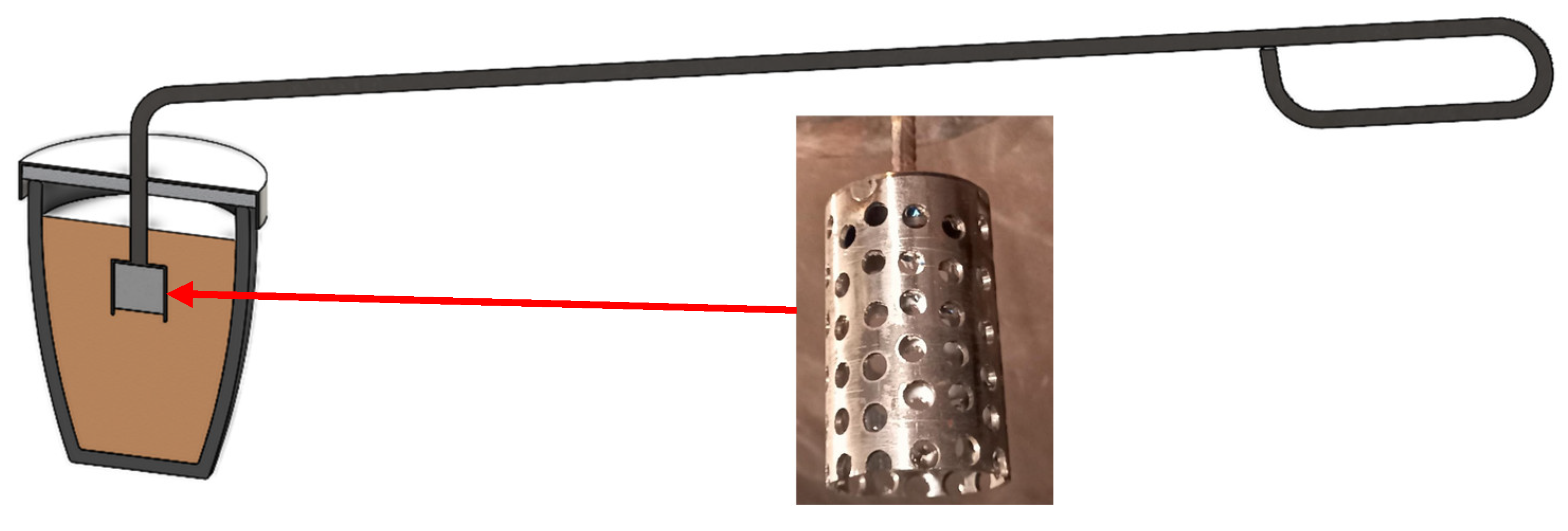

Figure 1.

Steel container (bell) containing nodulant and inoculant used in the process of nodularisation of molten metal.

Figure 1.

Steel container (bell) containing nodulant and inoculant used in the process of nodularisation of molten metal.

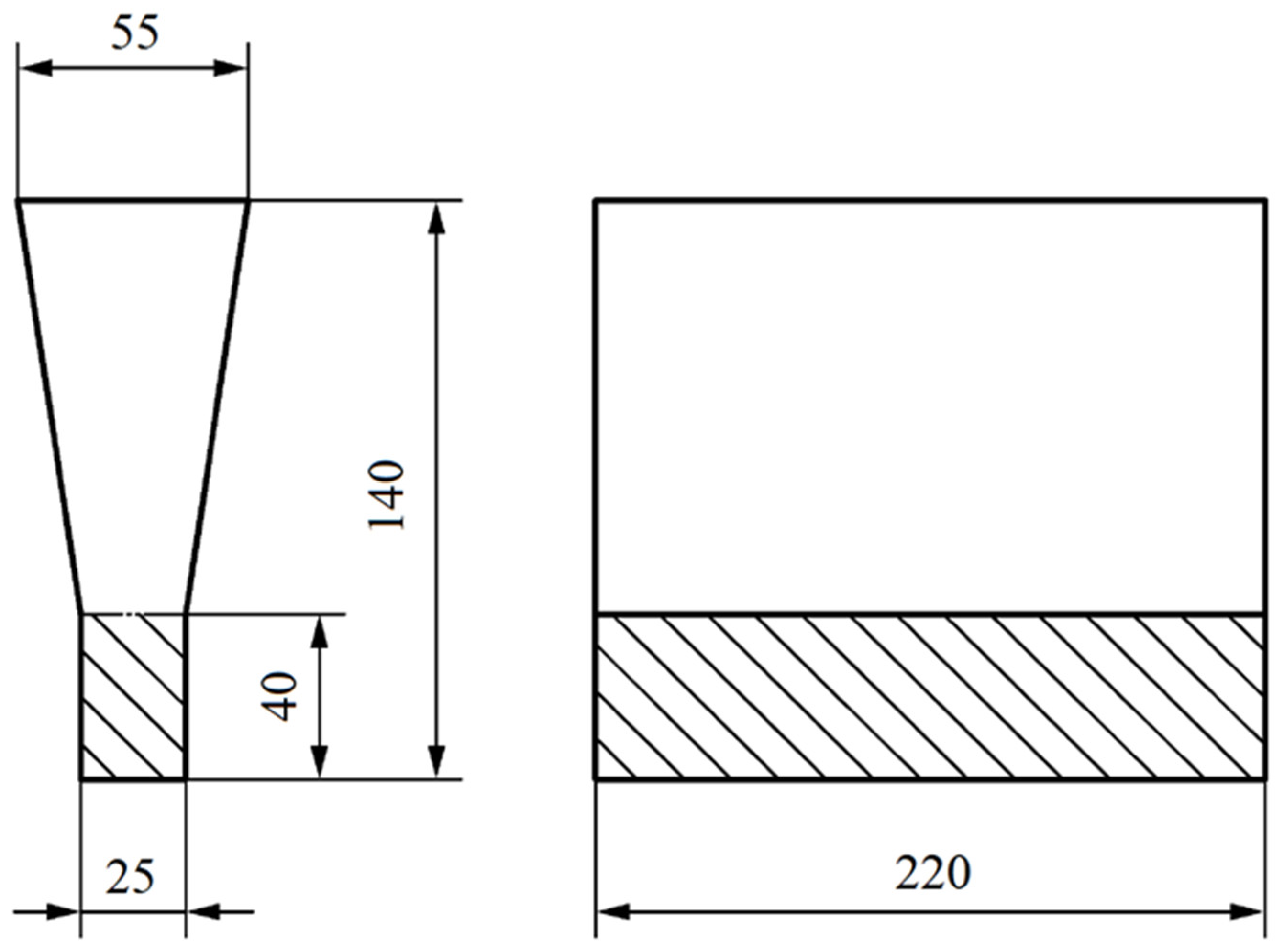

Figure 2.

Type 2 Y ingot with marked test sampling areas and dimensions in mm.

Figure 2.

Type 2 Y ingot with marked test sampling areas and dimensions in mm.

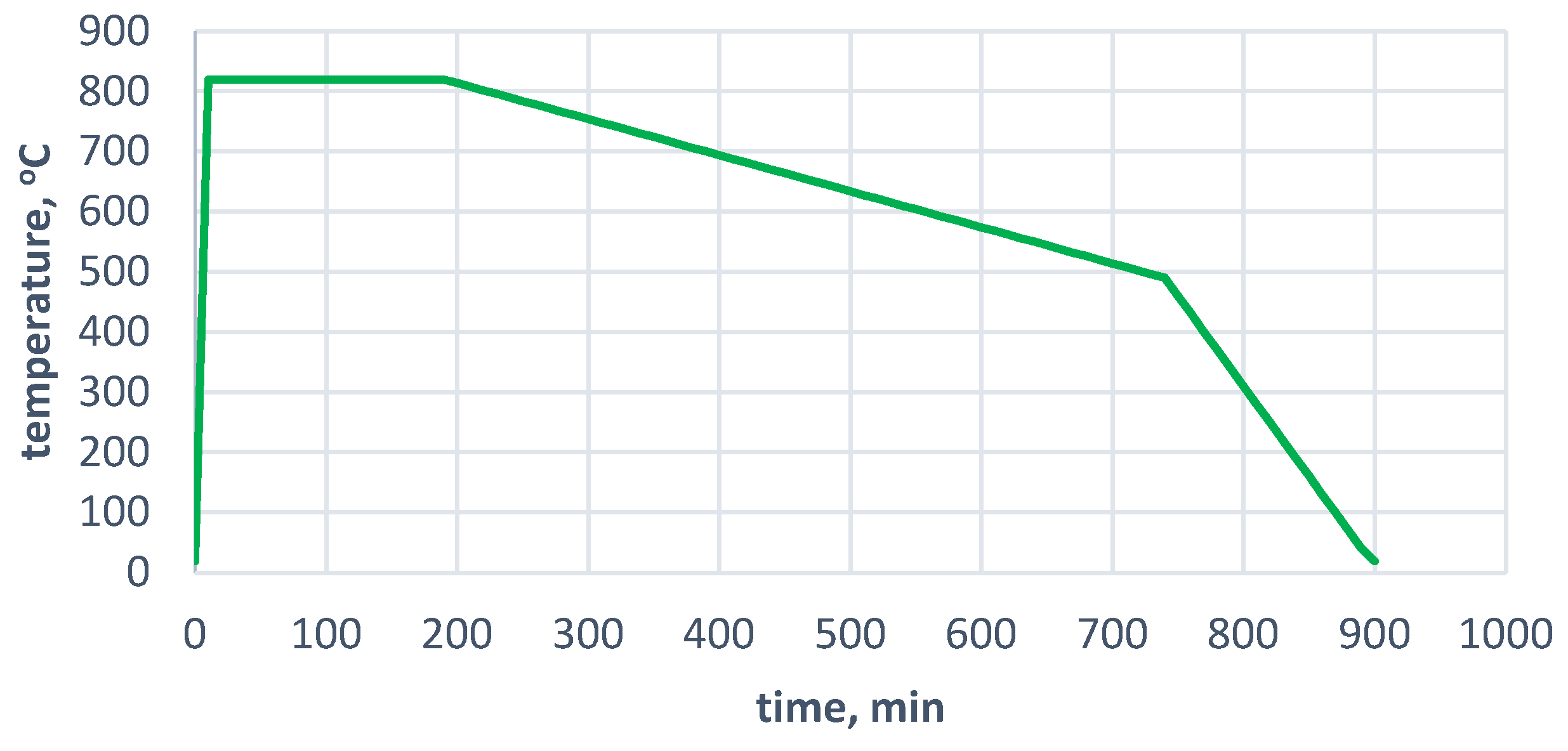

Figure 3.

Scheme of ferritising annealing procedure that was used for SiMo cast iron carried out at METALPOL Węgierska Górka foundry.

Figure 3.

Scheme of ferritising annealing procedure that was used for SiMo cast iron carried out at METALPOL Węgierska Górka foundry.

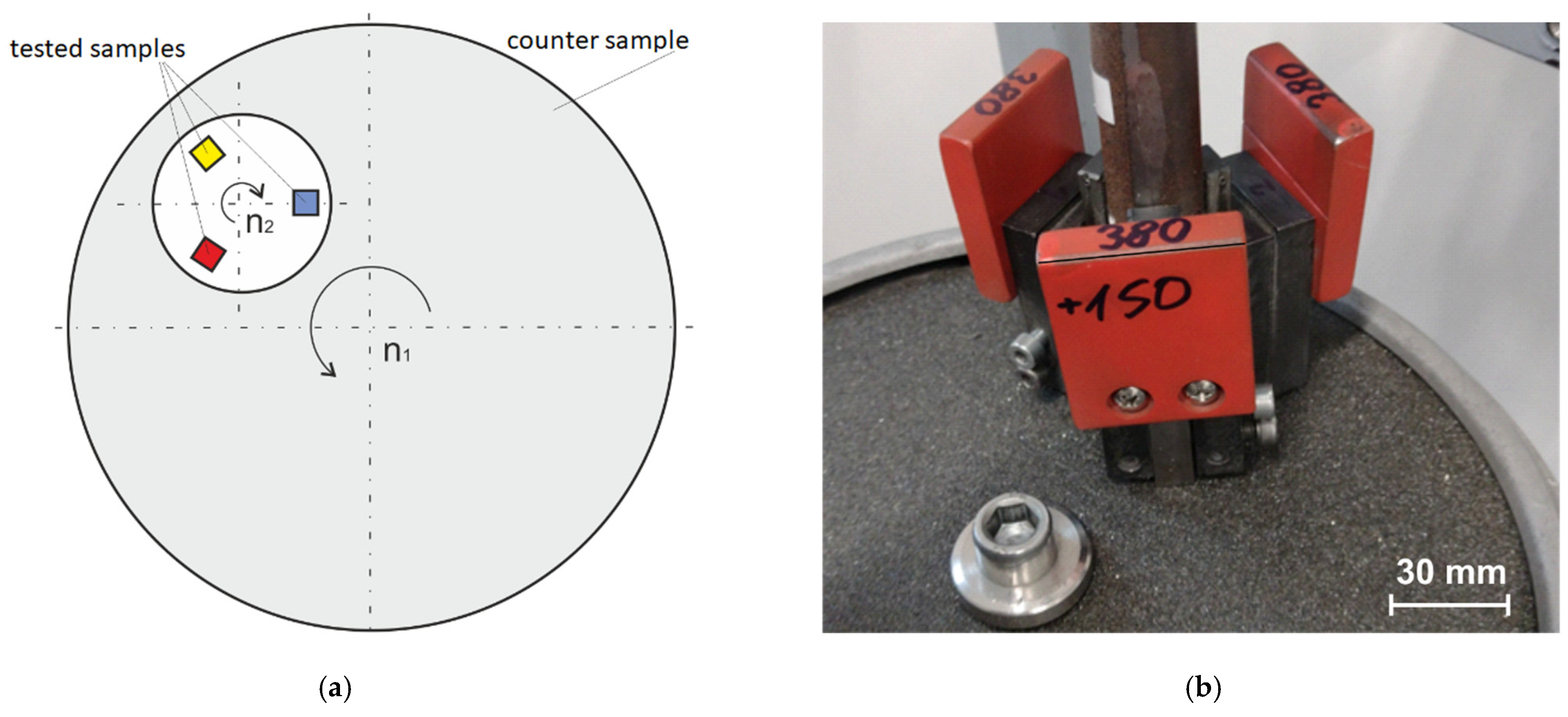

Figure 4.

3-POD tribotester: (a) device operation diagram; (b) view of working system (research samples–counter sample).

Figure 4.

3-POD tribotester: (a) device operation diagram; (b) view of working system (research samples–counter sample).

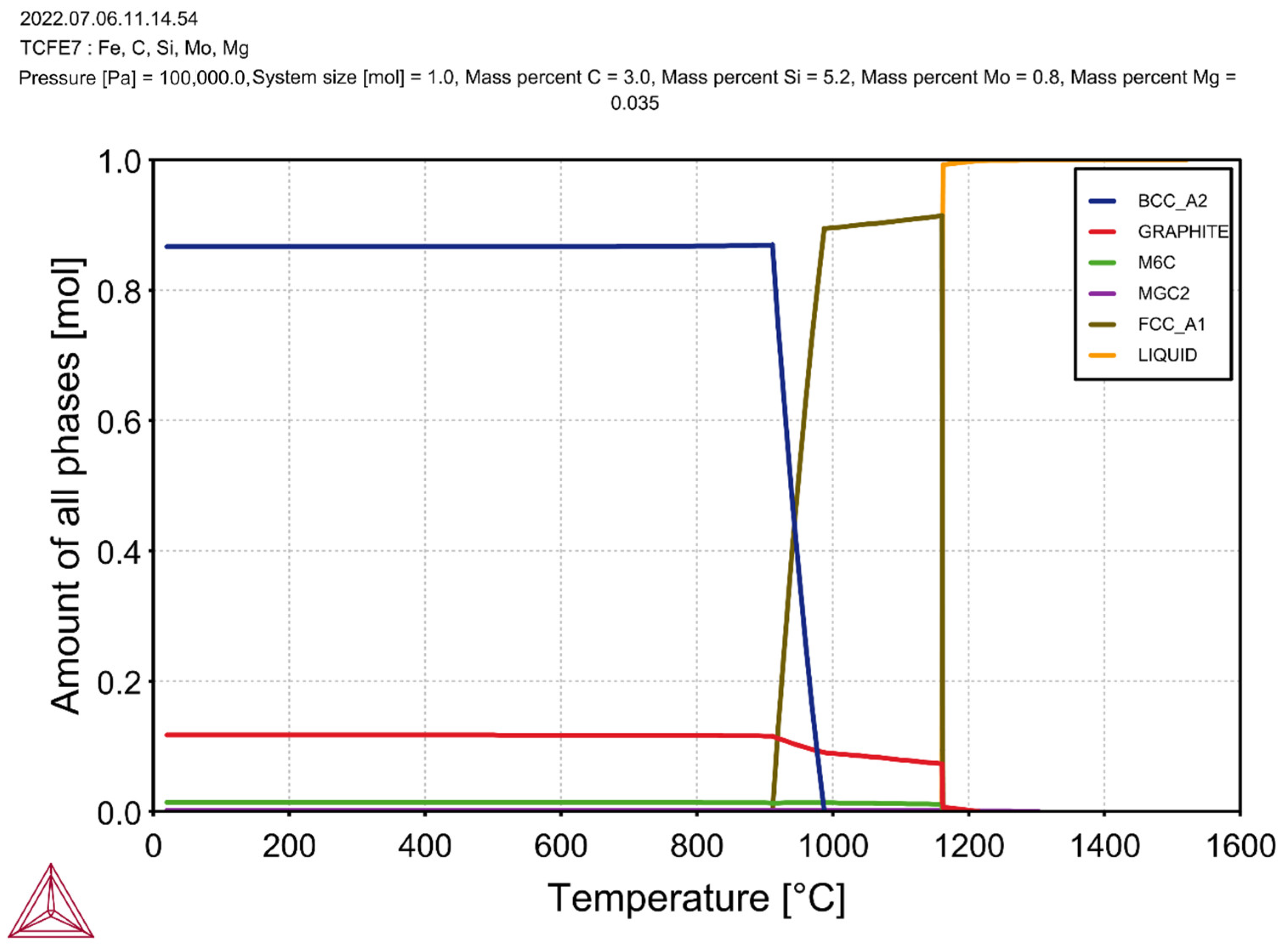

Figure 5.

Simulation results for cast iron without addition of Cr and Al.

Figure 5.

Simulation results for cast iron without addition of Cr and Al.

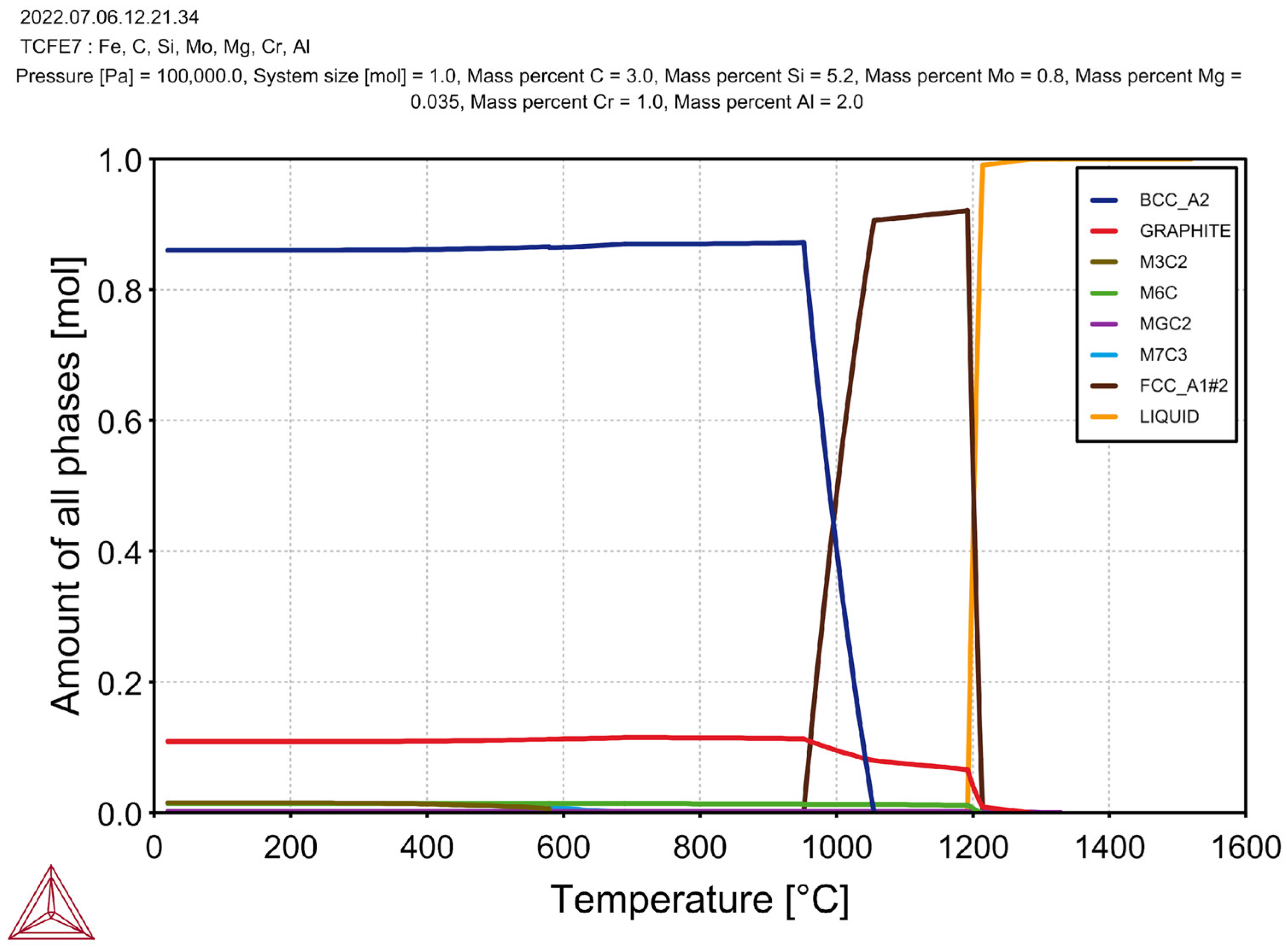

Figure 6.

Simulation results for cast iron with addition of 1% Cr and 2% Al.

Figure 6.

Simulation results for cast iron with addition of 1% Cr and 2% Al.

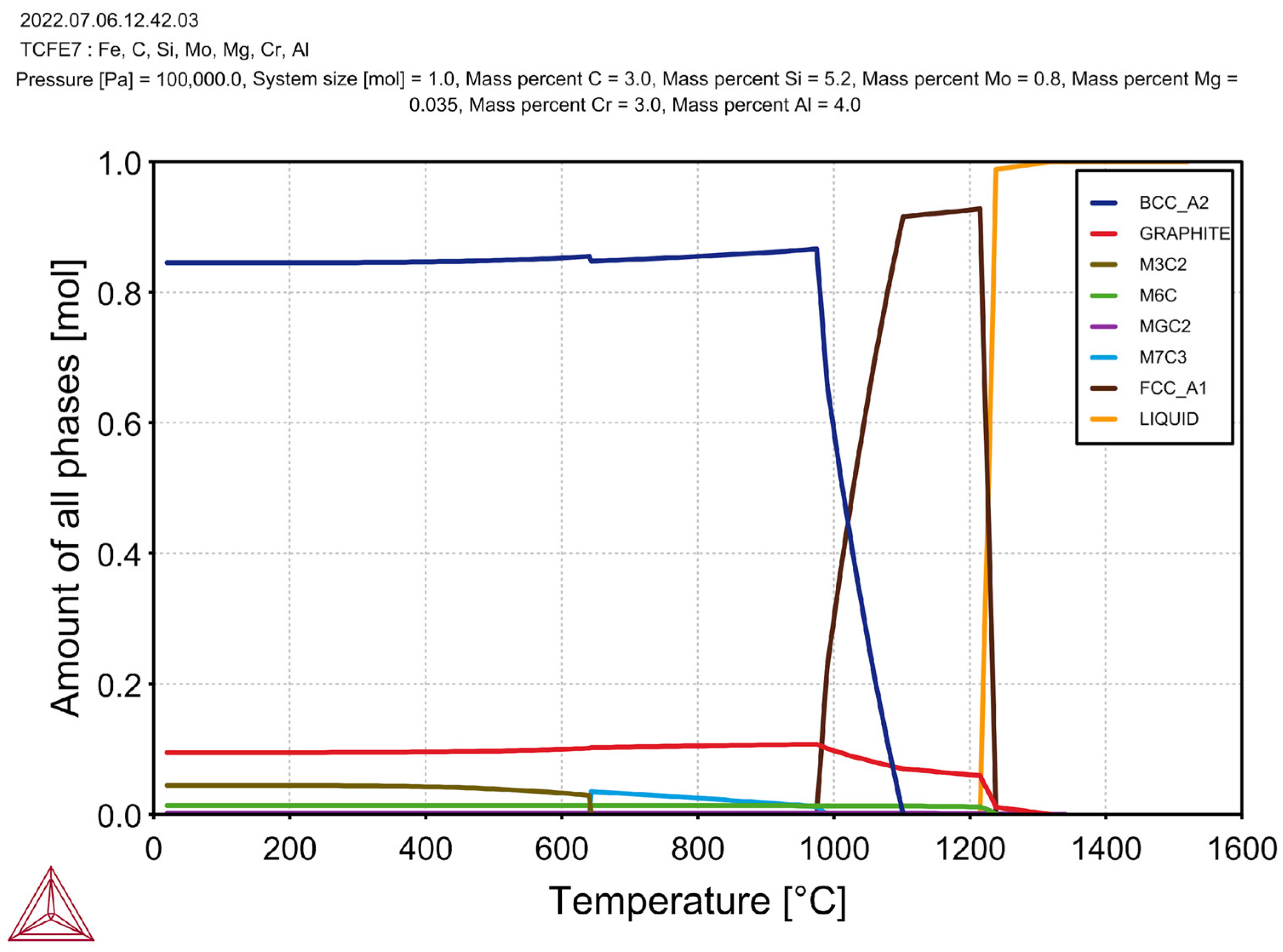

Figure 7.

Simulation results for cast iron with addition of 3% Cr and 4% Al.

Figure 7.

Simulation results for cast iron with addition of 3% Cr and 4% Al.

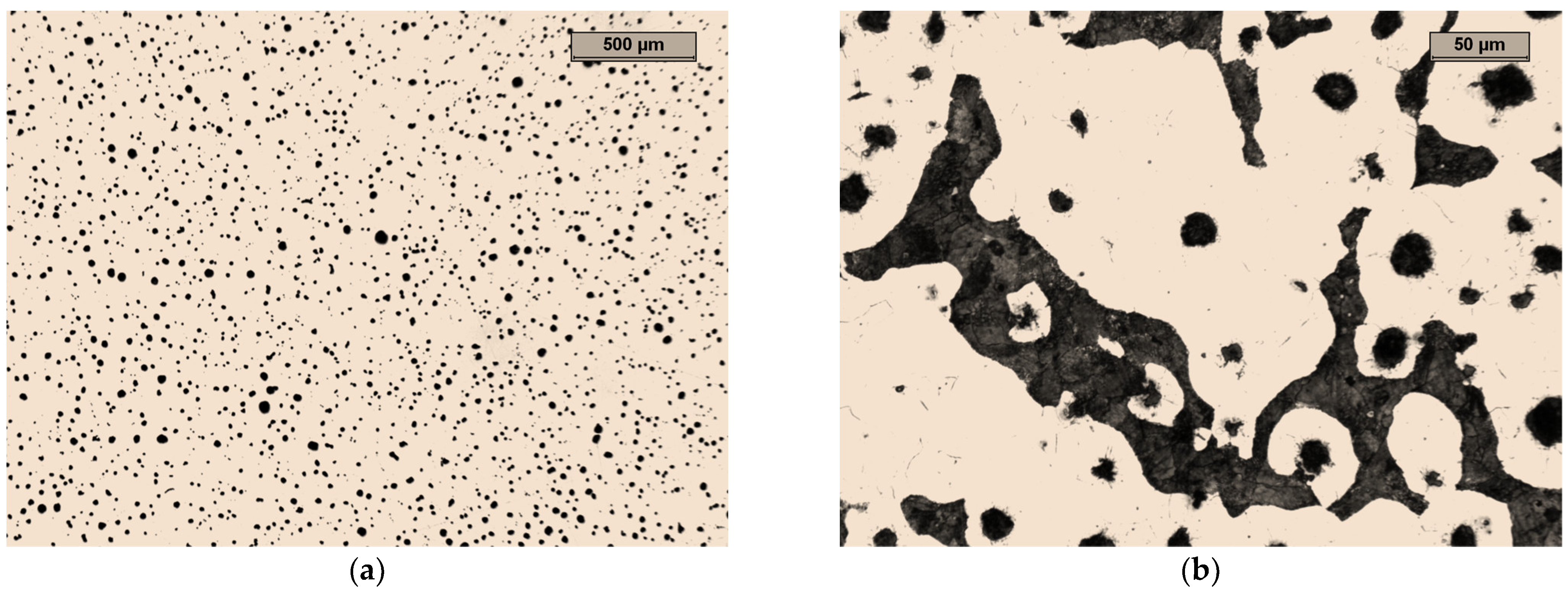

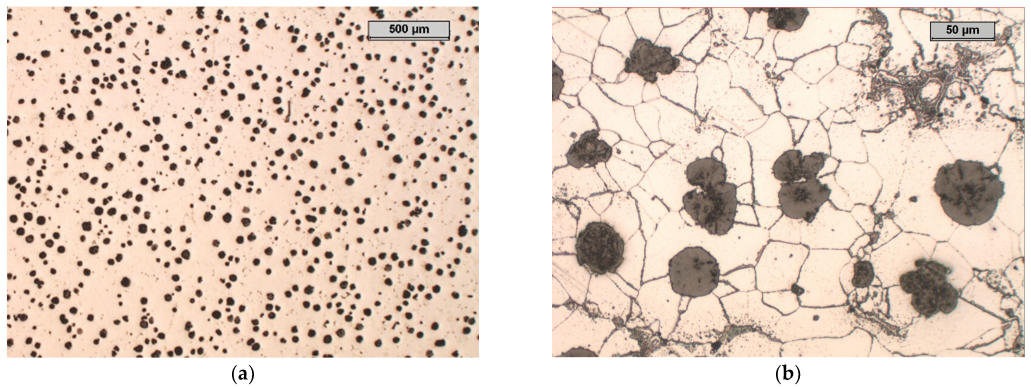

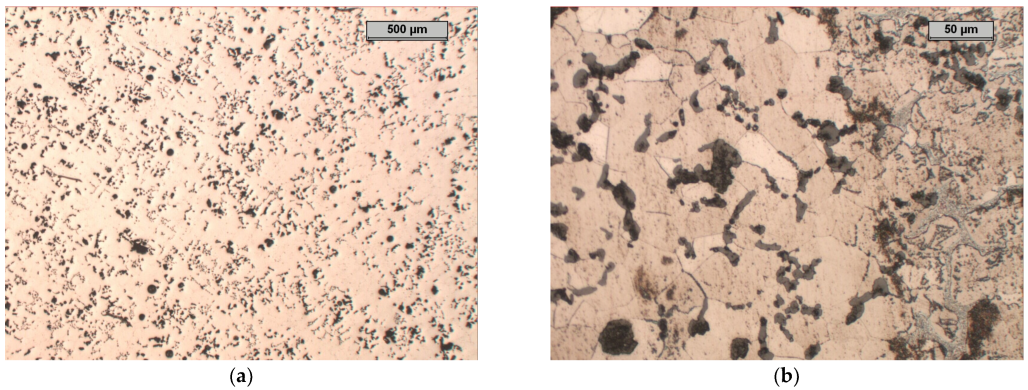

Figure 8.

Microstructure of sample 0: (a) optical microscope: unetched, magnification 25×; (b) etched with nital, phases: light—ferrite, dark brown—perlite, black with a round shape—graphite, magnification 200×.

Figure 8.

Microstructure of sample 0: (a) optical microscope: unetched, magnification 25×; (b) etched with nital, phases: light—ferrite, dark brown—perlite, black with a round shape—graphite, magnification 200×.

Figure 9.

Microstructure of sample A, optical microscope: unetched, magnification 25× (a); etched with nital, phases: light—ferrite, shades of grey—carbides, black—graphite, magnification 200× (b).

Figure 9.

Microstructure of sample A, optical microscope: unetched, magnification 25× (a); etched with nital, phases: light—ferrite, shades of grey—carbides, black—graphite, magnification 200× (b).

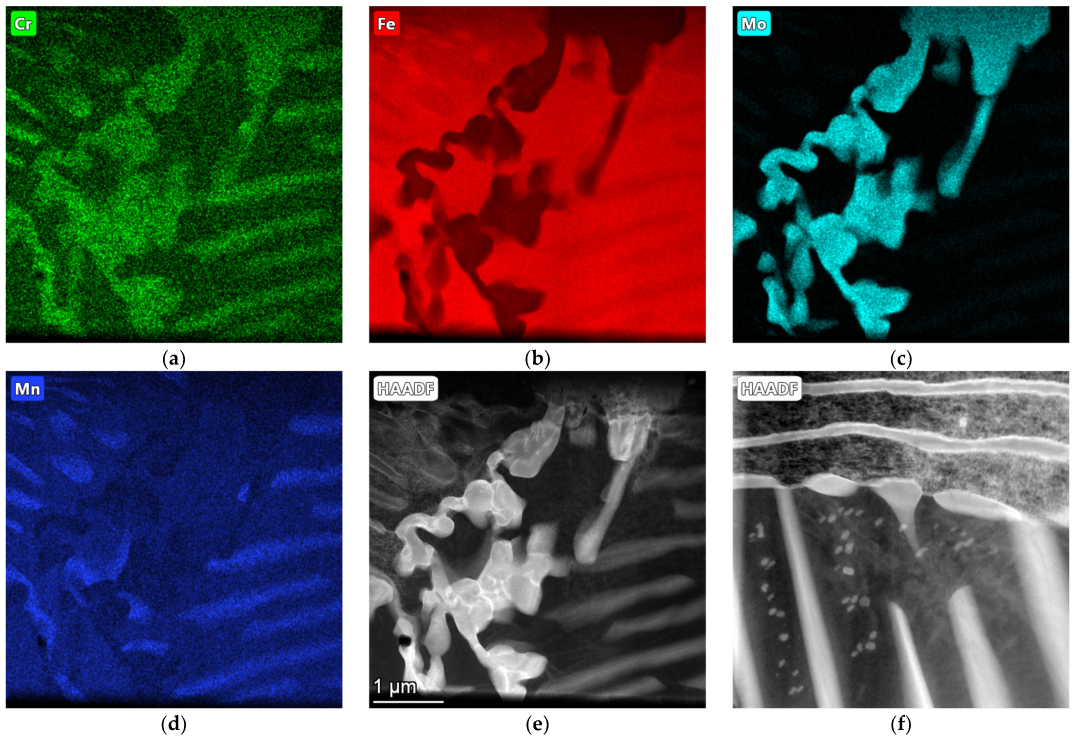

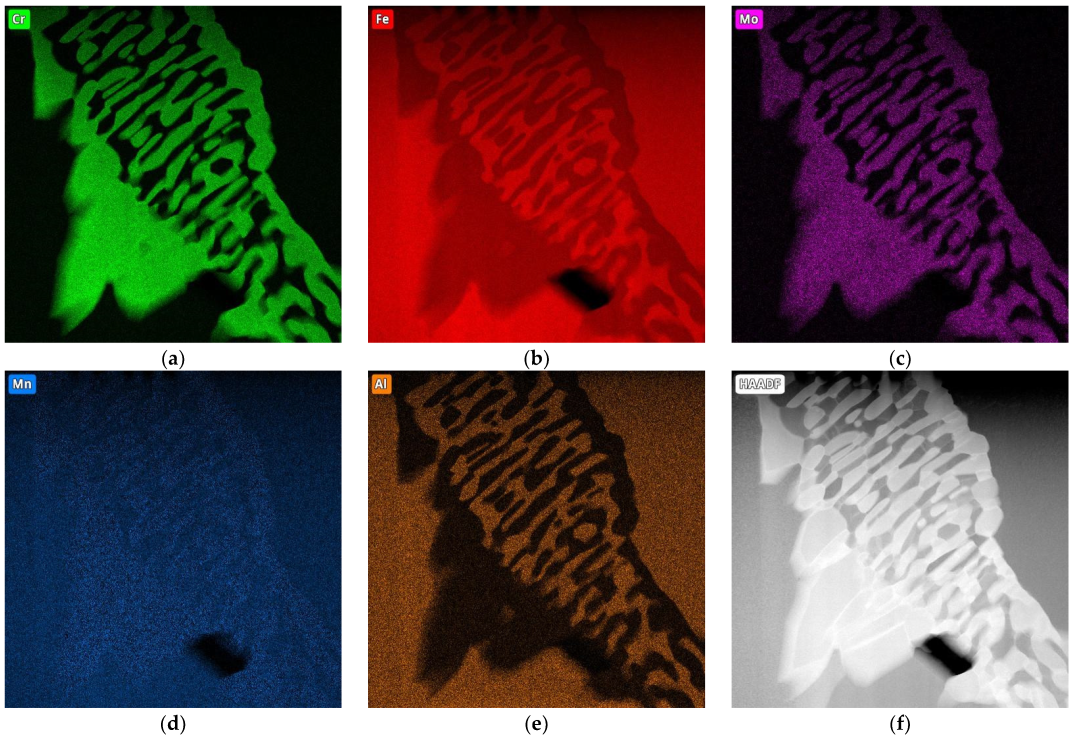

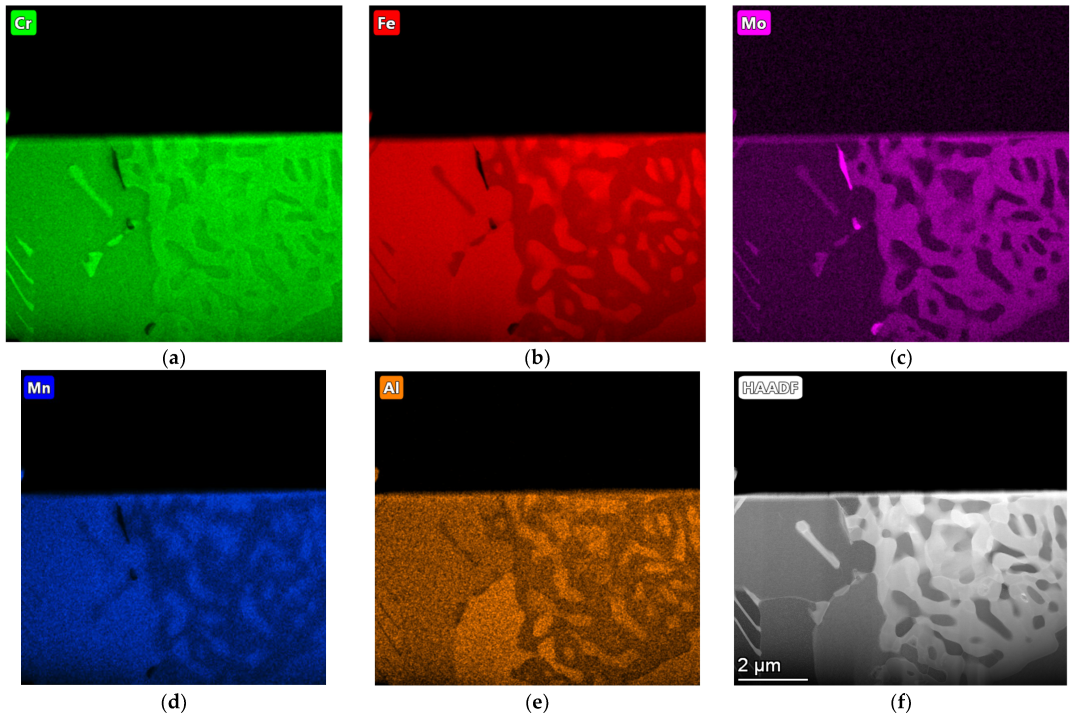

Figure 10.

EDS maps of sample A, indicating concentrations of (a) chromium, (b) iron, (c) molybdenum, and (d) manganese; (e,f) HAADF imaging (transmission microscope).

Figure 10.

EDS maps of sample A, indicating concentrations of (a) chromium, (b) iron, (c) molybdenum, and (d) manganese; (e,f) HAADF imaging (transmission microscope).

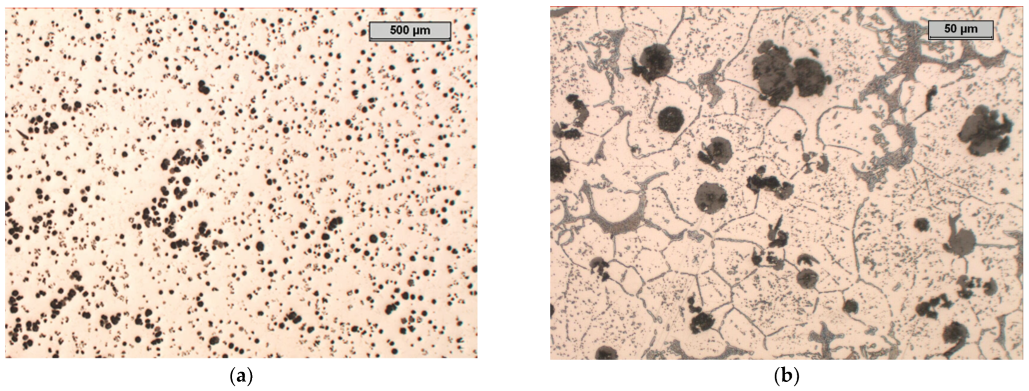

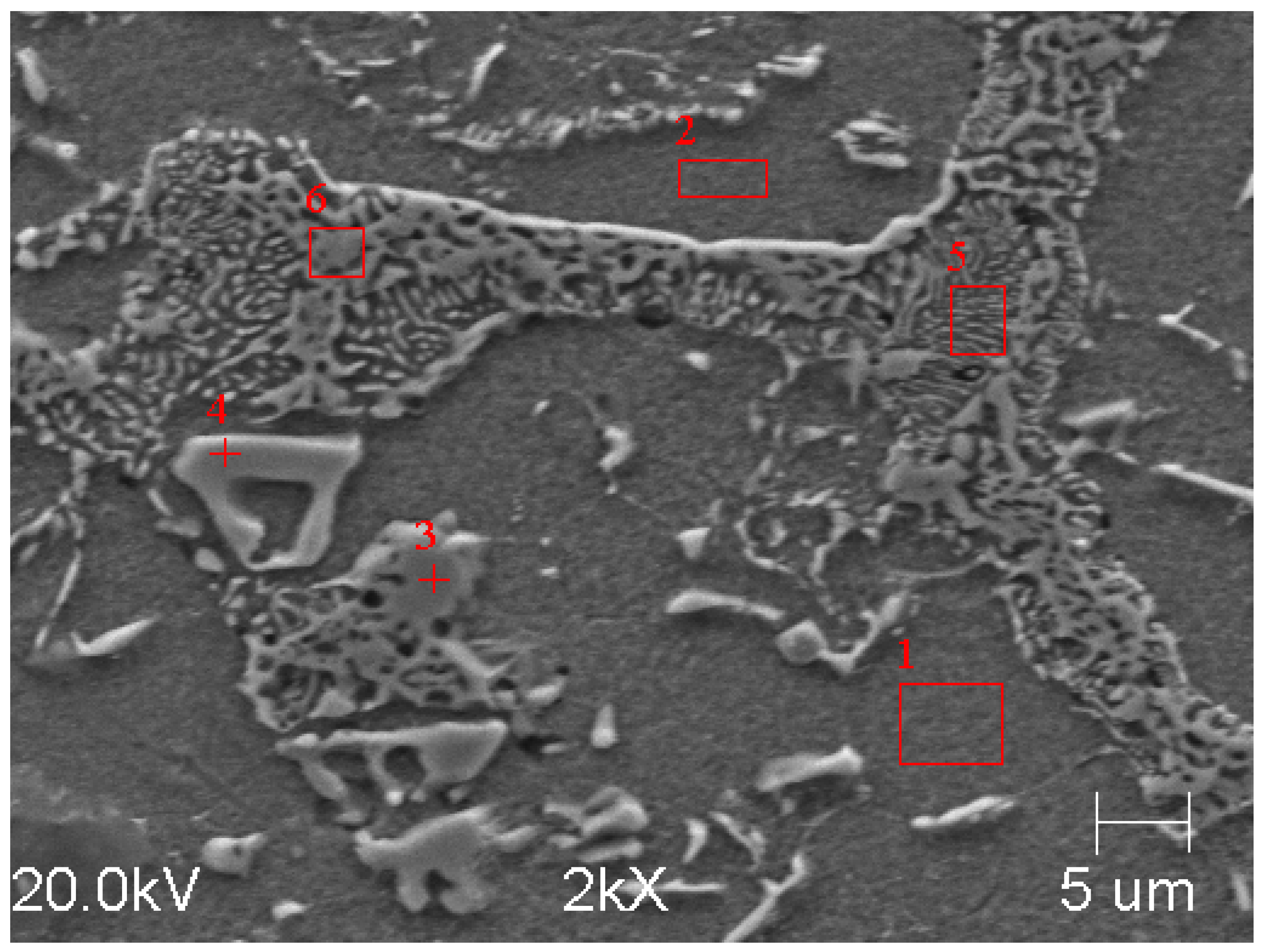

Figure 11.

Microstructure of sample B, optical microscope: (a) unetched, magnification 25×; (b) etched with nital, phases: light—ferrite, shades of grey—carbides, black—graphite, magnification 200× (b).

Figure 11.

Microstructure of sample B, optical microscope: (a) unetched, magnification 25×; (b) etched with nital, phases: light—ferrite, shades of grey—carbides, black—graphite, magnification 200× (b).

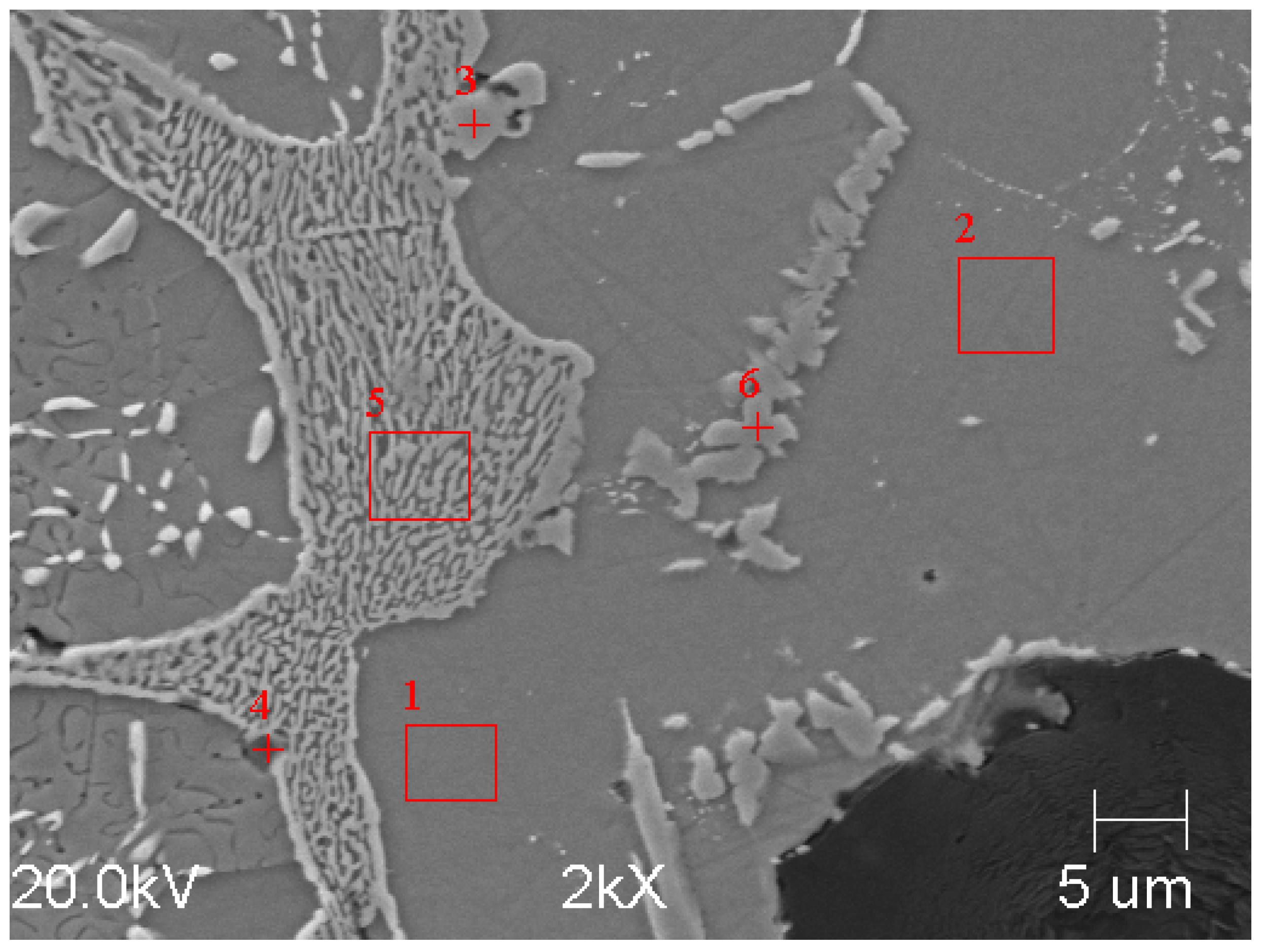

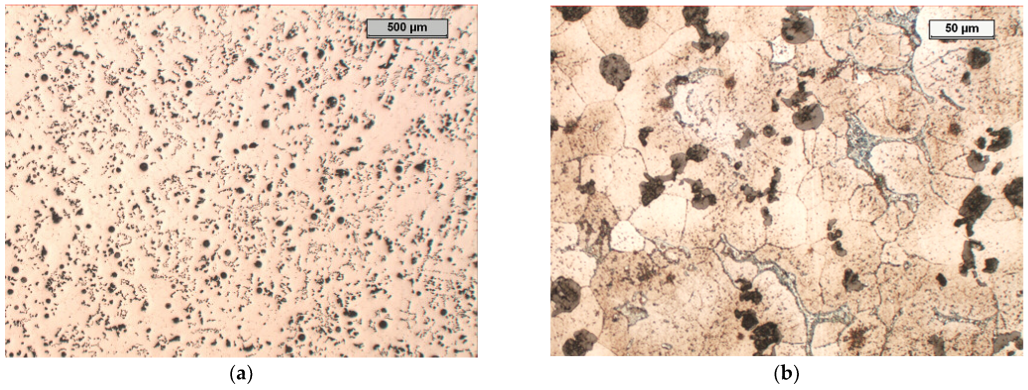

Figure 12.

Microstructure of sample B, etched with nital, magnification 2000× (SEM), 1 and 2—metal matrix, 3, 4 and 6—carbides, 5—molybdenum carbide precipitates.

Figure 12.

Microstructure of sample B, etched with nital, magnification 2000× (SEM), 1 and 2—metal matrix, 3, 4 and 6—carbides, 5—molybdenum carbide precipitates.

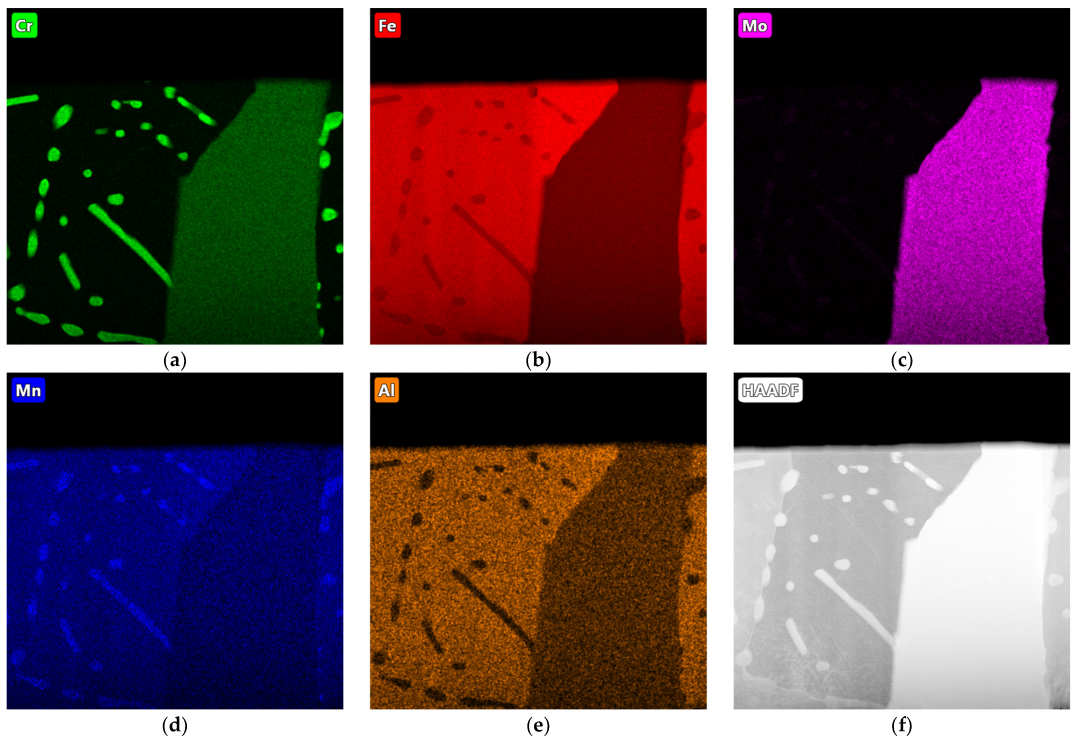

Figure 13.

EDS maps of Sample B, indicating concentrations of (a) chromium, (b) iron, (c) molybdenum, (d) manganese, and (e) aluminium; (f) HAADF imaging (transmission microscope).

Figure 13.

EDS maps of Sample B, indicating concentrations of (a) chromium, (b) iron, (c) molybdenum, (d) manganese, and (e) aluminium; (f) HAADF imaging (transmission microscope).

Figure 14.

Microstructure of Sample C, optical microscope: (a) unetched, magnification 25×; (b) etched with nital, phases: light—ferrite, shades of grey—carbides, black—graphite, magnification 200× (b).

Figure 14.

Microstructure of Sample C, optical microscope: (a) unetched, magnification 25×; (b) etched with nital, phases: light—ferrite, shades of grey—carbides, black—graphite, magnification 200× (b).

Figure 15.

Sample C etched with nital, magnification 2000× (SEM), 1 and 2—metal matrix, 3 and 4—carbides, 5 and 6—molybdenum carbide precipitates.

Figure 15.

Sample C etched with nital, magnification 2000× (SEM), 1 and 2—metal matrix, 3 and 4—carbides, 5 and 6—molybdenum carbide precipitates.

Figure 16.

EDS maps of sample C, indicating concentrations of (a) chromium, (b) iron, (c) molybdenum, (d) manganese, and (e) aluminium; (f) HAADF imaging (transmission microscope).

Figure 16.

EDS maps of sample C, indicating concentrations of (a) chromium, (b) iron, (c) molybdenum, (d) manganese, and (e) aluminium; (f) HAADF imaging (transmission microscope).

Figure 17.

Microstructure of sample D, optical microscope: (a) unetched, magnification 25×; (b) etched with nital, phases: light—ferrite, shades of grey—carbides, black—graphite, magnification 200× (b).

Figure 17.

Microstructure of sample D, optical microscope: (a) unetched, magnification 25×; (b) etched with nital, phases: light—ferrite, shades of grey—carbides, black—graphite, magnification 200× (b).

Figure 18.

EDS maps of sample D, indicating concentrations of (a) chromium, (b) iron, (c) molybdenum, (d) manganese, and (e) aluminium; (f) HAADF imaging (transmission microscope).

Figure 18.

EDS maps of sample D, indicating concentrations of (a) chromium, (b) iron, (c) molybdenum, (d) manganese, and (e) aluminium; (f) HAADF imaging (transmission microscope).

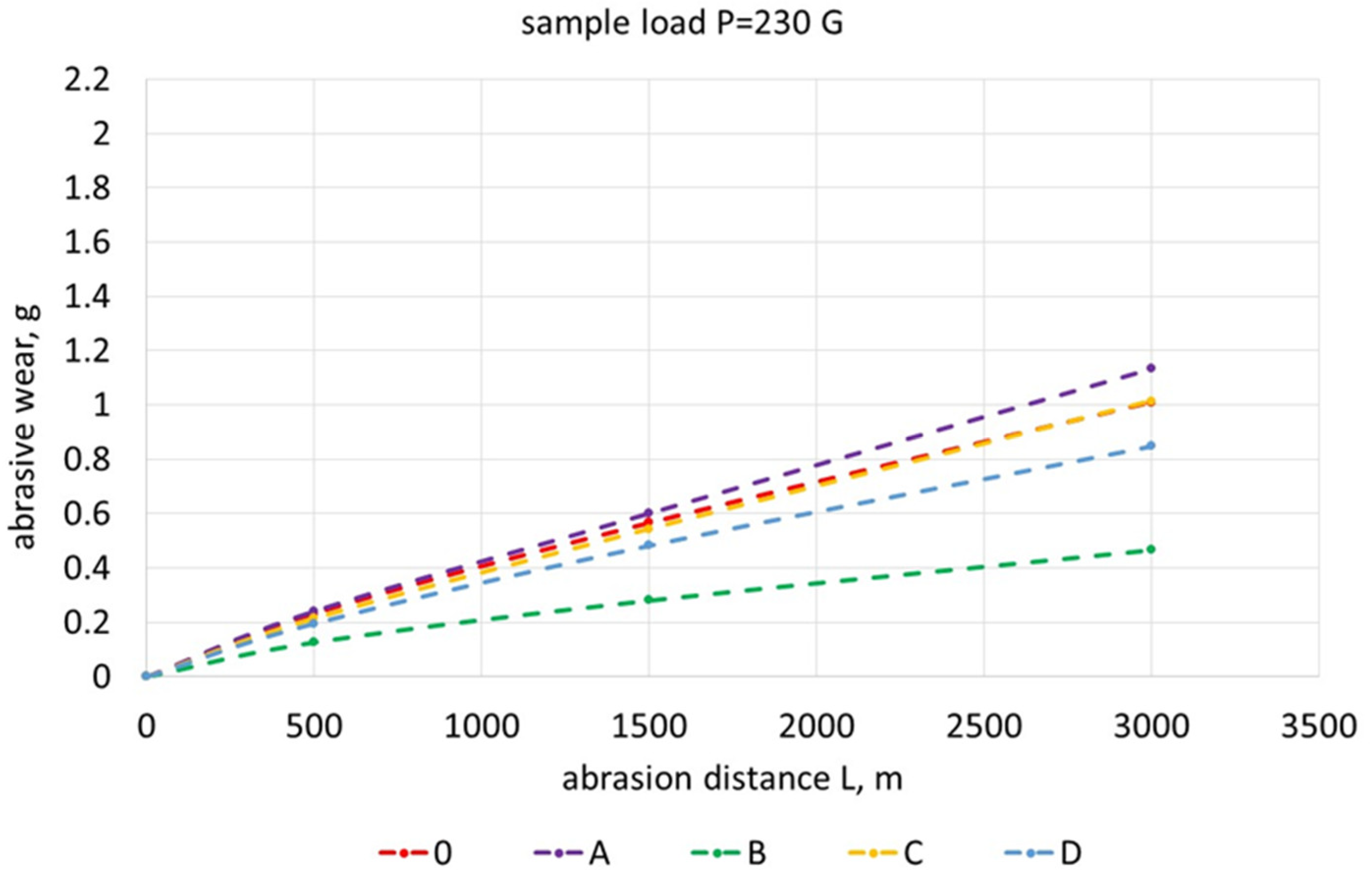

Figure 19.

Abrasive wear of tested samples as function of abrasion path with sample load of 230 G.

Figure 19.

Abrasive wear of tested samples as function of abrasion path with sample load of 230 G.

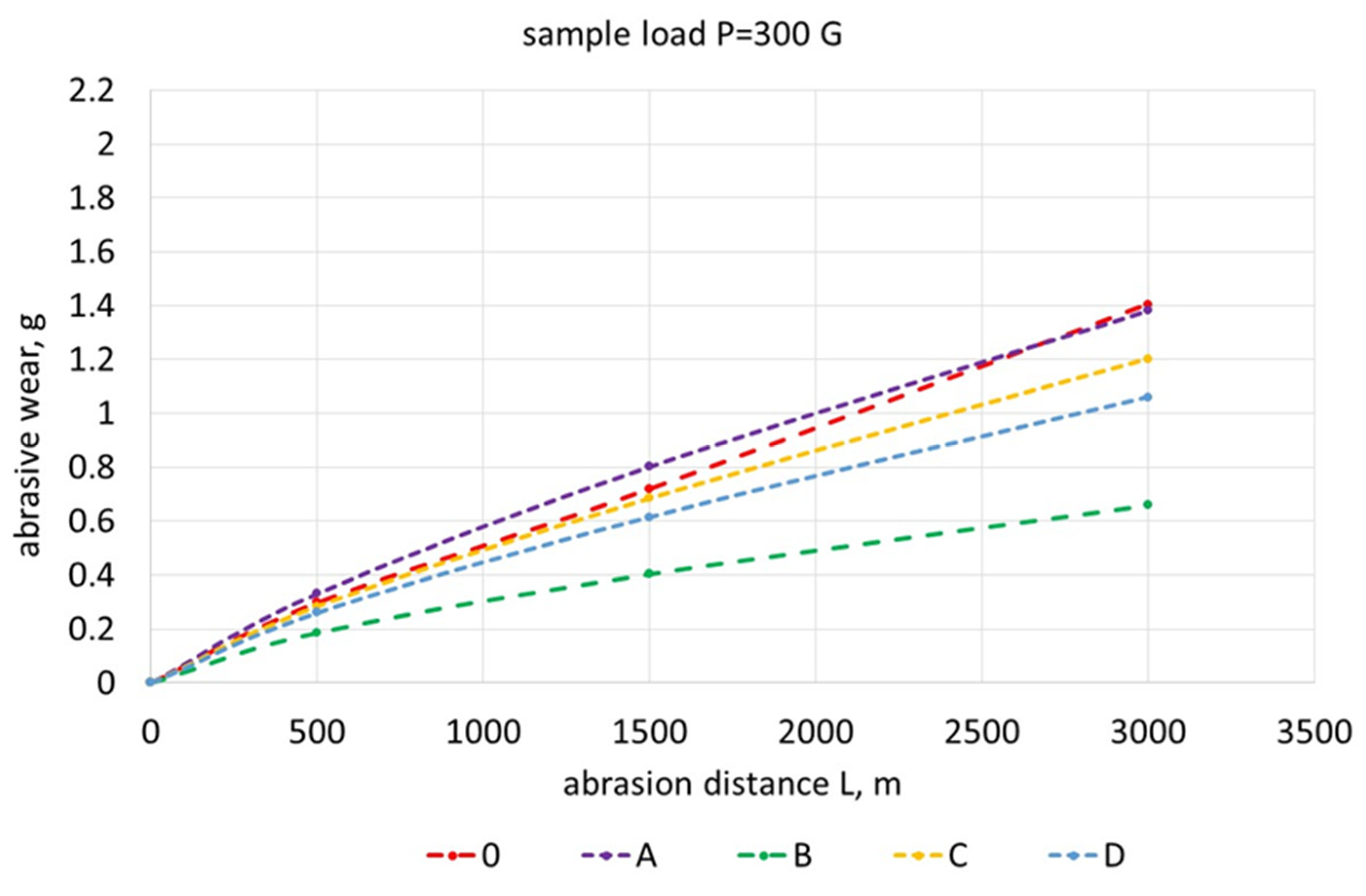

Figure 20.

Abrasive wear of tested samples as function of abrasion path with sample load of 300 G.

Figure 20.

Abrasive wear of tested samples as function of abrasion path with sample load of 300 G.

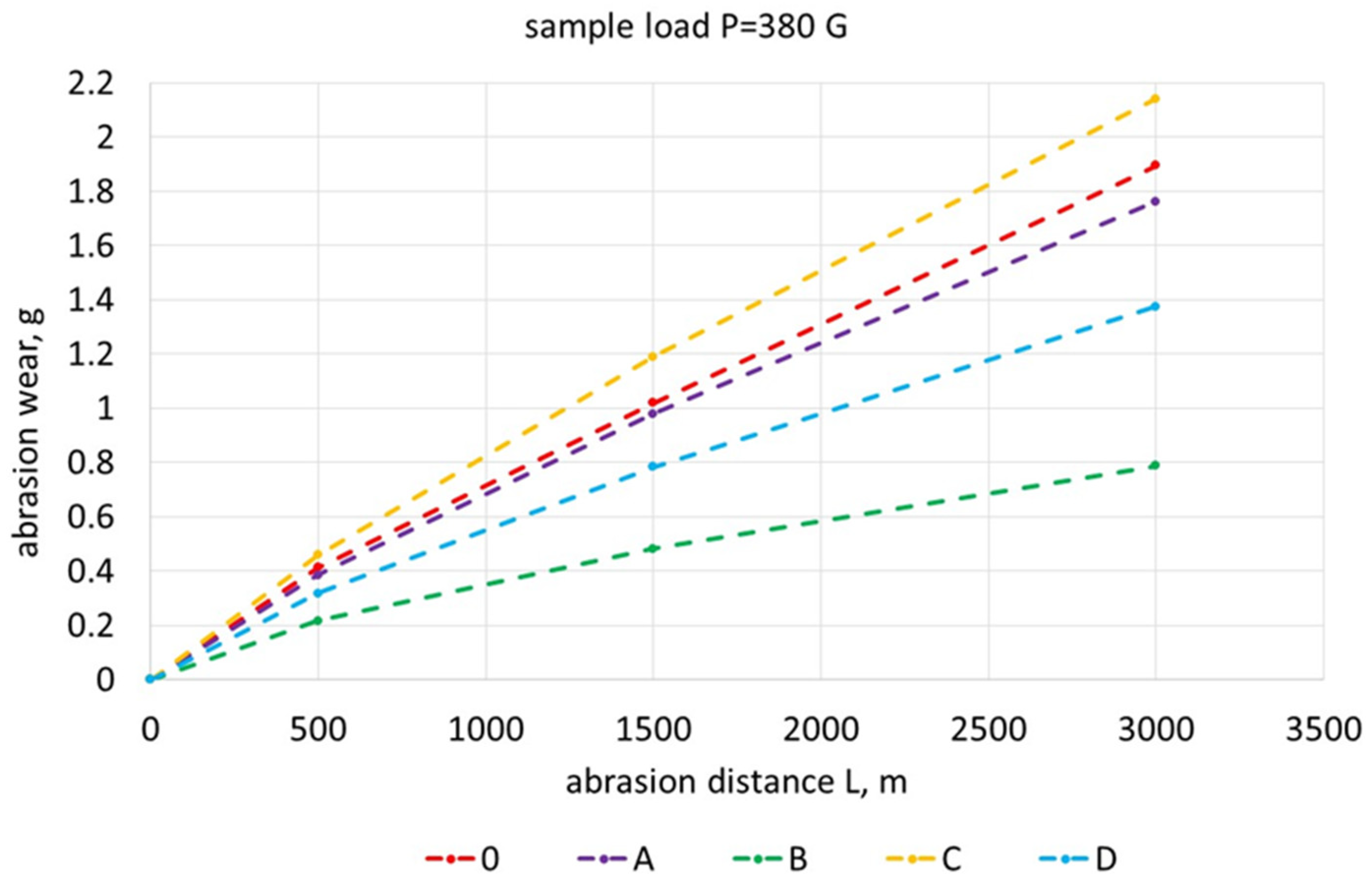

Figure 21.

Abrasive wear of tested samples as function of abrasion path with sample load of 380 G.

Figure 21.

Abrasive wear of tested samples as function of abrasion path with sample load of 380 G.

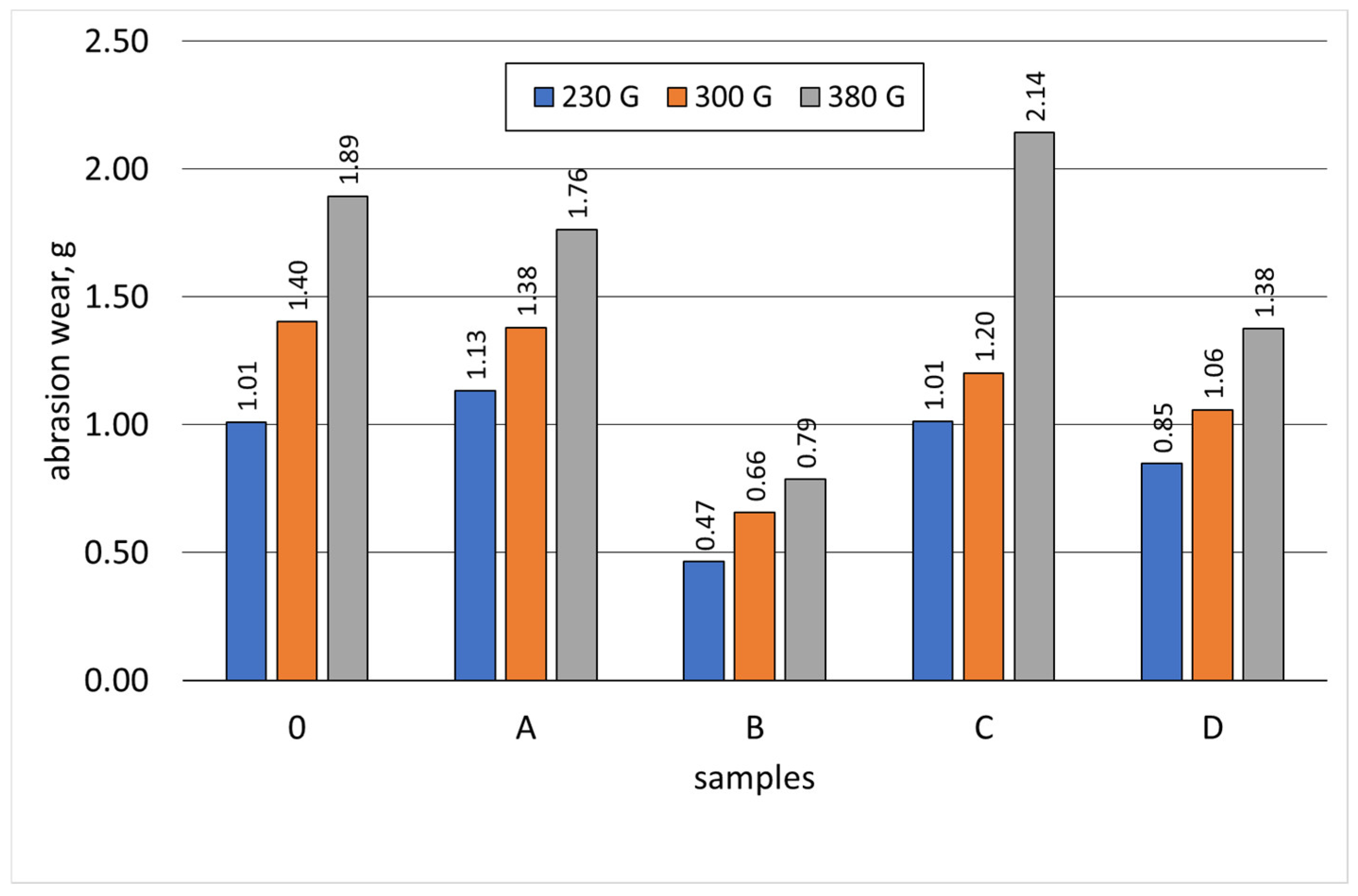

Figure 22.

Effect of sample load on abrasive wear.

Figure 22.

Effect of sample load on abrasive wear.

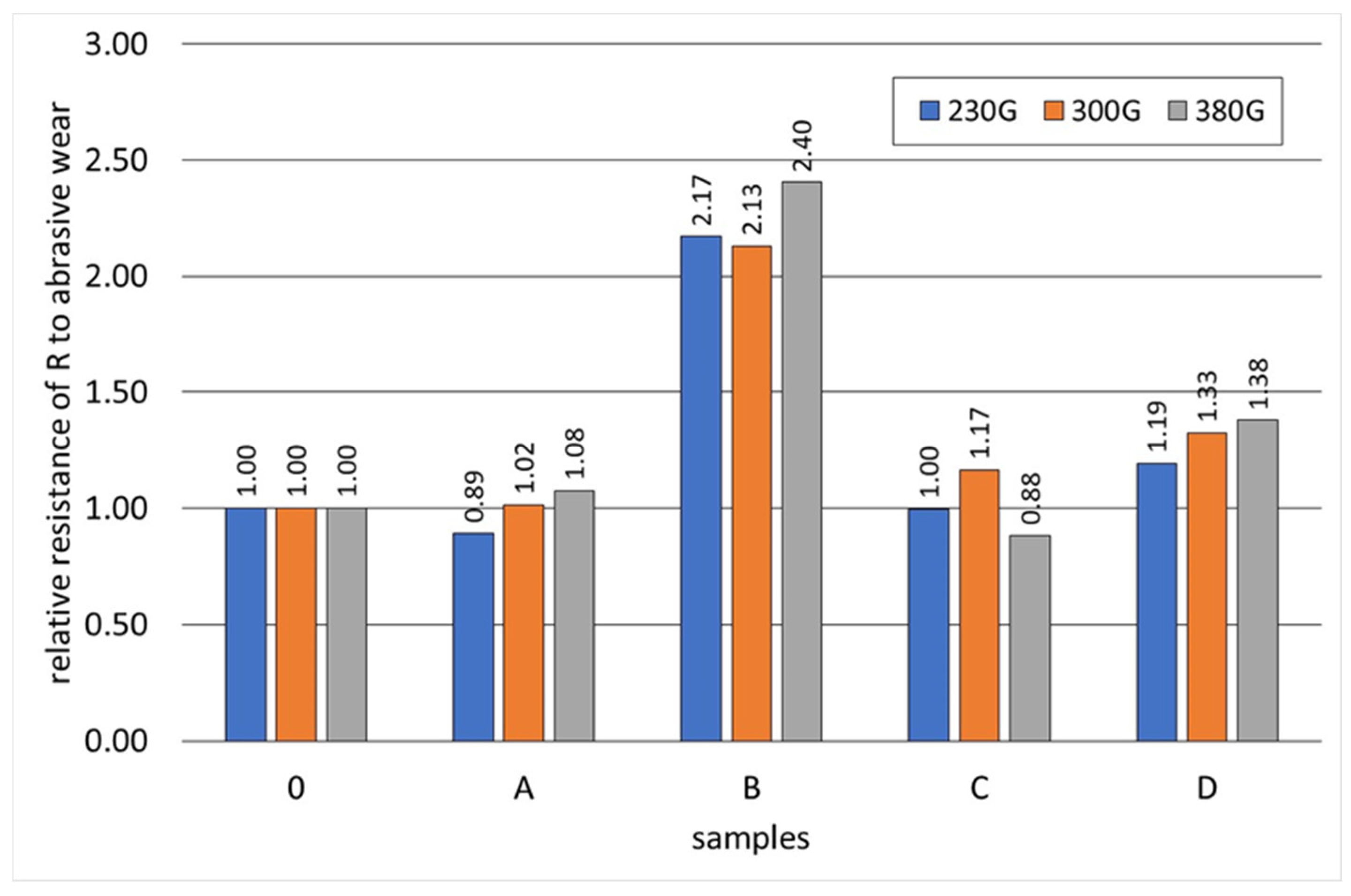

Figure 23.

Relative resistance R to abrasive wear of tested samples (Reference Sample 0).

Figure 23.

Relative resistance R to abrasive wear of tested samples (Reference Sample 0).

Table 1.

Chemical composition of charge materials used during cast iron melting.

Table 1.

Chemical composition of charge materials used during cast iron melting.

| Charge Material | C | Si | Mn | P | S | Mo | Cr | Al | Fe |

|---|

| wt.% | |

|---|

| Foundry pig iron | 4.44 | 0.81 | 0.02 | 0.025 | 0.009 | - | - | - | rest |

| W3 silicon steel scrap | 0.02 | 1.60 | 0.37 | 0.074 | 0.01 | - | - | - | rest |

| W3 manganese steel scrap | 0.25 | 0.25 | 0.40 | 0.009 | 0.02 | - | - | - | rest |

| Cast iron scrap | 3.50 | 2.60 | 0.35 | 0.035 | 0.004 | - | - | - | rest |

| FeSi | 0.12 | 75.21 | - | 0.017 | 0.004 | - | - | - | rest |

| FeMo | 0.20 | 0.30 | - | - | - | 68.0 | - | - | rest |

| FeCr | - | - | - | - | - | - | 65.0 | - | rest |

| Al | - | - | - | - | - | - | - | 100.0 | rest |

| Carburizer 9904 | 99.59 | - | - | - | 0.020 | - | - | - | |

Table 2.

Chemical composition of Zircinoc inoculant.

Table 2.

Chemical composition of Zircinoc inoculant.

| Inoculant | Si | Zr | Ca | Al |

|---|

| %mas. |

|---|

| Zircinoc | 73.0–78.0 | 1.3–1.8 | 2.0–2.5 | 1.0–1.5 |

Table 3.

Chemical composition of tested cast iron.

Table 3.

Chemical composition of tested cast iron.

| Melts | Chemical Composition, % mas. |

|---|

| C | Cr | Cu | Mg | Mn | P | S | Si | Ti | Mo | Al | Fe |

|---|

| 0 | 3.56 | 0.016 | 0.176 | 0.037 | 0.416 | 0.033 | 0.009 | 2.741 | 0.011 | - | 0.006 | rest |

| A | 2.67 | 0.099 | 0.095 | 0.031 | 0.384 | 0.021 | 0.008 | 5.56 | 0.019 | 0.81 | 0.023 | rest |

| B | 2.66 | 2.18 | 0.115 | 0.047 | 0.475 | 0.045 | 0.012 | 5.91 | 0.024 | 1.19 | 3.41 | rest |

| C | 2.60 | 0.97 | 0.126 | 0.034 | 0.455 | 0.047 | 0.013 | 5.61 | 0.020 | 1.02 | 1.66 | rest |

| D | 3.13 | 0.092 | 0.108 | 0.038 | 0.461 | 0.032 | 0.007 | 5.27 | 0.020 | 0.78 | 1.48 | rest |

Table 4.

Chemical compositions of carbide phases calculated by Thermo-Calc program.

Table 4.

Chemical compositions of carbide phases calculated by Thermo-Calc program.

| Phase | | Chemical Composition, % mas. |

|---|

| C | Si | Mo | Mg | Cr | Fe |

|---|

| M6C | 3.2 | 15.1 | 51.6 | - | - | rest |

| M3C2 | 13.3 | - | - | - | 86.6 | rest |

Table 5.

Quantitative EDS analysis of Area 5 of Sample B.

Table 5.

Quantitative EDS analysis of Area 5 of Sample B.

| Chemical Composition |

|---|

| % mas. |

|---|

| C | Mg | Al | Si | P | S | Ti | Cr | Mn | Fe | Mo |

|---|

| 10.967 | 0.122 | 0.890 | 4.339 | 0.000 | 0.000 | 0.144 | 9.376 | 0.598 | 66.036 | 7.529 |

Table 6.

Quantitative EDS analysis of Point 6 of Sample B.

Table 6.

Quantitative EDS analysis of Point 6 of Sample B.

| Chemical Composition |

|---|

| % mas. |

|---|

| C | Mg | Al | Si | P | S | Ti | Cr | Mn | Fe | Mo |

|---|

| 19.791 | 0.229 | 1.612 | 4.917 | 0.070 | 0.888 | 0.000 | 5.219 | 0.144 | 66.431 | 0.699 |

Table 7.

Quantitative EDS analysis from Point 4 of Sample C.

Table 7.

Quantitative EDS analysis from Point 4 of Sample C.

| Chemical Composition |

|---|

| % mas. |

|---|

| C | Mg | Al | Si | P | S | Ti | Cr | Mn | Fe | Mo |

|---|

| 15.358 | 0.091 | 0.706 | 4.626 | 0.065 | 0.000 | 0.291 | 2.788 | 0.146 | 74.697 | 1.233 |

Table 8.

Quantitative EDS analysis from Area 5 of Sample C.

Table 8.

Quantitative EDS analysis from Area 5 of Sample C.

| Chemical Composition |

|---|

| % mas. |

|---|

| C | Mg | Al | Si | P | S | Ti | Cr | Mn | Fe | Mo |

|---|

| 6.221 | 0.138 | 1.739 | 5.828 | 0.000 | 0.441 | 0.047 | 0.693 | 0.250 | 83.484 | 1.160 |

Table 9.

Characteristics of structures of tested samples.

Table 9.

Characteristics of structures of tested samples.

| Sample | 0 | A | B | C | D |

|---|

| Metal matrix | Ferritic-pearlitic | Ferritic | Ferritic | Ferritic | Ferritic |

| Graphite precipitation | Nodular graphite

(>90%) | Nodular graphite

(>75%) | Nodular graphite (approx. 50%) | Nodular graphite (approx. 25%) + compacted graphite (approx. 75%) | Nodular graphite (approx. 10%) + compacted graphite (approx. 70%) |

| Carbides | - | M6C carbides at grain boundaries | M3C2 carbides and MC at grain boundaries | M6C carbides and MC at grain boundaries | M6C carbides and MC at grain boundaries |

Table 10.

Abrasive wear test results (total abrasive wear and resistance R) and Vickers hardness.

Table 10.

Abrasive wear test results (total abrasive wear and resistance R) and Vickers hardness.

| Set | Sample | Hardness

HV | Sample Load, G | Sample Load, G |

|---|

| 230 | 300 | 380 | 230 | 300 | 380 |

|---|

| Total Abrasive Wear, g | Relative Resistance, R |

|---|

| 1 | 0 | 197 | 1.010 | 1.403 | 1.895 | 1.00 | 1.00 | 1.00 |

| B | 412 | 0.465 | 0.658 | 0.788 | 2.17 | 2.13 | 2.40 |

| 2 | C | 355 | 1.013 | 1.203 | 2.143 | 1.00 | 1.17 | 0.88 |

| D | 362 | 0.848 | 1.058 | 1.375 | 1.19 | 1.33 | 1.38 |

| A | 250 | 1.132 | 1.381 | 1.763 | 0.89 | 1.02 | 1.08 |