Experimental Study on the Strength and Durability of Manufactured Sand HPC in the Dalian Bay Undersea Immersed Tube Tunnel and Its Engineering Application

Abstract

1. Introduction

2. Raw Material and Mix Ratio

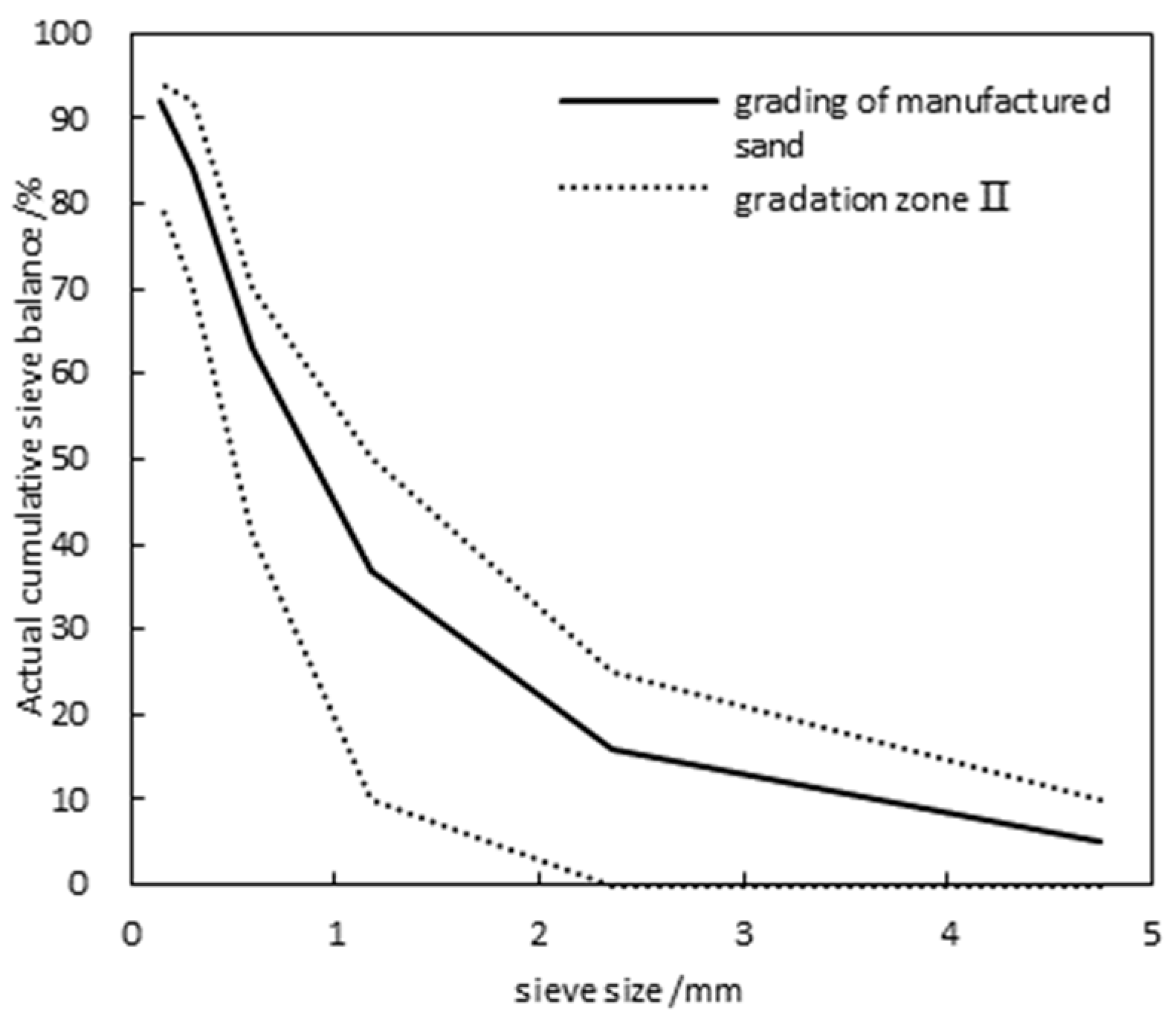

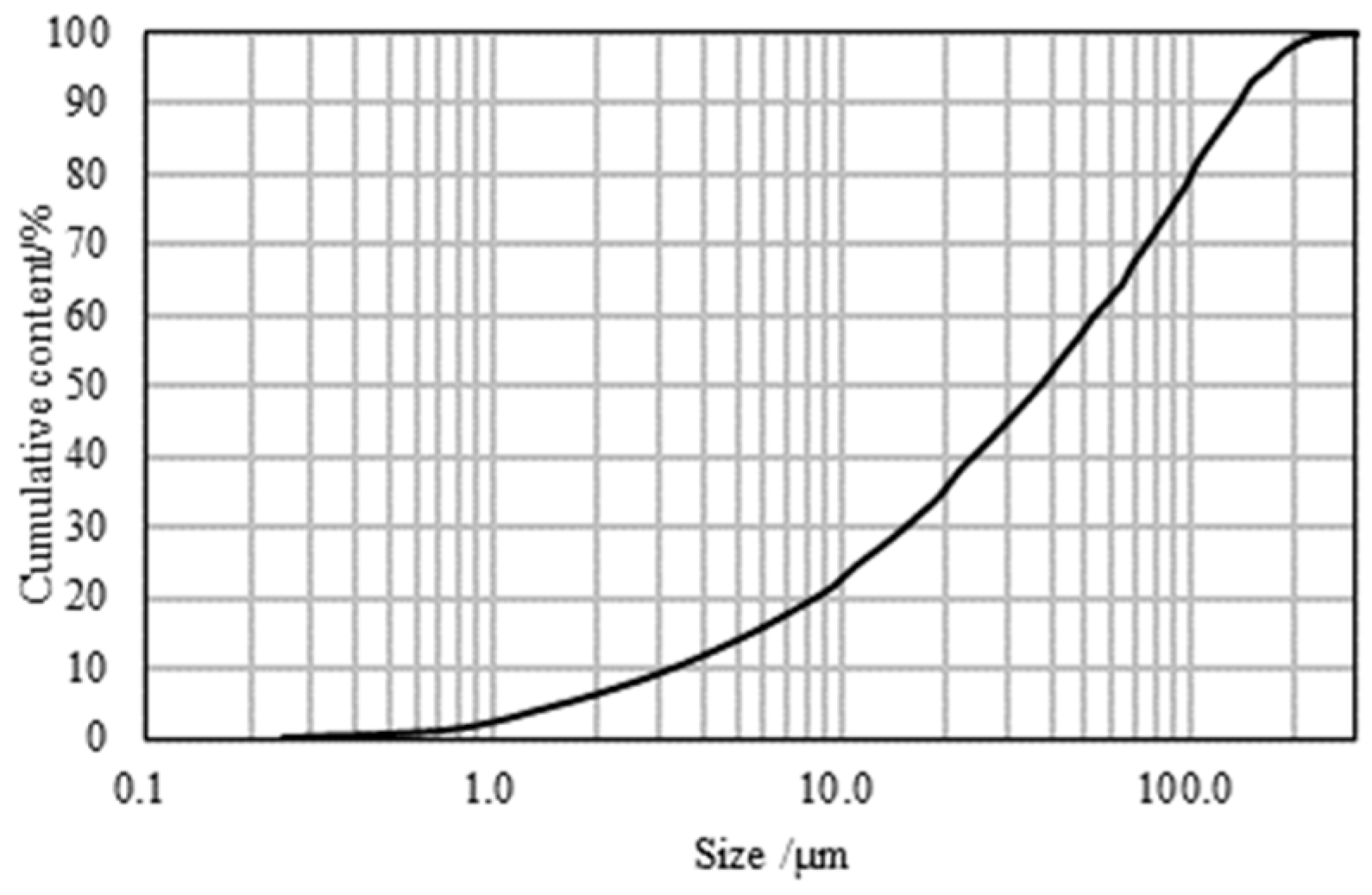

2.1. Raw Materials

2.2. Mix Ratio

3. Test Method

3.1. Preparation and Curing of Concrete Specimens

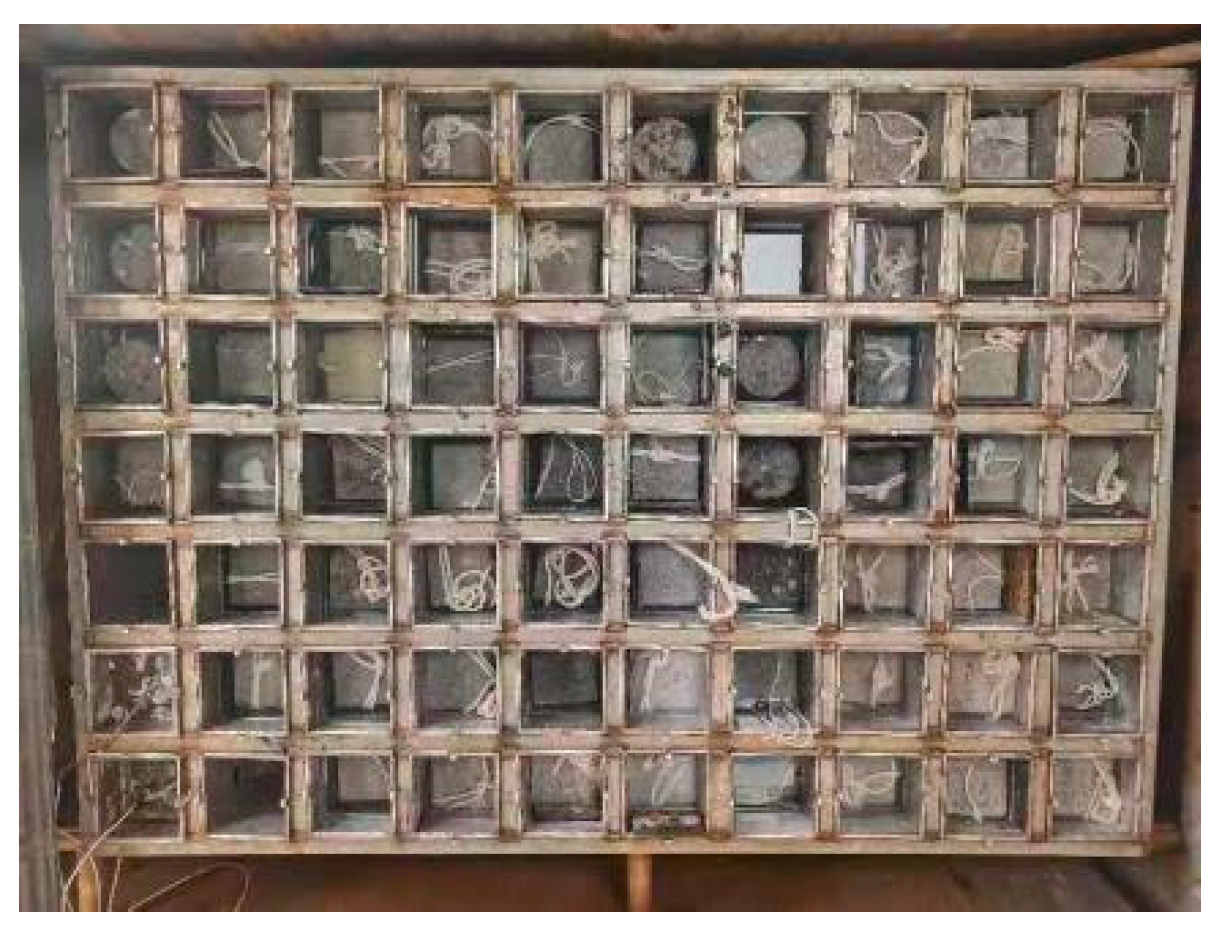

3.2. Early Crack Resistance Test

3.3. Strength Test

3.4. Test of Freezing Resistance and Salt Freezing Resistance

3.5. Impermeability Test

3.6. Electrical Flux Permeability and RCM Method for Unsteady-State Electromigration Chloride Diffusion Test

4. Results and Discussion

4.1. Workability of MSHPC

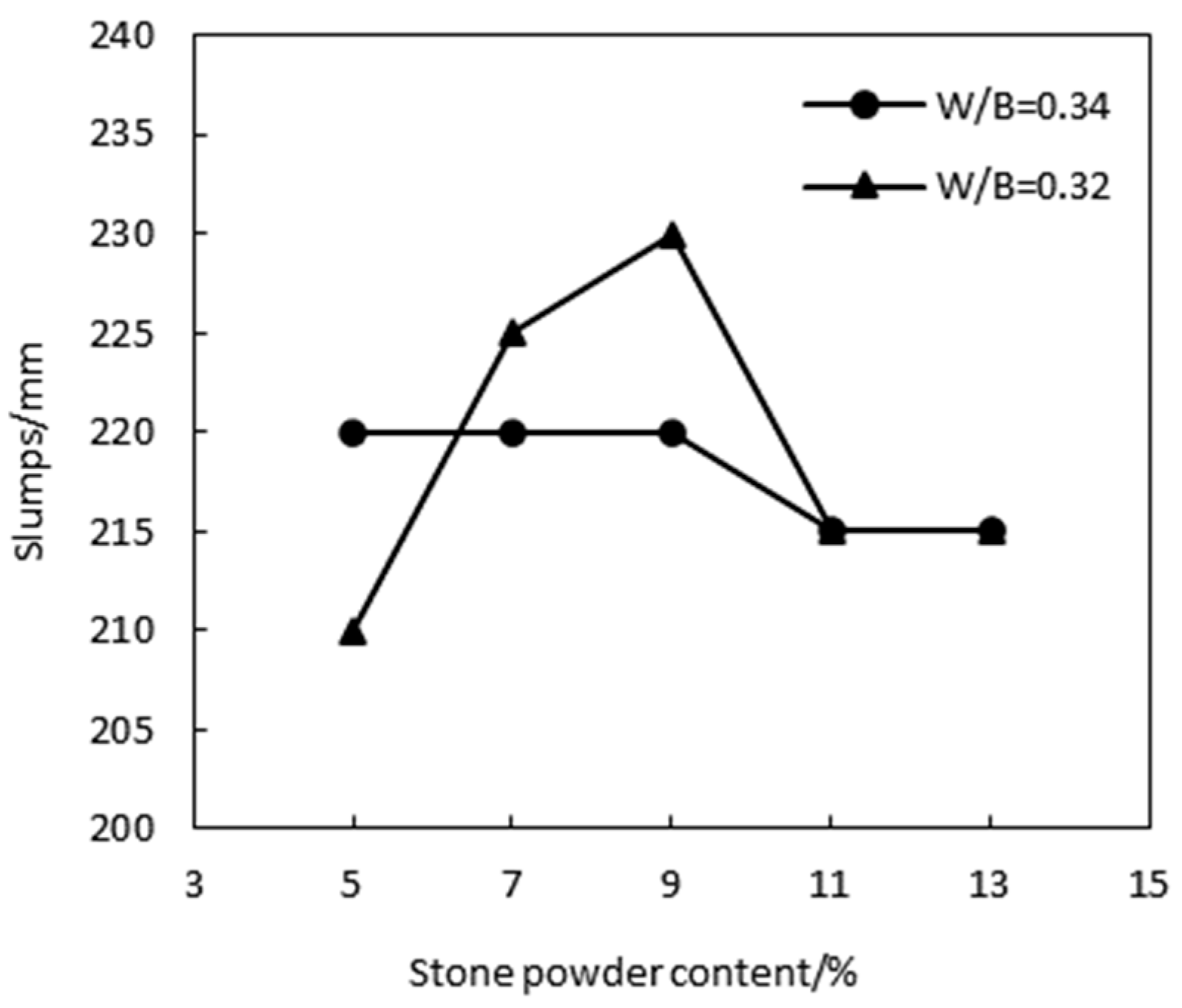

4.1.1. Effect of Stone Powder Content on the Slump of MSHPC

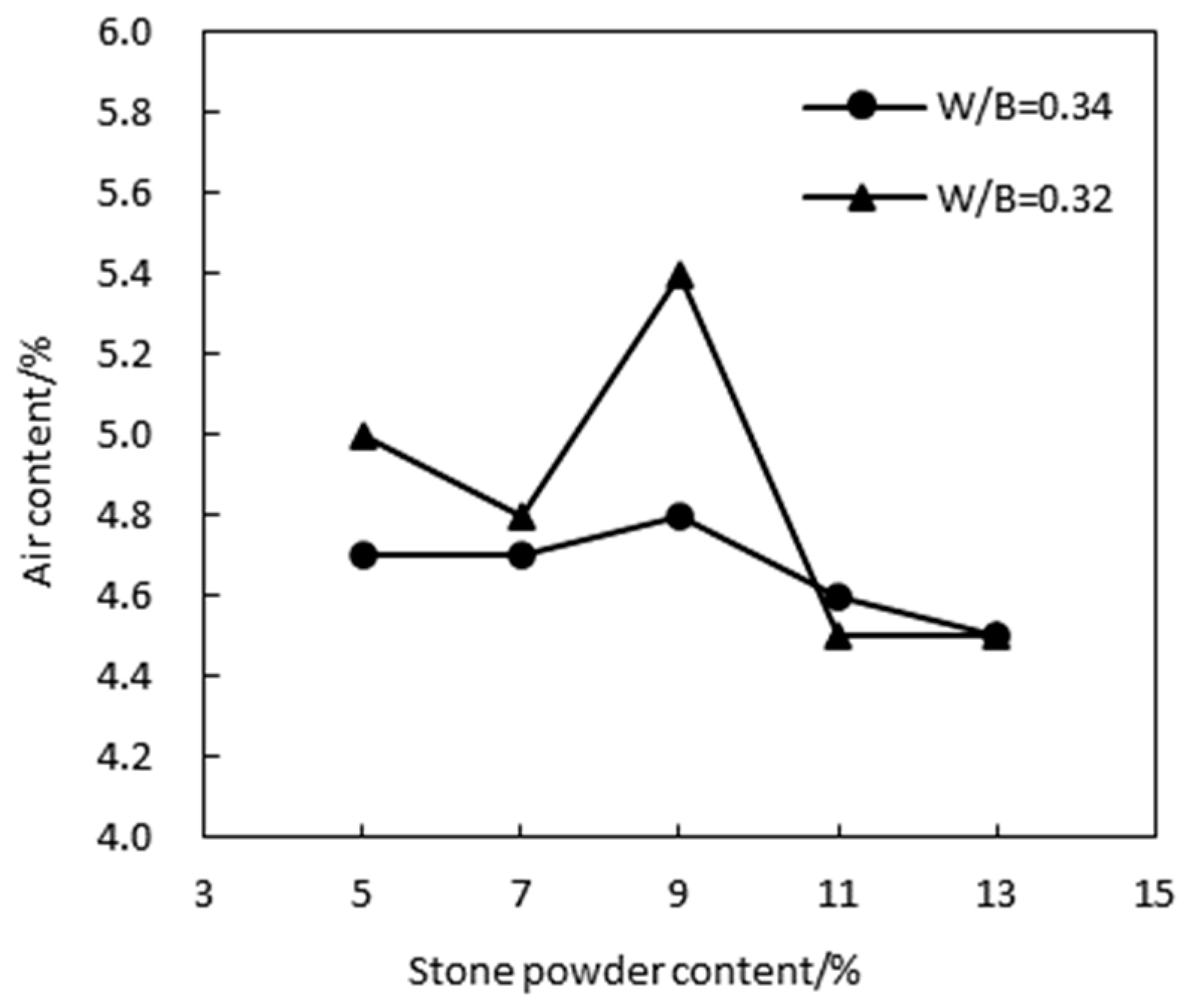

4.1.2. Effect of Stone Powder Content on Air Content of HPC with Manufactured Sand

4.2. Early Cracking Resistance of MSHPC

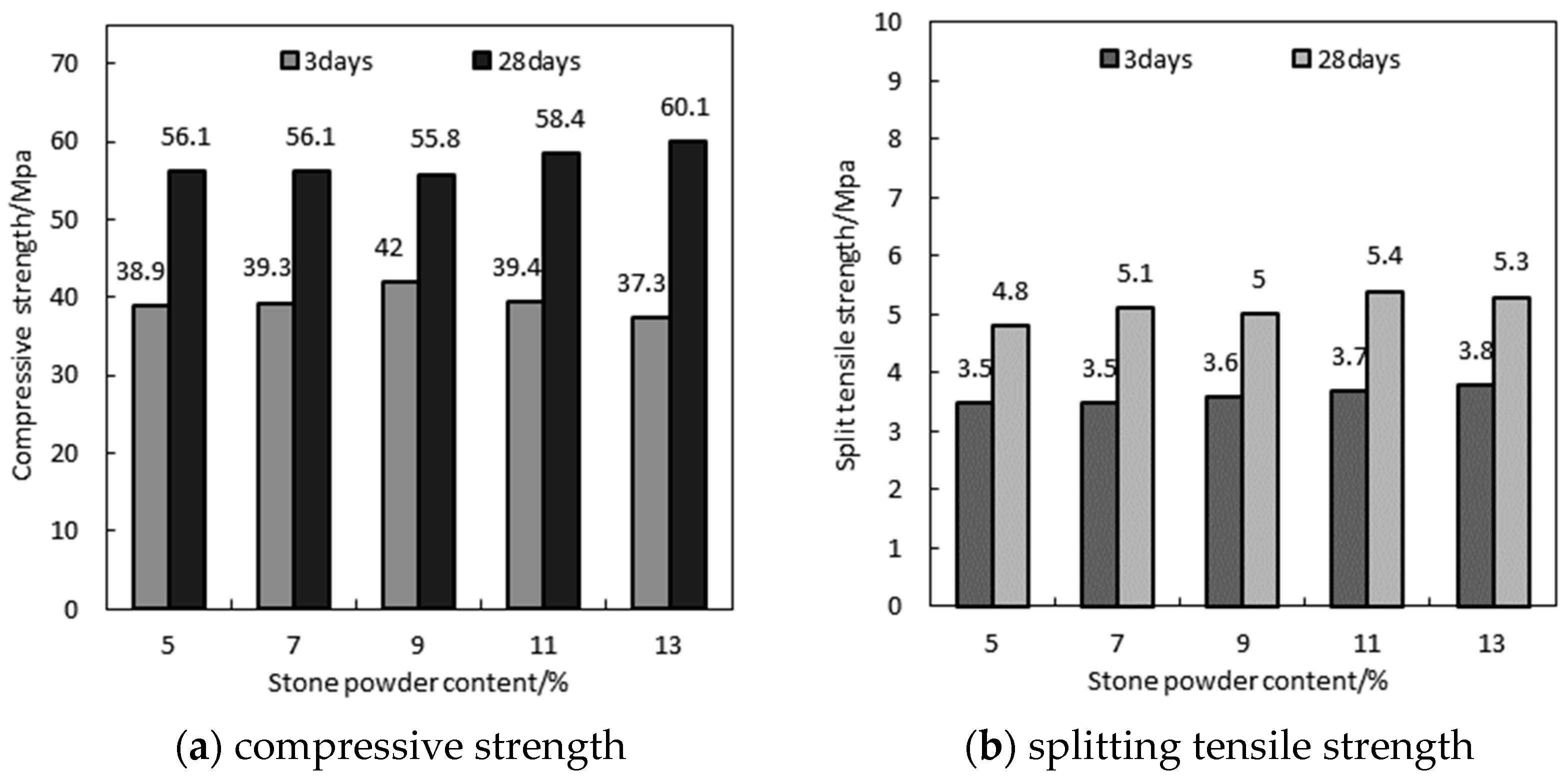

4.3. Compressive Strength and Splitting Tensile Strength of MSHPC

4.3.1. Effect of Stone Powder Content on MSHPC Strength

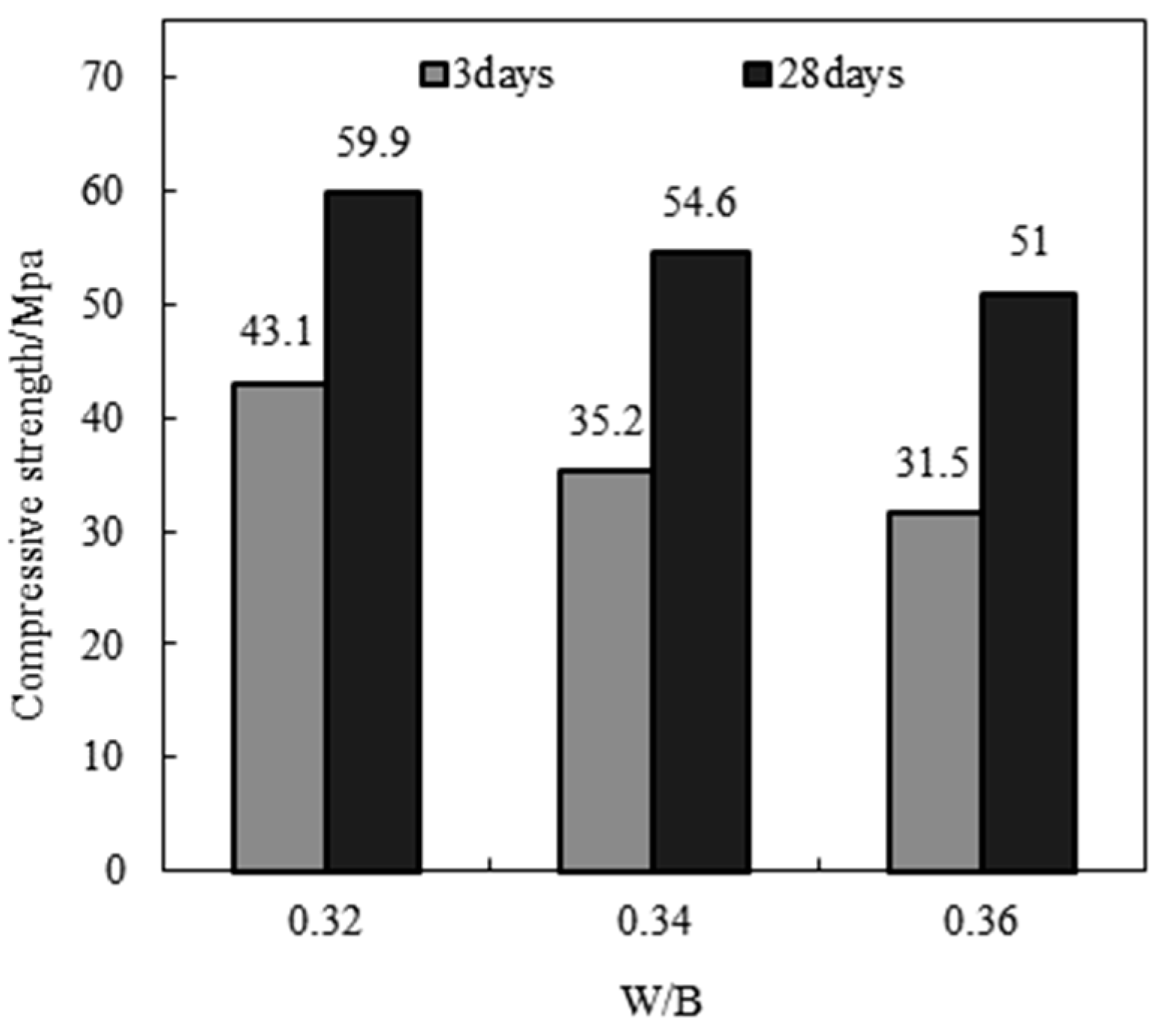

4.3.2. Effect of Water–Binder Ratio on Strength of MSHPC

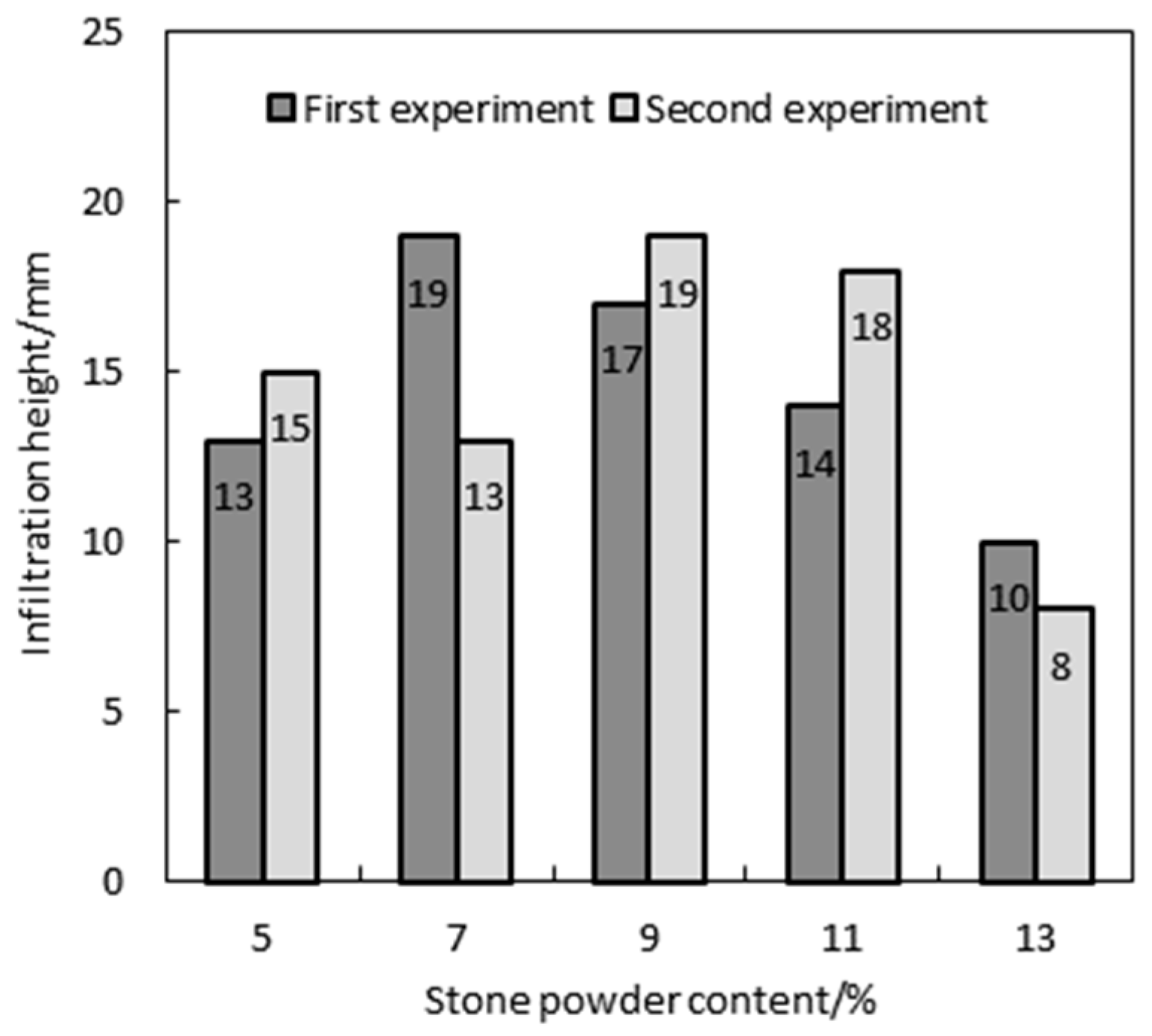

4.4. Permeability of HPC with Manufactured Sand

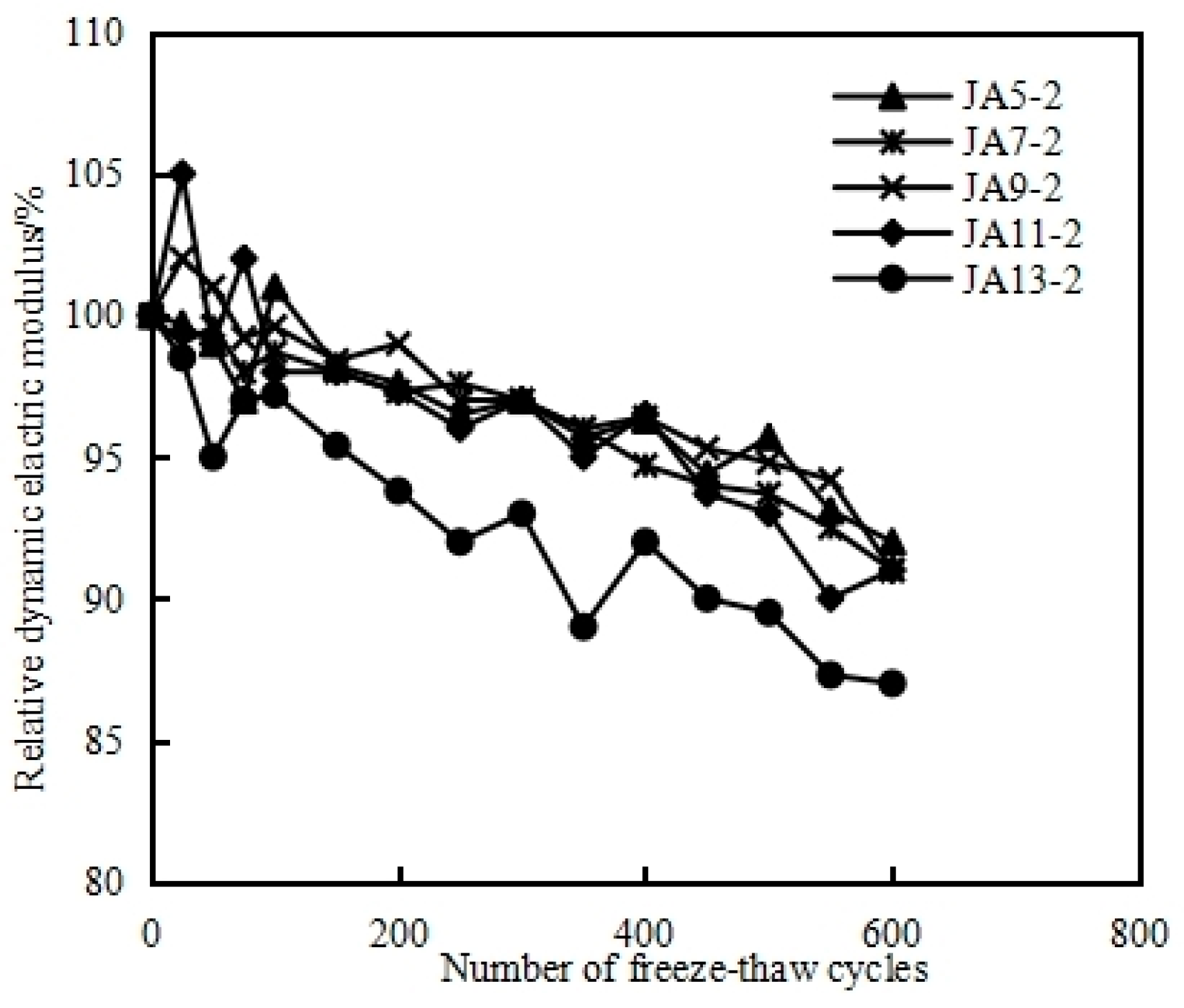

4.5. Frost Resistance and Salt Freezing Resistance of MSHPC

Frost Resistance of MSHPC in Seawater

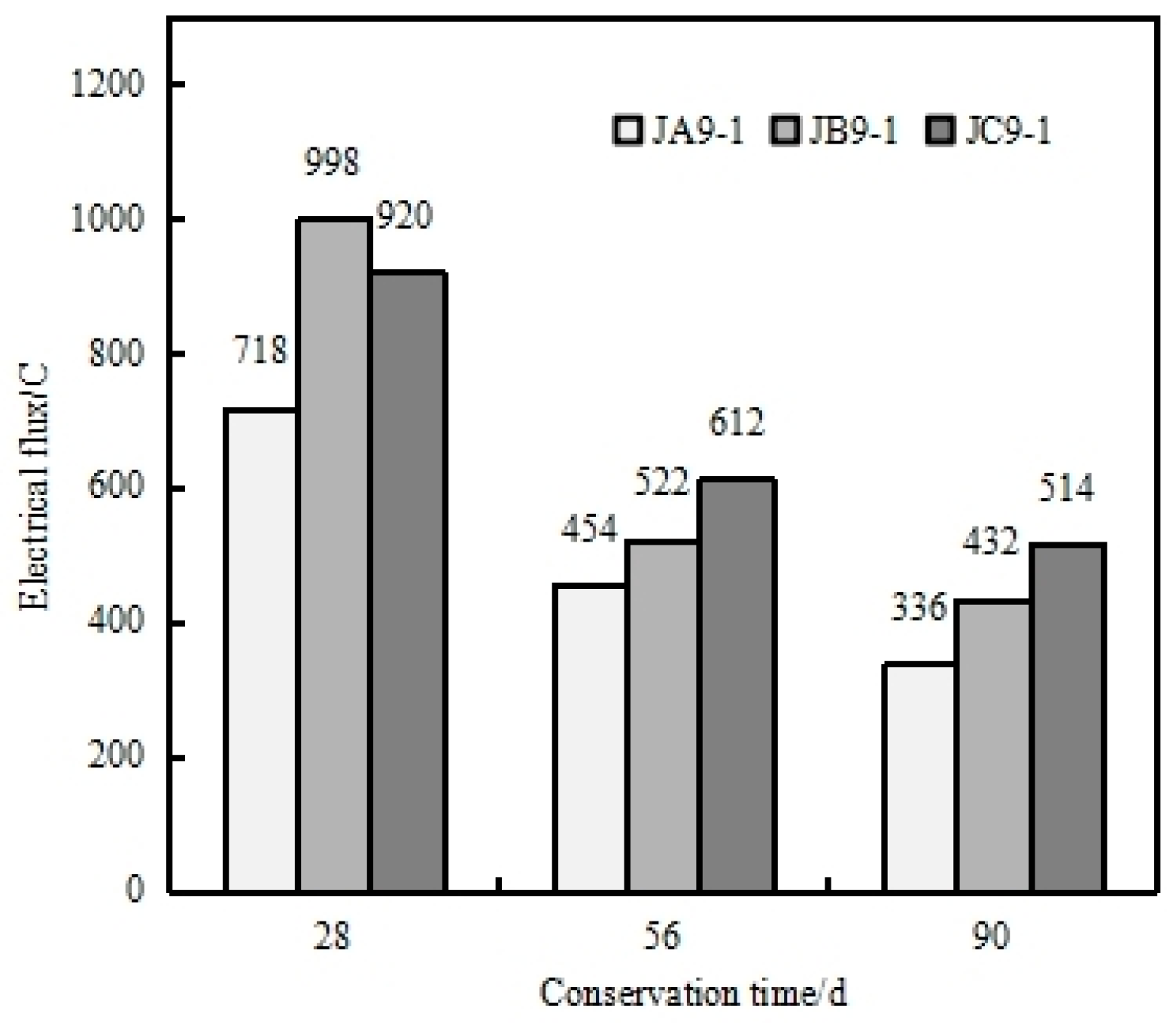

4.6. Electrical Flux of MSHPC

4.7. Chloride Diffusion Resistance of MSHPC

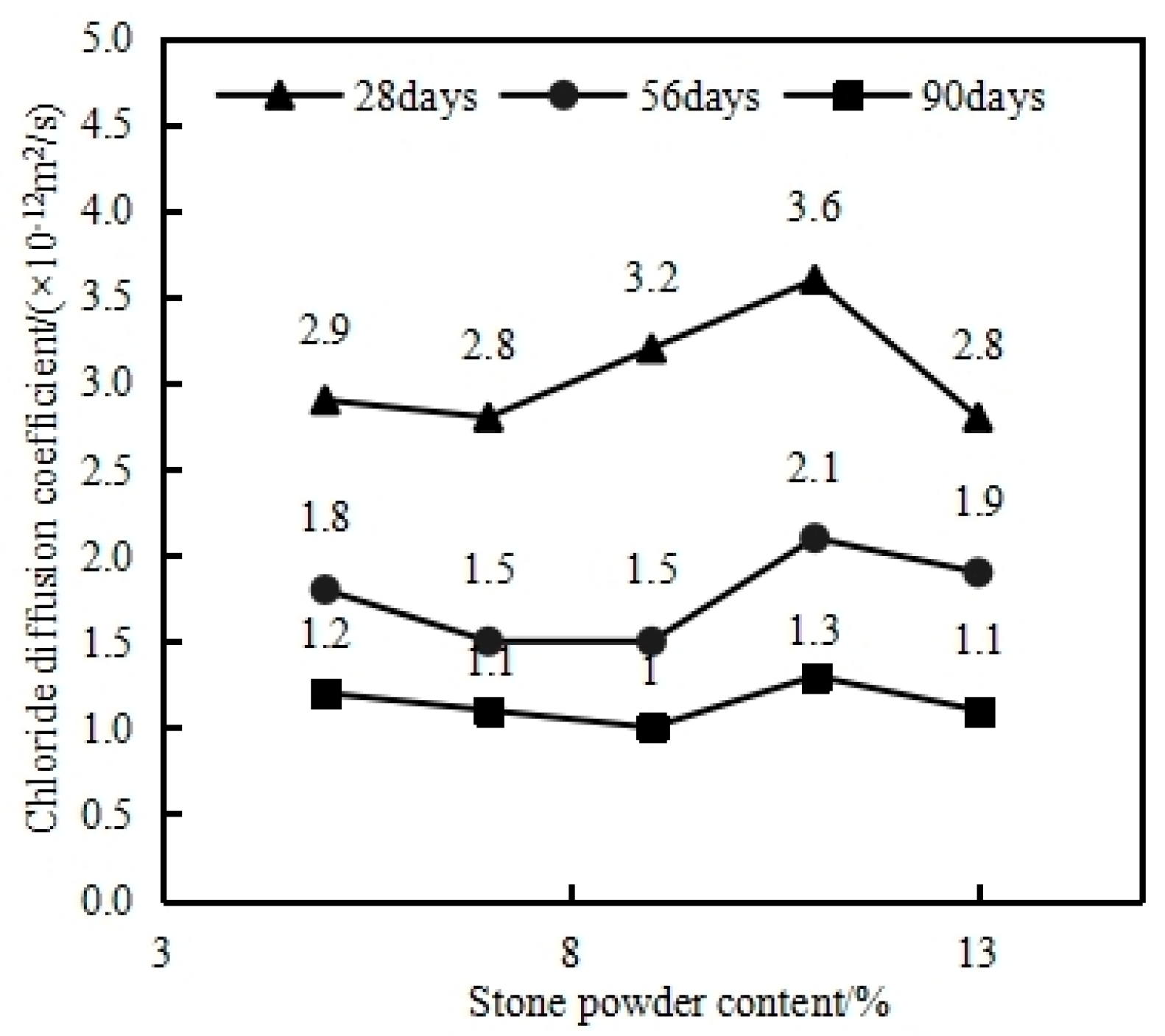

4.7.1. Effect of Stone Powder Content on Chloride Diffusion Coefficient of MSHPC

4.7.2. Effect of Water–Binder Ratio on Chloride Diffusion Coefficient of MSHPC

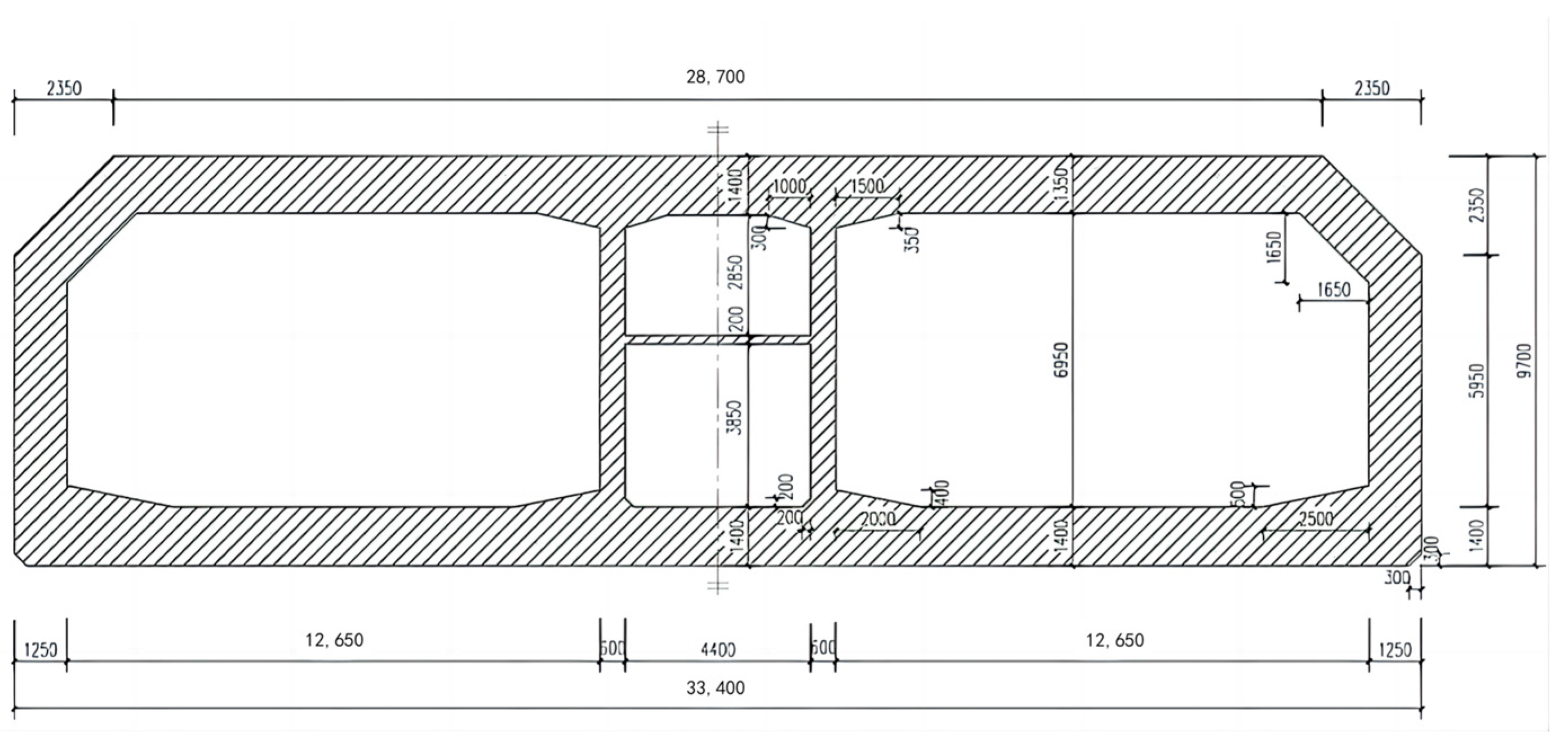

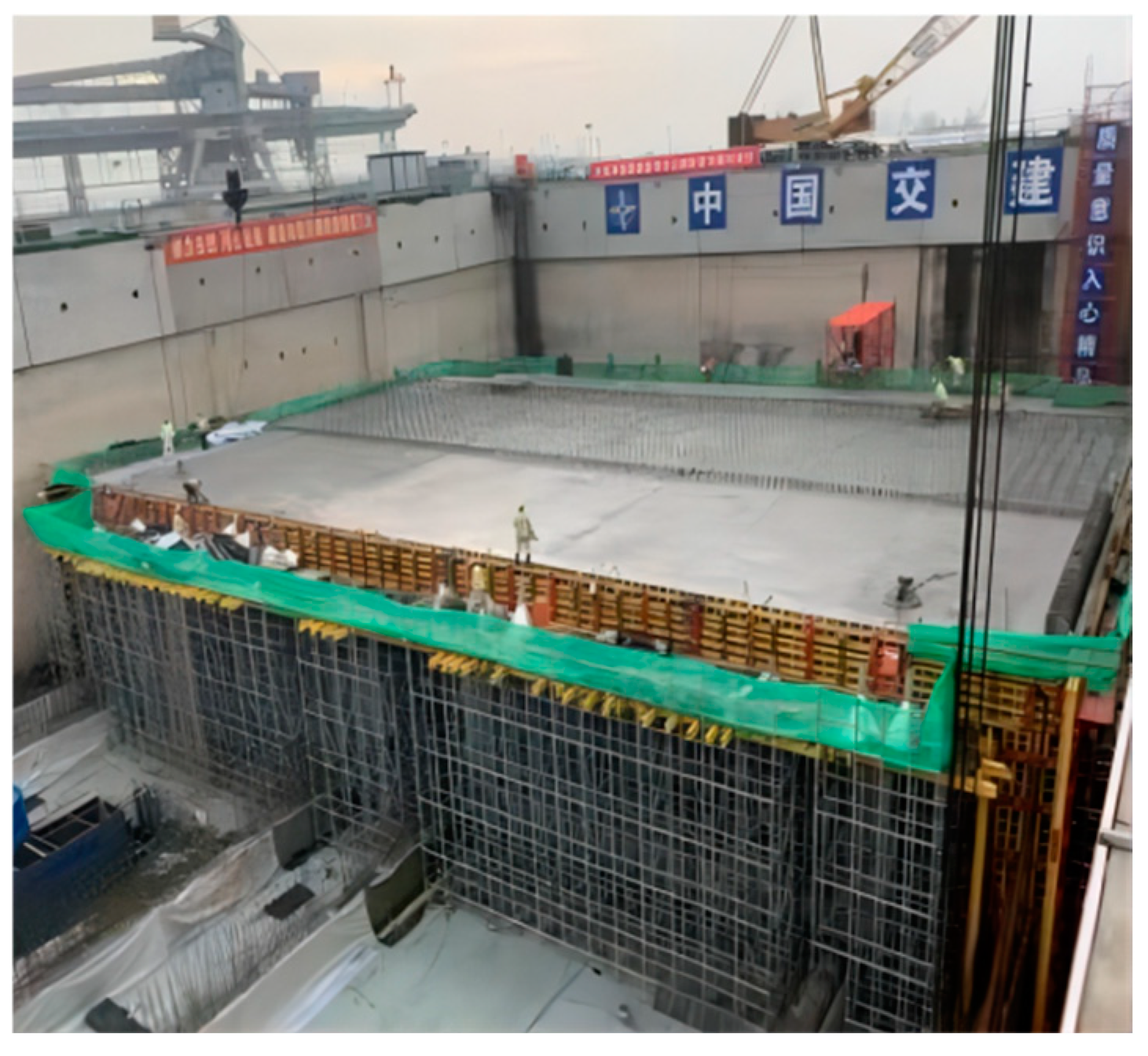

4.8. Application of MSHPC in the Dalian Bay Submarine Immersed Tube Tunnel

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- ASTM C33-2008; Standard Specification for Concrete Aggregates. ASTM: West Conshohocken, PA, USA, 2008.

- JISA 5005-2009; Crushed Stone and Manufactured Sand for Concrete. Japanese Standards Association: Tokyo, Japan, 2009.

- AS 2758.1-2014; Aggregates and Rock for Engineering Purposes-Concrete Aggregates. Standard Australia: Sydney, Australia, 2014.

- GB/T 14684-2011; Construction Sand. Standards Press of China: Beijing, China, 2011. (In Chinese)

- Wang, Y.; He, H.; Wang, J.; Li, F.; Ding, Y.; Xu, L. Effect of aggregate micro fines in manufactured sand on bleeding, autogenous shrinkage and plastic shrinkage cracking of concrete. Mater. Struct. 2022, 55, 106. [Google Scholar] [CrossRef]

- Liu, D.; Zhang, W.; Tang, Y.; Jian, Y.; Lai, Y. Orthogonal Experimental Study on Concrete Properties of Machine-Made Tuff Sand. Materials 2022, 15, 3516. [Google Scholar] [CrossRef] [PubMed]

- He, H.; Wang, Y.; Wang, J. Compactness and hardened properties of manufactured sand mortar with aggregate micro fines. Constr. Build. Mater. 2020, 250, 118828. [Google Scholar] [CrossRef]

- Bonavetti, V.L.; Rahhal, V.F.; Irassar, E.F. Studies on the carboaluminate formation in limestonefiller-blended cements. Cem. Concr. Res. 2001, 31, 853–859. [Google Scholar] [CrossRef]

- Tang, Y.; Qiu, W.; Liu, D.; Zhang, W.; Zhang, R. Experimental Study on the Properties of Mortar and Concrete Made with Tunnel Slag manufactured sand. Materials 2022, 15, 4817. [Google Scholar] [CrossRef] [PubMed]

- Chen, F.; Liu, J.; Jiao, H.; Yang, L.; Niu, H.; Shen, H.; Xu, Y. Effect of stone powder content on concrete mixing properties and mechanical properties of mechanism sand[J/OL]. Concrete 2024, 1–8. Available online: http://kns.cnki.net/kcms/detail/21.1259.tu.20240308.1915.002.html (accessed on 7 October 2024). (In Chinese).

- Liu, X.; Tao, Z. Characteristics of mechanism sand and its effect on concrete properties. Fly Ash 2012, 24, 36–38+42. (In Chinese) [Google Scholar]

- Jiang, Z.; Shi, L.; Sun, Z. Research on the formulation of self-compacting concrete with mechanism sand. J. Build. Mater. 2007, 2, 154–160. (In Chinese) [Google Scholar]

- Meng, F.; Chen, F. Application of mechanism sand concrete in the project of South-to-North Water Diversion East Line through Yellow River. China Rural Water Conserv. Hydropower 2009, 10, 96–98. (In Chinese) [Google Scholar]

- Zhang, J. Application research on mechanism sand of Sichuan-Tibet railway hole slag. Cement 2023, 3, 28–31. (In Chinese) [Google Scholar]

- Zhang, Q.; Yu, H.; Huang, S. Quality control of mechanism sand and high pumping concrete in Pingtang Special Bridge. Highway 2019, 64, 114–116. (In Chinese) [Google Scholar]

- Wang, D.; Shi, C.; Farzadnia, N.; Shi, Z.; Jia, H.; Ou, Z. A review on use of limestone powder in cement-based materials: Mechanism, hydration and microstructures. Constr. Build. Mater. 2018, 181, 659–672. [Google Scholar] [CrossRef]

- Liao, Y.; Lv, Y.; Huang, G.; Ren, S.; Wang, X.Y.; Guo, R.; Tian, Y.; Deng, S.; Lin, R.S. Strength and microstructure analysis of subgrade materials containing red sandstone-limestone-cement composites and red sandstone gravel. Constr. Build. Mater. 2024, 416, 135190. [Google Scholar] [CrossRef]

- Yu, H.; Feng, T.; Xu, M.; Xu, Y.; Xu, Z. Research Report on Durability Assessment and Preliminary Design of 120-Year Life of Immersed Tube Tunnel Structure in Dalian Bay; Nanjing University of Aeronautics and Astronautics, CCCC First Aviation Bureau Third Company: Nanjing, China, 2017. (In Chinese) [Google Scholar]

- Ma, H.; Song, S.; Yu, H.; Sun, Y.; Xu, Y. Research and analysis on long life of marine concrete structures in Bohai Bay. J. Build. Mater. 2023, 26, 897–905. (In Chinese) [Google Scholar]

- JC/T2234-2014; Ministry of Industry and Information Technology of the People’s Republic of China, Test Method for Early Cracking Resistance of Cement. China Building Material Industry Press: Beijing, China, 2011. (In Chinese)

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. GB/T 50081-2019; Standard for Test Methods for Physical and Mechanical Properties of Concrete. China Construction Industry Press: Beijing, China, 2019. (In Chinese)

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. GB/T 50082-2009; Standard for Long-term Performance and Durability Test Methods for Ordinary Concrete. China Construction Industry Press: Beijing, China, 2019. (In Chinese)

- Chrysanidis, T.A.; Panoskaltsis, V.P. Experimental investigation on cracking behavior of reinforced concrete tension ties. Case Stud. Constr. Mater. 2022, 16, e00810. [Google Scholar] [CrossRef]

- Xue, H.; Chen, M.; Tang, Z.; Fan, G.; Zhou, J. The influence mechanism of stone powder in mechanical sand on the physical and mechanical properties of concrete. Eng. Sci. Technol. 2023, 55, 151–160. (In Chinese) [Google Scholar]

- Yang, H.; Liang, D.; Deng, Z.; Qin, Y. Effect of Limestone Powder in Manufactured Sand on the Hydration Products and Microstructure of Recycled Aggregate Concrete. Constr. Build. Mater. 2018, 188, 1045–1049. [Google Scholar] [CrossRef]

- Liu, S.; Yan, P. Effect of Limestone Powder on Microstructure of Concrete. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2010, 25, 328–331. [Google Scholar] [CrossRef]

- Zhou, A.; Zhang, Y.; Qian, R.; Miao, T.; Xue, C. The influence of granite powder on the basic properties and gas permeability of mechanical sand concrete. J. Compos. Mater. 2024, 41, 3704–3715. (In Chinese) [Google Scholar]

- Liu, J.; Huang, Z.; Song, J.; Zeng, X.; Wang, M.; Zhou, H.; Wu, X. Effect of stone powder content on the durability performance of C50 self-compacting concrete in limestone mechanical sand. China Build. Mater. Technol. 2020, 29, 31–34. [Google Scholar]

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. GB/T 50476-2019; Durability Design Code for Concrete Structures. China Building Industry Press: Beijing, China, 2019. (In Chinese)

- Huang, W. Research on the Preparation and Performance of Mechanism Sand Immersed Pipe Concrete. Master’s Thesis, Chongqing University, Chongqing, China, 2019. (In Chinese). [Google Scholar]

- Yu, H.F. ChaDuraLife V1.0 Life Prediction Model and Computer Software for Concrete Structures in Chloride Salt Environment; Nanjing University of Aeronautics and Astronautics: Nanjing, China, 2015. (In Chinese) [Google Scholar]

| Cement | Compare Surface Area/(m2·kg−1) | Water Demand/% | Setting Time /min | Flexural Strength /MPa | Compressive Strength /MPa | |||

| Initial Set | Final Set | 3 d | 28 d | 3 d | 28 d | |||

| P·O | 347 | 27.9 | 180 | 245 | 5.9 | 8.6 | 30.9 | 53.1 |

| Cementing Material | SiO2 | Al2O3 | CaO | MgO | SO3 | Fe2O3 | Na2O | MnO | TiO2 | K2O | I.L |

| P·O | 31.44 | 5.22 | 49.82 | 2.10 | 2.50 | 4.39 | 0.30 | 0.20 | 0.04 | 0.20 | 3.50 |

| FA | 58.30 | 16.87 | 3.12 | 1.37 | 1.00 | 7.16 | 0.79 | 0.06 | 1.29 | 0.52 | 0.60 |

| SG | 42.66 | 7.86 | 34.26 | 1.86 | 0.82 | 2.71 | 0.47 | 3.71 | 0.02 | 0.12 | 1.22 |

| NO. | W/B | Stone Powder (%) | Amount of Raw Materials for Concrete Mix of Unit Volume/kg·m−3 | Slumps (mm) | Air Content (%) | |||||||

| Cement | Water | Manufactured Sand | Stone | Fly Ash | Slag | Water Reducer | Air Entraining Agent | |||||

| JA5-1 | 0.32 | 5 | 294 | 134.5 | 744 | 1151 | 63 (15%) | 63 (15%) | 11.34 | 1.71 | 210 | 5.0 |

| JA7-1 | 0.32 | 7 | 294 | 134.5 | 744 | 1151 | 63 (15%) | 63 (15%) | 11.34 | 1.71 | 225 | 4.8 |

| JA9-1 | 0.32 | 9 | 294 | 134.5 | 744 | 1151 | 63 (15%) | 63 (15%) | 12.18 | 1.84 | 230 | 5.4 |

| JA11-1 | 0.32 | 11 | 294 | 134.5 | 744 | 1151 | 63 (15%) | 63 (15%) | 12.18 | 1.84 | 215 | 4.5 |

| JA13-1 | 0.32 | 13 | 294 | 134.5 | 744 | 1151 | 63 (15%) | 63 (15%) | 12.18 | 1.84 | 215 | 4.5 |

| JA5-2 | 0.32 | 5 | 273 | 134.5 | 744 | 1151 | 63 (15%) | 84 (20%) | 11.34 | 1.71 | 220 | 4.7 |

| JA7-2 | 0.32 | 7 | 273 | 134.5 | 744 | 1151 | 63 (15%) | 84 (20%) | 11.34 | 1.71 | 220 | 4.7 |

| JA9-2 | 0.32 | 9 | 273 | 134.5 | 744 | 1151 | 63 (15%) | 84 (20%) | 12.18 | 1.84 | 220 | 4.8 |

| JA11-2 | 0.32 | 11 | 273 | 134.5 | 744 | 1151 | 63 (15%) | 84 (20%) | 12.18 | 1.84 | 215 | 4.6 |

| JA13-2 | 0.32 | 13 | 273 | 134.5 | 744 | 1151 | 63 (15%) | 84 (20%) | 12.18 | 1.84 | 215 | 4.5 |

| JB9-1 | 0.34 | 9 | 292 | 142 | 737 | 1139 | 63 (15%) | 63 (15%) | 9.61 | 1.7 | 225 | 4.5 |

| JC9-1 | 0.36 | 9 | 293 | 151 | 727 | 1124 | 63 (15%) | 63 (15%) | 8.38 | 1.44 | 220 | 5.0 |

| PH | Cl− | SO42− | Na+ | K+ | CO32− | HCO3− | Ca2+ | Mg2+ | Undissolved Substance | Soluble Total Solid |

| 7.8 | 19,179.4 | 2481.1 | 10,633.7 | 384.8 | 17.7 | 99.6 | 413 | 1612 | 688 | 35,137 |

| NO. | Stone Powder (%) | Crack Counts per Unit Area | Average Crack Area per Crack (mm2) | Total Crack Area per Unit Area (mm2/m2) | Anti-Cracking Grade |

| JA5-1 | 5 | 18 | 4.46 | 80.26 | L-V |

| JA7-1 | 7 | 15 | 9.16 | 137.43 | L-IV |

| JA9-1 | 9 | 18 | 10.29 | 185.26 | L-IV |

| JA11-1 | 11 | 15 | 21.72 | 325.75 | L-IV |

| JA13-1 | 13 | 15 | 24.50 | 367.52 | L-IV |

| NO. | Gel Material (kg/m3) | W/B | Cement (%) | Fly Ash (%) | Slag (%) |

| 1# | 438 | 0.34 | 65 | 20 | 15 |

| 2# | 420 | 0.34 | 70 | 15 | 15 |

| 3# | 420 | 0.33 | 55 | 15 | 30 |

| Gel Material | Cement | Water | Fly Ash | Slag | Sand | Stone (5–10 mm) | Stone (10–20 mm) | Water Reducer | Air Entraining Agent |

| 419 | 293 | 142 | 63 | 63 | 754 | 225 | 898 | 8.38 | 1.44 |

| Mix Ratio Number | Compressive Strength/MPa | Appearance Density/kg·m3 | Slumps/mm | Air Content/% | |||

| 3 d | 7 d | 28 d | 56 d | ||||

| JB9-1 | 28.7 | 41.7 | 58.2 | 62.5 | 2390 | 210 | 5.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Y.; Song, S.; Yu, H.; Ma, H.; Xu, Y.; Zu, G.; Ruan, Y. Experimental Study on the Strength and Durability of Manufactured Sand HPC in the Dalian Bay Undersea Immersed Tube Tunnel and Its Engineering Application. Materials 2024, 17, 5003. https://doi.org/10.3390/ma17205003

Sun Y, Song S, Yu H, Ma H, Xu Y, Zu G, Ruan Y. Experimental Study on the Strength and Durability of Manufactured Sand HPC in the Dalian Bay Undersea Immersed Tube Tunnel and Its Engineering Application. Materials. 2024; 17(20):5003. https://doi.org/10.3390/ma17205003

Chicago/Turabian StyleSun, Yuefeng, Shanshan Song, Hongfa Yu, Haiyan Ma, Yu Xu, Guojia Zu, and Yang Ruan. 2024. "Experimental Study on the Strength and Durability of Manufactured Sand HPC in the Dalian Bay Undersea Immersed Tube Tunnel and Its Engineering Application" Materials 17, no. 20: 5003. https://doi.org/10.3390/ma17205003

APA StyleSun, Y., Song, S., Yu, H., Ma, H., Xu, Y., Zu, G., & Ruan, Y. (2024). Experimental Study on the Strength and Durability of Manufactured Sand HPC in the Dalian Bay Undersea Immersed Tube Tunnel and Its Engineering Application. Materials, 17(20), 5003. https://doi.org/10.3390/ma17205003