Damage Monitoring and Localization Imaging of Aluminum Alloy Thin-Walled Structure Based on Remote Bonding Fiber Bragg Gratings Sensing

Abstract

1. Introduction

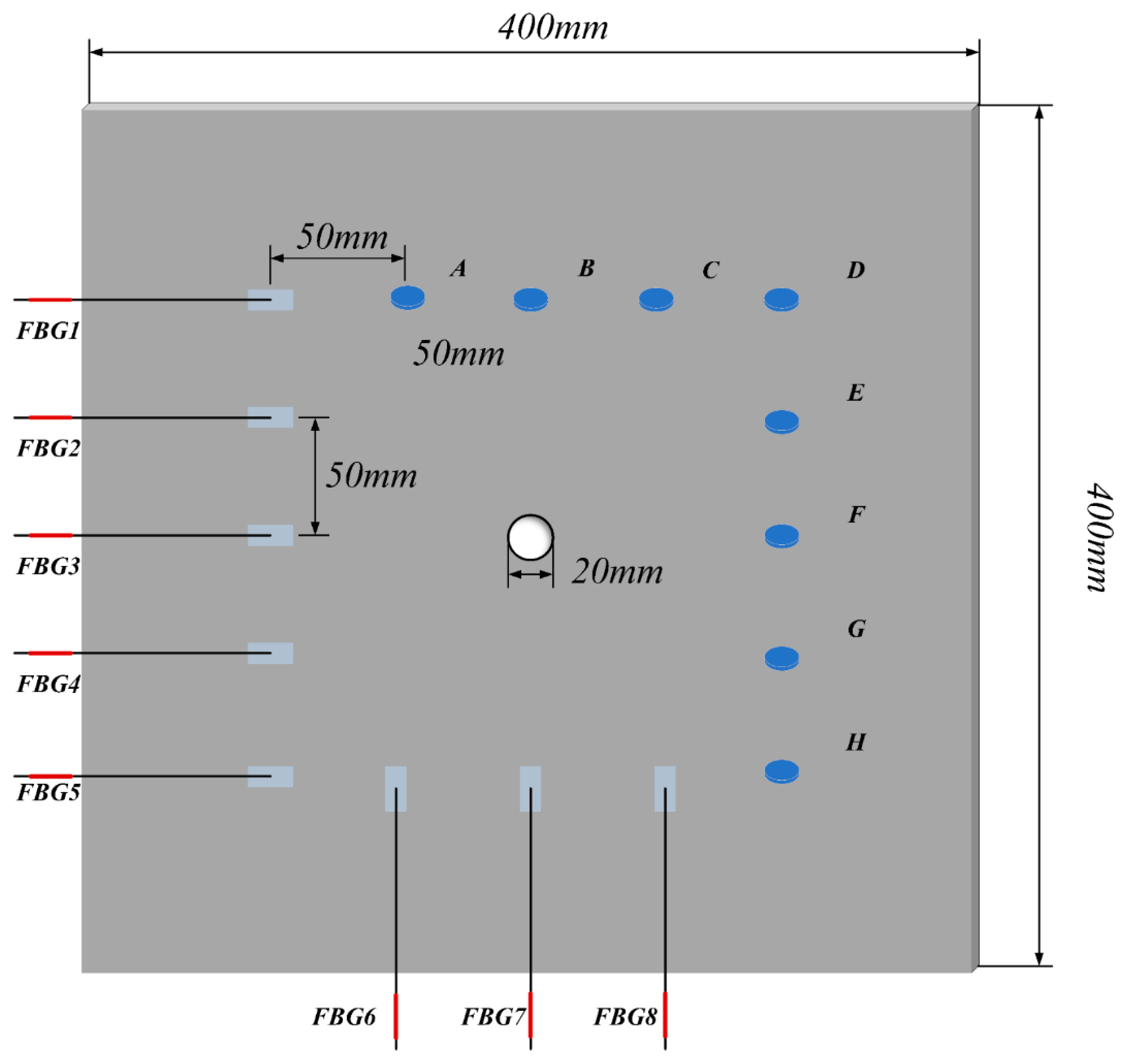

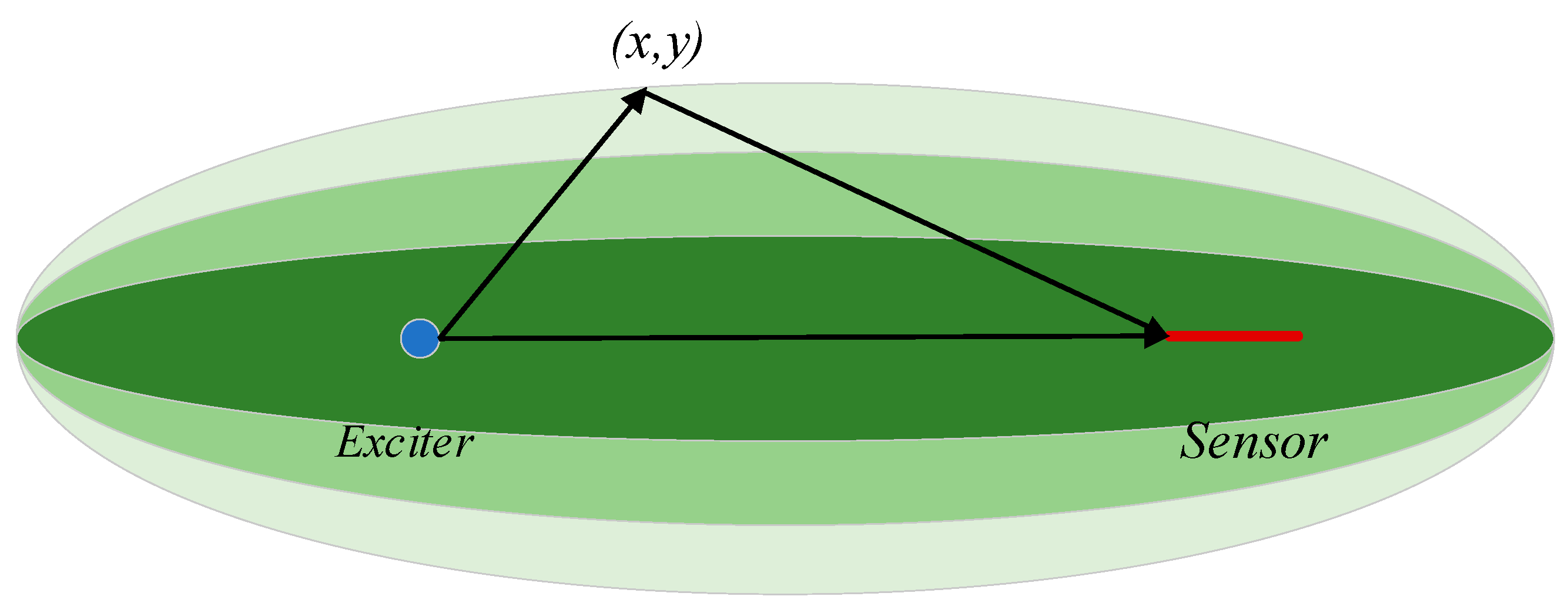

2. Experiment

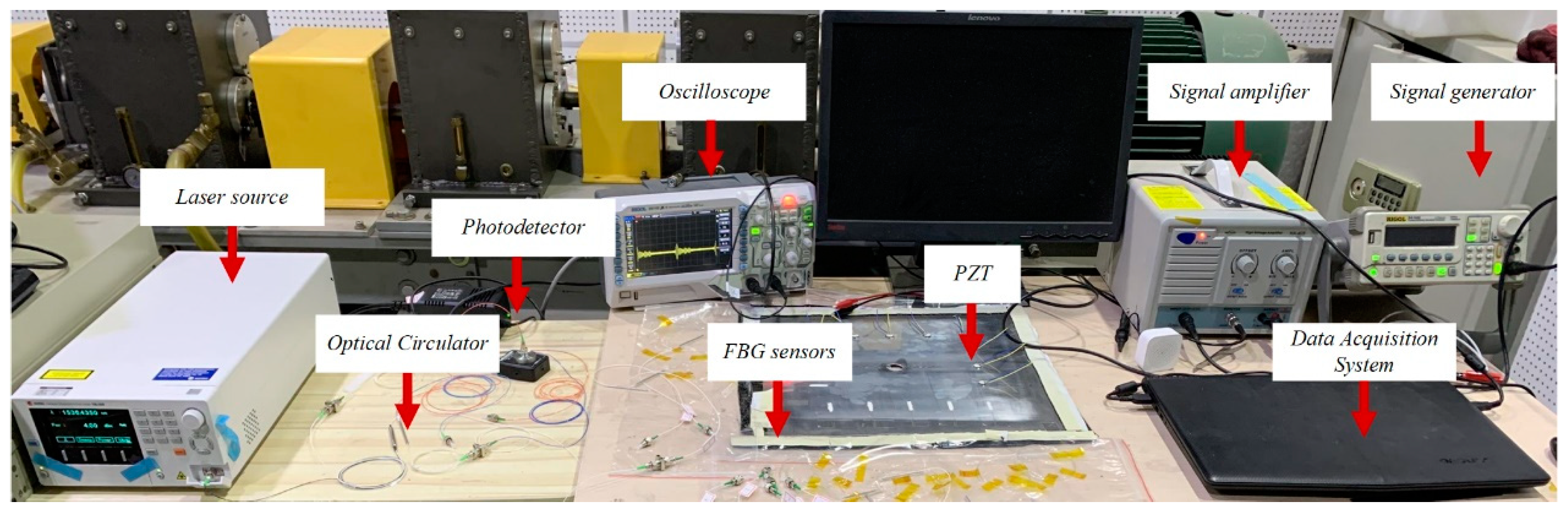

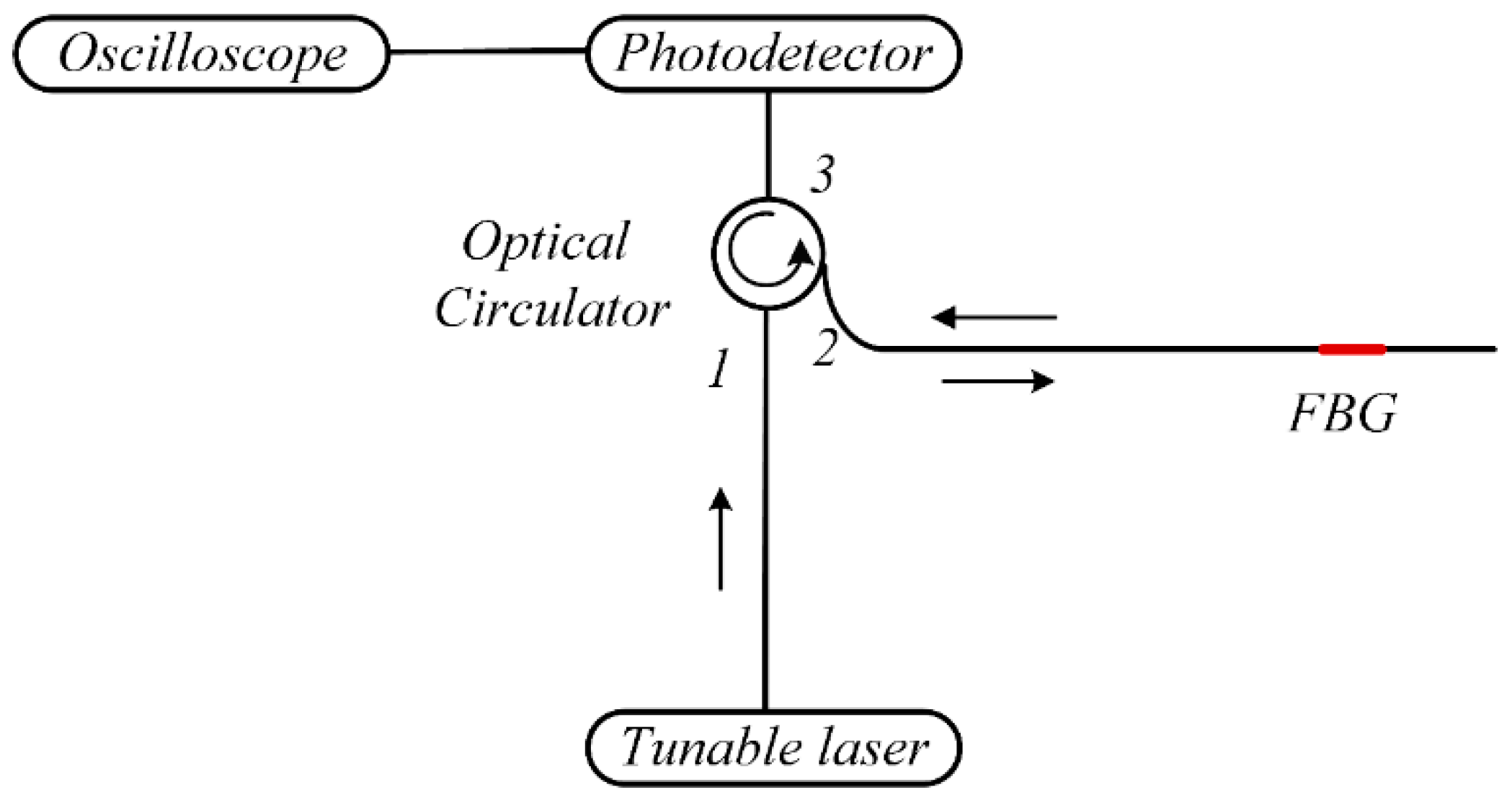

2.1. Experimental Platform Setup

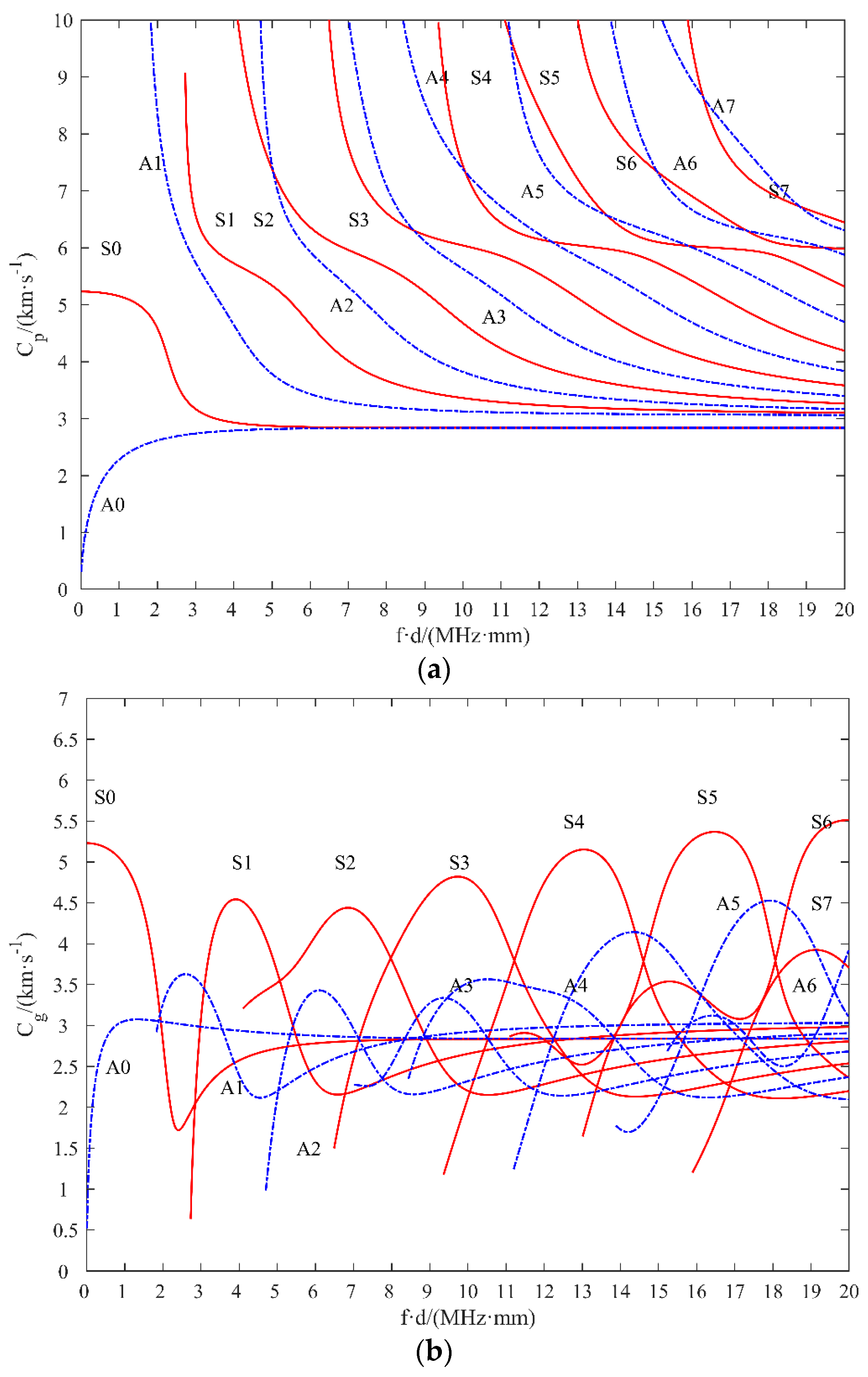

2.2. Experimental Parameters Selection

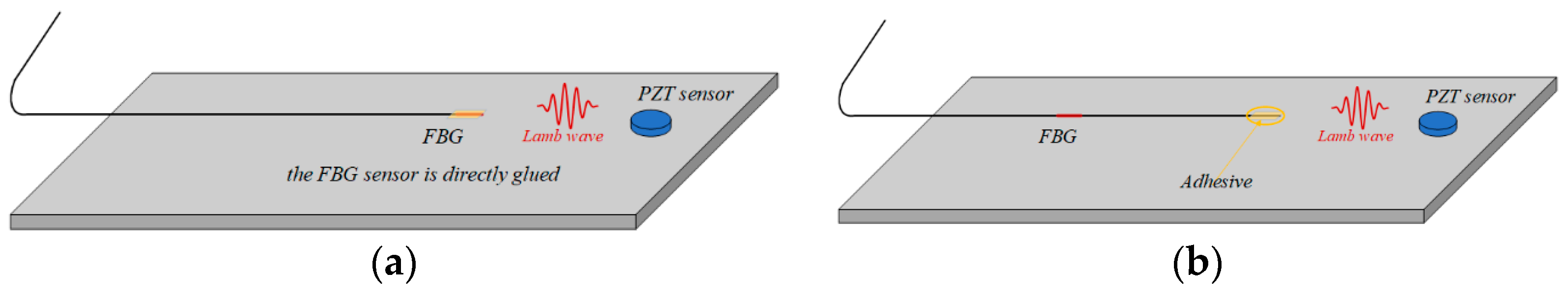

2.2.1. Grating Length

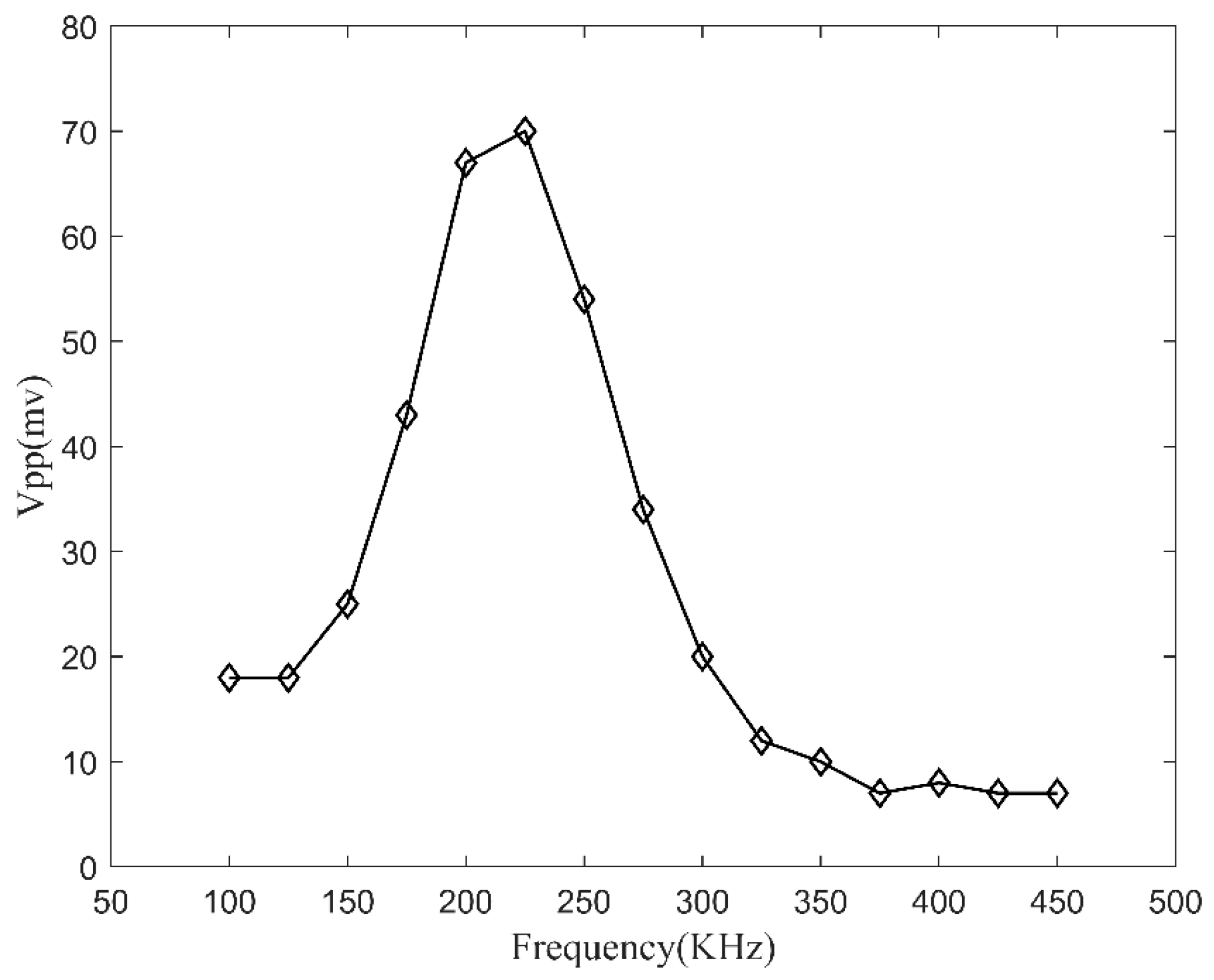

2.2.2. Frequency

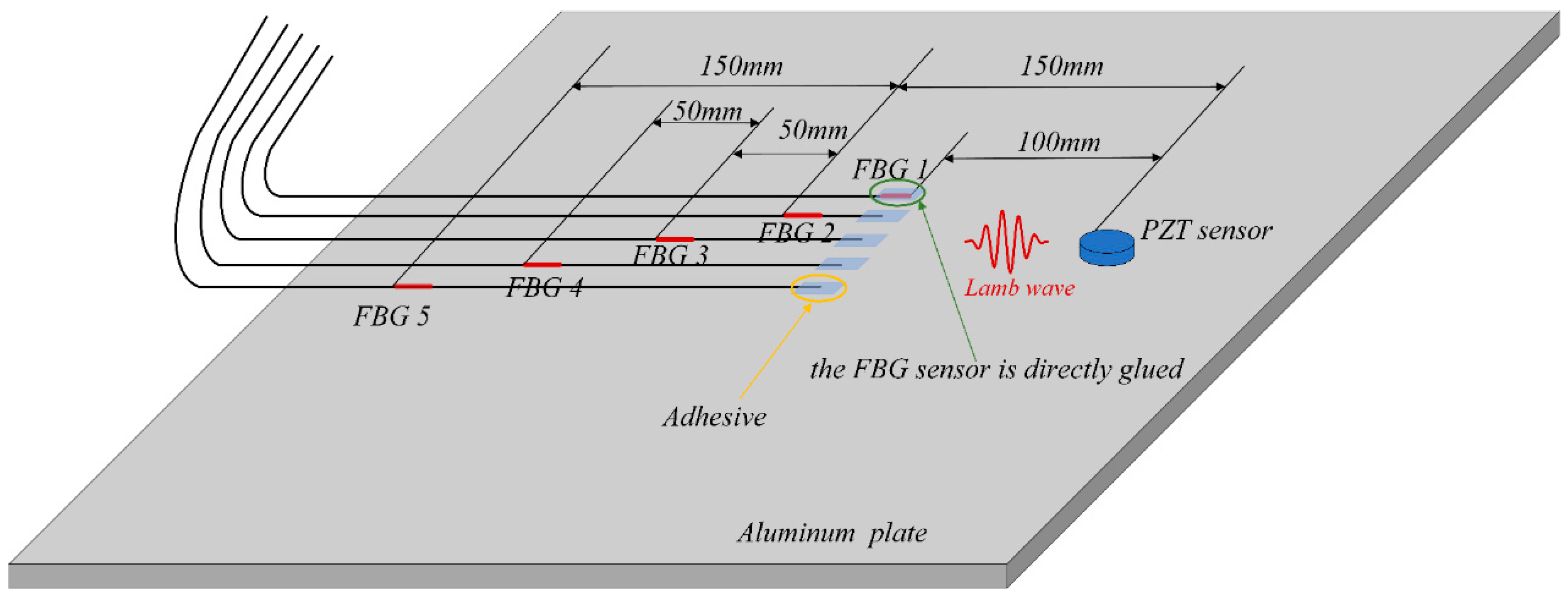

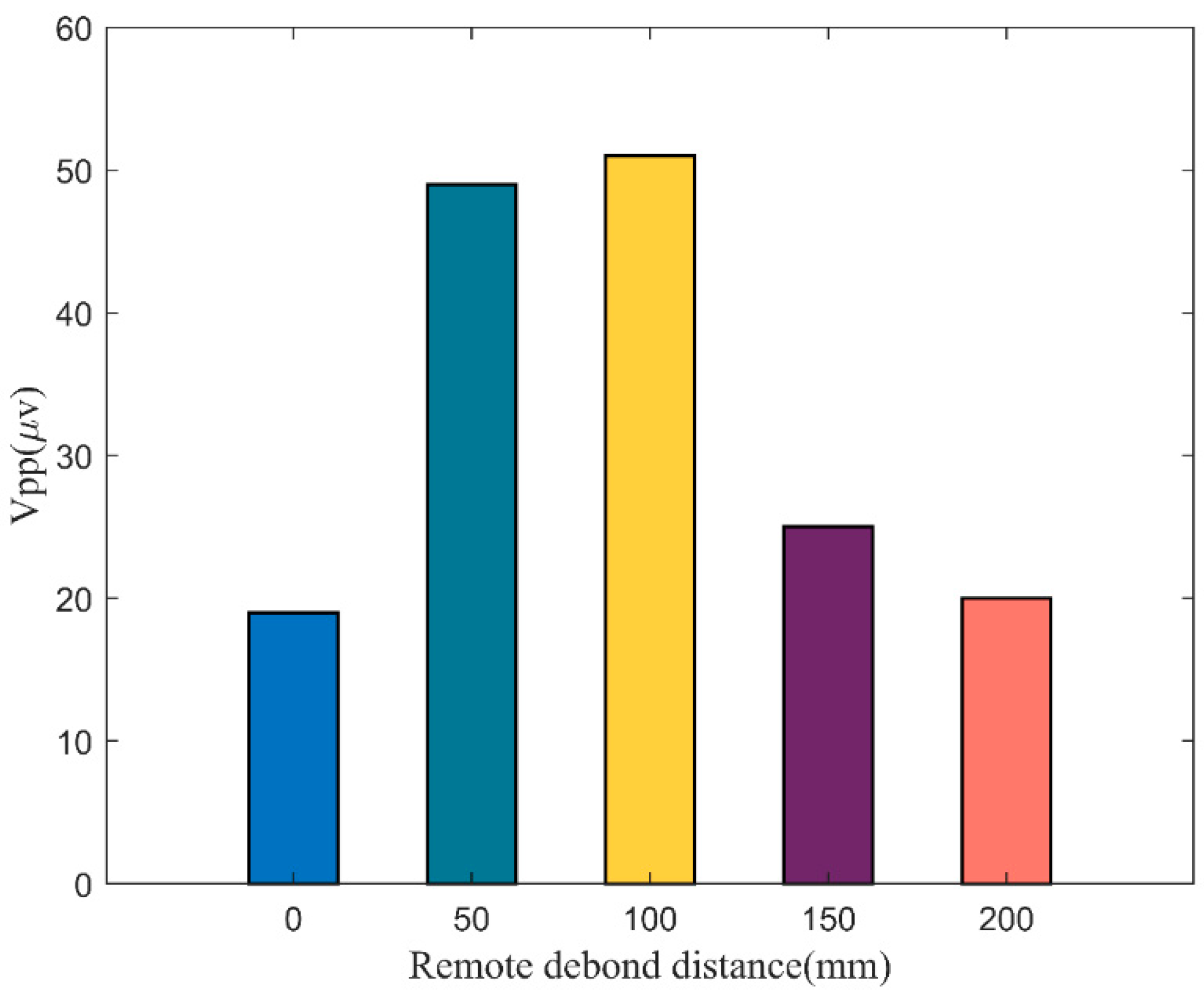

2.3. Remote Bonding Parameters

2.4. Experimental Setup

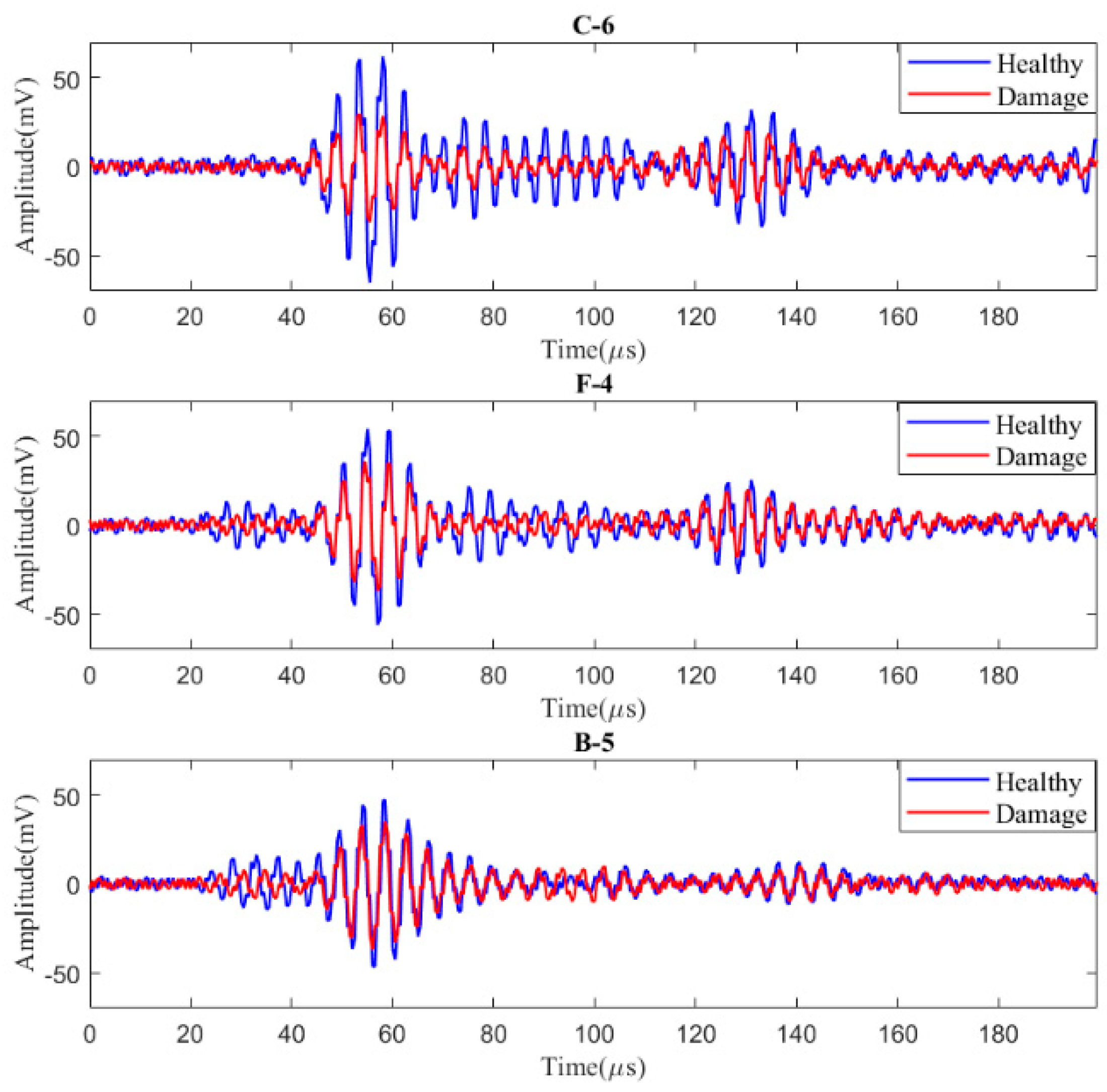

3. Results

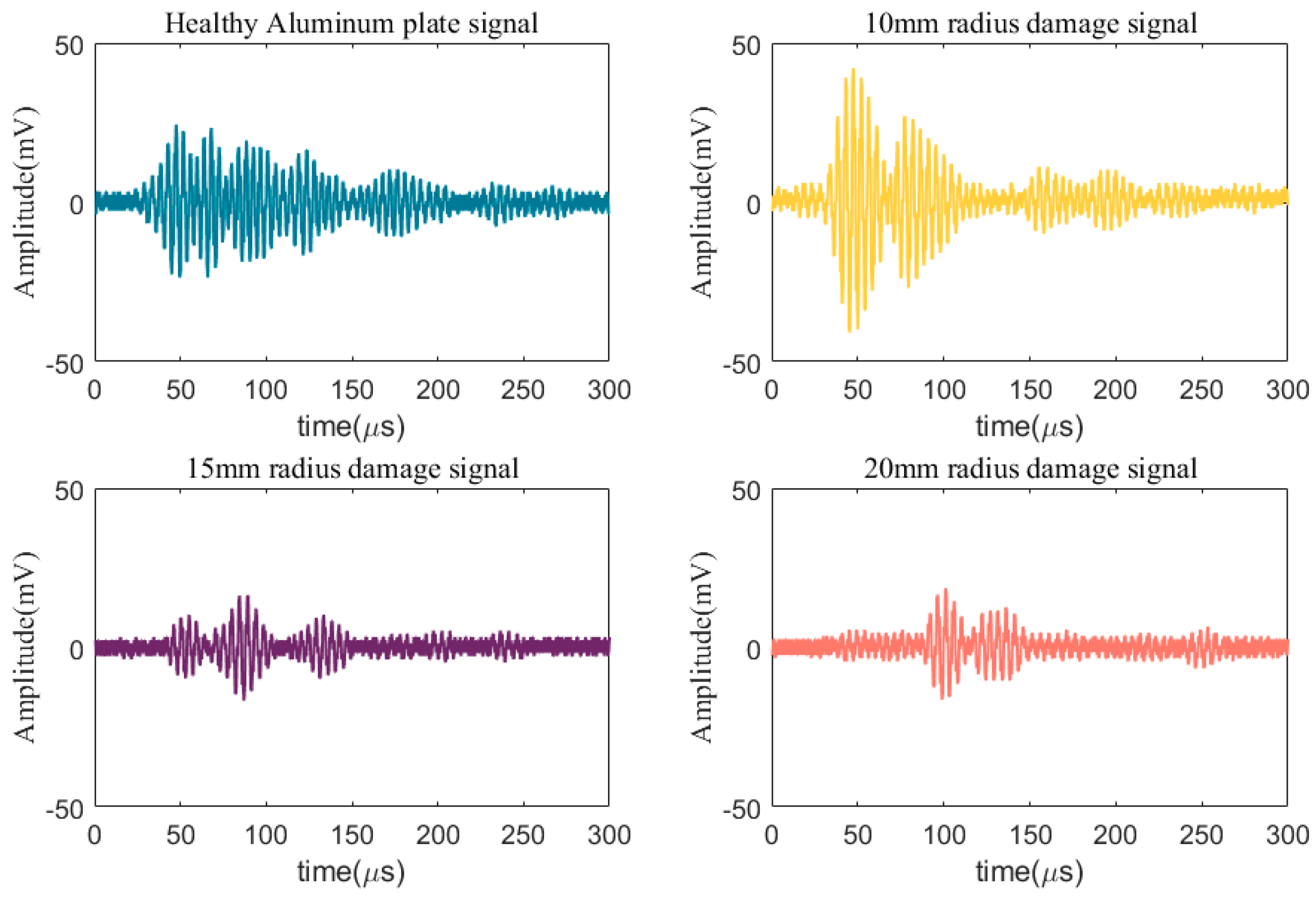

3.1. Signal Processing

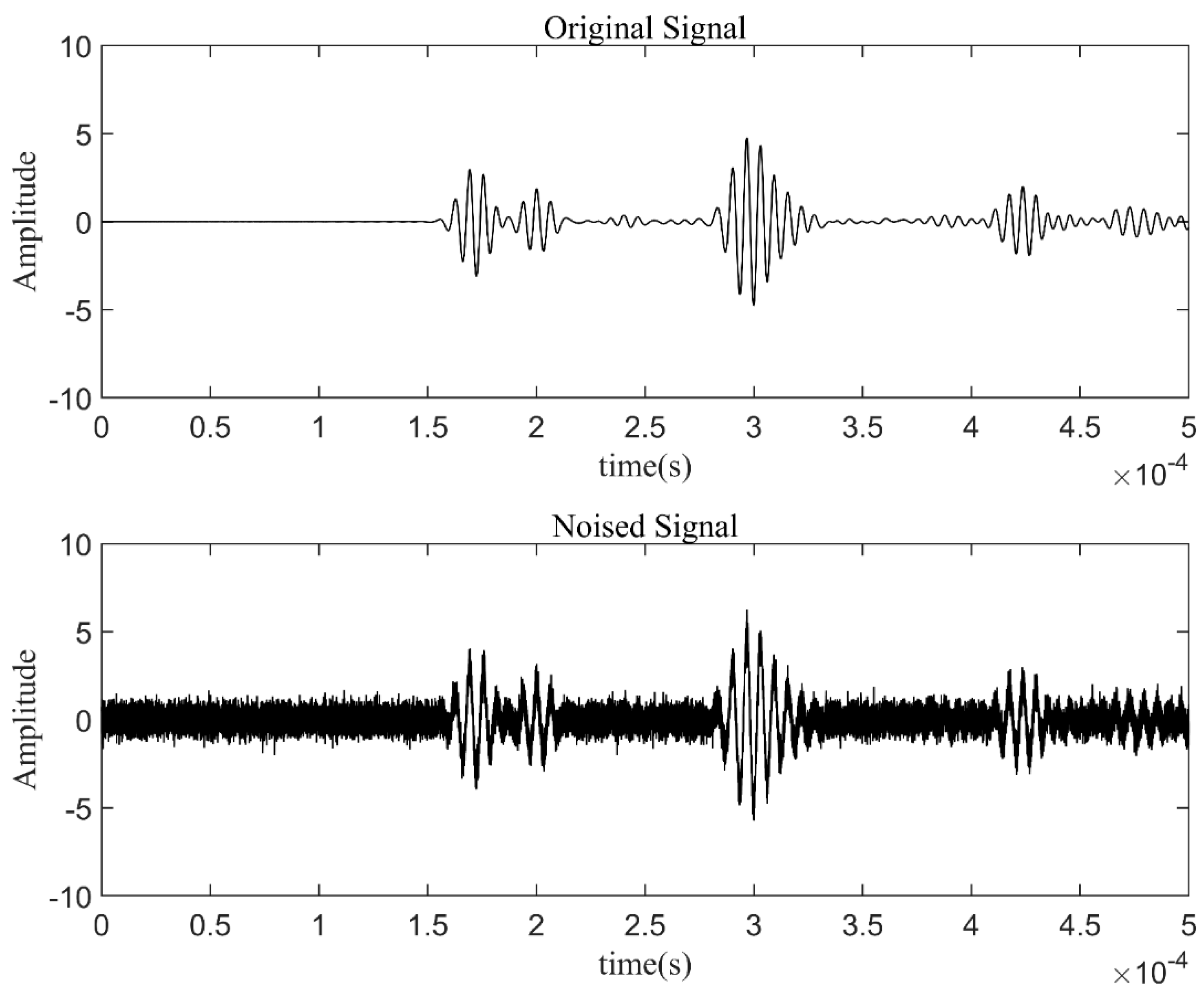

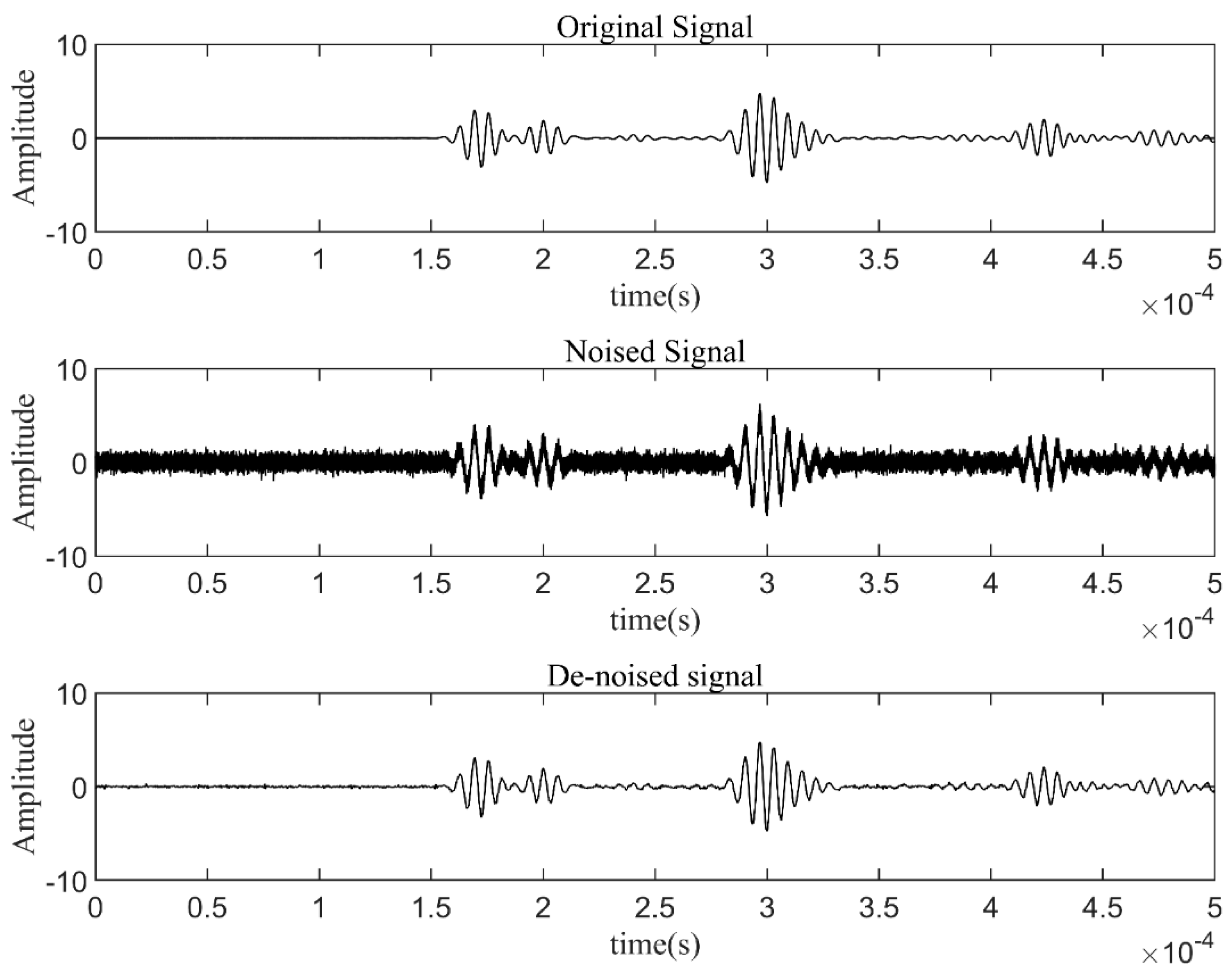

3.1.1. Lamb Wave Signal Denoising

- (1)

- Selection of wavelet threshold and threshold function

- (2)

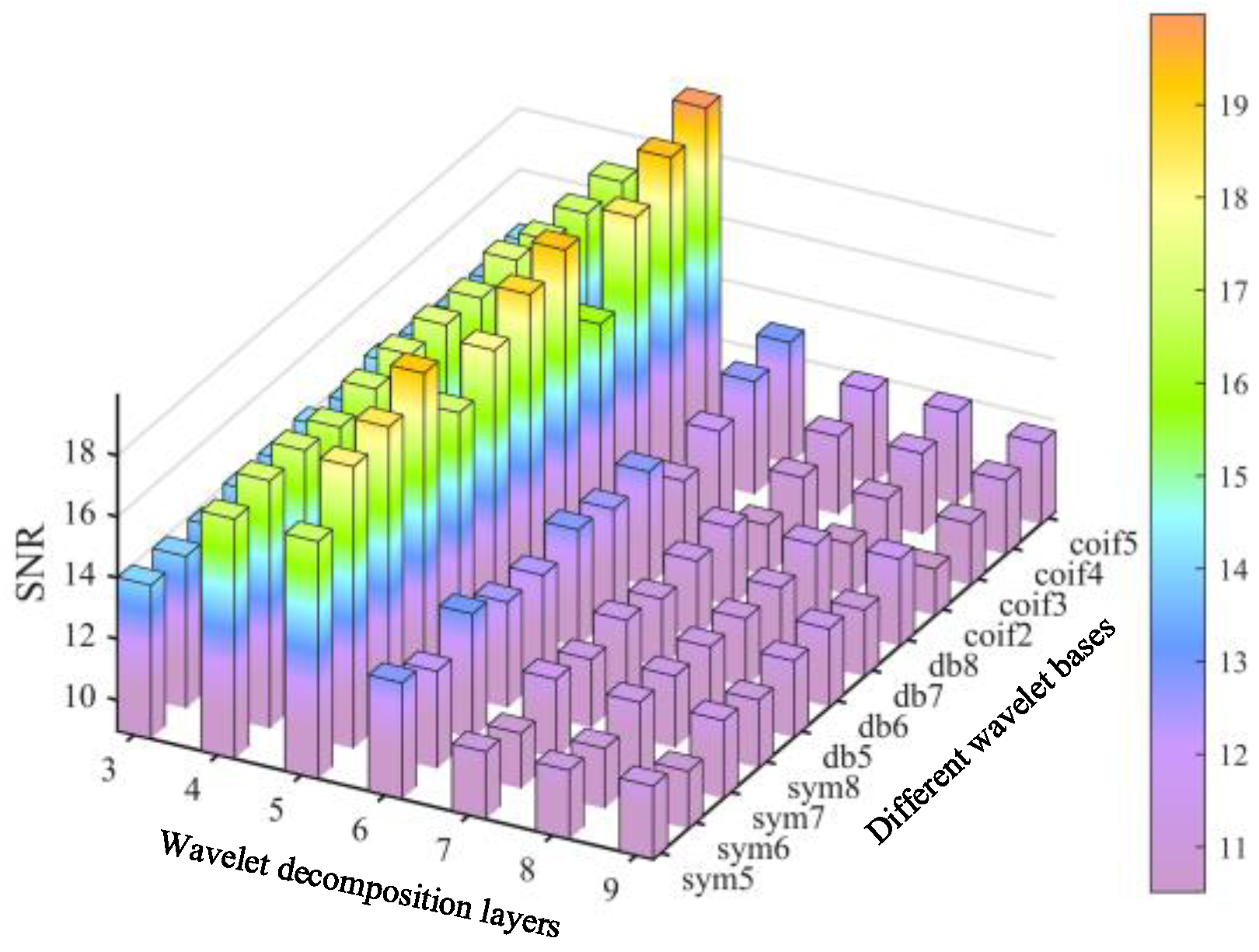

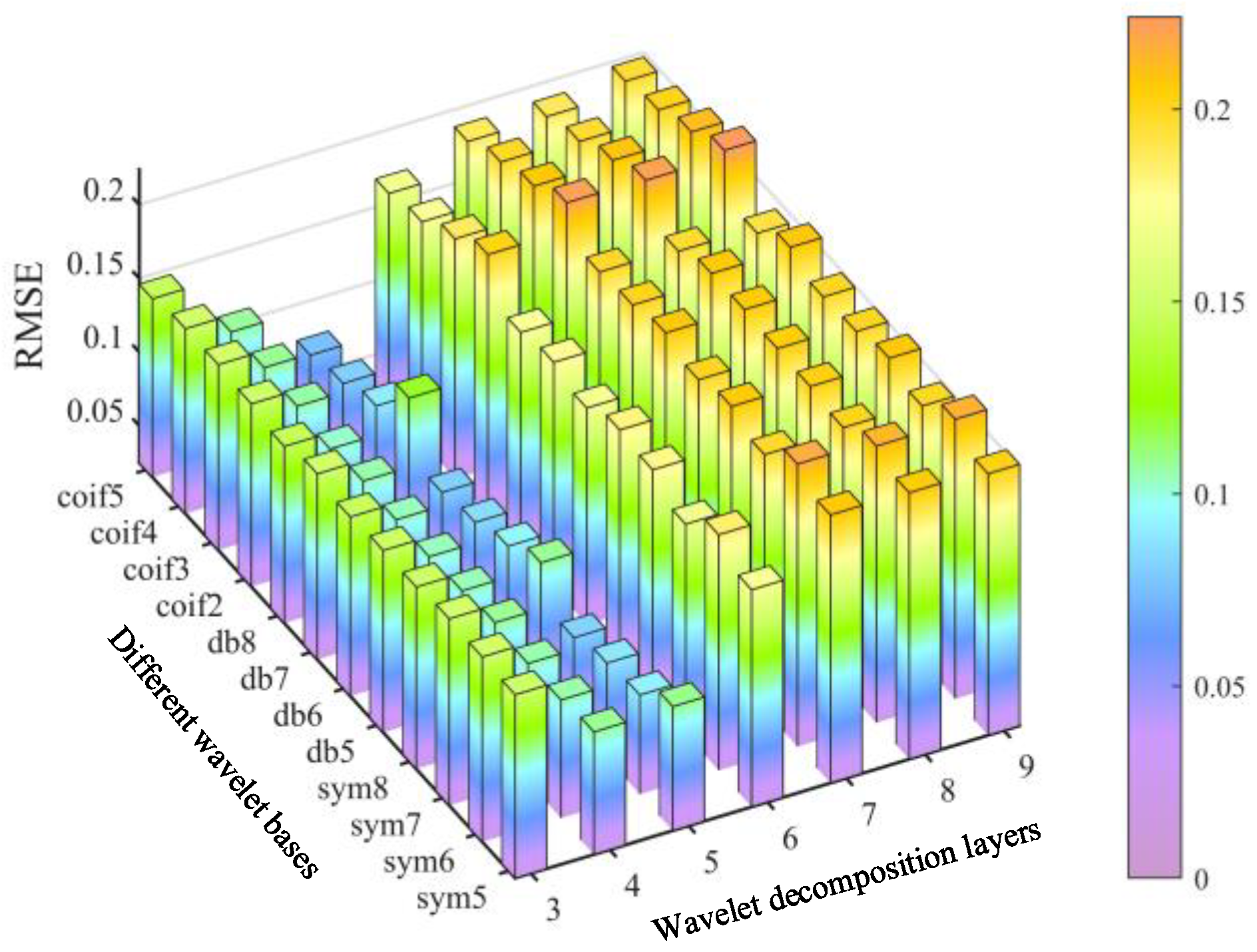

- Selection of wavelet basis function, wavelet basis order and decomposition level

3.1.2. Evaluation Metrics for Denoising Performance

3.1.3. Simulation Experiment for Denoising

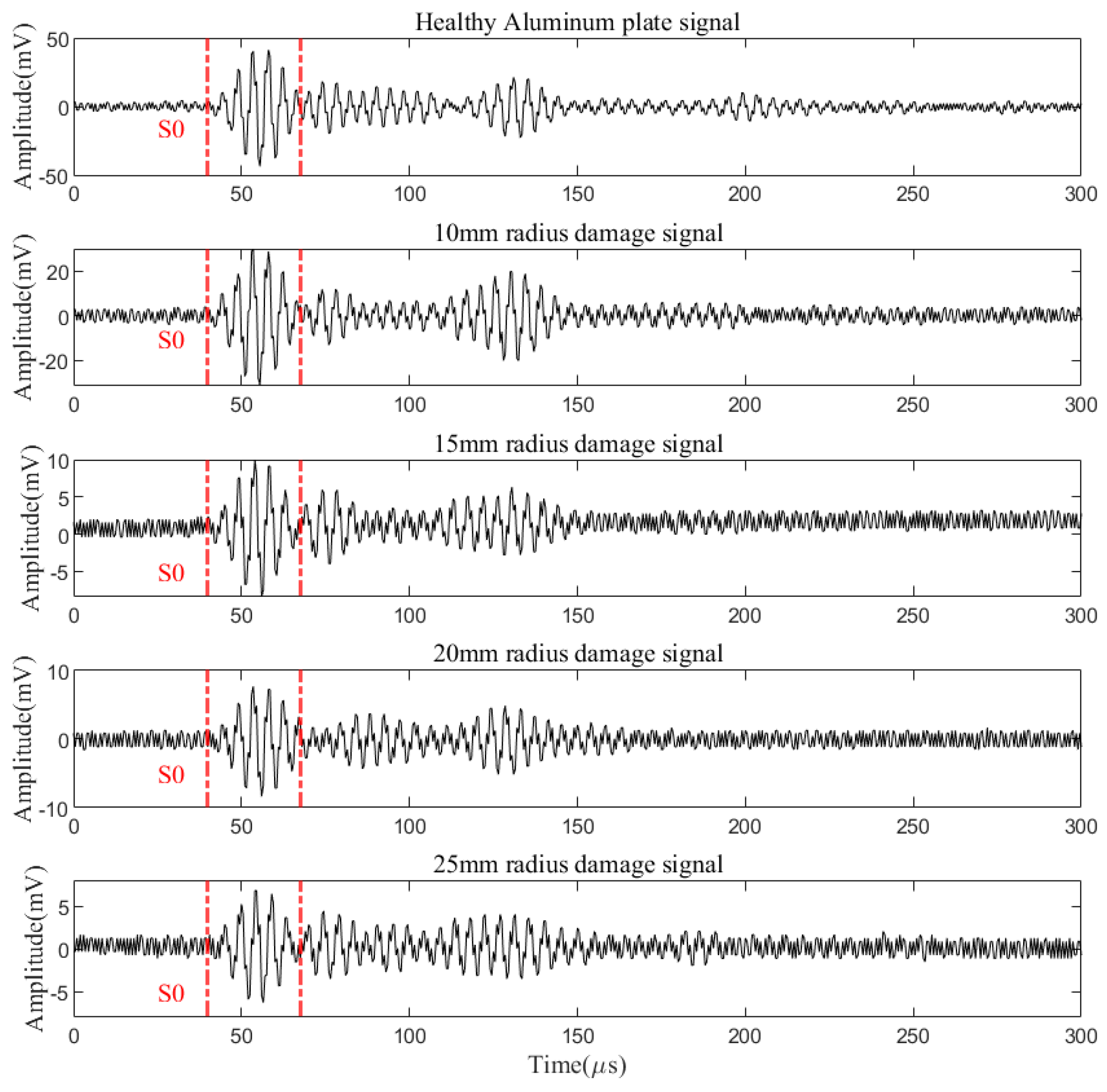

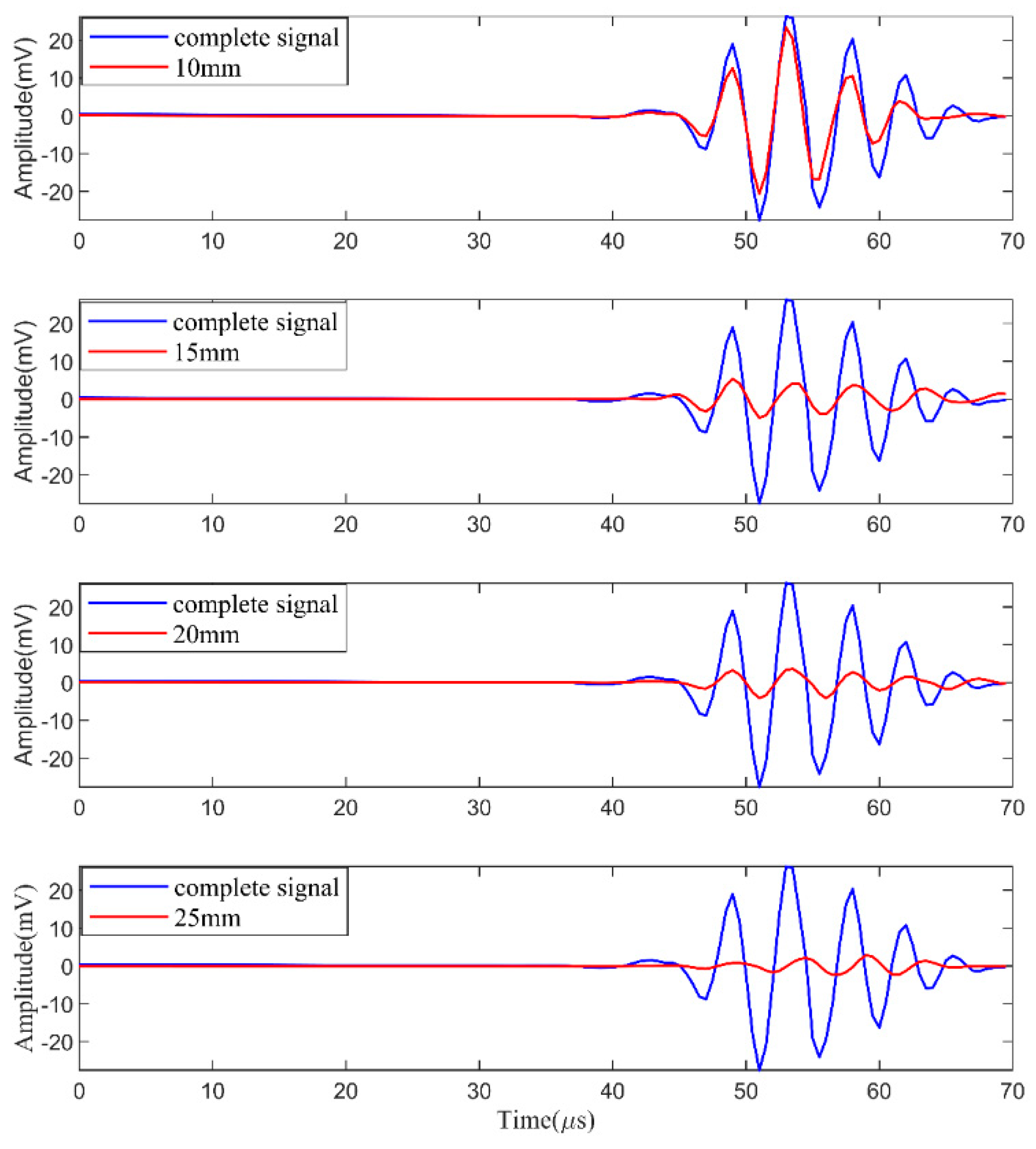

3.2. Damage Indexes

- (1)

- RMSE

- (2)

- SDC

- (3)

- (4)

- NCM

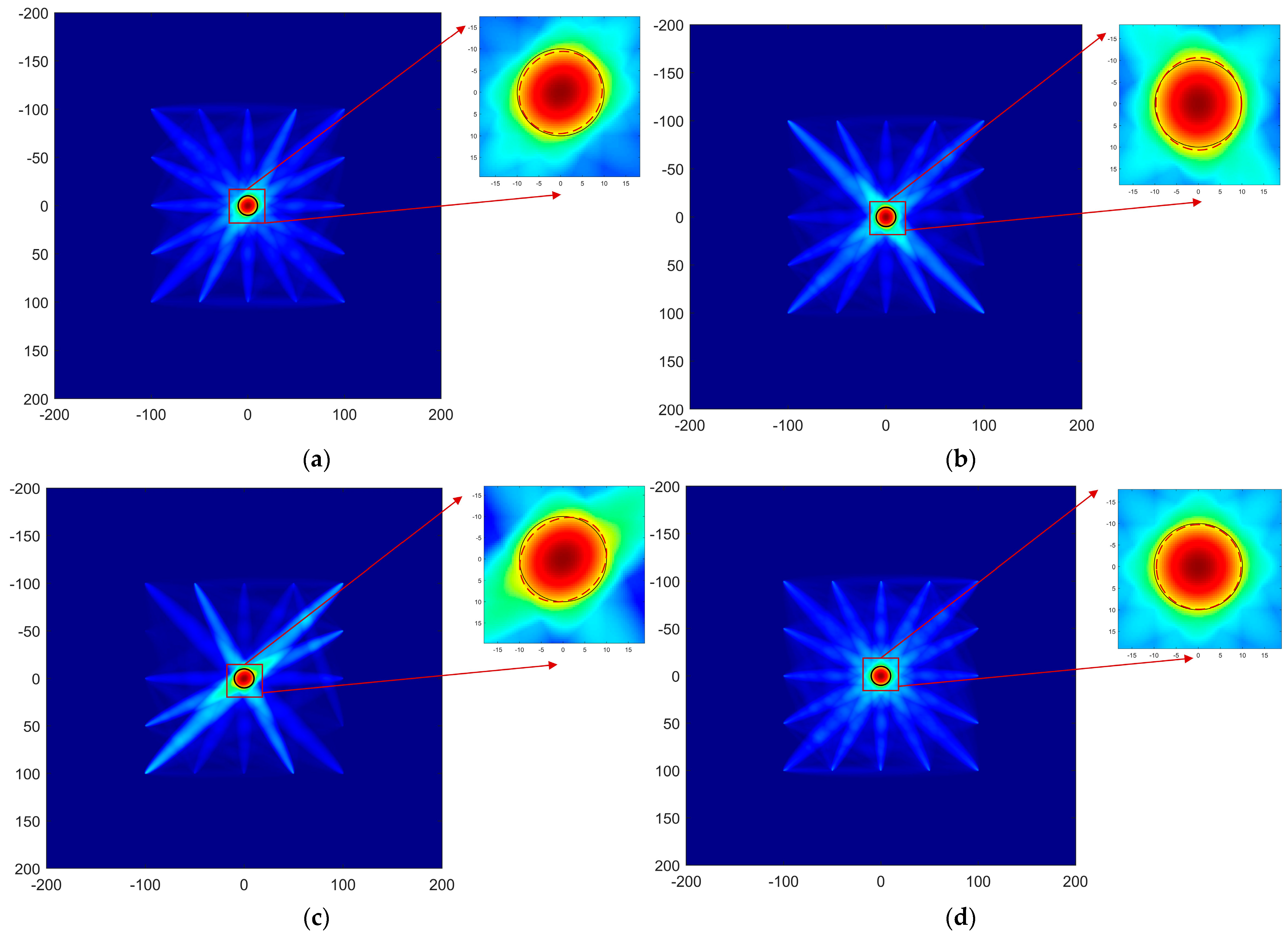

3.3. The Improved Imaging Algorithm

4. Discussion and Conclusions

- (1)

- A remote bonding FBGs damage monitoring system is established. The signal response characteristics of direct bonding and different remote bonding distances are investigated. It is found that 100 mm is the appropriate remote bonding distance, which ensures small signal amplitude attenuation and is convenient for signal extraction and analysis.

- (2)

- The soft threshold wavelet transform-based noise reduction is investigated. Different wavelet basis functions, orders and decomposition levels have an impact on the noise reduction results, and the coif5 wavelet with five decomposition levels has the best effect. A sensitivity analysis of the damage index is performed, which reveals that SDC, RMSE, E3, and NCM are all sensitive enough to give an accurate prediction of the location and shape of the damage.

- (3)

- The damage localization and imaging of hole defects is achieved by an improved damage probability detection reconstruction algorithm with an error smaller than 2%.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ostachowicz, W.; Kudela, P.; Krawczuk, M.; Zak, A. Guided Waves in Structures for SHM: The Time-Domain Spectral Element Method; Guided Waves in Structures for SHM: The Time-Domain Spectral Element Method; John Wiley and Sons: New York, NY, USA, 2012; ISBN 978-0-470-97983-9. [Google Scholar]

- Scuro, C.; Lamonaca, F.; Porzio, S.; Milani, G.; Olivito, R.S. Internet of Things (IoT) for masonry structural health monitoring (SHM): Overview and examples of innovative systems. Constr. Build. Mater. 2021, 290, 123092. [Google Scholar] [CrossRef]

- Senyurek, V.Y. Detection of cuts and impact damage at the aircraft wing slat by using Lamb wave method. Measurement 2015, 67, 10–23. [Google Scholar] [CrossRef]

- Sun, X.; Guo, C.; Yuan, L.; Kong, Q.; Ni, Y. Diffuse Ultrasonic Wave-Based Damage Detection of Railway Tracks Using PZT/FBG Hybrid Sensing System. Sensors 2022, 22, 2504. [Google Scholar] [CrossRef]

- Ladpli, P.; Kopsaftopoulos, F.; Chang, F.-K. Estimating state of charge and health of lithium-ion batteries with guided waves using built-in piezoelectric sensors/actuators. J. Power Sources 2018, 384, 342–354. [Google Scholar] [CrossRef]

- Zhao, G.; Liu, C.; Sun, L.; Yang, N.; Zhang, L.; Jiang, M.; Jia, L.; Sui, Q. Aluminum Alloy Fatigue Crack Damage Prediction Based on Lamb Wave-Systematic Resampling Particle Filter Method. Struct. Durab. Health Monit. 2022, 16, 81–96. [Google Scholar] [CrossRef]

- Gaumet, A.V.; Ball, R.J.; Nogaret, A. Graphite-polydimethylsiloxane composite strain sensors for in-situ structural health monitoring. Sens. Actuators Phys. 2021, 332, 113139. [Google Scholar] [CrossRef]

- Tang, D.; Chen, J.; Wu, W.; Jin, L.; Yue, Q.; Xie, B.; Wang, S.; Feng, J. Research on sampling rate selection of sensors in offshore platform shm based on vibration. Appl. Ocean Res. 2020, 101, 102192. [Google Scholar] [CrossRef]

- Cao, P.; Zhang, S.; Wang, Z.; Zhou, K. Damage identification using piezoelectric electromechanical Impedance: A brief review from a numerical framework perspective. Structures 2023, 50, 1906–1921. [Google Scholar] [CrossRef]

- Dai, D.; He, Q. Structure damage localization with ultrasonic guided waves based on a time–frequency method. Signal Process. 2014, 96, 21–28. [Google Scholar] [CrossRef]

- Murthy, M.N.; Kakade, P.D. Review on Strain Monitoring of Aircraft Using Optical Fibre Sensor. Int. J. Electron. Telecommun. 2022, 68, 625–634. [Google Scholar] [CrossRef]

- Li, F.; Peng, H.; Meng, G. Quantitative damage image construction in plate structures using a circular PZT array and lamb waves. Sens. Actuators Phys. 2014, 214, 66–73. [Google Scholar] [CrossRef]

- Jang, B.-W.; Kim, C.-G. Real-time detection of low-velocity impact-induced delamination onset in composite laminates for efficient management of structural health. Compos. Part B Eng. 2017, 123, 124–135. [Google Scholar] [CrossRef]

- Wee, J.; Hackney, D.A.; Bradford, P.D.; Peters, K.J. Simulating increased Lamb wave detection sensitivity of surface bonded fiber Bragg grating. Smart Mater. Struct. 2017, 26, 045034. [Google Scholar] [CrossRef]

- Wild, G.; Hinckley, S. Acousto-Ultrasonic Optical Fiber Sensors: Overview and State-of-the-Art. IEEE Sens. J. 2008, 8, 1184–1193. [Google Scholar] [CrossRef]

- Perez, I.; Cui, H.-L.; Udd, E. High Frequency Ultrasonic Wave Detection Using Fiber Bragg Gratings; SPIE 7th Annu. Int. Symp. Smart Struct. Mater.: Newport Beach, CA, USA, 6–9 March 2000. [Google Scholar]

- Tsuda, H. Ultrasound and damage detection in CFRP using fiber Bragg grating sensors. Compos. Sci. Technol. 2006, 66, 676–683. [Google Scholar] [CrossRef]

- Jiang, M.; Sui, Q.; Jia, L.; Peng, P.; Cao, Y. FBG-based ultrasonic wave detection and acoustic emission linear location system. Optoelectron. Lett. 2012, 8, 220–223. [Google Scholar] [CrossRef]

- Wu, Q.; Yu, F.; Okabe, Y.; Kobayashi, S. Application of a novel optical fiber sensor to detection of acoustic emissions by various damages in CFRP laminates. Smart Mater. Struct. 2015, 24, 015011. [Google Scholar] [CrossRef]

- Davis, C.; Rosalie, C.; Norman, P.; Rajic, N.; Habel, J.; Bernier, M. Remote Sensing of Lamb Waves Using Optical Fibres—An Investigation of Modal Composition. J. Light. Technol. 2018, 36, 2820–2826. [Google Scholar] [CrossRef]

- Wee, J.; Wells, B.; Hackney, D.; Bradford, P.; Peters, K. Increasing signal amplitude in fiber Bragg grating detection of Lamb waves using remote bonding. Appl. Opt. 2016, 55, 5564. [Google Scholar] [CrossRef]

- Yu, F.; Okabe, Y. Linear damage localization in CFRP laminates using one single fiber-optic Bragg grating acoustic emission sensor. Compos. Struct. 2020, 238, 111992. [Google Scholar] [CrossRef]

- Yu, F.; Okabe, Y.; Wu, Q.; Shigeta, N. Fiber-optic sensor-based remote acoustic emission measurement of composites. Smart Mater. Struct. 2016, 25, 105033. [Google Scholar] [CrossRef]

- Sheen, B.; Cho, Y. A study on quantitative lamb wave tomogram via modified RAPID algorithm with shape factor optimization. Int. J. Precis. Eng. Manuf. 2012, 13, 671–677. [Google Scholar] [CrossRef]

- Rogers, W.P. Elastic Property Measurement Using Rayleigh-Lamb Waves. Res. Nondestruct. Eval. 1995, 6, 185–208. [Google Scholar] [CrossRef]

- Fan, Y.; Kahrizi, M. Characterization of a FBG strain gage array embedded in composite structure. Sens. Actuators Phys. 2005, 121, 297–305. [Google Scholar] [CrossRef]

- Betz, D.C.; Staszewski, W.J.; Thursby, G.; Culshaw, B. Identification of structural damage using multifunctional Bragg grating sensors: I. Theory and implementation. Smart Mater. Struct. 2006, 15, 1305–1312. [Google Scholar] [CrossRef]

- Lee, J.-R.; Tsuda, H.; Toyama, N. Impact wave and damage detections using a strain-free fiber Bragg grating ultrasonic receiver. NDT E Int. 2007, 40, 85–93. [Google Scholar] [CrossRef]

- Tsuda, H.; Kumakura, K.; Ogihara, S. Ultrasonic Sensitivity of Strain-Insensitive Fiber Bragg Grating Sensors and Evaluation of Ultrasound-Induced Strain. Sensors 2010, 10, 11248–11258. [Google Scholar] [CrossRef]

- Teng, F.; Wei, J.; Lv, S.; Peng, C.; Zhang, L.; Ju, Z.; Jia, L.; Jiang, M. Ultrasonic Guided Wave Damage Localization in Hole-Structural Bearing Crossbeam Based on Improved RAPID Algorithm. IEEE Trans. Instrum. Meas. 2022, 71, 1–13. [Google Scholar] [CrossRef]

- Daubechies, I. The wavelet transform, time-frequency localization and signal analysis. IEEE Trans. Inf. Theory 1990, 36, 961–1005. [Google Scholar] [CrossRef]

- Feldman, M. Hilbert transform in vibration analysis. Mech. Syst. Signal Process. 2011, 25, 735–802. [Google Scholar] [CrossRef]

- Wang, Z.; Qiao, P.; Shi, B. Application of soft-thresholding on the decomposed Lamb wave signals for damage detection of plate-like structures. Measurement 2016, 88, 417–427. [Google Scholar] [CrossRef]

- Park, S.; Yun, C.-B.; Roh, Y.; Lee, J.-J. PZT-based active damage detection techniques for steel bridge components. Smart Mater. Struct. 2006, 15, 957. [Google Scholar] [CrossRef]

- Wu, Z.; Qing, X.P.; Ghosh, K.; Karbhar, V.; Chang, F.-K. Health monitoring of bonded composite repair in bridge rehabilitation. Smart Mater. Struct. 2008, 17, 045014. [Google Scholar] [CrossRef]

- Torkamani, S.; Roy, S.; Barkey, M.E.; Sazonov, E.; Burkett, S.; Kotru, S. A novel damage index for damage identification using guided waves with application in laminated composites. Smart Mater. Struct. 2014, 23, 095015. [Google Scholar] [CrossRef]

| Elastic Modulus (E) | Poisson Ratio (v) | Density (ρ) |

|---|---|---|

| 70 GPa | 0.32 | 2.85 g/cm3 |

| Si | Fe | Cu | Mn | Mg | C | Zn | Ti | V | Zr | |

|---|---|---|---|---|---|---|---|---|---|---|

| Max % weight | 0.4 | 0.50 | 2.0 | 0.30 | 2.9 | 0.28 | 6.1 | 0.20 | 0.05 | 0.05 |

| Wavelet Function Name | sym8 | db8 | coif5 |

|---|---|---|---|

| RMSE | 0.0817 | 0.0813 | 0.0754 |

| DI | Damage Area/mm2 | Predicted Area/mm2 | Damage Shape Ratio % |

|---|---|---|---|

| SDC | 314 | 296.75 | 94.50 |

| RMSE | 314 | 317.25 | 101.03 |

| E3 | 314 | 298 | 94.90 |

| NCM | 314 | 307.75 | 98.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, L.; Wang, M.; Chai, L.; Liu, D.; Zhang, W.; Zhang, W. Damage Monitoring and Localization Imaging of Aluminum Alloy Thin-Walled Structure Based on Remote Bonding Fiber Bragg Gratings Sensing. Materials 2024, 17, 652. https://doi.org/10.3390/ma17030652

Han L, Wang M, Chai L, Liu D, Zhang W, Zhang W. Damage Monitoring and Localization Imaging of Aluminum Alloy Thin-Walled Structure Based on Remote Bonding Fiber Bragg Gratings Sensing. Materials. 2024; 17(3):652. https://doi.org/10.3390/ma17030652

Chicago/Turabian StyleHan, Lu, Mi Wang, Lindong Chai, Dingyun Liu, Weifang Zhang, and Wei Zhang. 2024. "Damage Monitoring and Localization Imaging of Aluminum Alloy Thin-Walled Structure Based on Remote Bonding Fiber Bragg Gratings Sensing" Materials 17, no. 3: 652. https://doi.org/10.3390/ma17030652

APA StyleHan, L., Wang, M., Chai, L., Liu, D., Zhang, W., & Zhang, W. (2024). Damage Monitoring and Localization Imaging of Aluminum Alloy Thin-Walled Structure Based on Remote Bonding Fiber Bragg Gratings Sensing. Materials, 17(3), 652. https://doi.org/10.3390/ma17030652