Permeable Asphalt Pavements (PAP): Benefits, Clogging Factors and Methods for Evaluation and Maintenance—A Review

Abstract

1. Introduction

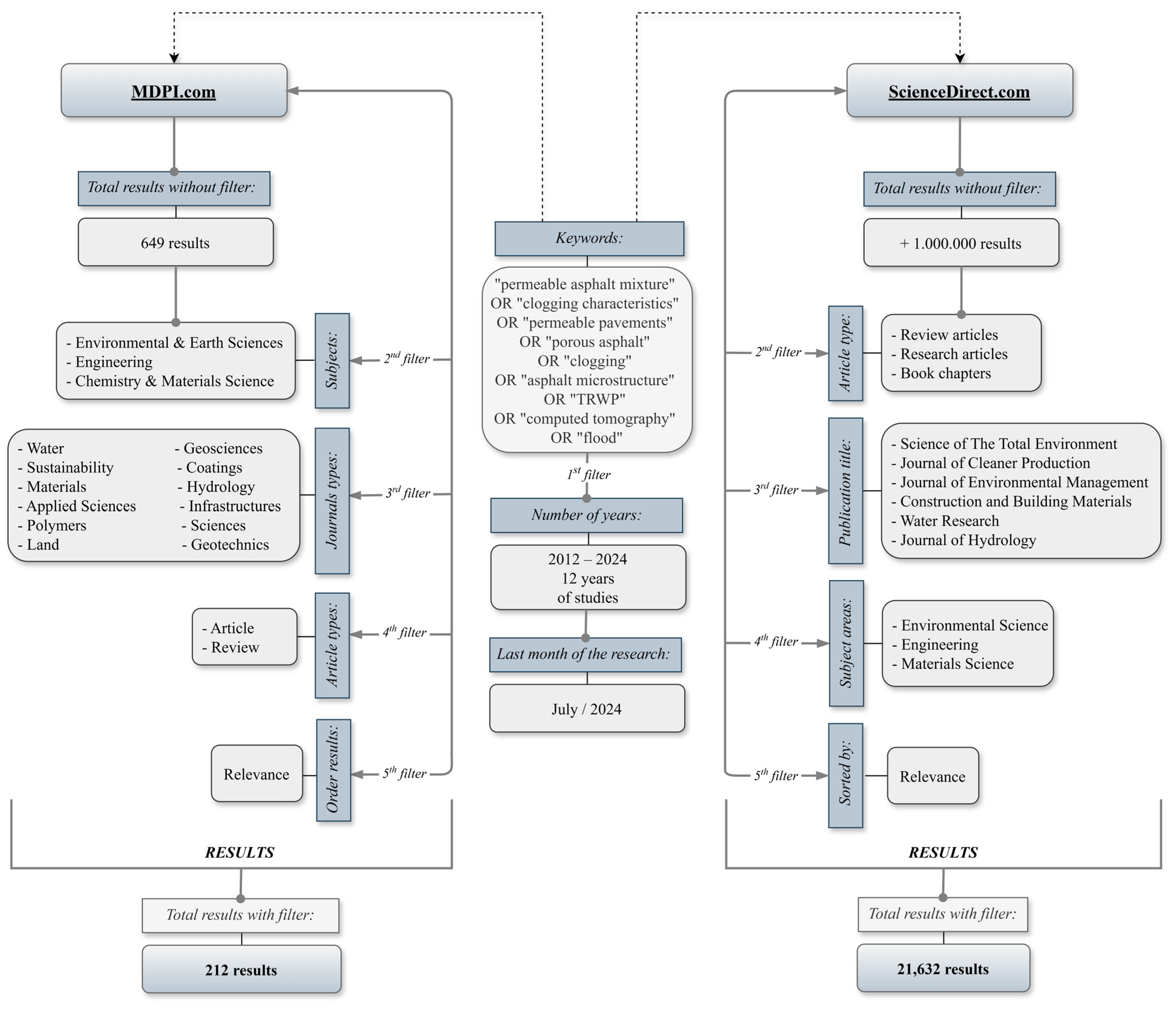

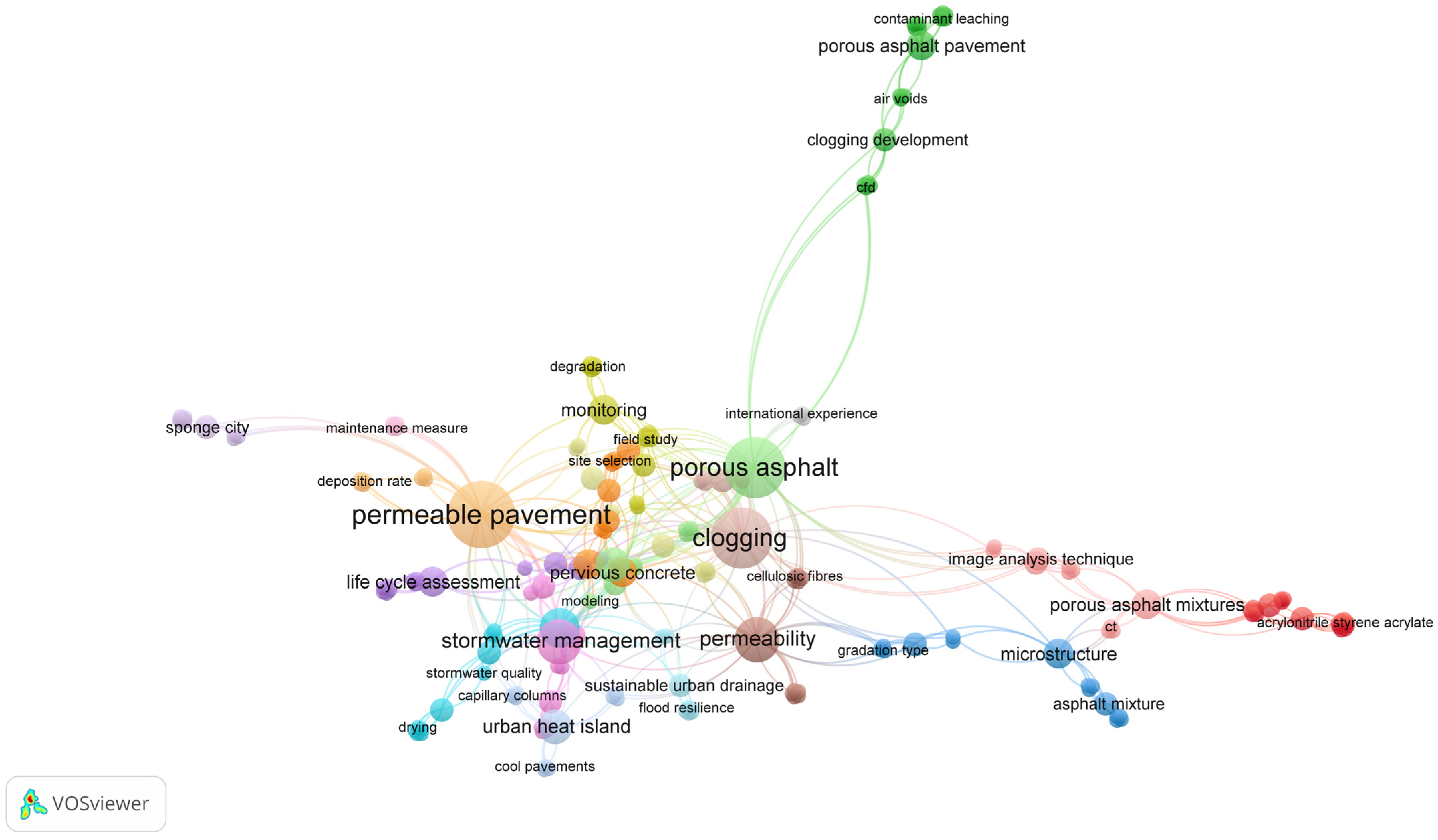

2. Methodology

3. Permeable Asphalt Pavements (PAPs)

3.1. Definition

3.2. Benefits

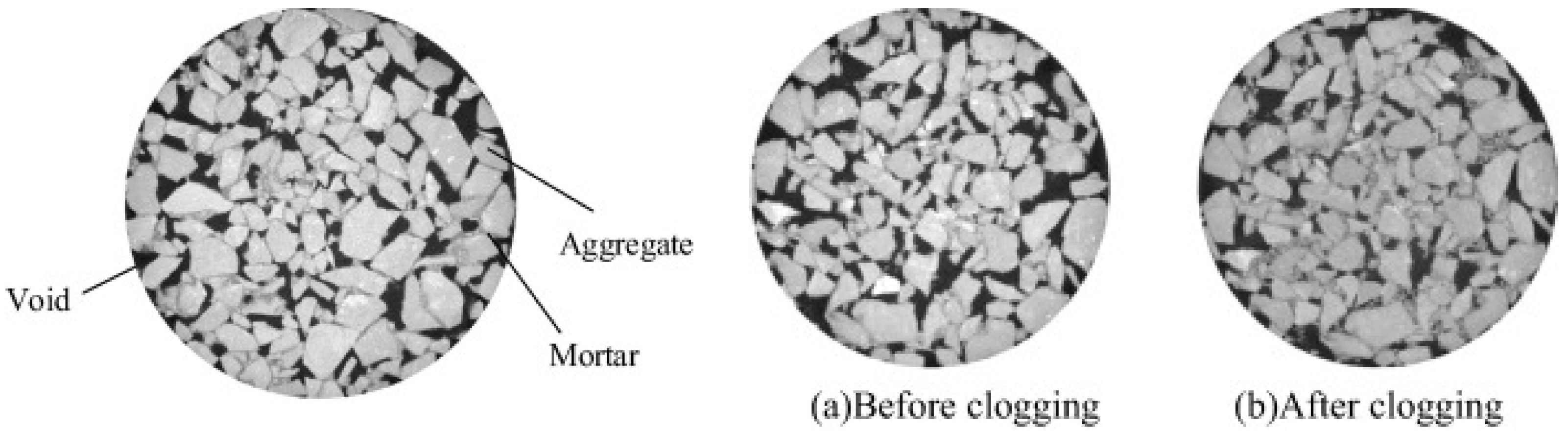

3.3. Clogging

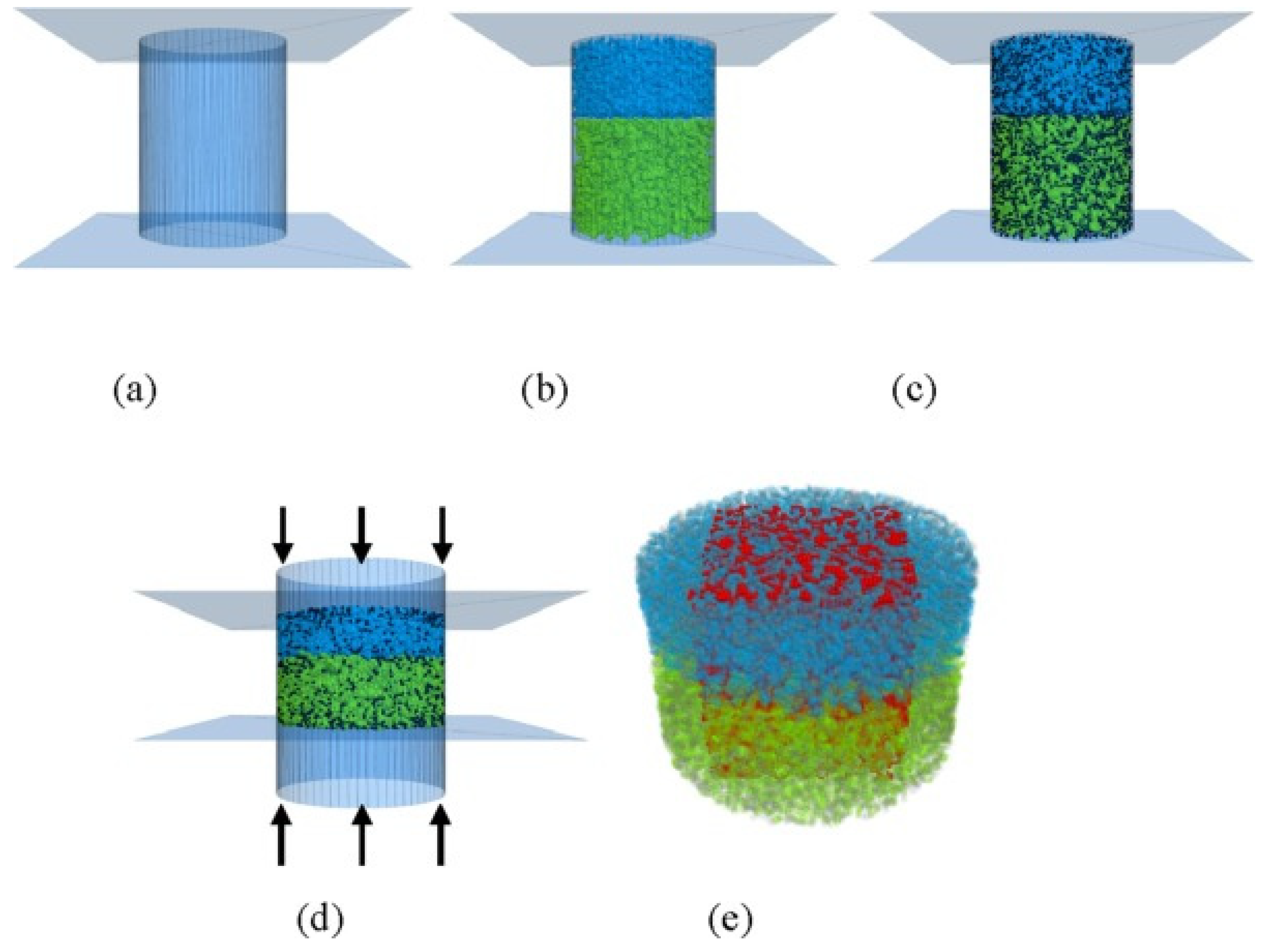

3.4. Methods of Evaluating Clogging

3.5. Maintenance Techniques

4. Results Analysis of Clogging in Pavements

5. Discussion and Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Antunes, L.N.; Ghisi, E.; Severis, R.M. Environmental assessment of a permeable pavement system used to harvest stormwater for non-potable water uses in a building. Sci. Total Environ. 2020, 746, 141087. [Google Scholar] [CrossRef] [PubMed]

- Mustafa, A.; Bruwier, M.; Archambeau, P.; Erpicum, S.; Pirotton, M.; Dewals, B.; Teller, J. Effects of spatial planning on future flood risks in urban environments. J. Environ. Manag. 2018, 225, 193–204. [Google Scholar] [CrossRef] [PubMed]

- Brunetti, G.; Šimůnek, J.; Piro, P. A comprehensive numerical analysis of the hydraulic behavior of a permeable pavement. J. Hydrol. 2016, 540, 1146–1161. [Google Scholar] [CrossRef]

- Vaz, I.C.M.; Ghisi, E.; Thives, L.P. Life cycle energy assessment and economic feasibility of stormwater harvested from pervious pavements. Water Res. 2020, 170, 115322. [Google Scholar] [CrossRef]

- Meng, A.; Xing, C.; Tan, Y.; Xiao, S.; Li, J.; Li, G. Investigation on clogging characteristics of permeable asphalt mixtures. Constr. Build. Mater. 2020, 264, 120273. [Google Scholar] [CrossRef]

- Chu, L.; Fwa, T.F. Evaluation of surface infiltration performance of permeable pavements. J. Environ. Manag. 2019, 238, 136–143. [Google Scholar] [CrossRef] [PubMed]

- Jin, D.; Meyer, T.K.; Chen, S.; Boateng, K.A.; Pearce, J.M.; You, Z. Evaluation of lab performance of stamp sand and acrylonitrile styrene acrylate waste composites without asphalt as road surface materials. Constr. Build. Mater. 2022, 338, 127569. [Google Scholar] [CrossRef]

- MDPI. MDPI|About. Available online: https://www.mdpi.com/about (accessed on 17 November 2024).

- ScienceDirect. Browse Engineering Journals and Books—Page 1|ScienceDirect.com. Available online: https://www.sciencedirect.com/browse/journals-and-books?subject=engineering (accessed on 17 November 2024).

- VOSviewerVisualizing Scientific Landscapes. Available online: https://www.vosviewer.com/ (accessed on 17 November 2024).

- Garcia, A.; Aboufoul, M.; Asamoah, F.; Jing, D. Study the influence of the air void topology on porous asphalt clogging. Constr. Build. Mater. 2019, 227, 116791. [Google Scholar] [CrossRef]

- CIRIA. CIRIA. Available online: https://www.ciria.org/ (accessed on 17 November 2024).

- Afonso, M.L.; Dinis-Almeida, M.; Fael, C.S. Study of the porous asphalt performance with cellulosic fibres. Constr. Build. Mater. 2017, 135, 104–111. [Google Scholar] [CrossRef]

- Jato-Espino, D.; Sillanpää, N.; Charlesworth, S.M.; Andrés-Doménech, I. Coupling GIS with stormwater modelling for the location prioritization and hydrological simulation of permeable pavements in urban catchments. Water 2016, 8, 451. [Google Scholar] [CrossRef]

- Woods, B.; Wilson, S.; Udale-Clarke, H.; Illman, S.; Scott, T.; Ashley, R.; Kellagher, R. The Suds Manual—Pervious Pavements. CIRIA 2015, 1, 386–435. Available online: https://www.ciria.org/ItemDetail?iProductCode=C753F&Category=FREEPUBS (accessed on 25 July 2024).

- Jiang, W.; Sha, A.; Xiao, J.; Li, Y.; Huang, Y. Experimental study on filtration effect and mechanism of pavement runoff in permeable asphalt pavement. Constr. Build. Mater. 2015, 100, 102–110. [Google Scholar] [CrossRef]

- Azadgoleh, M.A.; Mohammadi, M.M.; Ghodrati, A.; Sharifi, S.S.; Palizban, S.M.M.; Ahmadi, A.; Vahidi, E.; Ayar, P. Characterization of contaminant leaching from asphalt pavements: A critical review of measurement methods, reclaimed asphalt pavement, porous asphalt, and waste-modified asphalt mixtures. Water Res. 2022, 219, 118584. [Google Scholar] [CrossRef] [PubMed]

- Elizondo-Martínez, E.-J.; Andrés-Valeri, V.-C.; Rodríguez-Hernández, J.; Sangiorgi, C. Selection of Additives and Fibers for Improving the Mechanical and Safety Properties of Porous Concrete Pavements through Multi-Criteria Decision-Making Analysis. Sustainability 2020, 12, 2392. [Google Scholar] [CrossRef]

- Chen, H.; Lu, C.; Yang, H. Lanthanum compounds-modified rectorite composites for highly efficient phosphate removal from wastewater. Appl. Clay Sci. 2020, 199, 105875. [Google Scholar] [CrossRef]

- Alam, T.; Mahmoud, A.; Jones, K.D.; Bezares-Cruz, J.C.; Guerrero, J. A Comparison of Three Types of Permeable Pavements for Urban Runoff Mitigation in the Semi-Arid South Texas, U.S.A. Water 2019, 11, 1992. [Google Scholar] [CrossRef]

- Huang, J.; He, J.; Valeo, C.; Chu, A. Temporal evolution modeling of hydraulic and water quality performance of permeable pavements. J. Hydrol. 2016, 533, 15–27. [Google Scholar] [CrossRef]

- Hashim, T.M.; Al-Mulali, M.Z.; Al-Khafaji, F.F.; Alwash, A.A.A.; Ali, Y.A. An experimental comparison between different types of surface patterns of permeable interlocking concrete pavement for roadway subsurface drainage. Case Stud. Constr. Mater. 2022, 17, e01227. [Google Scholar] [CrossRef]

- Rodríguez-Rojas, M.I.; Huertas-Fernández, F.; Moreno, B.; Martínez, G.; Grindlay, A.L. A study of the application of permeable pavements as a sustainable technique for the mitigation of soil sealing in cities: A case study in the south of Spain. J. Environ. Manag. 2018, 205, 151–162. [Google Scholar] [CrossRef]

- Akbari, H.; Kolokotsa, D. Three decades of urban heat islands and mitigation technologies research. Energy Build. 2016, 133, 834–842. [Google Scholar] [CrossRef]

- Coseo, P.; Larsen, L. Cooling the Heat Island in Compact Urban Environments: The Effectiveness of Chicago’s Green Alley Program. Procedia Eng. 2015, 118, 691–710. [Google Scholar] [CrossRef]

- Fang, M.; Wang, X.; Liu, J.; Xu, Z.; Chen, Y. Design, application and performance improvement of Eco-Permeable pavement materials (Eco-PPMs): A review. Constr. Build. Mater. 2022, 360, 129558. [Google Scholar] [CrossRef]

- Wang, J.; Meng, Q.; Zou, Y.; Qi, Q.; Tan, K.; Santamouris, M.; He, B.-J. Performance synergism of pervious pavement on stormwater management and urban heat island mitigation: A review of its benefits, key parameters, and co-benefits approach. Water Res. 2022, 221, 118755. [Google Scholar] [CrossRef]

- Qin, Y.; Ghalambaz, S.; Sheremet, M.; Baro, M.; Ghalambaz, M. Deciphering Urban Heat Island Mitigation: A Comprehensive Analysis of Application Categories and Research Trends. Sustain. Cities Soc. 2024, 101, 105081. [Google Scholar] [CrossRef]

- Raeesi, R.; Xue, Y.; Disfani, M.M.; Arora, M. Hydrological and water quality performance of Waste Tire Permeable Pavements: Field monitoring and numerical analysis. J. Environ. Manag. 2022, 323, 116199. [Google Scholar] [CrossRef]

- Suriya, S.; Mudgal, B.V. Impact of urbanization on flooding: The Thirusoolam sub watershed—A case study. J. Hydrol. 2012, 412–413, 210–219. [Google Scholar] [CrossRef]

- Lai, F.; Huang, Z.; Guo, F. Noise Reduction Characteristics of Macroporous Asphalt Pavement Based on A Weighted Sound Pressure Level Sensor. Materials 2021, 14, 4356. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.; Huang, X.; Xue, G. Effects of double layer porous asphalt pavement of urban streets on noise reduction. Int. J. Sustain. Built Environ. 2016, 5, 183–196. [Google Scholar] [CrossRef]

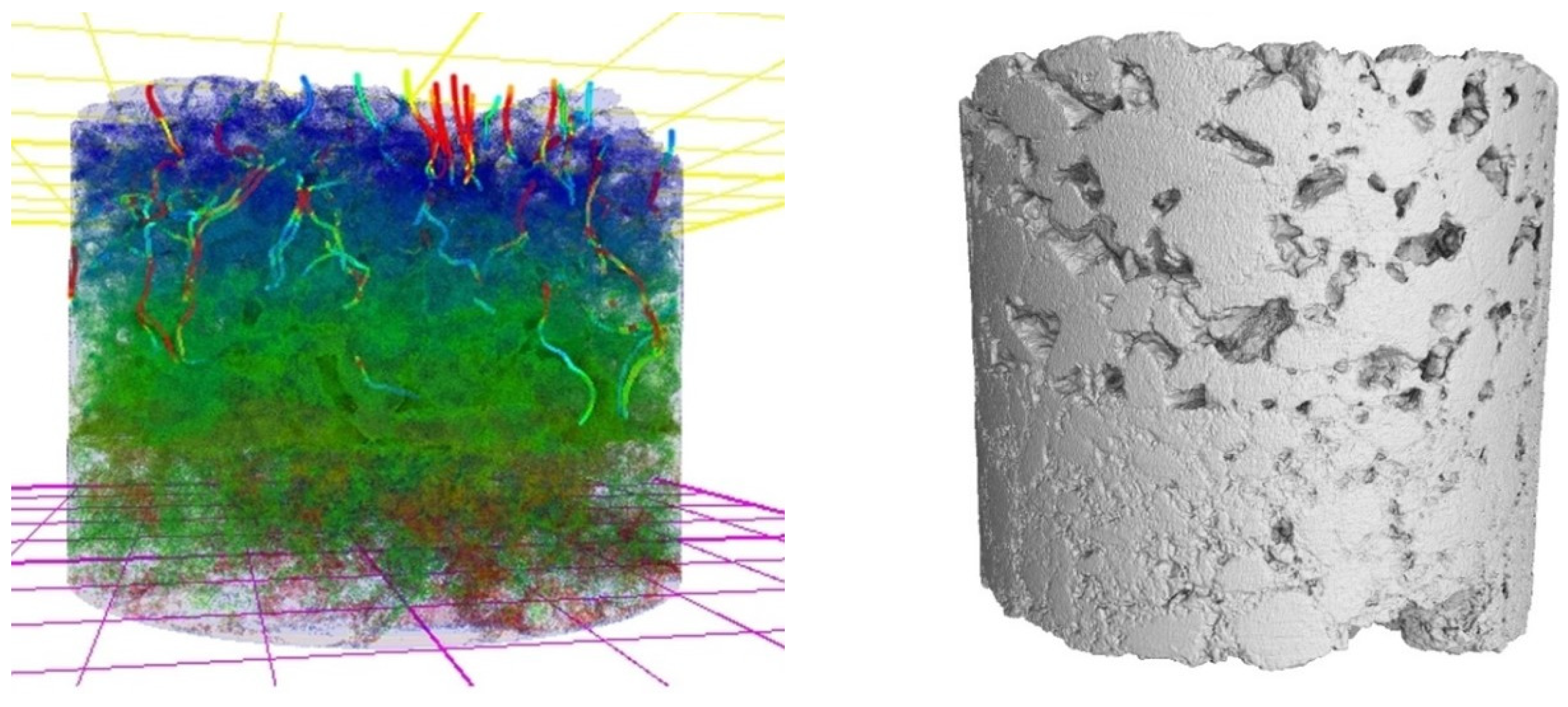

- Sun, J.; Zhang, H.; Yu, T.; Shi, Y.; Liu, Y. Microscopic void characteristics of OGFC in Sponge City and its effect on noise reduction performance using X-ray CT. Constr. Build. Mater. 2023, 408, 133729. [Google Scholar] [CrossRef]

- Rasmussen, L.A.; Lykkemark, J.; Andersen, T.R.; Vollertsen, J. Permeable pavements: A possible sink for tyre wear particles and other microplastics? Sci. Total Environ. 2023, 869, 161770. [Google Scholar] [CrossRef]

- Sambito, M.; Severino, A.; Freni, G.; Neduzha, L. A Systematic Review of the Hydrological, Environmental and Durability Performance of Permeable Pavement Systems. Sustainability 2021, 13, 4509. [Google Scholar] [CrossRef]

- Jung, U.; Choi, S.S. Classification and Characterization of Tire-Road Wear Particles in Road Dust by Density. Polymers 2022, 14, 1005. [Google Scholar] [CrossRef] [PubMed]

- Khan, F.R.; Halle, L.L.; Palmqvist, A. Acute and long-term toxicity of micronized car tire wear particles to Hyalella azteca. Aquat. Toxicol. 2019, 213, 105216. [Google Scholar] [CrossRef]

- Li, Y.; Shi, T.; Li, X.; Sun, H.; Xia, X.; Ji, X.; Zhang, J.; Liu, M.; Lin, Y.; Zhang, R.; et al. Inhaled tire-wear microplastic particles induced pulmonary fibrotic injury via epithelial cytoskeleton rearrangement. Environ. Int. 2022, 164, 107257. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Li, T.; Yu, L. Urban heat island mitigation and hydrology performance of innovative permeable pavement: A pilot-scale study. J. Clean. Prod. 2020, 244, 118938. [Google Scholar] [CrossRef]

- Meng, A.; Xing, C.; Tan, Y.; Li, G.; Li, J.; Lv, H. Investigation on the distributing behaviors of clogging particles in permeable asphalt mixtures from the microstructure perspective. Constr. Build. Mater. 2020, 263, 120531. [Google Scholar] [CrossRef]

- Xu, S.; Lu, G.; Hong, B.; Jiang, X.; Peng, G.; Wang, D.; Oeser, M. Experimental investigation on the development of pore clogging in novel porous pavement based on polyurethane. Constr. Build. Mater. 2020, 258, 120378. [Google Scholar] [CrossRef]

- Kumar, K.; Kozak, J.; Hundal, L.; Cox, A.; Zhang, H.; Granato, T. In-situ infiltration performance of different permeable pavements in a employee used parking lot—A four-year study. J. Environ. Manag. 2016, 167, 8–14. [Google Scholar] [CrossRef] [PubMed]

- Goßmann, I.; Halbach, M.; Scholz-Böttcher, B.M. Car and truck tire wear particles in complex environmental samples—A quantitative comparison with ‘traditional’ microplastic polymer mass loads. Sci. Total Environ. 2021, 773, 145667. [Google Scholar] [CrossRef]

- Klöckner, P.; Reemtsma, T.; Eisentraut, P.; Braun, U.; Ruhl, A.S.; Wagner, S. Tire and road wear particles in road environment—Quantification and assessment of particle dynamics by Zn determination after density separation. Chemosphere 2019, 222, 714–721. [Google Scholar] [CrossRef]

- Wagner, S.; Hüffer, T.; Klöckner, P.; Wehrhahn, M.; Hofmann, T.; Reemtsma, T. Tire wear particles in the aquatic environment—A review on generation, analysis, occurrence, fate and effects. Water Res. 2018, 139, 83–100. [Google Scholar] [CrossRef] [PubMed]

- Baensch-Baltruschat, B.; Kocher, B.; Stock, F.; Reifferscheid, G. Tyre and road wear particles (TRWP)—A review of generation, properties, emissions, human health risk, ecotoxicity, and fate in the environment. Sci. Total Environ. 2020, 733, 137823. [Google Scholar] [CrossRef] [PubMed]

- Jayakaran, A.D.; Knappenberger, T.; Stark, J.D.; Hinman, C. Remediation of Stormwater Pollutants by Porous Asphalt Pavement. Water 2019, 11, 520. [Google Scholar] [CrossRef]

- Hernández-Crespo, C.; Fernández-Gonzalvo, M.; Martín, M.; Andrés-Doménech, I. Influence of rainfall intensity and pollution build-up levels on water quality and quantity response of permeable pavements. Sci. Total Environ. 2019, 684, 303–313. [Google Scholar] [CrossRef] [PubMed]

- Coleri, E.; Kayhanian, M.; Harvey, J.T.; Yang, K.; Boone, J.M. Clogging evaluation of open graded friction course pavements tested under rainfall and heavy vehicle simulators. J. Environ. Manag. 2013, 129, 164–172. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Li, Y.; Han, Z.; Du, Y.; Mohammed, M.A.; Wang, W.; Huang, J. A novel multiphase segmentation method for interpreting the 3D mesoscopic structure of asphalt mixture using CT images. Constr. Build. Mater. 2022, 327, 127010. [Google Scholar] [CrossRef]

- Mahmud, M.Z.H.; Hassan, N.A.; Hainin, M.R.; Ismail, C.R. Microstructural investigation on air void properties of porous asphalt using virtual cut section. Constr. Build. Mater. 2017, 155, 485–494. [Google Scholar] [CrossRef]

- Mahmud, M.Z.H.; Hassan, N.A.; Hainin, M.R.; Ismail, C.R.; Jaya, R.P.; Warid, M.N.M.; Yaacob, H.; Mashros, N. Characterisation of microstructural and sound absorption properties of porous asphalt subjected to progressive clogging. Constr. Build. Mater. 2021, 283, 122654. [Google Scholar] [CrossRef]

- Kollmann, J.; Liu, P.; Lu, G.; Wang, D.; Oeser, M.; Leischner, S. Investigation of the microstructural fracture behaviour of asphalt mixtures using the finite element method. Constr. Build. Mater. 2019, 227, 117078. [Google Scholar] [CrossRef]

- Xing, C.; Xu, H.; Tan, Y.; Liu, X.; Zhou, C.; Scarpas, T. Gradation measurement of asphalt mixture by X-Ray CT images and digital image processing methods. Measurement 2019, 132, 377–386. [Google Scholar] [CrossRef]

- Yu, B.; Gu, X.; Ni, F.; Gao, L. Microstructure characterization of cold in-place recycled asphalt mixtures by X-ray computed tomography. Constr. Build. Mater. 2018, 171, 969–976. [Google Scholar] [CrossRef]

- Deng, H.; Gu, X.; Wang, X.; Wu, C.; Zhu, C. Evaluation of high-temperature deformation of porous asphalt mixtures based on microstructure using X-ray computed tomography. Constr. Build. Mater. 2019, 227, 116623. [Google Scholar] [CrossRef]

- Hu, J.; Ma, T.; Ma, K. DEM-CFD simulation on clogging and degradation of air voids in double-layer porous asphalt pavement under rainfall. J. Hydrol. 2021, 595, 126028. [Google Scholar] [CrossRef]

- Ling, S.; Sun, Y.; Sun, D.; Jelagin, D. Pore characteristics and permeability simulation of porous asphalt mixture in pouring semi-flexible pavement. Constr. Build. Mater. 2022, 330, 127253. [Google Scholar] [CrossRef]

- Jerjen, I.; Poulikakos, L.D.; Plamondon, M.; Schuetz, P.; Luethi, T.; Flisch, A. Drying of Porous Asphalt Concrete Investigated by X-Ray Computed Tomography. Phys. Procedia 2015, 69, 451–456. [Google Scholar] [CrossRef]

- Poulikakos, L.D.; Gilani, M.S.; Derome, D.; Jerjen, I.; Vontobel, P. Time resolved analysis of water drainage in porous asphalt concrete using neutron radiography. Appl. Radiat. Isot. 2013, 77, 5–13. [Google Scholar] [CrossRef]

- Yong, C.F.; McCarthy, D.T.; Deletic, A. Predicting physical clogging of porous and permeable pavements. J. Hydrol. 2013, 481, 48–55. [Google Scholar] [CrossRef]

- Kia, A.; Wong, H.S.; Cheeseman, C.R. Clogging in Permeable Concrete: A Review; Academic Press: Cambridge, MA, USA, 2017. [Google Scholar] [CrossRef]

- Hung, A.; Li, L.Y.; Swei, O. Evaluation of permeable highway pavements via an integrated life-cycle model. J. Clean. Prod. 2021, 314, 128043. [Google Scholar] [CrossRef]

- Winston, R.J.; Al-Rubaei, A.M.; Blecken, G.T.; Viklander, M.; Hunt, W.F. Maintenance measures for preservation and recovery of permeable pavement surface infiltration rate—The effects of street sweeping, vacuum cleaning, high pressure washing, and milling. J. Environ. Manag. 2016, 169, 132–144. [Google Scholar] [CrossRef]

- Wu, Y.; Li, J.; Zhang, X.; Lin, C.; Guo, X.; Zhang, X. A systematic field effectiveness evaluation of three maintenance measures for three permeable pavements. Constr. Build. Mater. 2022, 352, 128821. [Google Scholar] [CrossRef]

- Razzaghmanesh, M.; Beecham, S. A Review of Permeable Pavement Clogging Investigations and Recommended Maintenance Regimes. Water 2018, 10, 337. [Google Scholar] [CrossRef]

- Valeo, C.; Gupta, R. Determining surface infiltration rate of permeable pavements with digital imaging. Water 2018, 10, 133. [Google Scholar] [CrossRef]

- Dreelin, E.A.; Fowler, L.; Carroll, C.R. A test of porous pavement effectiveness on clay soils during natural storm events. Water Res. 2006, 40, 799–805. [Google Scholar] [CrossRef]

- Zhang, Z.; Xuan, D.L.; Qiao, Y.; Giustozzi, F. Investigation of the effect of sediment clogging on the hydraulic conductivity of porous asphalt mixes using CFD and DEM methods. Constr. Build. Mater. 2024, 431, 136566. [Google Scholar] [CrossRef]

- Maia, R.S.; Lu, Y.; Hajj, R. Porous asphalt mixture performance in cold regions: Case study of Chicago. Case Stud. Constr. Mater. 2024, 20, e03250. [Google Scholar] [CrossRef]

- Sañudo-Fontaneda, L.A.; Andres-Valeri, V.C.; Costales-Campa, C.; Cabezon-Jimenez, I.; Cadenas-Fernandez, F. The long-term hydrological performance of Permeable Pavement Systems in Northern Spain: An approach to the ‘end-of-life’ concept. Water 2018, 10, 497. [Google Scholar] [CrossRef]

- García-Haba, E.; Naves, J.; Hernández-Crespo, C.; Goya-Heredia, A.; Suárez, J.; Anta, J.; Andrés-Doménech, I. Influence of sediment characteristics on long-term hydrology and water quality behaviour during the clogging process of a permeable asphalt. J. Water Process Eng. 2023, 53, 103658. [Google Scholar] [CrossRef]

| Type of Pavement | Maintenance Method | Efficiency | References |

|---|---|---|---|

| Concrete grid pavers (CGPs) (Residential street) | Manual removal of upper 2 cm | Infiltration improvement was limited (9–55%) and ineffective for deep clogging; manual removal failed. | [64] |

| Permeable interlocking concrete pavers (PICPs) (Residential street) | Manual removal of upper 2 cm | Manual removal was effective for surface cleaning (61–100% infiltration) but ineffective for deep clogging (4–22% infiltration). | [64] |

| Porous asphalt (Residential street) | Vacuuming, pressure washing, milling | Milling restored infiltration, while pressure washing was partially ineffective (3–5% improvement). | [64] |

| Permeable interlocking concrete pavers (PICPs) (Parking lot) | Regenerative air street sweeper or mechanical street sweeper | The regenerative air sweeper was highly efficient (16–100% infiltration), surpassing the mechanical sweeper (2–68%). | [64] |

| Permeable interlocking concrete pavers (PICPs) (Community center parking lot) | Vacuum truck with 1 pass and 3 passes | Percentage of infiltration after maintenance: Vacuum 1 pass: 100%. Vacuum 3 passes: 76–100%. | [64] |

| Concrete pavement (PC), Interlocking impermeable concrete brick pavement (IIC), Interlocking permeable concrete brick pavement (IPC) | High-pressure water washing (HW), Low-pressure suction (LS), High-pressure air flushing (HA) | Maintenance solutions varied by pavement type, with LS, HW and HA proving most efficient. | [65] |

| Porous pavement of grass pavers (Parking lot) Traditional asphalt pavement (Parking lot) | Regular sediment removal and cleaning of pavement voids, along with surface waste maintenance, are essential | Porous pavements reduce runoff (up to 93%) but require regular maintenance, unlike asphalt, which increases runoff and turbidity. | [68] |

| Porous asphalt (PA) PA with 20% porosity and PA with 25% porosity | Surface cleaning Surface cleaning with water pressure Deep vacuuming | Simulation results: Unclogged PA 20%: Porosity of 19.02%. Unclogged PA 25%: Porosity of 25.68%. Clogged PA 20%: Porosity reduced to 16.88%. Clogged PA 25%: Porosity reduced to 23.72%. | [69] |

| Porous asphalt mixtures (PAMs) Performance evaluation of PAMs in cold regions | CT scan and surface texture analyses, binder extraction and recovery, along with regular snow and ice removal maintenance | Reduced surface texture quality, increased binder stiffness and brittleness, with altered air void distribution. | [70] |

| Hydrological performance (Car park “Las Llamas”) Interlocking Concrete Block Pavements (ICBPs) Permeable Pavement Systems (PPSs) | Permeability tests using permeameter, Spanish standards and ASTM test. | After 10 years without maintenance, the clogged pavement reached the end of its operational life. | [71] |

| Simulation study: Permeable Pavements (PPs) | Two rainfall simulators were built to study sediment gradation effects on clogging (University—UDC) and pollutant reduction at different clogging levels (University—UPV). | Surface vacuuming reduced permeability by 22–99% due to sediment load, with recovery ranging from 8–100% post-cleaning. | [72] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sousa, M.; Dinis Almeida, M.; Fael, C.; Bentes, I. Permeable Asphalt Pavements (PAP): Benefits, Clogging Factors and Methods for Evaluation and Maintenance—A Review. Materials 2024, 17, 6063. https://doi.org/10.3390/ma17246063

Sousa M, Dinis Almeida M, Fael C, Bentes I. Permeable Asphalt Pavements (PAP): Benefits, Clogging Factors and Methods for Evaluation and Maintenance—A Review. Materials. 2024; 17(24):6063. https://doi.org/10.3390/ma17246063

Chicago/Turabian StyleSousa, Maria, Marisa Dinis Almeida, Cristina Fael, and Isabel Bentes. 2024. "Permeable Asphalt Pavements (PAP): Benefits, Clogging Factors and Methods for Evaluation and Maintenance—A Review" Materials 17, no. 24: 6063. https://doi.org/10.3390/ma17246063

APA StyleSousa, M., Dinis Almeida, M., Fael, C., & Bentes, I. (2024). Permeable Asphalt Pavements (PAP): Benefits, Clogging Factors and Methods for Evaluation and Maintenance—A Review. Materials, 17(24), 6063. https://doi.org/10.3390/ma17246063