3.1. Simulation Based on the Segmented Simulation Method

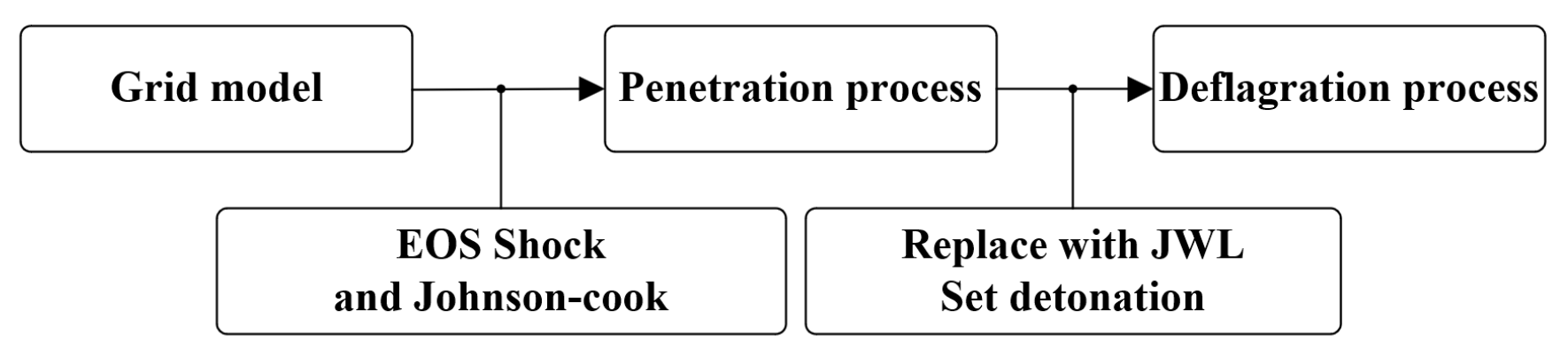

We applied a previously described segmented simulation methodology [

21] in our subsequent studies of reactive materials. An inert material model was used to simulate the penetration process and determine the internal pressure of the material. Subsequently, the ignition criterion for reactive materials proposed by Mock [

22] was considered to determine whether the reactive material reacts. Following penetration, the material was replaced with a reactive material described by the JWL equation.

The numerical simulation study was conducted using the ANSYS AUTODYN 3D platform. AUTODYN features various outstanding solvers, including Euler, Lagrange, ALE, and SPH, along with multiple material databases and algorithmic techniques. The nonlinear problems it tackles encompass large deformation and geometrical nonlinearity, plasticity, failure, strain hardening and softening, as well as material nonlinearity, which are described using segmented EOSs. Of the algorithms in AUTODYN, the Lagrange algorithm is primarily employed for simulating the nonlinear dynamics of solids and structures, while the smoothed particle hydrodynamics (SPH) algorithm is a meshless numerical technique that is particularly effective for handling mechanics problems involving high-speed collisions or brittle materials. The segmented simulation method is detailed in AUTODYN. An inert simulation was first performed to check whether detonation occurred; second, the inert material was replaced with the JWL equation; and a detonation point was manually added to ignite the JWL material. The main reason we used AUTODYN for the simulation is that AUTODYN allows the user to easily replace the material equations in the calculation process. The specific operational workflow is illustrated in

Figure 5.

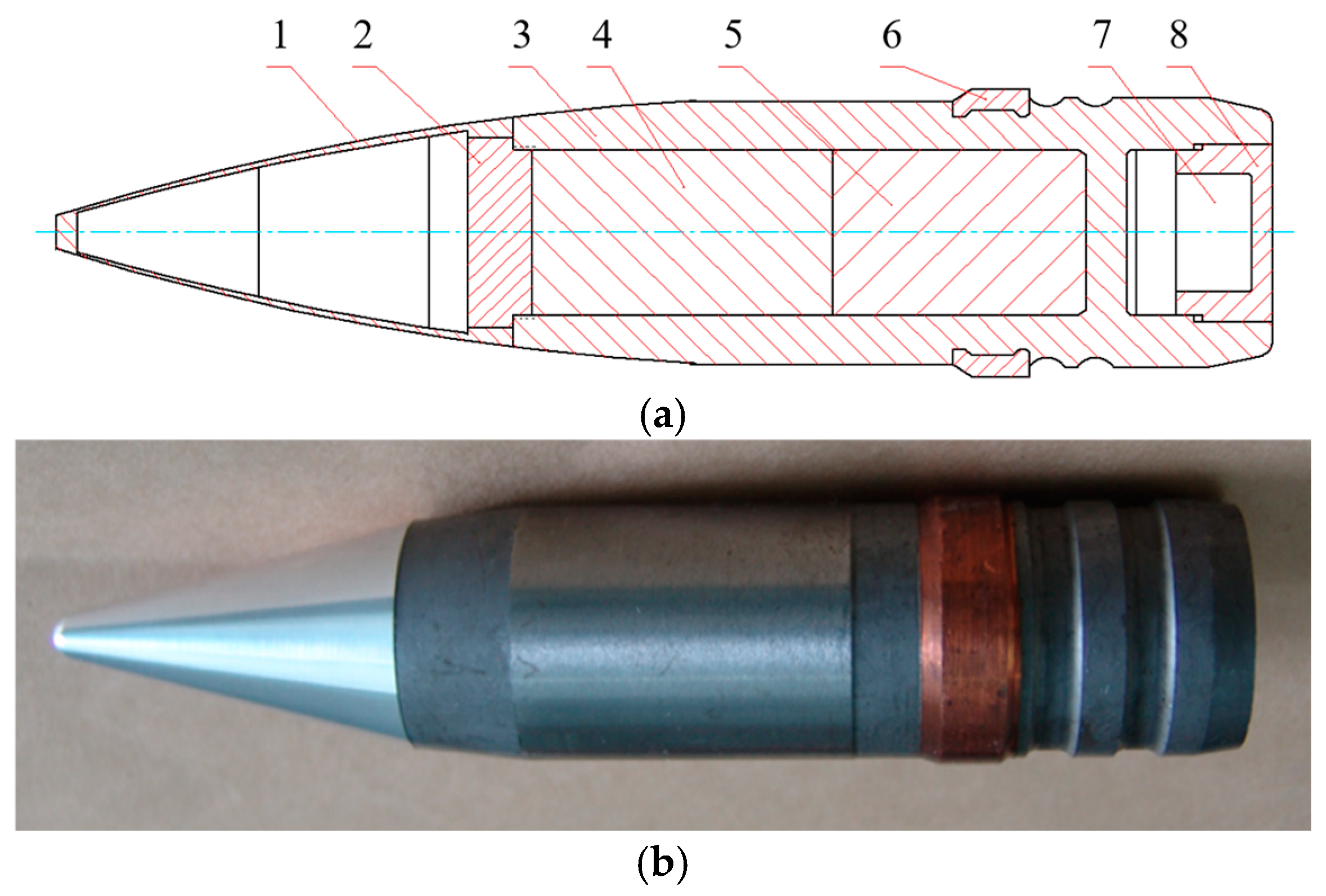

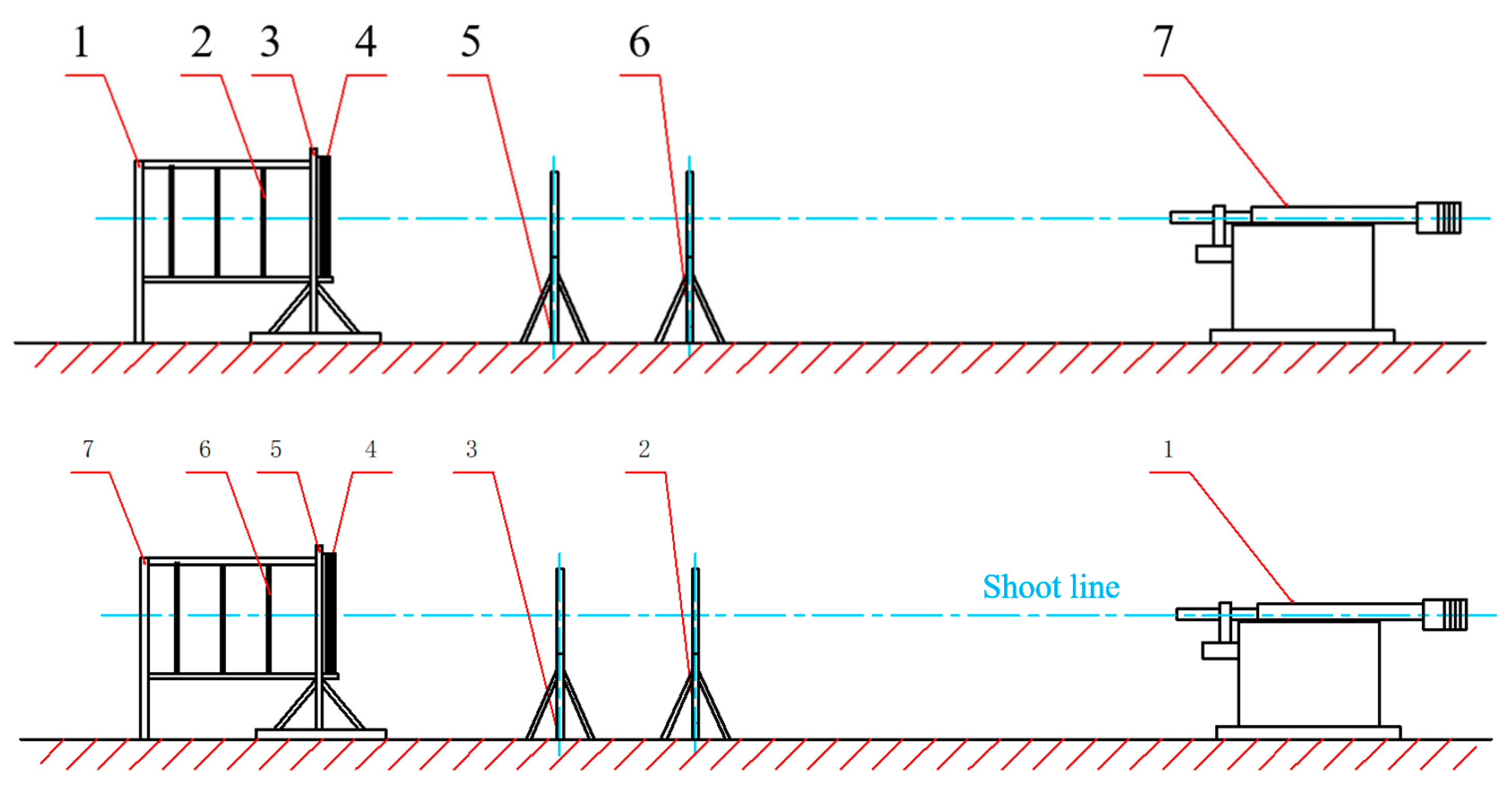

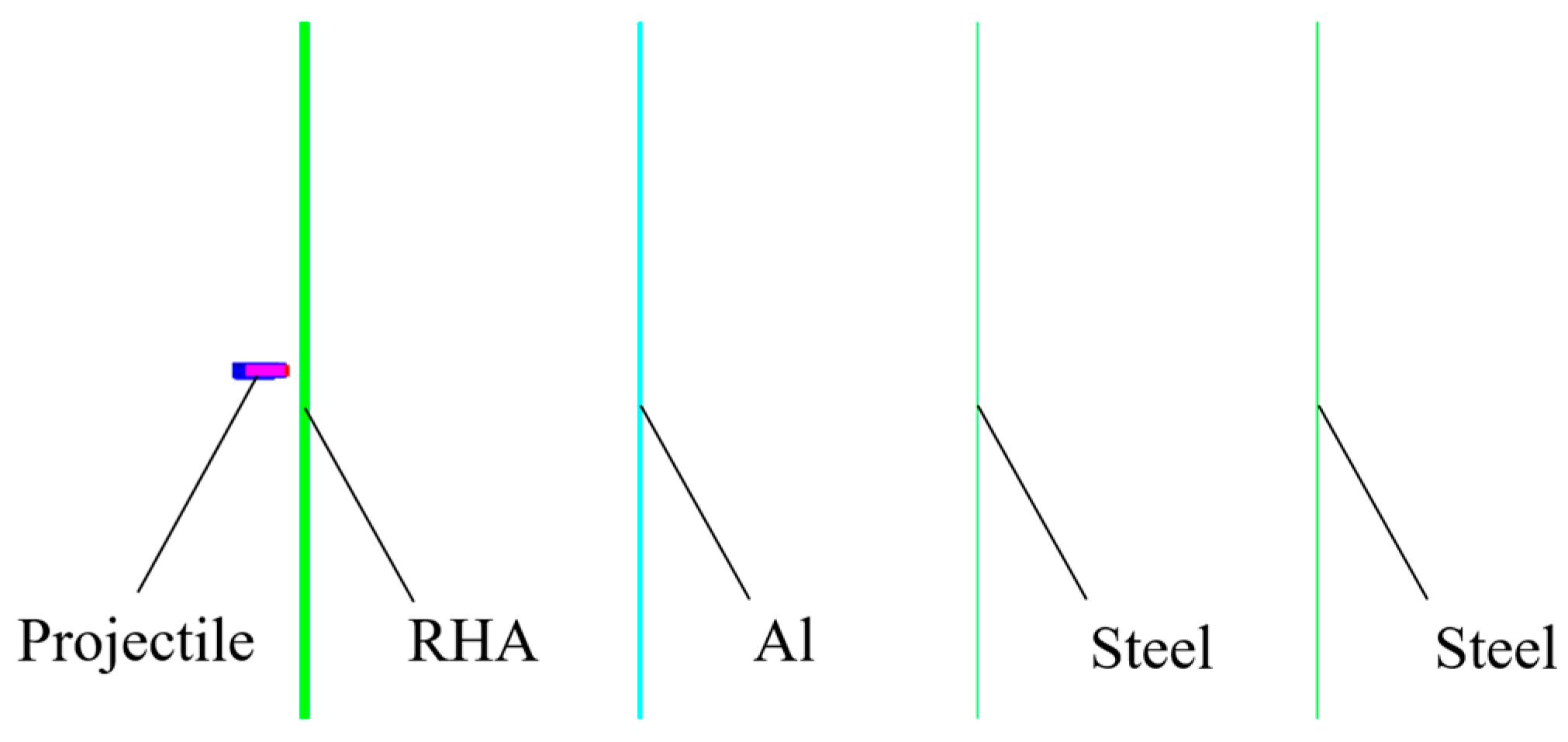

Considering the symmetry during the impact process, a one-quarter simulation of the penetration of a reactive core projectile through multiple layers of targets was established using grid generation software (True-Grid3.13) and the finite element simulation software (AUTODYN). The ogive of the reactive core projectile, composed of a thin layer of aluminum alloy, was neglected in the model. The tungsten head, shell, and core of the projectile were partitioned using SPH grids, whereas the target plate was partitioned using Lagrange grids. The target plate was subjected to fixed boundaries. The grid size influenced the accuracy of the calculations; therefore, the area where the target plate was impacted was meshed with a grid size of 2 mm × 2 mm × 2 mm, and the penetration body was meshed with a grid size of 1 mm × 1 mm × 1 mm. The computational model is depicted in

Figure 6.

In the calculation process, the Johnson–Cook and EOS Grüneisen methods were used to describe the steel, tungsten alloy, aluminum, and nonreactive materials. The Johnson–Cook strength model is expressed as

where the three product terms represent the strain, strain rate, and temperature effects, respectively;

A is the yield strength of the material;

B denotes the strain hardening constant of the material;

N denotes the strain hardening index;

denotes the effective plastic strain;

C denotes the strain rate hardening coefficient;

denotes the plastic strain rate;

denotes the critical strain rate;

m denotes the thermal softening coefficient;

T denotes the initial temperature;

Tm denotes the melting point of metal; and

T denotes the material process temperature. The failure strain given in the material model is

where

denotes the ratio of pressure to effective stress;

denotes the ratio of effective plastic strain rate to the quasi-static critical rate;

denotes the specific temperature; and

D1–

D5 are corresponding constants.

EOS Grüneisen can be expressed as

where

P denotes the pressure state of material;

denotes the initial density;

denotes the sound velocity of the material;

s denotes the material coefficient;

denotes the Grüneisen coefficient;

denotes the internal energy; and

.

In the simulation, steel, aluminum, and the tungsten alloy were represented by the above constitutive equations and EOS, with the specific parameters listed in

Table 1,

Table 2,

Table 3 and

Table 4.

For the detonated reactivated material, we used the JWL equation to describe the pressure state of the reaction products. The basic form of the JWL equation is

where

P denotes the pressure state of material;

denotes the density of the material;

;

denotes the internal energy; and

w,

R1,

R2,

A, and

B are coefficients that can be obtained through cylindrical experiments [

14]. The parameters’ values are listed in

Table 5.

The activated portion of the reactive material was determined according to a previously described method [

21]. Several observation points are set up along the axial direction of the reactive material core. During the impact of the projectile with the target plate, if the pressure peak at the observation points exceeds the critical activation pressure of the reactive material, the reactive material at that location is considered effectively activated during the impact process. The impact activation pressure is 300 MPa [

21].

We recorded and analyzed the pressure history at the observation point, finding that the historical pressure peak in almost all areas of the core exceeded 300 MPa. The main reason for the activation of all materials during penetration was attributed to the thick tar-get plate, resulting in slow pressure decay during penetration. Additionally, the steel shell constrained the core, resulting in a minimal influence from lateral rarefaction waves. These combined factors contributed to the nearly complete activation of the reactive material core during the penetration of the first layer of the target plate.

Figure 7 depicts the pressure recorded at the observation point in the core during penetration, showing that the peak pressure of the core material near the bottom of the bullet was lower.

According to the simulation method outlined in Reference [

21], after the reactive core penetrated the target plate, we changed the EOS for the parts of the core where the pressure exceeded 300 MPa. The JWL parameters in

Table 5 were applied, and then the initiation points were set in the core.

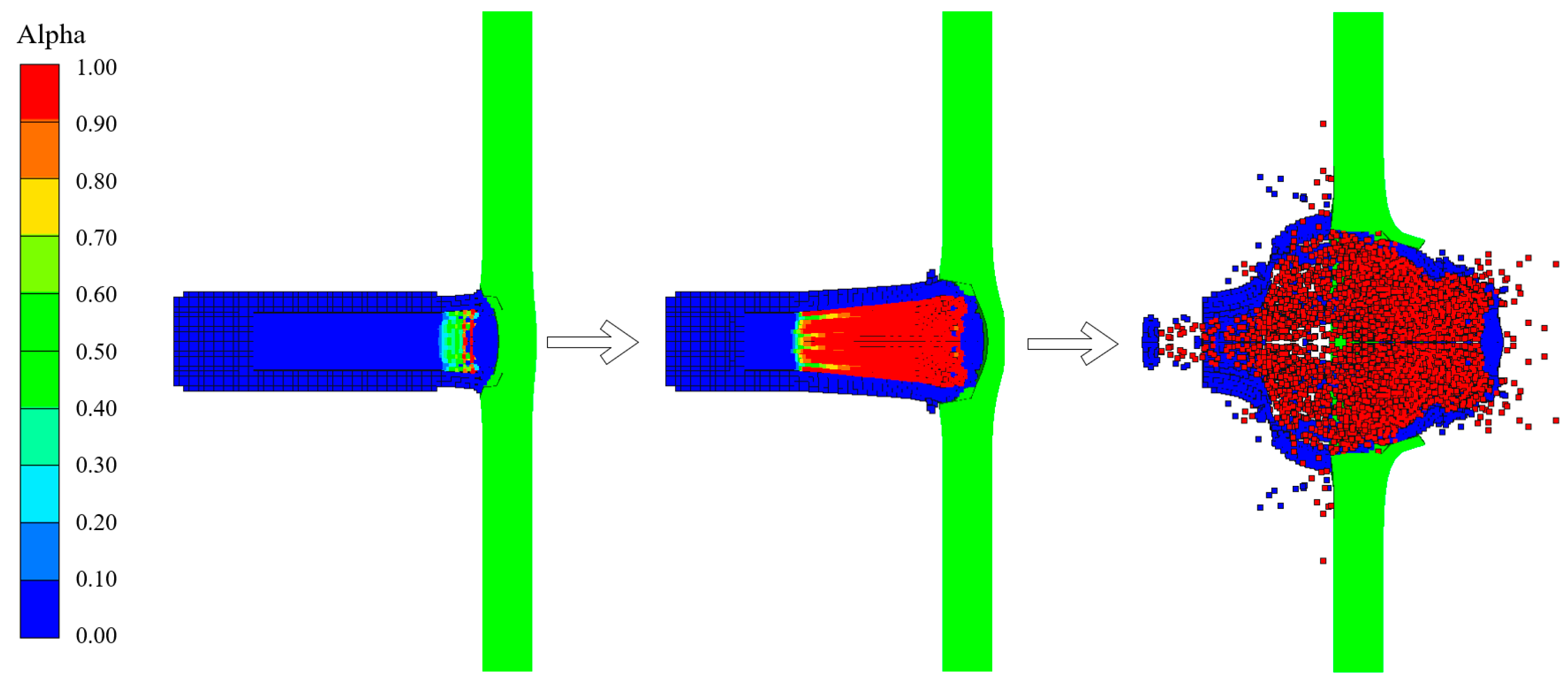

Figure 8 shows a typical penetration process using a simulation of an encroachment section.

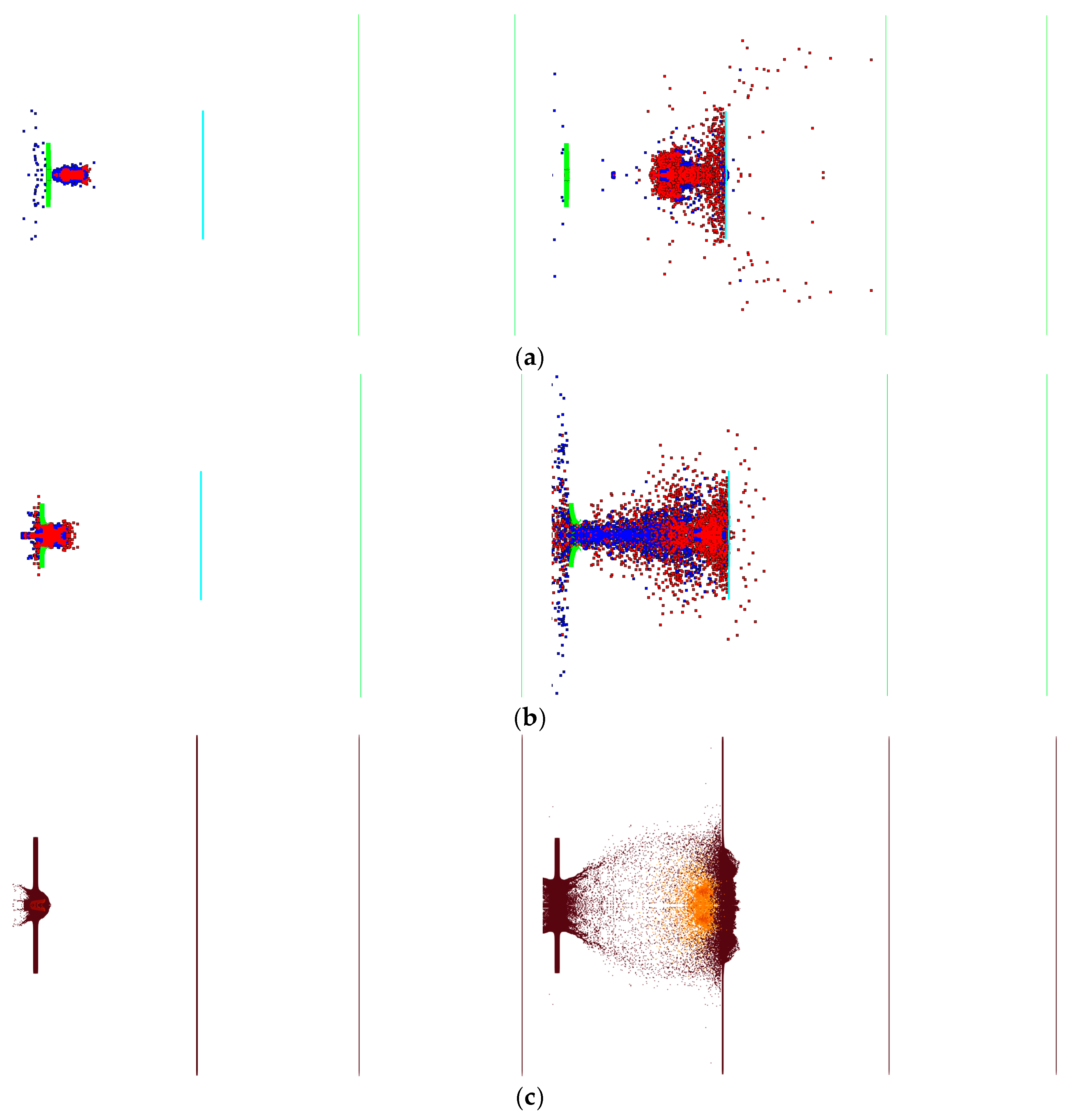

The results of the interaction between the reactive penetrator, the steel target encountered, and the subsequent target plates are depicted in

Figure 9. The steel target encountered by the reactive penetrator exhibited circular perforations nearing Φ 50 mm in diameter. The first 5 mm post-target aluminum plate was punctured with a hole measuring 190 mm × 112 mm due to the impact of the fragmentation cloud. Perforations in the second and third 1.2 mm post-target plates primarily stemmed from the residual large fragments of the shattered casing of the projectile. Additionally, owing to the expansion effect following the explosion of the reactive material, the radial velocity of the fragmented casing resulted in an expanding trend in the perforated area on the subsequent target plates.

3.2. Simulation Based on the Lee–Tarver EOS

Researchers [

16] first introduced the use of the Lee–Tarver equation to describe the process through which reactive materials initiate under impact and determine the relevant parameters.

For the numerical simulation, we used the ANSYS AUTODYN 3D platform. Among the various algorithms in AUTODYN 3D, the Lagrange algorithm is primarily employed to simulate nonlinear dynamic problems of solids and structures, whereas the SPH algorithm is a meshless numerical technique that is particularly effective at handling high-/ultrahigh-speed collisions and brittle material mechanics problems. Specifically, we conducted partial optimizations, the results of which we compared to those of previously used methods [

16,

23], addressing certain compatibility issues with the simultaneous use of the Lee–Tarver and Johnson–Cook models in LS-DYNA.

The simultaneously use of the Lee–Tarver EOS and Johnson–Cook models in LS-DYNA prevents the program from performing the computation. The authors of [

16] used the *MAT_NULL strength model to describe unreacted reactive materials, which was inappropriate and substantially impacted the calculation of penetration processes. In AUTODYN 3D, the Johnson–Cook strength model and the EOS Lee–Tarver model can be simultaneously employed. EOS Shock can better describe unreacted substances than the*MAT_NULL model.

The impact response process reactive material is described using the Lee–Tarver EOS, whereas the mechanical response of the unreacted portion is initially described using EOS Shock as follows:

where

U, up, and

denote the shock, particle, and acoustic velocities; and

s is a parameter.

We used the JWL equation to describe the pressure state of the reaction products.

In the mixture of unreacted materials and reaction products,

F defines the degree of reaction. The values of

F range from zero to one, where zero indicates no reaction, and one indicates the complete reaction of the material. The basic form of reaction rate equation is

where FREQ, FRER, CCRIT, and EETAL are the material constants of the part where the ignition term is located; GROW1, ES1, AR1, and EM are the material constants of the part where the reaction growth term is located; and GROW2, ES1, AR1, and EN are the material constants of the part where the reaction completion term is located, all of which need to be calibrated through tests. The reactive material parameters are listed in

Table 6 [

16].

The process of penetrating the steel target is illustrated in

Figure 10. The core is subjected to the impact of shock waves, resulting in pressure and enabling spontaneous reactions to occur upon impact. During the reaction process, reactions occur as the pressure wave propagates. Compared with the segmented method, the reactions begin before penetrating the target plate, and considerable expansion of the shell occurs during penetration.

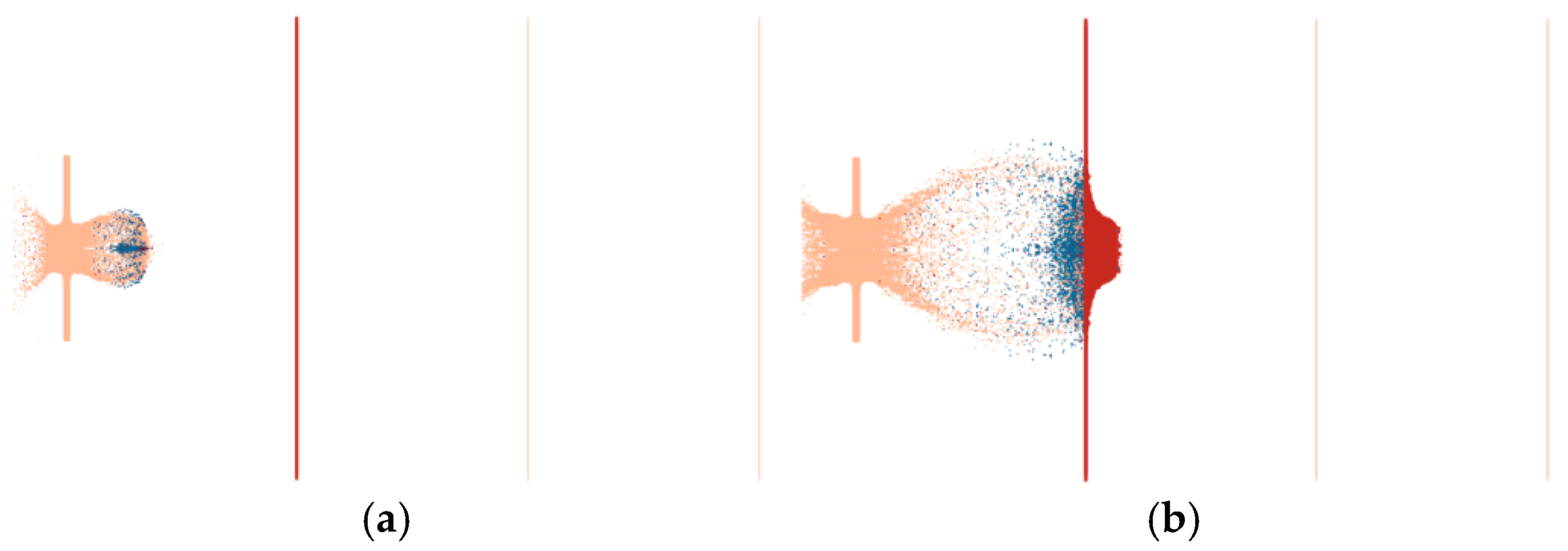

The interaction between the penetrating projectile with a reactive material core and the steel and subsequent targets is shown in

Figure 11. The steel target was perforated after being hit by the projectile, forming a circular through-hole nearing Φ88 mm in diameter The main reason for this is the strong radial expansion of the shell during the penetration process, which resulted in a strong expansion effect. The subsequent (first) 5 mm aluminum target was pierced by the impact of the fragment cloud, forming a rupture hole of 248 mm × 166 mm. The holes pierced in the next (second) 1.2 mm target plate were mainly caused by the remaining large fragments of the fractured projectile after penetration. No obvious holes formed owing to fragment penetration on the next (third) 1.2 mm target plate; the perforations in this target plate were mainly caused by the impact of the plug blocks from the previous target. Compared with the results of the segmented simulation method, fewer perforations were recorded in the last two target plates in our study. The main reason for this is that the reaction rate of the reactive material is higher and the initiation time was earlier, leading to larger diffusion of the fragment cloud. This means that the mass of the fragment cloud is more dispersed, resulting in smaller individual fragments and a decreased penetration capability, and causing few perforations in the last two target plates.

3.3. Simulation of the Impact Reaction Model Based on the MPM-SICR

Our numerical simulation mainly relied on MPM3.0, developed by Tsinghua University, for a platform. In MPM3.0, the Lagrange algorithm is mainly used to simulate the nonlinear dynamic problems associated with solids and structures; the MPM algorithm, on the other hand, is a meshless numerical technique used for material points, in which particles carry material state information. When updating the state, this information is mapped to the background grid, and stress–strain velocity updating processes are calculated using integral equations. The MPM algorithm is particularly effective at handling mechanics problems such as high-/ultrahigh-speed collisions and brittle materials. The state equation for reactive materials was derived from the literature [

13], employing an improved impact initiation model based on the Lee–Tarver state equation, which was integrated into the MPM3.0 platform. The software platform was available for trial through the Tsinghua Computational Dynamics Lab.

A one-quarter numerical simulation of the penetration of an active core projectile into a multilayer target was established using SolidWorks2020 modeling software and LS-PERPOST finite element simulation software. The wind cap of the active core projectile, composed of thin-layer aluminum alloy, was neglected in the modeling process, and all grids were implemented using the MPM method. The particle size used for the projectile was 1.2 mm’ for the target plate, and the particle size ranged from 1.2 mm to 2.5 mm. Due to the inability to set boundary conditions in the MPM3D program, two solid blocks with constant velocities of zero were used to sandwich the target plate. The partitioned grid model is illustrated in

Figure 12.

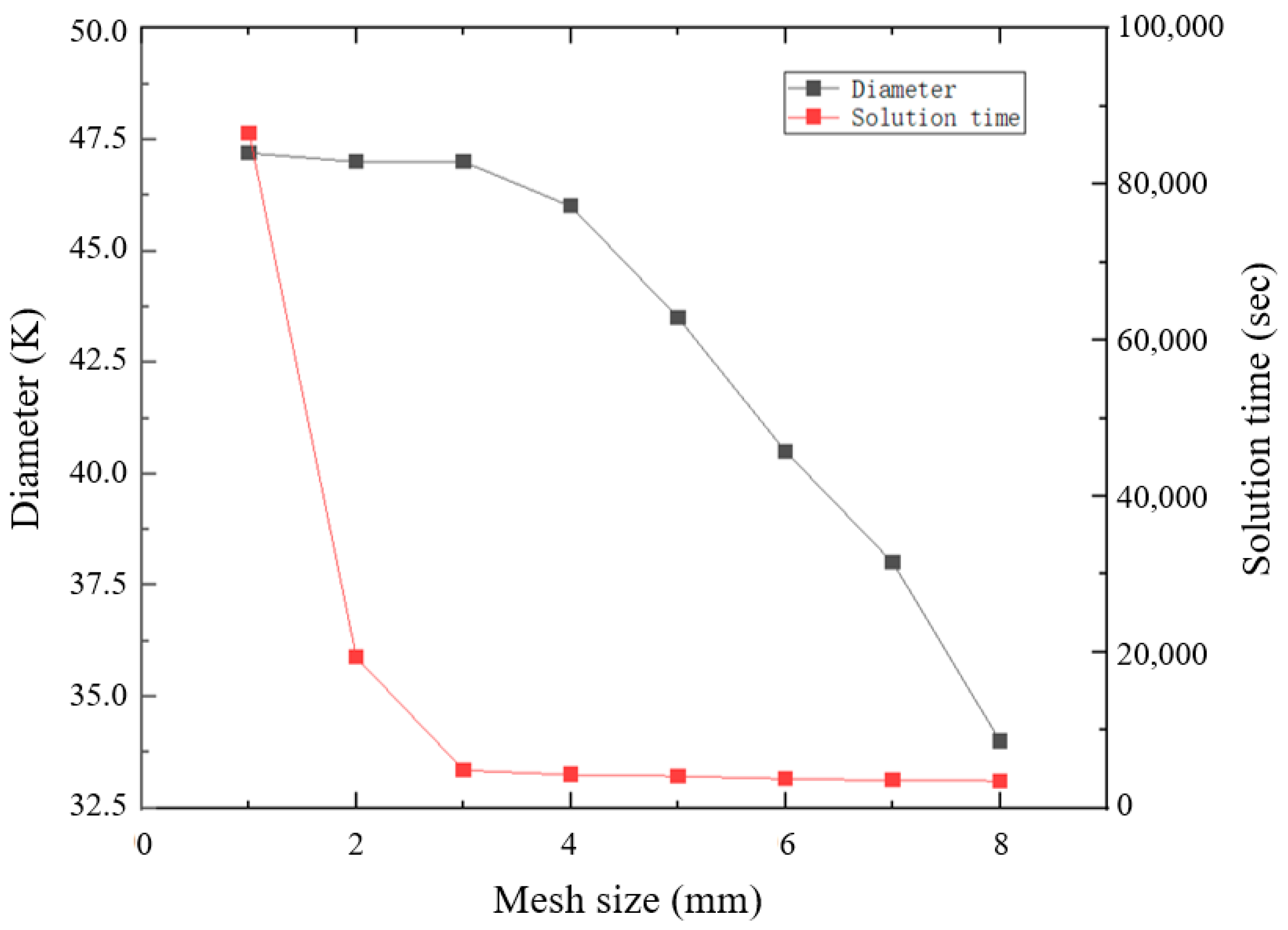

We analyzed the grid convergence on MPM-SICR. We did not verify convergence for the first two methods because the literature provides suggestions for the grid size. Convergence was verified using the diameter of the fragmented cloud at a certain moment after penetrating the first layer of the target plate as a variable. The results of the analysis are shown in

Figure 13. When the grid size was reduced to 3 mm, the diameter of the fragmented cloud no longer substantially changed. The time for obtaining a solution was notably increased when the grid was reduced to 3 mm.

During the simulation, for the core material, we used the impact initiation model of the reactive material, applying the parameters listed in

Table 7 and

Table 8.

The impact initiation equation of the reactive material in this study was a model dominated by the Arrhenius formula for the reaction rate, with pressure and temperature as reaction thresholds. The process of the core penetrating the target plate is illustrated in

Figure 14, where the core is affected by the impact, reaching the reaction threshold and spontaneously reacting upon impact. The projectile begins to react before penetrating the target plate, and significant expansion occurs in the shell during penetration, leading to a strong spalling effect and forming a fragment cloud containing a mixture of the target plate, shell, and core material. Compared with the previous two simulation methods, the main characteristic of the proposed method is that during the penetration of the RHA, the core does not completely react, leaving a considerable amount of unreacted material. Moreover, the reaction continues during the subsequent penetration of the aluminum target plate. In terms of the process, the results of this approach are closer to those obtained via the experimental high-speed photography and the reaction mode proposed in

Section 2.2.

The interaction between the projectile and the target plate is shown in

Figure 15. After being struck by the projectile, the steel target plate had circular through-holes of approximately Φ 55 mm in diameter. The main reason for the circular through-holes that were larger than the projectile diameter was the radial expansion of the shell during penetration, which resulted in a spalling effect. The first 5 mm aluminum target plate was pierced by the impact of the fragment cloud, forming a Φ 340 mm rupture hole. The perforations in the second 1.2 mm target plate primarily resulted from the fractured shell of the penetrating projectile and fragments from the previous target. Similarly, fewer but visible perforations were caused by fragment penetration in the third 1.2 mm target plate. The main reasons for the lower number of perforations in the latter two target plates were the decreases in projectile velocity and penetration capability after the fragments penetrated the second target, resulting in a reduced ability to penetrate.