Effects of O2/Ar Ratio on Preparation and Dielectric Properties of CaZrO3 Films by Radio Frequency (RF) Magnetron Sputtering

Abstract

1. Introduction

- (i)

- Development Requirements for High-Performance Chips

- (ii)

- High-Frequency Integrated Circuit and Discrete Component Requirements

2. Materials and Methods

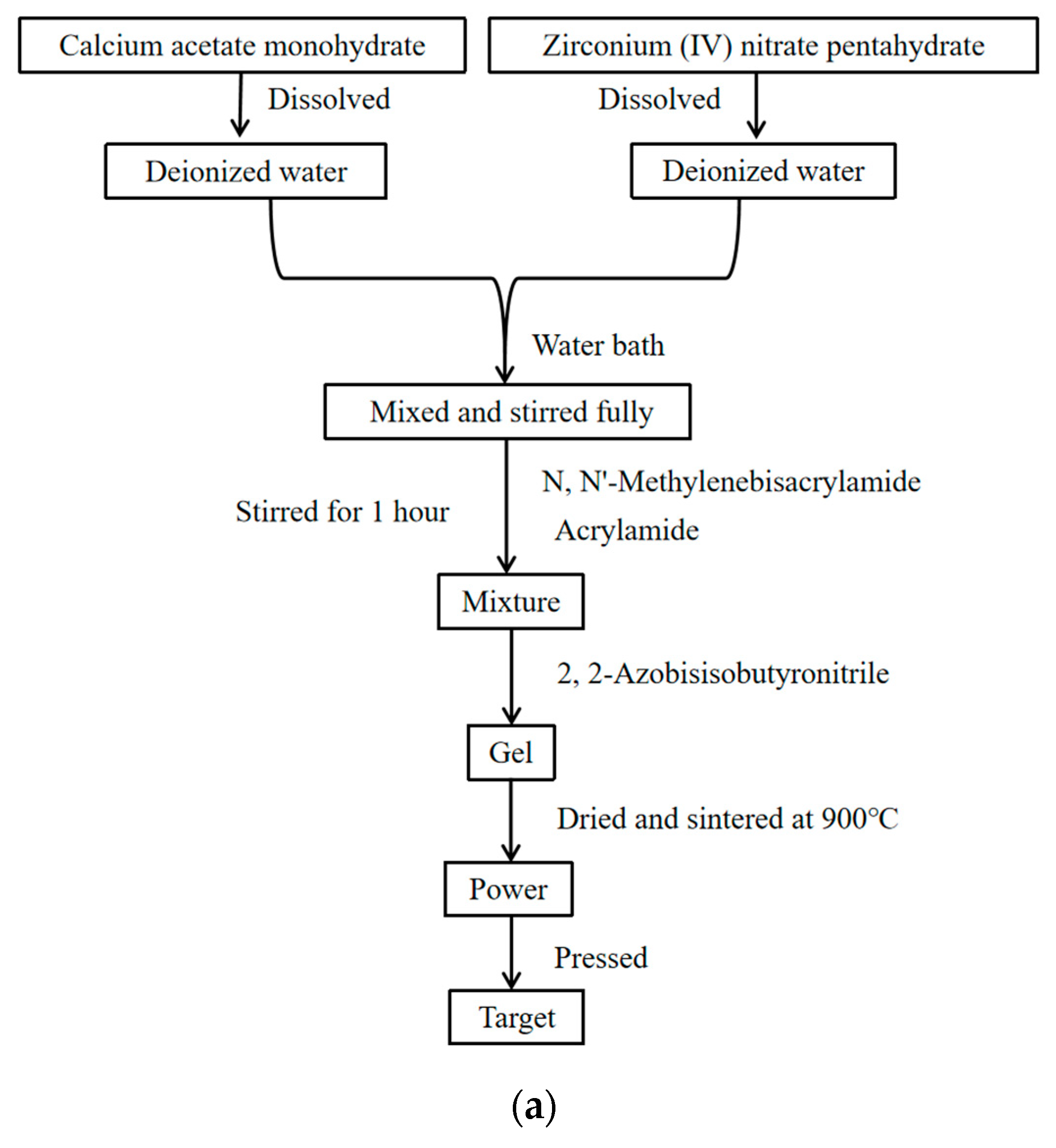

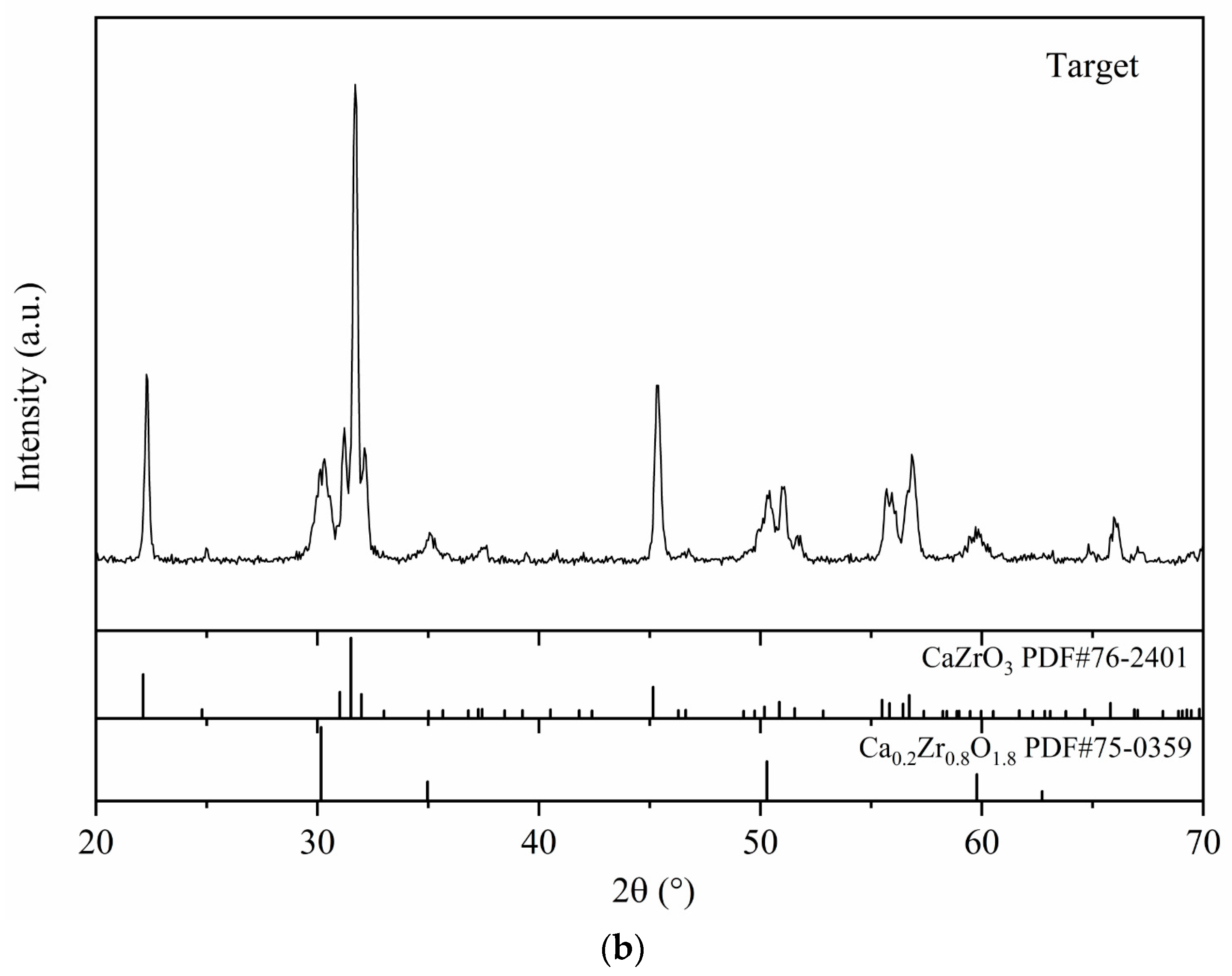

2.1. Sputtering Target Preparation

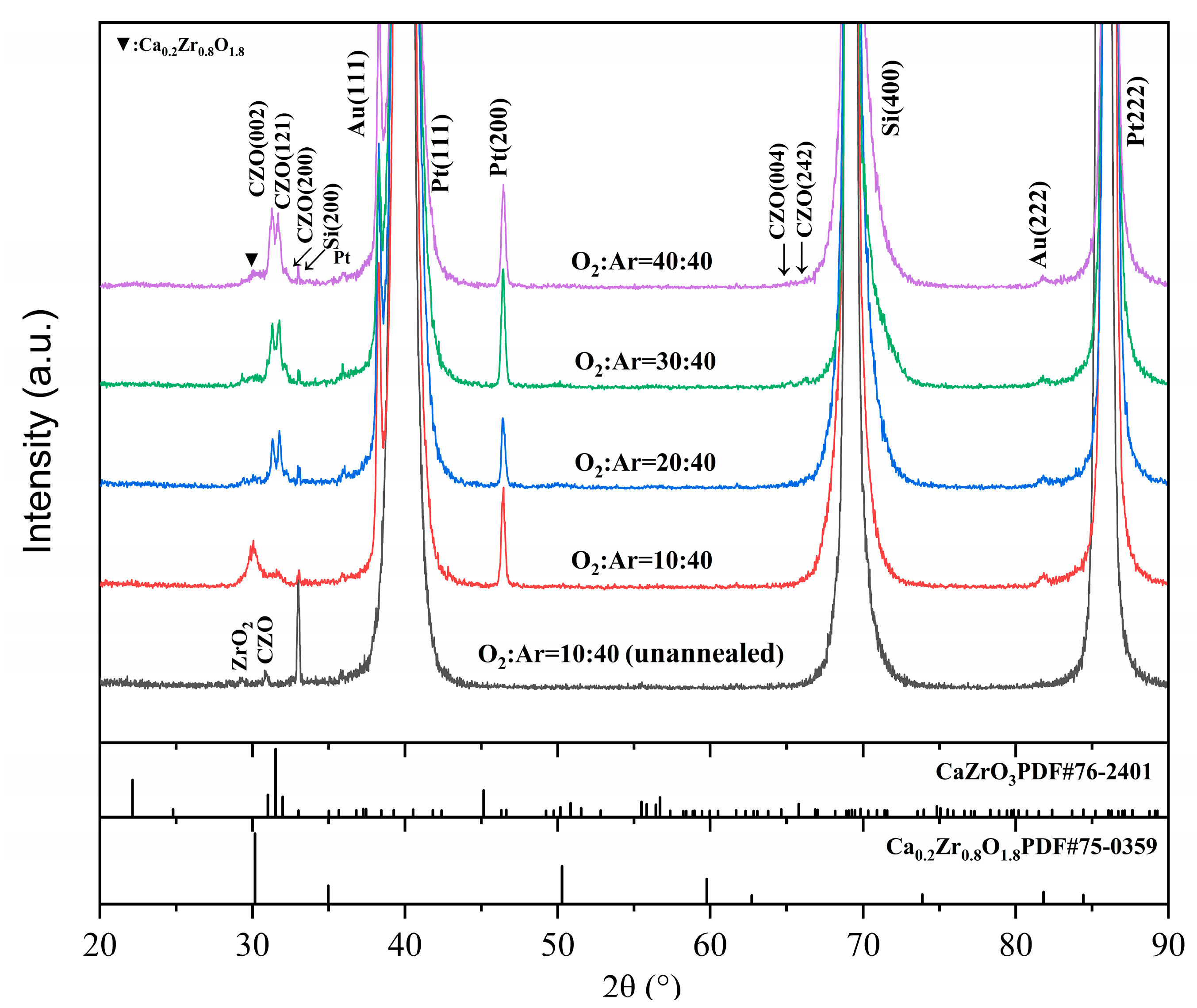

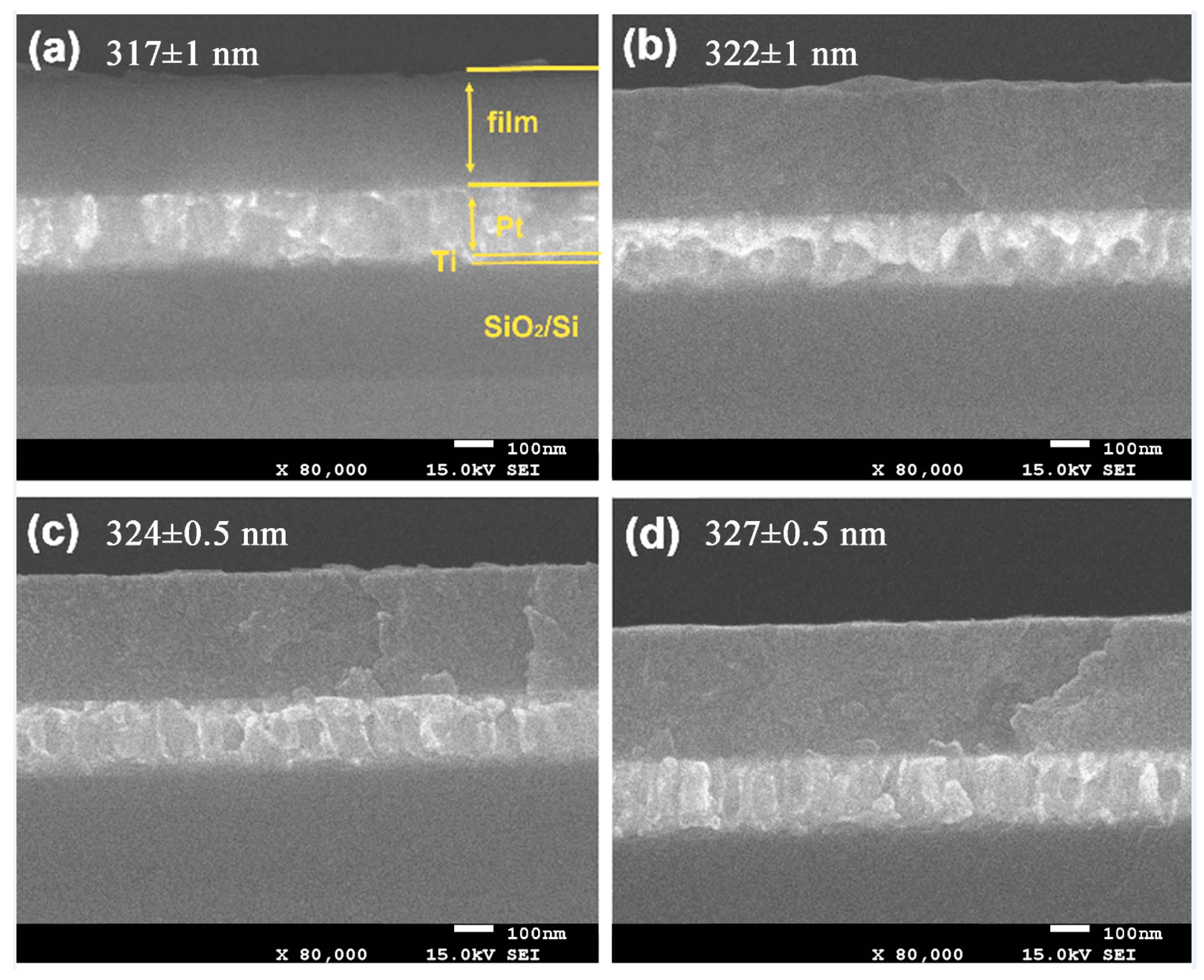

2.2. Thin Film Preparation

2.3. Characterization of Thin Film Structure and Dielectric Properties

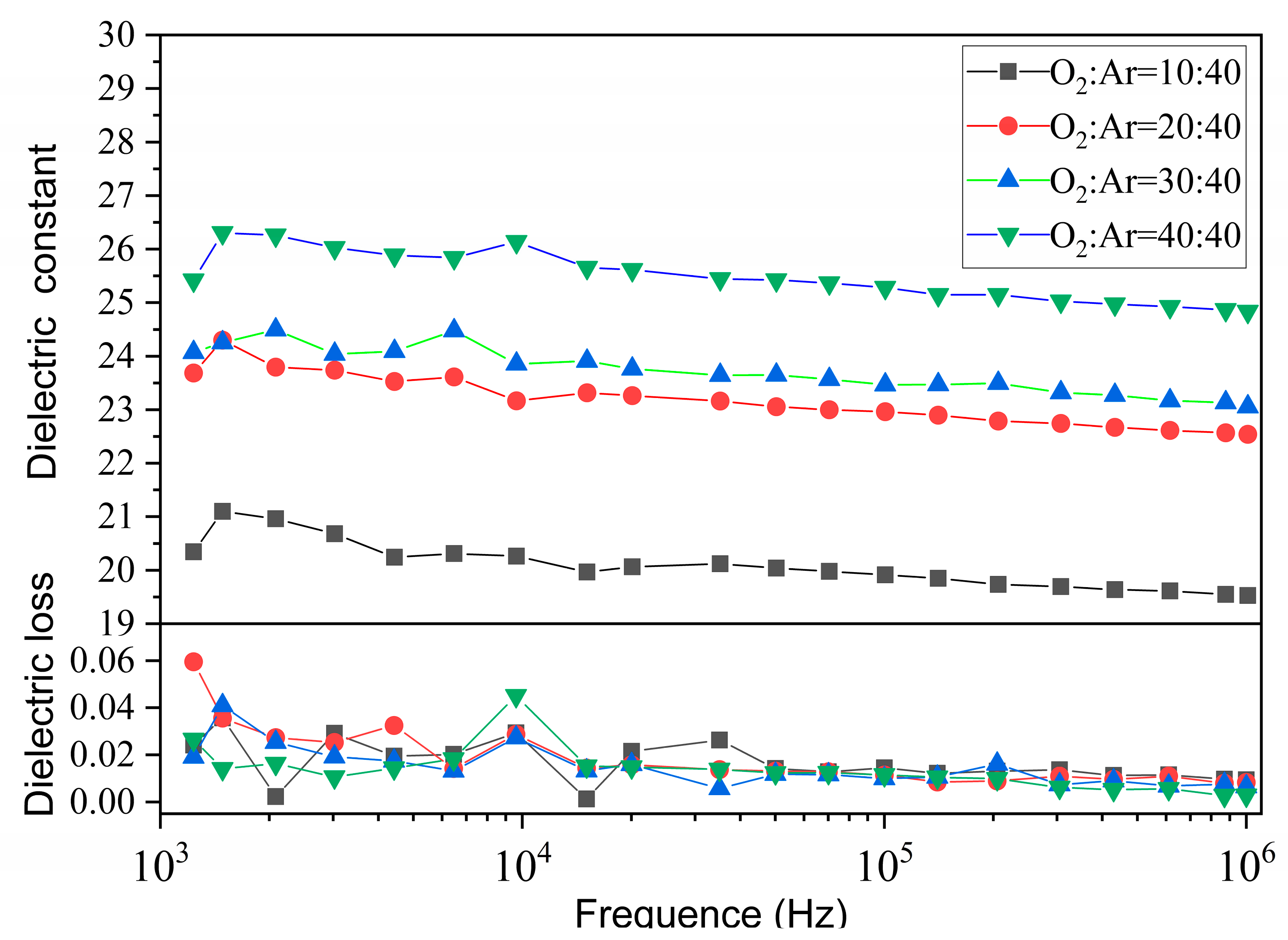

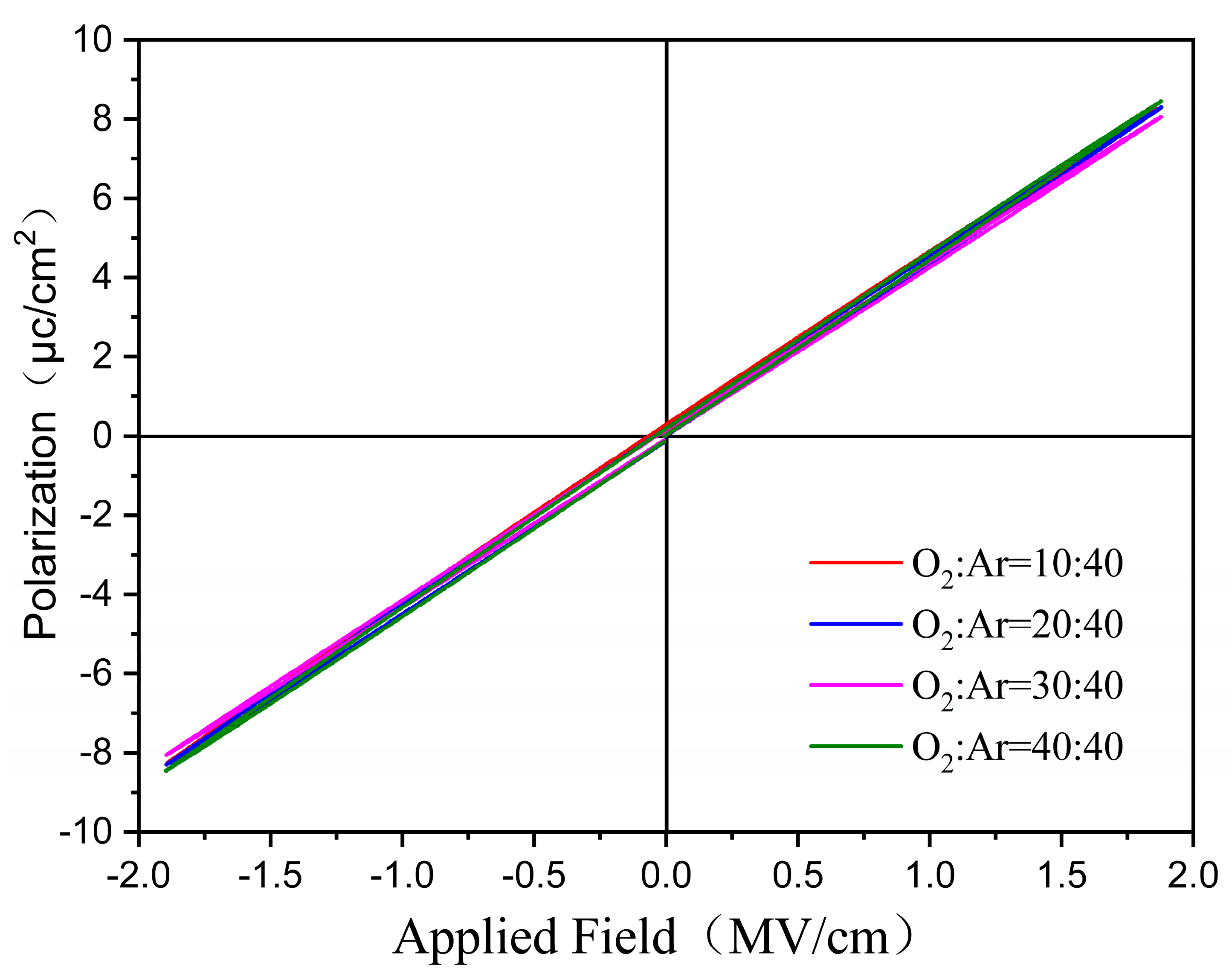

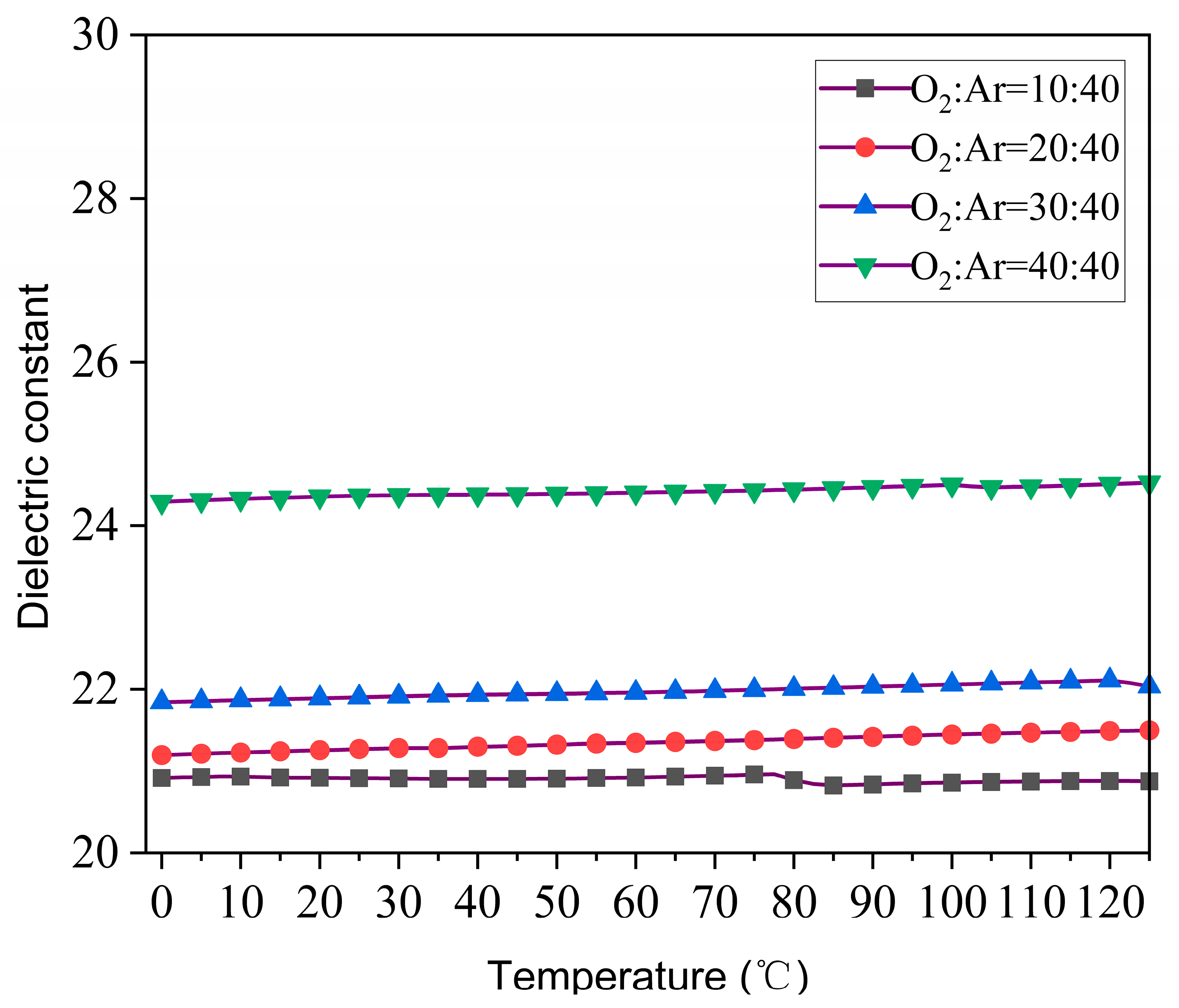

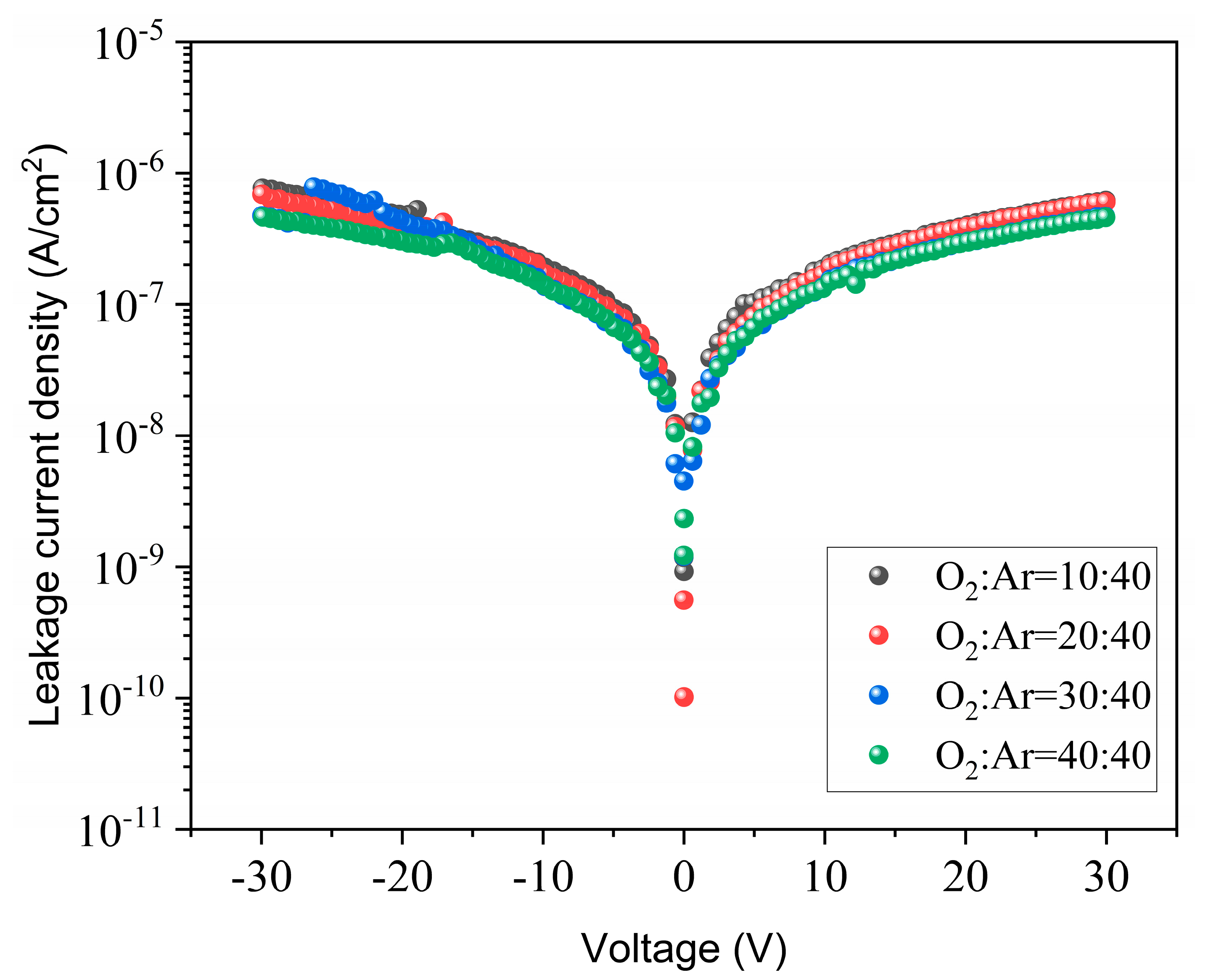

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Qiu, X.; Liu, H.; Fang, F.; Ha, M.; Zhou, X.; Liu, J.-M. Thermal stability and dielectric properties of ultrathin CaZrO x films prepared by pulsed laser deposition. Appl. Phys. A 2005, 81, 1431–1434. [Google Scholar] [CrossRef]

- Robertson, J.; Wallace, R.M. High-K materials and metal gates for CMOS applications. Mater. Sci. Eng. R Rep. 2015, 88, 1–41. [Google Scholar] [CrossRef]

- Chiu, F.-C. Interface characterization and carrier transportation in metal/HfO2/silicon structure. J. Appl. Phys. 2006, 100, 114102. [Google Scholar] [CrossRef]

- Muthana, P.; Engin, A.E.; Swaminathan, M.; Tummala, R.; Sundaram, V.; Wiedenman, B.; Amey, D.; Dietz, K.H.; Banerji, S. Design, modeling, and characterization of embedded capacitor networks for core decoupling in the package. IEEE Trans. Adv. Packag. 2007, 30, 809–822. [Google Scholar] [CrossRef]

- Gandhi, S.; Xiang, S.; Raj, P.M.; Sundaram, V.; Swaminathan, M.; Tummala, R. A low-cost approach to high-k thinfilm decoupling capacitors on silicon and glass interposers. In Proceedings of the 2012 IEEE 62nd Electronic Components and Technology Conference, San Diego, CA, USA, 29 May–1 June 2012; IEEE: Piscataway, NJ, USA, 2012; pp. 1356–1360. [Google Scholar]

- Song, C.; Wang, Q.; Zheng, K.; Zhou, Y.; Cai, J. Design and Simulation of Deep Trench Capacitor on High-Performance Silicon Interposer. In Proceedings of the 2022 23rd International Conference on Electronic Packaging Technology (ICEPT), Dalian, China, 10–13 August 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 1–6. [Google Scholar]

- Lau, J.H. Recent advances and trends in advanced packaging. IEEE Trans. Compon. Packag. Manuf. Technol. 2022, 12, 228–252. [Google Scholar] [CrossRef]

- Jatlaoui, M.M.; Aubry, Y.; Gaborieau, S.; Longuet, S.; Dubos, L.; Nakano, H.; Matsuoka, T.; Kushima, T.; Ohara, T.; Ando, S. Low ESL High Voltage Si-IPD as Enabler for 140 W LD Output and Less 1 ns FWHM LiDAR Module. In Proceedings of the 2021 IEEE 71st Electronic Components and Technology Conference (ECTC), San Diego, CA, USA, 1 June–4 July 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 256–262. [Google Scholar]

- Zhou, P.; Chen, J.; Yan, P.; Hou, D.; Gao, H.; Hong, W. A broadband power amplifier in 130-nm SiGe BiCMOS technology. IEEE Solid-State Circuits Lett. 2021, 4, 44–47. [Google Scholar] [CrossRef]

- Li, Z.; Chen, J.; Li, H.; Wang, Z.; Hou, D.; Yan, P.; Chen, Z.; Hong, W. A 220-GHz power amplifier with 22.5-dB gain and 9-dBm P sat in 130-nm SiGe. IEEE Microw. Wirel. Compon. Lett. 2021, 31, 1166–1169. [Google Scholar] [CrossRef]

- Johari, H.; Ayazi, F. High-density embedded deep trench capacitors in silicon with enhanced breakdown voltage. IEEE Trans. Compon. Packag. Technol. 2009, 32, 808–815. [Google Scholar] [CrossRef]

- Roozeboom, F.; Kemmeren, A.; Verhoeven, J.; Van den Heuvel, F.; Klootwijk, J.; Kretschman, H.; Frič, T.; Van Grunsven, E.; Bardy, S.; Bunel, C. Passive and heterogeneous integration towards a Si-based System-in-Package concept. Thin Solid Film. 2006, 504, 391–396. [Google Scholar] [CrossRef]

- Jatlaoui, M.M.; Fourneaud, L.; Voiron, F. New Ultra Low ESR Mosaïc PICS Capacitors for Power Conversion. In Proceedings of the 2015 10th European Microwave Integrated Circuits Conference (EuMIC), Paris, France, 7–8 September 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 203–206. [Google Scholar]

- Voiron, F.; Fourneaud, L. Silicon high-density capacitors for power decoupling applications. In Proceedings of the 2015 IEEE International Workshop on Integrated Power Packaging (IWIPP), Chicago, IL, USA, 3–6 May 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 48–51. [Google Scholar]

- Stoch, P.; Szczerba, J.; Lis, J.; Madej, D.; Pędzich, Z. Crystal structure and ab initio calculations of CaZrO3. J. Eur. Ceram. Soc. 2012, 32, 665–670. [Google Scholar] [CrossRef]

- Levin, I.; Amos, T.G.; Bell, S.M.; Farber, L.; Vanderah, T.A.; Roth, R.S.; Toby, B.H. Phase equilibria, crystal structures, and dielectric anomaly in the BaZrO3–CaZrO3 system. J. Solid State Chem. 2003, 175, 170–181. [Google Scholar] [CrossRef]

- Silva, A.P.; Booth, F.; Garrido, L.; Aglietti, E.; Pena, P.; Baudín, C. Young’s modulus and hardness of multiphase CaZrO3-MgO ceramics by micro and nanoindentation. J. Eur. Ceram. Soc. 2018, 38, 2194–2201. [Google Scholar] [CrossRef]

- Schafföner, S.; Qin, T.; Fruhstorfer, J.; Jahn, C.; Schmidt, G.; Jansen, H.; Aneziris, C.G. Refractory castables for titanium metallurgy based on calcium zirconate. Mater. Des. 2018, 148, 78–86. [Google Scholar] [CrossRef]

- Lyagaeva, J.; Danilov, N.; Korona, D.; Farlenkov, A.; Medvedev, D.; Demin, A.; Animitsa, I.; Tsiakaras, P. Improved ceramic and electrical properties of CaZrO3-based proton-conducting materials prepared by a new convenient combustion synthesis method. Ceram. Int. 2017, 43, 7184–7192. [Google Scholar] [CrossRef]

- Macedo, W.D., Jr.; Souza, A.E.; Santos, G.T.; Teixeira, S.R.; Longo, E. Microwave-assisted hydrothermal synthesis followed by heat treatment: A new route to obtain CaZrO3. Ceram. Int. 2018, 44, 953–958. [Google Scholar] [CrossRef]

- Huang, Z.; Deng, X.; Liu, J.; Jiao, C.; Lu, L.; Zhang, H.; Zhang, S. Preparation of CaZrO3 powders by a microwave–assisted molten salt method. J. Ceram. Soc. Jpn. 2016, 124, 593–596. [Google Scholar] [CrossRef]

- Joseph, M.; Sivakumar, N.; Manoravi, P.; Vanavaramban, S. Preparation of thin film of CaZrO3 by pulsed laser deposition. Solid State Ion. 2001, 144, 339–346. [Google Scholar] [CrossRef]

- Yaginuma, S.; Yamaguchi, J.; Itaka, K.; Koinuma, H. Pulsed laser deposition of oxide gate dielectrics for pentacene organic field-effect transistors. Thin Solid Film. 2005, 486, 218–221. [Google Scholar] [CrossRef]

- Yu, T.; Chen, C.; Chen, X.; Zhu, W.; Krishnan, R. Fabrication and characterization of perovskite CaZrO3 oxide thin films. Ceram. Int. 2004, 30, 1279–1282. [Google Scholar] [CrossRef]

- Yu, T.; Zhu, W.; Chen, C.; Chen, X.; Krishnan, R.G. Preparation and Characterizations of High-k Gate Dielectric CaZrO3 Thin Films by Sol-gel Technology. AIP Conf. Proc. 2003, 683, 143–147. [Google Scholar]

- Yu, T.; Zhu, W.; Chen, X.; Lu, Y. Leakage Current Behavior in CaZrO3 Thin Films for High-k Applications; Cambridge University Press: Cambridge, UK, 2004; Volume 811. [Google Scholar]

- Yu, T.; Zhu, W.; Chen, C.; Chen, X.; Krishnan, R.G. Preparation and characterization of sol–gel derived CaZrO3 dielectric thin films for high-k applications. Phys. B Condens. Matter 2004, 348, 440–445. [Google Scholar] [CrossRef]

- He, Q.; Zhang, Y.; Chen, X.; Wang, Z.; Ji, H.; Ding, M.; Xie, B.; Yu, P. The effects of substrate temperatures on the electrical properties of CaZrO3 thin films prepared by RF magnetron sputtering. Curr. Appl. Phys. 2020, 20, 557–561. [Google Scholar] [CrossRef]

- Khan, S.B.; Zhang, Z.; Lee, S.L. Annealing influence on optical performance of HfO2 thin films. J. Alloys Compd. 2020, 816, 152552. [Google Scholar] [CrossRef]

- Ashraf, M.; Akhtar, S.; Khan, A.; Ali, Z.; Qayyum, A. Effect of annealing on structural and optoelectronic properties of nanostructured ZnSe thin films. J. Alloys Compd. 2011, 509, 2414–2419. [Google Scholar] [CrossRef]

- Malghe, Y.; Dharwadkar, S. Ca0.15Zr0.85O1.85 powder from oxalate precursor: Microwave aided synthesis and thermal characterization. Thermochim. Acta 2008, 476, 66–68. [Google Scholar] [CrossRef]

- Chiu, F.-C. A review on conduction mechanisms in dielectric films. Adv. Mater. Sci. Eng. 2014, 2014, 578168. [Google Scholar] [CrossRef]

- Croset, M.; Mercandalli, L.; Siejka, J. Calcia-stabilized zirconia thin films in GaAs metal/insulator/semiconductor technology: Reduction of GaAs native oxide. Thin Solid Film. 1983, 103, 221–242. [Google Scholar] [CrossRef]

| Parameters | |

|---|---|

| Base pressure (Pa) | 4.0 × 10−4 |

| Substrate temperature (°C) | 450 |

| Sputtering pressure (Pa) | 2.0 |

| Sputtering power (W) | 70 |

| Deposition time (min) | 300 |

| Post-deposition cooling condition | 4.0 × 10−4 Pa, naturally |

| Flow ratio of O2:Ar | 10:40, 20:40, 30:40, 40:40 |

| Annealing condition | 700 °C × 3 h, 2 °C/min |

| Tε (Sample) | Unit | 0 °C | 125 °C |

|---|---|---|---|

| TCC(O2:Ar = 10:40) | ppm/°C | −5.58 | −17.58 |

| TCC(O2:Ar = 20:40) | 136.7 | 108.1 | |

| TCC(O2:Ar = 30:40) | 109.8 | 60.1 | |

| TCC(O2:Ar = 40:40) | 122.7 | 65.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, M.; Xie, B.; Lv, M.; Lu, Z. Effects of O2/Ar Ratio on Preparation and Dielectric Properties of CaZrO3 Films by Radio Frequency (RF) Magnetron Sputtering. Materials 2024, 17, 1120. https://doi.org/10.3390/ma17051120

Ding M, Xie B, Lv M, Lu Z. Effects of O2/Ar Ratio on Preparation and Dielectric Properties of CaZrO3 Films by Radio Frequency (RF) Magnetron Sputtering. Materials. 2024; 17(5):1120. https://doi.org/10.3390/ma17051120

Chicago/Turabian StyleDing, Mingjian, Bing Xie, Ming Lv, and Zhenya Lu. 2024. "Effects of O2/Ar Ratio on Preparation and Dielectric Properties of CaZrO3 Films by Radio Frequency (RF) Magnetron Sputtering" Materials 17, no. 5: 1120. https://doi.org/10.3390/ma17051120

APA StyleDing, M., Xie, B., Lv, M., & Lu, Z. (2024). Effects of O2/Ar Ratio on Preparation and Dielectric Properties of CaZrO3 Films by Radio Frequency (RF) Magnetron Sputtering. Materials, 17(5), 1120. https://doi.org/10.3390/ma17051120