Assessing the Conformity of Mycelium Biocomposites for Ecological Insulation Solutions

Highlights

- Mycelium biocomposites (MB) proved themselves as a sustainable alternative for insulation in buildings.

- Physicomechanical, thermal, and fire properties of MB were influenced by the types of substrates, co-substrates, and additives.

- The insulation properties of MB can be tailored by selecting the ingredients and development conditions.

- The novelty is attributed to the unique dataset analyzing the relationship between modifications in the composition of MB and variances in the final properties.

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

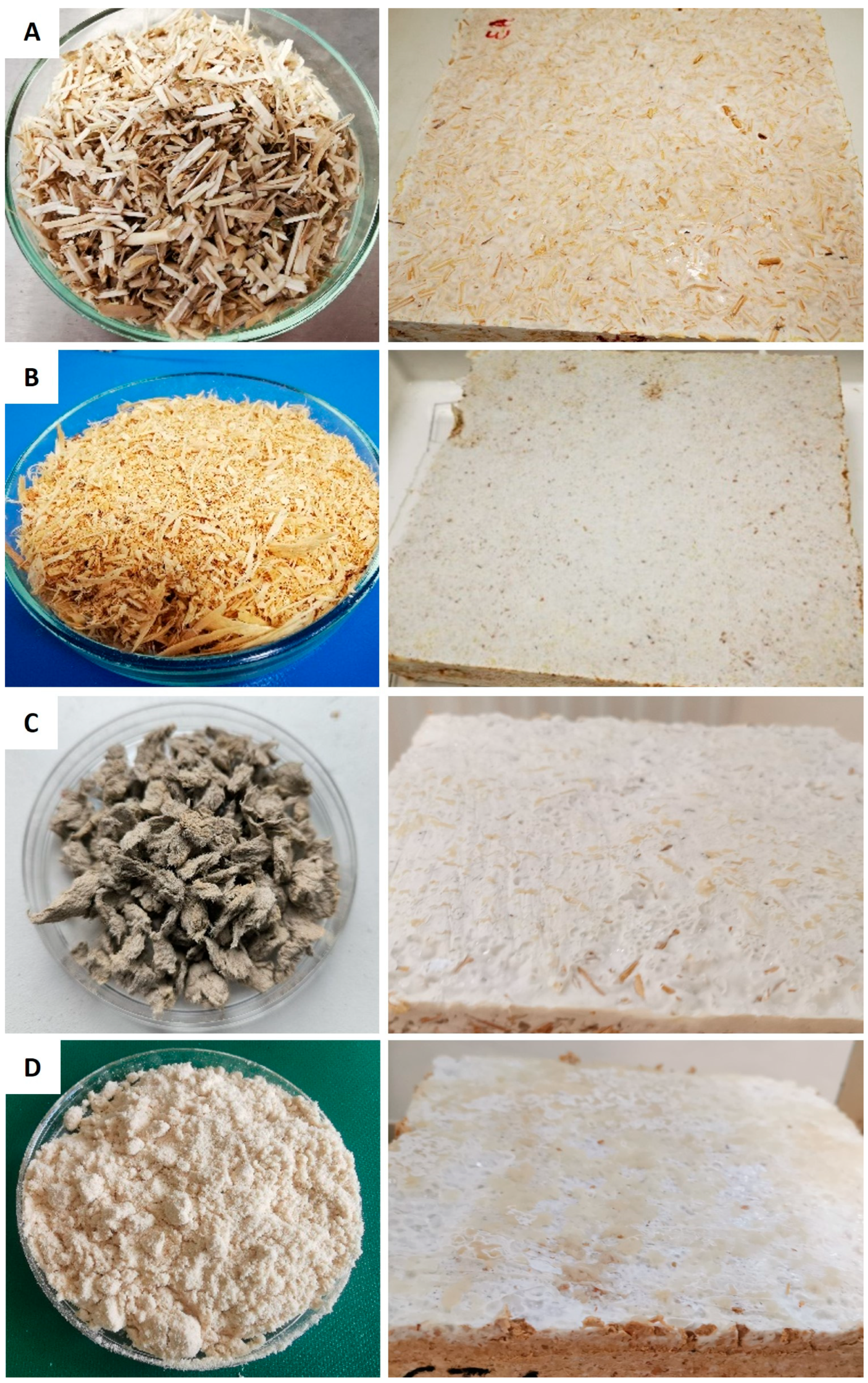

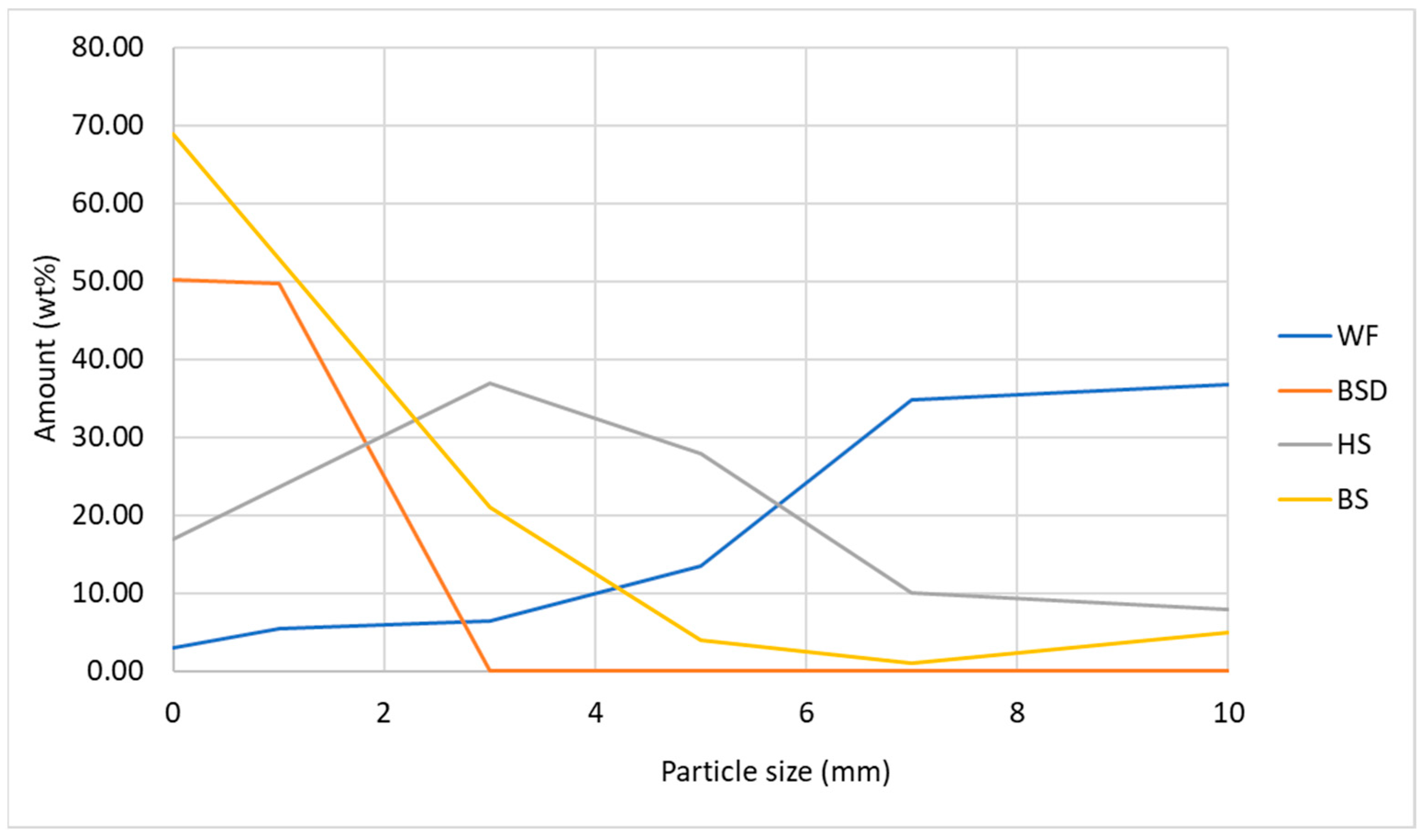

3.1. Granulometry

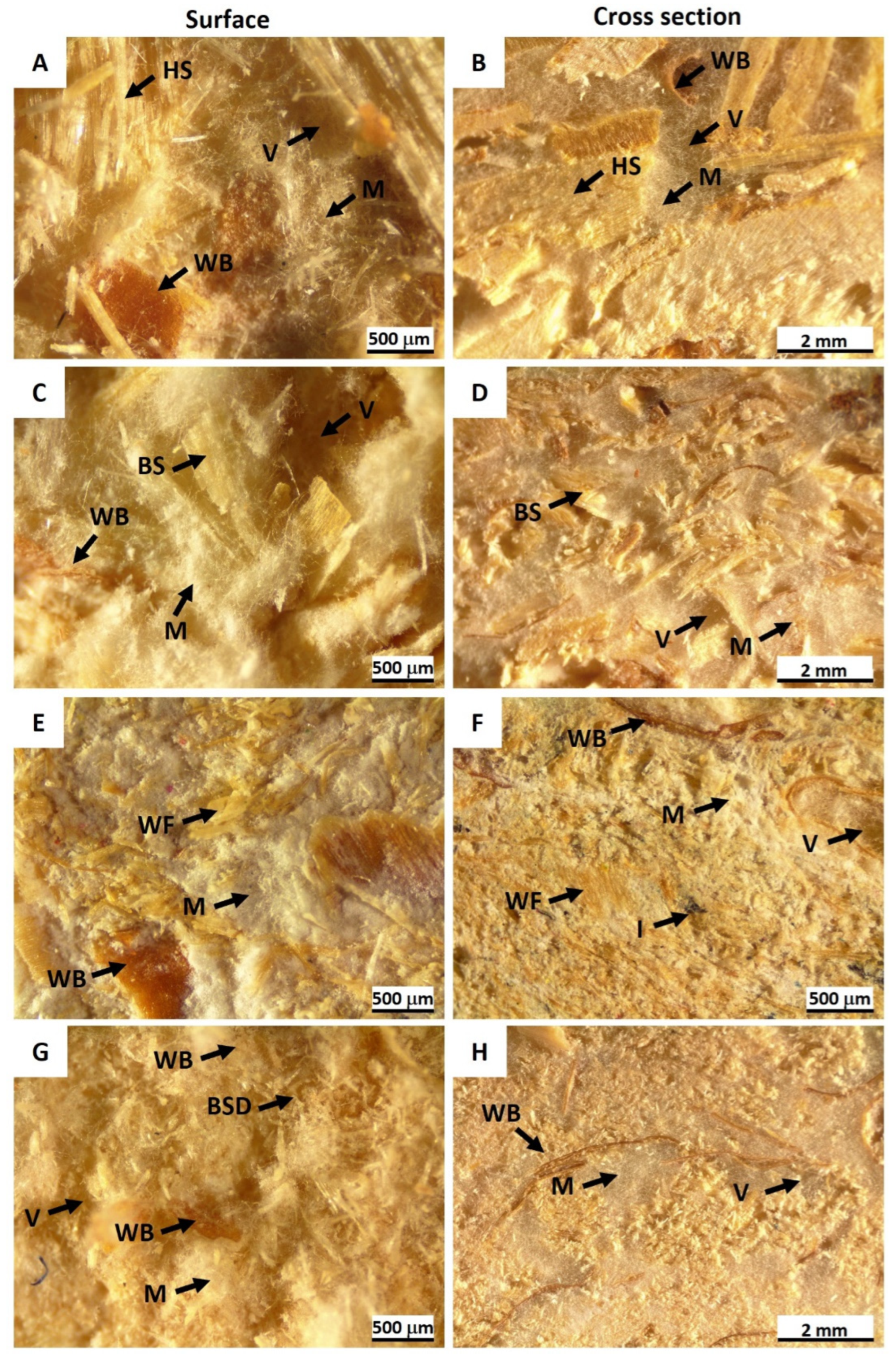

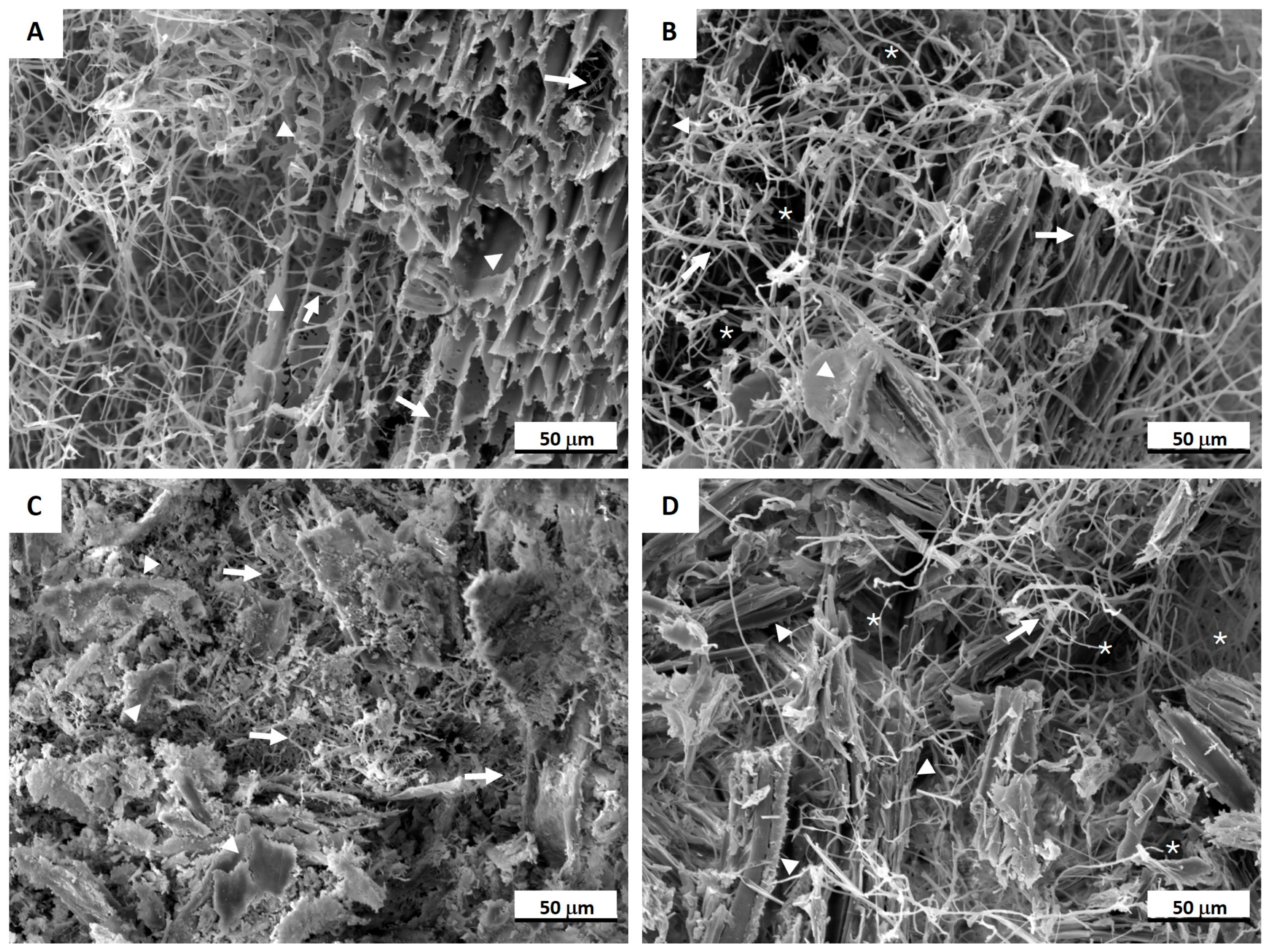

3.2. Micromorphology

3.3. Bending Strength

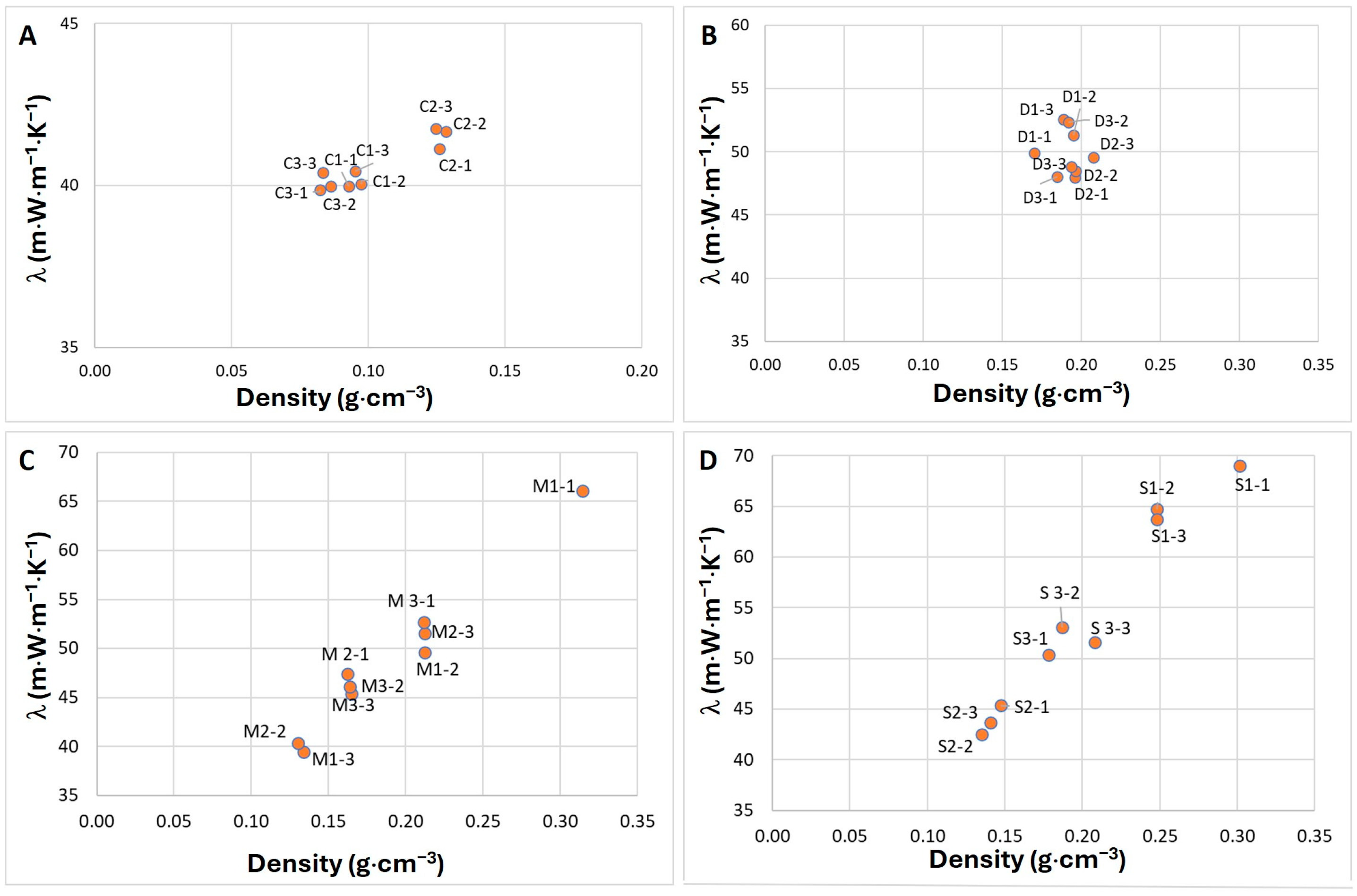

3.4. Thermal Properties

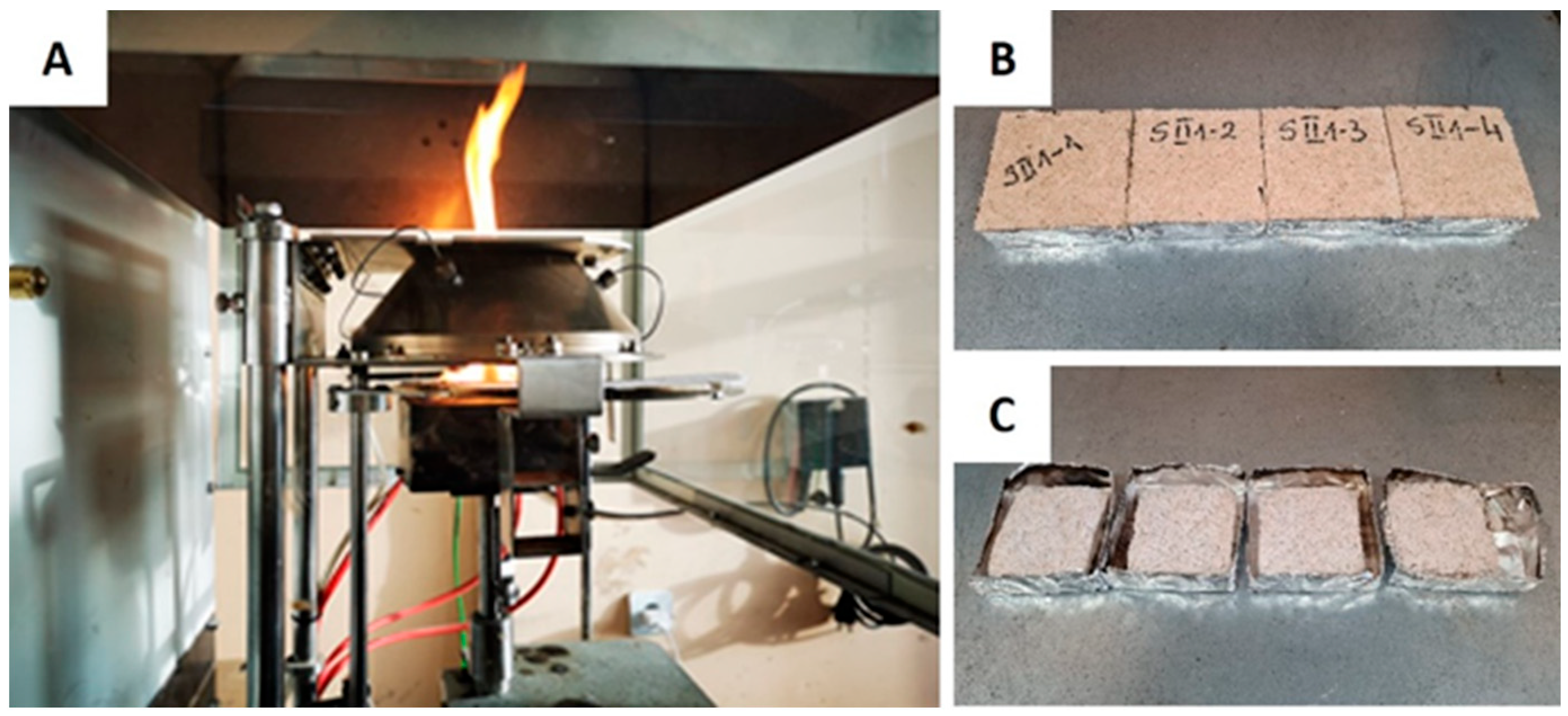

3.5. Reaction to Fire

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jelle, B.P. Traditional, state-of-the-art and future thermal building insulation materials and solutions—Properties, requirements and possibilities. Energy Build. 2011, 43, 2549–2563. [Google Scholar] [CrossRef]

- Abu-Jdayil, B.; Mourad, A.-H.; Hittini, W.; Hassan, M.; Hameedi, S. Traditional, state-of-the-art and renewable thermal building insulation materials: An overview. Constr. Build. Mater. 2019, 214, 709–735. [Google Scholar] [CrossRef]

- Wi, S.; Kang, Y.; Yang, S.; Kim, Y.U.; Kim, S. Hazard evaluation of indoor environment based on long-term pollutant emission characteristics of building insulation materials: An empirical study. Environ. Pollut. 2021, 285, 117223. [Google Scholar] [CrossRef] [PubMed]

- Grazieschi, G.; Asdrubali, F.; Thomas, G. Embodied energy and carbon of building insulating materials: A critical review. Clean. Environ. Syst. 2021, 2, 100032. [Google Scholar] [CrossRef]

- Kim, J.-H.; Lee, T.; Lee, J.; Choi, H.; Kwon, E.E. Conversion of toxic pyrogenic products into syngas through catalytic pyrolysis of insulation material waste under the presence of CO2. J. Hazard. Mater. 2024, 476, 134916. [Google Scholar] [CrossRef]

- Available online: https://www.eea.europa.eu/en/newsroom/news/renovations-sustainable-building-materials (accessed on 3 October 2024).

- Geß, A.; Lorenz, M.; Tolsdorf, A.; Albrecht, S. Environmental Impacts of Renewable Insulation Materials. Sustainability 2021, 13, 8505. [Google Scholar] [CrossRef]

- Zerari, S.; Franchino, R.; Pisacane, N. Industry Experts’ Perspectives on the Difficulties and Opportunities of the Integration of Bio-Based Insulation Materials in the European Construction Sector. Sustainability 2024, 16, 7314. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Bhusan Das, B. A comprehensive review on the use of hemp in concrete. Constr. Build. Mater. 2022, 341, 127857. [Google Scholar] [CrossRef]

- Jones, M.; Mautner, A.; Luenco, S.; Bismarck, A.; John, S. Engineered mycelium composite construction materials from fungal biorefineries: A critical review. Mater. Des. 2020, 187, 108397. [Google Scholar] [CrossRef]

- Aiduang, W.; Kumla, J.; Srinuanpan, S.; Thamjaree, W.; Lumyong, S.; Suwannarach, N. Mechanical, Physical, and Chemical Properties of Mycelium-Based Composites Produced from Various Lignocellulosic Residues and Fungal Species. J. Fungi 2022, 8, 1125. [Google Scholar] [CrossRef]

- Sydor, M.; Bonenberg, A.; Doczekalska, B.; Cofta, G. Mycelium-Based Composites in Art, Architecture, and Interior Design: A Review. Polymers 2022, 14, 145. [Google Scholar] [CrossRef] [PubMed]

- Volk, R.; Schröter, M.; Saeidi, N.; Steffl, S.; Javadian, A.; Hebel, D.E.; Schultmann, F. Life cycle assessment of mycelium-based composite materials. Resour. Conserv. Recycl. 2024, 205, 107579. [Google Scholar] [CrossRef]

- Irbe, I.; Loris, G.D.; Filipova, I.; Andze, L.; Skute, M. Characterization of Self-Growing Biomaterials Made of Fungal Mycelium and Various Lignocellulose-Containing Ingredients. Materials 2022, 15, 7608. [Google Scholar] [CrossRef] [PubMed]

- Girometta, C.; Picco, A.M.; Baiguera, R.M.; Dondi, D.; Babbini, S.; Cartabia, M.; Pellegrini, M.; Savino, E. Physico-Mechanical and Thermodynamic Properties of Mycelium-Based Biocomposites: A Review. Sustainability 2019, 11, 281. [Google Scholar] [CrossRef]

- Haneef, M.; Ceseracciu, L.; Canale, C.; Bayer, I.S.; Heredia-Guerrero, J.A.; Athanassiou, A. Advanced Materials From Fungal Mycelium: Fabrication and Tuning of Physical Properties. Sci. Rep. 2017, 7, 41292. [Google Scholar] [CrossRef]

- Filipova, I.; Andze, L.; Skute, M.; Zoldners, J.; Irbe, I.; Dabolina, I. Improving Recycled Paper Materials through the Incorporation of Hemp, Wood Virgin Cellulose Fibers, and Nanofibers. Fibers 2023, 11, 101. [Google Scholar] [CrossRef]

- EN 12089:2013; Thermal Insulating Products for Building Applications-Determination of Bending Behaviour. CEN (European Committee for Standardization): Brussels, Belgium, 2013.

- ISO 8301:1991; Thermal Insulation—Determination of Steady-State Thermal Resistance and Related Properties—Heat Flow Meter Apparatus. ISO (International Organization for Standardization): Geneva, Switzerland, 1991.

- ISO 5660-1:2015; Reaction-to-Fire Tests—Heat Release, Smoke Production and Mass Loss Rate. Part 1: Heat Release Rate (Cone Calorimeter Method) and Smoke Production Rate (Dynamic Measurement). ISO (International Organization for Standardization): Geneva, Switzerland, 2015.

- Elisashvili, V.; Irbe, I.; Andersone, I.; Andersons, B.; Tsiklauri, N. Hydrolytic enzyme activity of EN113 standard basidiomycetes in the fermentation of lignocellulosic material and wood colonization. Holzforschung 2012, 66, 841–847. [Google Scholar] [CrossRef]

- Appels, F.V.W.; Camere, S.; Montalti, M.; Karana, E.; Jansen, K.M.B.; Dijksterhuis, J.; Krijgsheld, P.; Wösten, H.A.B. Fabrication factors influencing mechanical, moisture- and water-related properties of mycelium-based composites. Mater. Des. 2019, 161, 64–71. [Google Scholar] [CrossRef]

- Lu, Z.; Jónsdóttir, F.; Arason, S.; Margeirsson, B. Assessment of Compressive and Flexural Properties and Stacking Strength of Expanded Polystyrene Boxes: Experimental and Simulation Study. Appl. Sci. 2023, 13, 5852. [Google Scholar] [CrossRef]

- Yoshihara, H.; Yoshinobu, M.; Maruta, M. Effects of Testing Methods and Sample Configuration on the Flexural Properties of Extruded Polystyrene. Polymers 2024, 16, 1857. [Google Scholar] [CrossRef]

- Salari, A.; Tabarsa, T.; Khazaeian, A.; Saraeian, A. Improving some of applied properties of oriented strand board (OSB) made from underutilized low quality paulownia (Paulownia fortunie) wood employing nano-SiO2. Ind. Crops Prod. 2013, 42, 1–9. [Google Scholar] [CrossRef]

- Jakob, M.; Mahendran, A.R.; Gindl-Altmutter, W.; Bliem, P.; Konnerth, J.; Müller, U.; Veigel, S. The strength and stiffness of oriented wood and cellulose-fibre materials: A review. Prog. Mater. Sci. 2022, 125, 100916. [Google Scholar] [CrossRef]

- Teeraphantuvat, T.; Jatuwong, K.; Jinanukul, P.; Thamjaree, W.; Lumyong, S.; Aiduang, W. Improving the Physical and Mechanical Properties of Mycelium-Based Green Composites Using Paper Waste. Polymers 2024, 16, 262. [Google Scholar] [CrossRef] [PubMed]

- Rowell, R.M. Handbook of Wood Chemistry and Wood Composites, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- Nussbaumer, M.; Van Opdenbosch, D.; Engelhardt, M.; Briesen, H.; Benz, J.P.; Karl, T. Material characterization of pressed and unpressed wood–mycelium composites derived from two Trametes species. Environ. Technol. Innov. 2023, 30, 103063. [Google Scholar] [CrossRef]

- Schritt, H.; Vidi, S.; Pleissner, D. Spent mushroom substrate and sawdust to produce mycelium-based thermal insulation composites. J. Clean. Prod. 2021, 313, 127910. [Google Scholar] [CrossRef]

- Holt, G.A.; Mcintyre, G.; Flagg, D.; Bayer, E.; Wanjura, J.D.; Pelletier, M.G. Fungal Mycelium and Cotton Plant Materials in the Manufacture of Biodegradable Molded Packaging Material: Evaluation Study of Select Blends of Cotton Byproducts. J. Biobased Mater. Bioenergy 2012, 6, 431–439. [Google Scholar] [CrossRef]

- Wimmers, G.; Klick, J.; Tackaberry, L.; Zwiesigk, C.; Egger, K.; Massicotte, H. Fundamental studies for designing insulation panels from wood shavings and filamentous fungi. BioResources 2019, 14, 5506–5520. [Google Scholar] [CrossRef]

- Kunič, R. Forest-Based Bioproducts Used for Construction and Its Impact on the Environmental Performance of a Building in the Whole Life Cycle. In Environmental Impacts of Traditional and Innovative Forest-based Bioproducts; Kutnar, A., Muthu, S.S., Eds.; Springer: Singapore, 2016; pp. 173–204. [Google Scholar]

- Available online: https://kimpur.com/en/what-is-rigid-polyurethane-foam-what-are-the-application-areas/ (accessed on 10 October 2024).

- Nwe, N.; Stevens, W.F. Effect of urea on fungal chitosan production in solid substrate fermentation. Process Biochem. 2004, 39, 1639–1642. [Google Scholar] [CrossRef]

- Ates, M.; Karadag, S.; Eker, A.A.; Eker, B. Polyurethane foam materials and their industrial applications. Polym. Int. 2022, 71, 1157–1163. [Google Scholar] [CrossRef]

- Galakhova, A.; Santiago-Calvo, M.; Tirado-Mediavilla, J.; Villafañe, F.; Rodríguez-Pérez, M.Á.; Riess, G. Identification and Quantification of Cell Gas Evolution in Rigid Polyurethane Foams by Novel GCMS Methodology. Polymers 2019, 11, 1192. [Google Scholar] [CrossRef]

- Hossain, M.D.; Hassan, M.K.; Akl, M.; Pathirana, S.; Rahnamayiezekavat, P.; Douglas, G.; Bhat, T.; Saha, S. Fire Behaviour of Insulation Panels Commonly Used in High-Rise Buildings. Fire 2022, 5, 81. [Google Scholar] [CrossRef]

- Jones, M.; Bhat, T.; Kandare, E.; Thomas, A.; Joseph, P.; Dekiwadia, C.; Yuen, R.; John, S.; Ma, J.; Wang, C.-H. Thermal Degradation and Fire Properties of Fungal Mycelium and Mycelium—Biomass Composite Materials. Sci. Rep. 2018, 8, 17583. [Google Scholar] [CrossRef] [PubMed]

- Ayrilmis, N.; Candan, Z.; White, R. Physical, mechanical, and fire properties of oriented strandboard with fire retardant treated veneers. Holz Als Roh Und Werkst. 2007, 65, 449–458. [Google Scholar] [CrossRef]

- Hansen-Bruhn, I.; Hull, T.R. Flammability and burning behaviour of fire protected timber. Fire Saf. J. 2023, 140, 103918. [Google Scholar] [CrossRef]

- Dorez, G.; Ferry, L.; Sonnier, R.; Taguet, A.; Lopez-Cuesta, J.M. Effect of cellulose, hemicellulose and lignin contents on pyrolysis and combustion of natural fibers. J. Anal. Appl. Pyrolysis 2014, 107, 323–331. [Google Scholar] [CrossRef]

- Walker, G.M.; White, N.A. Introduction to Fungal Physiology. In Fungi; Wiley: Hoboken, NJ, USA, 2017; pp. 1–35. [Google Scholar]

- Tshinyangu, K.K.; Hennebert, G.L. Protein and chitin nitrogen contents and protein content in Pleurotus ostreatus var. columbinus. Food Chem. 1996, 57, 223–227. [Google Scholar] [CrossRef]

- Kairytė, A.; Kirpluks, M.; Ivdre, A.; Cabulis, U.; Vaitkus, S.; Pundienė, I. Cleaner production of polyurethane foam: Replacement of conventional raw materials, assessment of fire resistance and environmental impact. J. Clean. Prod. 2018, 183, 760–771. [Google Scholar] [CrossRef]

- Kurańska, M.; Cabulis, U.; Auguścik, M.; Prociak, A.; Ryszkowska, J.; Kirpluks, M. Bio-based polyurethane-polyisocyanurate composites with an intumescent flame retardant. Polym. Degrad. Stab. 2016, 127, 11–19. [Google Scholar] [CrossRef]

- BRANZ. Toxicity of gases released by construction materials during building fires. In BRANZ Research Now: Fire Safety Design; BRANZ: Porirua, New Zealand, 2020; p. 4. [Google Scholar]

- Tišma, M.; Žnidaršič-Plazl, P.; Šelo, G.; Tolj, I.; Šperanda, M.; Bucić-Kojić, A.; Planinić, M. Trametes versicolor in lignocellulose-based bioeconomy: State of the art, challenges and opportunities. Bioresour. Technol. 2021, 330, 124997. [Google Scholar] [CrossRef]

| Variant | Component (g) | |||||

|---|---|---|---|---|---|---|

| HS | BS | WF | BSD | WB | BB | |

| C1 | 600 | - | - | - | 48 | - |

| C2 | 420 | - | - | - | 48 | 180 |

| C3 | 648 | - | - | - | - | - |

| D1 | - | 600 | - | - | 48 | - |

| D2 | - | 420 | - | - | 48 | 180 |

| D3 | - | 648 | - | - | - | - |

| M1 | - | - | 600 | - | 48 | - |

| M2 | 300 | - | 300 | - | 48 | - |

| M3 | - | 300 | 300 | - | 48 | - |

| S1 | - | - | - | 600 | 48 | - |

| S2 | 300 | - | - | 300 | 48 | - |

| S3 | - | 300 | - | 300 | 48 | - |

| Variant | Density g·cm−3 | σfM MPa | E MPa |

|---|---|---|---|

| C1 | 0.10 ± 0.00 | 0.11 ± 0.03 | 5.55 ± 1.26 |

| C2 | 0.14 ± 0.00 | 0.15 ± 0.01 | 5.11 ± 0.47 |

| C3 | 0.09 ± 0.00 | 0.10 ± 0.01 | 4.42 ± 0.27 |

| D1 | 0.21 ± 0.00 | 0.25 ± 0.02 | 14.66 ± 1.76 |

| D2 | 0.22 ± 0.00 | 0.17 ± 0.01 | 8.78 ± 1.31 |

| D3 | - | - | - |

| M1 | 0.32 ± 0.01 | 0.39 ± 0.05 | 26.66 ± 7.34 |

| M2 | 0.16 ± 0.00 | 0.42 ± 0.04 | 9.06 ± 1.98 |

| M3 | 0.23 ± 0.00 | 0.45 ± 0.06 | 9.38 ± 4.46 |

| S1 | 0.19 ± 0.00 | 0.10 ± 0.01 | 4.10 ± 0.17 |

| S2 | 0.14 ± 0.01 | 0.51 ± 0.05 | 17.87 ± 2.88 |

| S3 | 0.22 ± 0.00 | 0.32 ± 0.03 | 5.82 ± 1.92 |

| Variant | TTI s | TTF s | THR k·W·m−2 | pHRR k·W·m−2 | TTP s | TSR m2·m−2 |

|---|---|---|---|---|---|---|

| C1 | 7 ± 1 | 372 ± 39 | 12.5 ± 2.0 | 150.0 ±0.9 | 19 ± 1 | 16.0 ± 3.1 |

| C2 | 10 ± 0 | 747 ± 94 | 30.1 ± 1.5 | 199.0 ± 2.2 | 23 ± 1 | 142.1 ± 7.7 |

| C3 | 8 ± 1 | 279 ± 13 | 12.3 ± 0.5 | 162.7 ± 6.0 | 19 ± 1 | 13.6 ± 0.6 |

| D1 | 13 ± 2 | 708 ± 63 | 33.6 ± 1.7 | 183.0 ± 10.4 | 26 ± 3 | 24.0 ± 4.7 |

| D2 | 15 ± 1 | 1181 ± 74 | 62.1 ± 3.5 | 181.1 ± 13.4 | 30 ± 2 | 281.5 ± 26.2 |

| D3 | 12 ± 1 | 711± 12 | 35.0 ± 2.1 | 243.1 ± 10.2 | 25 ± 1 | 40.6 ± 8.2 |

| M1 | 15 ± 5 | 149 ± 69 | 5.8 ± 0.6 | 133.9 ± 12.2 | 26 ± 6 | 36.0 ± 2.7 |

| M2 | 9 ± 0 | 755 ± 21 | 11.9 ± 5.9 | 144.6 ± 10.7 | 21 ± 1 | 90.7 ± 23.1 |

| M3 | 18 ± 2 | 854 ± 61 | 22.3 ± 4.2 | 141.5 ± 7.4 | 31 ± 2 | 7.4 ± 1.1 |

| S1 | 14 ± 2 | 818 ± 363 | 55.3 ± 6.0 | 190.2 ± 12.1 | 23 ± 8 | 11.3 ± 0.5 |

| S2 | 9 ± 1 | 548 ± 25 | 19.8 ± 2.1 | 164.2 ± 7.0 | 21 ± 1 | 10.5 ± 1.4 |

| S3 | 13 ± 2 | 695 ± 57 | 32.8 ± 5.1 | 184.8 ± 27.2 | 26 ± 1 | 15.3 ± 1.2 |

| XPS [38] | 5 | 174 | 26.2 | 423 | 33 | - |

| EPS [38] | 29 | 135 | 11.2 | 377 | 32 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Irbe, I.; Kirpluks, M.; Kampuss, M.; Andze, L.; Milbreta, U.; Filipova, I. Assessing the Conformity of Mycelium Biocomposites for Ecological Insulation Solutions. Materials 2024, 17, 6111. https://doi.org/10.3390/ma17246111

Irbe I, Kirpluks M, Kampuss M, Andze L, Milbreta U, Filipova I. Assessing the Conformity of Mycelium Biocomposites for Ecological Insulation Solutions. Materials. 2024; 17(24):6111. https://doi.org/10.3390/ma17246111

Chicago/Turabian StyleIrbe, Ilze, Mikelis Kirpluks, Mikus Kampuss, Laura Andze, Ulla Milbreta, and Inese Filipova. 2024. "Assessing the Conformity of Mycelium Biocomposites for Ecological Insulation Solutions" Materials 17, no. 24: 6111. https://doi.org/10.3390/ma17246111

APA StyleIrbe, I., Kirpluks, M., Kampuss, M., Andze, L., Milbreta, U., & Filipova, I. (2024). Assessing the Conformity of Mycelium Biocomposites for Ecological Insulation Solutions. Materials, 17(24), 6111. https://doi.org/10.3390/ma17246111