The Effect of Post Heat Treatment on the Microstructure and Mechanical Properties of Cold-Sprayed Zn-6Cu Deposits

Abstract

1. Introduction

2. Experimental Procedure

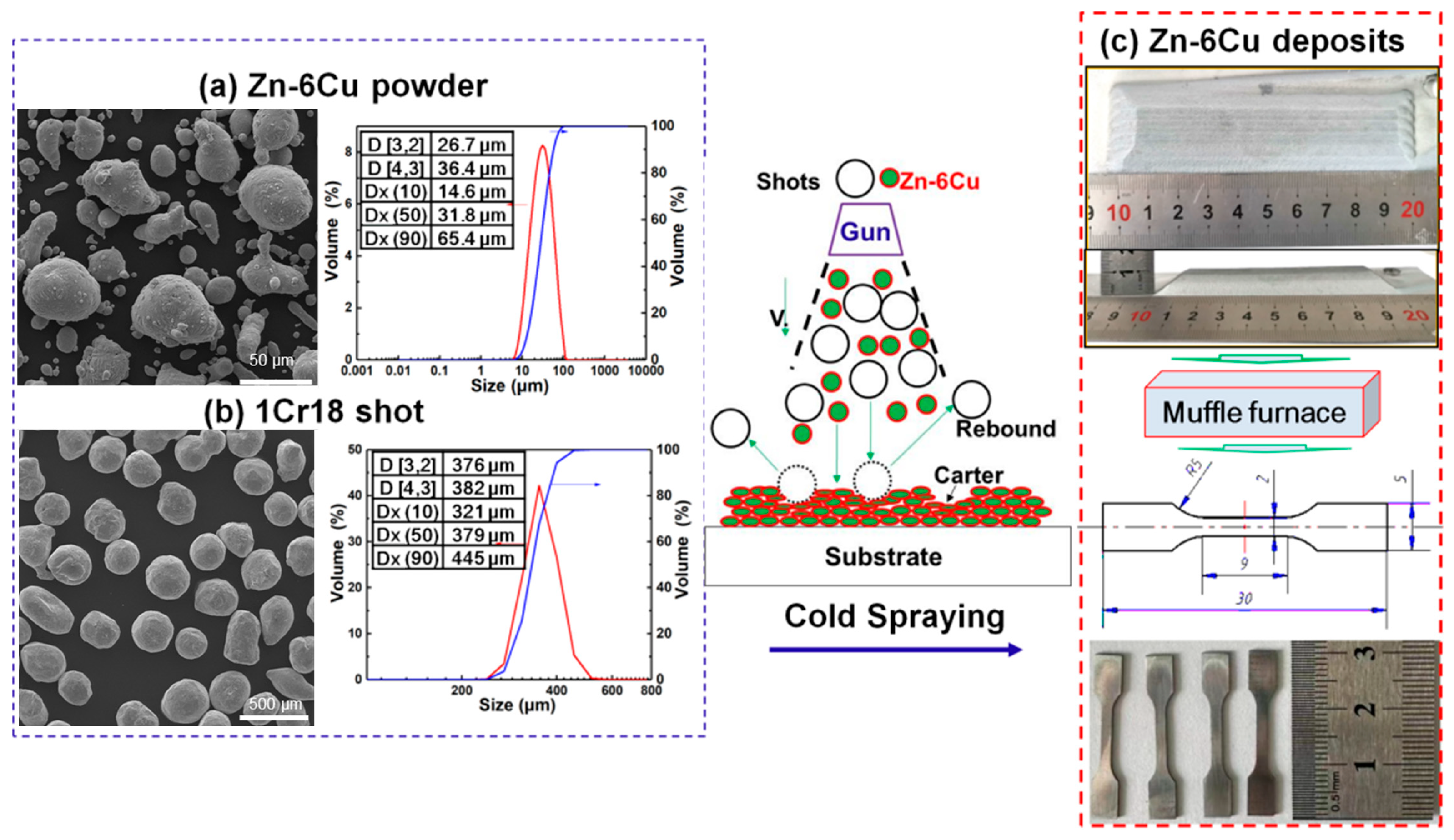

2.1. Materials

2.2. Preparation of Zn-6Cu Deposit

2.3. Post Heat Treatment

2.4. Tensile Testing

2.5. Wear Testing

3. Results and Discussion

3.1. Phase of Zn-6Cu Deposits Before and After Heat Treatment

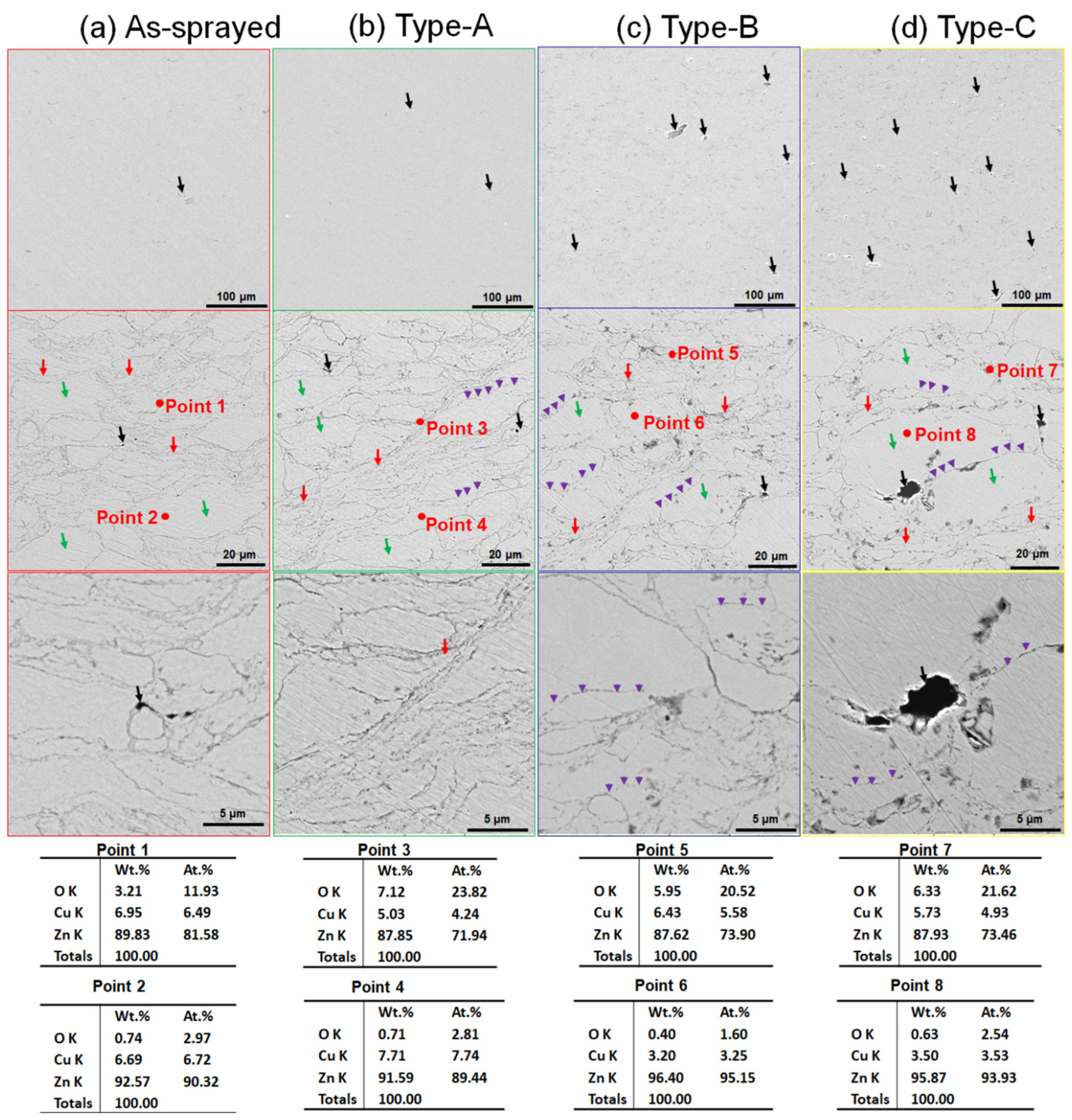

3.2. Microstructure of Zn-6Cu Deposits Before and After Heat Treatment

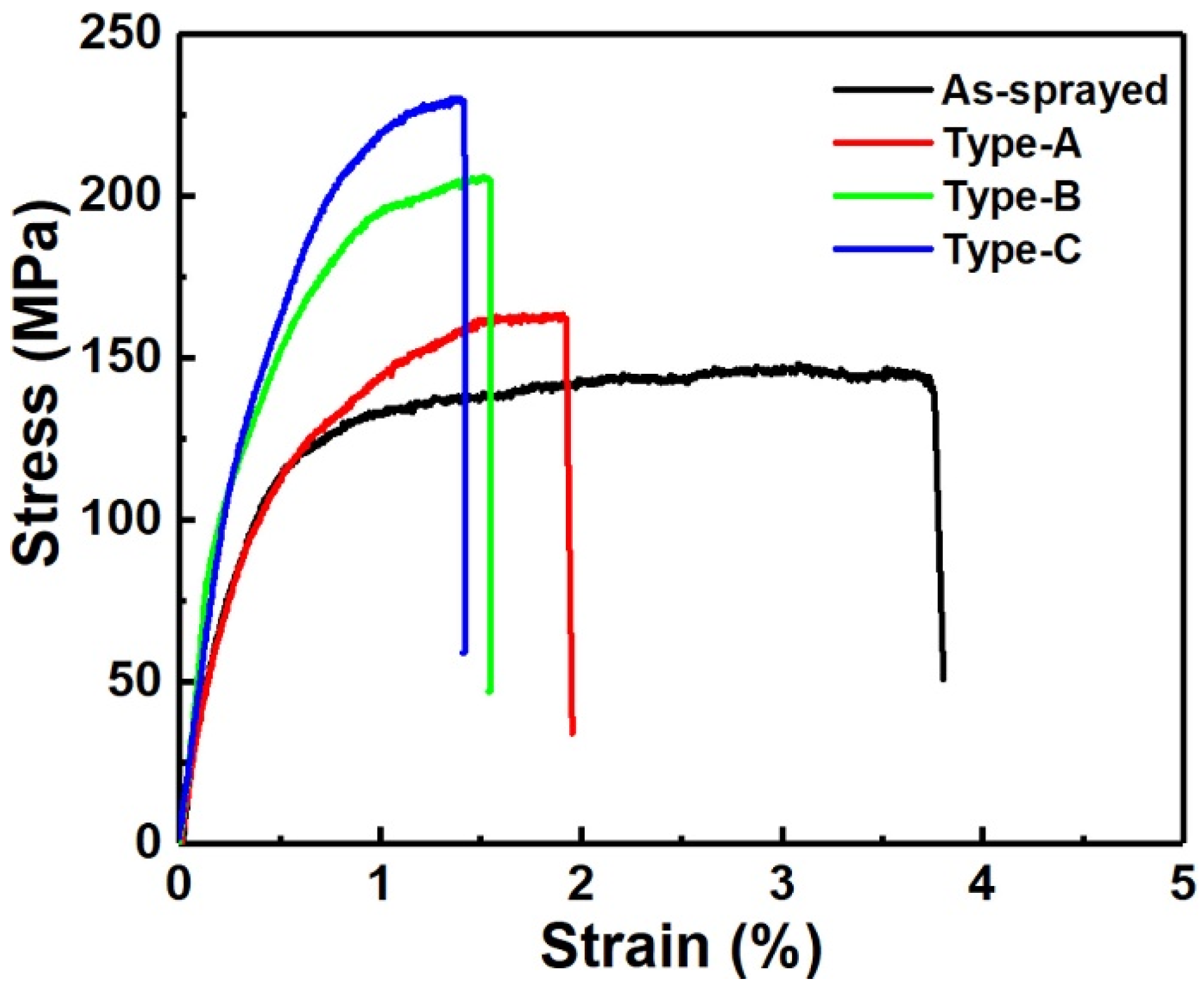

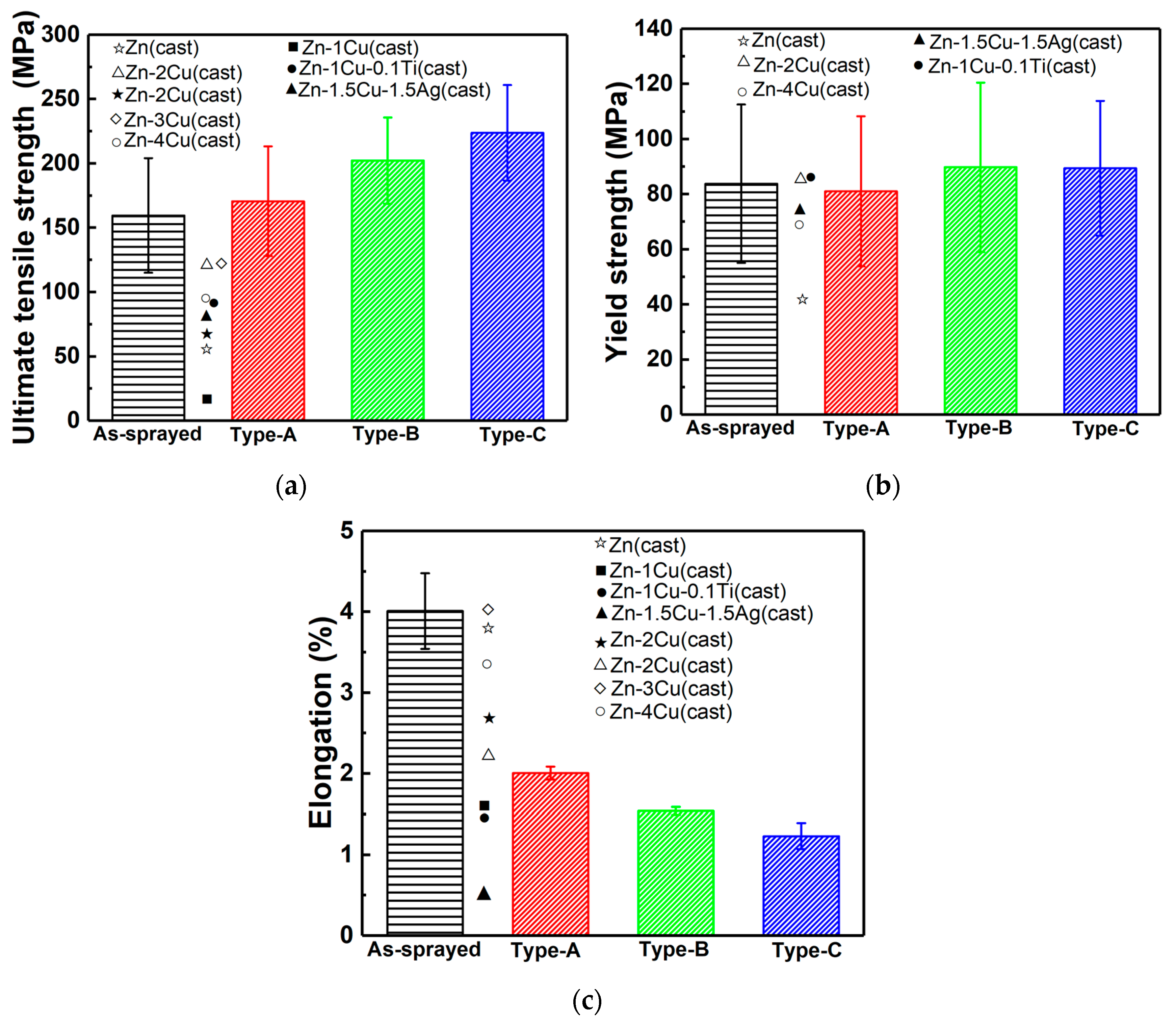

3.3. The Tensile Properties of Zn-6Cu Deposits Before and After Heat Treatment

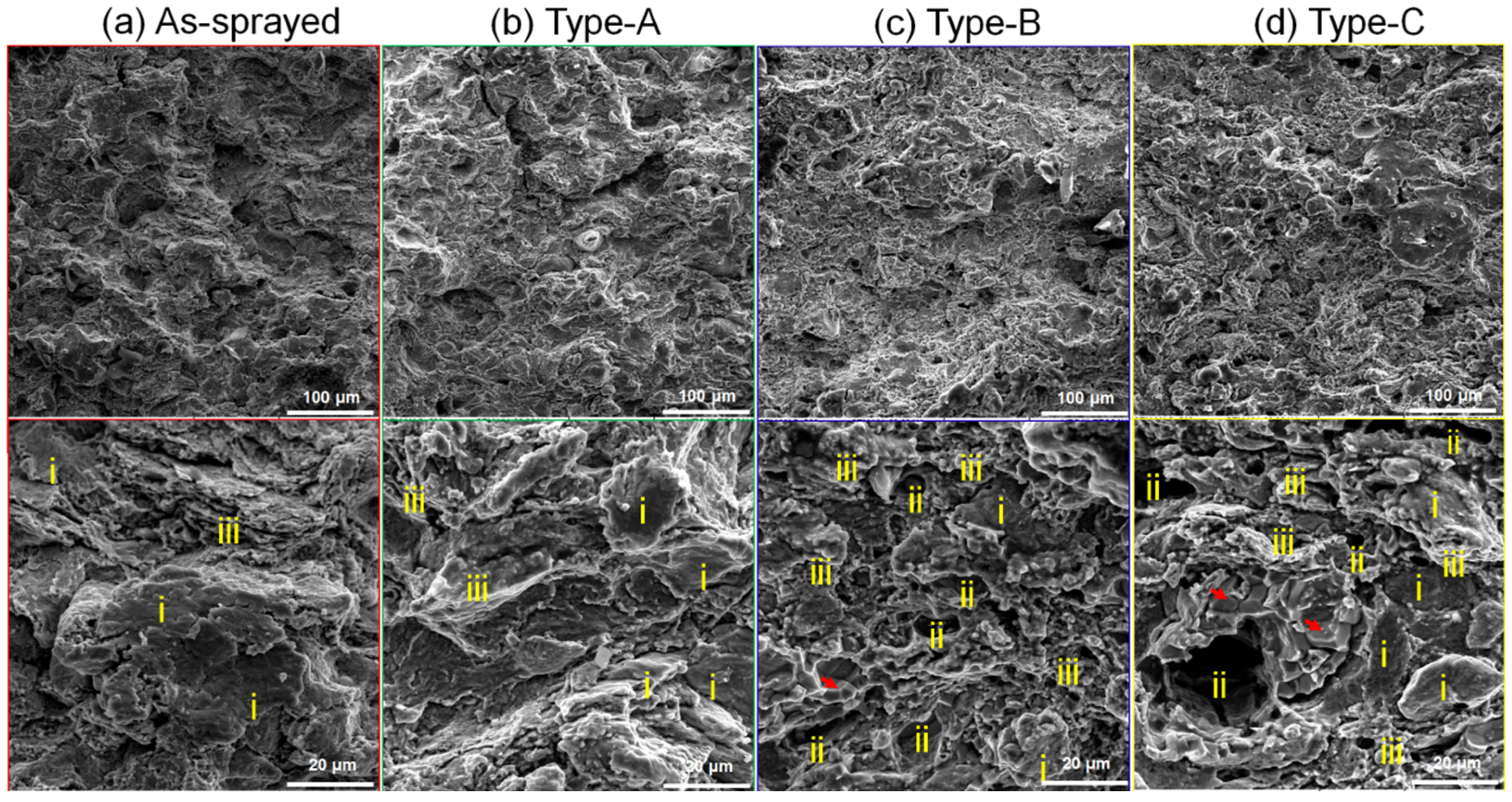

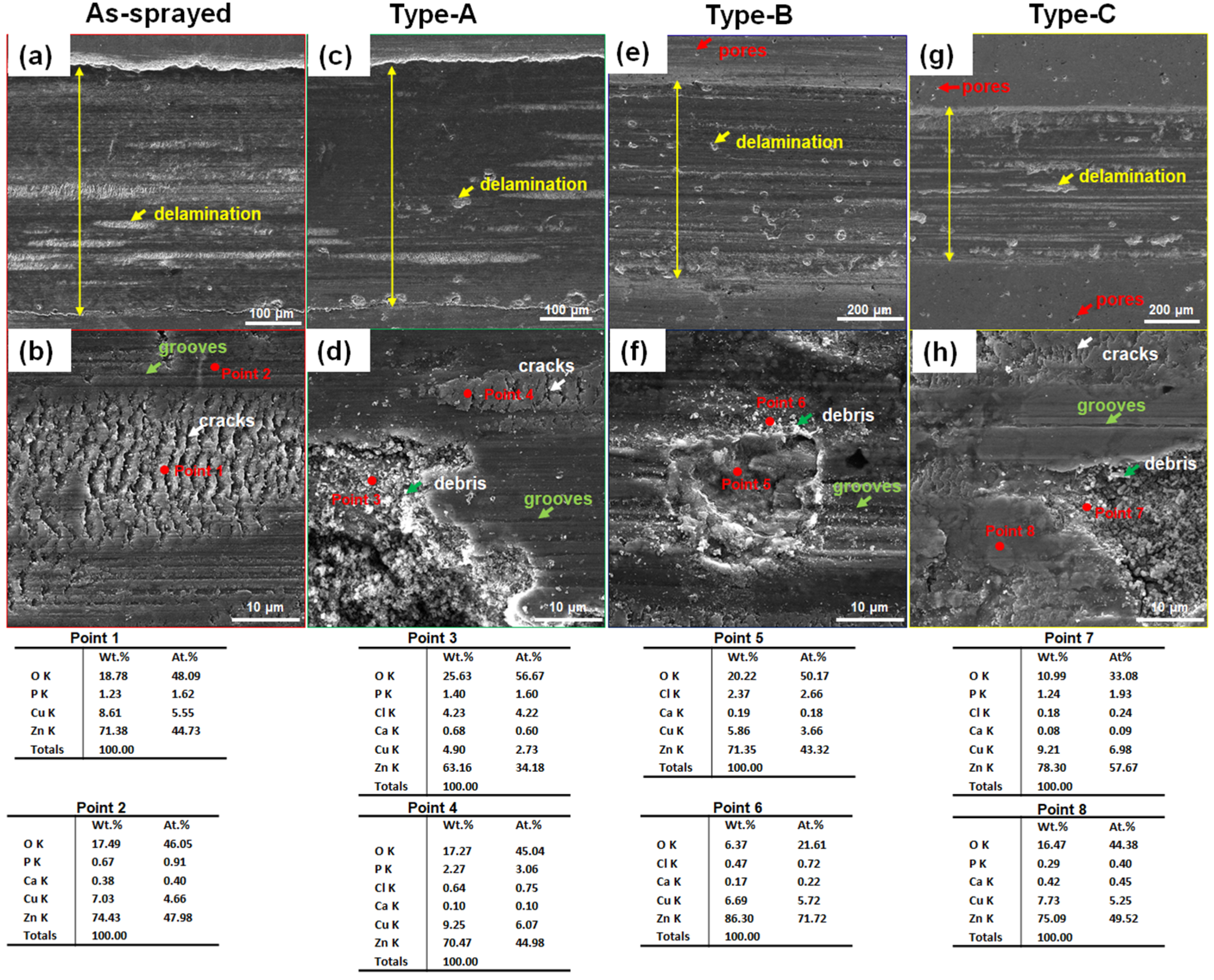

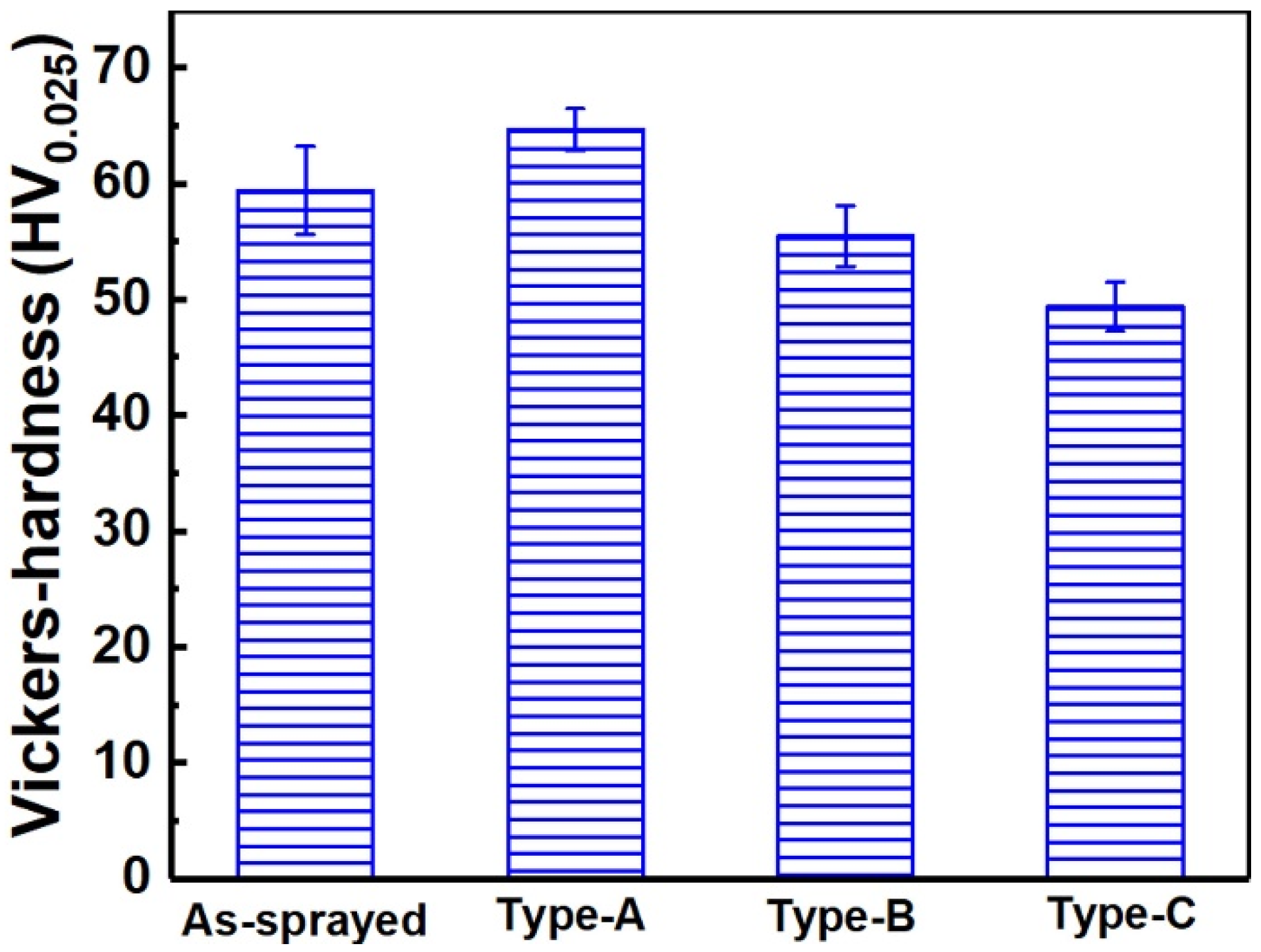

3.4. The Fracture Morphology of Zn-6Cu Deposits After Tensile Testing

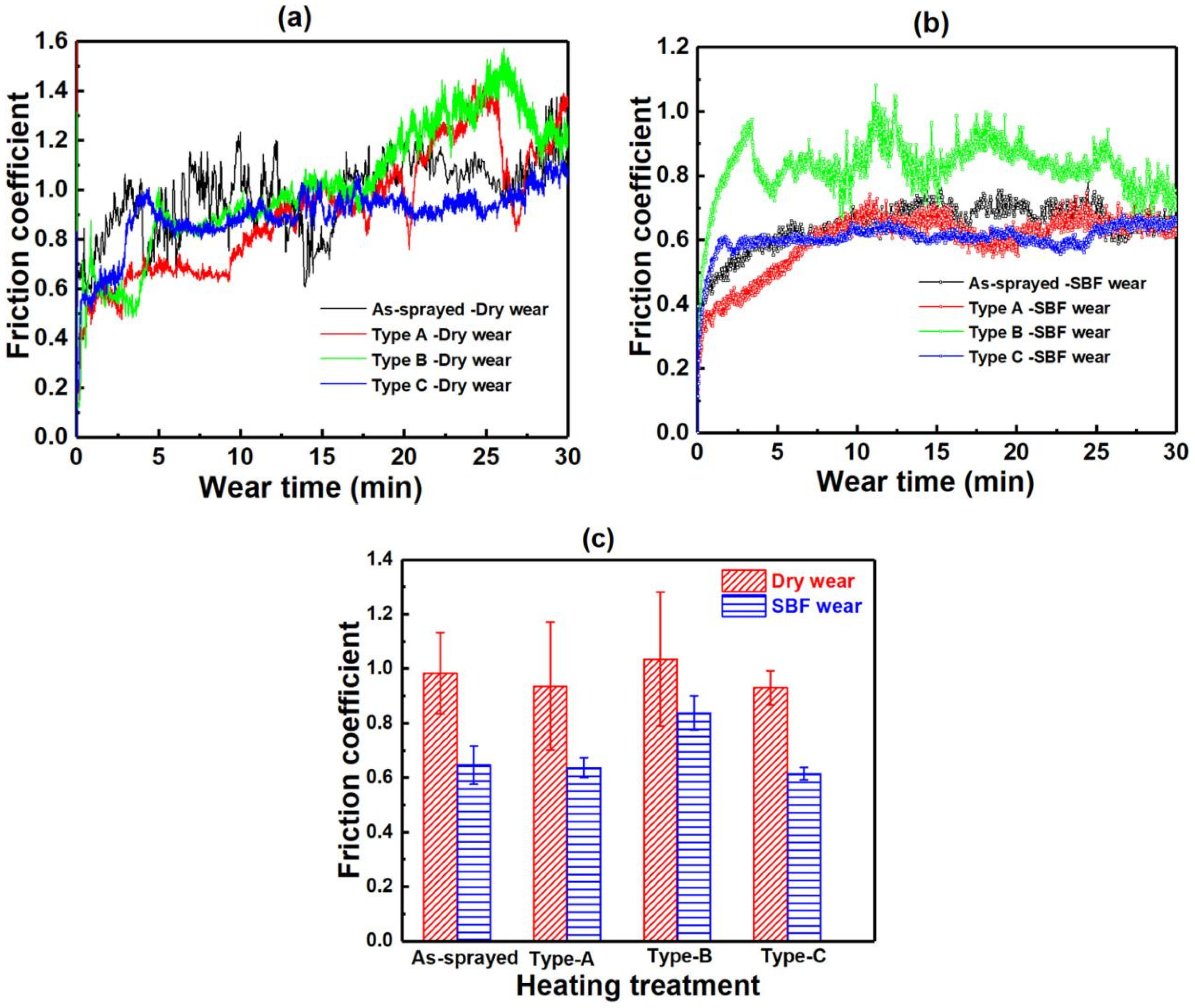

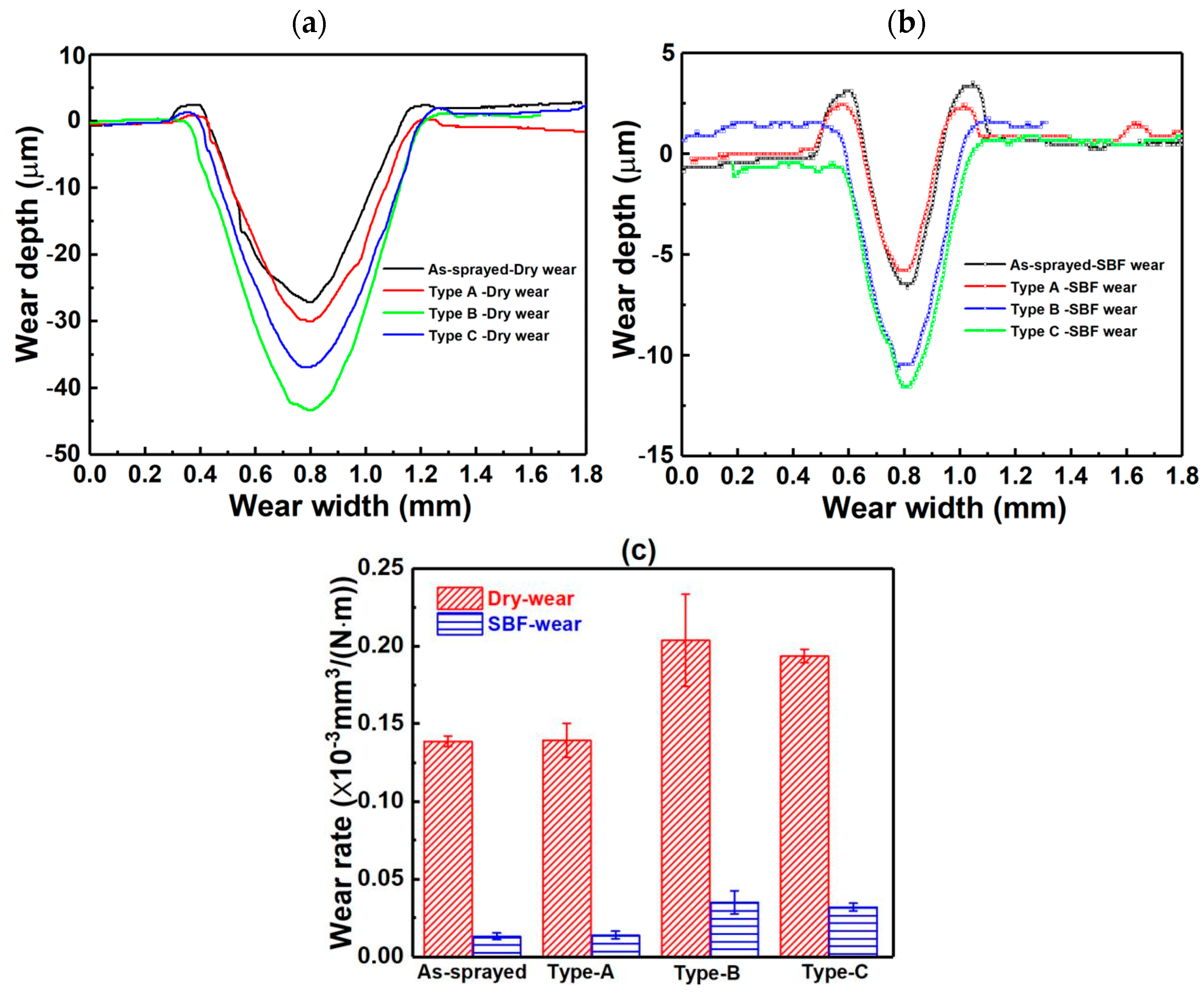

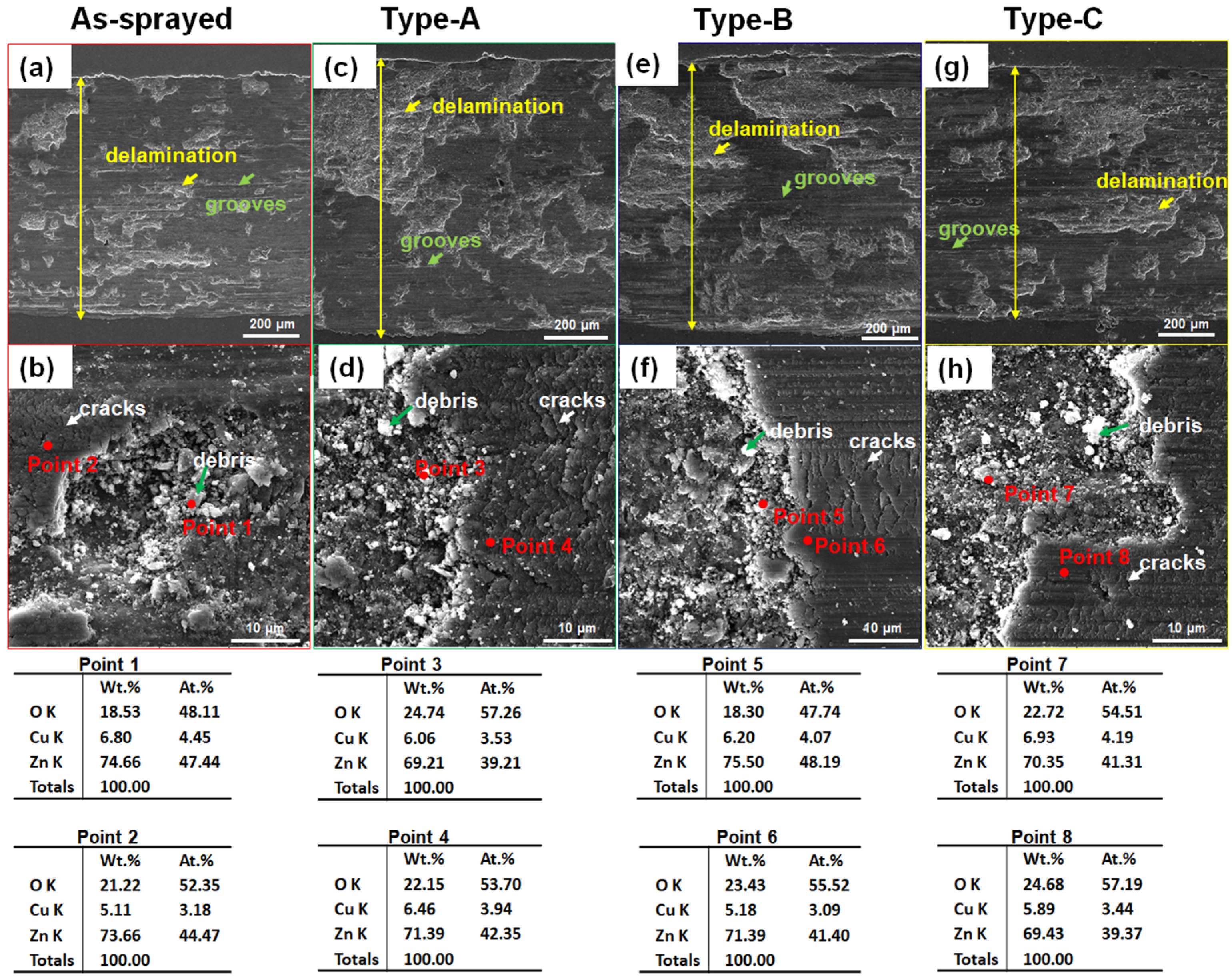

3.5. Friction and Wear Behavior of Zn-6Cu Deposits Under Dry and SBF Conditions

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xia, D.D.; Yang, F.; Zheng, Y.F.; Liu, Y.S.; Zhou, Y.S. Research status of biodegradable metals designed for oral and maxillofacial applications: A review. Bioact. Mater. 2021, 6, 4186–4208. [Google Scholar] [CrossRef] [PubMed]

- Giulio, M.; Caroli, S.; Sharma, V.K. Tables of Standard Electrode Potentials; Wiley: Hoboken, NY, USA, 1978. [Google Scholar]

- Tang, Z.B.; Huang, H.; Niu, J.L.; Zhang, L.; Zhang, H.; Pei, J.; Tan, J.Y.; Yuan, G.Y. Design and characterizations of novel biodegradable Zn-Cu-Mg alloys for potential biodegradable implants. Mater. Des. 2017, 117, 84–94. [Google Scholar] [CrossRef]

- Ardakani, M.S.; Mostaed, E.; Sikora-Jasinska, M.; Kampe, S.L.; Drelich, J.W. The effects of alloying with Cu and Mn and thermal treatments on the mechanicainstability of Zn-0.05Mg alloy. Mat. Sci. Eng. A-Struct. 2020, 770, 138529. [Google Scholar] [CrossRef]

- Zhao, S.; McNamara, C.T.; Bowen, P.K.; Verhun, N.; Braykovich, J.P.; Goldman, J.; Drelich, J.W. Structural characteristics and biodegradation of a novel Zn-Li alloy prepared by induction melting and hot rolling. Metall. Mater. Trans. A 2017, 48A, 1204–1215. [Google Scholar] [CrossRef]

- Shi, Z.Z.; Yu, J.; Liu, X.F. Microalloyed Zn-Mn alloys: From extremely brittle to extraordinarily ductile at room temperature. Mater. Des. 2018, 144, 343–352. [Google Scholar] [CrossRef]

- Bednarczyk, W.; Watroba, M.; Kawalko, J.; Bala, P. Determination of room-temperature superplastic asymmetry and anisotropy of Zn-0.8Ag alloy processed by ECAP. Mater. Sci. Eng. A 2019, 759, 55–58. [Google Scholar] [CrossRef]

- Yang, H.T.; Jia, B.; Zhang, Z.C.; Qu, X.H.; Li, G.N.; Lin, W.J.; Zhu, D.H.; Dai, K.R.; Zheng, Y.F. Alloying design of biodegradable zinc as promising bone implants for load-bearing applications. Nat. Commun. 2020, 11, 401. [Google Scholar] [CrossRef]

- Shi, Z.Z.; Gao, X.X.; Chen, H.T.; Liu, X.F.; Li, A.; Zhang, H.J.; Wang, L.N. Enhancement in mechanical and corrosion resistance properties of a biodegradable Zn-Fe alloy through second phase refinement. Mater. Sci. Eng. C 2020, 116, 111197. [Google Scholar] [CrossRef]

- Wang, K.; Tong, X.; Lin, J.X.; Wei, A.P.; Li, Y.C.; Dargusch, M.; Wen, C.E. Binary Zn-Ti alloys for orthopedic applications: Corrosion and degradation behaviors, friction and wear performance, and cytotoxicity. J. Mater. Sci. Technol. 2021, 74, 216–229. [Google Scholar] [CrossRef]

- Niu, J.L.; Tang, Z.B.; Huang, H.; Pei, J.; Zhang, H.; Yuan, G.Y.; Ding, W.J. Research on a Zn-Cu alloy as a biodegradable material for potential vascular stents application. Mater. Sci. Eng. C 2016, 69, 407–413. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Ma, Z.; Zhu, Y.; Xia, H.; Yao, M.Y.; Chu, X.; Wang, X.L.; Yang, K.; Yang, M.Y.; Zhang, Y.; et al. Toward a molecular understanding of the antibacterial mechanism of copper-bearing titanium alloys against staphylococcus aureus. Adv. Healthc. Mater. 2016, 5, 557–566. [Google Scholar] [CrossRef] [PubMed]

- Ferraris, S.; Spriano, S. Antibacterial titanium surfaces for medical implants. Mater. Sci. Eng. C 2016, 61, 965–978. [Google Scholar] [CrossRef]

- Weder, J.E.; Dillon, C.T.; Hambley, T.W.; Kennedy, B.J.; Lay, P.A.; Biffin, J.R.; Regtop, H.L.; Davies, N.M. Copper complexes of non-steroidal anti-inflammatory drugs: An opportunity yet to be realized. Coord. Chem. Rev. 2002, 232, 95–126. [Google Scholar] [CrossRef]

- Liu, R.; Memarzadeh, K.; Chang, B.; Zhang, Y.M.; Ma, Z.; Allaker, R.P.; Ren, L.; Yang, K. Antibacterial effect of copper-bearing titanium alloy (Ti-Cu) against streptococcus mutans and Porphyromonas gingivalis. Sci. Rep. 2016, 6, 29985. [Google Scholar] [CrossRef]

- Zhuo, X.R.; Wu, Y.N.; Ju, J.; Liu, H.; Jiang, J.H.; Hu, Z.C.; Bai, J.; Xue, F. Recent progress of novel biodegradable zinc alloys: From the perspective of strengthening and toughening. J. Mater. Res. Technol. 2022, 17, 244–269. [Google Scholar] [CrossRef]

- Ren, K.X.; Zhang, K.X.; Zhang, Y.; Ju, J.; Yan, K.; Jiang, J.H.; Ma, A.B.; Xue, F.; Bai, J.; Liu, H. Effect of ECAP temperature on formation of triple heterogeneous microstructure and mechanical properties of Zn-1Cu alloy. Mater. Sci. Eng. A 2021, 826, 141990. [Google Scholar] [CrossRef]

- Bednarczyk, W.; Kawalko, J.; Watroba, M.; Gao, N.; Starink, M.J.; Bala, P.; Langdon, T.G. Microstructure and mechanical properties of a Zn-0.5Cu alloy processed by high-pressure torsion. Mater. Sci. Eng. A 2020, 776, 139047. [Google Scholar] [CrossRef]

- Lin, J.X.; Tong, X.; Shi, Z.M.; Zhang, D.C.; Zhang, L.S.; Wang, K.; Wei, A.P.; Jin, L.F.; Lin, J.G.; Li, Y.C.; et al. A biodegradable Zn-1Cu-0.1Ti alloy with antibacterial properties for orthopedic applications. Acta Biomater. 2020, 106, 410–427. [Google Scholar] [CrossRef]

- Mostaed, E.; Ardakani, M.S.; Sikora-Jasinska, M.; Drelich, J.W. Precipitation induced room temperature superplasticity in Zn-Cu alloys. Mater. Lett. 2019, 244, 203–206. [Google Scholar] [CrossRef] [PubMed]

- Lin, J.X.; Tong, X.; Wang, K.; Shi, Z.M.; Li, Y.C.; Dargusch, M.; Wen, C.E. Biodegradable Zn-3Cu and Zn-3Cu-0.2Ti alloys with ultrahigh ductility and antibacterial ability for orthopedic applications. J. Mater. Sci. Technol. 2021, 68, 76–90. [Google Scholar] [CrossRef]

- García-Mintegui, C.; Córdoba, L.C.; Buxadera-Palomero, J.; Marquina, A.; Jiménez-Piqué, E.; Ginebra, M.P.; Cortina, J.L.; Pegueroles, M. Zn-Mg and Zn-Cu alloys for stenting applications: From nanoscale mechanical characterization to degradation and biocompatibility. Bioact. Mater. 2021, 6, 4430–4446. [Google Scholar] [CrossRef] [PubMed]

- Huskins, E.L.; Cao, B.; Ramesh, K.T. Strengthening mechanisms in an Al-Mg alloy. Mater. Sci. Eng. A 2010, 527, 1292–1298. [Google Scholar] [CrossRef]

- Huang, T.L.; Shuai, L.F.; Wakeel, A.; Wu, G.L.; Hansen, N.; Huang, X.X. Strengthening mechanisms and Hall-Petch stress of ultrafine grained Al-0.3%Cu. Acta Mater. 2018, 156, 369–378. [Google Scholar] [CrossRef]

- Zhuo, X.R.; Zhang, Q.; Liu, H.; Hu, Z.C.; Zhang, P.; Jiang, J.H.; Ma, A.B.; Wu, Y.N. Enhanced tensile strength and ductility of an Al-6Si-3Cu alloy processed by room temperature rolling. J. Alloys Compd. 2022, 899, 163321. [Google Scholar] [CrossRef]

- Huang, H.; Liu, H.; Wang, L.S.; Li, Y.H.; Agbedor, S.O.; Bai, J.; Xue, F.; Jiang, J.H. A high-strength and biodegradable Zn-Mg alloy with refined ternary eutectic structure processed by ECAP. Acta Metall. Sin. (Eng. Lett.) 2020, 33, 1191–1200. [Google Scholar] [CrossRef]

- Ye, L.F.; Huang, H.; Sun, C.; Zhuo, X.R.; Dong, Q.S.; Liu, H.; Ju, J.; Xue, F.; Bai, J.; Jiang, J.H. Effect of grain size and volume fraction of eutectic structure on mechanical properties and corrosion behavior of as-cast Zn-Mg binary alloys. J. Mater. Res. Technol. 2022, 16, 1673–1685. [Google Scholar] [CrossRef]

- Capek, J.; Pinc, J.; Msallamová, S.; Jablonská, E.; Vertát, P.; Kubásek, J.; Vojtech, D. Thermal plasma spraying as a new approach for preparation of Zinc biodegradable scaffolds: A complex material characterization. J. Therm. Spray Technol. 2019, 28, 826–841. [Google Scholar] [CrossRef]

- Demir, A.G.; Monguzzi, L.; Previtali, B. Selective laser melting of pure Zn with high density for biodegradable implant manufacturing. Addit. Manuf. 2017, 15, 20–28. [Google Scholar] [CrossRef]

- Wen, P.; Jauer, L.; Voshage, M.; Chen, Y.Z.; Poprawe, R.; Schleifenbaum, J.H. Densification behavior of pure Zn metal parts produced by selective laser melting for manufacturing biodegradable implants. J. Mater. Process. Technol. 2018, 258, 128–137. [Google Scholar] [CrossRef]

- Wen, P.; Qin, Y.; Chen, Y.Z.; Voshage, M.; Jauer, L.; Poprawe, R.; Schleifenbaum, J.H. Laser additive manufacturing of Zn porous scaffolds: Shielding gas flow, surface quality and densification. J. Mater. Sci. Technol. 2019, 35, 368–376. [Google Scholar] [CrossRef]

- Wen, P.; Voshage, M.; Jauer, L.; Chen, Y.Z.; Qin, Y.; Poprawe, R.; Schleifenbaum, J.H. Laser additive manufacturing of Zn metal parts for biodegradable applications: Processing, formation quality and mechanical properties. Mater. Des. 2018, 155, 36–45. [Google Scholar] [CrossRef]

- Raoelison, R.N.; Xie, Y.; Sapanathan, T.; Planche, M.P.; Kromer, R.; Costil, S.; Langlade, C. Cold gas dynamic spray technology: A comprehensive review of processing conditions for various technological developments till to date. Addit. Manuf. 2018, 19, 134–159. [Google Scholar] [CrossRef]

- Li, W.Y.; Yang, K.; Yin, S.; Yang, X.W.; Xu, Y.X.; Lupoi, R. Solid-state additive manufacturing and repairing by cold spraying: A review. J. Mater. Sci. Technol. 2018, 34, 440–457. [Google Scholar] [CrossRef]

- Wei, Y.K.; Luo, X.T.; Chu, X.; Huang, G.S.; Li, C.J. Solid-state additive manufacturing high performance aluminum alloy 6061 enabled by an in-situ micro-forging assisted cold spray. Mater. Sci. Eng. A 2020, 776, 139024. [Google Scholar] [CrossRef]

- Boruah, D.; Zhang, X.; McNutt, P.; Khan, R.; Begg, H. Effect of Post-Deposition Thermal Treatments on Tensile Properties of Cold Sprayed Ti6Al4V. Metals 2022, 12, 1908. [Google Scholar] [CrossRef]

- Huang, J.; Yan, X.C.; Chang, C.; Xie, Y.C.; Ma, W.Y.; Huang, R.Z.; Zhao, R.M.; Li, S.H.; Liu, M.; Liao, H.L. Pure copper components fabricated by cold spray (CS) and selective laser melting (SLM) technology. Surf. Coat. Technol. 2020, 395, 125936. [Google Scholar] [CrossRef]

- Rokni, M.R.; Nutt, S.R.; Widener, C.A.; Champagne, V.K.; Hrabe, R.H. Review of relationship between particle deformation, coating microstructure, and properties in high-pressure cold spray. J. Therm. Spray Technol. 2017, 26, 1308–1355. [Google Scholar] [CrossRef]

- Zhu, L.; Jen, T.C.; Pan, Y.T.; Chen, H.S. Particle bonding mechanism in cold gas dynamic spray: A three-dimensional approach. J. Therm. Spray Technol. 2017, 26, 1859–1873. [Google Scholar] [CrossRef]

- Grujicic, M.; Zhao, C.L.; Derosset, W.S.; Helfritch, D. Adiabatic shear instability based mechanism for particles/substrate bonding in the cold-gas dynamic-spray process. Mater. Des. 2004, 25, 681–688. [Google Scholar] [CrossRef]

- Hassani-Gangaraj, M.; Veysset, D.; Nelson, K.A.; Schuh, C.A. Melting can hinder impact-induced adhesion. Phys. Rev. Lett. 2017, 119, 175701. [Google Scholar] [CrossRef]

- Coddet, P.; Verdy, C.; Coddet, C.; Debray, F. Mechanical properties of Cu-0.1Ag alloys deposited by cold spray with various powder feed rate and heat treatment. J. Therm. Spray Technol. 2015, 24, 119–125. [Google Scholar] [CrossRef]

- Coddet, P.; Verdy, C.; Coddet, C.; Lecouturier, F.; Debray, F. Comparison of the properties of cold-sprayed Cu-0.5Cr-0.05Zr alloys after various heat treatments versus forged and vacuum plasma-sprayed alloys. J. Therm. Spray Technol. 2014, 23, 486–491. [Google Scholar] [CrossRef]

- Bagherifard, S.; Roscioli, G.; Zuccoli, M.V.; Hadi, M.; D’Elia, G.; Demir, A.G.; Previtali, B.; Kondás, J.; Guagliano, M. Cold spray deposition of freestanding Inconel samples and comparative analysis with selective laser melting. J. Therm. Spray Technol. 2017, 26, 1517–1526. [Google Scholar] [CrossRef]

- DIN EN ISO 6892-1; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. Deutsches Institut für Normung: Berlin, Germany, 2016.

- Frattolin, J.; Roy, R.; Rajagopalan, S.; Walsh, M.; Yue, S.; Bertrand, O.F.; Mongrain, R. A manufacturing and annealing protocol to develop a cold-sprayed Fe-316L stainless steel biodegradable stenting material. Acta Biomater. 2019, 99, 479–494. [Google Scholar] [CrossRef] [PubMed]

- Fan, N.S.; Cizek, J.; Huang, C.J.; Xie, X.L.; Chlup, Z.; Jenkins, R.; Lupoi, R.; Yin, S. A new strategy for strengthening additively manufactured cold spray deposits through in-process densification. Addit. Manuf. 2020, 36, 101626. [Google Scholar] [CrossRef]

- Huang, R.Z.; Sone, M.; Ma, W.H.; Fukanuma, H. The effects of heat treatment on the mechanical properties of cold-sprayed coatings. Surf. Coat. Technol. 2015, 261, 278–288. [Google Scholar] [CrossRef]

- Huang, C.J.; Arseenko, M.; Zhao, L.; Xie, Y.C.; Elsenberg, A.; Li, W.Y.; Gärtner, F.; Simar, A.; Klassen, T. Property prediction and crack growth behavior in cold sprayed Cu deposits. Mater. Des. 2021, 206, 109826. [Google Scholar] [CrossRef]

- Huang, J.J.; Lai, Y.L.; Jin, H.L.; Guo, H.M.; Ai, F.R.; Xing, Q.; Yang, X.J.; Ross, D.J. Preparation and properties of Zn-Cu alloy for potential stent material. J. Mater. Eng. Perform. 2020, 29, 6484–6493. [Google Scholar] [CrossRef]

- Zhou, H.X.; Li, C.X.; Ji, G.; Fu, S.L.; Yang, H.; Luo, X.T.; Yang, G.J.; Li, C.J. Local microstructure inhomogeneity and gas temperature effect in shot-peening assisted cold-sprayed Ti-6Al-4V coating. J. Alloys Compd. 2018, 766, 694–704. [Google Scholar] [CrossRef]

- List, A.; Huang, C.; Wiehler, L.; Gieseler, C.P.; Schulze, M.; Gaertner, F.; Klassen, T. Influence of ductility on fracture in tensile testing of cold gas sprayed deposits. J. Therm. Spray Technol. 2023, 32, 1780–1795. [Google Scholar] [CrossRef]

- Singh, S.; Singh, H.; Chaudhary, S.; Buddu, R.K. Effect of substrate surface roughness on properties of cold-sprayed copper coatings on SS316L steel. Surf. Coat. Technol. 2020, 389, 125619. [Google Scholar] [CrossRef]

- Sundararajan, G.; Phani, P.S.; Jyothirmayi, A.; Gundakaram, R.C. The influence of heat treatment on the microstructural, mechanical and corrosion behaviour of cold sprayed SS 316L coatings. J. Mater. Sci. 2009, 44, 2320–2326. [Google Scholar] [CrossRef]

- Tang, Z.B.; Niu, J.L.; Huang, H.; Zhang, H.; Pei, J.; Ou, J.M.; Yuan, G.Y. Potential biodegradable Zn-Cu binary alloys developed for cardiovascular implant applications. J. Mech. Behav. Biomed. 2017, 72, 182–191. [Google Scholar] [CrossRef] [PubMed]

- Li, P.; Zhang, W.T.; Dai, J.T.; Xepapadeas, A.B.; Schweizer, E.; Alexander, D.; Scheideler, L.; Zhou, C.; Zhang, H.J.; Wan, G.; et al. Investigation of zinc-copper alloys as potential materials for craniomaxillofacial osteosynthesis implants. Mater. Sci. Eng. C 2019, 103, 109826. [Google Scholar] [CrossRef]

- Chen, C.; Yue, R.; Zhang, J.; Huang, H.; Niu, J.L.; Yuan, G.Y. Biodegradable Zn-1.5Cu-1.5Ag alloy with anti-aging ability and strain hardening behavior for cardiovascular stents. Mater. Sci. Eng. C 2020, 116, 111172. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Liu, X.Y.; Huang, H.; Zhan, W. Effects of Ti on microstructure, mechanical properties and biodegradation behavior of Zn-Cu alloy. Mater. Lett. 2019, 244, 119–122. [Google Scholar] [CrossRef]

- Liu, J.B.; Wang, D.K.; Liu, B.; Li, N.; Liang, L.X.; Chen, C.; Zhou, K.C.; Baker, I.; Wu, H. Microstructural evolution, mechanical properties and corrosion mechanisms of additively manufactured biodegradable Zn-Cu alloys. J. Mater. Sci. Technol. 2024, 186, 142–157. [Google Scholar] [CrossRef]

- Zhao, Z.P.; Tariq, N.U.; Tang, J.R.; Jia, C.L.; Qiu, X.; Ren, Y.P.; Liu, H.H.; Shen, Y.F.; Du, H.; Cui, X.Y.; et al. Microstructural evolutions and mechanical characteristics of Ti/steel clad plates fabricated through cold spray additive manufacturing followed by hot-rolling and annealing. Mater. Des. 2020, 185, 108249. [Google Scholar] [CrossRef]

- Melero, H.; Torrell, M.; Fernández, J.; Gomes, J.R.; Guilemany, J.M. Tribological characterization of biocompatible HAp-TiO2 coatings obtained by high velocity oxy-fuel spray. Wear 2013, 305, 8–13. [Google Scholar] [CrossRef]

- Savaskan, T.; Maleki, R.A. Friction and wear properties of Zn-25Al-based bearing alloys. Tribol. Trans. 2014, 57, 435–444. [Google Scholar] [CrossRef]

- Hanna, M.D.; Carter, J.T.; Rashid, M.S. Sliding wear and friction characteristics of six Zn-based die-casting alloys. Wear 1997, 203–204, 11–21. [Google Scholar] [CrossRef]

- El-Khair, M.T.A.; Daoud, A.; Ismail, A. Effect of different Al contents on the microstructure, tensile and wear properties of Zn-based alloy. Mater. Lett. 2004, 58, 1754–1760. [Google Scholar] [CrossRef]

- Kabir, H.; Munir, K.; Wen, C.; Li, Y.C. Recent research and progress of biodegradable zinc alloys and composites for biomedical applications: Biomechanical and biocorrosion perspectives. Bioact. Mater. 2021, 6, 836–879. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, X.-Z.; Tan, X.-B.; Xie, B.; Yao, H.-L.; Yang, C.; Zhou, T. The Effect of Post Heat Treatment on the Microstructure and Mechanical Properties of Cold-Sprayed Zn-6Cu Deposits. Materials 2024, 17, 6096. https://doi.org/10.3390/ma17246096

Hu X-Z, Tan X-B, Xie B, Yao H-L, Yang C, Zhou T. The Effect of Post Heat Treatment on the Microstructure and Mechanical Properties of Cold-Sprayed Zn-6Cu Deposits. Materials. 2024; 17(24):6096. https://doi.org/10.3390/ma17246096

Chicago/Turabian StyleHu, Xiao-Zhen, Xiao-Bo Tan, Bin Xie, Hai-Long Yao, Chao Yang, and Tao Zhou. 2024. "The Effect of Post Heat Treatment on the Microstructure and Mechanical Properties of Cold-Sprayed Zn-6Cu Deposits" Materials 17, no. 24: 6096. https://doi.org/10.3390/ma17246096

APA StyleHu, X.-Z., Tan, X.-B., Xie, B., Yao, H.-L., Yang, C., & Zhou, T. (2024). The Effect of Post Heat Treatment on the Microstructure and Mechanical Properties of Cold-Sprayed Zn-6Cu Deposits. Materials, 17(24), 6096. https://doi.org/10.3390/ma17246096