditions cannot well simulate the field site water damage conditions, especially the dynamic water pressure caused by the vehicle load. In practice, water damage of asphalt pavement is a gradually increasing process; the repeated action of the vehicle load will generate circulating dynamic water pressure inside the voids, and asphalt mixture in this process will be continuously scoured, resulting in the gradual accumulation of damage and then developing into water damage [

16,

17]. Therefore, it is necessary to consider the effect of dynamic water pressure when evaluating the water damage resistance of asphalt mixture. Considering the dynamic water pressure will damage the internal structure of asphalt mixture [

18], analyzing water stability from the changes in structure of asphalt mixture such as voids would be highly efficient, Mohammed et al. [

19] used a plastic-modified asphalt mixture, and in the experiment, it was found that the void rate decreased as the plastic content increased. The water stability of the mixture increases with the increase of plastic content, which indicates that the water resistance of the asphalt mixture may be related to the change of its void rate. In addition, Sanfilippo et al. [

20] prepared asphalt mixtures with different voids and performed X-ray scans before and after freezing and thawing, and they found that the properties of the asphalt mixture were closely related to the void characteristics. CT technology can detect the internal structure of the object without contact; find the internal defects of the product quickly, accurately, and intuitively; and analyze them, so as to find the root cause of the defect. In fact, as early as 2007, Arambula et al. [

21] used CT technology to analyze the internal void characteristics of asphalt mixture and found that the water stability of asphalt mixture is closely related to the spatial distribution of internal voids. On this basis, Alawneh et al. [

22] collected nine ray slices at different parts of the asphalt mixture before and after the freeze-thaw cycle to replace the overall internal structure of the sample and used ImageJ software (

https://imagej.net/ij/download.html, bundled with 64-bit Java 8) to analyze to evaluate the change law of the internal voids of the sample, Omranian et al. [

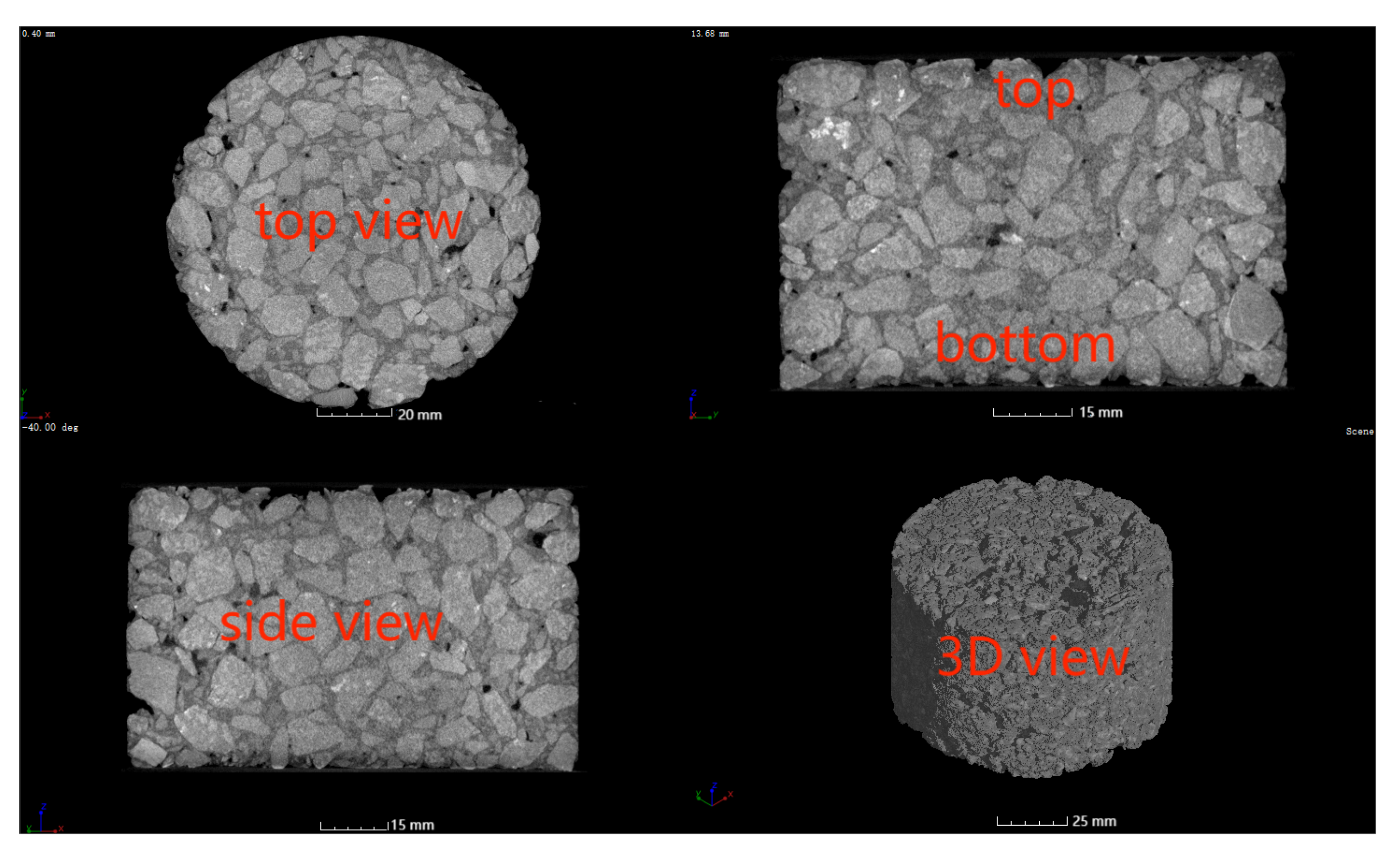

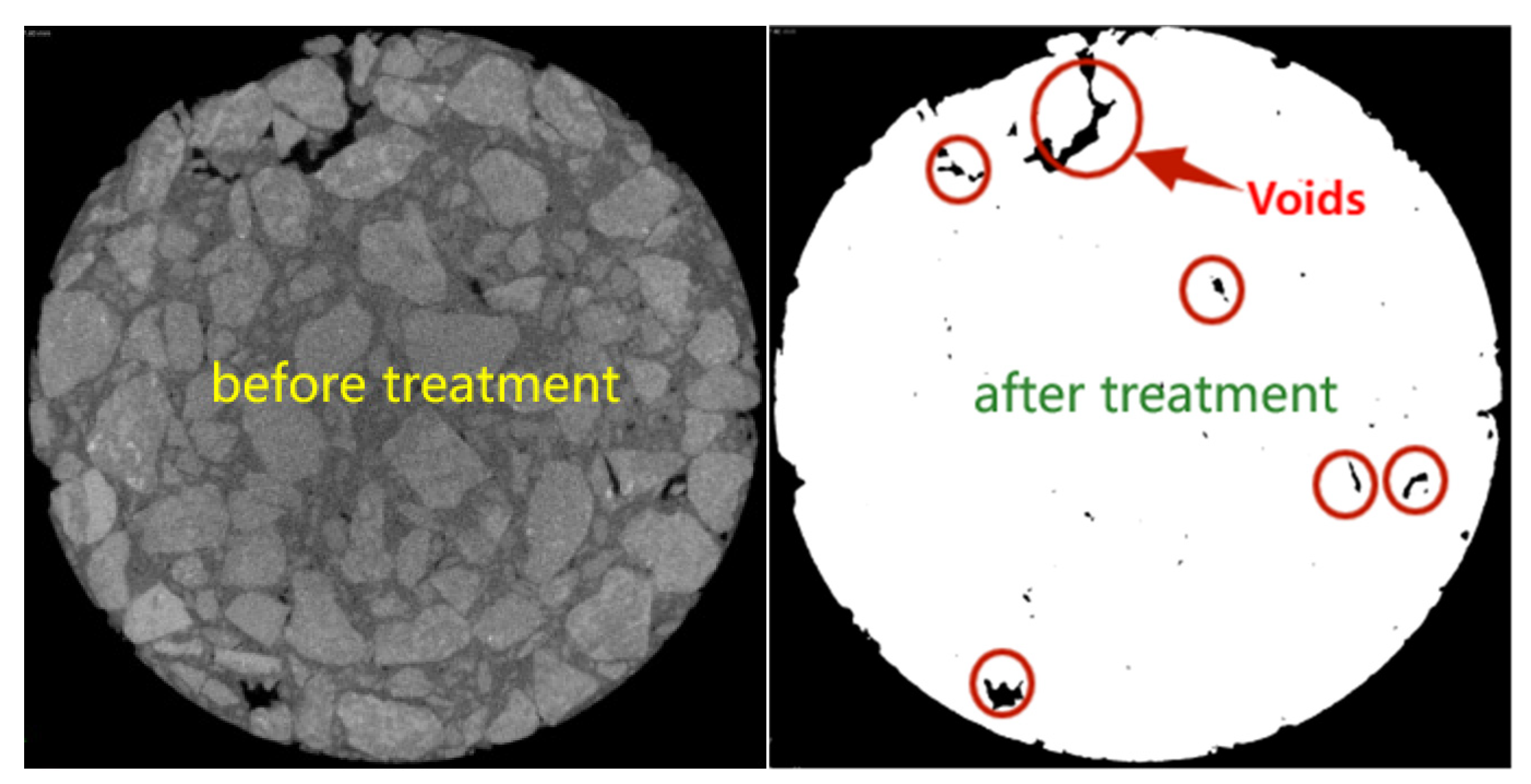

23] converted the CT image into a 3D model and detected the structural failure of the asphalt mixture by the color threshold method. However, although CT technology is well established for analyzing the structural changes of asphalt mixtures after water damage, at present, there is still little CT image analysis for the large number of asphalt mixtures, especially the lack of CT scanning studies of asphalt mixtures based on dynamic water quality testing methods.

There are many ways to improve the performance of asphalt mixtures, which can be done by laying hands on the asphalt, through SBS modification and composite material modification, etc. [

24,

25,

26]; it can also be directly improved in the mixture by adding additives, such as hydrated lime, rubber, fiber, etc. [

27,

28,

29]. It has been shown that the introduction of fibers in asphalt mixtures can enhance the strength and stiffness of the mixtures [

30], giving them higher modulus, viscosity, water stability, high-temperature stability, low-temperature crack resistance, and durability, which prolongs the service life of asphalt mixtures as pavement materials [

31,

32]. Qin et al. [

33] examined the effect of basalt fibers of varied lengths (6 mm, 9 mm, and 15 mm) and contents (3–10%) on the properties of asphalt mastics and found out that the addition of basalt fibers generally improved the properties of asphalt mastics especially the crack resistance. Tang et al. [

34] explored the effect of alkali-treated waste betel nut fiber (BNF) on the water stability of asphalt mixture; the results showed that for the AC-13 gradation, the optimal combination of multi-response variables was a fiber content of 0.2561%, fiber shear time of 12.78 min, and asphalt-aggregate rate of 5.82%. Abdelsalam et al. [

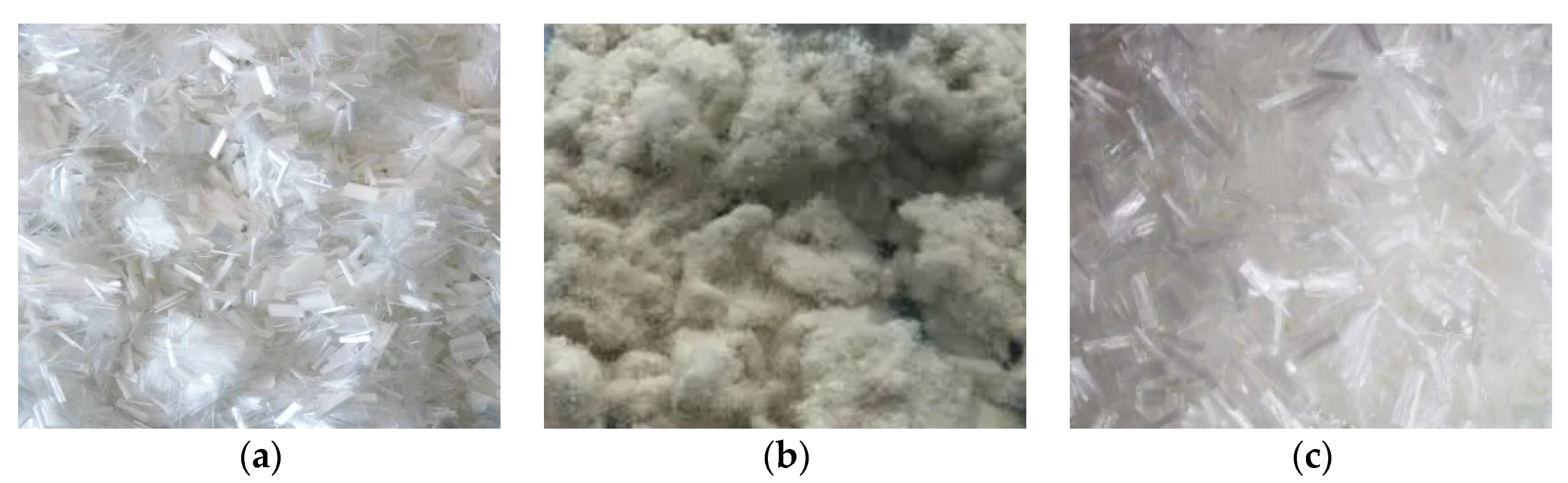

35] carried out a laboratory study on the properties of asphalt mixture modified with a new composite composed of diatomaceous earth powder and lignin fibers. Results revealed that the use of the composite in asphalt mixture led to an enhancement in the asphalt pavement performance. Previous studies have confirmed that the reliability of using fibers to improve a series of properties of asphalt mixtures. It also indicates that using fibers to strengthen the water damage resistance of asphalt mixture has advantages because many other performances of asphalt mixture can also be synchronously enhanced. Among the many types of fibers, lignin fibers, polyester fibers, and polypropylene fibers are not only more common but also have better economic benefits.

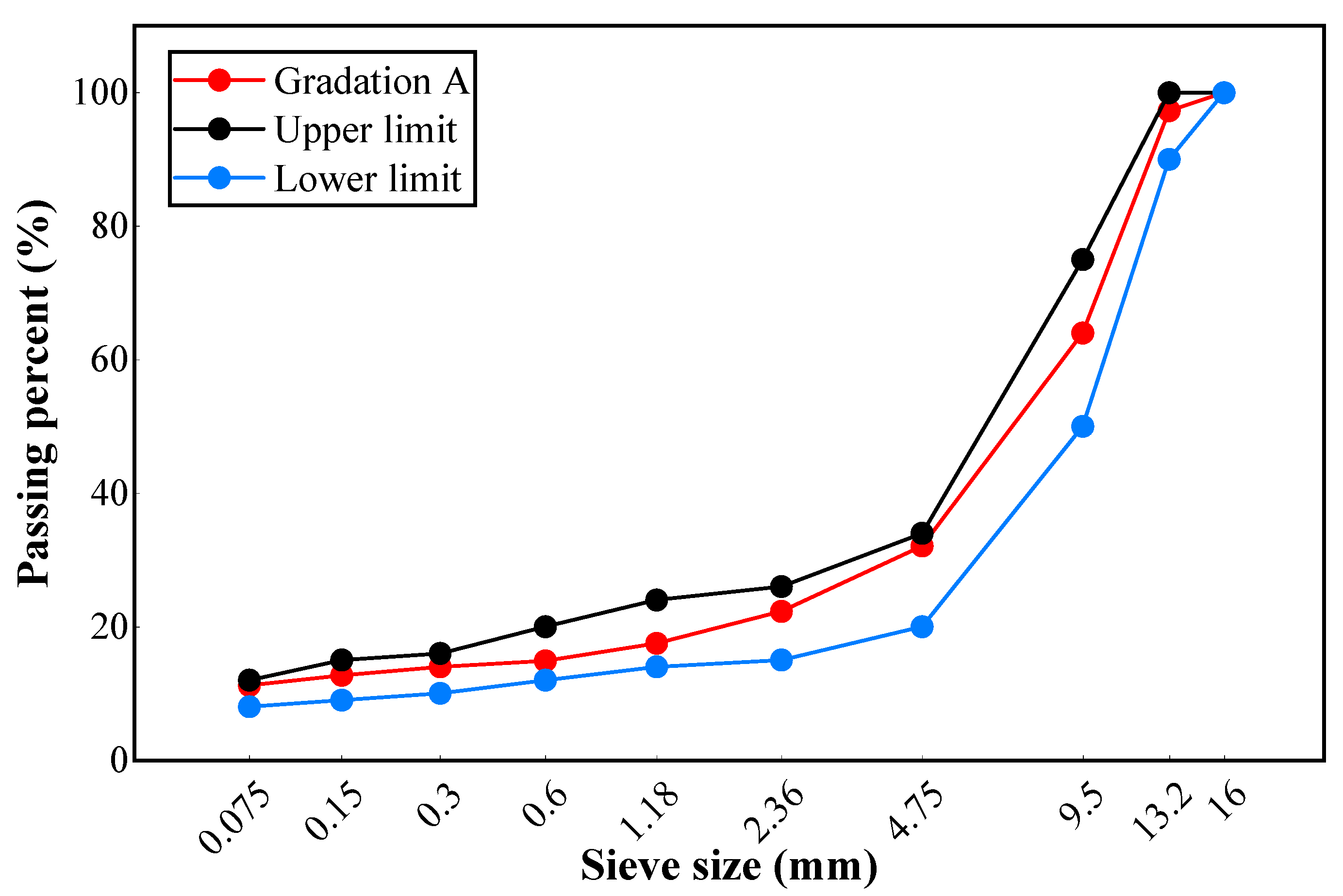

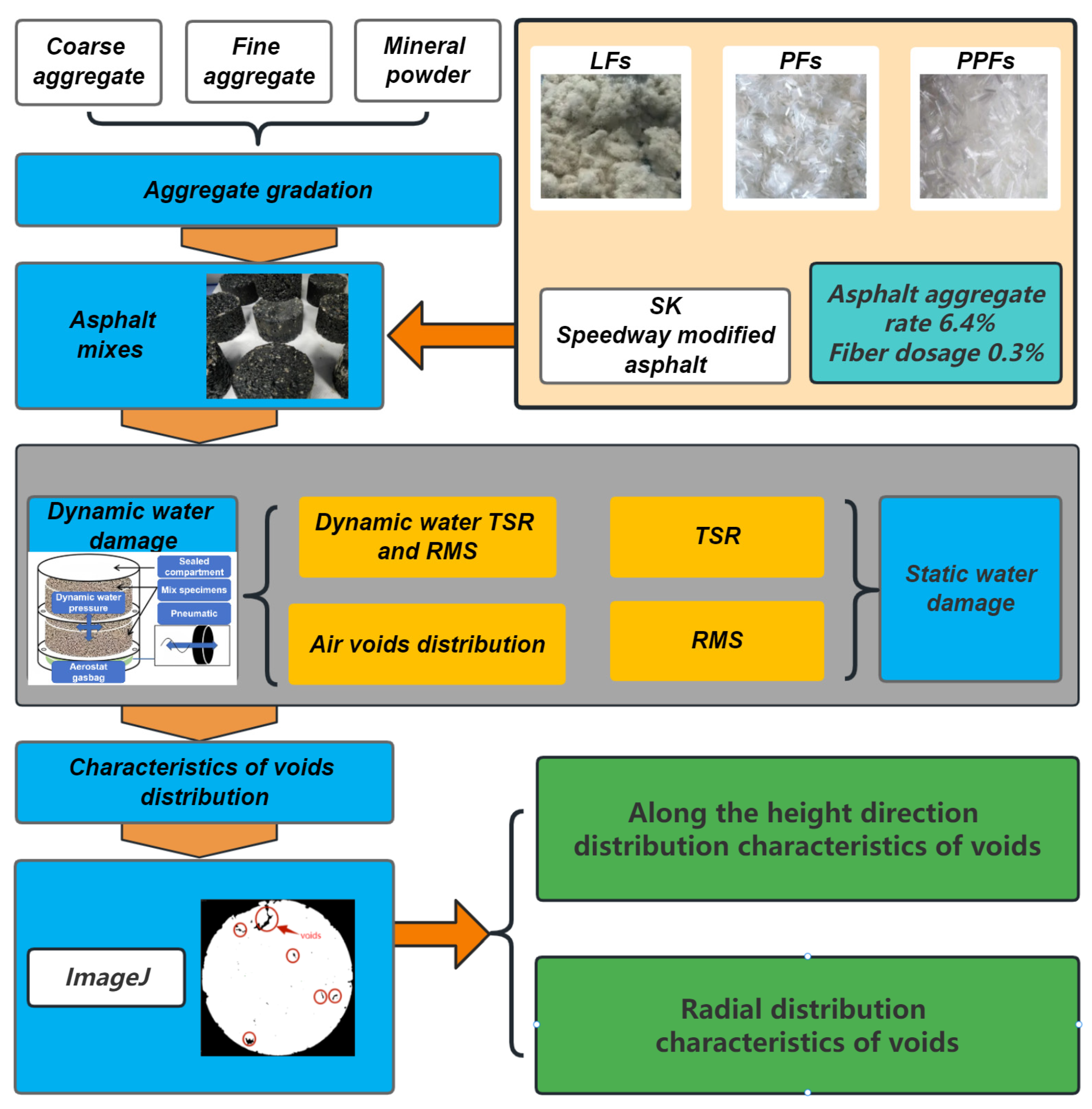

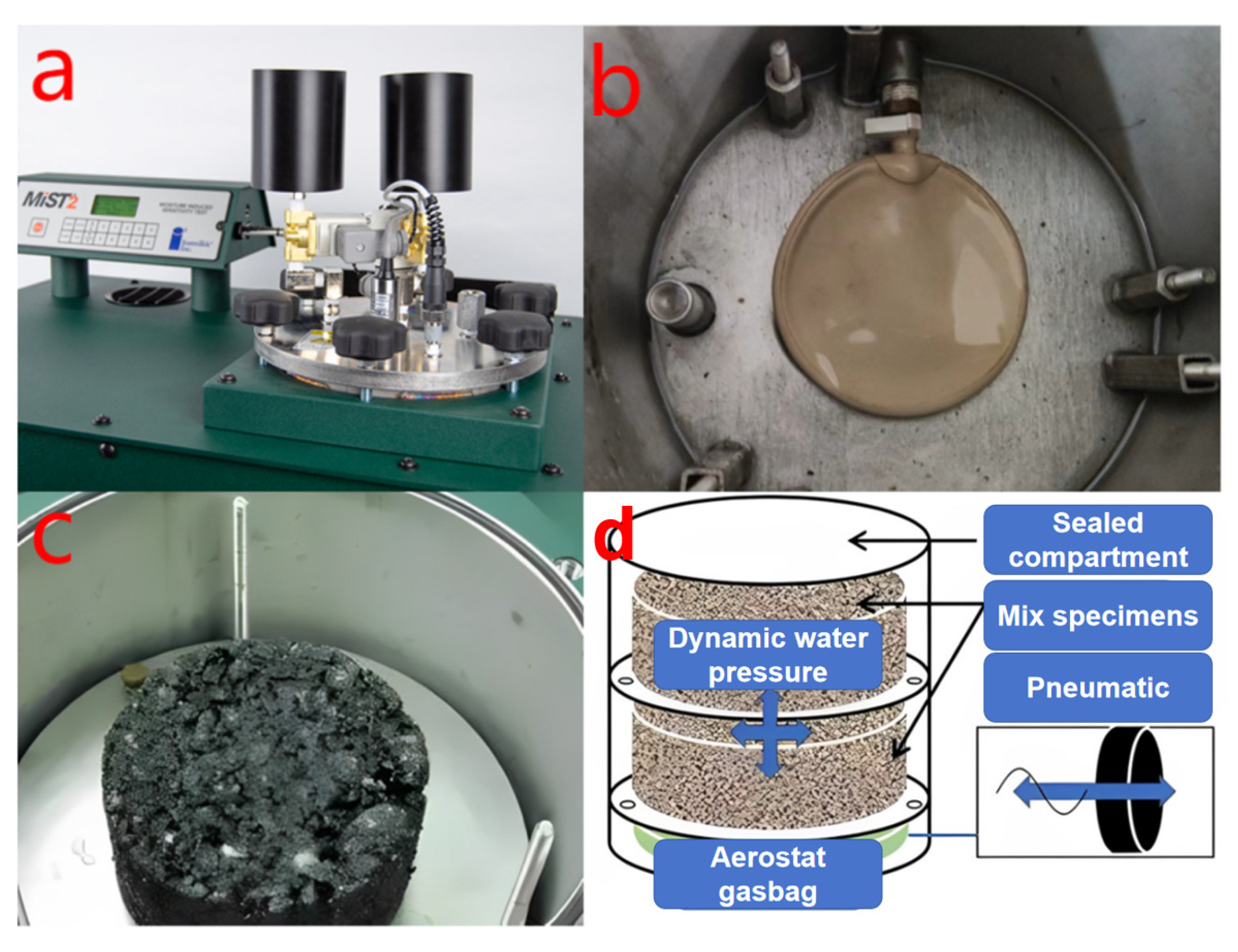

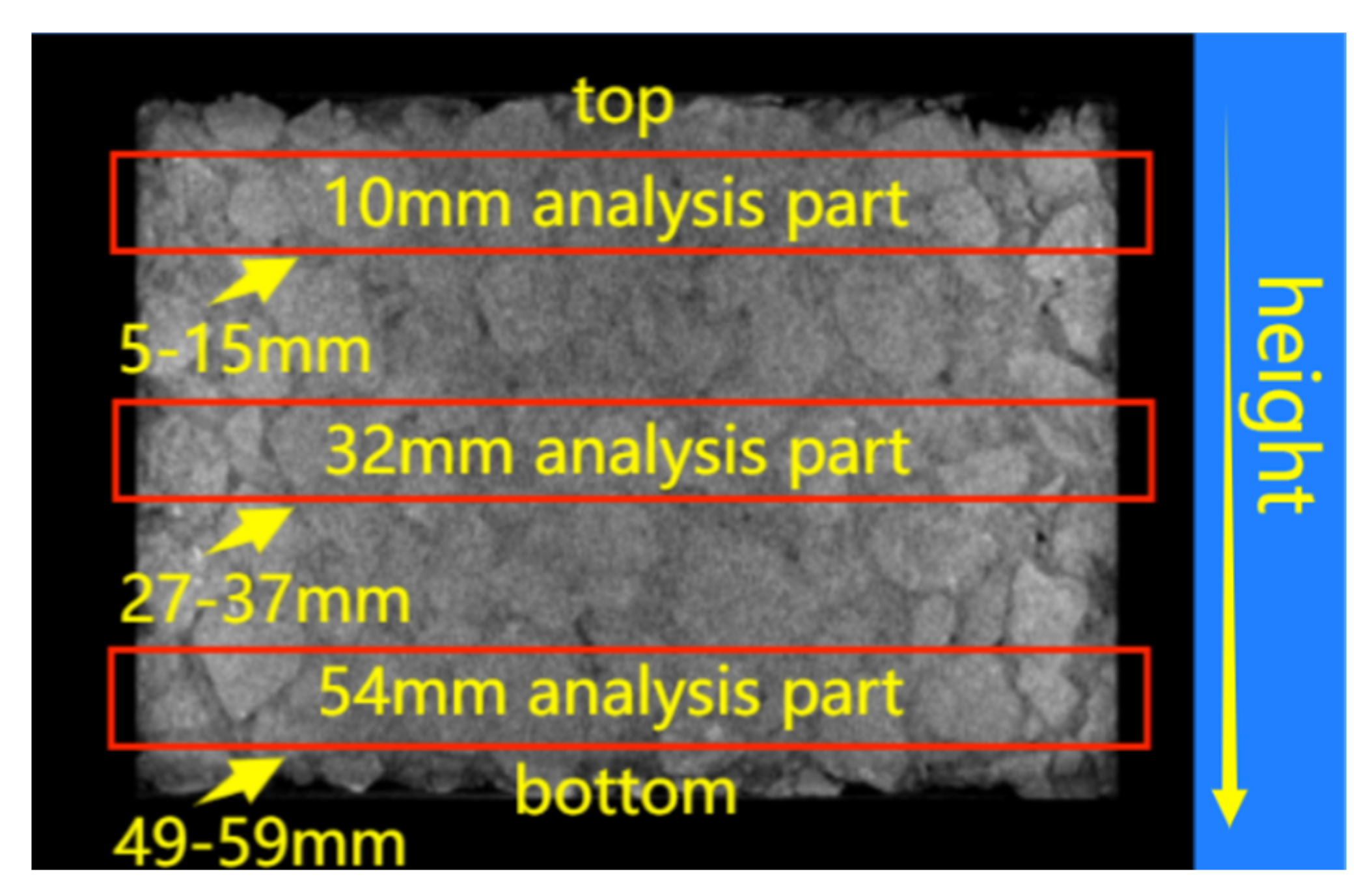

Based on the above, in order to fully understand the water damage characteristics and improve the water stability of asphalt mixture, in this research, multiple water damage conditions were used. In addition to the traditional static water-soaked condition and water freeze-thaw condition, the dynamic water pressure condition was also adopted. The fiber was also used to enhance asphalt mixture. Firstly, fiber enhanced asphalt mixtures were designed by Marshall method, and three types of fibers, namely lignin fibers (LFs), polyester fibers (PFs), and polypropylene fibers (PPFs), were involved. Then, the moisture stability of fiber enhanced asphalt mixtures was further investigated. It included two tasks; for static water conditions, the RMS test (determining the loss of Marshall stability of asphalt mixture after hot water-soaked damage) and the TSR test (determining the loss of splitting tensile strength of asphalt mixture after freeze-thaw damage) were conducted. For dynamic water pressure conditions, besides the dynamic water RMS test and TSR test, X-ray CT scanning technology with image recognition and processing software ImageJ was further used to extract and analyze voids, and the influence of fibers on the water damage resistance behavior of asphalt mixture was analyzed based on the distribution feature of voids and the change rule of voids after the dynamic water scouring test.

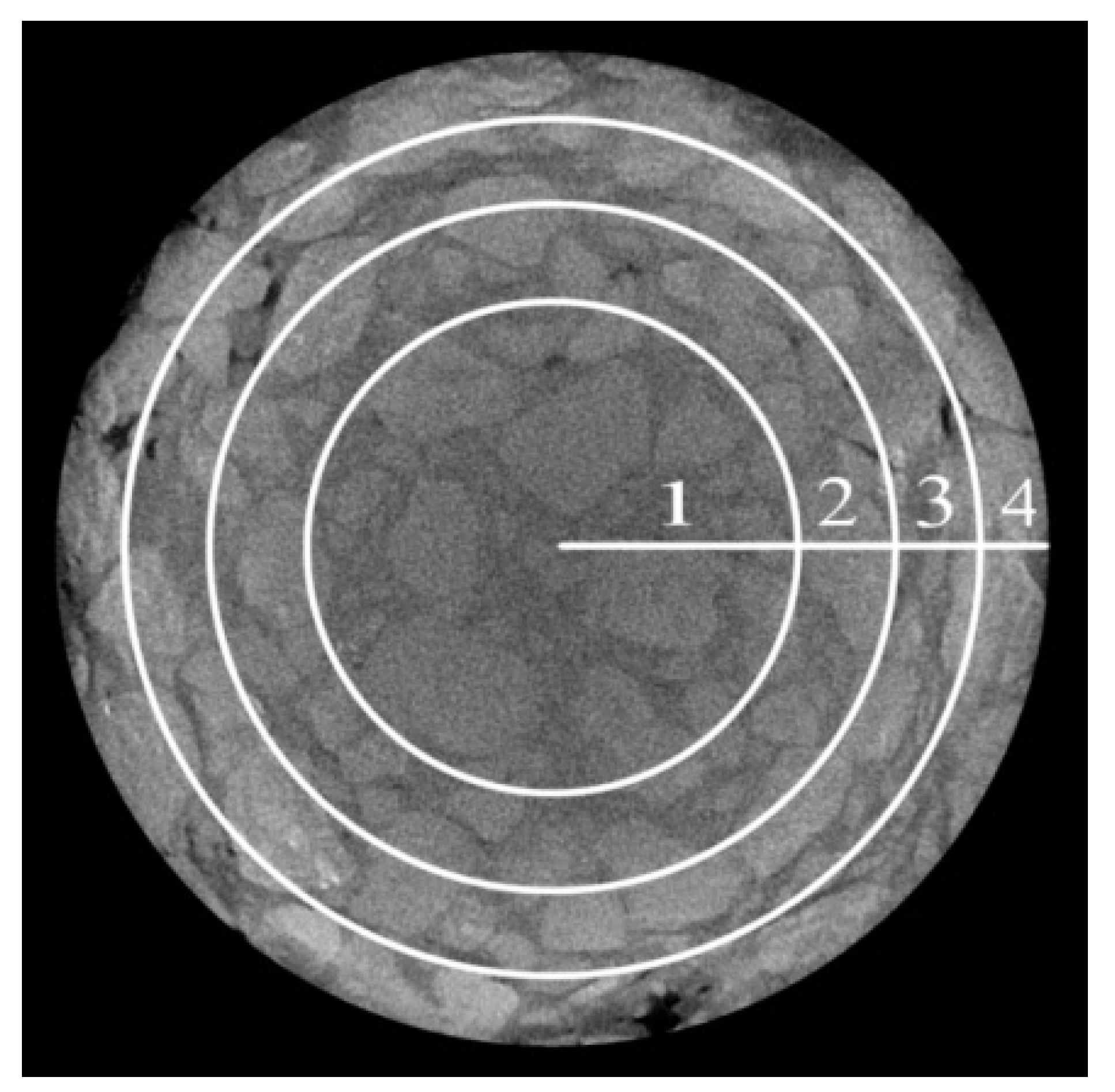

In this paper, by combining the traditional static water conditions and dynamic water conditions test methods, we can not only achieve a comprehensive evaluation of asphalt mixture performance but also compare the differences between the two methods. In addition, by improving the previous test method, the CT scan image of asphalt mixture is divided into three different analysis parts, which can better describe its overall characteristics. With the help of dynamic water condition test, the improvement of water stability by adding fibers into asphalt mixtures can be also forwarded.

4. Conclusions

In this study, three types of fibers, LFs, PFs, and PPFs, were used to prepare fiber-enhanced SMA asphalt mixtures. The TSR and RMS of these three fibers-enhanced asphalt mixtures were first measured under static water damage conditions and dynamic water pressure conditions, and then the CT scanning test was further used to analyze the void characteristics of asphalt mixture under dynamic water pressure condition. The main conclusions of the study were as follows:

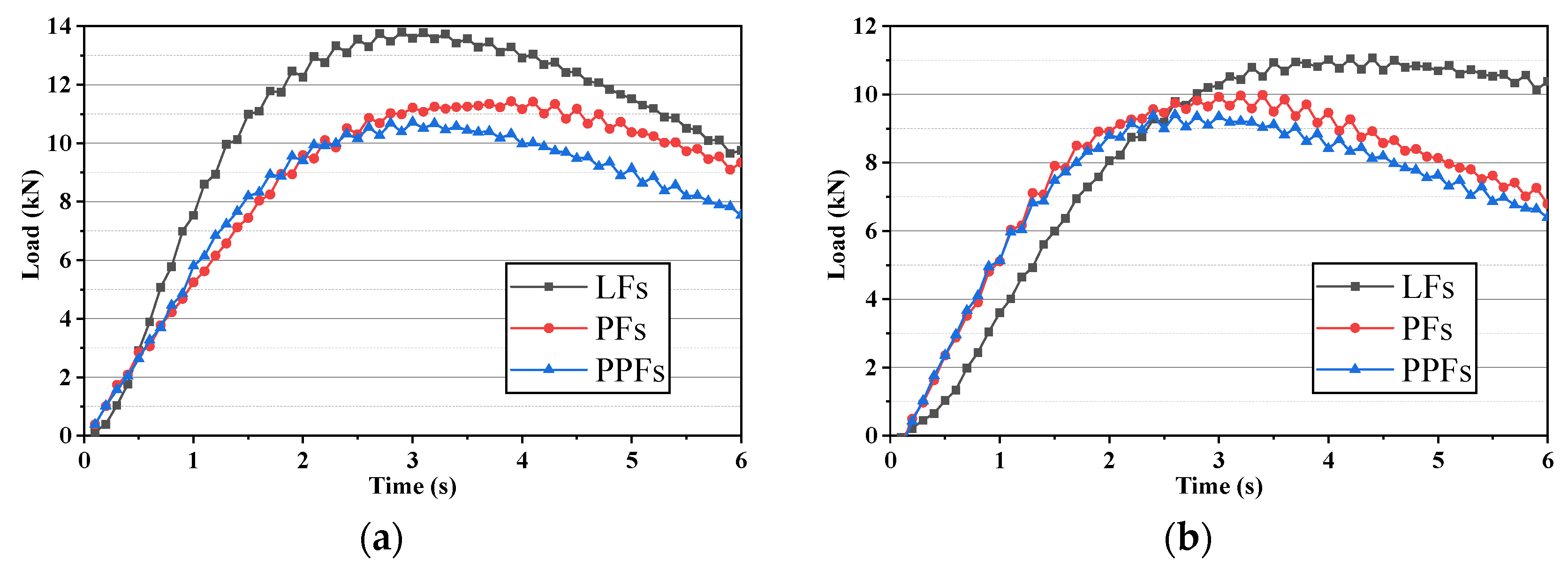

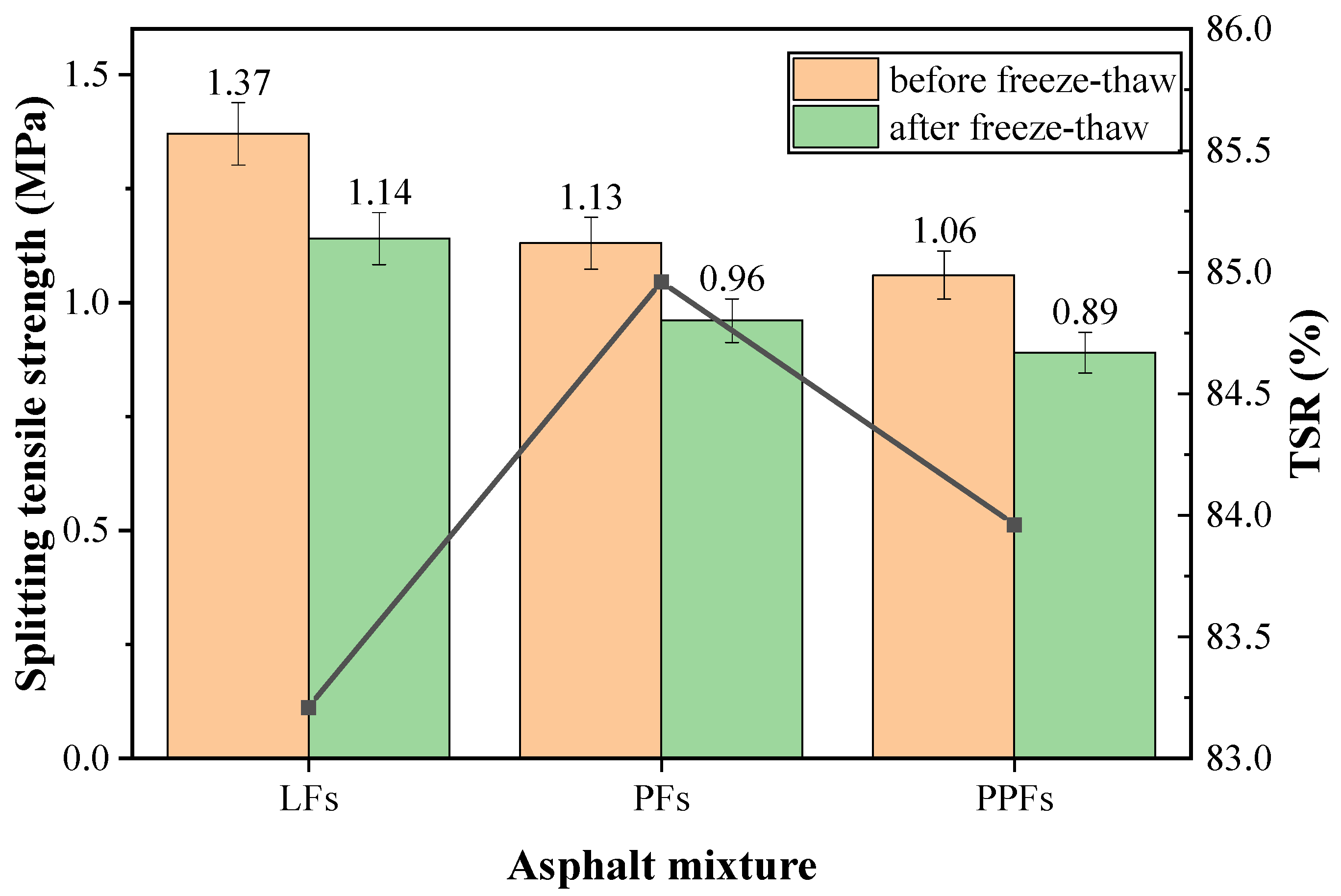

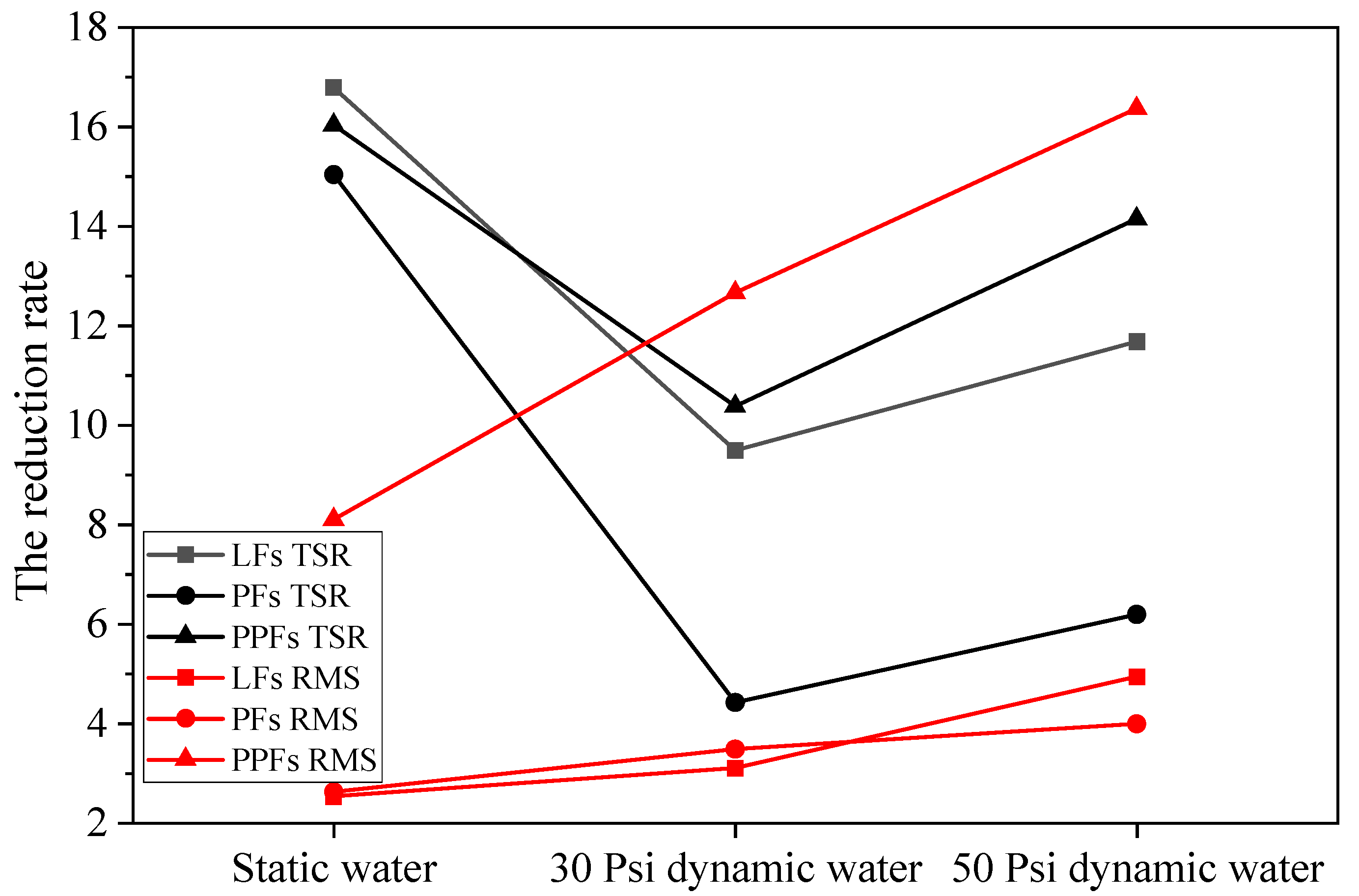

(1) Results of traditional static water TSR and RMS tests suggested that PFs endowed the asphalt mixture with excellent water stability. For the PFs-enhanced asphalt mixture, its TSR value was the highest, reaching 85%. Although its RMS value was a little lower than that of the LFs-enhanced asphalt mixture, the difference was quite small; they were 97.38% and 97.47%, respectively.

(2) Results of the dynamic water TSR and RMS tests showed that the splitting tensile strength and Marshall stability of asphalt mixtures decreased with the increase of dynamic water pressure, and the PFs-enhanced asphalt mixtures possessed larger TSR and MRS even after damage with high dynamic water pressure of 50 Psi, which were 93.81% and 96.01%, respectively.

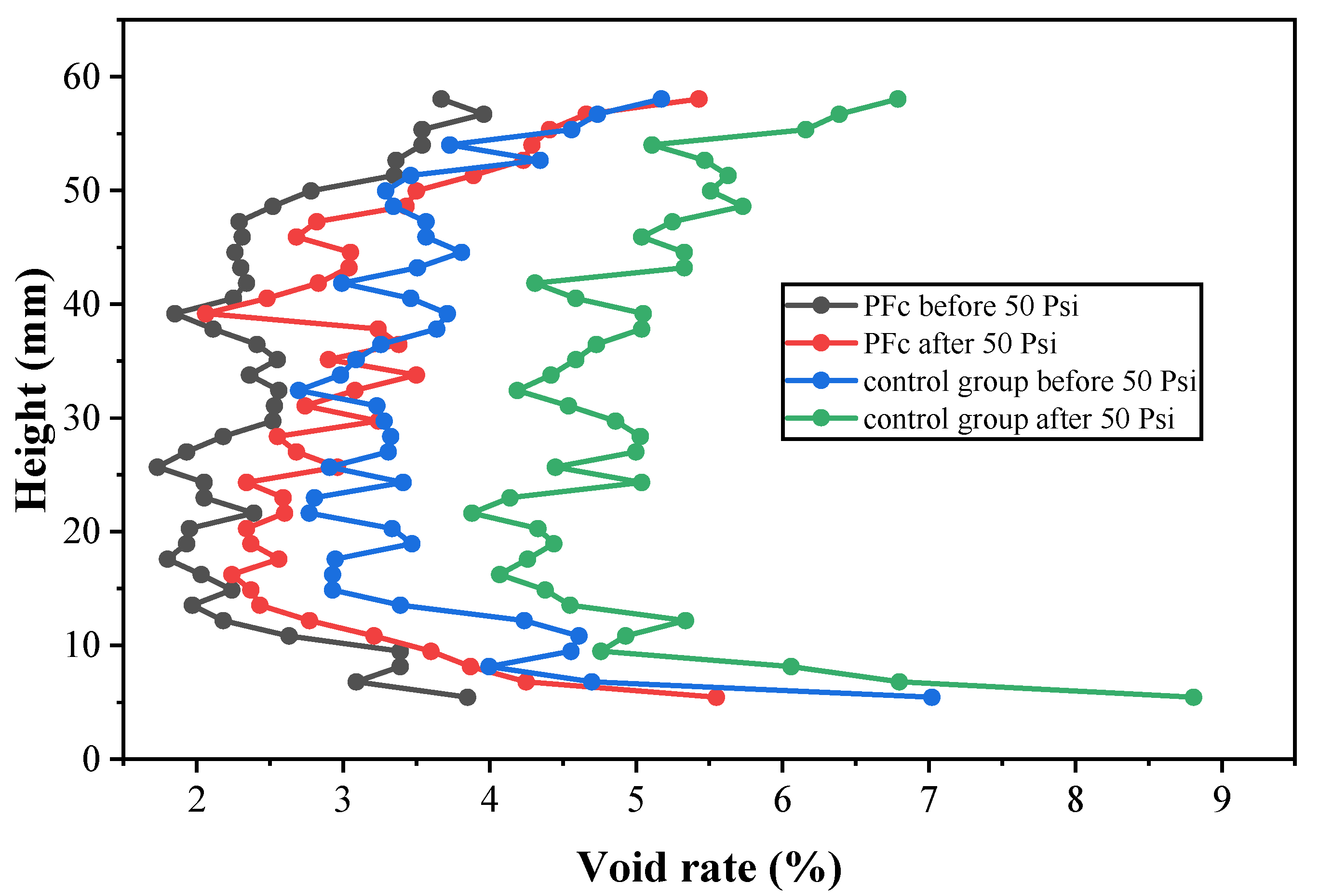

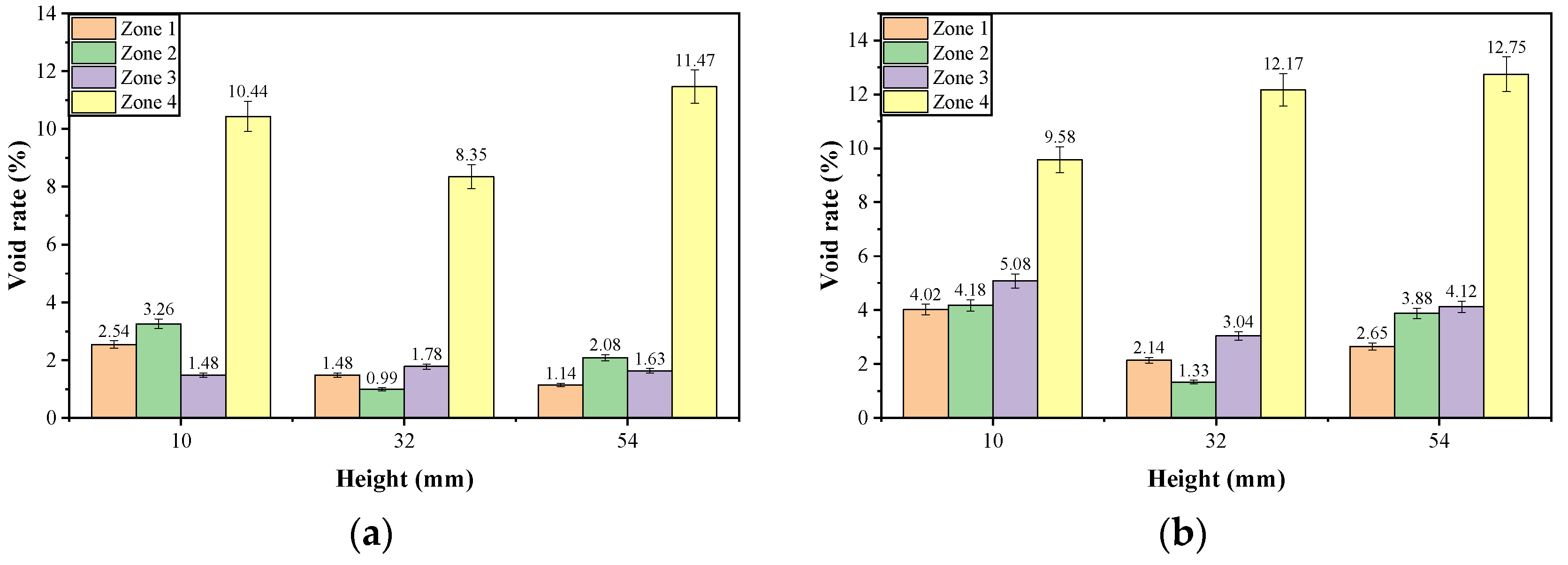

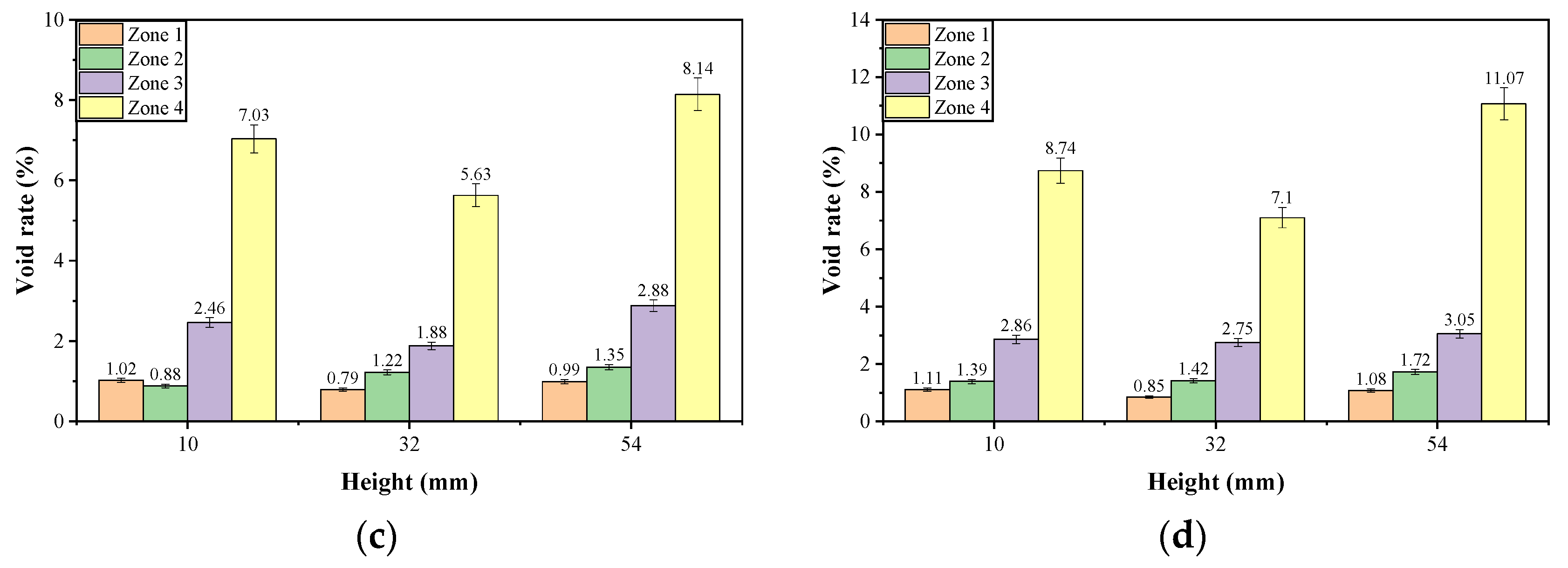

(3) The distribution characteristics of voids in the height and radius directions analyzed by the CT scanning technique both indicated that the void rate of the PFs-enhanced asphalt mixture was smaller than that of the fiber-free control group, and after applying dynamic water pressure, the increase in the total void rate of the PFs-enhanced asphalt mixture was 25.49% lower than the control group.

The dynamic water simulation method adopted in this study is closer to the actual condition of asphalt mixture, and the test results obtained based on this method are more accurate, which is conducive to guiding the formulation of subsequent research and the development of asphalt pavement.