Impregnated Polymeric Sorbent for the Removal of Noble Metal Ions from Model Chloride Solutions and the RAM Module

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Impregnation Process

2.2.2. Analysis of the SIR

2.2.3. Sorption and Desorption Studies

2.2.4. Kinetic, Thermodynamic and Isotherm Studies

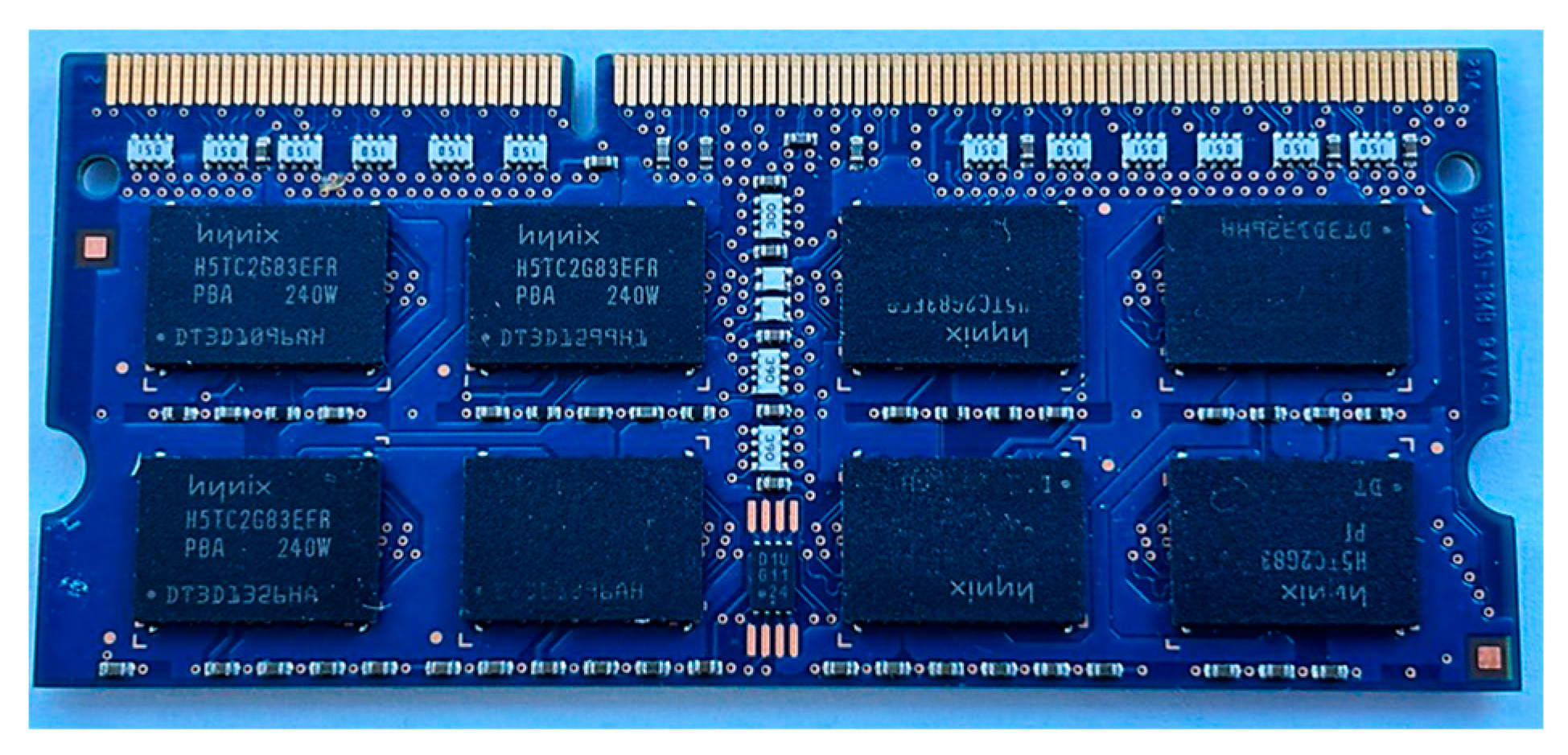

2.2.5. Noble Metal Recovery from the Spent RAM Module

3. Results and Discussion

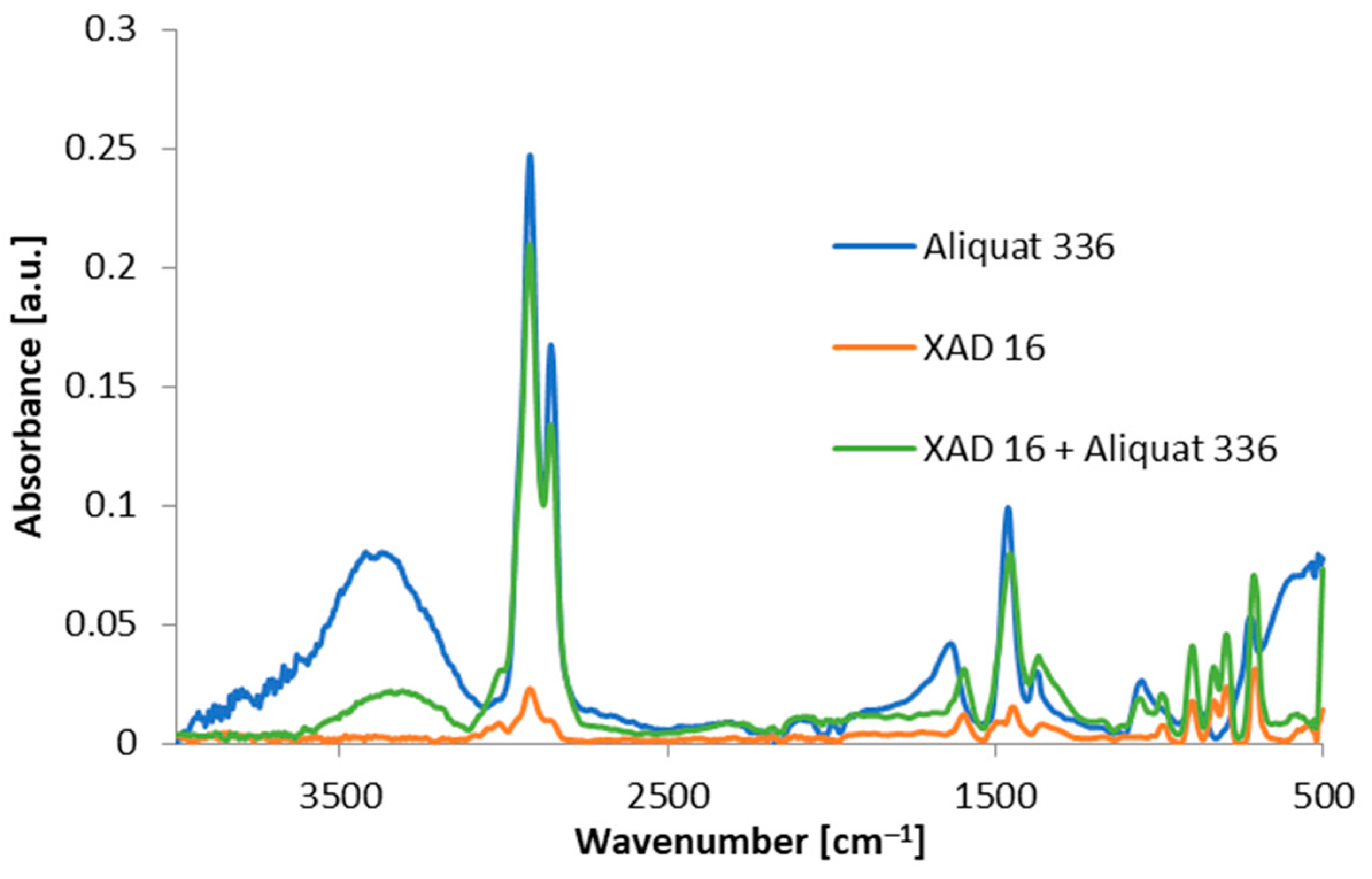

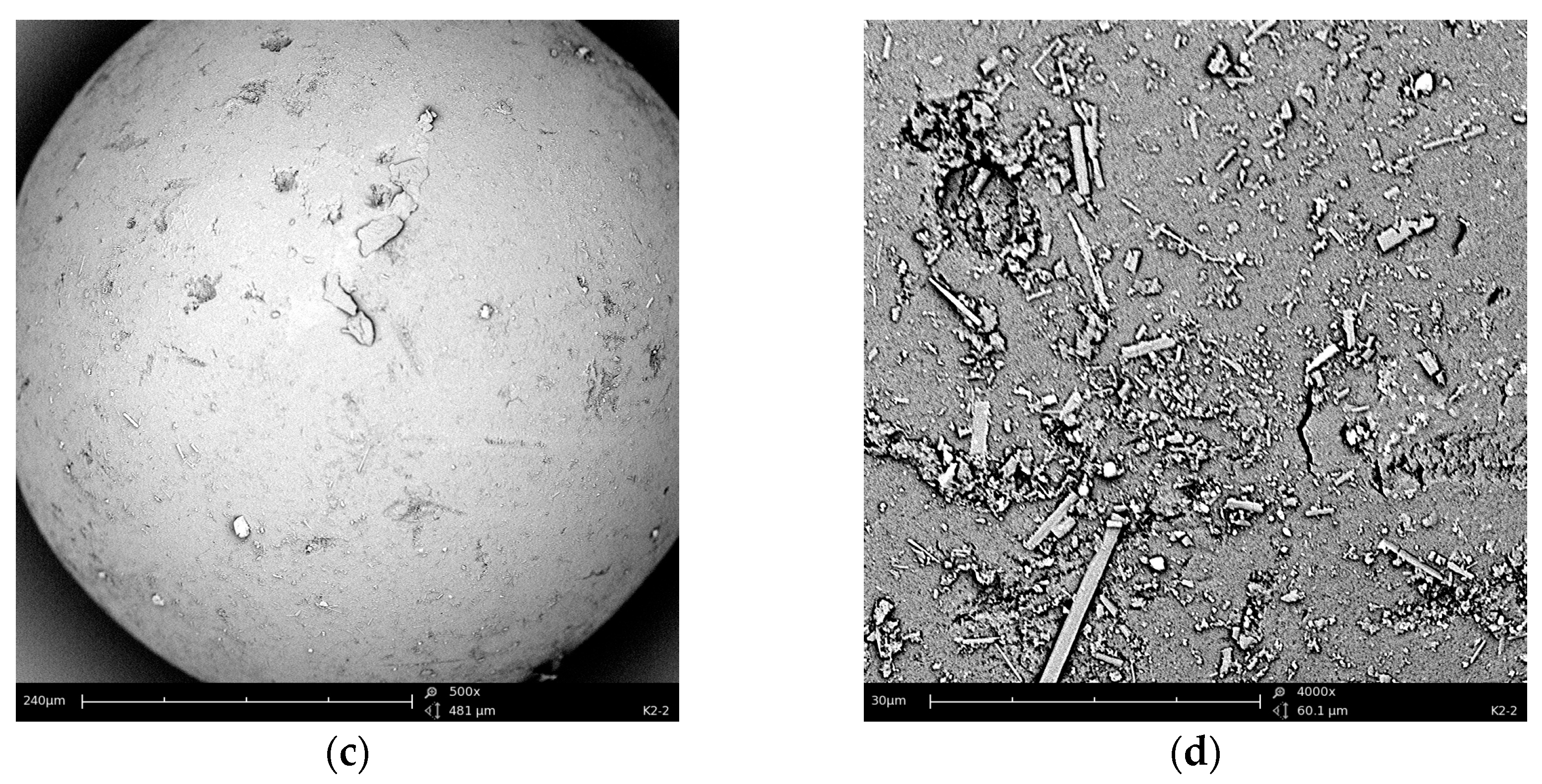

3.1. Analysis of Impregnated XAD-16

3.2. Sorption Studies

3.2.1. Influence of the Impregnated Sorbent Mass

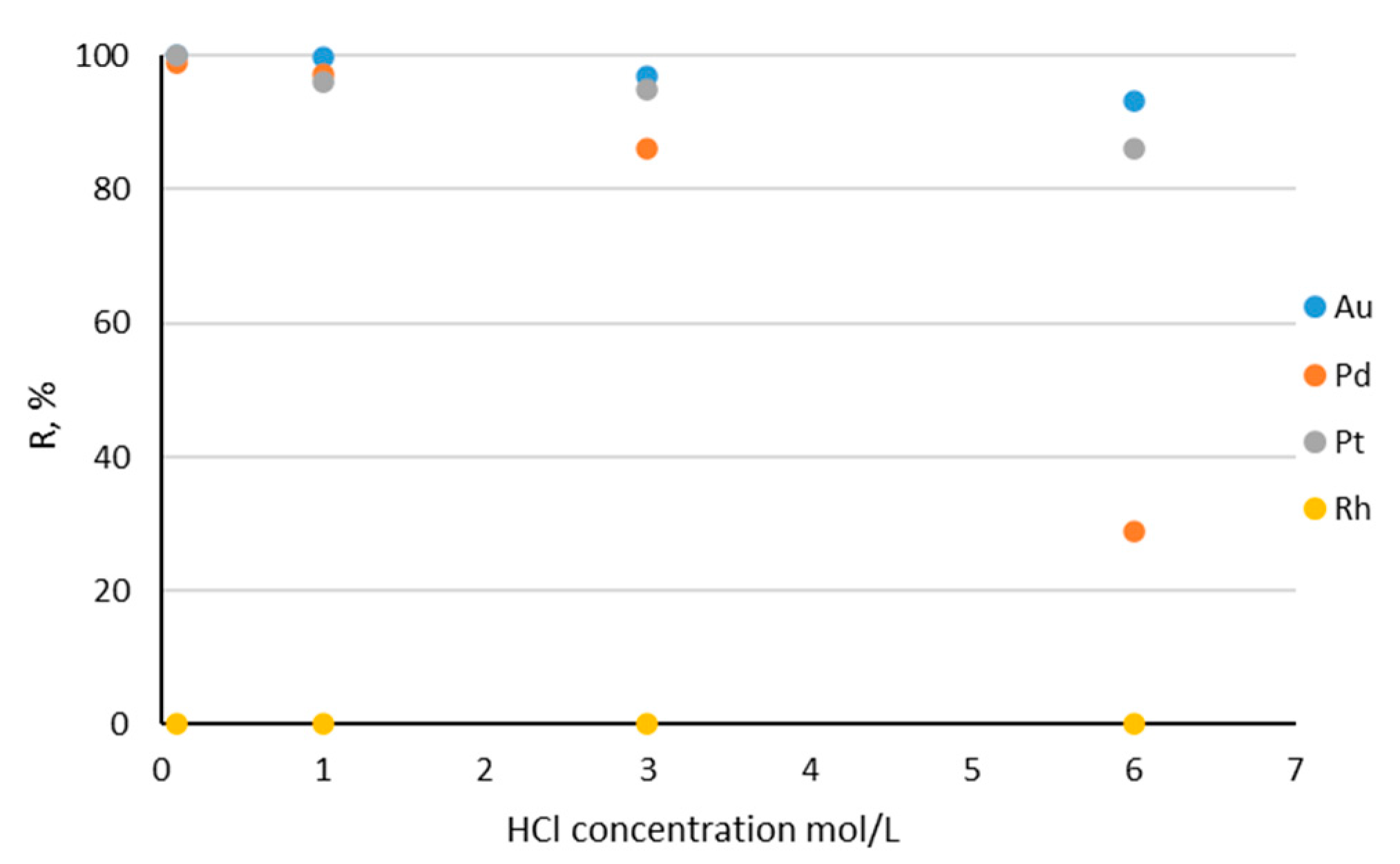

3.2.2. Influence of Hydrochloric Acid Concentration

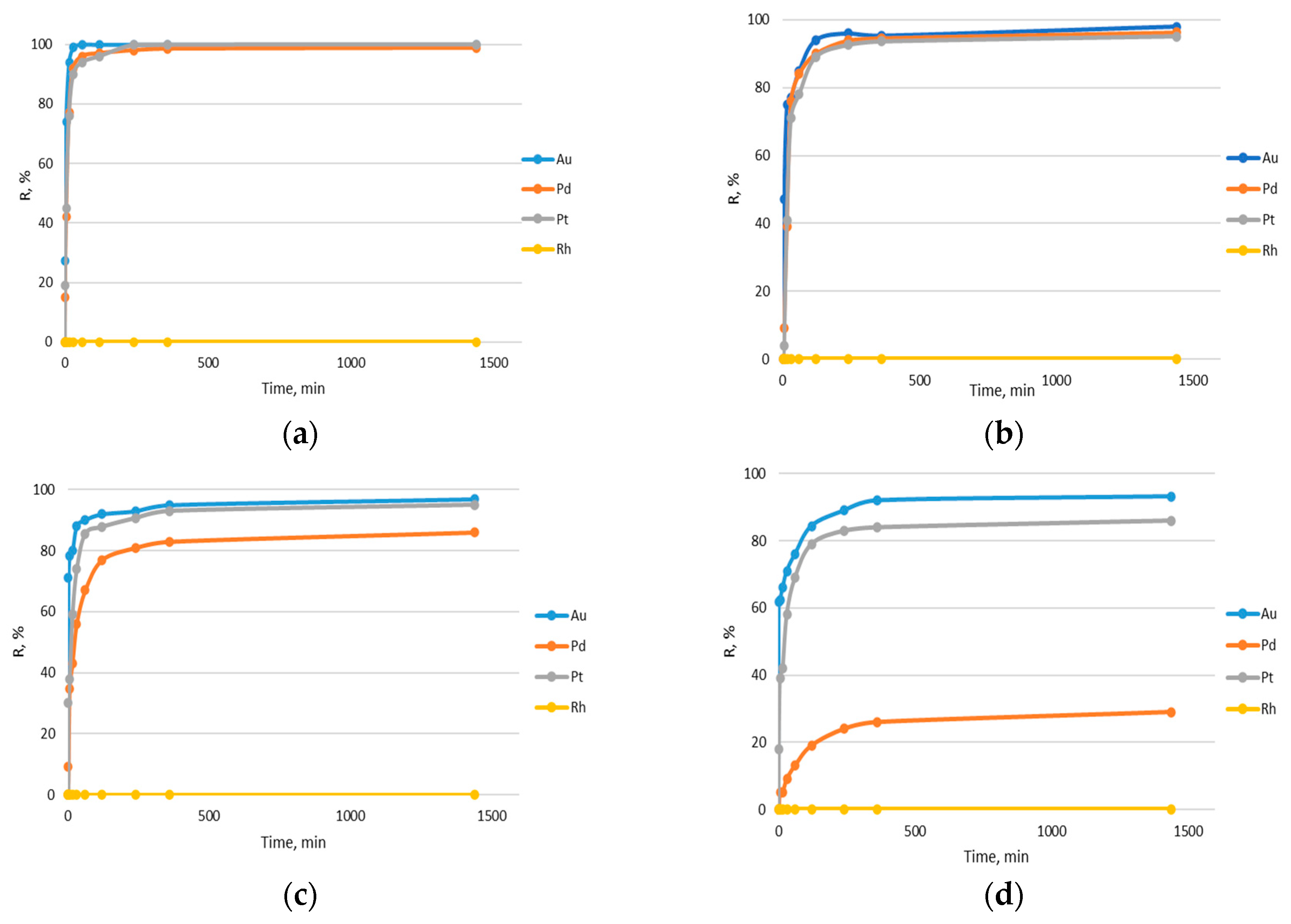

3.2.3. Influence of Contact Time

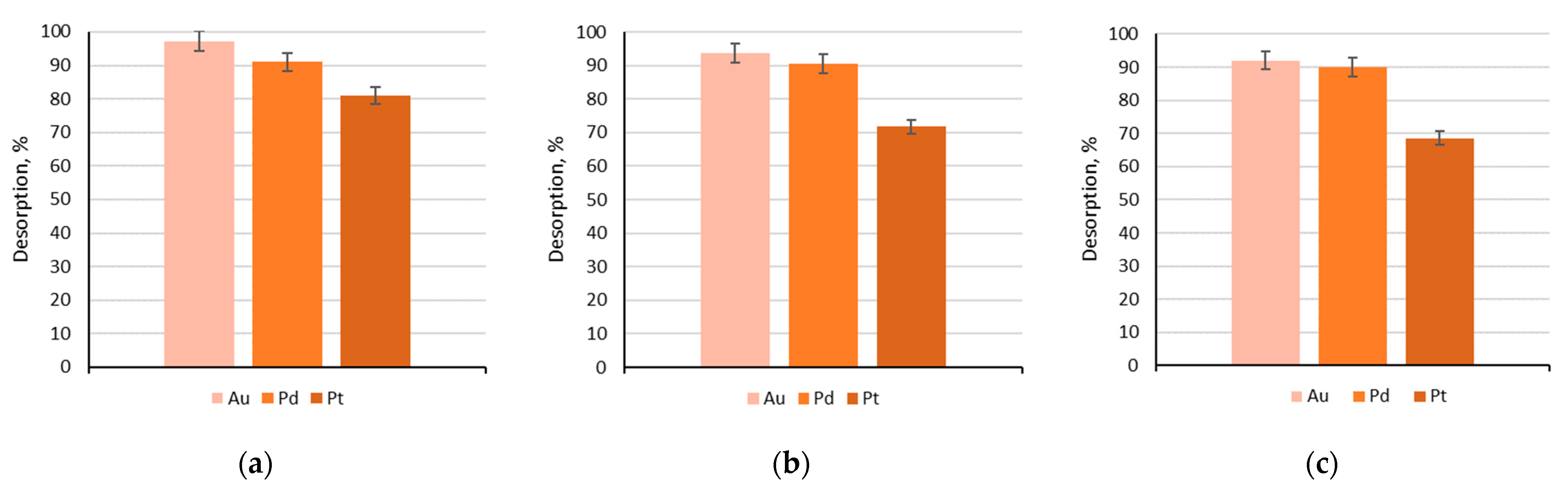

3.3. Desorption Studies

3.4. Kinetic, Thermodynamic and Isotherm Studies

3.4.1. Kinetics

3.4.2. Thermodynamic Studies

3.4.3. Isotherms

3.5. Noble Metal Recovery from the Spent RAM Module

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- World Gold Council. Gold Demand Trends Q2. 2023. Available online: https://www.gold.org/goldhub/research/gold-demand-trends/gold-demand-trends-q2-2023/technology (accessed on 24 January 2024).

- Kepp, K.P. Chemical Causes of Metal Nobleness. ChemPhysChem 2020, 21, 360–369. [Google Scholar] [CrossRef] [PubMed]

- Graedel, T.E.; Harper, E.M.; Nassar, N.T.; Nuss, P.; Reck, B.K.; Turner, B.L. Criticality of metals and metalloids. Proc. Natl. Acad. Sci. USA 2015, 112, 4257–4262. [Google Scholar] [CrossRef] [PubMed]

- Natarajan, G.; Ting, Y.P. Pretreatment of e-waste and mutation of alkali-tolerant cyanogenic bacteria promote gold biorecovery. Bioresour. Technol. 2014, 152, 80–85. [Google Scholar] [CrossRef] [PubMed]

- Willner, J.; Fornalczyk, A. Złom elektroniczny jako źródło metali szlachetnych. Przemysł Chem. 2014, 91, 517–522. [Google Scholar]

- Parajuly, K.; Kuehr, R.; Fitzpatrick, C.; Zeng, X. Future e-Waste Scenarios; StEP Initiative: Bonn, Germany, 2019. [Google Scholar]

- EUR-Lex. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:02012L0019-20180704 (accessed on 24 January 2024).

- Hák, T.; Janoušková, S.; Moldan, B. Sustainable Development Goals: A need for relevant indicators. Ecol. Indic. 2016, 60, 565–573. [Google Scholar] [CrossRef]

- Eurostat. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Waste_statistics_-_electrical_and_electronic_equipment#Electrical_and_electronic_equipment_.28EEE.29_put_on_the_market_and_WEEE_processed_in_the_EU (accessed on 24 January 2024).

- Cieszynska, A. Waste electronic and electrical equipment (WEEE)-scraps or valuable source of precious metals. Towarozn. Probl. Jakości 2016, 4, 43–54. [Google Scholar]

- Ebin, B.; Isik, M.I. Pyrometallurgical Processes for the Recovery of Metals from WEEE. In WEEE Recycling; Chagnes, A., Cote, G., Ekberg, C., Nilsson, M., Retegan, T., Eds.; Elsevier: Amsterdam, The Netherlands, 2016; Chapter 5; pp. 107–137. ISBN 978-0-12-803363-0. [Google Scholar]

- Willner, J.; Fornalczyk, A.; Cebulski, J.; Janiszewski, K. Preliminary studies on simultaneous recovery of precious metals from different waste materials by pyrometallurgical method. Arch. Metall. Mater. 2014, 59, 801–804. [Google Scholar] [CrossRef]

- Petter, P.M.H.; Veit, H.M.; Bernardes, A.M. Evaluation of gold and silver leaching from printed circuit board of cellphones. Waste Manag. 2014, 34, 475–482. [Google Scholar] [CrossRef]

- Jing-ying, L.; Xiu-li, X.; Wen-quan, L. Thiourea leaching gold and silver from the printed circuit boards of waste mobile phones. Waste Manag. 2012, 32, 1209–1212. [Google Scholar] [CrossRef]

- Zulkernain, N.H.; Basant, N.; Ng, C.C.; Kriti; Salari, M.; Mallick, S. Recovery of precious metals from e-wastes through conventional and phytoremediation treatment methods: A review and prediction. J. Mater. Cycles Waste Manag. 2023, 25, 2726–2752. [Google Scholar] [CrossRef]

- Tatariants, M.; Yousef, S.; Denafas, G.; Tichonovas, M.; Bendikiene, R. Recovery of gold, other metallic and non-metallic components of full-size waste random access memory. J. Clean. Prod. 2018, 172, 2811–2823. [Google Scholar] [CrossRef]

- Rao, M.D.; Singh, K.K.; Morrison, C.A.; Love, J.B. Recycling copper and gold from e-waste by a two-stage leaching and solvent extraction process. Sep. Purif. Technol. 2021, 263, 118400. [Google Scholar] [CrossRef]

- Barnwal, A.; Dhawan, N. Recycling of discarded mobile printed circuit boards for extraction of gold and copper. Sustain. Mater. Technol. 2020, 25, e00164. [Google Scholar] [CrossRef]

- Gámez, S.; Garcés, K.; de la Torre, E.; Guevara, A. Precious metals recovery from waste printed circuit boards using thiosulfate leaching and ion exchange resin. Hydrometallurgy 2019, 186, 1–11. [Google Scholar] [CrossRef]

- Kabay, N.; Cortina, J.L.; Trochimczuk, A.; Streat, M. Solvent-impregnated resins (SIRs)—Methods of preparation and their applications. React. Funct. Polym. 2010, 70, 484–496. [Google Scholar] [CrossRef]

- Ashiq, A.; Kulkarni, J.; Vithanage, M. Hydrometallurgical Recovery of Metals From E-waste. In Electronic Waste Management and Treatment Technology; Prasad, M.N.V., Vithanage, M., Eds.; Butterworth-Heinemann: Oxford, UK, 2019; Chapter 10; pp. 225–246. ISBN 978-0-12-816190-6. [Google Scholar]

- Hubicki, Z.; Zinkowska, K.; Wójcik, G. A New Impregnated Adsorbent for Noble Metal Ion Sorption. Molecules 2023, 28, 6040. [Google Scholar] [CrossRef] [PubMed]

- Zinkowska, K.; Hubicki, Z.; Wójcik, G. Kinetic and Thermodynamic Studies of Precious Metals Sorption on Impregnated Lewatit VP OC 1026 from Chloride Solutions. ChemPhysChem 2023, 25, e202300817. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, A.; Siddique, J.A.; Laskar, M.A.; Kumar, R.; Mohd-Setapar, S.H.; Khatoon, A.; Shiekh, R.A. New generation Amberlite XAD resin for the removal of metal ions: A review. J. Environ. Sci. 2015, 31, 104–123. [Google Scholar] [CrossRef]

- Chung, N.H.; Tabata, M. Selective extraction of gold(III) in the presence of Pd(II) and Pt(IV) by salting-out of the mixture of 2-propanol and water. Talanta 2002, 58, 927–933. [Google Scholar] [CrossRef] [PubMed]

- Gamal, R.; Rizk, S.E.; El-Hefny, N.E. Sorption of Palladium(II) from Aqueous Solution Using Diphenylthiocarbazone Immobilized onto Kieselguhr. J. Inorg. Organomet. Polym. Mater. 2022, 32, 2455–2472. [Google Scholar] [CrossRef]

- Mihăilescu, M.; Negrea, A.; Ciopec, M.; Davidescu, C.M.; Negrea, P.; Duţeanu, N.; Rusu, G. Gold (III) adsorption from dilute waste solutions onto Amberlite XAD7 resin modified with L-glutamic acid. Sci. Rep. 2019, 9, 8757. [Google Scholar] [CrossRef] [PubMed]

- Tran, H.N.; You, S.-J.; Chao, H.-P. Thermodynamic parameters of cadmium adsorption onto orange peel calculated from various methods: A comparison study. J. Environ. Chem. Eng. 2016, 4, 2671–2682. [Google Scholar] [CrossRef]

- Milonjić, S.K. A consideration of the correct calculation of thermodynamic parameters of adsorption. J. Serbian Chem. Soc. 2007, 72, 1363–1367. [Google Scholar] [CrossRef]

| HCl Concentration | Noble Metal Ion | qm (mg/g) | Pseudo-First-Order | Pseudo-Second-Order | ||||

| k1 (L/min) | qe (mg/g) | R2 | k2 (L/min) | qe (mg/g) | R2 | |||

| 0.1 M | Au(III) | 2.50 | 0.00949 | 0.1882 | 0.4450 | 0.32016 | 2.4966 | 0.9999 |

| Pt(IV) | 2.50 | 0.01833 | 0.8504 | 0.9297 | 0.07888 | 2.5346 | 0.9999 | |

| Pd(II) | 2.47 | 0.01371 | 0.5722 | 0.7856 | 0.56958 | 2.4965 | 0.9998 | |

| 1 M | Au(III) | 3.74 | 0.00766 | 0.5280 | 0.7400 | 0.14691 | 3.7005 | 0.9998 |

| Pt(IV) | 2.65 | 0.01112 | 0.8091 | 0.8179 | 0.06773 | 2.6644 | 0.9999 | |

| Pd(II) | 2.48 | 0.00185 | 2.1225 | 0.4303 | 0.06829 | 2.4934 | 0.9998 | |

| 3 M | Au(III) | 2.42 | 0.00620 | 0.3832 | 0.8409 | 0.18192 | 2.3738 | 0.9998 |

| Pt(IV) | 2.38 | 0.00886 | 0.8902 | 0.8445 | 0.06112 | 2.3554 | 0.9996 | |

| Pd(II) | 2.15 | 0.00456 | 1.3444 | 0. 7828 | 0.03739 | 2.1372 | 0.9993 | |

| 6 M | Au(III) | 2.33 | 0.00887 | 0.7576 | 0.9923 | 0.06321 | 2.3143 | 0.9987 |

| Pt(IV) | 2.40 | 0.00969 | 1.0379 | 0.9102 | 0.04672 | 2.4032 | 0.9991 | |

| Pd(II) | 0.78 | 0.00089 | 2.1443 | 0.8658 | 0.02970 | 0.7692 | 0.9864 | |

| HCl Concentration | Noble Metal Ion | Dumwald–Wagner | Intra-Particle Diffusion | |||||

| K (min−1) | R2 | K (m/g × min0.5) | C (mg/g) | R2 | ||||

| 0.1 M | Au(III) | 0.00897 | 0.4620 | 0.0245 | 2.4998 | 0.2214 | ||

| Pt(IV) | 0.01749 | 0.9471 | 0.0379 | 2.4998 | 0.3684 | |||

| Pd(II) | 0.01285 | 0.8212 | 0.0377 | 2.4700 | 0.3316 | |||

| 1 M | Au(III) | 0.00515 | 0.4845 | 0.0242 | 3.7425 | 0.4367 | ||

| Pt(IV) | 0.01020 | 0.8581 | 0.0416 | 2.6500 | 0.3775 | |||

| Pd(II) | 0.00116 | 0.5004 | 0.0401 | 2.4825 | 0.3613 | |||

| 3 M | Au(III) | 0.00415 | 0.6296 | 0.0145 | 2.4225 | 0.5973 | ||

| Pt(IV) | 0.00801 | 0.8787 | 0.0377 | 2.3750 | 0.5056 | |||

| Pd(II) | 0.00355 | 0.8451 | 0.0425 | 2.1500 | 0.5645 | |||

| 6 M | Au(III) | 0.00519 | 0.9232 | 0.0233 | 2.3300 | 0.7254 | ||

| Pt(IV) | 0.00881 | 0.9323 | 0.0395 | 2.4000 | 0.5683 | |||

| Pd(II) | 0.00027 | 0.9538 | 0.0201 | 0.7750 | 0.7708 | |||

| Parameter | Au(III) | Pt(IV) | Pd(II) | |

|---|---|---|---|---|

| ΔG° | T = 293 K | −9.15 | −4.29 | −6.92 |

| T = 303 K | −11.69 | −4.48 | −11.3 | |

| T = 333 K | −12.98 | −4.95 | −12.98 | |

| ΔS° | 192.85 | 32.28 | 305.89 | |

| ΔH° | 47.16 | 5.21 | 82.34 | |

| Isotherm Model | Parameter | Au(III) | Pt(IV) | Pd(II) |

|---|---|---|---|---|

| Freundlich | KF | 25.65 | 18.05 | 11.75 |

| n | 4.65 | 3.42 | 3.59 | |

| R2 | 0.8581 | 0.8809 | 0.6443 | |

| Langmuir | Q0 | 99.12 | 46.69 | 46.26 |

| KL | 0.1639 | 0.064 | 0.3911 | |

| RL | 0.1162 | 0.2136 | 0.0584 | |

| R2 | 0.9955 | 0.9834 | 0.9997 | |

| Temkin | KT | 3.27 | 6.86 | 162.03 |

| bT | 1.53 | 1.83 | 12.43 | |

| R2 | 0.8161 | 0.4296 | 0.8231 |

| Metal Ions | Fe3+ | Ni2+ | Cu2+ | Zn2+ | Pd2+ | Au3+ |

|---|---|---|---|---|---|---|

| Concentration (mg/L) | 4.54 | 490 | 7018 | 1.12 | 1.76 | 38.10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zinkowska, K.; Hubicki, Z.; Wójcik, G. Impregnated Polymeric Sorbent for the Removal of Noble Metal Ions from Model Chloride Solutions and the RAM Module. Materials 2024, 17, 1234. https://doi.org/10.3390/ma17061234

Zinkowska K, Hubicki Z, Wójcik G. Impregnated Polymeric Sorbent for the Removal of Noble Metal Ions from Model Chloride Solutions and the RAM Module. Materials. 2024; 17(6):1234. https://doi.org/10.3390/ma17061234

Chicago/Turabian StyleZinkowska, Karolina, Zbigniew Hubicki, and Grzegorz Wójcik. 2024. "Impregnated Polymeric Sorbent for the Removal of Noble Metal Ions from Model Chloride Solutions and the RAM Module" Materials 17, no. 6: 1234. https://doi.org/10.3390/ma17061234