Near-Field Direct Write Electrospinning of PET-Carbon Quantum Dot Solutions

Abstract

1. Introduction

2. Material and Methods

2.1. Materials

2.2. Preparation of Spinning Dope

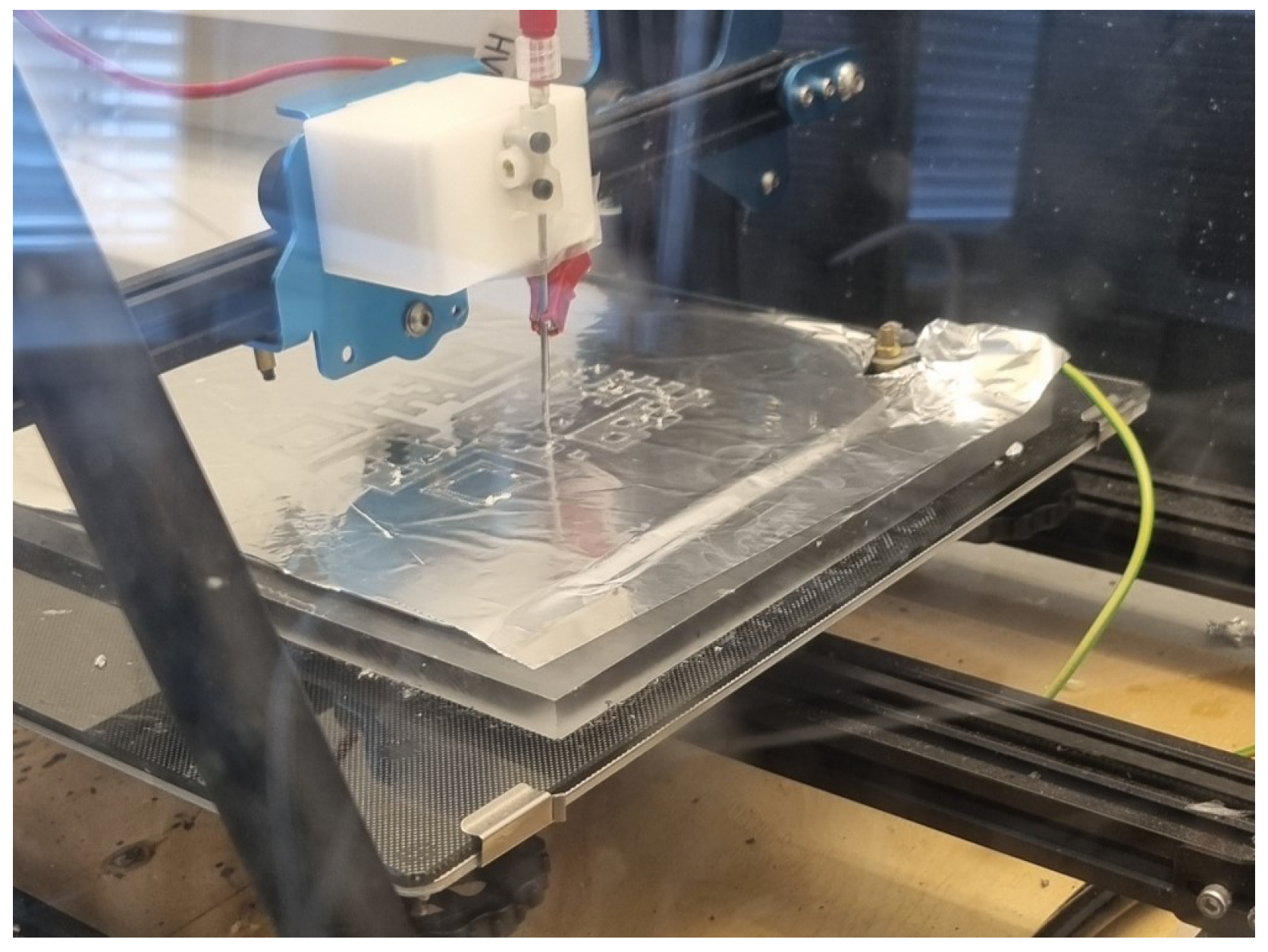

2.3. Electrospinning Process

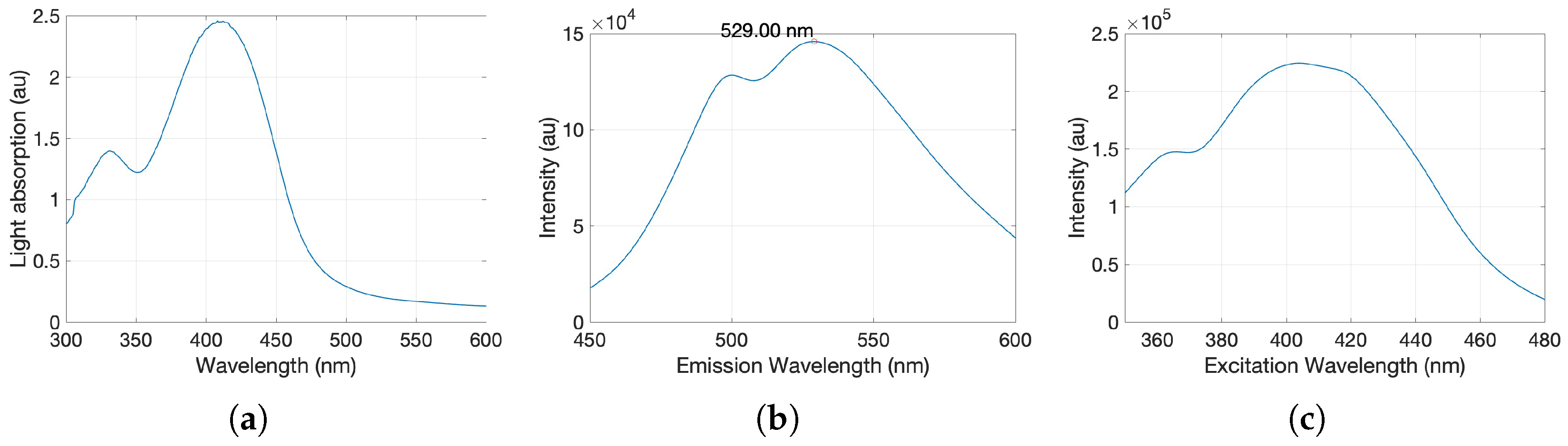

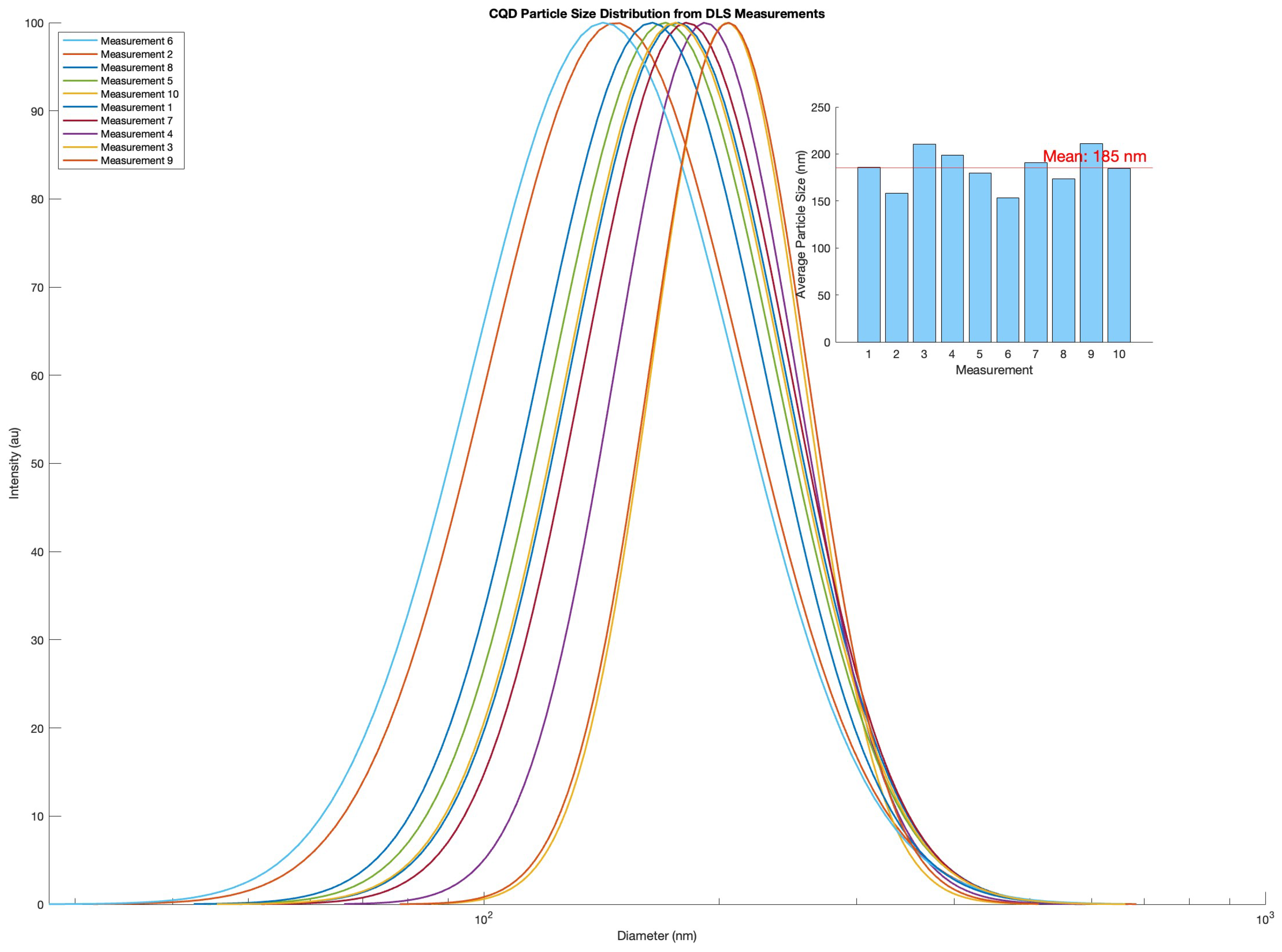

2.4. Preparation and Characterization of Carbon Quantum Dots

3. Results and Discussion

3.1. Carbon Quantum Dots Synthesis and Characterization

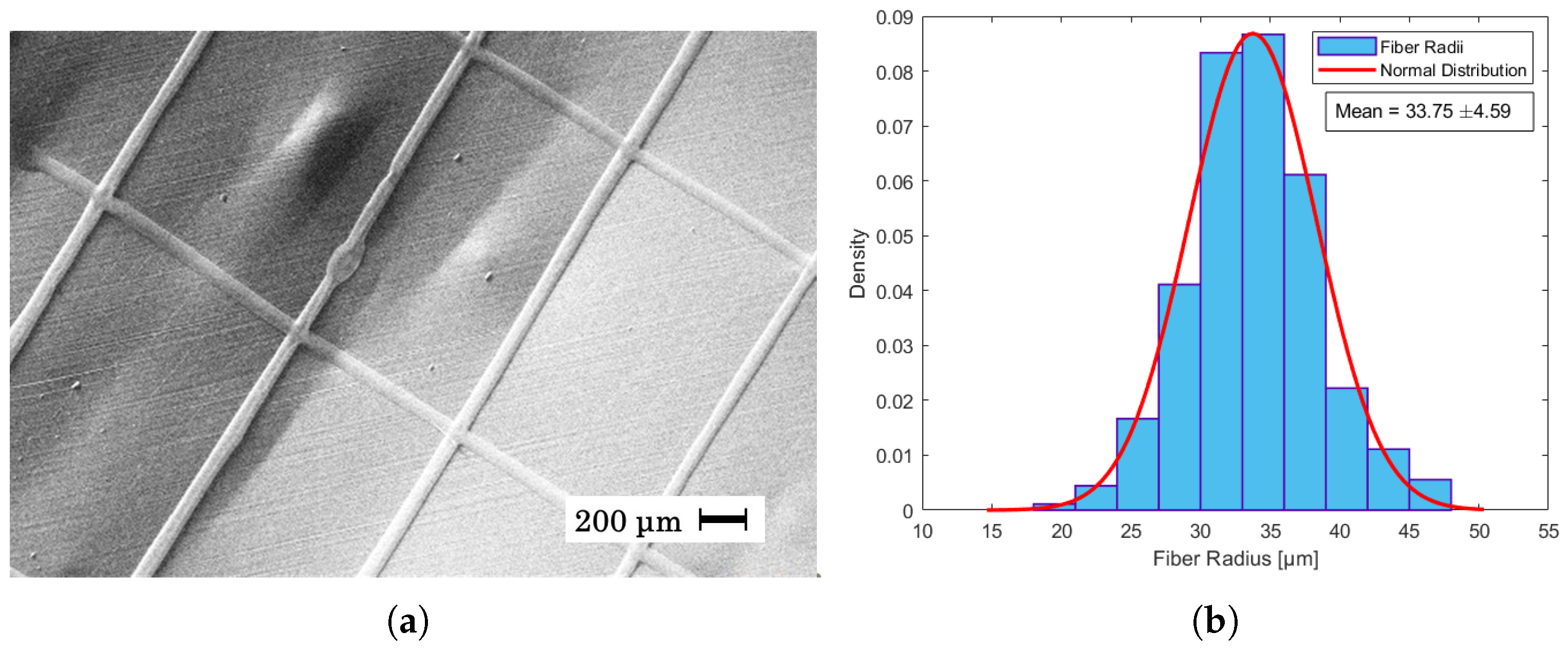

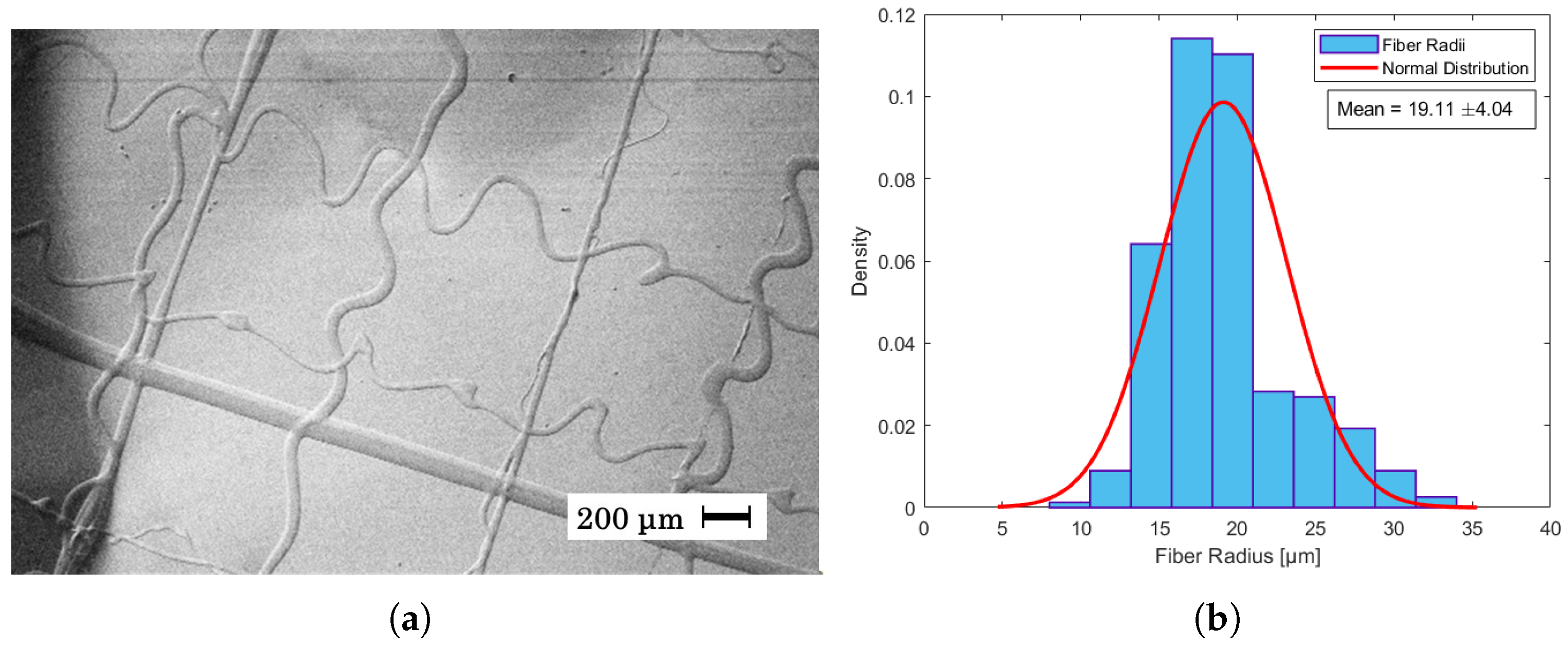

3.2. Near-Field Direct Writing of PET Spinning Dope

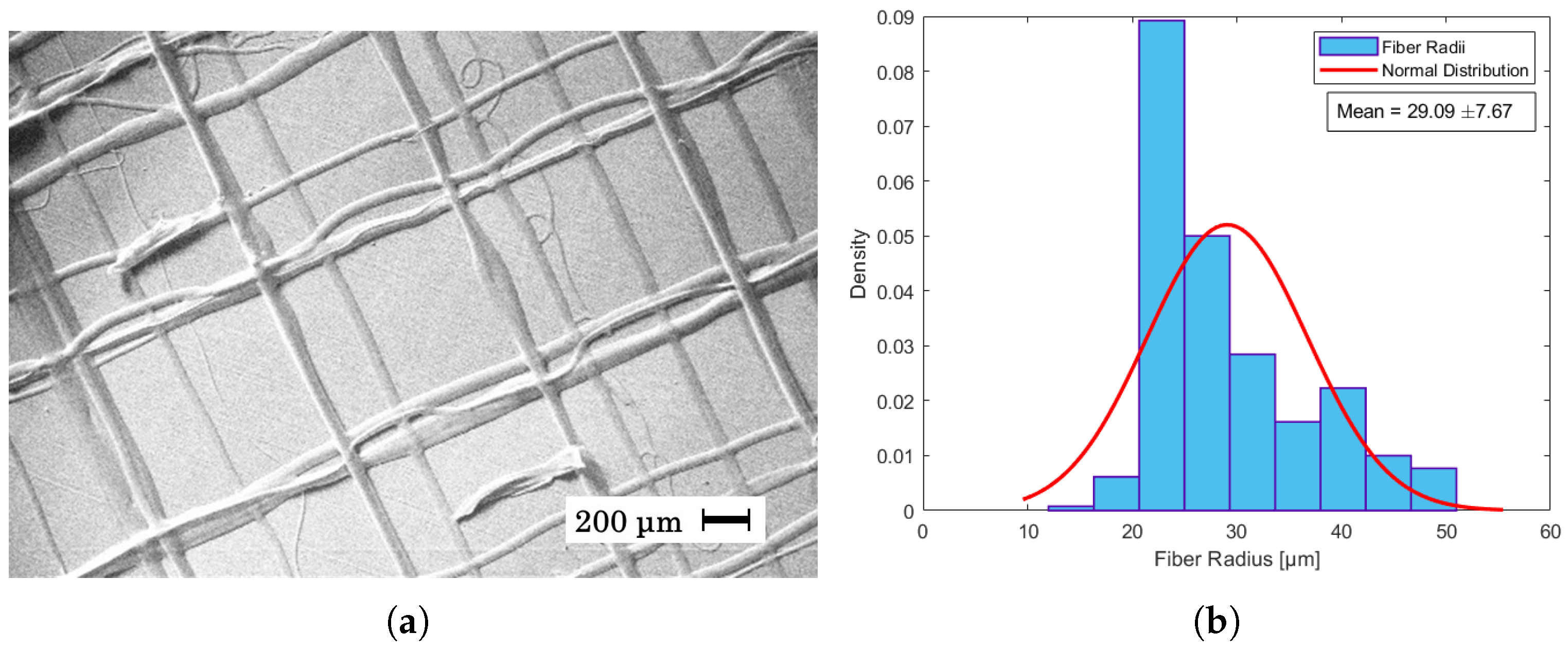

3.3. Solution Direct Write Electrospinning Containing Carbon Quantum Dots

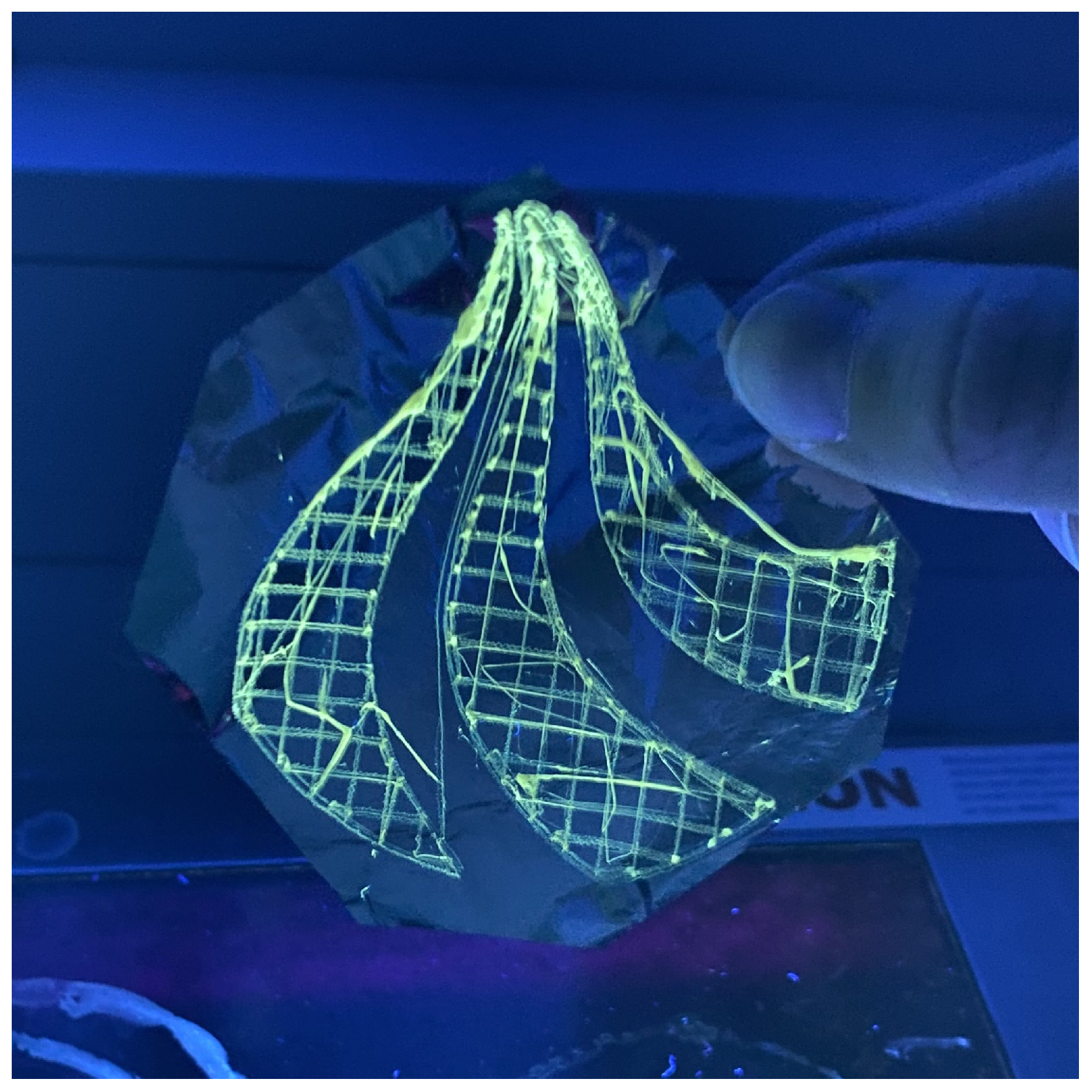

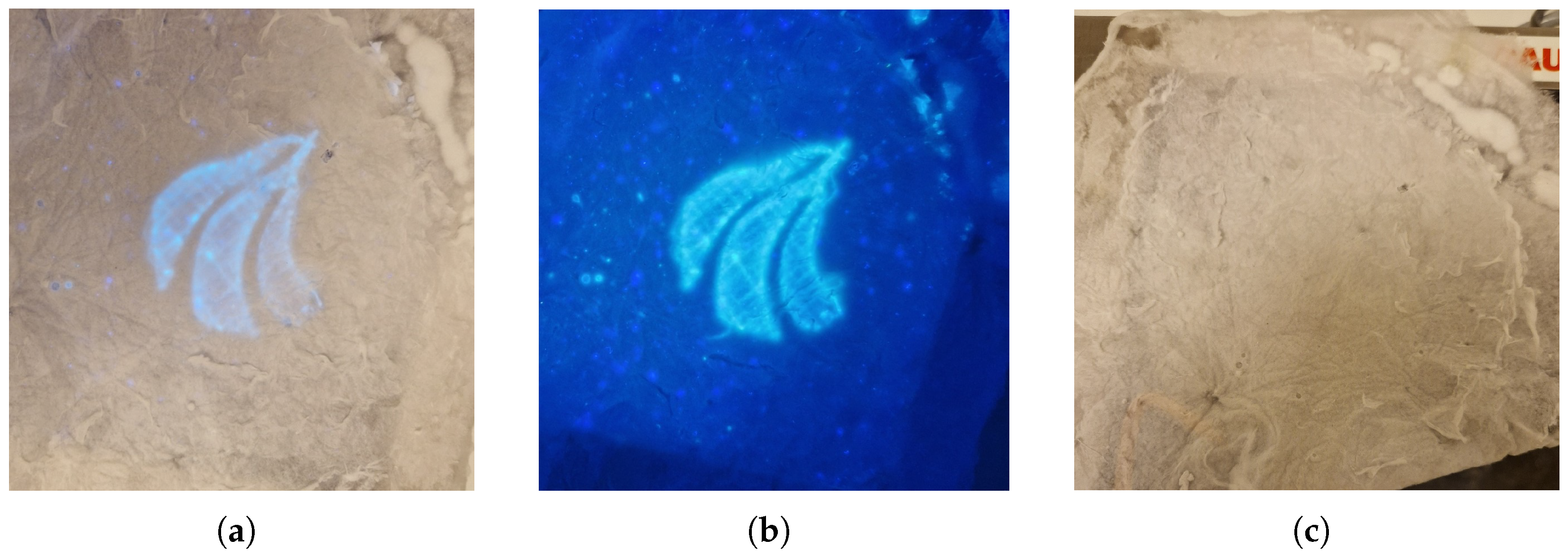

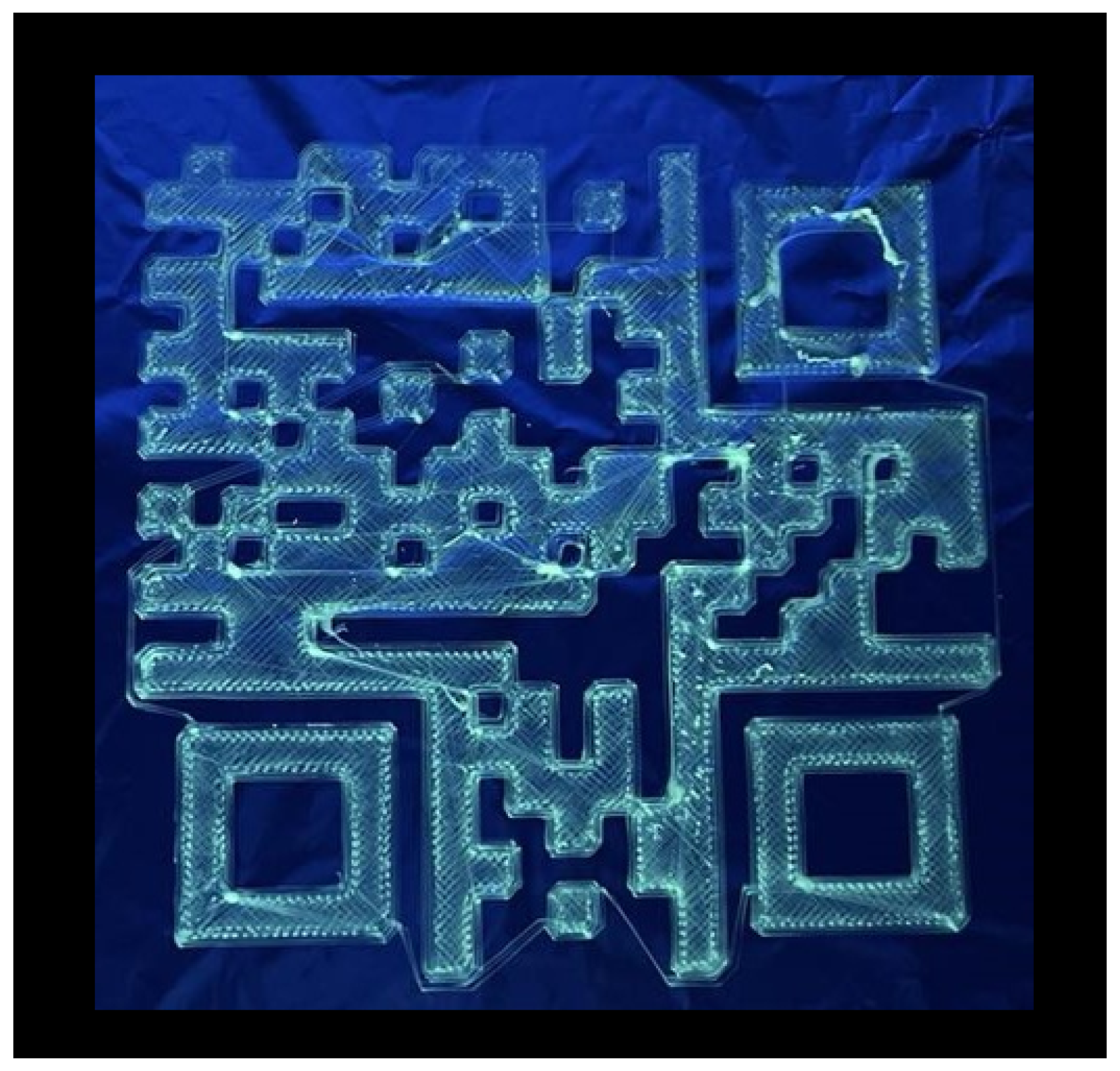

3.4. Precision and Information Storage with Solution Near-Field Direct Write Electrospinning

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Aman Mohammadi, M.; Hosseini, S.M.; Yousefi, M. Application of electrospinning technique in development of intelligent food packaging: A short review of recent trends. Food Sci. Nutr. 2020, 8, 4656–4665. [Google Scholar] [CrossRef] [PubMed]

- Cui, J.; Li, F.; Wang, Y.; Zhang, Q.; Ma, W.; Huang, C. Electrospun nanofiber membranes for wastewater treatment applications. Sep. Purif. Technol. 2020, 250, 117116. [Google Scholar] [CrossRef]

- Pu, S.; Zan, G.; Zhou, H.; Dong, K.; Mao, X.; Wu, Q.; Wu, T. Sustaining 500,000 Folding Cycles through Bioinspired Stress Dispersion Design in Sodium-Ion Batteries. Angew. Chem. Int. Ed. 2024, e202417589. [Google Scholar] [CrossRef]

- Lin, H.; Peng, Y.; Zhang, F.; Ke, X.; Sai, L.; Wang, F.; Zhou, H.; Zheng, N.; Huang, Z.; Zhou, H. Sandwich-structured electrospun polyvinylidene difluoride sensor for structural health monitoring of glass fiber reinforced polymer composites. Microstructures 2024, 4, 2024053. [Google Scholar] [CrossRef]

- Mohtaram, F.; Borhani, S.; Ahmadpour, M.; Fojan, P.; Behjat, A.; Rubahn, H.G.; Madsen, M. Electrospun ZnO nanofiber interlayers for enhanced performance of organic photovoltaic devices. Sol. Energy 2020, 197, 311–316. [Google Scholar] [CrossRef]

- He, F.; Wang, Y.; Liu, J.; Yao, X. One-dimensional carbon based nanoreactor fabrication by electrospinning for sustainable catalysis. Exploration 2023, 3, 20220164. [Google Scholar] [CrossRef]

- Ji, D.; Lin, Y.; Guo, X.; Ramasubramanian, B.; Wang, R.; Radacsi, N.; Jose, R.; Qin, X.; Ramakrishna, S. Electrospinning of nanofibres. Nat. Rev. Methods Prim. 2024, 4, 1. [Google Scholar] [CrossRef]

- Xu, H.; Yagi, S.; Ashour, S.; Du, L.; Hoque, M.E.; Tan, L. A review on current nanofiber technologies: Electrospinning, centrifugal spinning, and electro-centrifugal spinning. Macromol. Mater. Eng. 2023, 308, 2200502. [Google Scholar] [CrossRef]

- Nadaf, A.; Gupta, A.; Hasan, N.; Ahmad, S.; Kesharwani, P.; Ahmad, F.J. Recent update on electrospinning and electrospun nanofibers: Current trends and their applications. RSC Adv. 2022, 12, 23808–23828. [Google Scholar] [CrossRef]

- Xie, Y.S.; Cheng, Y.; Lyu, Y.; Li, R.; Han, J.C. Printable, flexible ceramic fiber paper based on electrospinning. Rare Met. 2024, 43, 2739–2746. [Google Scholar] [CrossRef]

- King, W.E., III; Bowlin, G.L. Near-field electrospinning and melt electrowriting of biomedical polymers—Progress and limitations. Polymers 2021, 13, 1097. [Google Scholar] [CrossRef] [PubMed]

- Nazemi, M.M.; Khodabandeh, A.; Hadjizadeh, A. Near-field electrospinning: Crucial parameters, challenges, and applications. ACS Appl. Bio Mater. 2022, 5, 394–412. [Google Scholar] [CrossRef] [PubMed]

- Zhong, H.; Huang, J.; Luo, M.; Fang, Y.; Zeng, X.; Wu, J.; Du, J. Near-field electrospun PCL fibers/GelMA hydrogel composite dressing with controlled deferoxamine-release ability and retiform surface for diabetic wound healing. Nano Res. 2023, 16, 599–612. [Google Scholar] [CrossRef]

- Wang, W.; Stipp, P.N.; Ouaras, K.; Fathi, S.; Huang, Y.Y.S. Broad bandwidth, self-powered acoustic sensor created by dynamic near-field electrospinning of suspended, transparent piezoelectric nanofiber mesh. Small 2020, 16, 2000581. [Google Scholar] [CrossRef]

- Jiang, H.; Luo, X.; Chen, Q.; Xu, F.; Zhu, G.; Jiang, Z.; Guliakova, A.A. Near-field electrospinning fabrication of piezoelectric polymer microfiber sensors for detection of weak mechanical excitation. IET Nanodielectr. 2023, 6, 64–72. [Google Scholar] [CrossRef]

- George, D.; Garcia, A.; Pham, Q.; Perez, M.R.; Deng, J.; Nguyen, M.T.; Zhou, T.; Martinez-Chapa, S.O.; Won, Y.; Liu, C.; et al. Fabrication of patterned graphitized carbon wires using low voltage near-field electrospinning, pyrolysis, electrodeposition, and chemical vapor deposition. Microsyst. Nanoeng. 2020, 6, 7. [Google Scholar] [CrossRef]

- Chou, H.M.; Yang, H.C. 2D circular-shaped sensor of poly (vinylidene fluoride) piezoelectric fibers fabricated through near-field direct-write electrospinning. Mod. Phys. Lett. B 2023, 37, 2340013. [Google Scholar] [CrossRef]

- Huang, Y.; You, X.; Fan, X.; Wong, C.P.; Guo, P.; Zhao, N. Near-Field Electrospinning Enabled Highly Sensitive and Anisotropic Strain Sensors. Adv. Mater. Technol. 2020, 5, 2000550. [Google Scholar] [CrossRef]

- Huang, Y.; You, X.; Tang, Z.; Tong, K.Y.; Guo, P.; Zhao, N. Interface Engineering of Flexible Piezoresistive Sensors via near-Field Electrospinning Processed Spacer Layers. Small Methods 2021, 5, 2000842. [Google Scholar] [CrossRef]

- Guo, Y.; He, W.; Liu, J. Electrospinning polyethylene terephthalate/SiO2 nanofiber composite needle felt for enhanced filtration performance. J. Appl. Polym. Sci. 2020, 137, 48282. [Google Scholar] [CrossRef]

- Ko, Y.; Hinestroza, J.P.; Uyar, T. Structural Investigation on Electrospun Nanofibers from Postconsumer Polyester Textiles and PET Bottles. ACS Appl. Polym. Mater. 2023, 5, 7298–7307. [Google Scholar] [CrossRef]

- Jafari, S.; Hosseini Salekdeh, S.S.; Solouk, A.; Yousefzadeh, M. Electrospun polyethylene terephthalate (PET) nanofibrous conduit for biomedical application. Polym. Adv. Technol. 2020, 31, 284–296. [Google Scholar] [CrossRef]

- Ahmed, H.; Saleem, P.; Yasin, S.; Saeed, I. The application of modified polyetheleneterphthalate (pet) nanofibers; Characterization and isotherm study. J. Phys. Conf. Ser. 2021, 1853, 012006. [Google Scholar] [CrossRef]

- Bonfim, D.P.; Cruz, F.G.; Guerra, V.G.; Aguiar, M.L. Development of filter media by electrospinning for air filtration of nanoparticles from PET bottles. Membranes 2021, 11, 293. [Google Scholar] [CrossRef]

- Pebdeni, A.B.; Hosseini, M.; Barkhordari, A. Smart fluorescence aptasensor using nanofiber functionalized with carbon quantum dot for specific detection of pathogenic bacteria in the wound. Talanta 2022, 246, 123454. [Google Scholar] [CrossRef]

- Shahba, H.; Sabet, M. Two-step and green synthesis of highly fluorescent carbon quantum dots and carbon nanofibers from pine fruit. J. Fluoresc. 2020, 30, 927–938. [Google Scholar] [CrossRef]

- Nie, X.; Wu, S.; Mensah, A.; Lu, K.; Wei, Q. Carbon quantum dots embedded electrospun nanofibers for efficient antibacterial photodynamic inactivation. Mater. Sci. Eng. C 2020, 108, 110377. [Google Scholar] [CrossRef]

- Kenwright, A.; Peace, S.; Richards, R.; Bunn, A.; MacDonald, W. End group modification in poly (ethylene terephthalate). Polymer 1999, 40, 2035–2040. [Google Scholar] [CrossRef]

- Orlando, R.; Afshari, A.; Fojan, P. Cellulose acetate-TiO2 and activated carbon electrospun composite fibre membranes for toluene removal. J. Ind. Text. 2023, 53, 15280837221150200. [Google Scholar] [CrossRef]

- Creality. Creatily 3D Printer, CR-10 V2. Available online: https://www.crealitycloud.com/product/details/CR-10-V2-60482e235852812341df358c (accessed on 5 August 2024).

- UltiMaker. UltiMaker Cura 5.7.0. Available online: https://ultimaker.com/software/ultimaker-cura/ (accessed on 3 May 2024).

- Generator, T.I.B. Barcode.tec. Available online: https://barcode.tec-it.com/en/QRCode?data=AAU%0A (accessed on 3 May 2024).

- Qu, S.; Liu, X.; Guo, X.; Chu, M.; Zhang, L.; Shen, D. Amplified Spontaneous Green Emission and Lasing Emission from Carbon Nanoparticles. Adv. Funct. Mater. 2014, 24, 2689–2695. [Google Scholar] [CrossRef]

- Qu, S.; Zhou, D.; Li, D.; Ji, W.; Jing, P.; Han, D.; Liu, L.; Zeng, H.; Shen, D. Toward Efficient Orange Emissive Carbon Nanodots through Conjugated sp2-Domain Controlling and Surface Charges Engineering. Adv. Mater. 2016, 28, 3516–3521. [Google Scholar] [CrossRef] [PubMed]

- Mulkerns, N.M.C.; Hoffmann, W.H.; Ramos-Soriano, J.; de la Cruz, N.; Garcia-Millan, T.; Harniman, R.L.; Lindsay, I.D.; Seddon, A.M.; Galan, M.C.; Gersen, H. Measuring the refractive index and sub-nanometre surface functionalisation of nanoparticles in suspension. Nanoscale 2022, 14, 8145–8152. [Google Scholar] [CrossRef] [PubMed]

- Javed, N.; O’Carroll, D.M. Long-term effects of impurities on the particle size and optical emission of carbon dots. Nanoscale Adv. 2021, 3, 182–189. [Google Scholar] [CrossRef] [PubMed]

- Veleirinho, B.; Rei, M.F.; Lopes-DA-Silva, J. Solvent and concentration effects on the properties of electrospun poly (ethylene terephthalate) nanofiber mats. J. Polym. Sci. Part B Polym. Phys. 2008, 46, 460–471. [Google Scholar] [CrossRef]

- Mailley, D.; Hébraud, A.; Schlatter, G. A review on the impact of humidity during electrospinning: From the nanofiber structure engineering to the applications. Macromol. Mater. Eng. 2021, 306, 2100115. [Google Scholar] [CrossRef]

- Su, Y.; Qiu, T.; Song, W.; Han, X.; Sun, M.; Wang, Z.; Xie, H.; Dong, M.; Chen, M. Melt Electrospinning Writing of Magnetic Microrobots. Adv. Sci. 2021, 8, 2003177. [Google Scholar] [CrossRef]

- Zhu, Z.; Chen, X.; Huang, S.; Du, Z.; Zeng, J.; Liao, W.; Fang, F.; Peng, D.; Wang, H. The process of wavy fiber deposition via auxiliary electrodes in near-field electrospinning. Appl. Phys. A 2015, 120, 1435–1442. [Google Scholar] [CrossRef]

- Brown, T.D.; Dalton, P.D.; Hutmacher, D.W. Direct Writing By Way of Melt Electrospinning. Adv. Mater. 2011, 23, 5651–5657. [Google Scholar] [CrossRef]

- Ru, C.; Chen, J.; Shao, Z.; Pang, M.; Luo, J. A novel mathematical model for controllable near-field electrospinning. Aip Adv. 2014, 4, 017108. [Google Scholar] [CrossRef]

- Bisht, G.S.; Canton, G.; Mirsepassi, A.; Kulinsky, L.; Oh, S.; Dunn-Rankin, D.; Madou, M.J. Controlled Continuous Patterning of Polymeric Nanofiberson Three-Dimensional Substrates Using Low-VoltageNear-Field Electrospinning. Nano Lett. 2011, 11, 1831–1837. [Google Scholar] [CrossRef]

- Shin, D.; Kim, J.; Choi, S.; Lee, Y.B.; Chang, J. Droplet-jet mode near-field electrospinning for controlled helix patterns with sub-10 µm coiling diameter. J. Micromech. Microeng. 2019, 29, 045004. [Google Scholar] [CrossRef]

- Dansk Standard. Informationsteknologi—Teknikker til Automatisk Identifikation og Datafangst—Specifikation af Stregkodesymboler i QR-Kodefamilien = Information Technology—Automatic Identification and Data Capture Techniques—QR Code Bar Code Symbology Specification, 2nd ed.; DS/ISO/IEC 18004; Elektronisk Udgave; Danish Standards Association: Nordhavn, Denmark, 2015. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohtaram, F.; Petersen, M.; Ahrenst-Mortensen, M.; Boysen, L.S.; Gram, F.H.; Malling, H.H.; Bang, N.F.H.; Hess, Y.J.; Fojan, P. Near-Field Direct Write Electrospinning of PET-Carbon Quantum Dot Solutions. Materials 2024, 17, 6242. https://doi.org/10.3390/ma17246242

Mohtaram F, Petersen M, Ahrenst-Mortensen M, Boysen LS, Gram FH, Malling HH, Bang NFH, Hess YJ, Fojan P. Near-Field Direct Write Electrospinning of PET-Carbon Quantum Dot Solutions. Materials. 2024; 17(24):6242. https://doi.org/10.3390/ma17246242

Chicago/Turabian StyleMohtaram, Fatemeh, Michael Petersen, Maria Ahrenst-Mortensen, Liva Skou Boysen, Frederik Hejgaard Gram, Helene Halsen Malling, Noah Frederik Hallundbæk Bang, Yan Jurg Hess, and Peter Fojan. 2024. "Near-Field Direct Write Electrospinning of PET-Carbon Quantum Dot Solutions" Materials 17, no. 24: 6242. https://doi.org/10.3390/ma17246242

APA StyleMohtaram, F., Petersen, M., Ahrenst-Mortensen, M., Boysen, L. S., Gram, F. H., Malling, H. H., Bang, N. F. H., Hess, Y. J., & Fojan, P. (2024). Near-Field Direct Write Electrospinning of PET-Carbon Quantum Dot Solutions. Materials, 17(24), 6242. https://doi.org/10.3390/ma17246242