Microstructure Evolution and Mechanical Properties of 16-Layer 2195 Al-Li Alloy Components Manufactured by Additive Friction Stir Deposition

Abstract

1. Introduction

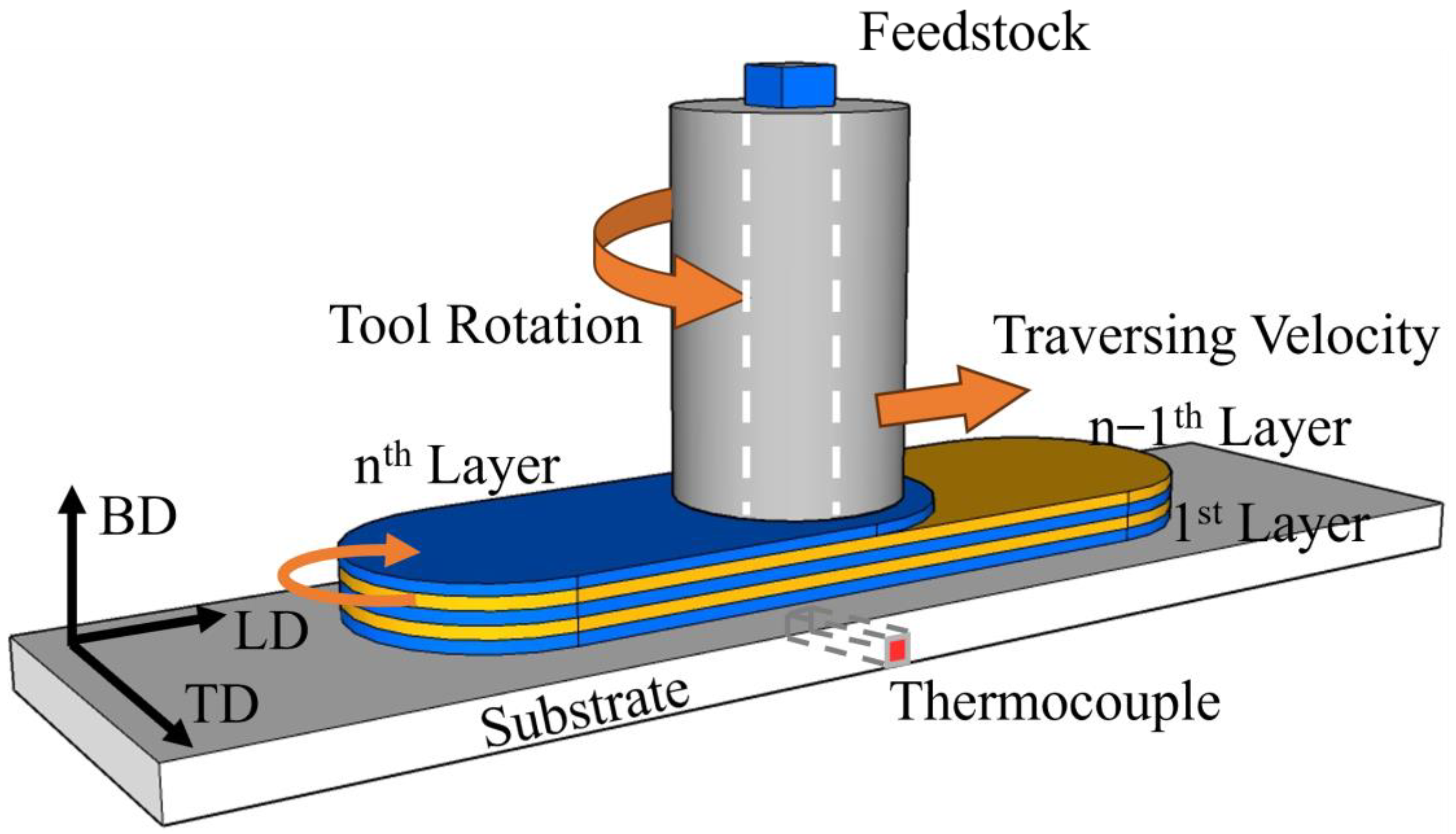

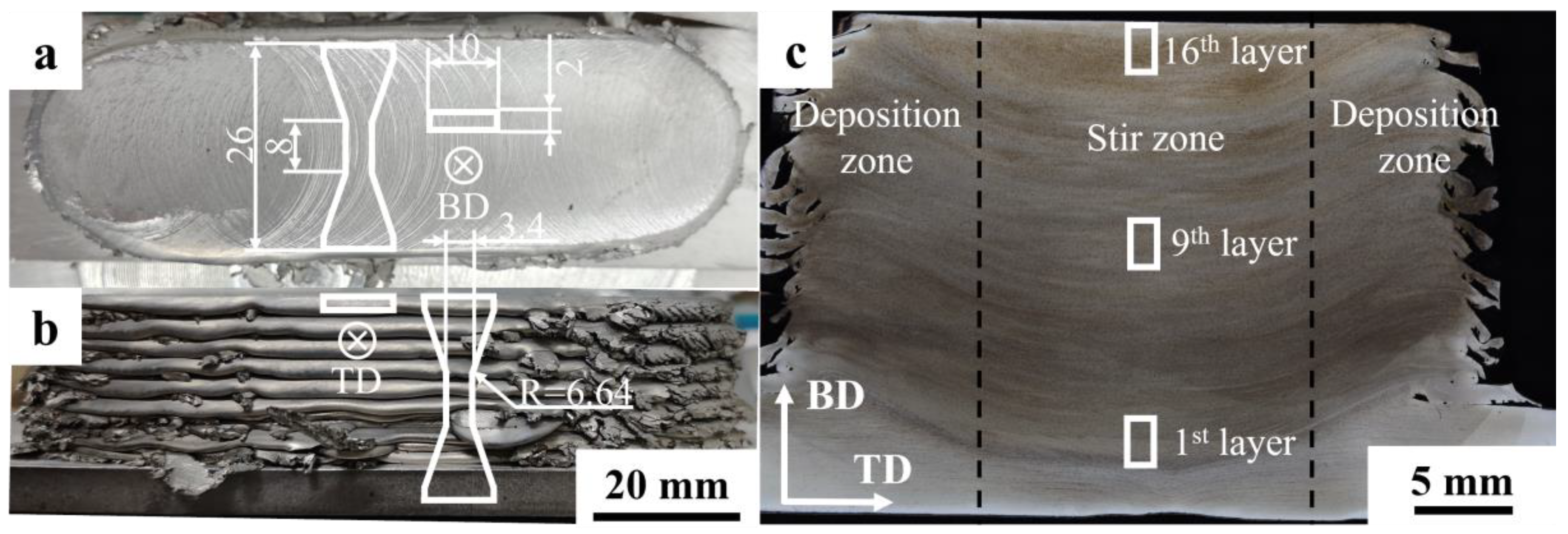

2. Experimental Methods

3. Results

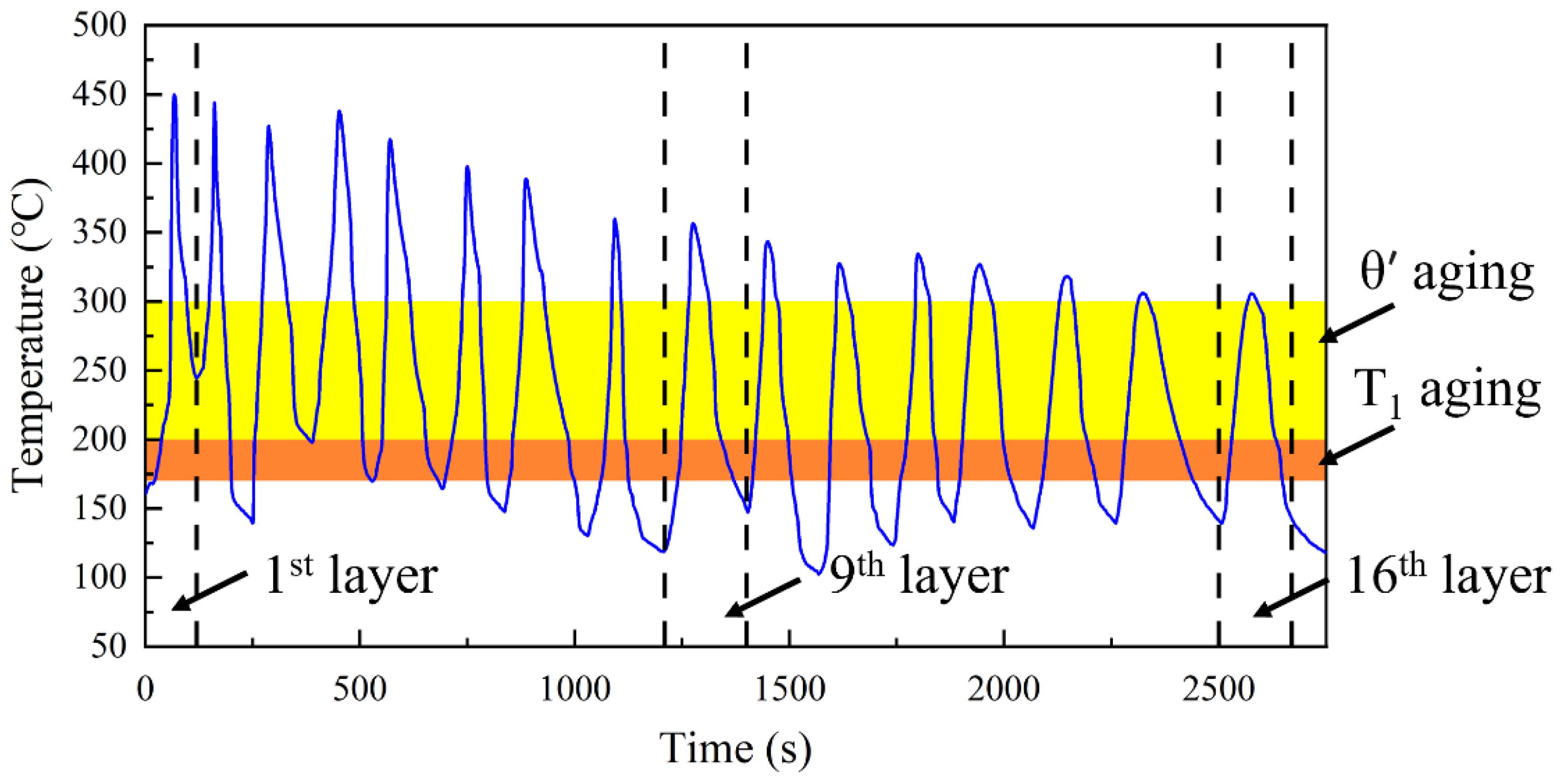

3.1. Thermal History

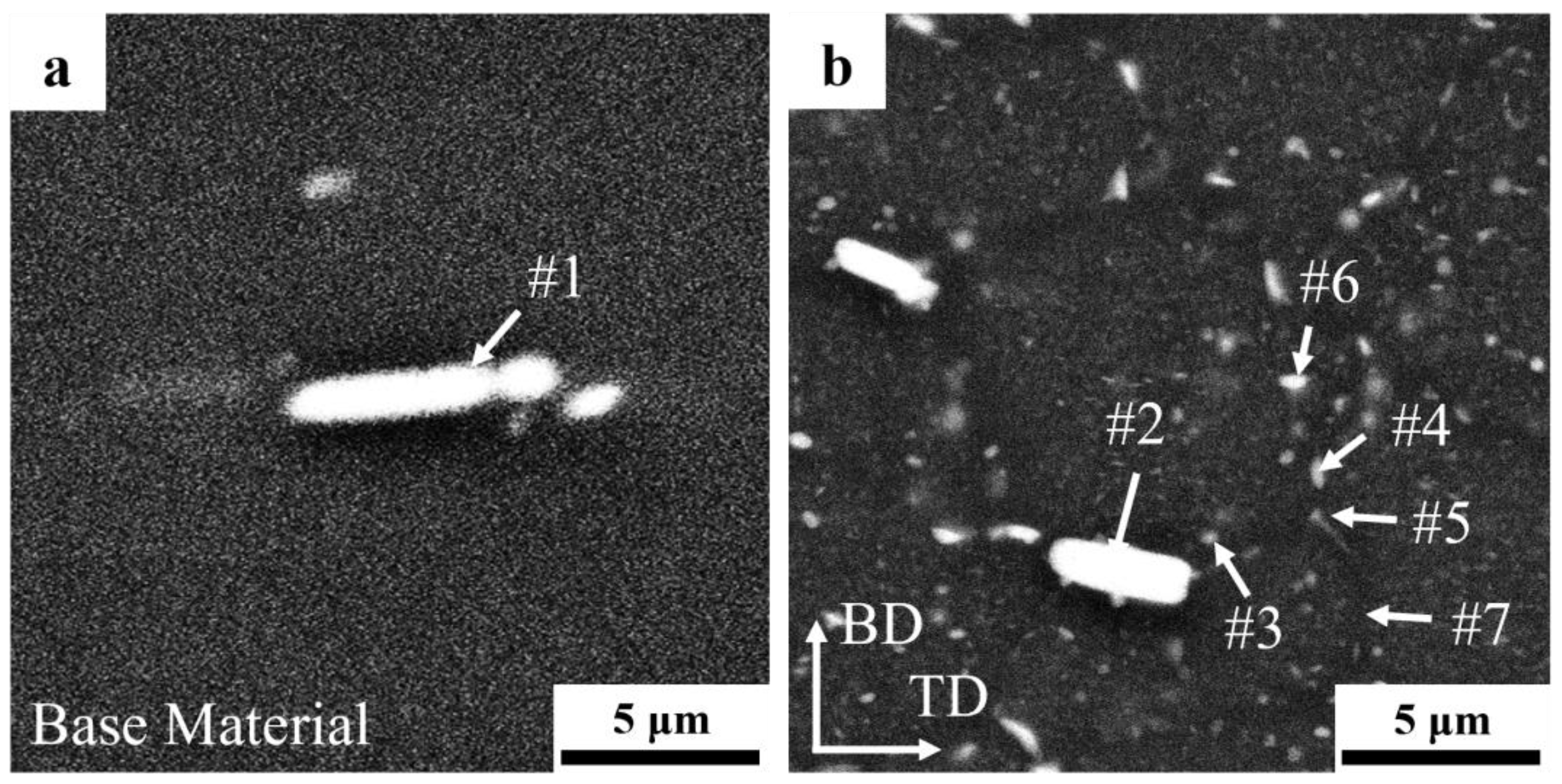

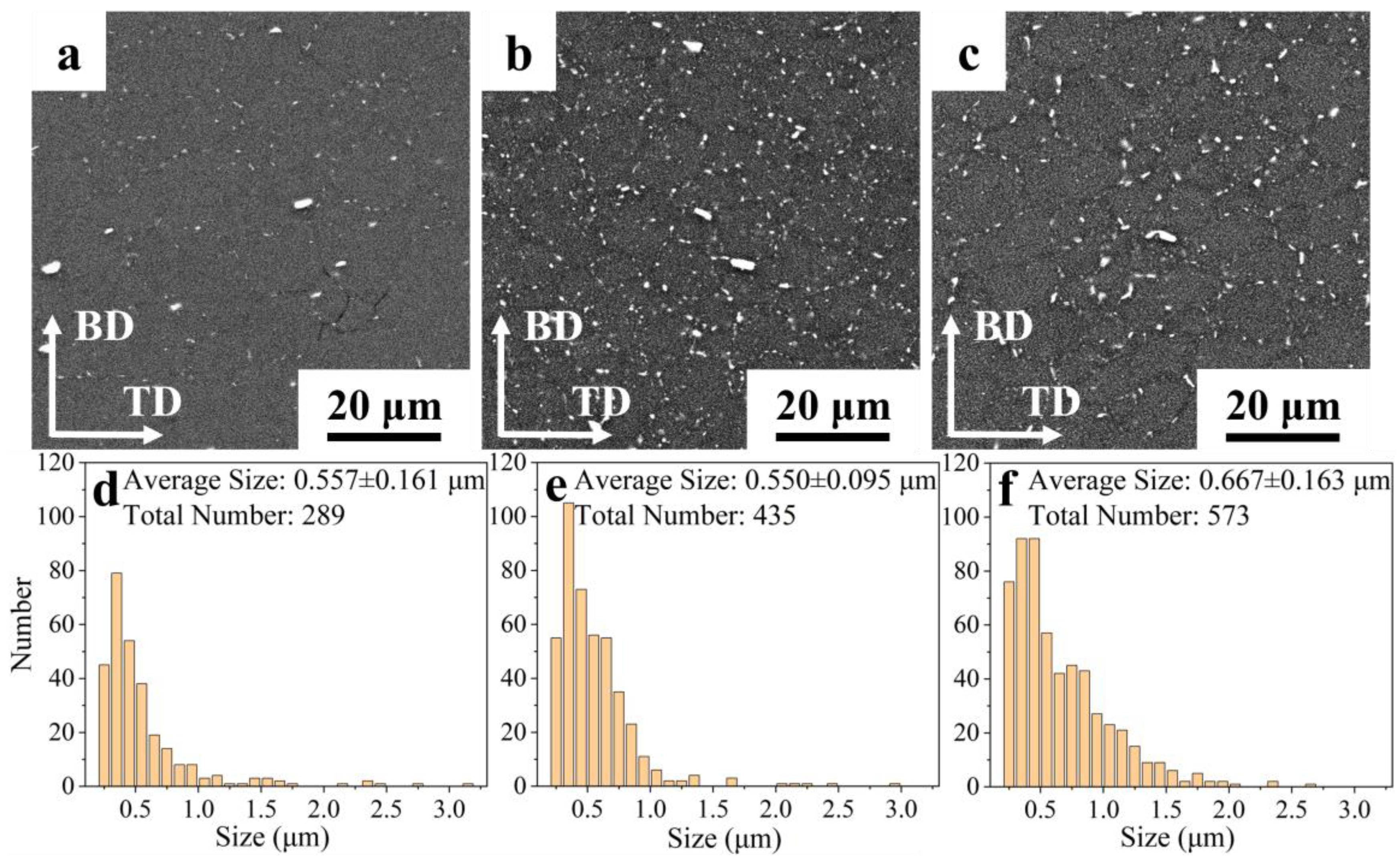

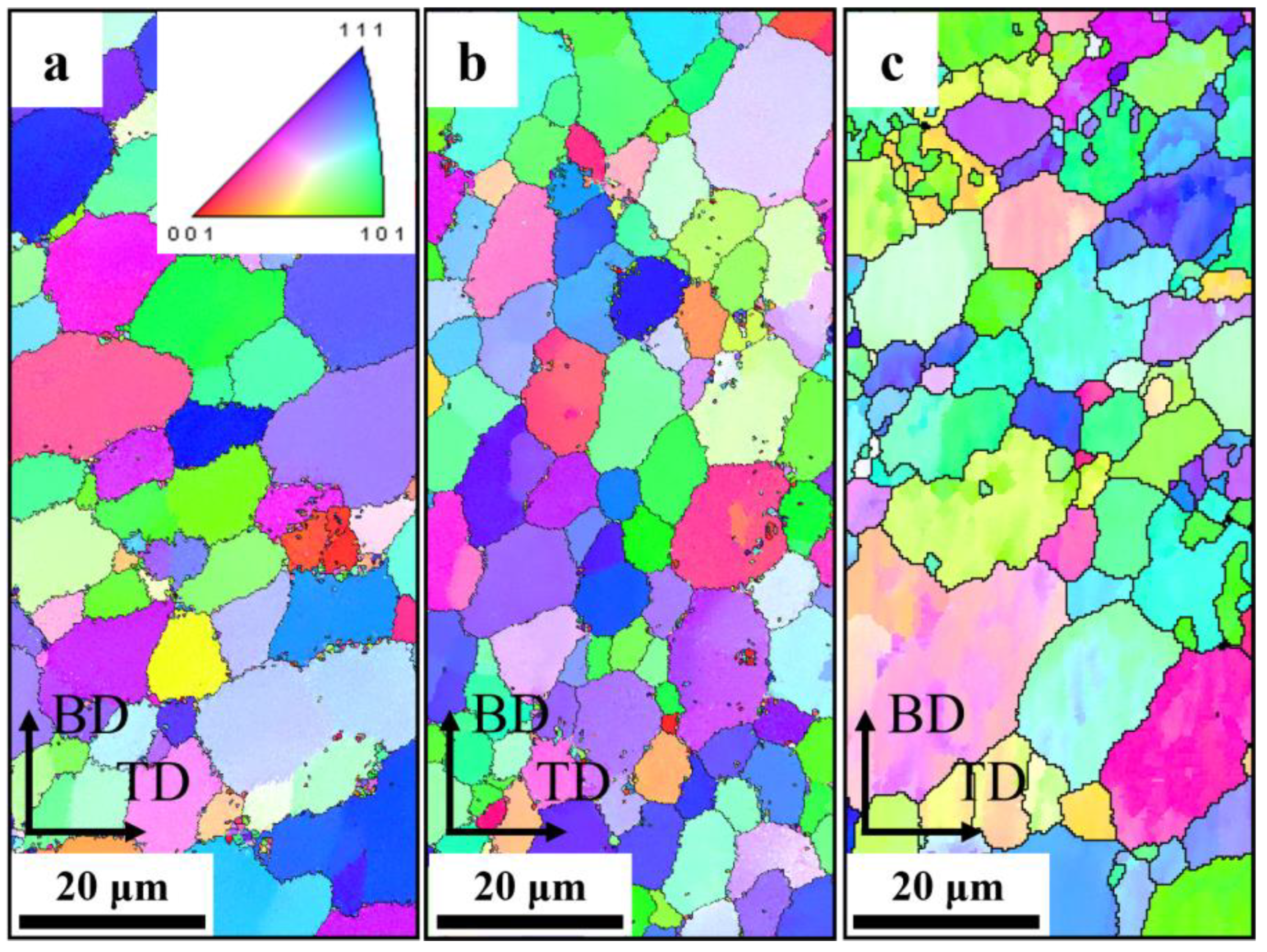

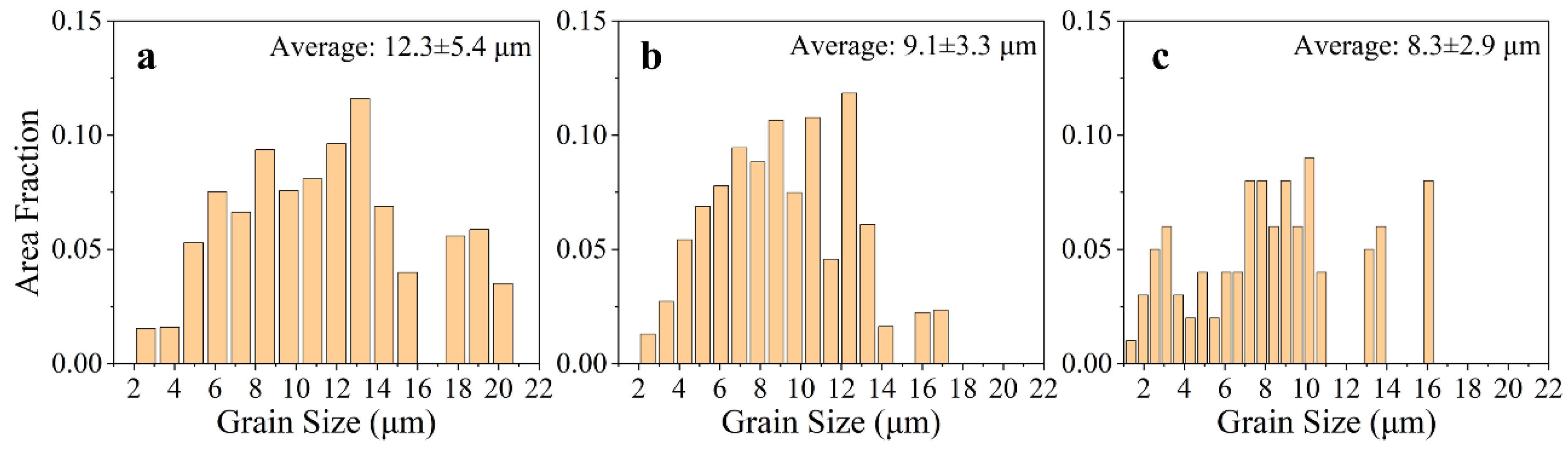

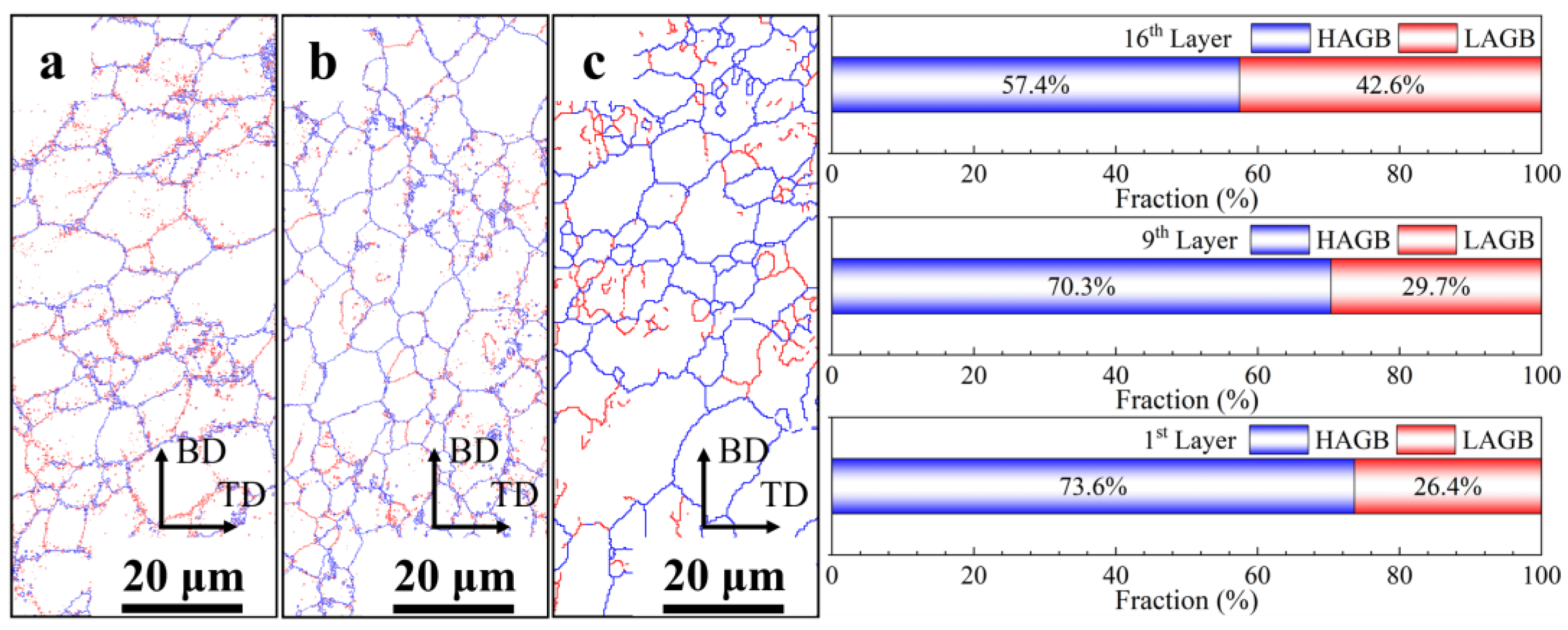

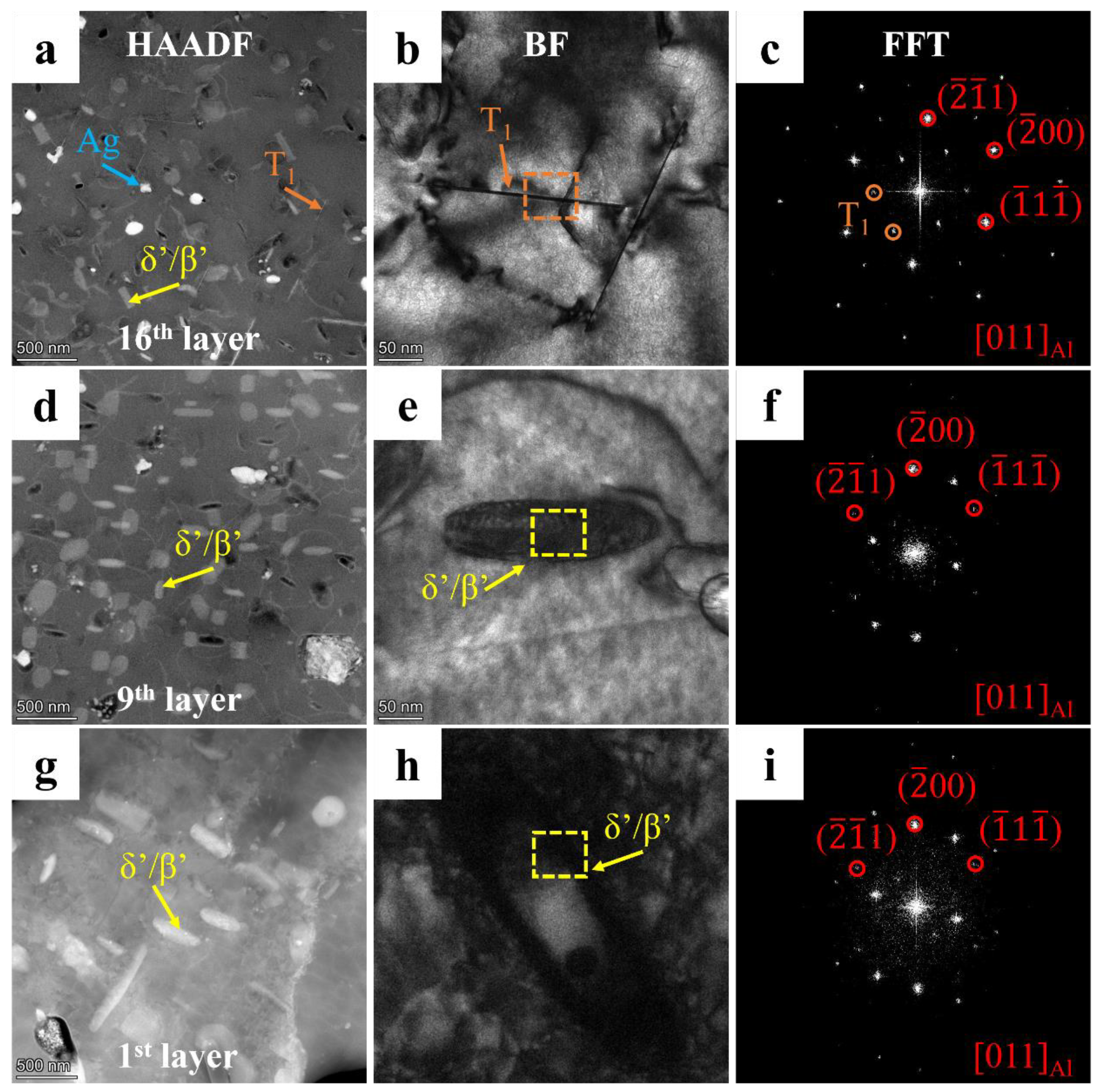

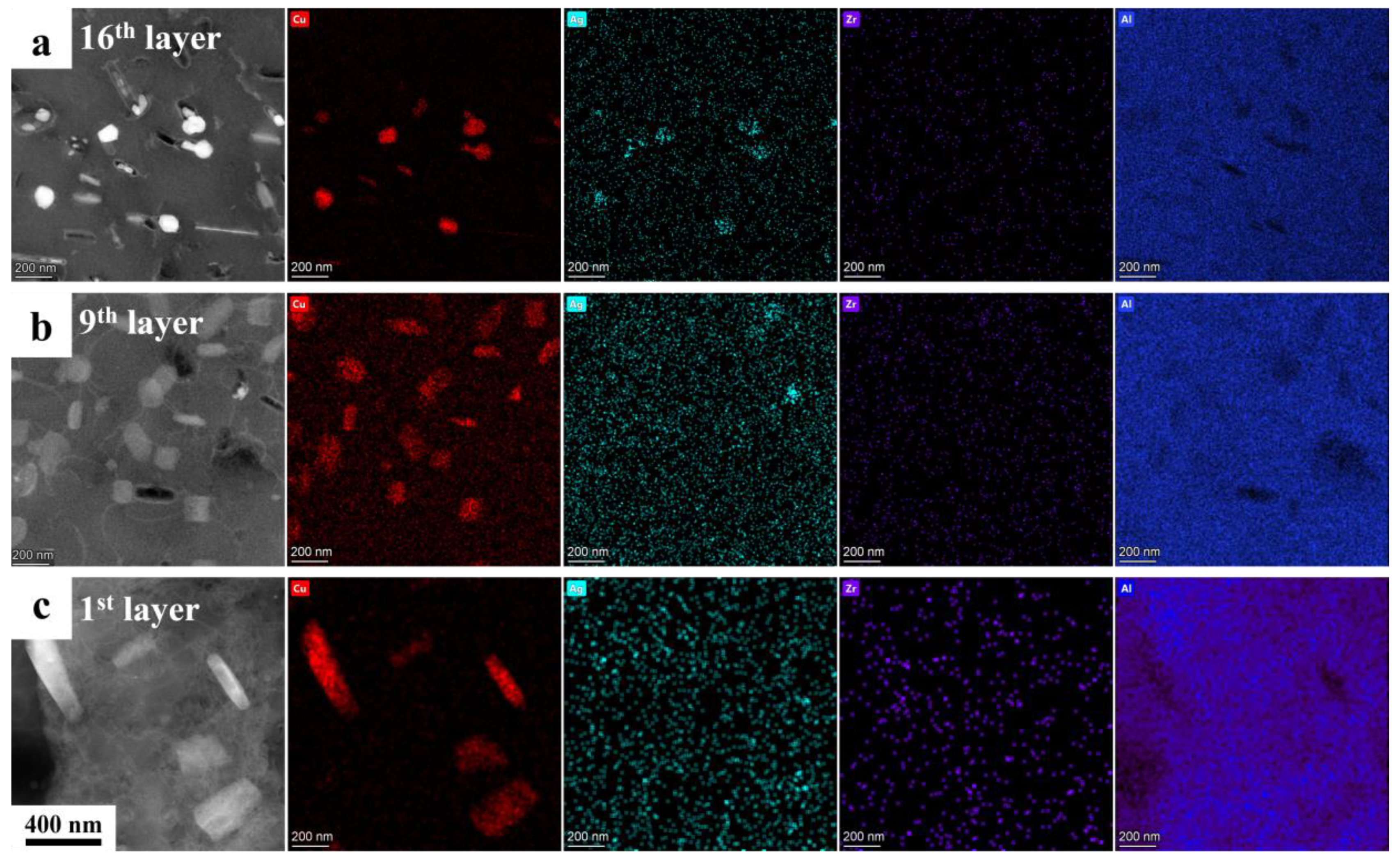

3.2. Gradient Microstructure

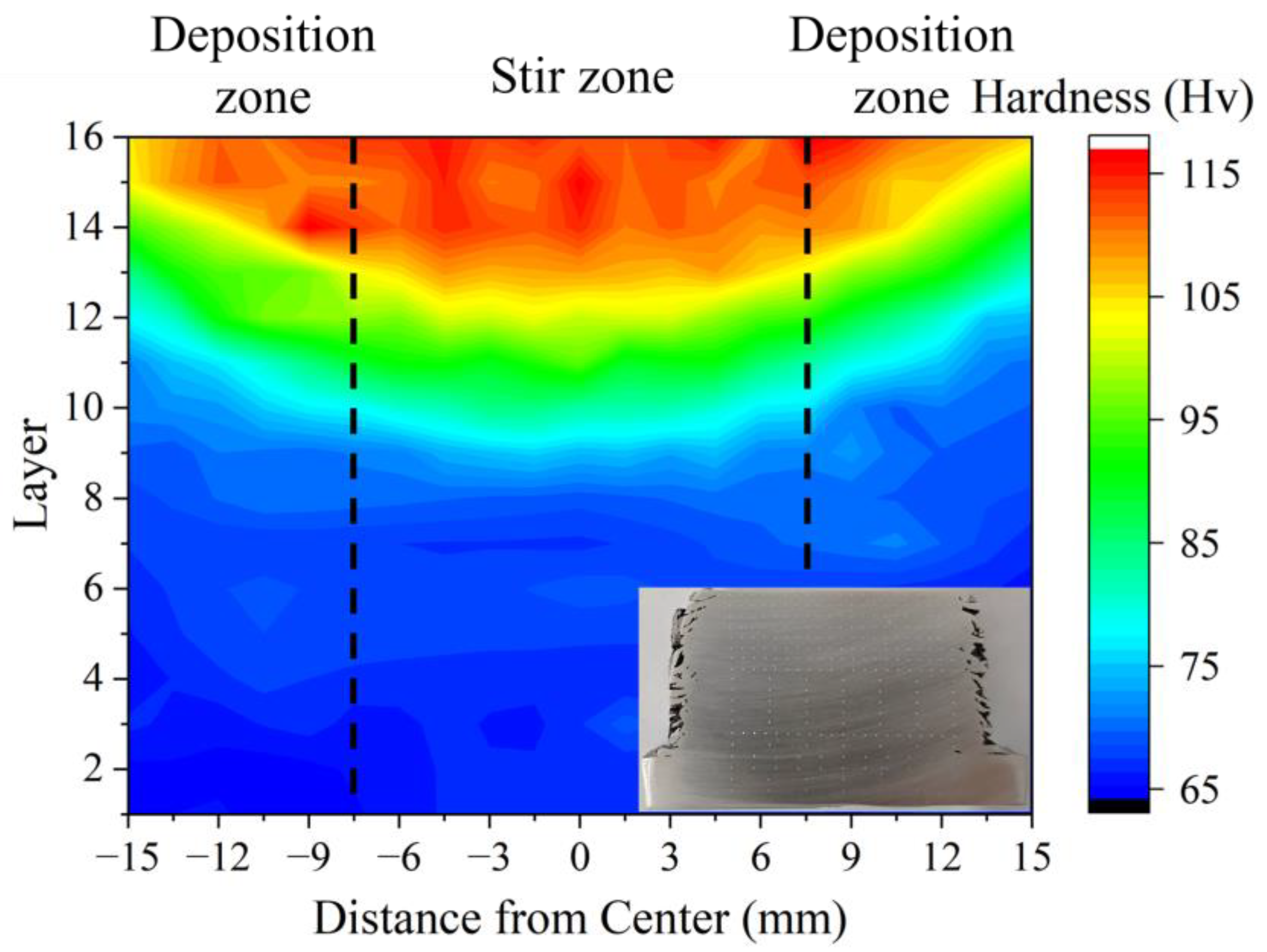

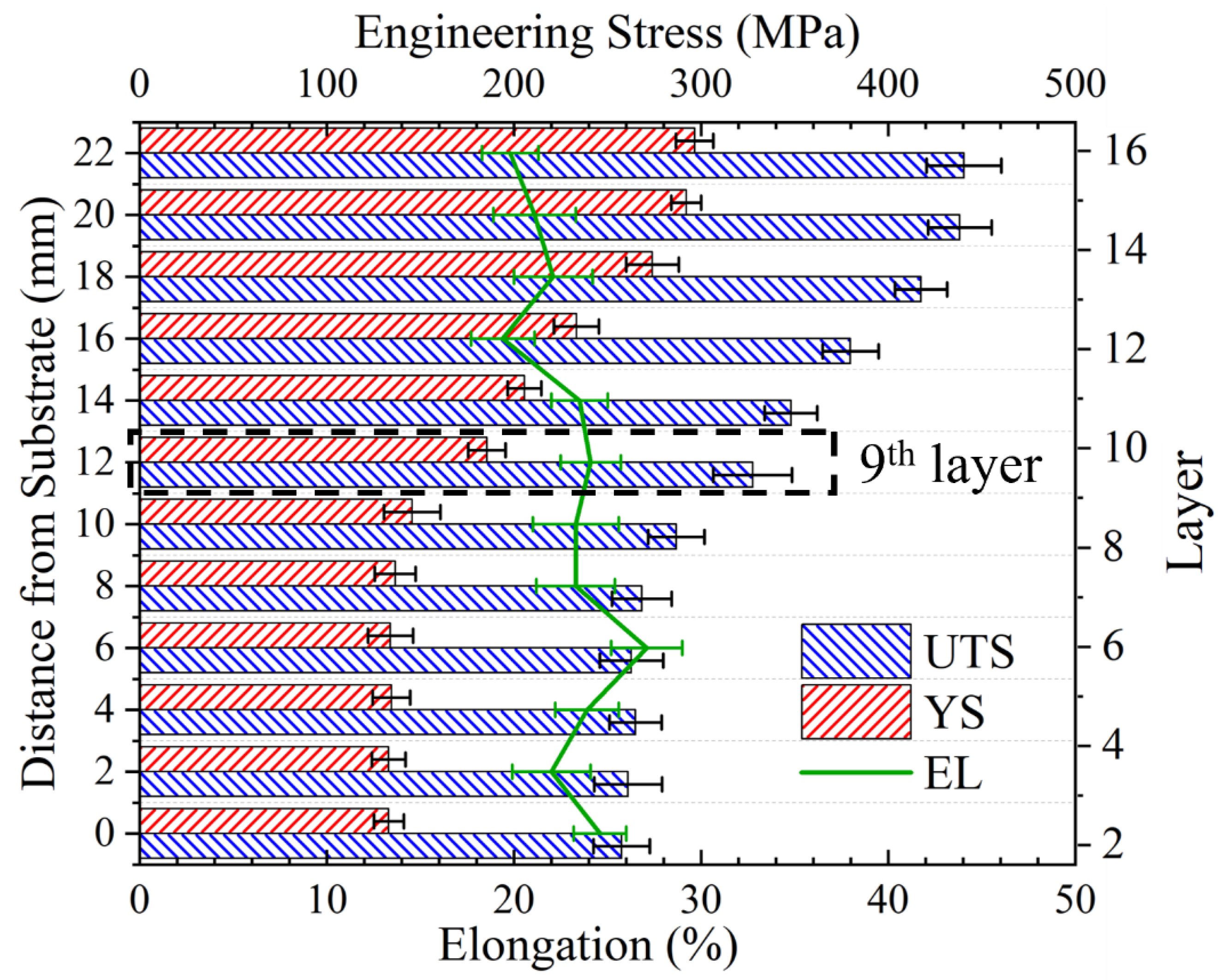

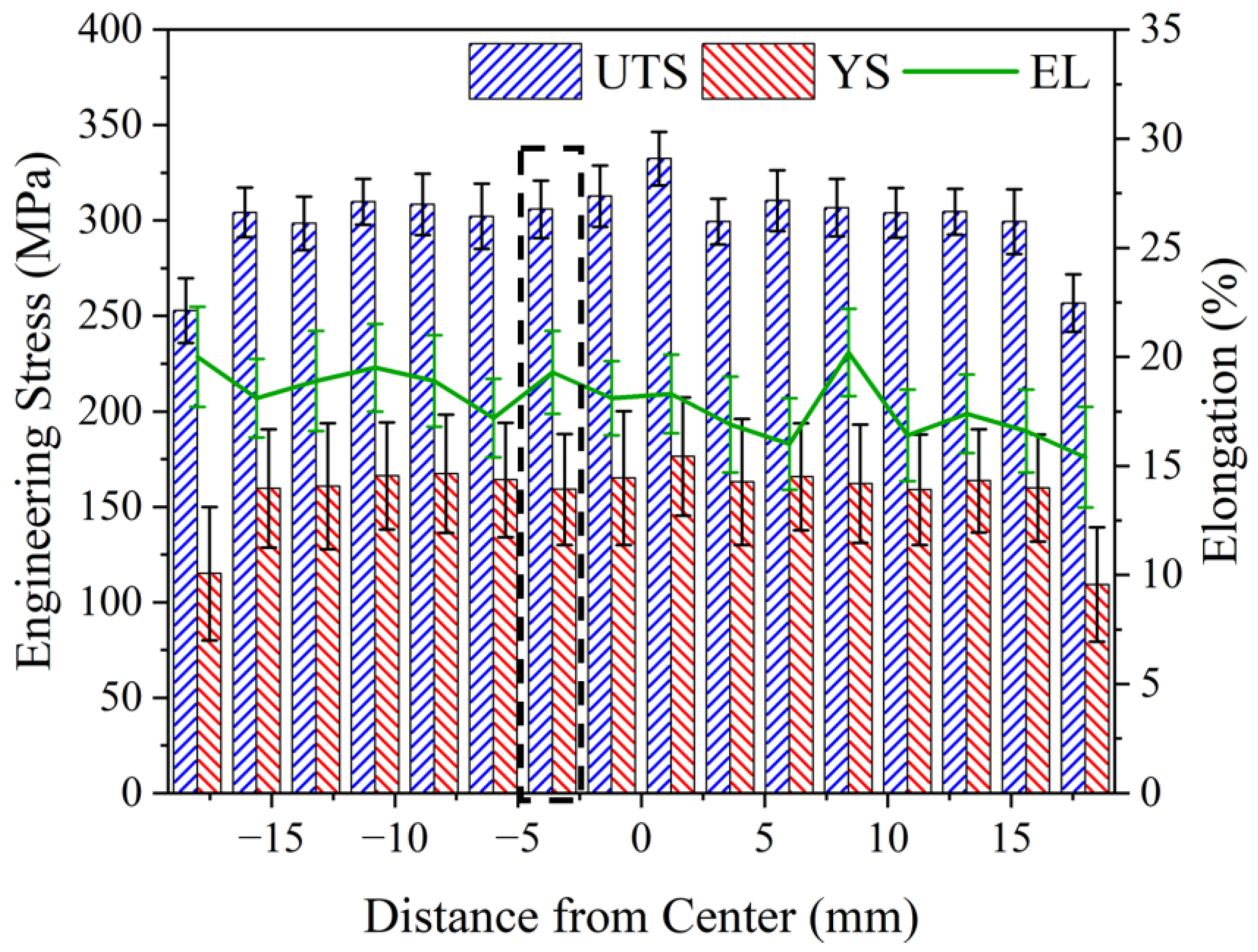

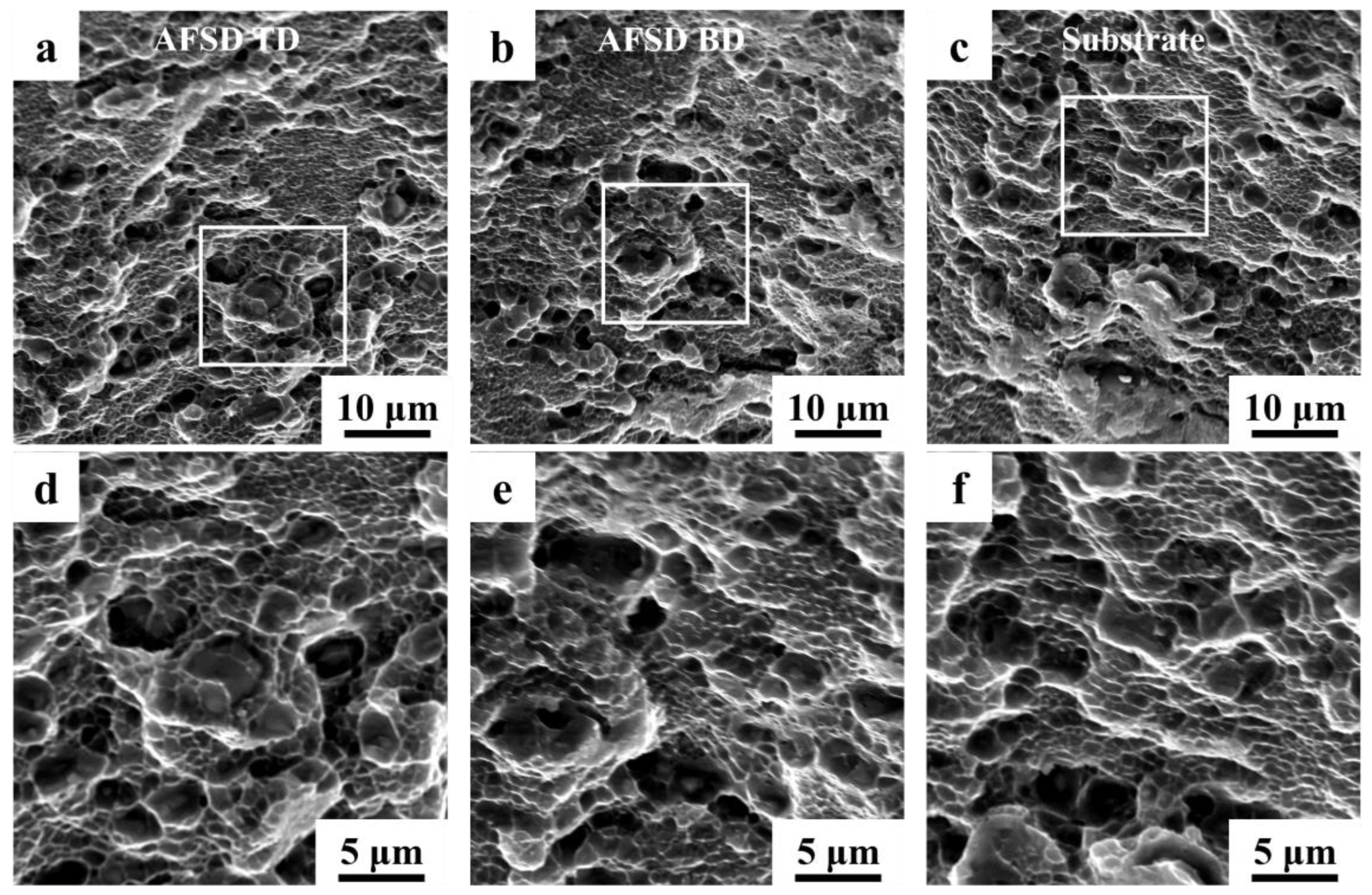

3.3. Mechanical Properties

4. Discussion

4.1. Microstructure and Mechanical Property Evolution Mechanisms During Each Thermal Cycle

4.2. Microstructure and Mechanical Property Evolution During Thermo-Mechanical Based AFSD Process

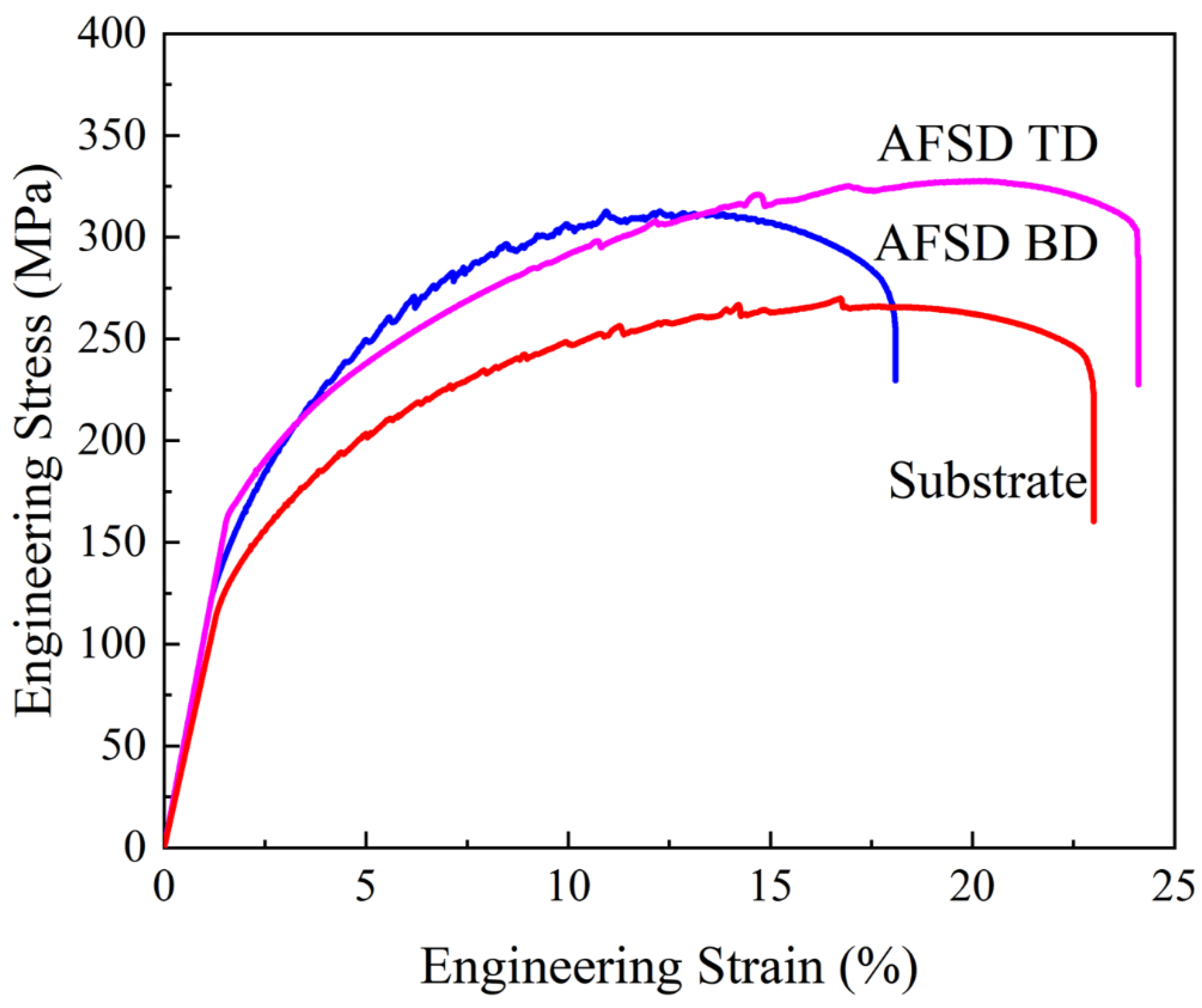

4.3. Anisotropy Mechanical Properties of AFSD Sample

5. Conclusions

- The thermo-mechanical behavior during the AFSD affects the evolution of microstructure and mechanical properties of the 2195 Al-Li alloy which can be classified into three areas. The last layers experiences stirring action and 2–3 thermal cycles. The intermediate layers experiences 4–9 thermal cycles. The first layers experiences 10–16 thermal cycles.

- The material flow through the layers can initiate a reset of the microstructure evolution caused by periodic heat input. The influence of periodic heat input results in the homogenization of grain size, the coarsening of the δ′/β′/θ′ ternary composite precipitate, and the dissolution of the T1 phase.

- The samples located in the last layers show superior mechanical properties compared to those of the intermediate layers and the first layers. Specifically, the samples located in the last layers show the highest microhardness of 117.0 Hv, YS of 296.6 MPa, UTS of 440.6 MPa, and EL of 27.1%, respectively.

- Despite the broken interlayer interface, the tensile properties in the BD were found to be diminished. The broken interface was aligned with the TD-LD plane, so the tensile properties in the TD remained unaffected. The tensile properties in the BD were higher in the stir zone, due to the interface in the deposition zone not being broken.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bi, J.; Liu, Z.; Chi, J.; Wang, H.; Tan, C.; Jia, X.; Yang, Z.; Starostenkov, M.D.; Dong, G. Formation mechanisms and control strategies of FQZ softening in Al–Li alloy welded joint. J. Mater. Res. Technol. 2023, 23, 2810–2823. [Google Scholar] [CrossRef]

- Ghosh, A.; Adesola, A.; Szpunar, J.A.; Odeshi, A.G.; Gurao, N.P. Effect of tempering conditions on dynamic deformation behaviour of an aluminium–lithium alloy. Mater. Des. 2015, 81, 1–10. [Google Scholar] [CrossRef]

- Rioja, R.J.; Liu, J. The Evolution of Al-Li Base Products for Aerospace and Space Applications. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2012, 43, 3325–3337. [Google Scholar] [CrossRef]

- Tayon, W. Exploration of Incompatibility in Al-Li alloys Using High Energy Diffraction Microscopy and a Crystal Plasticity Model. PhD Thesis, University of Illinois at Urbana-Champaign, Urbana, IL, USA, 2012. [Google Scholar]

- Zakharov, V.V. Some problems of the use of aluminum-lithium alloys. Met. Sci. Heat Treat. 2003, 45, 49–54. [Google Scholar] [CrossRef]

- Rioja, R.J. Fabrication methods to manufacture isotropic Al-Li alloys and products for space and aerospace applications. Mater. Sci. Eng. A 1998, 257, 100–107. [Google Scholar] [CrossRef]

- Csontos, A.A.; Starke, E.A. The effect of inhomogeneous plastic deformation on the ductility and fracture behavior of age hardenable aluminum alloys. Int. J. Plast. 2005, 21, 1097–1118. [Google Scholar] [CrossRef]

- Ma, J.; Liu, X.; Yan, D.; Rong, L. A novel GP-Li precursor and the correlated precipitation behaviors in Al-Cu-Li alloys with different Cu/Li ratio. Acta Mater. 2023, 243, 118442. [Google Scholar] [CrossRef]

- Sidhar, H.; Mishra, R.S. Aging kinetics of friction stir welded Al-Cu-Li-Mg-Ag and Al-Cu-Li-Mg alloys. Mater. Des. 2016, 110, 60–71. [Google Scholar] [CrossRef]

- Williams, J.C.; Starke, E.A. Progress in structural materials for aerospace systems. Acta Mater. 2003, 51, 5775–5799. [Google Scholar] [CrossRef]

- Chen, P.; Zou, S.Q.; Chen, J.; Qin, S.Y.; Yang, Q.B.; Zhang, Z.Q.; Jia, Z.H.; Zhang, L.; Jiang, T.; Liu, Q. Effect of rotation speed on microstructure evolution and mechanical properties of nugget zone in 2195-T8 Al-Li alloy friction stir welding joints. Mater. Charact. 2021, 176, 111079. [Google Scholar] [CrossRef]

- Xu, Y.; Li, G.; Jiang, W.; Zhan, J.; Yu, Y.; Fan, Z. Investigation on characteristic and formation mechanism of porosity defects of Al–Li alloys prepared by sand casting. J. Mater. Res. Technol. 2022, 19, 4063–4075. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Farabi, E.; Babaniaris, S.; Barnett, M.R.; Fabijanic, D.M. Microstructure and mechanical properties of Ti6Al4V alloys fabricated by additive friction stir deposition. Addit. Manuf. Lett. 2022, 2, 100034. [Google Scholar] [CrossRef]

- Li, Y.; Yang, B.; Zhang, M.; Wang, H.; Gong, W.; Lai, R.; Li, Y.; Teng, J. The corrosion behavior and mechanical properties of 5083 Al-Mg alloy manufactured by additive friction stir deposition. Corros. Sci. 2023, 213, 110972. [Google Scholar] [CrossRef]

- Cooke, S.; Ahmadi, K.; Willerth, S.; Herring, R. Metal additive manufacturing: Technology, metallurgy and modelling. J. Manuf. Process. 2020, 57, 978–1003. [Google Scholar] [CrossRef]

- Wu, B.; Pan, Z.; Ding, D.; Cuiuri, D.; Li, H.; Xu, J.; Norrish, J. A review of the wire arc additive manufacturing of metals: Properties, defects and quality improvement. J. Manuf. Process. 2018, 35, 127–139. [Google Scholar] [CrossRef]

- Murphy, A.; Lynch, F.; Price, M.; Gibson, A. Modified Stiffened Panel Analysis Methods for Laser Beam and Friction Stir Welded Aircraft Panels. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2006, 220, 267–278. [Google Scholar] [CrossRef]

- Zhang, Q.S.; Yan, A.; Chen, K.; Dong, F.B.; Jia, H.D.; Wang, M. Effect of tool traverse speed on joint line remnant and mechanical properties of friction stir welded 2195-T8 Al-Li alloy joints. High Temp. Mater. Process. 2023, 42, 20220265. [Google Scholar] [CrossRef]

- Zhao, Z.J.; Yang, X.Q.; Li, S.L.; Li, D.X. Interfacial bonding features of friction stir additive manufactured build for 2195-T8 aluminum-lithium alloy. J. Manuf. Process. 2019, 38, 396–410. [Google Scholar] [CrossRef]

- Chen, P.; Chen, J.; Qin, S.Y.; Zou, S.Q.; Song, S.B.; Jiang, T.; Zhang, Z.Q.; Jia, Z.H.; Liu, Q. Friction stir welding joints of 2195-T8 Al-Li alloys: Correlation of temperature evolution, microstructure and mechanical properties. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2021, 823, 141501. [Google Scholar] [CrossRef]

- Garcia, D.; Hartley, W.D.; Rauch, H.A.; Griffiths, R.J.; Wang, R.; Kong, Z.J.; Zhu, Y.; Yu, H.Z. In situ investigation into temperature evolution and heat generation during additive friction stir deposition: A comparative study of Cu and Al-Mg-Si. Addit. Manuf. 2020, 34, 101386. [Google Scholar] [CrossRef]

- Zhang, M.; Ye, X.; Li, Y.; Wang, H.; Lai, R.; Li, Y. Effect of Heat Treatment States of Feedstock on the Microstructure and Mechanical Properties of AA2219 Layers Deposited by Additive Friction Stir Deposition. Materials 2023, 16, 7591. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Li, Y.; Zhang, M.; Gong, W.; Lai, R.; Li, Y. Preheating-assisted solid-state friction stir repair of Al-Mg-Si alloy plate at different rotational speeds. Int. J. Miner. Metall. Mater. 2024, 31, 725–736. [Google Scholar] [CrossRef]

- Agrawal, P.; Haridas, R.S.; Yadav, S.; Thapliyal, S.; Gaddam, S.; Verma, R.; Mishra, R.S. Processing-structure-property correlation in additive friction stir deposited Ti-6Al-4V alloy from recycled metal chips. Addit. Manuf. 2021, 47, 102259. [Google Scholar] [CrossRef]

- Joshi, S.S.; Patil, S.M.; Mazumder, S.; Sharma, S.; Riley, D.A.; Dowden, S.; Banerjee, R.; Dahotre, N.B. Additive friction stir deposition of AZ31B magnesium alloy. J. Magnes. Alloys 2022, 10, 2404–2420. [Google Scholar] [CrossRef]

- Wang, H.; Li, Y.; Zhang, M.; Gong, W.; Liu, Q.; Zeng, Z.; Ma, K.; Lai, R.; Li, Y. Repairing the 7075 Al alloy plate by additive friction stir deposition with different feedstock rods. Int. J. Adv. Manuf. Technol. 2024, 134, 921–933. [Google Scholar] [CrossRef]

- Li, Y.; Wang, H.; Lai, R.; Yang, B.; Wang, Z.; Li, Y. Effect of overlapping deposition strategy on microstructure and mechanical properties of Al-clad steel by AFSD. J. Manuf. Process. 2024, 129, 51–61. [Google Scholar] [CrossRef]

- Zeng, Z.; Li, Y.; Wang, H.; Lai, R.; Teng, J.; Li, Y. Tribological behavior of AlSn20Cu alloy manufactured by additive friction stir deposition. Wear 2025, 560–561, 205606. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, M.; Wang, H.; Lai, R.; Yang, B.; Li, Y. Microstructure and mechanical properties of Al–Li alloy manufactured by additive friction stir deposition. Mater. Sci. Eng. A 2023, 887, 145753. [Google Scholar] [CrossRef]

- Jiang, N.; Gao, X.; Zheng, Z.-Q. Microstructure evolution of aluminum-lithium alloy 2195 undergoing commercial production. Trans. Nonferrous Met. Soc. China 2010, 20, 740–745. [Google Scholar] [CrossRef]

- Anderson-Wedge, K.; Stubblefield, G.; Zhu, N.; Long, B.; Daniewicz, S.R.; Allison, P.; Sowards, J.; Rodriguez, O.; Amaro, R. Characterization of the evolution of 2219-T87 aluminum as a function of the friction stir welding process. Int. J. Fatigue 2021, 142, 105954. [Google Scholar] [CrossRef]

- Ghadimi, H.; Ding, H.; Emanet, S.; Talachian, M.; Cox, C.; Eller, M.; Guo, S.M. Hardness Distribution of Al2050 Parts Fabricated Using Additive Friction Stir Deposition. Materials 2023, 16, 1278. [Google Scholar] [CrossRef] [PubMed]

- Jo, H.H.; Hirano, K.i. Precipitation Processes in Al-Cu-Li Alloy Studied by DSC. Mater. Sci. Forum 1987, 13–14, 377–382. [Google Scholar] [CrossRef]

- Qin, H.; Zhang, H.; Wu, H. The evolution of precipitation and microstructure in friction stir welded 2195-T8 Al–Li alloy. Mater. Sci. Eng. A 2015, 626, 322–329. [Google Scholar] [CrossRef]

- Xie, B.; Huang, L.; Xu, J.; Su, H.; Zhang, H.; Xu, Y.; Li, J.; Wang, Y. Effect of the aging process and pre-deformation on the precipitated phase and mechanical properties of 2195 Al–Li alloy. Mater. Sci. Eng. A 2022, 832, 142394. [Google Scholar] [CrossRef]

- Zeng, C.Y.; Ghadimi, H.; Ding, H.; Nemati, S.; Garbie, A.; Raush, J.; Guo, S.M. Microstructure Evolution of Al6061 Alloy Made by Additive Friction Stir Deposition. Materials 2022, 15, 3676. [Google Scholar] [CrossRef]

- Chen, G.; Wu, K.; Wang, Y.; Sun, Y.; Wang, X.H.; Zhu, Z.X.; Hu, F.F. Quantitative study on the correlation between microstructure and mechanical properties of additive friction stir deposited 6061-T6 Al-Mg-Si alloy. J. Mater. Res. Technol. 2023, 25, 6725–6736. [Google Scholar] [CrossRef]

- Khan, M.A.; Xu, C.; Hamza, M.; Afifi, M.A.; Qaisrani, N.A.; Sun, H.; Wang, B.; Khan, W.Q.; Yasin, G.; Liao, W.-B. Enhanced tensile strength in an Al–Zn–Mg–Cu alloy via engineering the precipitates along the grain boundaries. J. Mater. Res. Technol. 2023, 22, 696–705. [Google Scholar] [CrossRef]

- Dong, J.; Gao, N.; Chen, Y.; Cao, L.; Song, H.; Fröck, H.; Milkereit, B.; Starink, M.J. Achieving ultra-high strength of Al-Cu-Li alloys by the combination of high pressure torsion and age-hardening. Mater. Sci. Eng. A 2022, 832, 142504. [Google Scholar] [CrossRef]

- Chen, X.; Ma, X.; Xi, H.; Zhao, G.; Wang, Y.; Xu, X. Effects of heat treatment on the microstructure and mechanical properties of extruded 2196 Al-Cu-Li alloy. Mater. Des. 2020, 192, 108746. [Google Scholar] [CrossRef]

- Viloria-Estrada, A.; Mantilla-Nova, D.; García-Salinas, D.A.; Barbosa, W.; Palacio-Espinosa, C.C.; Romero-Toledo, F.A.; Peña-Ballesteros, D.Y.; Díaz-Rodríguez, J.G. Microhardness Profile and Residual Stresses Evaluation in a Shot Peened SAE 5160H Steel. Rev. UIS Ing. 2024, 23, 103–114. [Google Scholar] [CrossRef]

- Mičietová, A.; Čilliková, M.; Čep, R.; Mičieta, B.; Uríček, J.; Neslušan, M. An Investigation of Residual Stresses after the Turning of High-Tempered Bearing Steel. Machines 2024, 12, 139. [Google Scholar] [CrossRef]

- Zhang, J.; Yi, Y.; Huang, S.; Mao, X.; He, H.; Tang, J.; Guo, W.; Dong, F. Dynamic recrystallization mechanisms of 2195 aluminum alloy during medium/high temperature compression deformation. Mater. Sci. Eng. A 2021, 804, 140650. [Google Scholar] [CrossRef]

- Hu, F.F.; Chen, G.; Lin, Y.Y.; Wang, H.; Zhu, Z.X. Numerical and experimental study on the thermal process during additive friction stir deposition. CIRP J. Manuf. Sci. Technol. 2024, 48, 55–66. [Google Scholar] [CrossRef]

- Perry, M.E.J.; Rauch, H.A.; Griffiths, R.J.; Garcia, D.; Sietins, J.M.; Zhu, Y.; Zhu, Y.; Yu, H.Z. Tracing plastic deformation path and concurrent grain refinement during additive friction stir deposition. Materialia 2021, 18, 101159. [Google Scholar] [CrossRef]

- Cui, S.; Zhang, C.; Liu, M.; Chen, L.; Zhao, G. Precipitation behavior of an Al–Cu–Li–X alloy and competing relationships among precipitates at different aging temperatures. Mater. Sci. Eng. A 2021, 814, 141125. [Google Scholar] [CrossRef]

- Tan, Z.; Li, J.; Zhang, Z. Experimental and numerical studies on fabrication of nanoparticle reinforced aluminum matrix composites by friction stir additive manufacturing. J. Mater. Res. Technol. 2021, 12, 1898–1912. [Google Scholar] [CrossRef]

- Wang, D.; Zhan, L.; Liu, C.; He, D.; Lai, R.; Li, Y.; Zeng, Q.; Huang, M.; Hui, S. Stress-level dependency of creep ageing behavior for the nugget zone in a friction stir welded Al–Cu–Li alloy. Mater. Sci. Eng. A 2023, 881, 145383. [Google Scholar] [CrossRef]

- Chen, L.; Lu, L.K.; Zhu, L.; Yang, Z.W.; Zhou, W.F.; Ren, X.D.; Zhang, X.Z. Microstructure Evolution and Mechanical Properties of Multilayer AA6061 Alloy Fabricated by Additive Friction Stir Deposition. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2024, 55, 1049–1064. [Google Scholar] [CrossRef]

| Elements | Cu | Li | Mg | Ag | Zr | Fe | Ti | Al |

|---|---|---|---|---|---|---|---|---|

| wt.% | 3.89 | 0.96 | 0.40 | 0.35 | 0.13 | 0.045 | 0.037 | Bal. |

| Locations of EDS | Al | Cu | Fe | Mg | Ag | Zr | Precipitates |

|---|---|---|---|---|---|---|---|

| #1 | 81.1 | 14.1 | 4.8 | τ2 | |||

| #2 | 78.7 | 15.4 | 5.6 | 0.4 | τ2 | ||

| #3 | 93.6 | 5.8 | 0.6 | θ′/S′ | |||

| #4 | 91.6 | 6.7 | 1.2 | 0.4 | T2 | ||

| #5 | 93.1 | 4.3 | 2.0 | 0.6 | T2 | ||

| #6 | 90.9 | 7.8 | 0.6 | 0.2 | δ′/β′/θ′ | ||

| #7 | 98.2 | 1.2 | 0.6 | Matrix |

| Layer | 16 | 9 | 1 |

|---|---|---|---|

| at. % | 1.7 | 1.2 | 1.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Q.; Lai, R.; Wang, H.; Li, Y.; Li, Y.; Zhan, L. Microstructure Evolution and Mechanical Properties of 16-Layer 2195 Al-Li Alloy Components Manufactured by Additive Friction Stir Deposition. Materials 2024, 17, 5748. https://doi.org/10.3390/ma17235748

Liu Q, Lai R, Wang H, Li Y, Li Y, Zhan L. Microstructure Evolution and Mechanical Properties of 16-Layer 2195 Al-Li Alloy Components Manufactured by Additive Friction Stir Deposition. Materials. 2024; 17(23):5748. https://doi.org/10.3390/ma17235748

Chicago/Turabian StyleLiu, Qinglin, Ruilin Lai, Hui Wang, Yidi Li, Yunping Li, and Lihua Zhan. 2024. "Microstructure Evolution and Mechanical Properties of 16-Layer 2195 Al-Li Alloy Components Manufactured by Additive Friction Stir Deposition" Materials 17, no. 23: 5748. https://doi.org/10.3390/ma17235748

APA StyleLiu, Q., Lai, R., Wang, H., Li, Y., Li, Y., & Zhan, L. (2024). Microstructure Evolution and Mechanical Properties of 16-Layer 2195 Al-Li Alloy Components Manufactured by Additive Friction Stir Deposition. Materials, 17(23), 5748. https://doi.org/10.3390/ma17235748