Residual Stress Distribution in Dievar Tool Steel Bars Produced by Conventional Additive Manufacturing and Rotary Swaging Processes

Abstract

1. Introduction

2. Materials and Methods

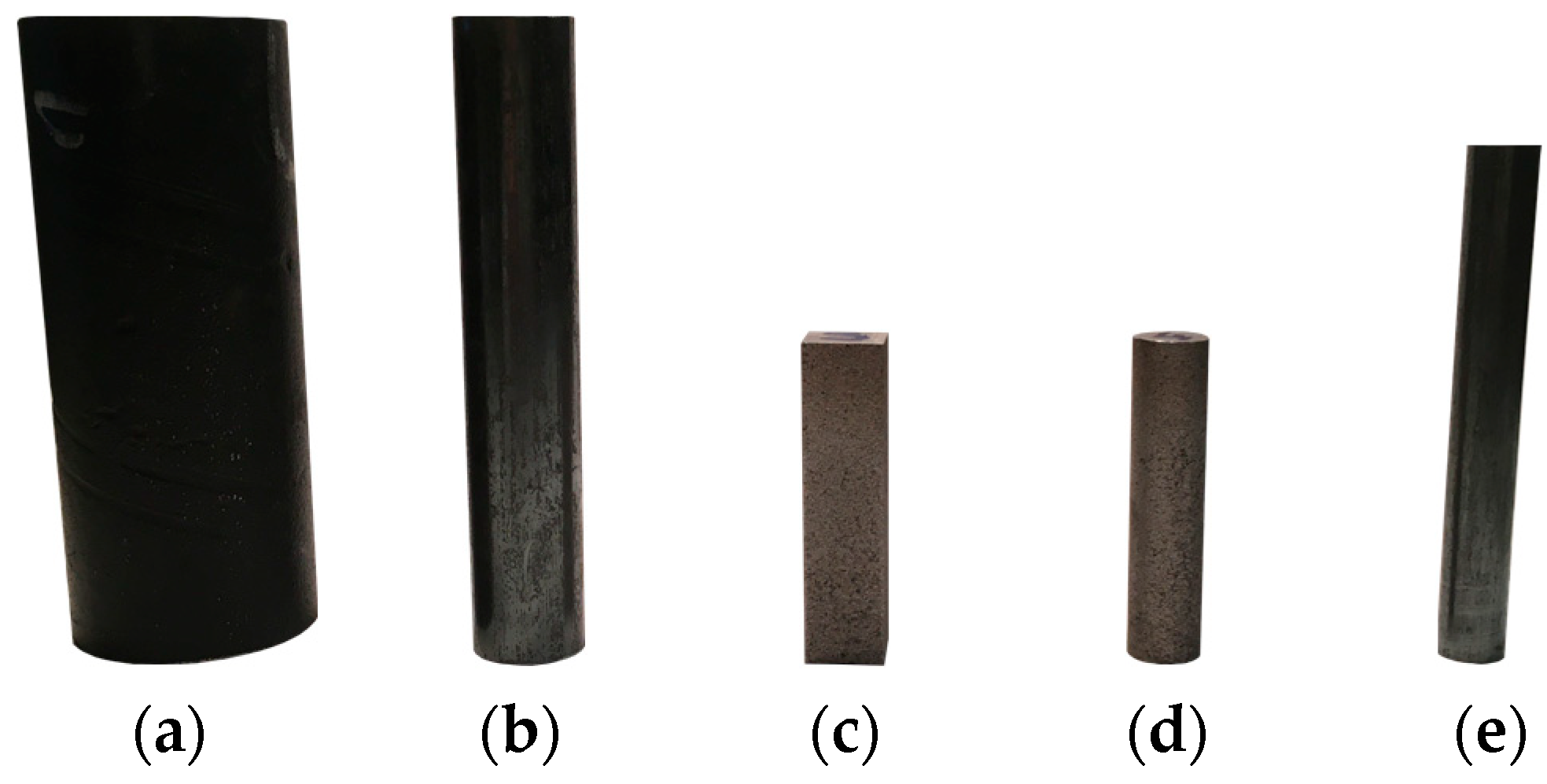

2.1. Material and Samples’ Preparation

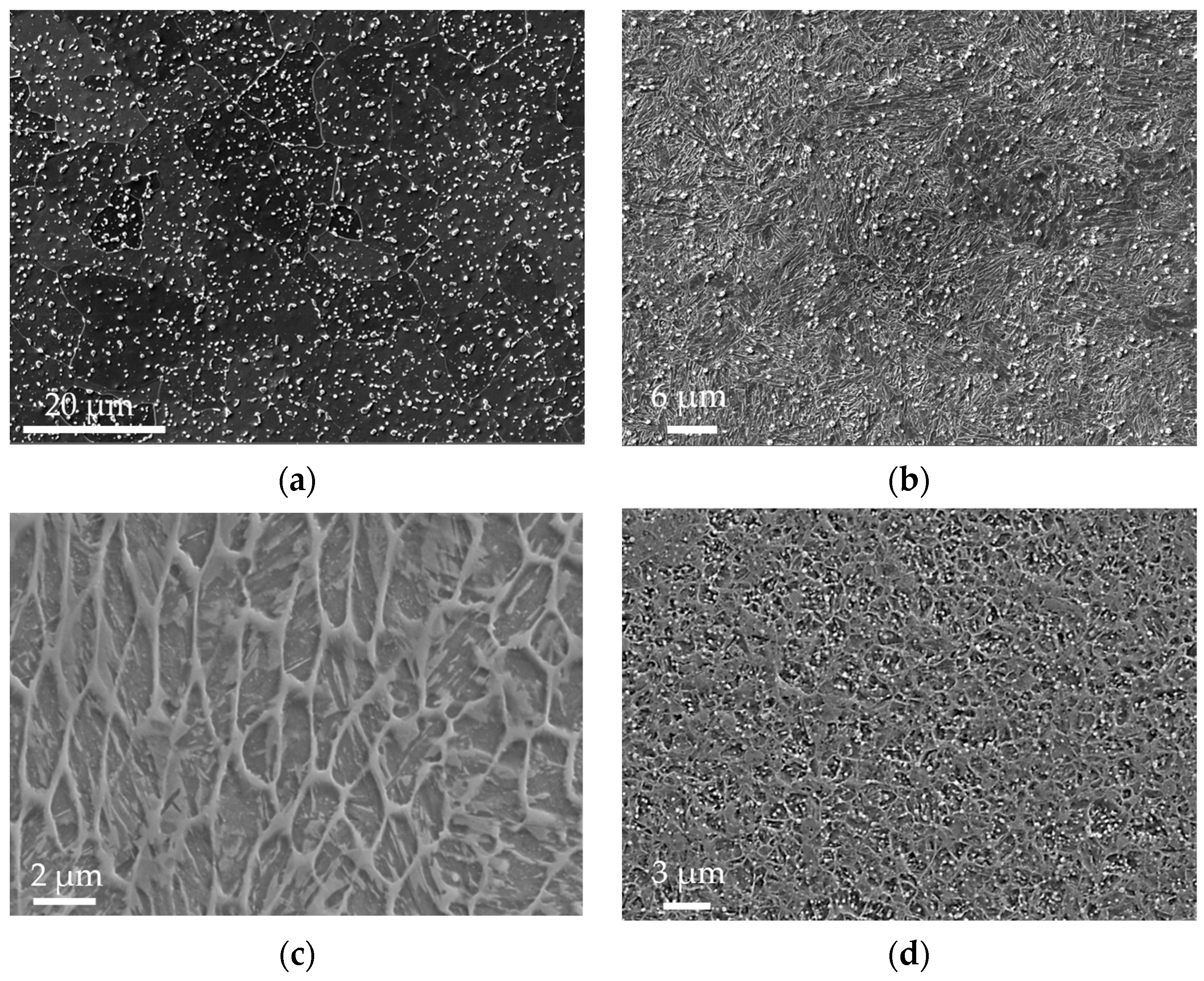

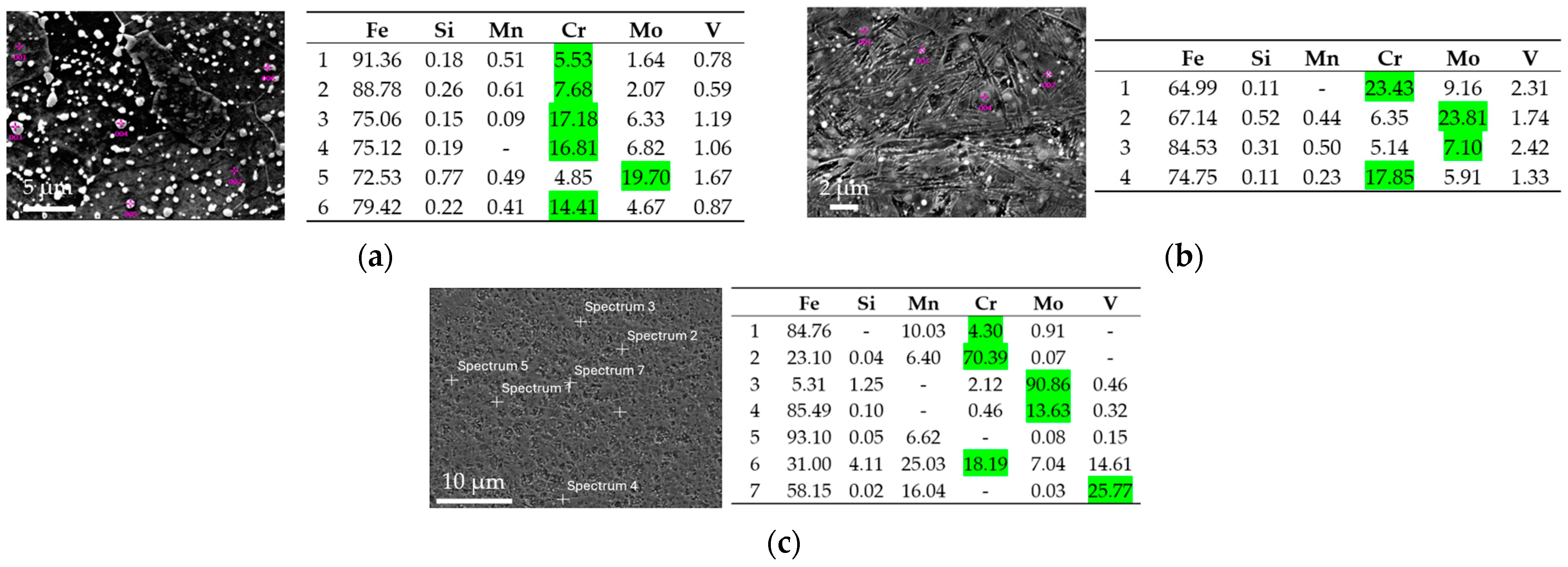

2.2. Microstructure, Precipitates, and Hardness

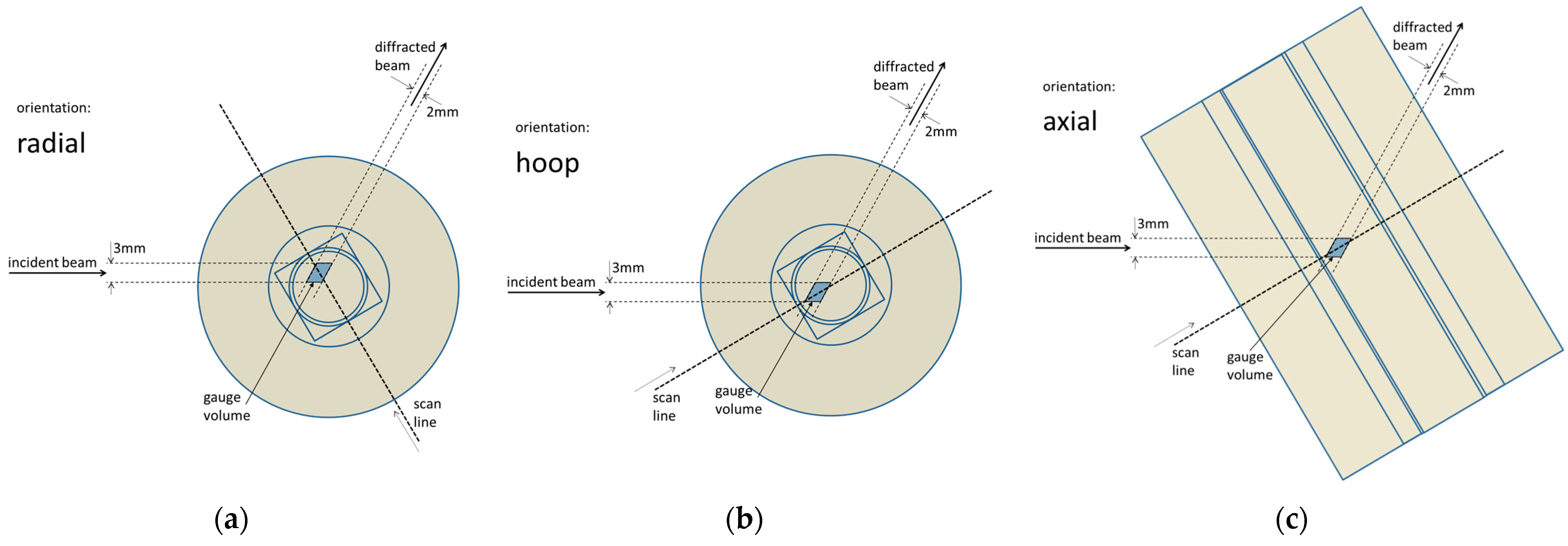

2.3. Neutron Diffraction

3. Results

3.1. Microstructure, Precipitates, and Hardness Evaluation

3.2. Neutron Diffraction Results

4. Residual Strain and Stress Evaluation

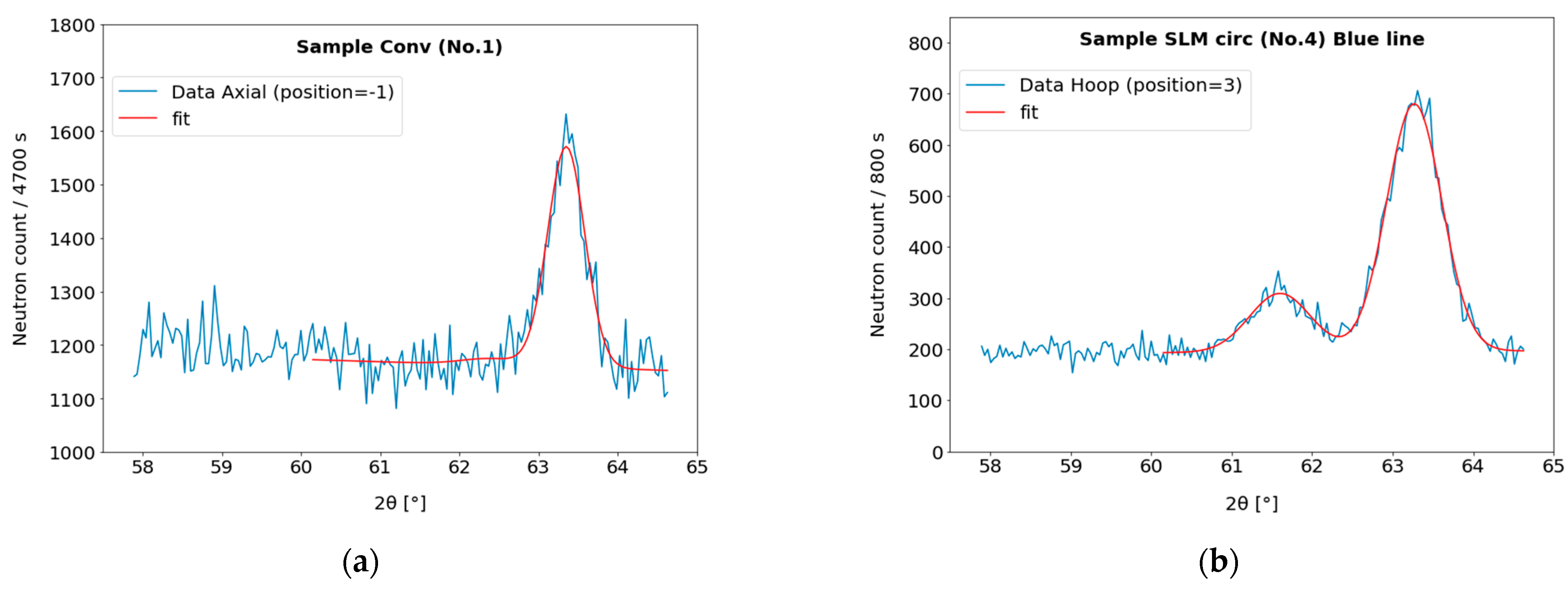

4.1. Pseudostrain and Other Disturbing Effects Treatment

- -

- Only partial use of the instrumental gauge volume at the sample boundaries;

- -

- Absorbtion across the gauge volume.

4.2. Determination of the Unconstrained Lattice Spacing

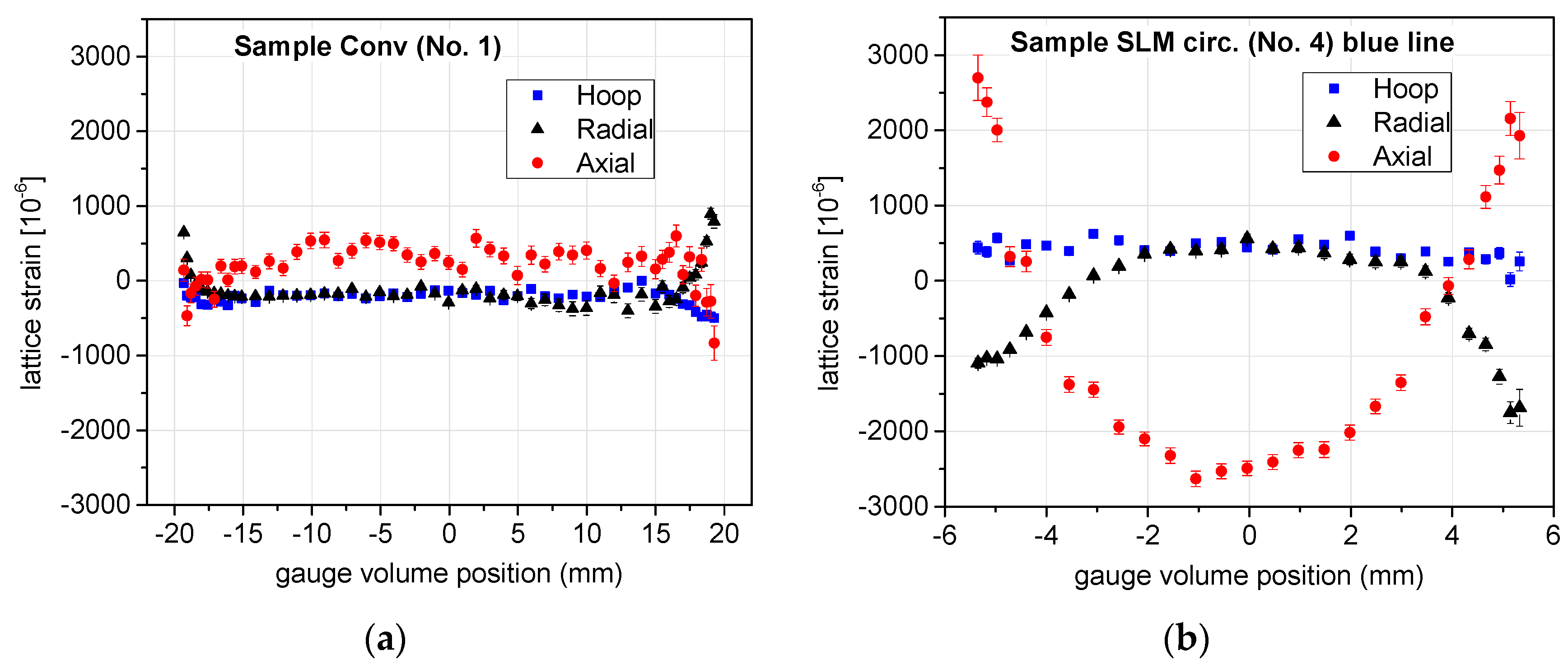

4.3. Residual Strains

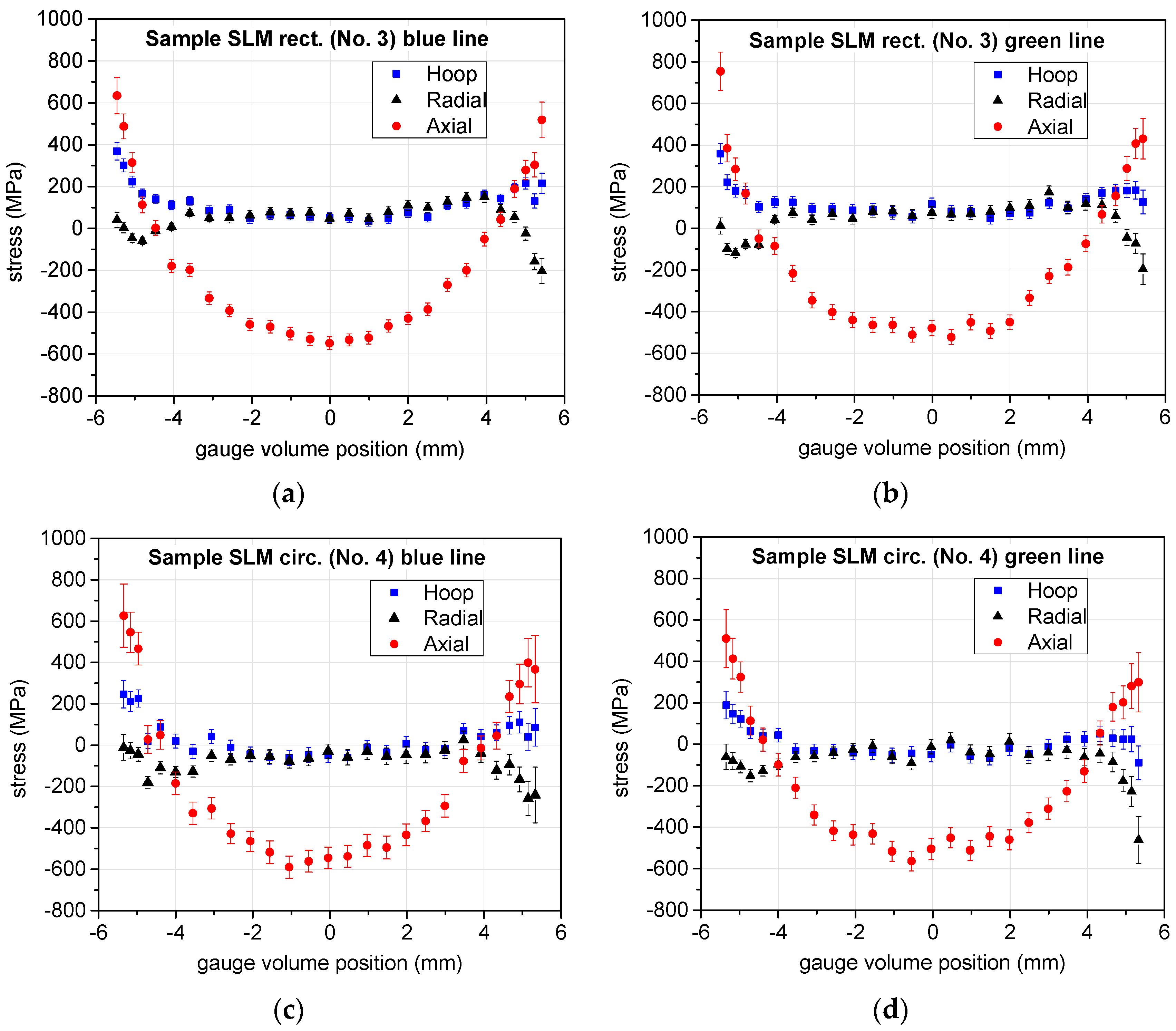

4.4. Residual Stresses

5. Discussion

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lu, Y.; Wu, S.; Gan, Y.; Huang, T.; Yang, C.; Junjie, L.; Lin, J. Study on the microstructure, mechanical property and residual stress of SLM Inconel-718 alloy manufactured by differing island scanning strategy. Opt. Laser Technol. 2015, 75, 197–206. [Google Scholar] [CrossRef]

- Valdez, M.; Kozuch, C.; Faierson, E.J.; Jasiuk, I. Induced porosity in Super Alloy 718 through the laser additive manufacturing process: Microstructure and mechanical properties. J. Alloys Compd. 2017, 725, 757–764. [Google Scholar] [CrossRef]

- Salmi, A.; Atzeni, E.; Iuliano, L.; Galati, M. Experimental Analysis of Residual Stresses on AlSi10Mg Parts Produced by Means of Selective Laser Melting (SLM). Procedia CIRP 2017, 62, 458–463. [Google Scholar] [CrossRef]

- Hauk, V.; Behnken, H. Structural and Residual Stress Analysis by Nondestructive Methods: Evaluation, Application, Assessment; Elsevier: Amsterdam, The Netherlands; New York, NY, USA, 1997. [Google Scholar]

- Sasaki, T.; Takahashi, S.; Kanematsu, Y.; Satoh, Y.; Iwafuchi, K.; Ishida, M.; Morii, Y. Measurement of residual stresses in rails by neutron diffraction. Wear 2008, 265, 1402–1407. [Google Scholar] [CrossRef]

- Harun, W.; Manam, N.; Kamariah, M.; Sharif, S.; Zulkifly, A.; Ahmad, I.; Miura, H. A review of powdered additive manufacturing techniques for Ti-6al-4v biomedical applications. Powder Technol. 2018, 331, 74–97. [Google Scholar] [CrossRef]

- Paolini, A.; Kollmannsberger, S.; Rank, E. Additive manufacturing in construction: A review on processes, applications, and digital planning methods. Addit. Manuf. 2019, 30, 100894. [Google Scholar] [CrossRef]

- Fette, M.; Sander, P.; Wulfsberg, J.; Zierk, H.; Herrmann, A.; Stoess, N. Optimized and Cost-efficient Compression Molds Manufactured by Selective Laser Melting for the Production of Thermoset Fiber Reinforced Plastic Aircraft Components. Procedia CIRP 2015, 35, 25–30. [Google Scholar] [CrossRef]

- Buchanan, C.; Gardner, L. Metal 3D printing in construction: A review of methods, research, applications, opportunities and challenges. Eng. Struct. 2019, 180, 332–348. [Google Scholar] [CrossRef]

- Ali, H.; Ghadbeigi, H.; Mumtaz, K. Effect of scanning strategies on residual stress and mechanical properties of Selective Laser Melted Ti6Al4V. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2018, 712, 175–187. [Google Scholar] [CrossRef]

- Vundru, C.; Singh, R.; Yan, W.; Karagadde, S. The Effect of Martensitic Transformation on the Evolution of Residual Stresses and Identification of the Critical Linear Mass Density in Direct Laser Metal Deposition–Based Repair. J. Manuf. Sci. Eng. 2020, 142, 71002. [Google Scholar] [CrossRef]

- Parry, L.; Ashcroft, I.; Wildman, R. Understanding the effect of laser scan strategy on residual stress in selective laser melting through thermo-mechanical simulation. Addit. Manuf. 2016, 12, 1–15. [Google Scholar] [CrossRef]

- Balbaa, M.; Mekhiel, S.; Elbestawi, M.; McIsaac, J. On selective laser melting of Inconel 718: Densification, surface roughness, and residual stresses. Mater. Des. 2020, 193, 108818. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Yadroitsava, I. Evaluation of residual stress in stainless steel 316L and Ti6Al4V samples produced by selective laser melting. Virtual Phys. Prototyp. 2015, 10, 67–76. [Google Scholar] [CrossRef]

- Kruth, J.; Froyen, L.; Van Vaerenbergh, J.; Mercelis, P.; Rombouts, M.; Lauwers, B. Selective laser melting of iron-based powder. J. Mater. Process. Technol. 2004, 149, 616–622. [Google Scholar] [CrossRef]

- Mukherjee, T.; Zhang, W.; DebRoy, T. An improved prediction of residual stresses and distortion in additive manufacturing. Comput. Mater. Sci. 2017, 126, 360–372. [Google Scholar] [CrossRef]

- Mishurova, T.; Cabeza, S.; Artzt, K.; Haubrich, J.; Klaus, M.; Genzel, C.; Requena, G.; Bruno, G. An assessment of subsurface residual stress analysis in SLM Ti-6Al-4V. Materials 2017, 10, 348. [Google Scholar] [CrossRef]

- Simson, T.; Emmel, A.; Dwars, A.; Böhm, J. Residual stress measurements on AISI 316L samples manufactured by selective laser melting. Addit. Manuf. 2017, 17, 183–189. [Google Scholar] [CrossRef]

- Ulbricht, A.; Altenburg, S.J.; Sprengel, M.; Sommer, K.; Mohr, G.; Fritsch, T.; Mishurova, T.; Serrano-Munoz, I.; Evans, A.; Hofmann, M.; et al. Separation of the formation mechanisms of residual stresses in lpbf 316l. Metals 2020, 10, 1234. [Google Scholar] [CrossRef]

- Liscic, B.; Tensi, H.M.; Canale, L.C.; Totten, G.E. Quenching Theory and Technology, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Lozano, D.E.; Totten, G.E.; Bedolla-Gil, Y.; Guerrero-Mata, M.; Carpio, M.; Martinez-Cazares, G.M. X-ray Determination of compressive residual stresses in spring steel generated by high-speed water quenching. Materials 2019, 12, 1154. [Google Scholar] [CrossRef]

- Zhao, X.; Munroe, P.; Habibi, D.; Xie, Z. Roles of compressive residual stress in enhancing the corrosion resistance of nano nitride composite coatings on steel. J. Asian Ceram. Soc. 2013, 1, 86–94. [Google Scholar] [CrossRef]

- Dunbar, A.; Denlinger, E.; Heigel, J.; Michaleris, P.; Guerrier, P.; Martukanitz, R.; Simpson, T. Development of experimental method for in situ distortion and temperature measurements during the laser powder bed fusion additive manufacturing process. Addit. Manuf. 2016, 12, 25–30. [Google Scholar] [CrossRef]

- Craeghs, T.; Clijsters, S.; Kruth, J.-P.; Bechmann, F.; Ebert, M.-C. Detection of Process Failures in Layerwise Laser Melting with Optical Process Monitoring. Phys. Procedia 2012, 39, 753–759. [Google Scholar] [CrossRef]

- Clijsters, S.; Craeghs, T.; Buls, S.; Kempen, K.; Kruth, J.-P. In situ quality control of the selective laser melting process using a high-speed, real-time melt pool monitoring system. Int. J. Adv. Manuf. Technol. 2014, 75, 1089–1101. [Google Scholar] [CrossRef]

- Santhoshsarang, D.M.; Divya, K.; Telasang, G.; Soundarapandian, S.; Bathe, R.; Padmanabham, G. Additively Manufactured High-Performance Conformally Cooled H13 Tool Steel Die Insert for Pressure Die Casting. Trans. Indian Natl. Acad. Eng. (Online) 2021, 6, 1037–1048. [Google Scholar] [CrossRef]

- Sjöström, J.; Bergström, J. Thermal fatigue testing of chromium martensitic hot-work tool steel after different austenitizing treatments. J. Mater. Process. Technol. 2004, 153–154, 1089–1096. [Google Scholar] [CrossRef]

- Xiang, S.; Wu, R.; Li, W.; Hu, T.; Huang, S. Improved Red Hardness and Toughness of Hot Work Die Steel through Tungsten Alloying. J. Mater. Eng. Perform. 2021, 30, 6146–6159. [Google Scholar] [CrossRef]

- Samuel, A.; Prabhu, K.N. Residual Stress and Distortion during Quench Hardening of Steels: A Review. J. Mater. Eng. Perform. 2022, 31, 5161–5188. [Google Scholar] [CrossRef]

- Macherauch, E.; Vöhringer, O. Residual Stresses After Quenching. In Theory and Technology of Quenching; Springer: Berlin/Heidelberg, Germany, 1992; pp. 117–181. [Google Scholar] [CrossRef]

- Furrer, D.U.; Semiatin, S.L. Modeling of Quenching, Residual-Stress Formation, and Quench Cracking. In ASM Handbook, Volume 22B—Metals Process Simulation; ASM International: Detroit, MI, USA, 2010; pp. 547–599. [Google Scholar]

- Macchi, J.; Gaudez, S.; Geandier, G.; Teixeira, J.; Denis, S.; Bonnet, F.; Allain, S.Y. Dislocation densities in a low-carbon steel during martensite transformation determined by in situ high energy X-Ray diffraction. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2021, 800, 140249. [Google Scholar] [CrossRef]

- Ding, W.; Liu, Y.; Xie, J.; Sun, L.; Liu, T.; Yuan, F.; Pan, J. Effect of carbide precipitation on the evolution of residual stress during tempering. Metals 2019, 9, 709. [Google Scholar] [CrossRef]

- Chen, Y.; Ding, W.; Liang, L.; Liu, X.; Wang, H.; Xiao, S.; Chen, Q.; Yang, Y.; Yang, W. Intervention mechanism of carbide precipitation during tempering and its impact on residual stress and mechanical properties of wear-resistant steels. Ironmak. Steelmak. 2024, 51, 502–512. [Google Scholar] [CrossRef]

- Kantaros, A.; Karalekas, D. Fiber Bragg grating based investigation of residual strains in ABS parts fabricated by fused deposition modeling process. Mater. Des. 2013, 50, 44–50. [Google Scholar] [CrossRef]

- Kantaros, A.; Karalekas, D. FBG Based in Situ Characterization of Residual Strains in FDM Process. In Conference Proceedings of the Society for Experimental Mechanics Series; Springer International Publishing: Cham, Switzerland, 2014; Volume 8, pp. 333–337. [Google Scholar] [CrossRef]

- Khorasani, M.; Ghasemi, A.; Rolfe, B.; Gibson, I. Additive manufacturing a powerful tool for the aerospace industry. Rapid Prototyp. J. 2022, 28, 87–100. [Google Scholar] [CrossRef]

- Masaylo, D.; Igoshin, S.; Popovich, A.; Orlov, A.; Kim, A.; Popovich, V. Microstructural and Hardness Behavior of H13 Tool Steel Manufactured by Ultrasound-Assisted Laser-Directed Energy Deposition. Metals 2022, 12, 450. [Google Scholar] [CrossRef]

- Yuan, M.; Cao, Y.; Karamchedu, S.; Hosseini, S.; Yao, Y.; Berglund, J.; Liu, L.; Nyborg, L. Characteristics of a modified H13 hot-work tool steel fabricated by means of laser beam powder bed fusion. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2022, 831, 142322. [Google Scholar] [CrossRef]

- Zhu, Y.; Chen, J.; Li, X. Numerical Simulation of Thermal Field and Performance Study on H13 Die Steel-Based Wire Arc Additive Manufacturing. Metals 2023, 13, 1484. [Google Scholar] [CrossRef]

- Yan, J.J.; Zheng, D.L.; Li, H.X.; Jia, X.; Sun, J.F.; Li, Y.L.; Qian, M.; Yan, M. Selective laser melting of H13: Microstructure and residual stress. J. Mater. Sci. 2017, 52, 12476–12485. [Google Scholar] [CrossRef]

- Sander, J.; Hufenbach, J.; Giebeler, L.; Wendrock, H.; Kühn, U.; Eckert, J. Microstructure and properties of FeCrMoVC tool steel produced by selective laser melting. Mater. Des. 2016, 89, 335–341. [Google Scholar] [CrossRef]

- Gallmeyer, T.G.; Moorthy, S.; Kappes, B.B.; Mills, M.J.; Amin-Ahmadi, B.; Stebner, A.P. Knowledge of process-structure-property relationships to engineer better heat treatments for laser powder bed fusion additive manufactured Inconel 718. Addit. Manuf. 2020, 31, 100977. [Google Scholar] [CrossRef]

- Voisin, T.; Forien, J.-B.; Perron, A.; Aubry, S.; Bertin, N.; Samanta, A.; Baker, A.; Wang, Y.M. New insights on cellular structures strengthening mechanisms and thermal stability of an austenitic stainless steel fabricated by laser powder-bed-fusion. Acta Mater. 2021, 203, 116476. [Google Scholar] [CrossRef]

- Pröbstle, M.; Neumeier, S.; Hopfenmüller, J.; Freund, L.; Niendorf, T.; Schwarze, D.; Göken, M. Superior creep strength of a nickel-based superalloy produced by selective laser melting. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2016, 674, 299–307. [Google Scholar] [CrossRef]

- Vrancken, B.; Thijs, L.; Kruth, J.-P.; Van Humbeeck, J. Heat treatment of Ti6Al4V produced by Selective Laser Melting: Microstructure and mechanical properties. J. Alloys Compd. 2012, 541, 177–185. [Google Scholar] [CrossRef]

- Charmi, A.; Falkenberg, R.; Ávila, L.; Mohr, G.; Sommer, K.; Ulbricht, A.; Sprengel, M.; Neumann, R.S.; Skrotzki, B.; Evans, A. Mechanical anisotropy of additively manufactured stainless steel 316L: An experimental and numerical study. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2021, 799, 140154. [Google Scholar] [CrossRef]

- Zhou, Y.H.; Li, W.P.; Wang, D.W.; Zhang, L.; Ohara, K.; Shen, J.; Ebel, T.; Yan, M. Selective Laser Melting Enabled Additive Manufacturing of Ti-22Al-25Nb Intermetallic: Excellent Combination of Strength and Ductility, and Unique Microstructural Features Associated. Acta Mater. 2019, 173, 117–129. [Google Scholar] [CrossRef]

- Seede, R.; Shoukr, D.; Zhang, B.; Whitt, A.; Gibbons, S.; Flater, P.; Elwany, A.; Arroyave, R.; Karaman, I. An ultra-high strength martensitic steel fabricated using selective laser melting additive manufacturing: Densification, microstructure, and mechanical properties. Acta Mater. 2020, 186, 199–214. [Google Scholar] [CrossRef]

- Boes, J.; Röttger, A.; Theisen, W.; Cui, C.; Uhlenwinkel, V.; Schulz, A.; Zoch, H.-W.; Stern, F.; Tenkamp, J.; Walther, F. Gas atomization and laser additive manufacturing of nitrogen-alloyed martensitic stainless steel. Addit. Manuf. 2020, 34, 101379. [Google Scholar] [CrossRef]

- Saeidi, K.; Zapata, D.L.; Lofaj, F.; Kvetkova, L.; Olsen, J.; Shen, Z.; Akhtar, F. Ultra-high strength martensitic 420 stainless steel with high ductility. Addit. Manuf. 2019, 29, 100803. [Google Scholar] [CrossRef]

- Bartlett, J.L.; Li, X. An overview of residual stresses in metal powder bed fusion. Addit. Manuf. 2019, 27, 131–149. [Google Scholar] [CrossRef]

- Chao, Q.; Thomas, S.; Birbilis, N.; Cizek, P.; Hodgson, P.D.; Fabijanic, D. The effect of post-processing heat treatment on the microstructure, residual stress and mechanical properties of selective laser melted 316L stainless steel. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2021, 821, 141611. [Google Scholar] [CrossRef]

- Jaber, H.; Kónya, J.; Kulcsár, K.; Kovács, T. Effects of Annealing and Solution Treatments on the Microstructure and Mechanical Properties of Ti6Al4V Manufactured by Selective Laser Melting. Materials 2022, 15, 1978. [Google Scholar] [CrossRef]

- Mercelis, P.; Kruth, J. Residual stresses in selective laser sintering and selective laser melting. Rapid Prototyp. J. 2006, 12, 254–265. [Google Scholar] [CrossRef]

- Levkulich, N.; Semiatin, S.; Gockel, J.; Middendorf, J.; DeWald, A.; Klingbeil, N. The effect of process parameters on residual stress evolution and distortion in the laser powder bed fusion of Ti-6Al-4V. Addit. Manuf. 2019, 28, 475–484. [Google Scholar] [CrossRef]

- Serrano-Munoz, I.; Fritsch, T.; Mishurova, T.; Trofimov, A.; Apel, D.; Ulbricht, A.; Kromm, A.; Hesse, R.; Evans, A.; Bruno, G. On the interplay of microstructure and residual stress in LPBF IN718. J. Mater. Sci. 2021, 56, 5845–5867. [Google Scholar] [CrossRef]

- Pertuz-Comas, A.D.; González-Estrada, O.A.; Martínez-Díaz, E.; Villegas-Bermúdez, D.F.; Díaz-Rodríguez, J.G. Strain-Based Fatigue Experimental Study on Ti–6Al–4V Alloy Manufactured by Electron Beam Melting. J. Manuf. Mater. Process. 2023, 7, 25. [Google Scholar] [CrossRef]

- Bagg, S.D.; Sochalski-Kolbus, L.M.; Bunn, J.R. The Effect of Laser Scan Strategy on Distortion and Residual Stresses of Arches Made With Selective Laser Melting. In NASA Center for AeroSpace Information (CASI). Conference Proceeding; NASA/Langley Research Center: Hampton, VA, USA, 2016. [Google Scholar]

- Schmidt, M.; Merklein, M.; Bourell, D.; Dimitrov, D.; Hausotte, T.; Wegener, K.; Overmeyer, L.; Vollertsen, F.; Levy, G.N. Laser based additive manufacturing in industry and academia. CIRP Ann. 2017, 66, 561–583. [Google Scholar] [CrossRef]

- Kunčická, L.; Macháčková, A.; Lavery, N.P.; Kocich, R.; Cullen, J.C.; Hlaváč, L.M. Effect of thermomechanical processing via rotary swaging on properties and residual stress within tungsten heavy alloy. Int. J. Refract. Met. Hard Mater. 2020, 87, 105120. [Google Scholar] [CrossRef]

- Kunčická, L.; Kocich, R.; Hervoches, C.; Macháčková, A. Study of structure and residual stresses in cold rotary swaged tungsten heavy alloy. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2017, 704, 25–31. [Google Scholar] [CrossRef]

- Izák, J.; Benč, M.; Kunčická, L.; Opěla, P.; Kocich, R. Influence of Imposed Strain on Weldability of Dievar Alloy. Materials 2024, 17, 2317. [Google Scholar] [CrossRef]

- Hansen, N. Hall–Petch relation and boundary strengthening. Scr. Mater. 2004, 51, 801–806. [Google Scholar] [CrossRef]

- Figueiredo, R.B.; Kawasaki, M.; Langdon, T.G. Seventy years of Hall-Petch, ninety years of superplasticity and a generalized approach to the effect of grain size on flow stress. Prog. Mater. Sci. 2023, 137, 101131. [Google Scholar] [CrossRef]

- Yan, J.-J.; Li, J.; Yang, Z.-L.; Gu, R.-N.; Yan, M.; Quach, W.-M. Neutron diffraction residual stress analysis and mechanical properties of additively manufactured high strength steel hollow sections. Thin-Walled Struct. 2022, 179, 109729. [Google Scholar] [CrossRef]

- Nadammal, N.; Mishurova, T.; Fritsch, T.; Serrano-Munoz, I.; Kromm, A.; Haberland, C.; Portella, P.D.; Bruno, G. Critical role of scan strategies on the development of microstructure, texture, and residual stresses during laser powder bed fusion additive manufacturing. Addit. Manuf. 2021, 38, 101792. [Google Scholar] [CrossRef]

- Hutchings, M.; Withers, P.; Holden, T.; Lorentzen, T. Introduction to the Characterization of Residual Stress by Neutron Diffraction; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar] [CrossRef]

- Withers, P.; Bhadeshia, H. Residual stress. Part 1—Measurement techniques. Mater. Sci. Technol. 2001, 17, 355–365. [Google Scholar] [CrossRef]

- Ramineni, L.; Almotari, A.; Ali, M.; Algamal, A.; Qattawi, A. Residual Stress Mapping in Heat-Assisted Additive Manufacturing of IN 718: An X-Ray Diffraction Study. J. Mater. Eng. Perform. 2024, 33, 4124–4135. [Google Scholar] [CrossRef]

- Marola, S.; Bosia, S.; Veltro, A.; Fiore, G.; Manfredi, D.; Lombardi, M.; Amato, G.; Baricco, M.; Battezzati, L. Residual stresses in additively manufactured AlSi10Mg: Raman spectroscopy and X-ray diffraction analysis. Mater. Des. 2021, 202, 109550. [Google Scholar] [CrossRef]

- Canelo-Yubero, D.; Kocich, R.; Hervoches, C.; Strunz, P.; Kunčická, L.; Krátká, L. Neutron Diffraction Study of Residual Stresses in a W–Ni–Co Heavy Alloy Processed by Rotary Swaging at Room and High Temperatures. Met. Mater. Int. 2022, 28, 919–930. [Google Scholar] [CrossRef]

- Strunz, P.; Kocich, R.; Canelo-Yubero, D.; Macháčková, A.; Beran, P.; Krátká, L. Texture and Differential Stress Development in W/Ni-Co Composite after Rotary Swaging. Materials 2020, 13, 2869. [Google Scholar] [CrossRef]

- Canelo-Yubero, D.; Kocich, R.; Šaroun, J.; Strunz, P. Residual Stress Distribution in a Copper-Aluminum Multifilament Composite Fabricated by Rotary Swaging. Materials 2023, 16, 2102. [Google Scholar] [CrossRef]

- Kunčická, L.; Kocich, R.; Dvořák, K.; Macháčková, A. Rotary swaged laminated Cu-Al composites: Effect of structure on residual stress and mechanical and electric properties. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2019, 742, 743–750. [Google Scholar] [CrossRef]

- Kunčická, L.; Kocich, R. Sub-Structure and Residual Stress in Rotary Swaged Cu/Al Clad Composite Wires. Key Eng. Mater. 2020, 865, 7–12. [Google Scholar] [CrossRef]

- Ishkina, S.; Charni, D.; Herrmann, M.; Liu, Y.; Epp, J.; Schenck, C.; Kuhfuss, B.; Zoch, H.-W. Influence of process fluctuations on residual stress evolution in rotary swaging of steel tubes. Materials 2019, 16, 855. [Google Scholar] [CrossRef]

- Ortmann-Ishkina, S.; Charni, D.; Herrmann, M.; Liu, Y.; Epp, J.; Schenck, C.; Kuhfuss, B. Development of residual stresses by infeed rotary swaging of steel tubes. Arch. Appl. Mech. (1991) 2021, 91, 3637–3647. [Google Scholar] [CrossRef]

- Yuan, L.; Wang, W.; Li, Y.; Yang, M.; Zhang, H.; Zhang, W. Effect of annealing temperature on texture and residual stress of Ti-6Al-4V alloy seamless tubing processed by cold rotary swaging. Vacuum 2020, 177, 109399. [Google Scholar] [CrossRef]

- Singh, G.; Kalita, B.; Vishnu Narayanan, K.I.; Arora, U.K.; Mahapatra, M.M.; Jayaganthan, R. Finite element analysis and experimental evaluation of residual stress of Zr-4 alloys processed through swaging. Metals 2020, 10, 1281. [Google Scholar] [CrossRef]

- HK4—Strain Scanner. Available online: https://www.ujf.cas.cz/en/departments/department-of-neutron-and-ion-methods/instruments/lvr15/HK4.html (accessed on 17 November 2024).

- Hodek, J.; Prantl, A.; Džugan, J.; Strunz, P. Determination of directional residual stresses by the contour method. Metals 2019, 9, 1104. [Google Scholar] [CrossRef]

- Šaroun, J.; Rebelo-Kornmeier, J.; Gibmeier, J.; Hofmann, M. Treatment of spatial resolution effects in neutron residual strain scanning. Physica. B Condens. Matter 2018, 551, 468–471. [Google Scholar] [CrossRef]

- Šaroun, J. STRESSFIT—Program for Fitting of Residual Stress Distributions. Available online: https://github.com/NPLtools/stressfit (accessed on 17 November 2024).

- Šaroun, J. SIMRES—Neutron Ray-Tracing Simulation Program. Available online: https://github.com/saroun/simres (accessed on 17 November 2024).

- Martinez-Perez, M.; Mompean, F.; Ruiz-Hervias, J.; Borlado, C.; Atienza, J.; Garcia-Hernandez, M.; Elices, M.; Gil-Sevillano, J.; Peng, R.L.; Buslaps, T. Residual stress profiling in the ferrite and cementite phases of cold-drawn steel rods by synchrotron X-ray and neutron diffraction. Acta Mater. 2004, 52, 5303–5313. [Google Scholar] [CrossRef]

- Fernández, P.; Bruno, G.; Gonzalezdoncel, G. Macro and micro-residual stress distribution in 6061 Al-15 vol.% SiCw under different heat treatment conditions. Compos. Sci. Technol. 2006, 66, 1738–1748. [Google Scholar] [CrossRef]

- Ju, D.Y.; Mukai, R.; Minakawa, N.; Morii, Y.; Moriai, A. A Measurement Method of Residual Stress in Quenched Steel by Neutron Diffracation. Key Eng. Mater. 2004, 270–273, 139–146. [Google Scholar] [CrossRef]

| C | Si | Mn | Cr | Mo | V |

|---|---|---|---|---|---|

| 0.35 | 0.20 | 0.50 | 5.00 | 2.50 | 0.60 |

| Sample Nr. | Sample Name | Cross-Sectional Dimension | Diameter after Reduction by RS | Imposed Strain (-) |

|---|---|---|---|---|

| 1 | Conv | ø 40.8 mm | N/A | 0 |

| 2 | Conv + RS | ø 40.8 mm | ø 18.8 mm | 1.55 |

| 3 | SLM-rectangular | 12 × 12 mm2 | N/A | 0 |

| 4 | SLM-circular | ø 12 mm | N/A | 0 |

| 5 | SLM+RS | ø 25.4 mm | ø 11.1 mm | 1.65 |

| Conv | Conv + RS | SLM | SLM + RS | |

|---|---|---|---|---|

| Microstructure | Ferritic-perlitic | Martensitic | Martensitic | Martensitic |

| Grain size (µm) | 10–15 | 3–5 | 2–5 | 3–4 |

| Hardness (HV1) | 172 | 613 | 560 | 606 |

| BC(C,T)/FCC | 99.8/0.2 | 98.2/1.8 | 96.3/3.7 | 98.5/1.5 |

| Carbides-based | Cr, Mo | Cr, Mo | - | Cr, Mo, V |

| von Mises stress | Low level, minimal fluctuations | Lower residual stress, more uniform | Significant, pronounced maxima at surface and in center | Overall low level, reduced surface value |

| Hydrostatic stress | Very low level, uniform—except surface | Low level, uniform—except surface | Parabolic-like distribution, tensile near the surface | Parabolic-like distribution, tensile near the surface |

| Overall characteristics | Low residual stress and uniform distribution | High hardness, improved strength of the material | High hardness and residual stress on the surface, risk of surface cracking | Improved residual stress level |

| Potential applications | Suitable for less demanding applications | Demanding applications | Demanding application with certain limitations | Suitable for more demanding applications (fatigue resistance) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Izák, J.; Strunz, P.; Levytska, O.; Németh, G.; Šaroun, J.; Kocich, R.; Pagáč, M.; Tuharin, K. Residual Stress Distribution in Dievar Tool Steel Bars Produced by Conventional Additive Manufacturing and Rotary Swaging Processes. Materials 2024, 17, 5706. https://doi.org/10.3390/ma17235706

Izák J, Strunz P, Levytska O, Németh G, Šaroun J, Kocich R, Pagáč M, Tuharin K. Residual Stress Distribution in Dievar Tool Steel Bars Produced by Conventional Additive Manufacturing and Rotary Swaging Processes. Materials. 2024; 17(23):5706. https://doi.org/10.3390/ma17235706

Chicago/Turabian StyleIzák, Josef, Pavel Strunz, Olena Levytska, Gergely Németh, Jan Šaroun, Radim Kocich, Marek Pagáč, and Kostyantyn Tuharin. 2024. "Residual Stress Distribution in Dievar Tool Steel Bars Produced by Conventional Additive Manufacturing and Rotary Swaging Processes" Materials 17, no. 23: 5706. https://doi.org/10.3390/ma17235706

APA StyleIzák, J., Strunz, P., Levytska, O., Németh, G., Šaroun, J., Kocich, R., Pagáč, M., & Tuharin, K. (2024). Residual Stress Distribution in Dievar Tool Steel Bars Produced by Conventional Additive Manufacturing and Rotary Swaging Processes. Materials, 17(23), 5706. https://doi.org/10.3390/ma17235706