Effect of Cooling Rate on α Variant Selection and Microstructure Evolution in TB17 Titanium Alloy

Abstract

1. Introduction

2. Materials and Experimental Section

2.1. Materials

2.2. Heat Treatment

2.3. Microstructure Characterization

3. Results and Discussion

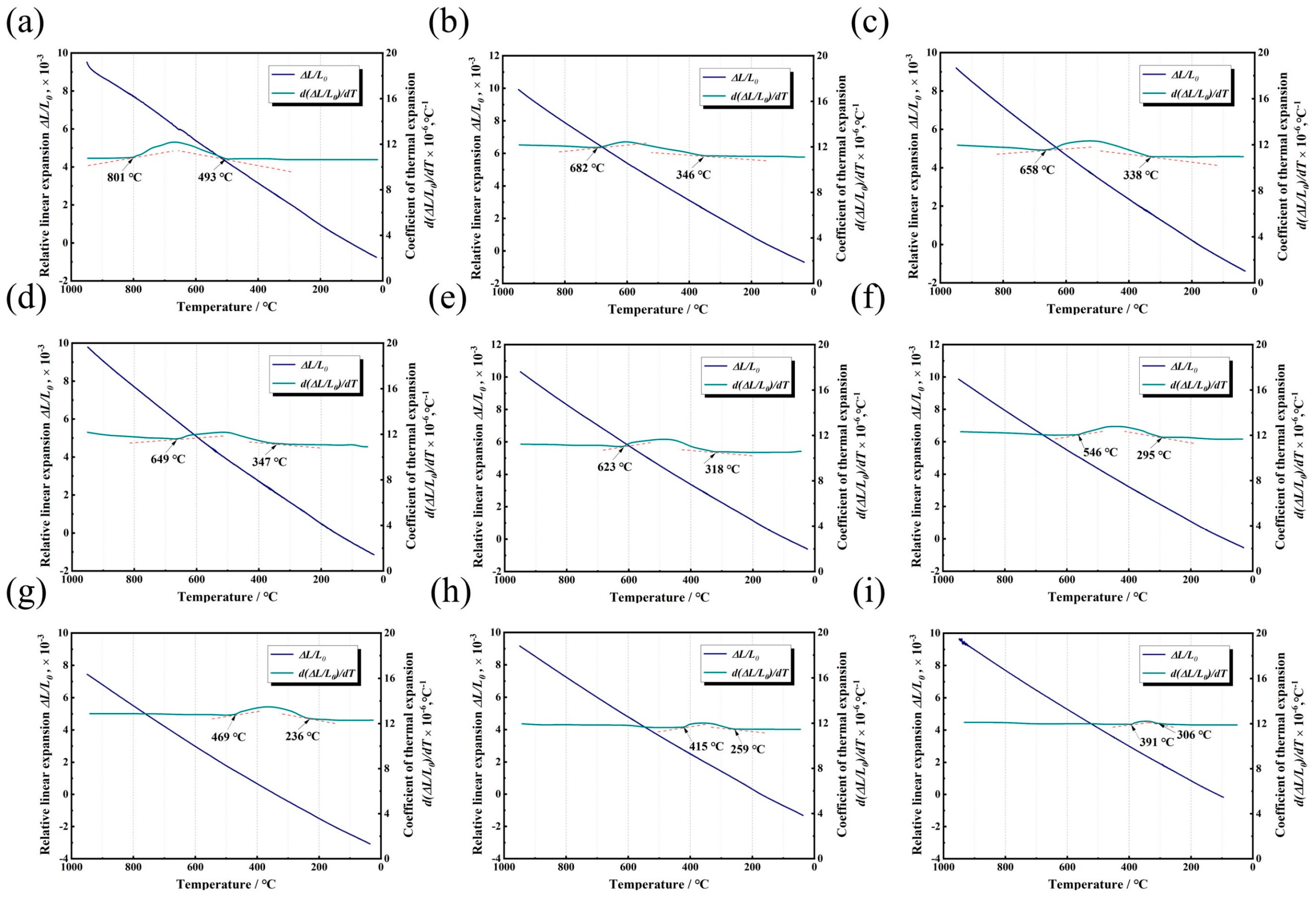

3.1. Dilatometric Behaviors

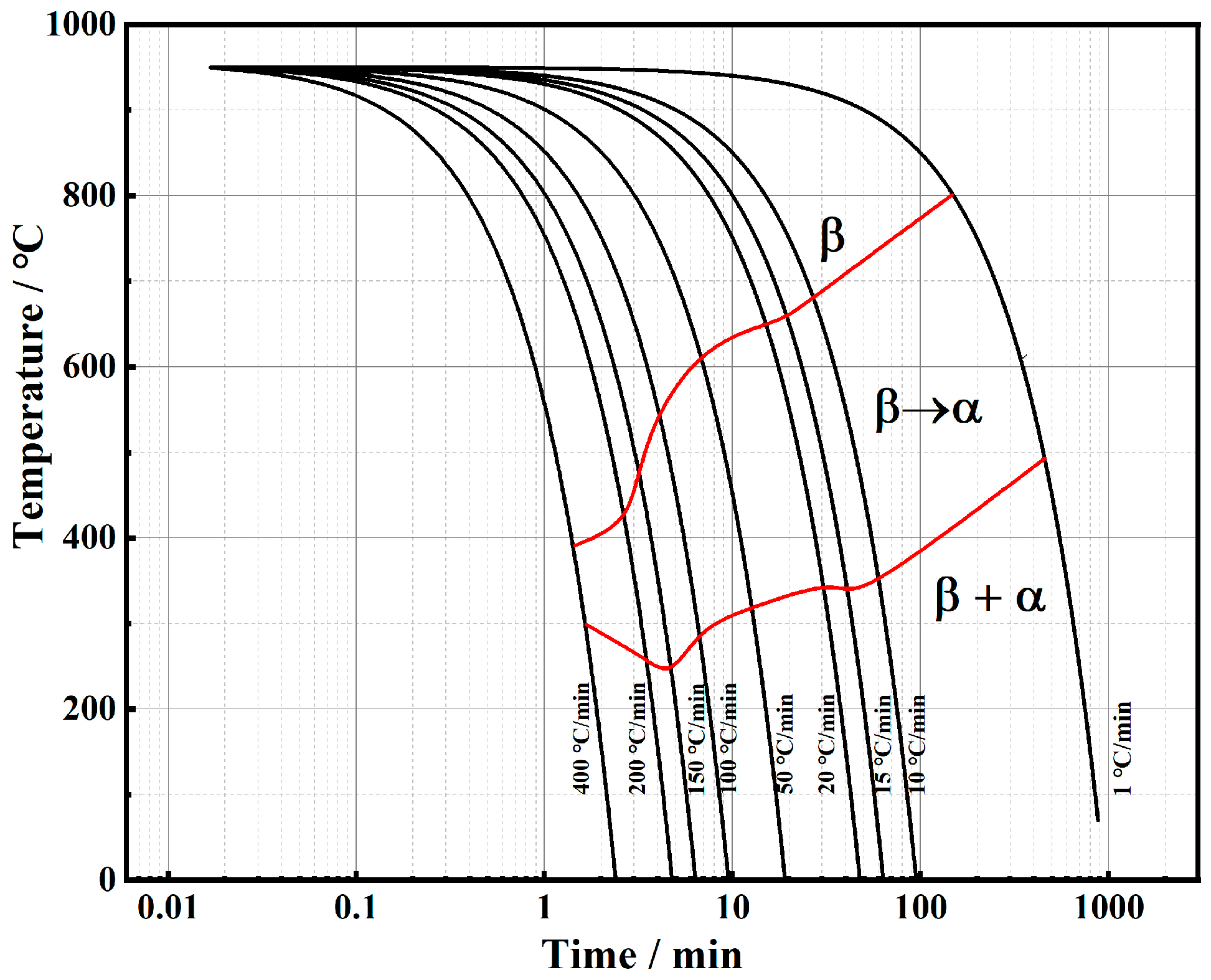

3.2. Establishment of CCT Curve of TB17 Titanium Alloy

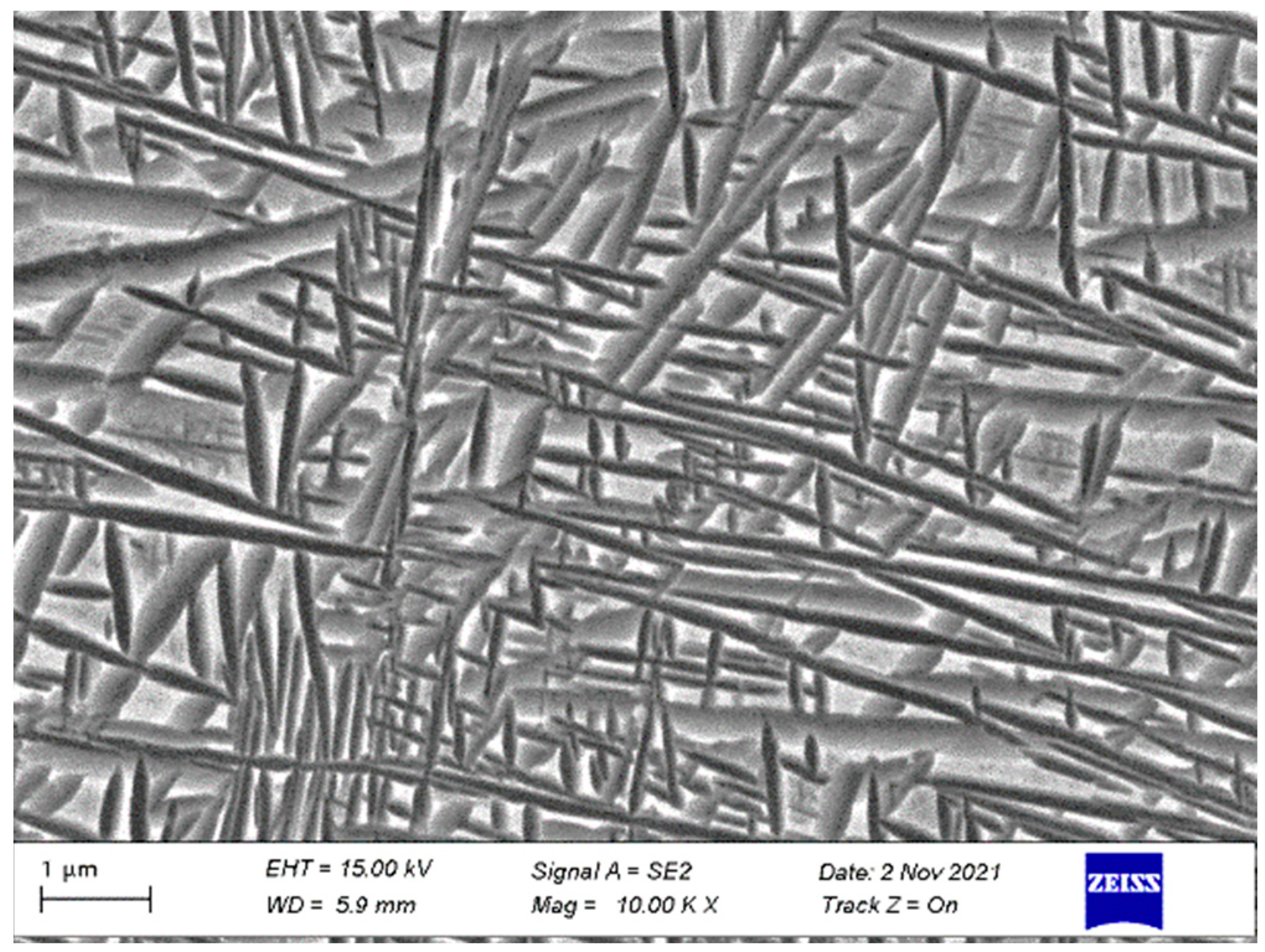

3.3. Microstructure Evolution

- (1)

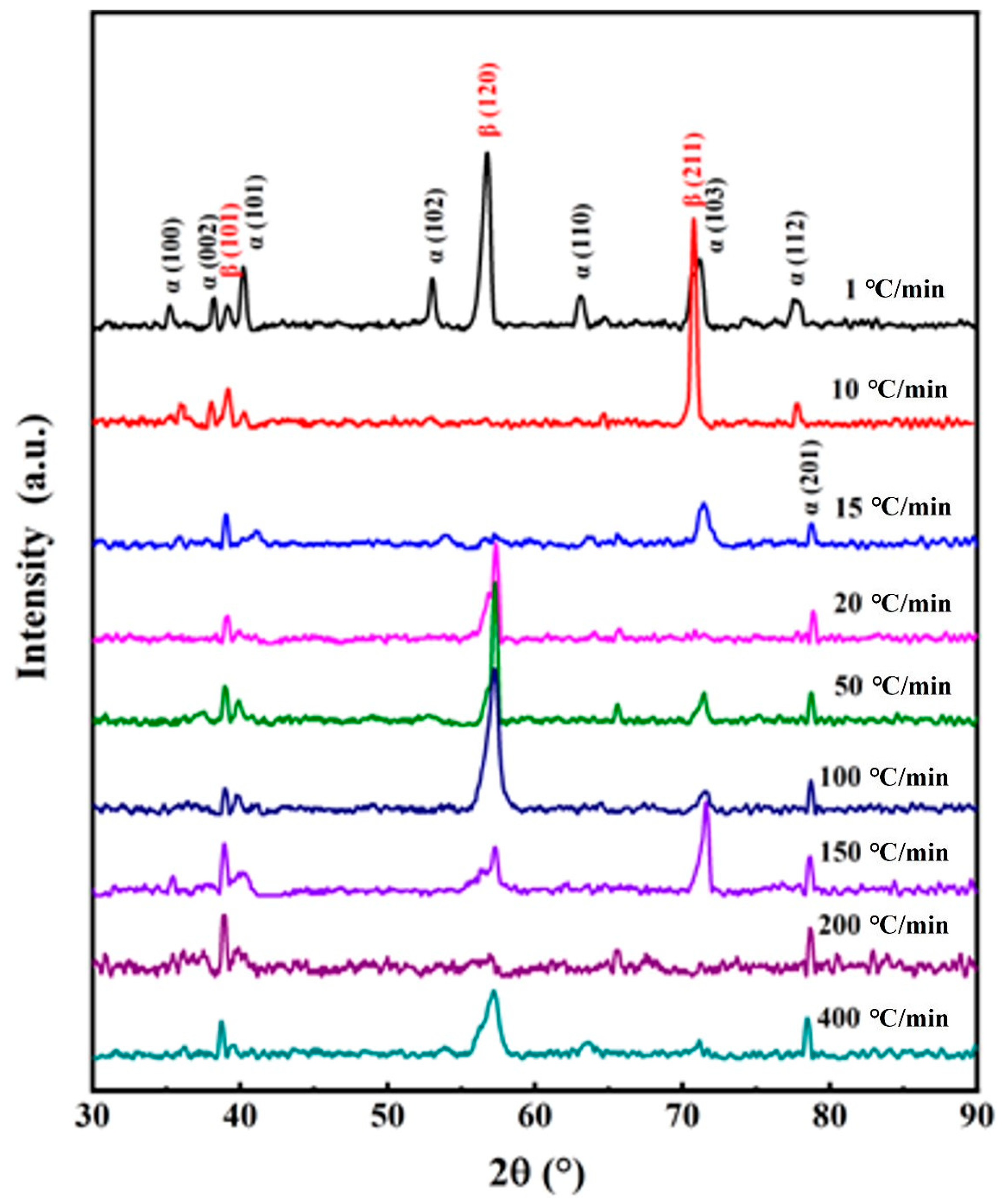

- XRD diffraction pattern of TB17 titanium alloy at different cooling rates

- (2)

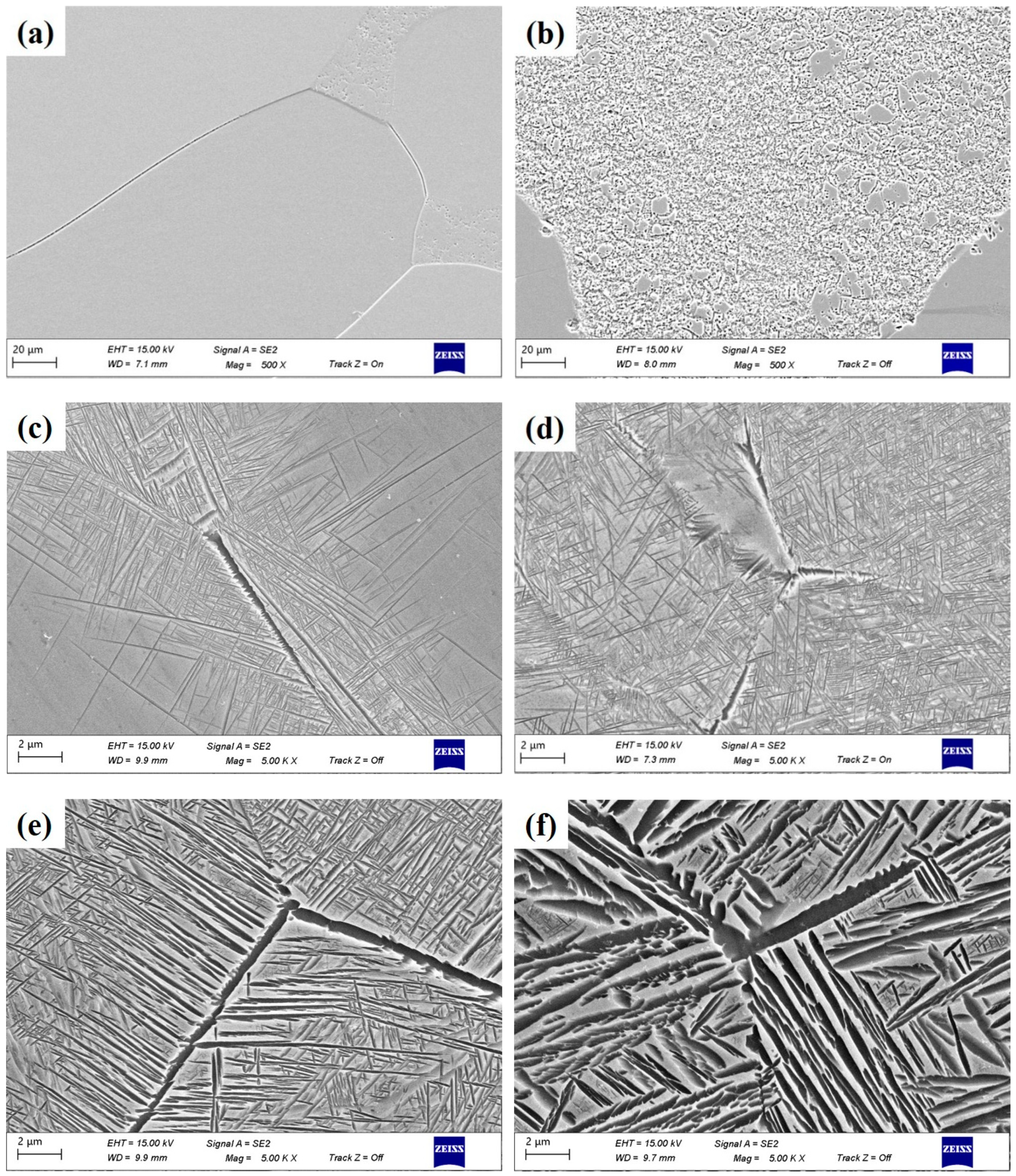

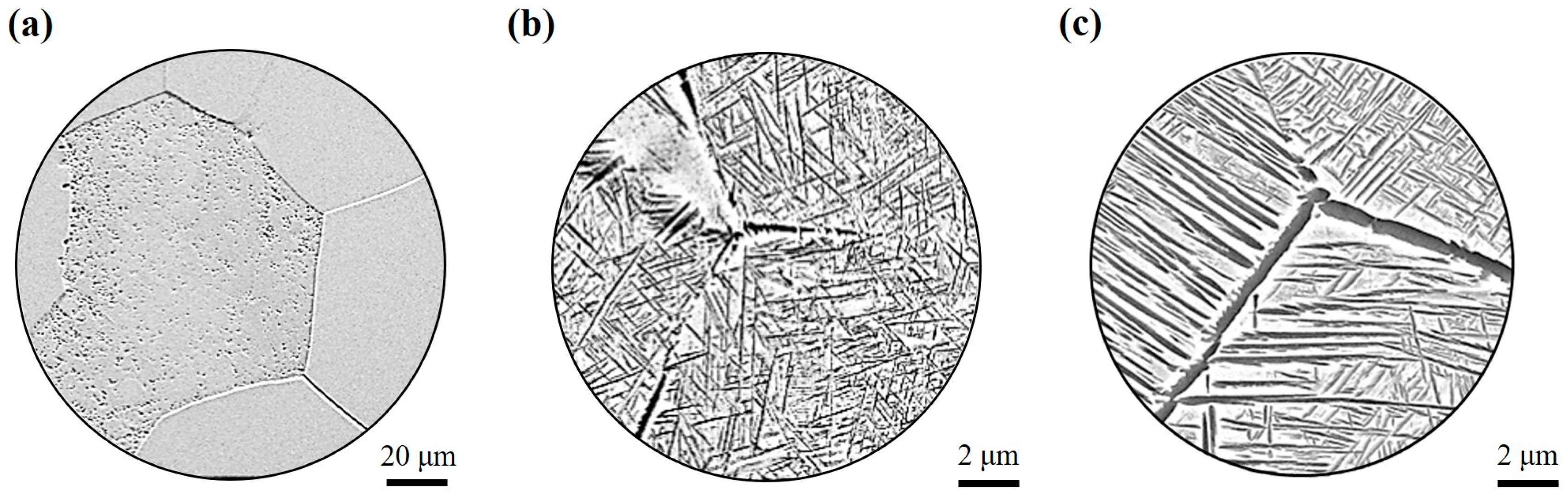

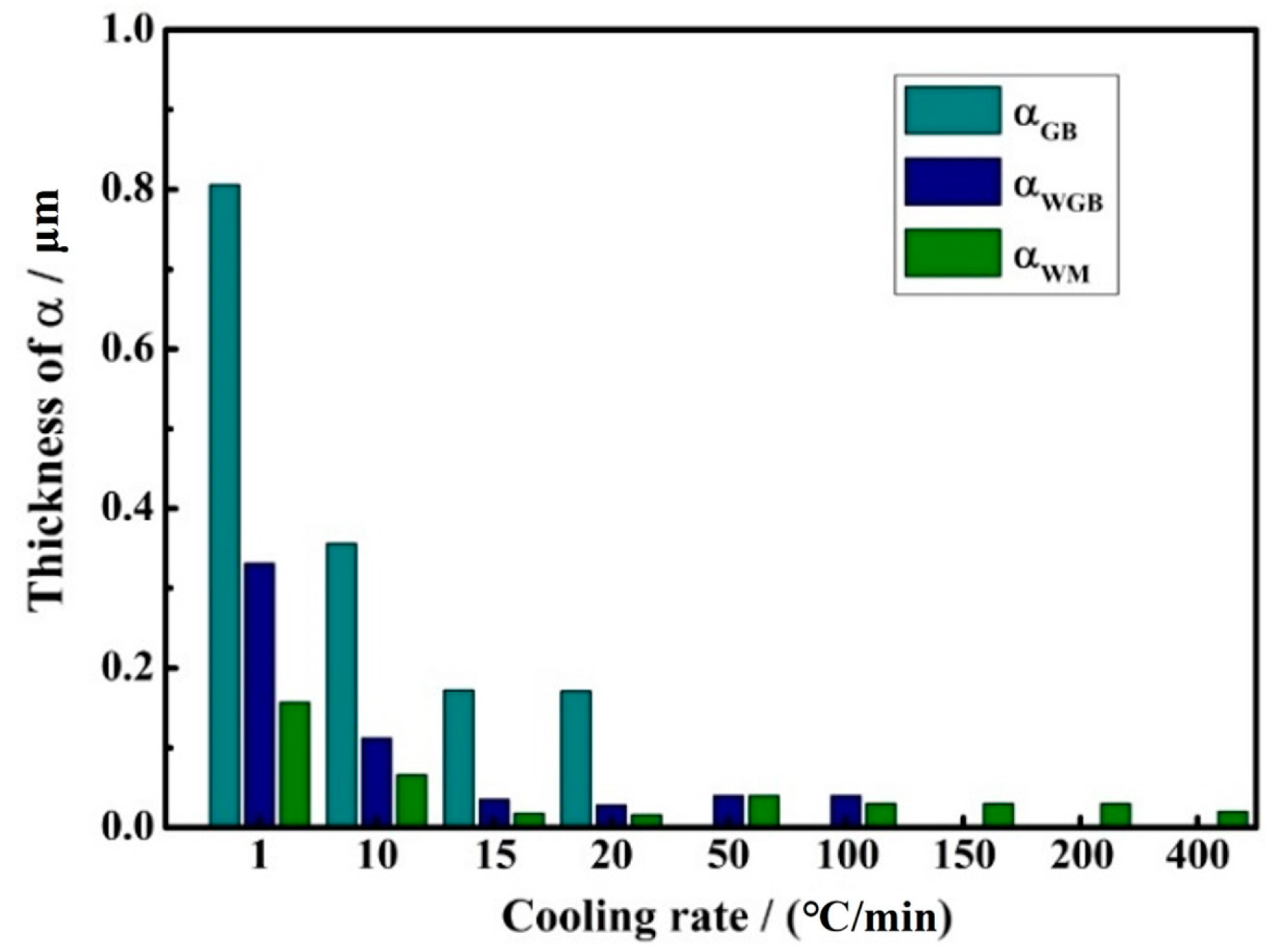

- Microstructure characteristics of TB17 titanium alloy at different cooling rates

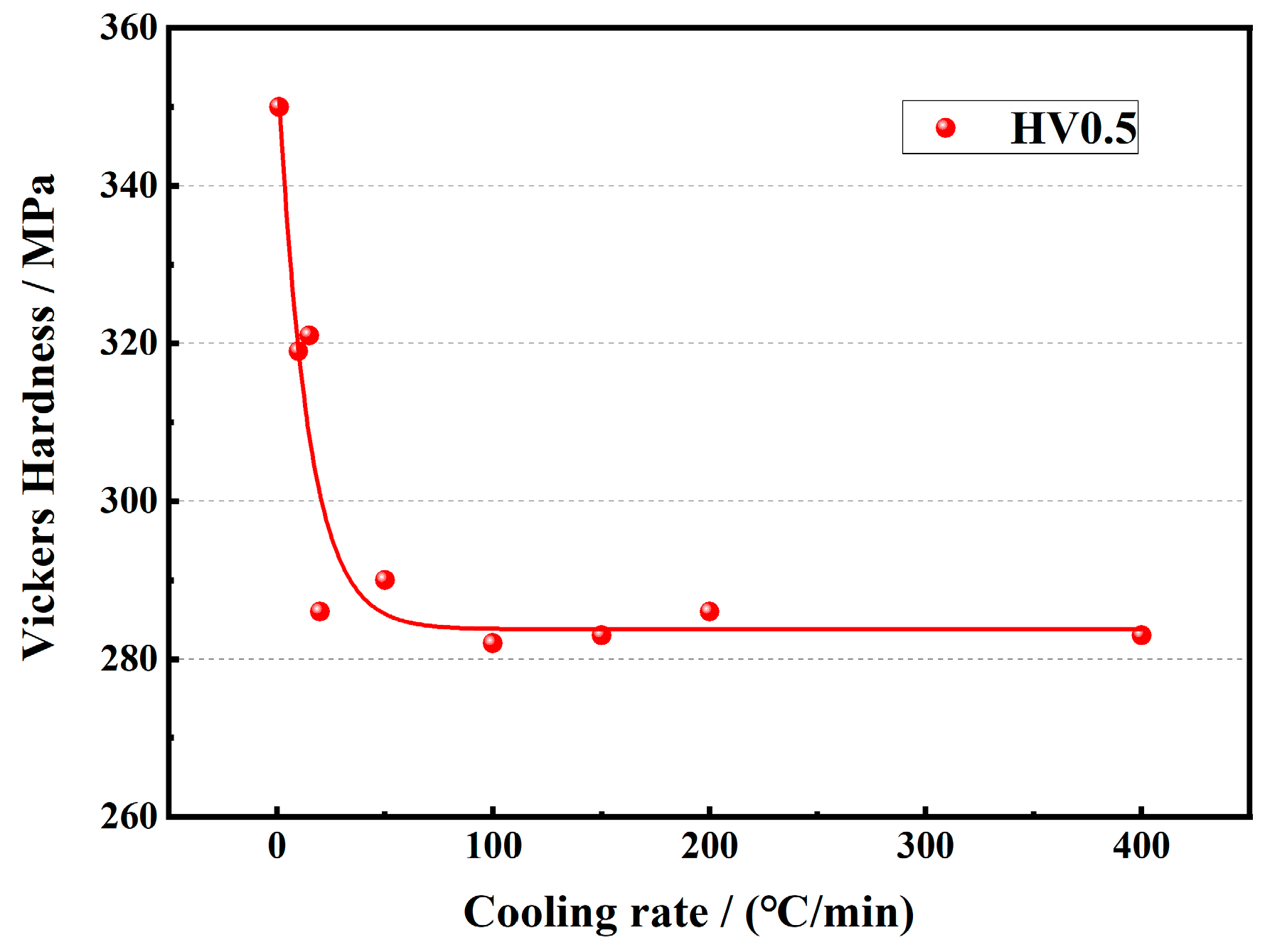

3.4. Microhardness

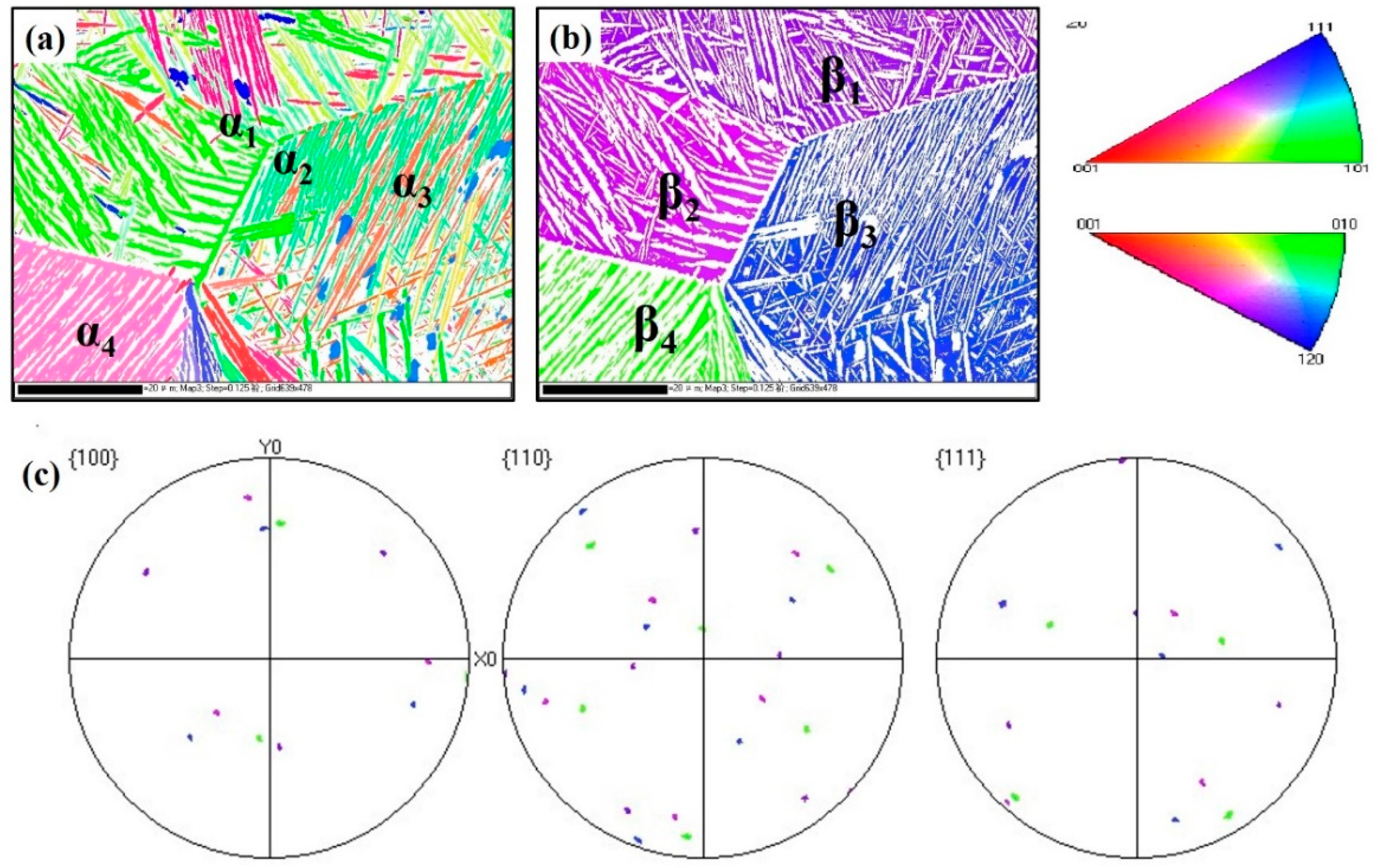

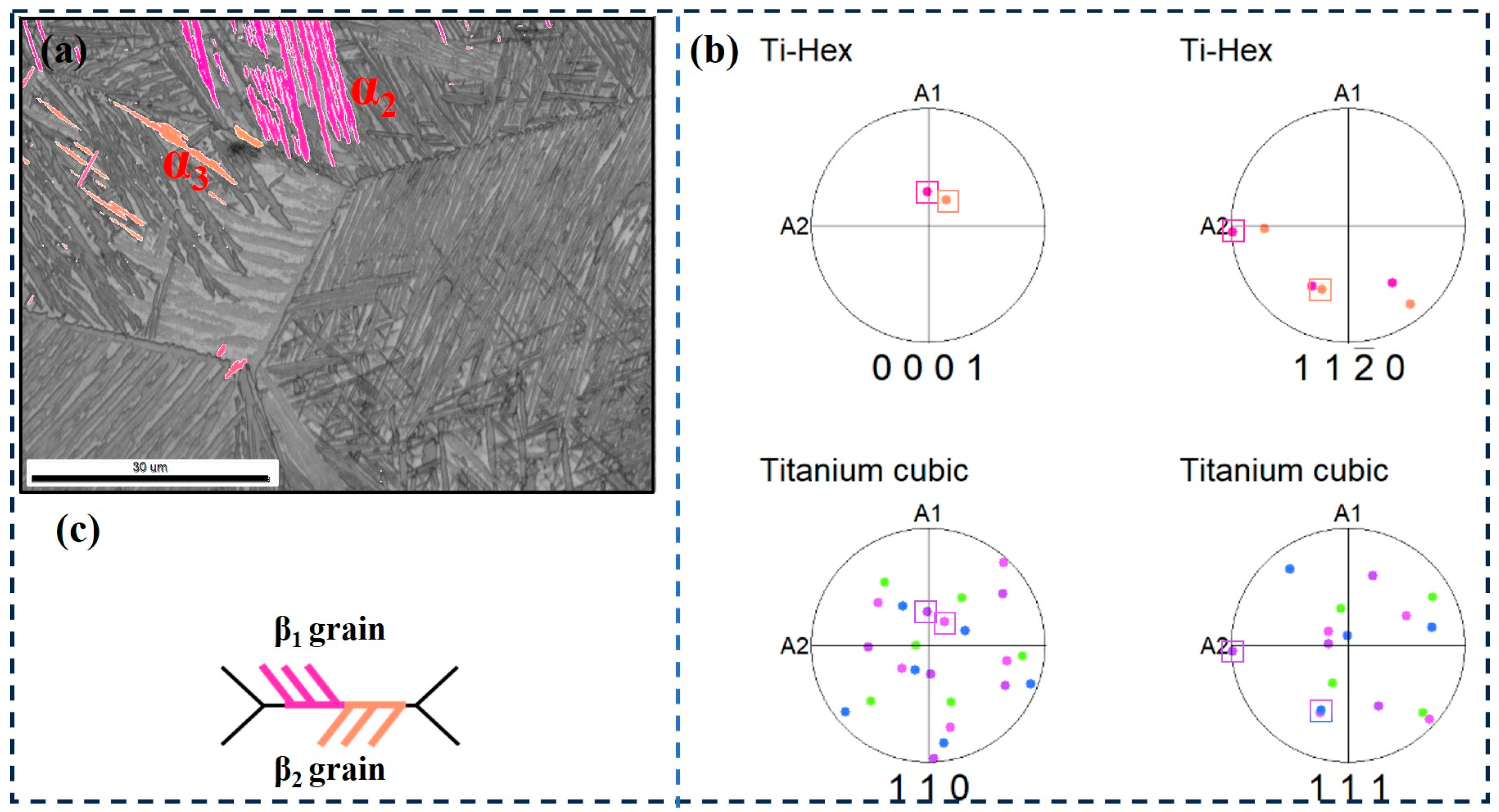

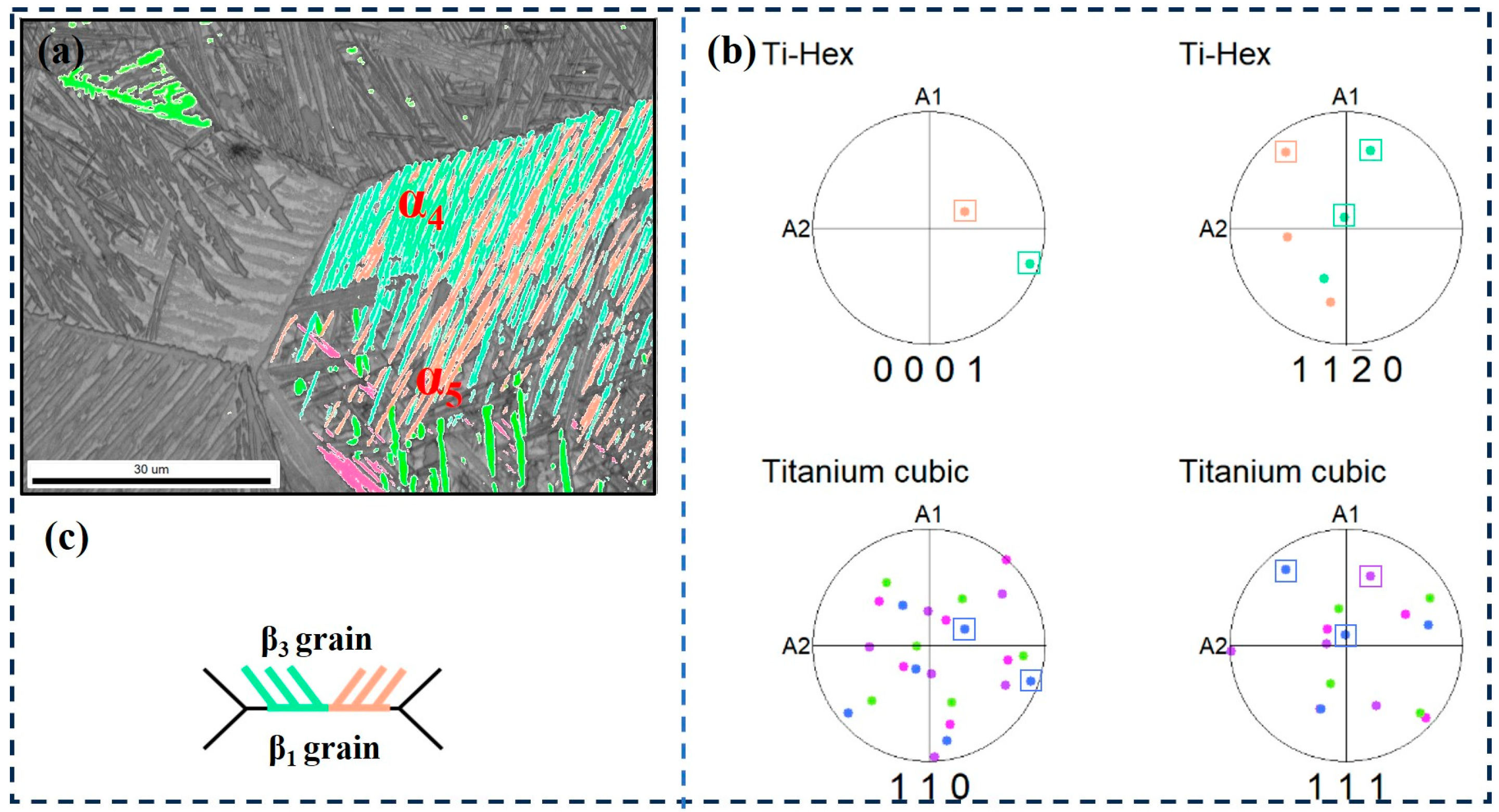

3.5. Selection of α Variants

4. Conclusions

- (1)

- The continuous cooling transformation (CCT) diagram reveals when the cooling rate is less than or equal to 400 °C/min, only α phase precipitation occurs, without β→ω phase transition or β→α″ non-equilibrium phase transition.

- (2)

- Not uniform of αWM precipitated phase, a small amount of fine lamellar αWGB precipitated phase formed under the low, intermediate, and high cooling rates, respectively. This is caused by the competitive growth of αGB, αWGB, and αWM.

- (3)

- As the cooling rate increases, the formation of α phase precipitations is inhibited and the strengthening effect of α phase cannot be obtained, resulting in the microhardness decreasing rapidly. The precipitation of the coarse α phase during slow cooling results in a significant increase in microhardness.

- (4)

- The selection of α variants near the original β grain boundary is mainly divided into three categories. The first type is that the α-clusters on both sides of the grain boundary maintain the BOR with either side of the adjacent β grains but grow in different directions. The second type is that the α-clusters on both sides of the grain boundary maintain BOR with one side of the adjacent β grains and grow in different directions. The third type is that the α clusters that precipitated only on one side of the grain boundary maintain the BOR with only one side of the adjacent β grains. It may have the same growth direction, but different crystallographic directions, and these two directions correspond to two variants of the given {0001}α//{110}β.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kolli, R.P.; Devaraj, A. A Review of Metastable Beta Titanium Alloys. Metals 2018, 8, 506. [Google Scholar] [CrossRef]

- Ren, L.; Xiao, W.; Kent, D.; Wan, M.; Ma, C.; Zhou, L. Simultaneously enhanced strength and ductility in a metastable β-Ti alloy by stress-induced hierarchical twin structure. Scr. Mater. 2020, 184, 6–11. [Google Scholar] [CrossRef]

- Pesode, P.; Barve, S. A review—Metastable β titanium alloy for biomedical applications. J. Eng. Appl. Sci. 2023, 70, 25. [Google Scholar] [CrossRef]

- Gao, J.; Knowles, A.J.; Guan, D.; Rainforth, W.M. ω phase strengthened 1.2GPa metastable β titanium alloy with high ductility. Scr. Mater. 2019, 162, 77–81. [Google Scholar] [CrossRef]

- Qiu, C.; Liu, Q.; Ding, R. Significant enhancement in yield strength for a metastable beta titanium alloy by selective laser melting. Mater. Sci. Eng. A 2021, 816, 141291. [Google Scholar] [CrossRef]

- Ferrero, J. Candidate materials for high-strength fastener applications in both the aerospace and automotive industries. J. Mater. Eng. Perform. 2005, 14, 691–696. [Google Scholar] [CrossRef]

- Cotton, J.D.; Briggs, R.D.; Boyer, R.R.; Tamirisakandala, S.; Russo, P.; Shchetnikov, N.; Fanning, J.C. State of the Art in beta titanium alloys for Airframe applications. J. Occup. Med. 2015, 67, 1281–1303. [Google Scholar] [CrossRef]

- Ghosh, A.; Sivaprasad, S.; Bhattacharjee, A.; Kar, S.K. Microstructure-fracture toughness correlation in an aircraft structural component alloy Ti-5Al-5V-5Mo-3Cr. Mater. Sci. Eng. A 2013, 568, 61–67. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, X.; Zhu, Z.; Li, C.; Zhou, K. Characterization of a new type grain boundary phase in near-β titanium alloys. Scr. Mater. 2020, 177, 118–122. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, X.; Zhu, Z. Characterization of high-temperature deformation behavior and processing map of TB17 titanium alloy. J. Alloys Compd. 2017, 692, 149–154. [Google Scholar] [CrossRef]

- Li, X.; Wang, X.N.; Liu, K.; Cao, G.H.; Li, M.B.; Zhu, Z.S.; Wu, S.J. Hierarchical structure and deformation behavior of a novel multicomponent βtitanium alloy with ultrahigh strength. J. Mater. Sci. Technol. 2022, 107, 227–242. [Google Scholar] [CrossRef]

- Mantri, S.A.; Choudhuri, D.; Alam, T.; Viswanathan, G.B.; Sosa, J.M.; Fraser, H.L.; Banerjee, R. Tuning the scale of a precipitates in b-titanium alloys for achieving high strength. Scr. Mater. 2018, 154, 139–144. [Google Scholar] [CrossRef]

- Srinivasu, G.; Natraj, Y.; Bhattacharjee, A.; Nandy, T.K.; Rao, G.N. Tensile and fracture toughness of high strength β titanium alloy, Ti-10V-2Fe-3Al, as a function of rolling and solution treatment temperatures. Mater. Des. 2013, 47, 323–330. [Google Scholar] [CrossRef]

- Shekhar, S.; Sarkar, R.; Kar, S.K.; Bhattacharjee, A. Effect of solution treatment and aging on microstructure and tensile properties of high strength β titanium alloy Ti-5Al-5V-5Mo-3Cr. Mater. Des. 2015, 66, 596–610. [Google Scholar] [CrossRef]

- Nag, S.; Banerjee, R.; Srinivasan, R.; Hwang, J.Y.; Harper, M.; Fraser, H.L. ω-Assisted nucleation and growth of a precipitates in the Ti-5Al-5Mo-5V-3Cr-0.5 Fe β titanium alloy. Acta Mater. 2009, 57, 2136–2147. [Google Scholar] [CrossRef]

- Afonso, C.R.M.; Aleixo, G.T.; Ramirez, A.J.; Caram, R. Influence of cooling rate on microstructure of Ti-Nb alloy for orthopedic implants. Mater. Sci. Eng. C 2007, 27, 908–913. [Google Scholar] [CrossRef]

- Ahmed, M.; Savvakin, D.G.; Ivasishin, O.M.; Pereloma, E.V. The effect of cooling rates on the microstructure and mechanical properties of thermo-mechanically processed Ti-Al-Mo-V-Cr-Fe alloys. Mater. Sci. Eng. A 2013, 576, 167–177. [Google Scholar] [CrossRef]

- Mantri, S.A.; Choudhuri, D.; Alam, T.; Ageh, V.; Sun, F.; Prima, F.; Banerjee, R. Change in the deformation mode resulting from beta-omega compositional partitioning in a Ti-Mo alloy: Room versus elevated temperature. Scr. Mater. 2017, 130, 69–73. [Google Scholar] [CrossRef]

- Prima, F.; Vermaut, P.; Texier, G.; Ansel, D.; Gloriant, T. Evidence of α-nanophase heterogeneous nucleation from ϖ particles in a β-metastable Ti-based alloy by high-resolution electron microcopy. Scr. Mater. 2006, 54, 645–648. [Google Scholar] [CrossRef]

- Ohmori, Y.; Ogo, T.; Nakai, K.; Kobayashi, S. Effect of ω-phase precipitation on β→α, α″ transformation in a metastable β titanium alloy. Mater. Sci. Eng. A 2001, 312, 182–188. [Google Scholar] [CrossRef]

- Angelier, C.; Bein, S.; Béchet, J. Building a continuous cooling transformation diagram of β-CEZ alloy by metallography and electrical resistivity measurements. Metall. Mater. Trans. 1997, 28, 2467–2475. [Google Scholar] [CrossRef]

- Xu, J.; Zeng, W.; Zhu, Z.; Li, M.; Du, J.; He, S.; Wang, X. Precipitation and evolution behaviors of grain boundary α and α side plates for ultra-high strength titanium alloy during continuous cooling. Mater. Des. 2023, 225, 111562. [Google Scholar] [CrossRef]

- Seward, G.G.E.; Celotto, S.; Prior, D.J.; Wheeler, J.; Pond, R.C. In situ SEM-EBSD observations of the hcp to bcc phase transformation in commercially pure titanium. Acta Mater. 2004, 52, 821–832. [Google Scholar] [CrossRef]

- Charpentier, M.; Hazotte, A.; Daloz, D. Lamellar transformation in near-γ TiAl alloys-Quantitative analysis of kinetics and microstructure. Mater. Sci. Eng. A 2008, 491, 321–330. [Google Scholar] [CrossRef]

- Yu, H.; Li, W.; Li, S.; Yang, Y.; Zou, H.; Liu, L. Phase Transformation Mechanism and Microstructure Evolution of TC4 Alloy during Continuous Cooling. Phys. Met. Metallogr. 2020, 121, 1375–1381. [Google Scholar] [CrossRef]

- Wang, Y.H.; Kou, H.; Chang, H.; Zhu, Z.S.; Zhang, F.S.; Li, J.; Zhou, L. Influence of solution temperature on phase transformation of TC21 alloy. Mater. Sci. Eng. A 2009, 508, 76–82. [Google Scholar] [CrossRef]

- Barriobero-Vila, P.; Requena, G.; Warchomicka, F.; Stark, A.; Schell, N.; Buslaps, T. Phase transformation kinetics during continuous heating of a b-quenched Ti-10V-2Fe-3Al alloy. J. Mater. Sci. 2015, 50, 1412–1426. [Google Scholar] [CrossRef]

- Zheng, Z.Y.; Chai, L.J.; Li, Z.H.; Huang, W.J.; Tian, L.; Wang, Y.F.; Liu, L.L. Effects of β-cooling rates on microstructural characteristics and hardness of Ti–5Al–5Mo–5V–3Cr–1Fe metastable β Ti alloy. Mater. Chem. Phys. 2022, 276, 125318. [Google Scholar] [CrossRef]

| Element | Al | Mo | V | Nb | Cr | Zr | Sn | Fe | O | Ti |

|---|---|---|---|---|---|---|---|---|---|---|

| wt.% | 3.91 | 6.84 | 1.19 | 2.05 | 2.71 | 1.02 | 1.02 | 0.04 | 0.089 | Bal. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shang, G.; Gan, X.; Wang, X.; Ge, J.; Li, C.; Zhu, Z.; Zhang, X.; Zhou, K. Effect of Cooling Rate on α Variant Selection and Microstructure Evolution in TB17 Titanium Alloy. Materials 2024, 17, 5010. https://doi.org/10.3390/ma17205010

Shang G, Gan X, Wang X, Ge J, Li C, Zhu Z, Zhang X, Zhou K. Effect of Cooling Rate on α Variant Selection and Microstructure Evolution in TB17 Titanium Alloy. Materials. 2024; 17(20):5010. https://doi.org/10.3390/ma17205010

Chicago/Turabian StyleShang, Guoqiang, Xueping Gan, Xinnan Wang, Jinyang Ge, Chao Li, Zhishou Zhu, Xiaoyong Zhang, and Kechao Zhou. 2024. "Effect of Cooling Rate on α Variant Selection and Microstructure Evolution in TB17 Titanium Alloy" Materials 17, no. 20: 5010. https://doi.org/10.3390/ma17205010

APA StyleShang, G., Gan, X., Wang, X., Ge, J., Li, C., Zhu, Z., Zhang, X., & Zhou, K. (2024). Effect of Cooling Rate on α Variant Selection and Microstructure Evolution in TB17 Titanium Alloy. Materials, 17(20), 5010. https://doi.org/10.3390/ma17205010